Patents

Literature

97results about How to "Ensure mixing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

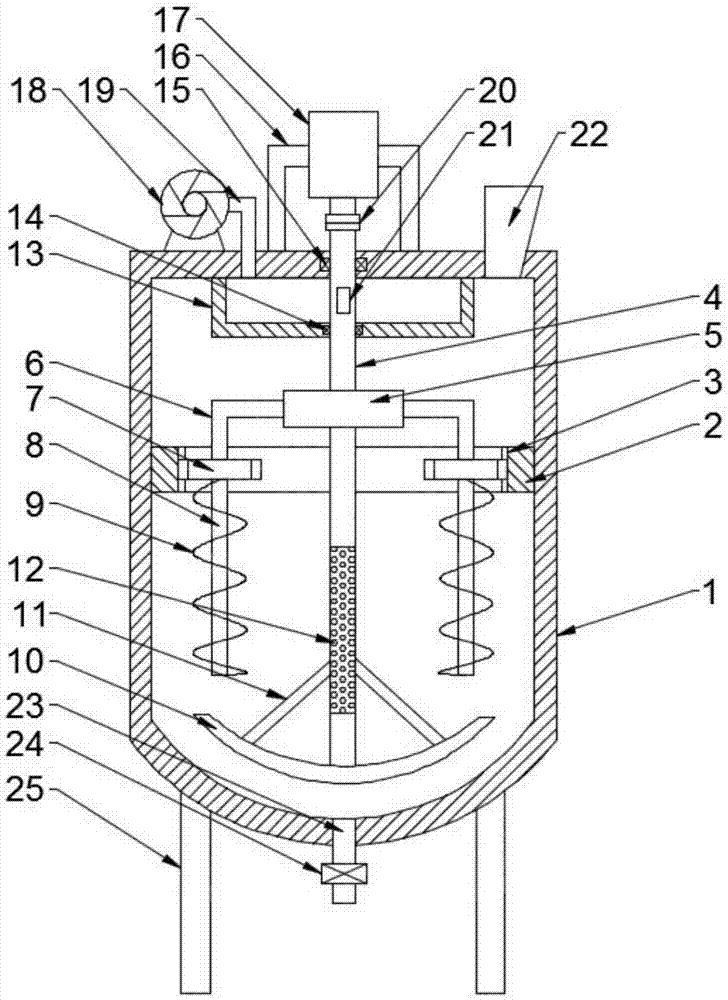

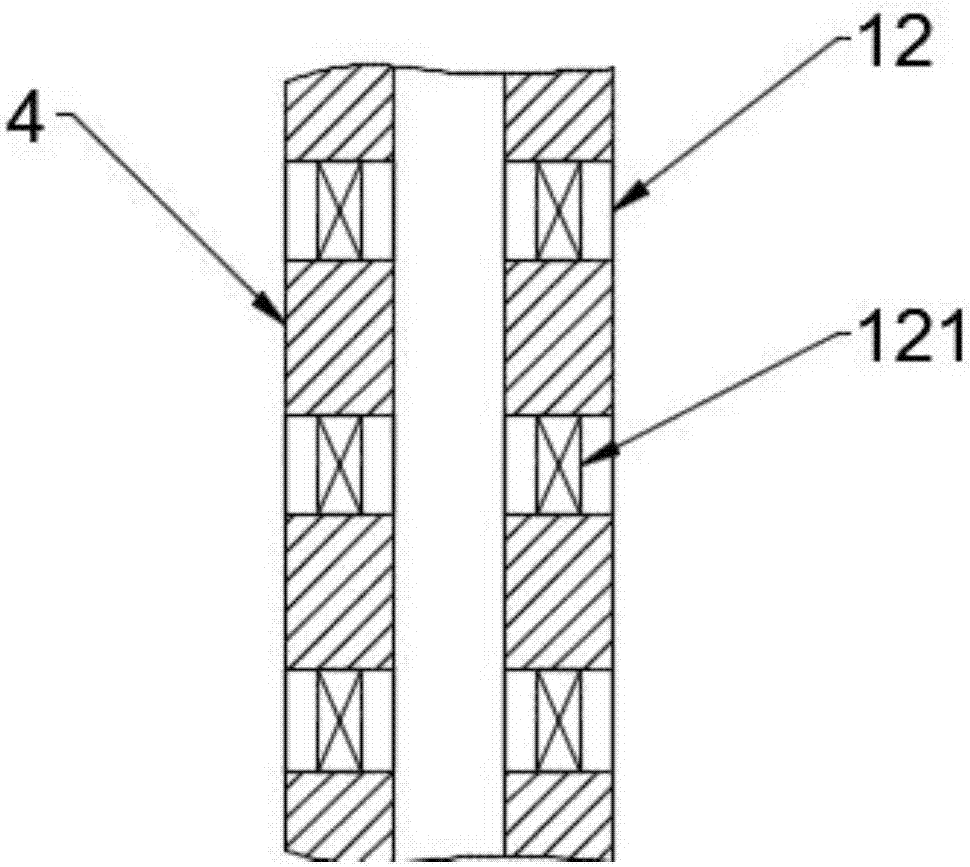

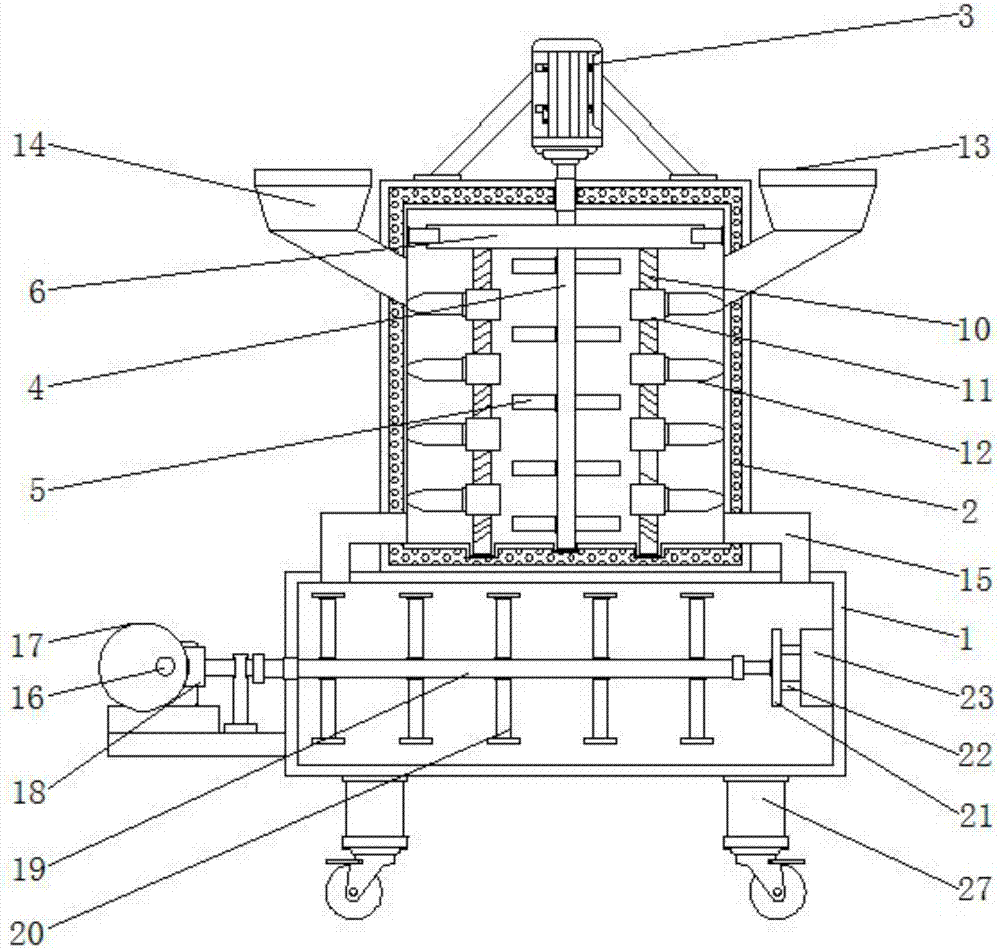

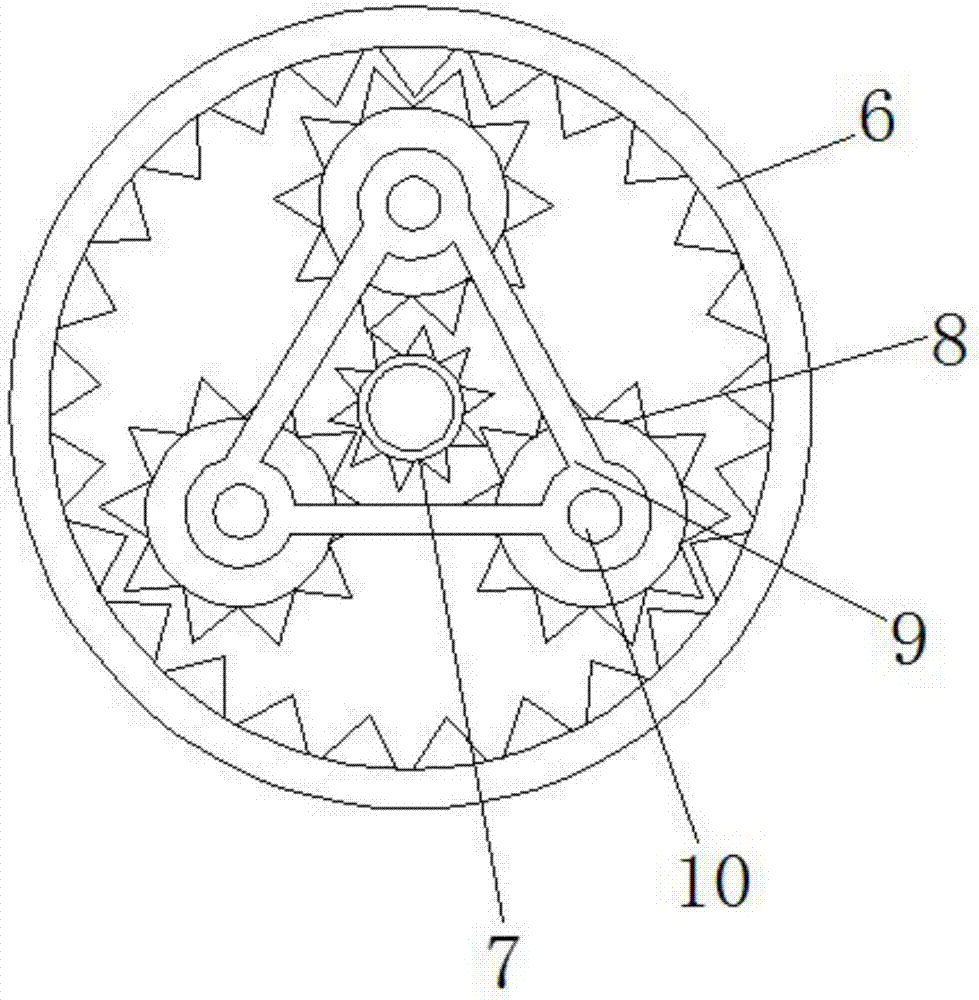

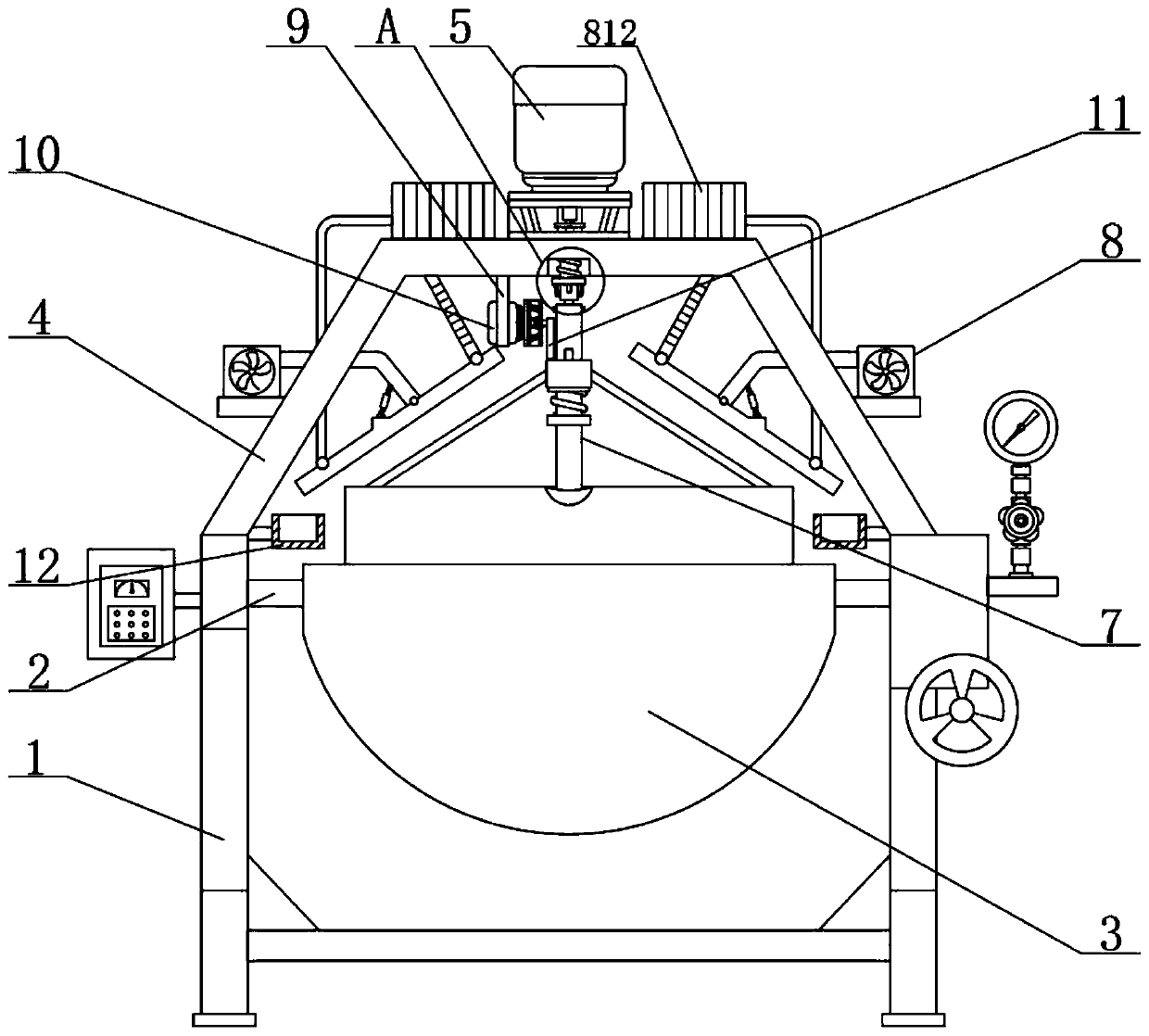

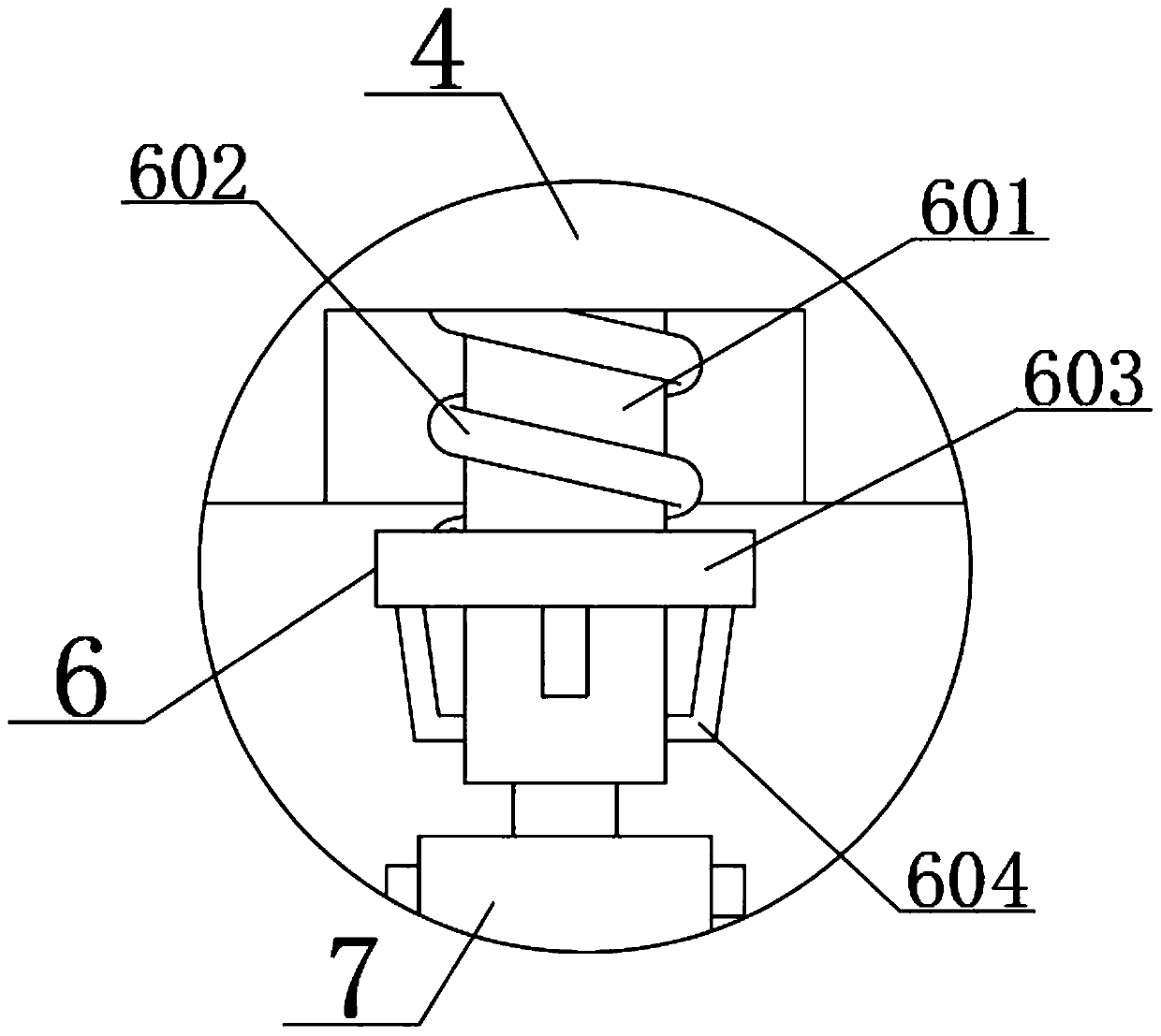

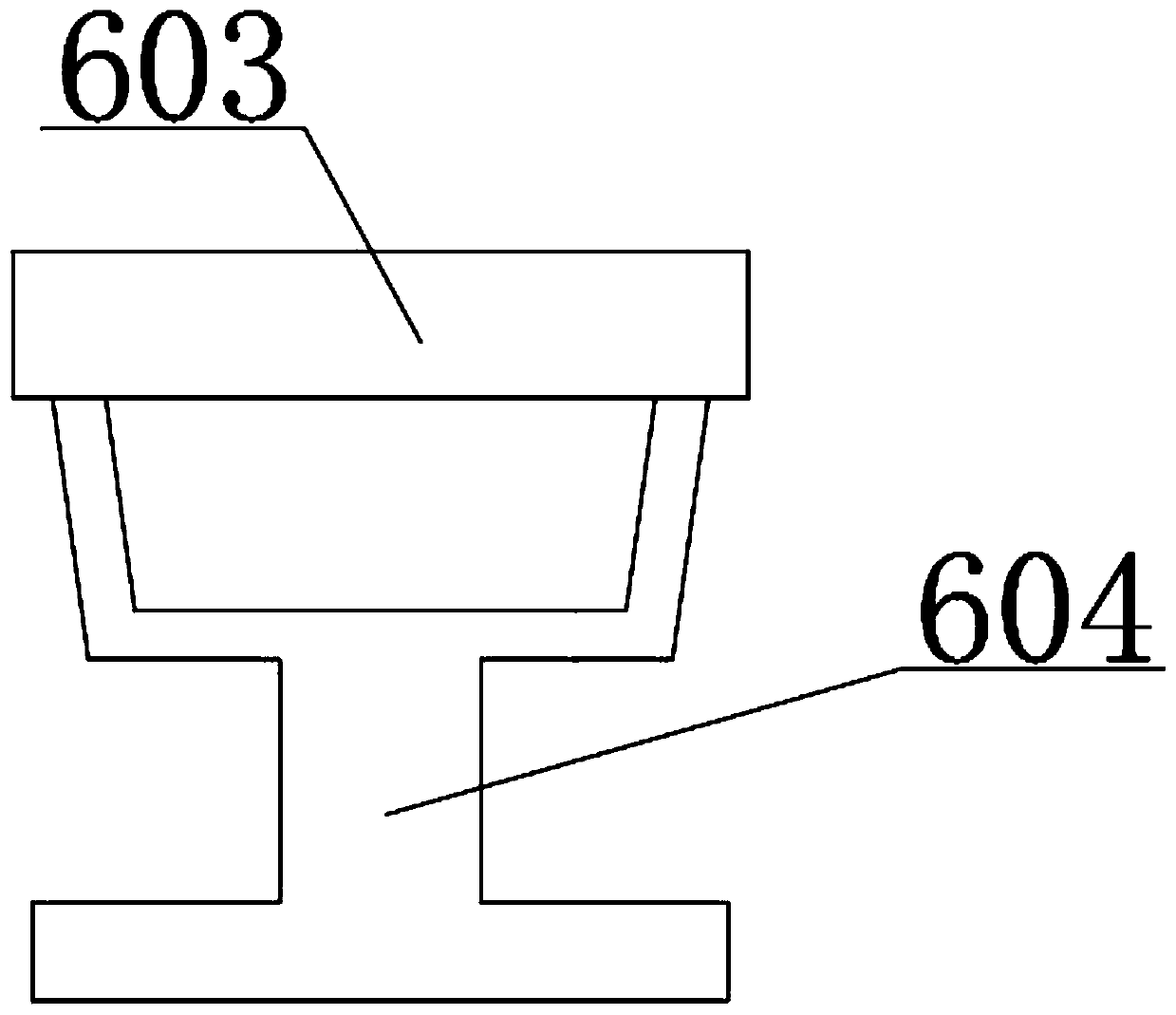

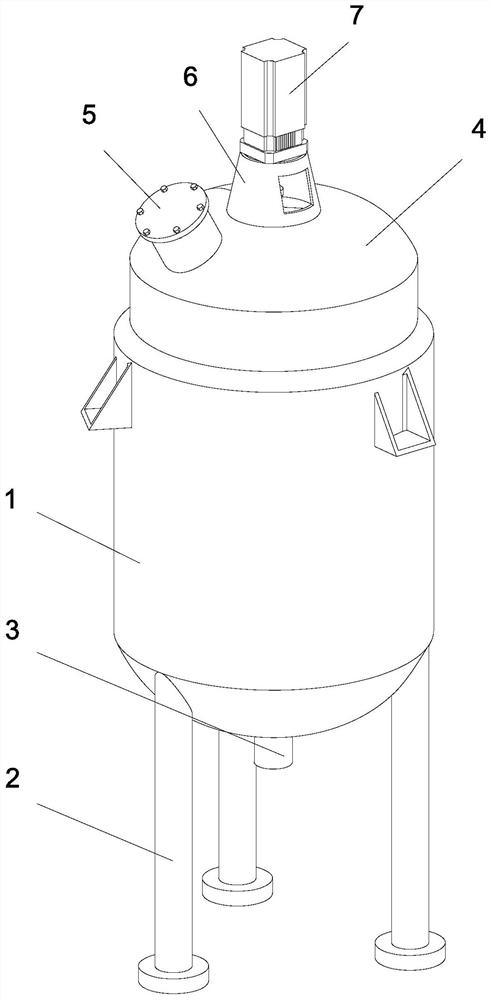

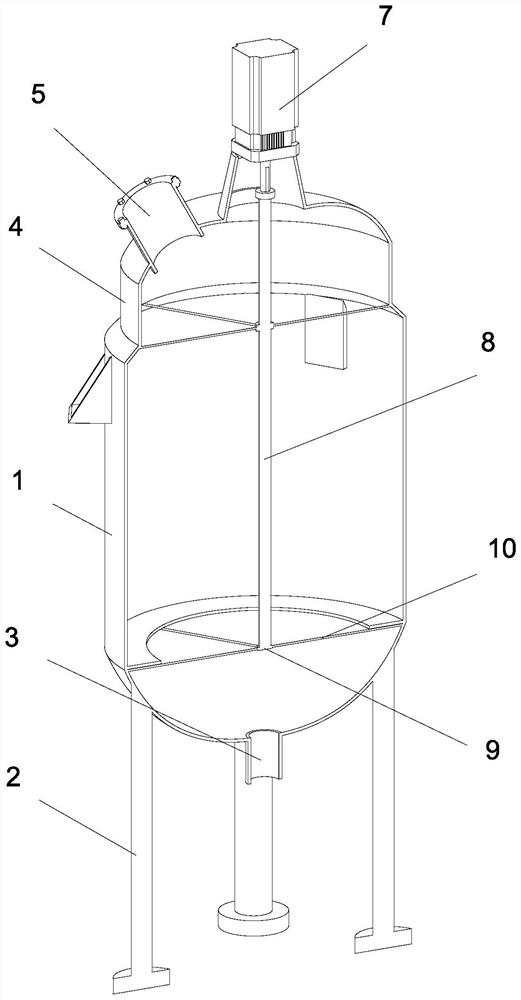

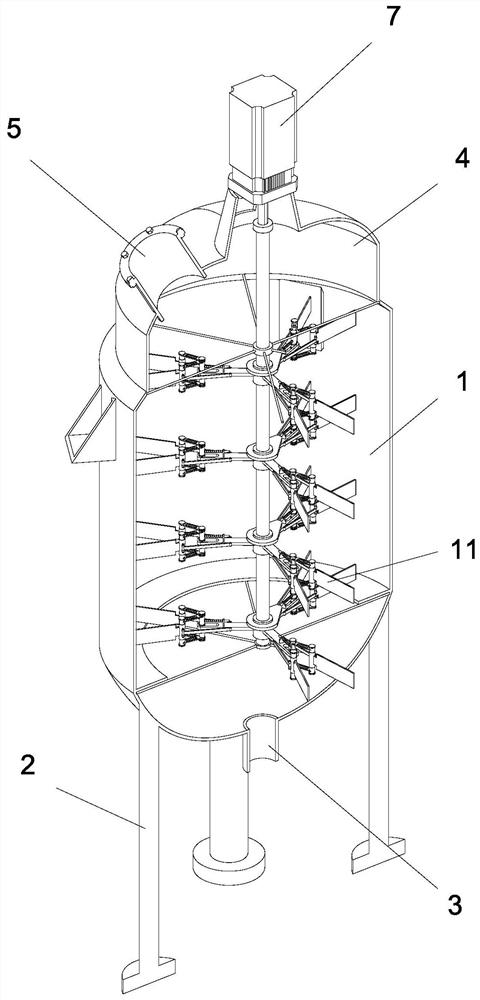

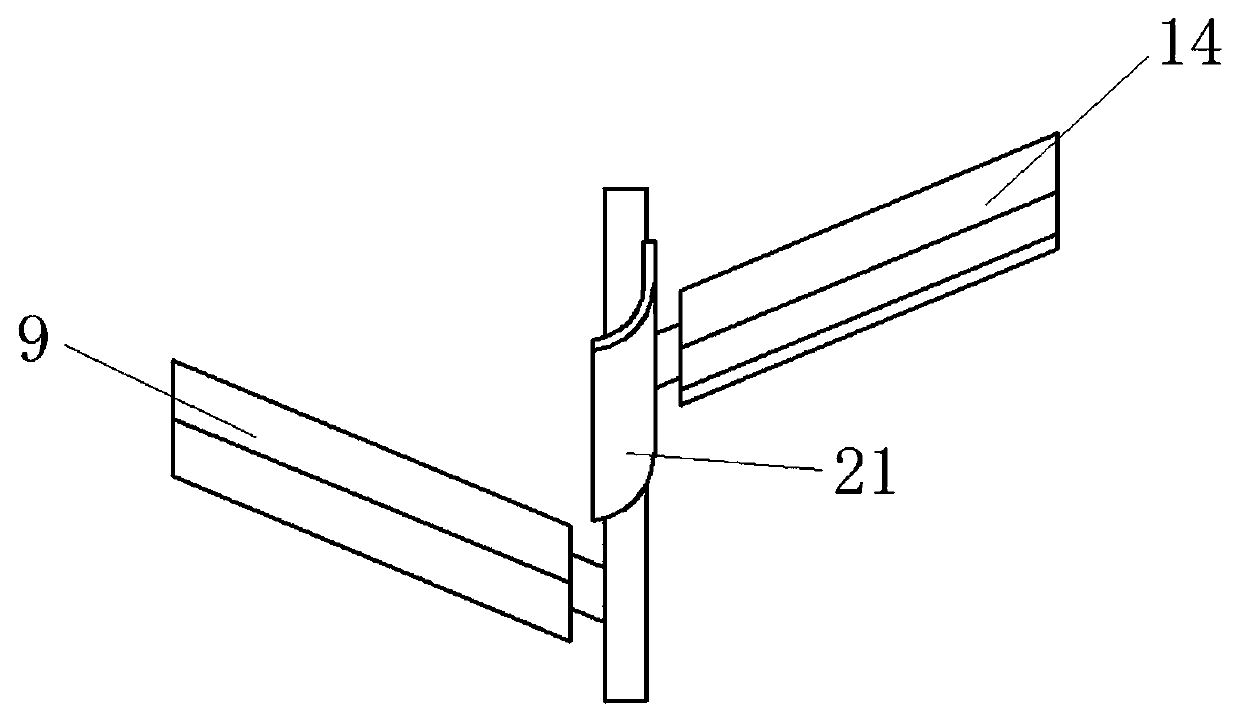

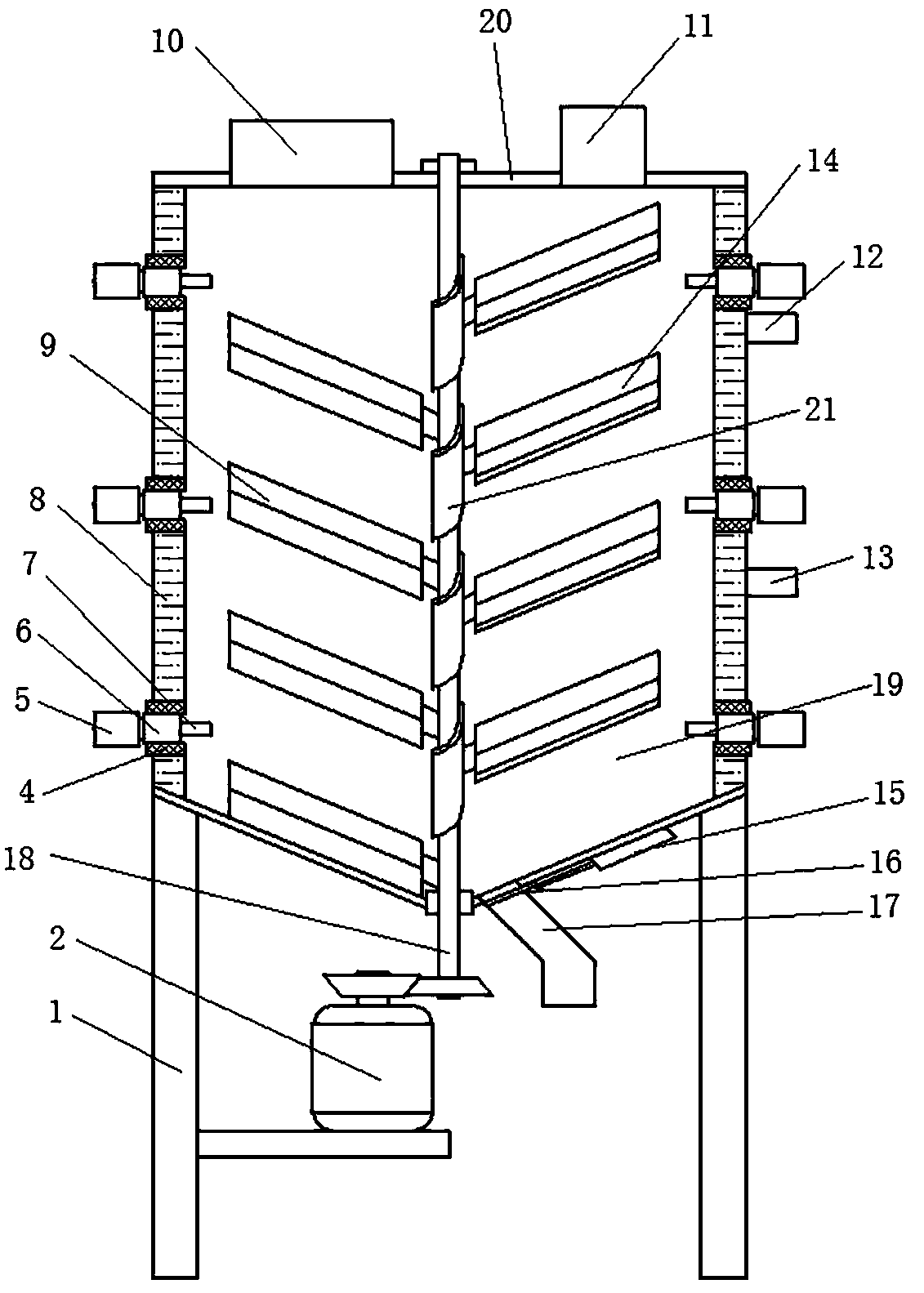

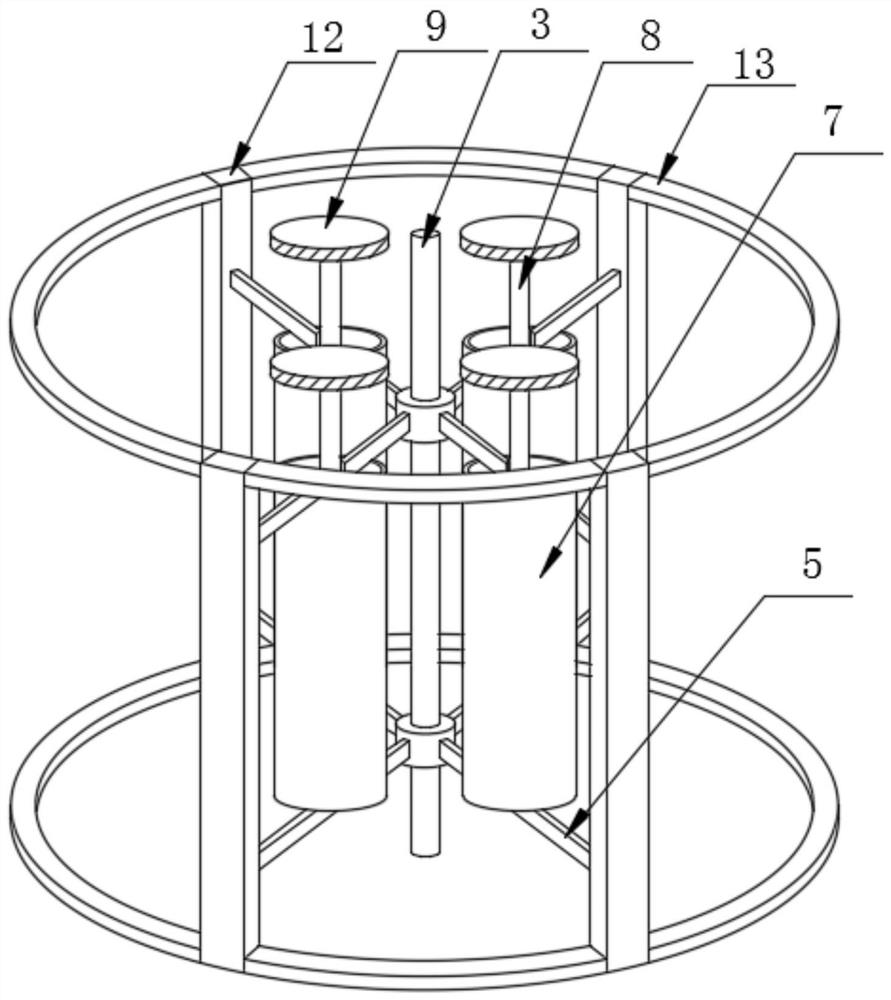

