Efficient chemical reagent conditioning reaction kettle

A reaction kettle and chemical technology, which is applied in the field of high-efficiency chemical reagent blending reaction kettle, can solve the problems of single structure, long stirring cycle, high production cost, etc., and achieve the effect of ensuring the stirring quality, improving the mixing efficiency and preventing the dead angle of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

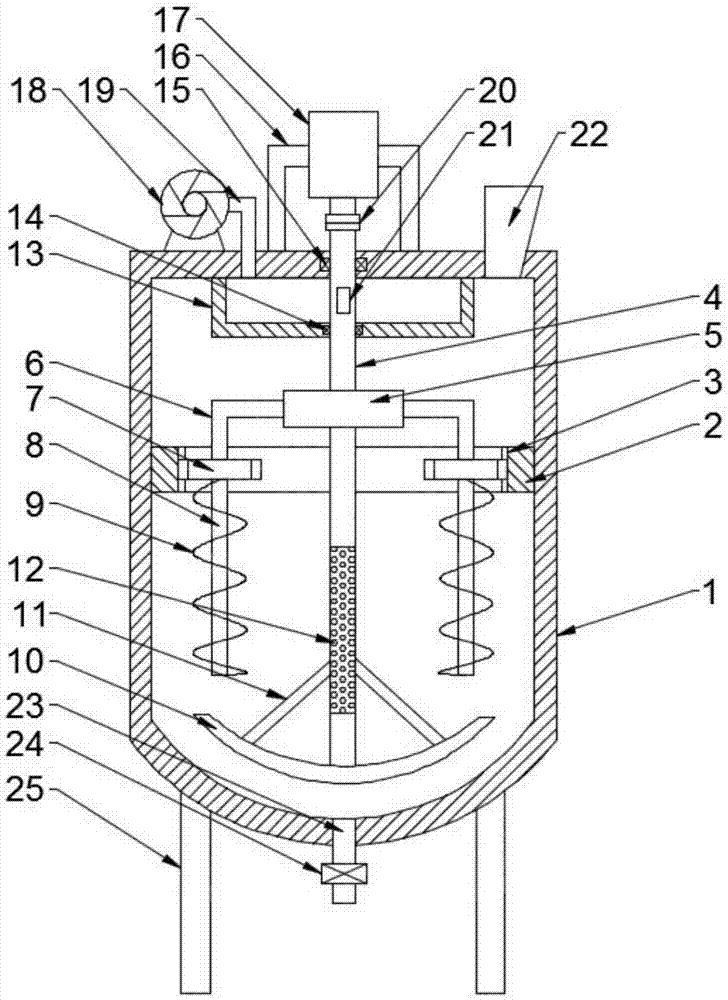

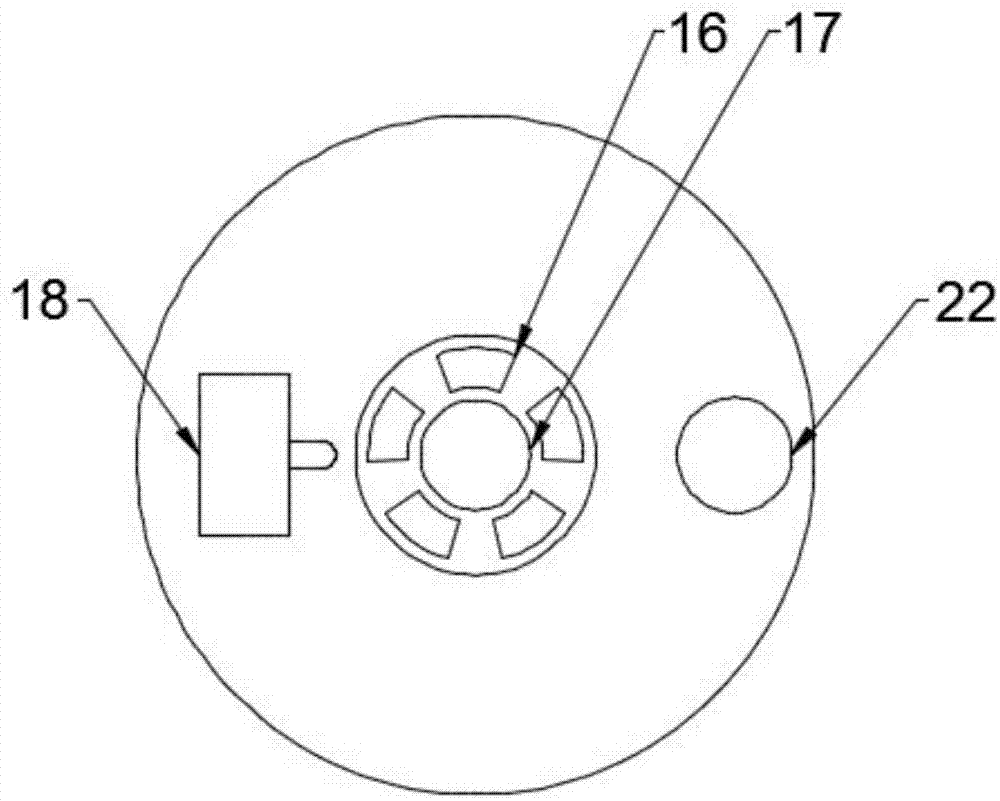

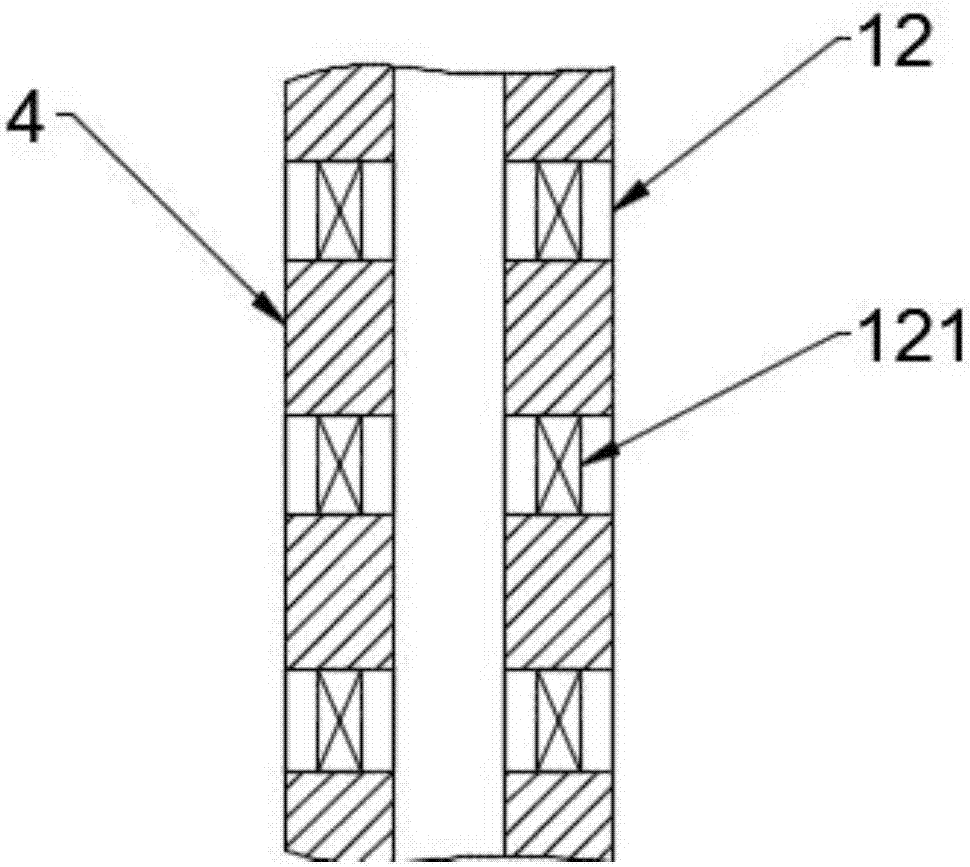

[0019] see Figure 1~2 , a high-efficiency chemical reagent blending reaction kettle, including a kettle body 1, the kettle body 1 is designed in a cylindrical structure, and a guide rail 2 is provided on the upper part of the inner cavity of the kettle body 1, and the guide rail 2 is designed in a ring structure, and the guide rail 2 is provided with an internal gear 3, the inner cavity of the kettle body 1 is provided with a rotating shaft 4, the axis of the rotating shaft 4 coincides with the axis of the kettle body 1, the rotating shaft 4 is a hollow shaft, and the upper part of the rotating shaft 4 is provided with Air intake hole 21, the middle part of rotating shaft 4 is provided with connection plate 5, and the bottom of rotating shaft 4 is evenly provided with some exhaust holes 12, and rotating shaft 4 is through connected with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com