Efficient chemical reagent conditioning reaction kettle

InactiveCN107349893AGuaranteed mixing concentrationImprove mixing efficiencyRotary stirring mixersTransportation and packagingGear wheelCompound (substance)

The invention discloses an efficient chemical reagent conditioning reaction kettle, which comprises a kettle body, wherein a guide rail is arranged at the upper part of an inner cavity of the kettle body; an inner gear is arranged on the inner circle surface of the guide rail; a rotating shaft is arranged in the inner cavity of the kettle body; a connecting disc is arranged in the middle part of the rotating shaft in a sleeving way; the bottom end of the rotating shaft is fixedly connected with a second stirring blade matched with the bottom wall of the kettle body; a plurality of connecting rods are uniformly arranged at the outer circle surface of the connecting disc; the other end of the connecting rod is rotationally connected with a gear matched with the inner gear; the bottom end of the gear is fixedly connected with a stirring rod; a first stirring blade is arranged on the stirring rod in a sleeving way; the bottom end of the kettle body is connected with a material discharging pipe in a penetrating way; a plurality of support legs are uniformly arranged at the bottom end of the kettle body. The second stirring blade arranged in the efficient chemical reagent conditioning reaction kettle is used for stirring the bottom of the inner cavity of the kettle body; the occurrence of the stirring dead corner is prevented; the mixing concentration of the solution is ensured; the second stirring blade does composite movement of autorotation and revolution around the rotating shaft under the driving of the gear, so that the stirring of the solution in the inner cavity of the kettle body becomes disordered; the reagent mixing efficiency is improved; the stirring quality is improved.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

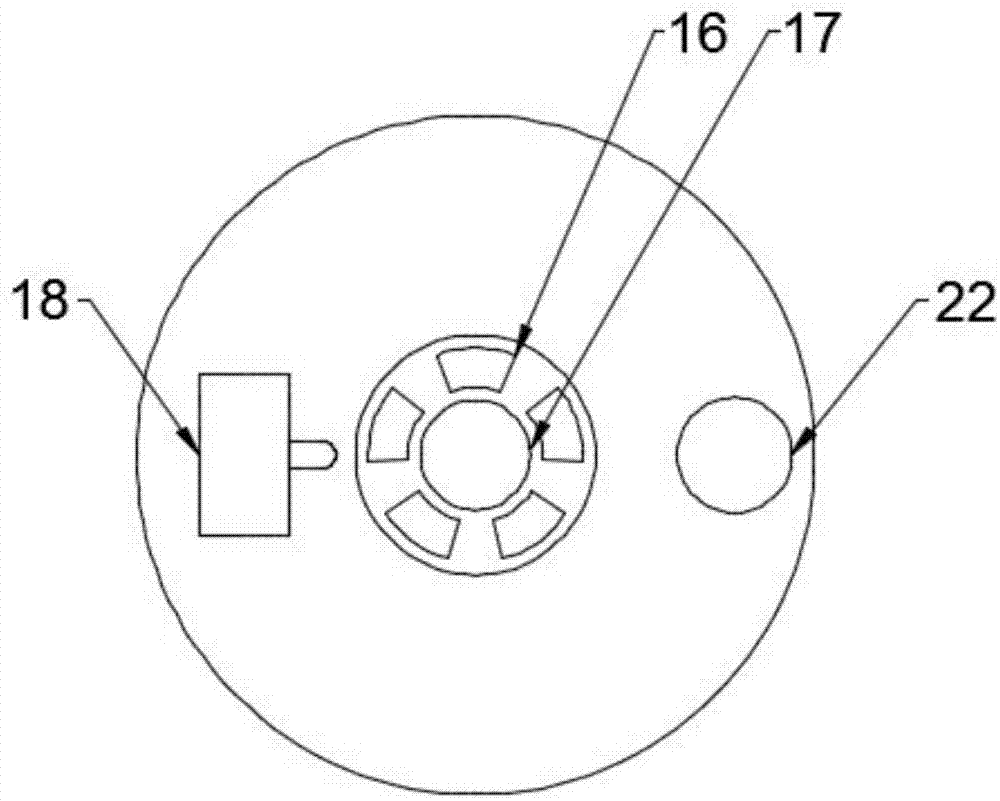

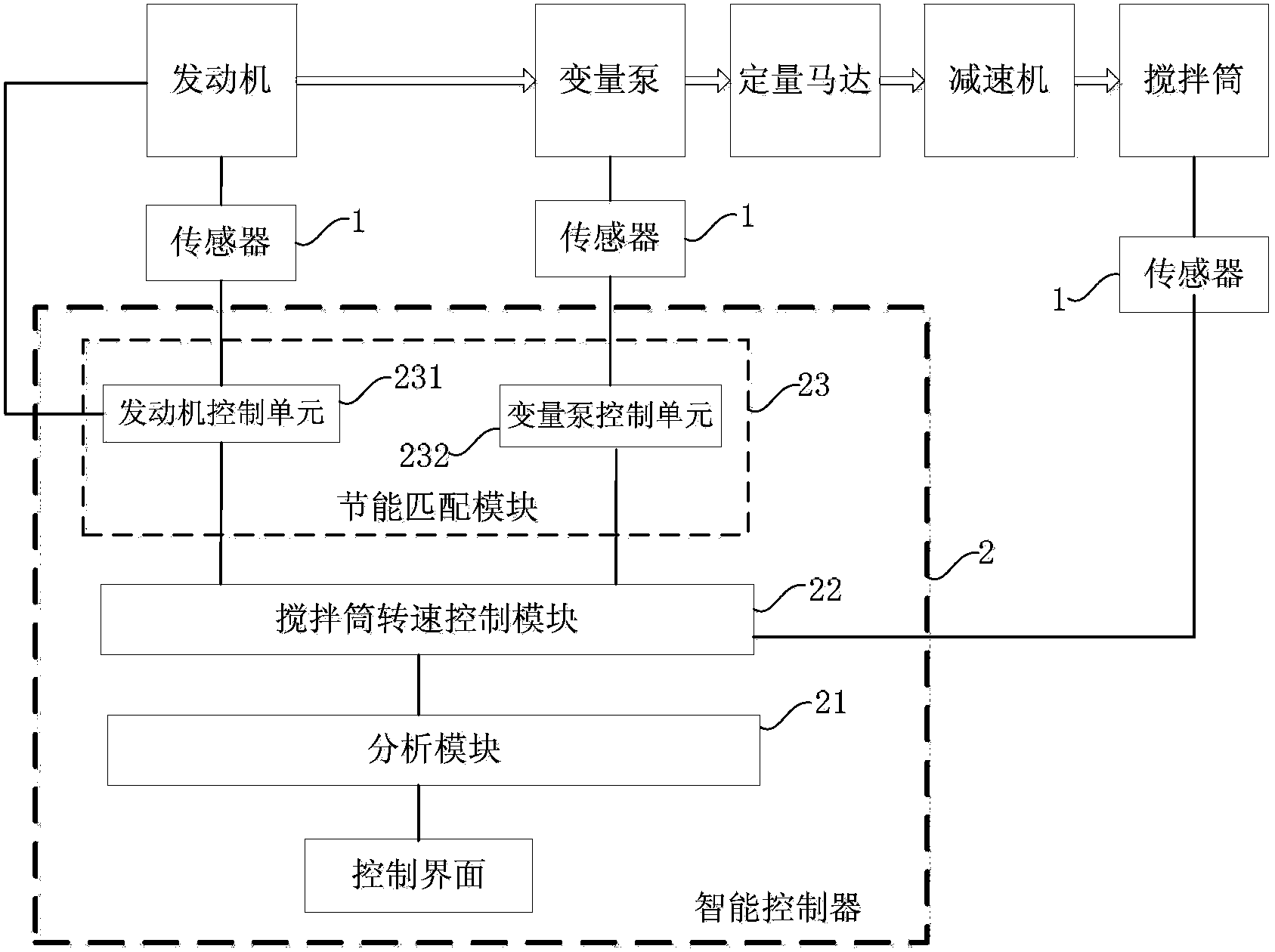

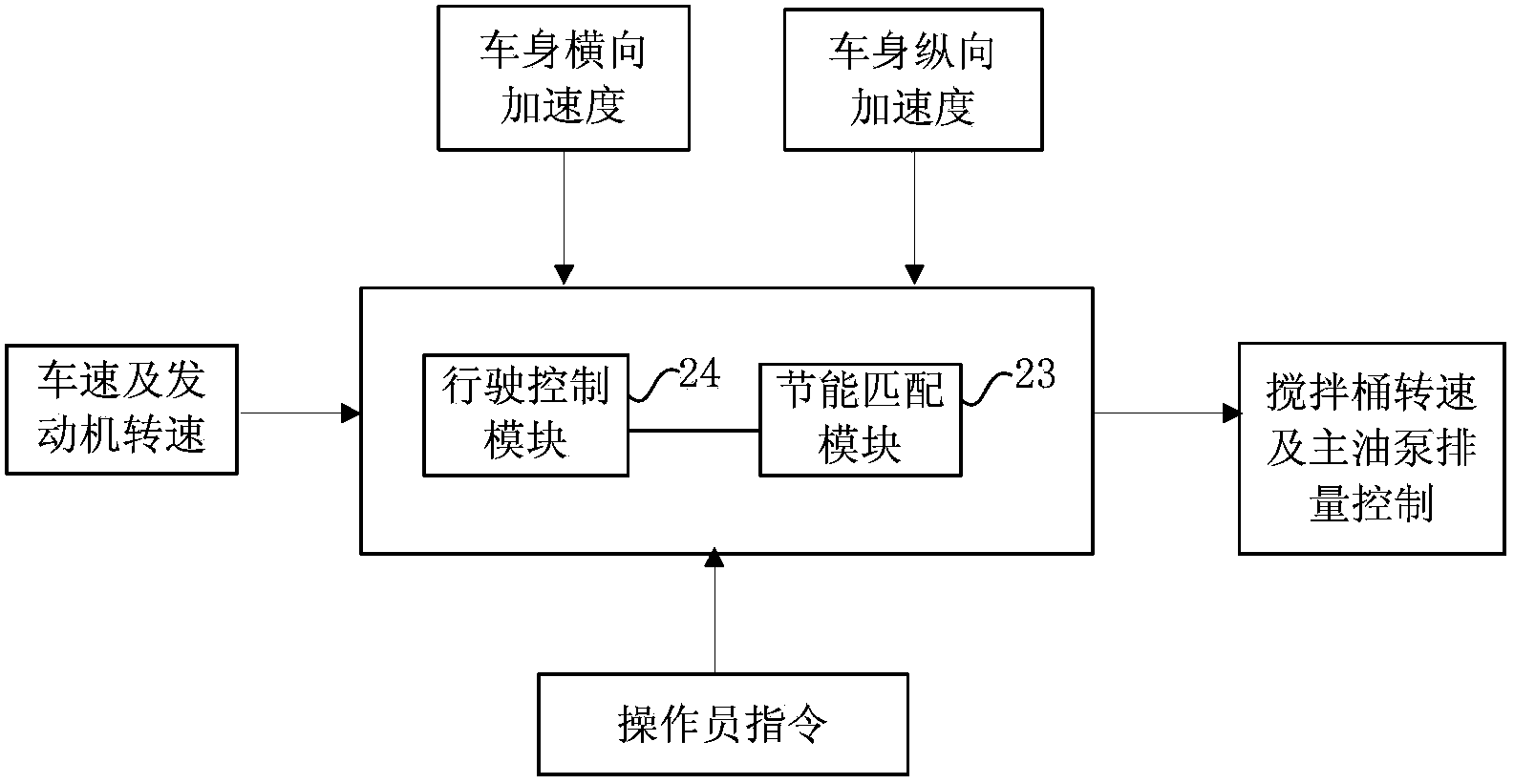

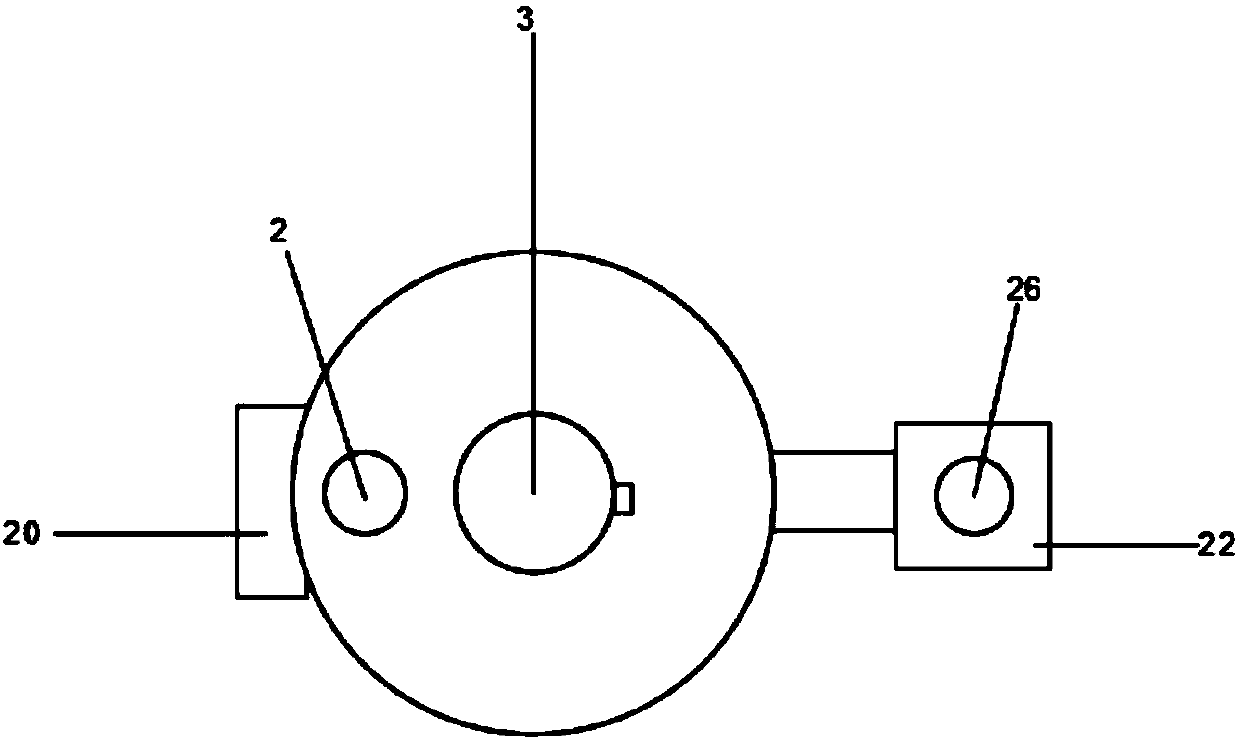

Concrete mixing truck, and control apparatus and control method thereof

ActiveCN103481373AEnsure mixing qualityReduce consumptionCement mixing apparatusControl apparatusComputer moduleFuel oil

The invention provides a concrete mixing truck, and a control apparatus and a control method thereof. The apparatus comprises a plurality of sensors and an intelligent controller; signals collected by the plurality of sensors at least comprise an engine rotating speed signal, a mixing drum rotating speed signal and a main oil pump displacement signal; the intelligent controller comprises an analysis module used for analyzing an expected mixing drum rotating speed based on a transit time of the transit mixing truck and a preset mixing drum revolution total frequency according to a concrete transit mixing standard, a mixing drum rotating speed control module used for controlling the mixing drum to mix concrete in the expected mixing drum rotating speed according to the mixing drum rotating speed signal or controlling the mixing drum rotating speed according to a preset concrete transmit mixing requirement, and an energy saving matching module used for controlling the engine rotating speed of the mixing truck and the main oil pump displacement according to a best fuel oil consumption curve. In the invention, the concrete mixing quality is guaranteed, and energy saving is also realized.

Owner:中集车辆(江门市)有限公司

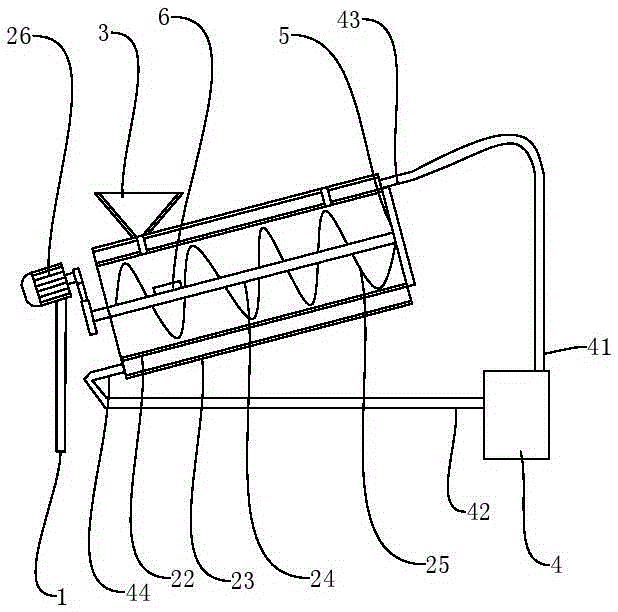

Bituminous mixture cold regeneration mixing method

InactiveCN101392488AImprove uniformityTake advantage of reactive featuresRoads maintainencePavement engineeringRoad engineering

The invention belongs to the production technology of a road engineering material, and relates to a cold-regeneration mixing method of asphalt mixture in the cold-regeneration equipment of asphalt mixture. The method comprises the following steps: the mixing process is carried out in a continuous mode mixing bowl and the addition of the various materials comprises the following steps: (1) adding aggregate at the feed inlet of of the initial end of the continuous type mixing bowl and carrying out spraying process to the aggregate simultaneously, then mixing in the mixing bowl, the amount of the spray water accounts for 20-30% of the total water amount; (2) adding cement and powdered ore into the mixing bowl to be mixed with the previously-added materials; (3) adding water for the second time and the amount of the water accounts for 50-60% of the total water amount; (4) spraying emulsified asphalt and mixing continuously; and (5) adding water for the third time and the amount of the water accounts for 10-20% of the total water amount until the asphalt mixture is obtained. The invention not only improves the uniformity of the mixing of the materials, but also fully utilizes the reaction characteristics between various materials, and guarantees the mixing quality of the final product.

Owner:ZHENJIANG HUACHEN HUATONG ROAD MASCH CO LTD

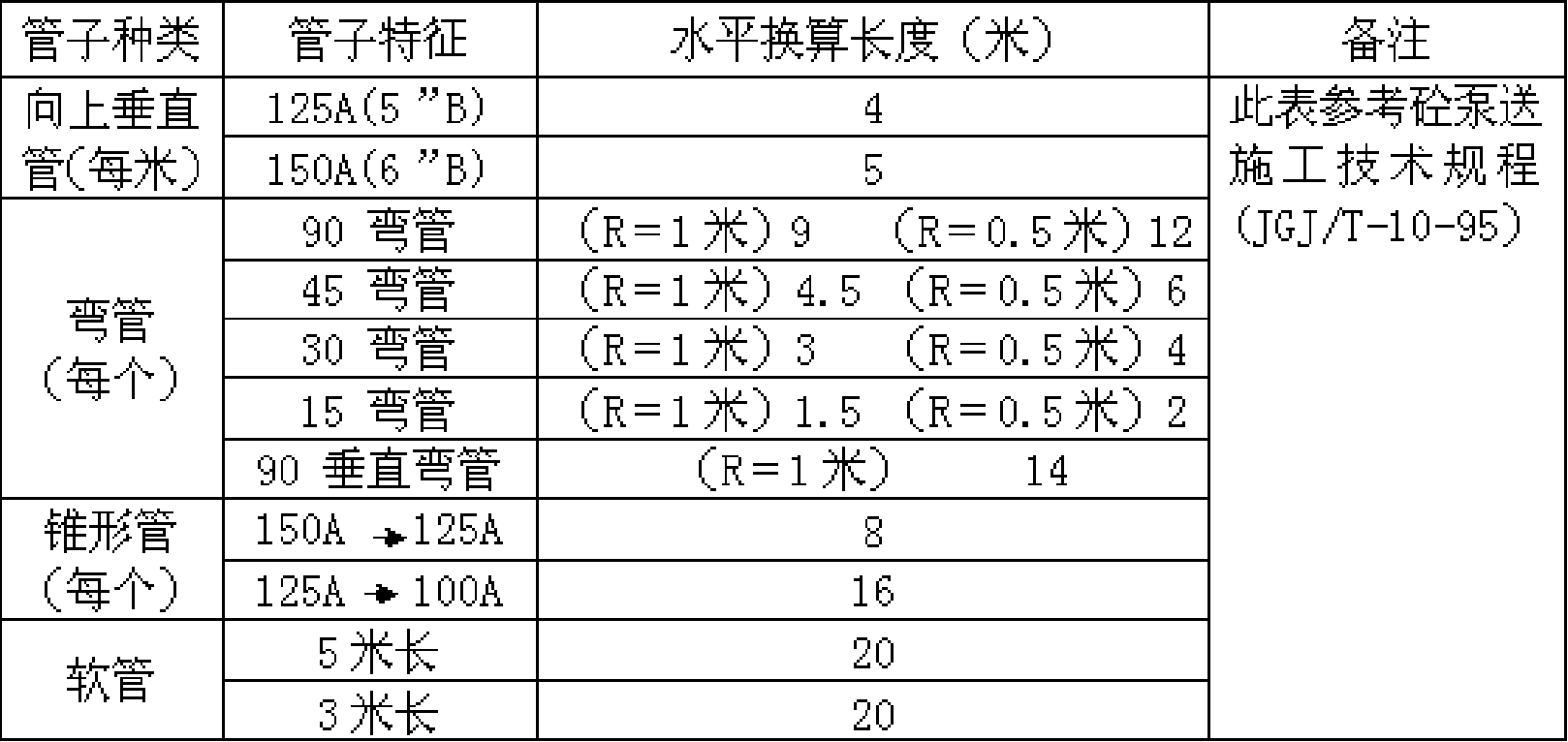

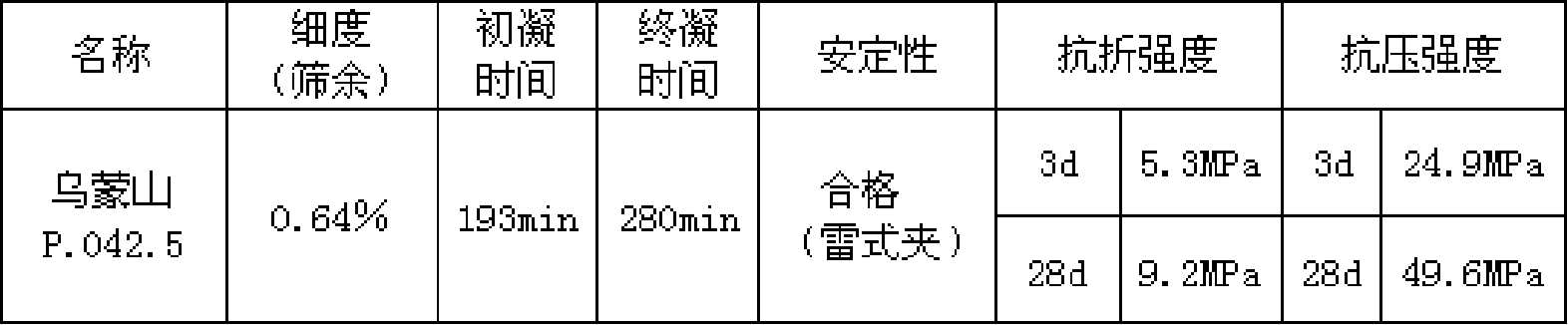

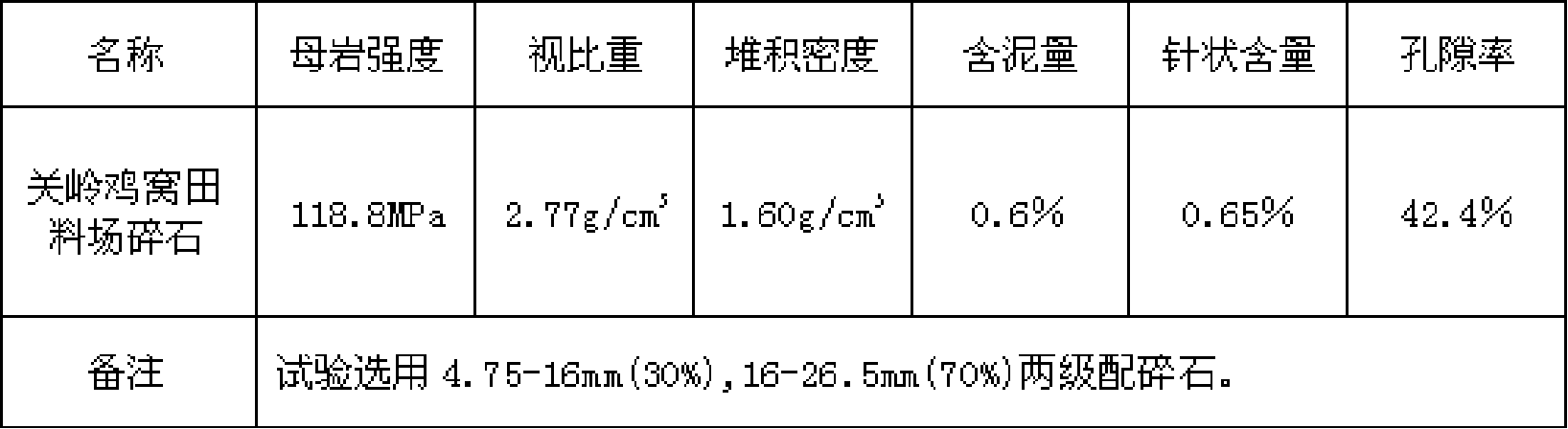

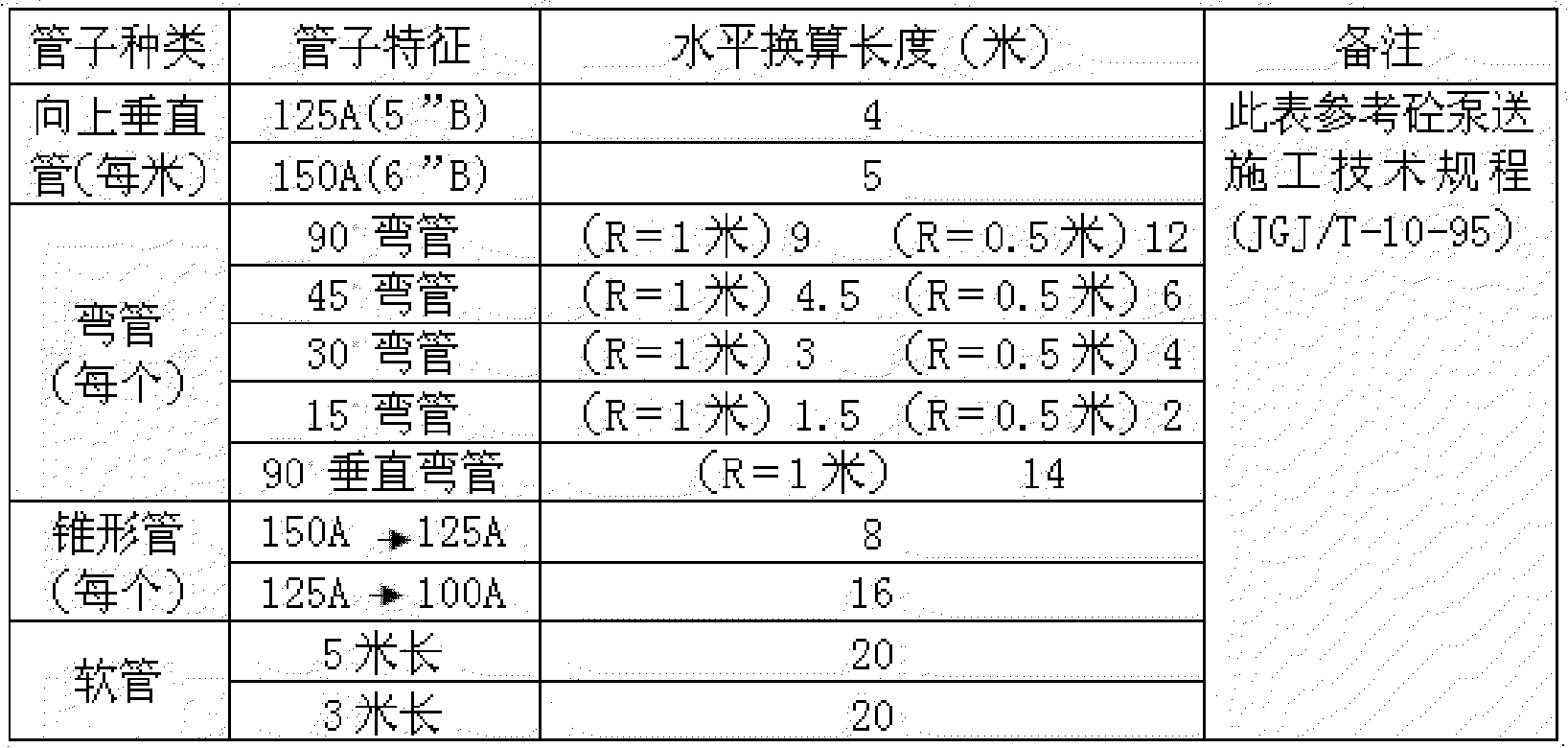

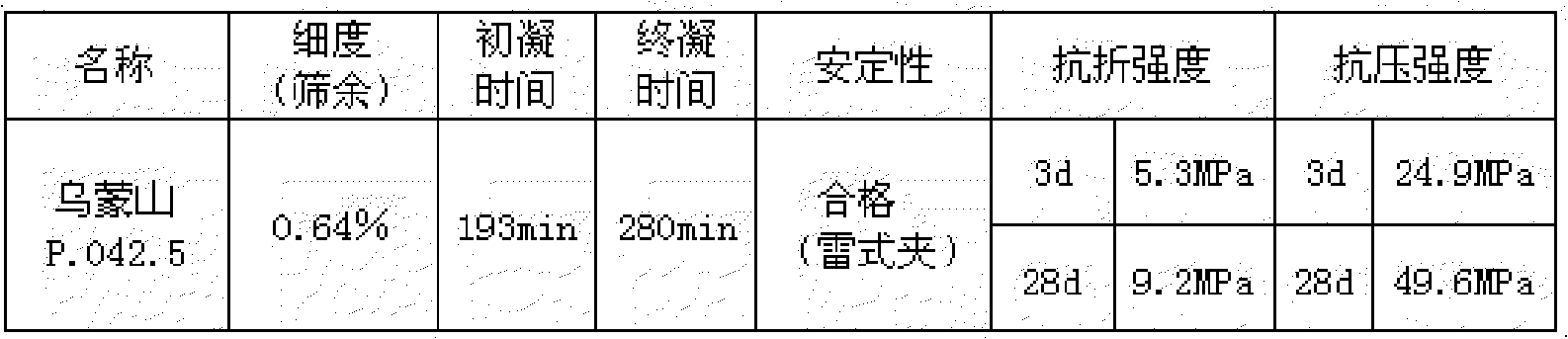

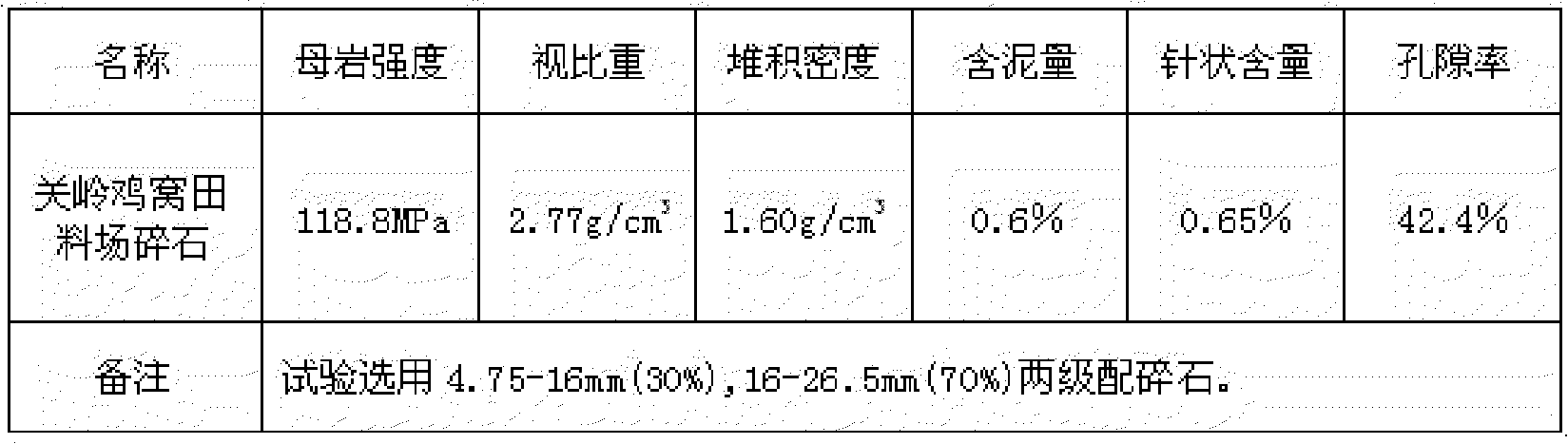

Long pumping distance machine-made sand concrete

ActiveCN101164959AEnsure mixing qualityQuality assuranceSolid waste managementCrushed stoneWater reducer

This invention relates to a high delivery lift type machine-finished sands concrete. The raw materials are (by weight ratio): cement 400-425, machine-finished sands 780-800, broken stone (grain size=5-16mm)300-310, broken stone (16-25mm) 700-720, water 155-160, coal ash 75-80, water reducing agent 18-24. This inventive concrete has better working properties, its delivery lift can be up to 200m. It can make the equipment being at normal operation.

Owner:GUIZHOU BRIDGE CONSTR GROUP

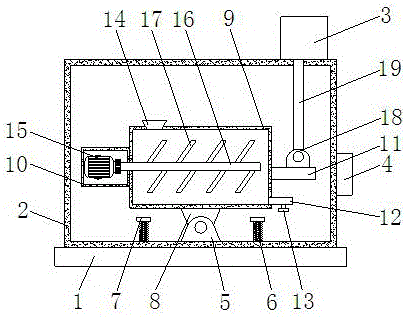

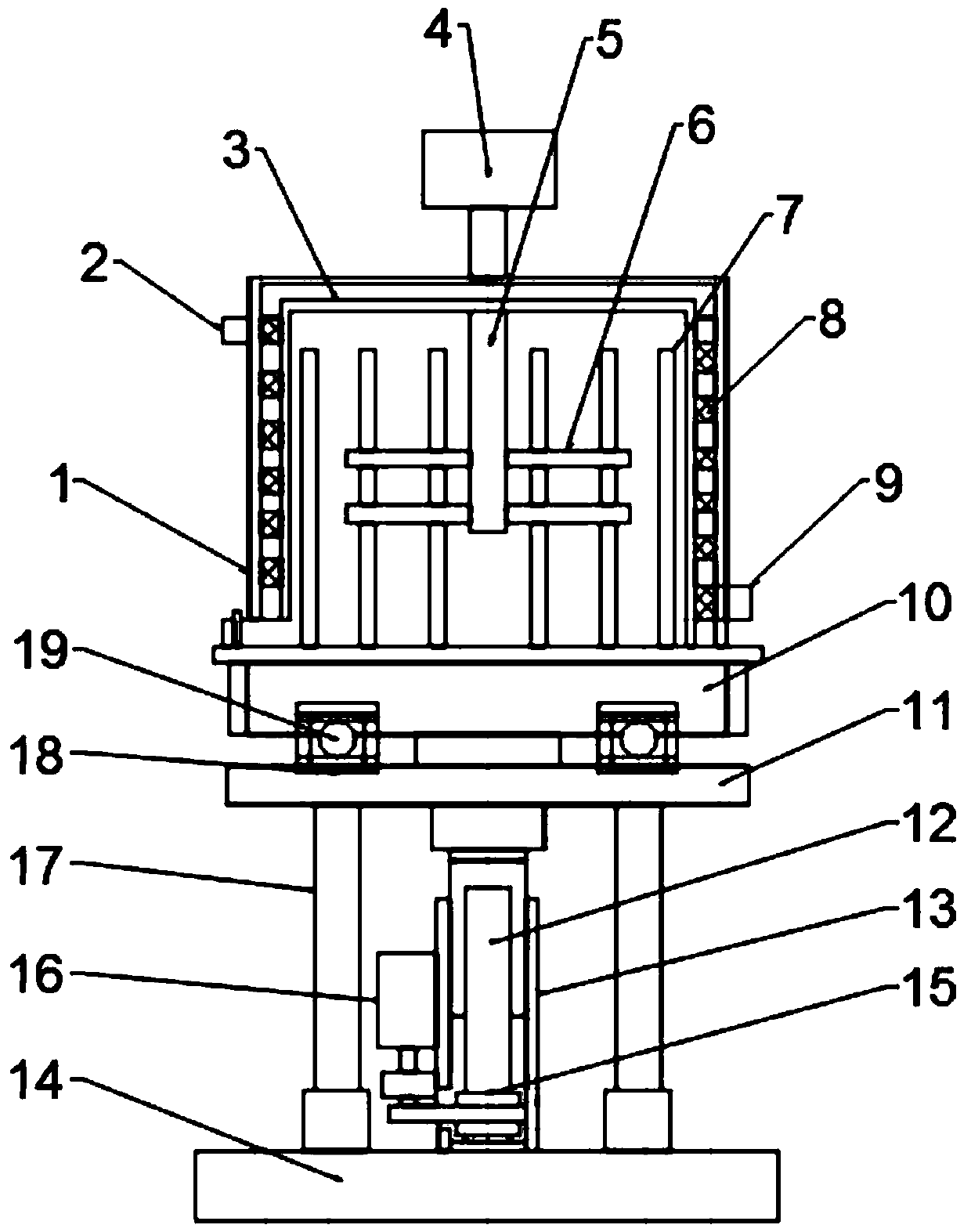

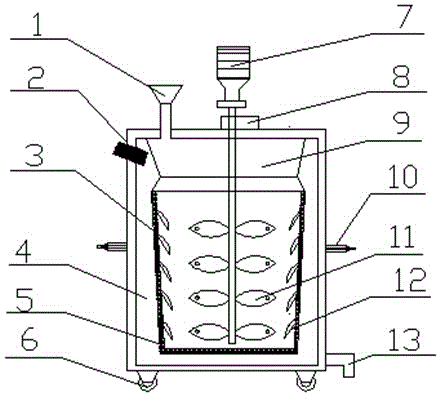

Stirring device capable of mixing uniformly

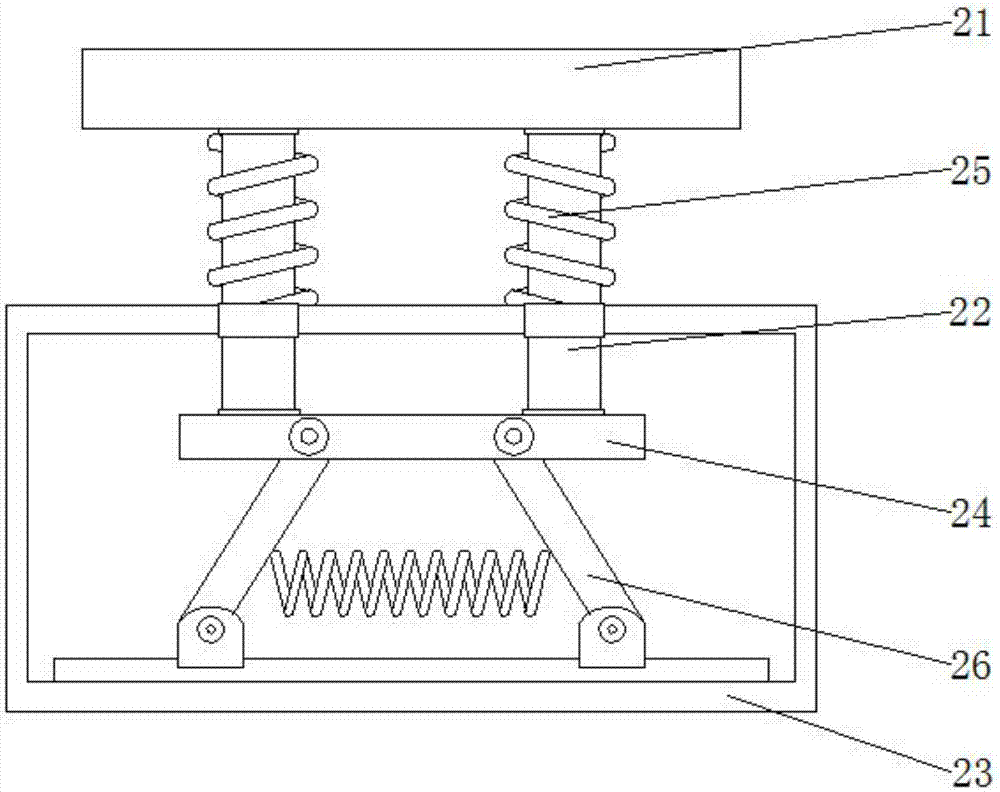

InactiveCN106732094AWell mixedIncrease the degree of mixingShaking/oscillating/vibrating mixersTransportation and packagingChemical productsEngineering

The invention discloses a stirring device capable of mixing uniformly. The stirring device capable of mixing uniformly comprises a base plate, wherein the top of the base plate is connected with a box body, a power box is arranged at the top of the box body, a controller is arranged at one side of the box body, the bottom of the inner wall of the box body is fixedly connected with a first supporting block, buffer springs are symmetrically connected with the bottom of the inner wall of the box body at the two sides of the first supporting block, the top end of the buffer spring is fixedly connected with a buffer block, the first supporting block is movably connected with a second supporting block, and the top of the second supporting block is fixedly connected with a stirring barrel. The stirring device capable of mixing uniformly has the advantages that the first supporting block, the second supporting block and the power box are used, and the stirring barrel can shake when chemical product raw materials are stirred by adopting a stirring rod, so that the chemical product raw materials are shaken and mixed, not only is chemical product mixing degree improved, but also working efficiency of a stirring machine is also improved, and stirring quality of chemical products is guaranteed.

Owner:WUXI JINWU AUX AGENT FACTORY CO LTD

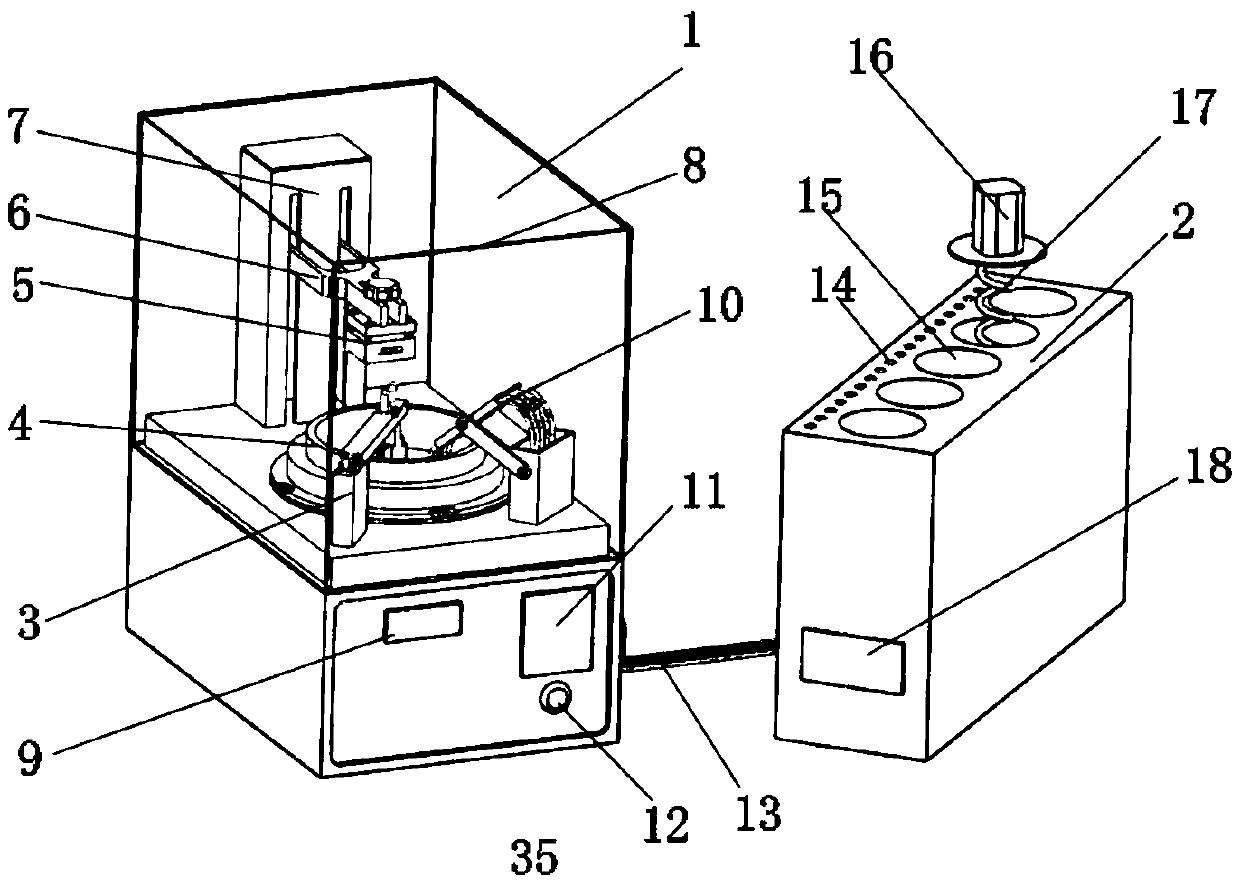

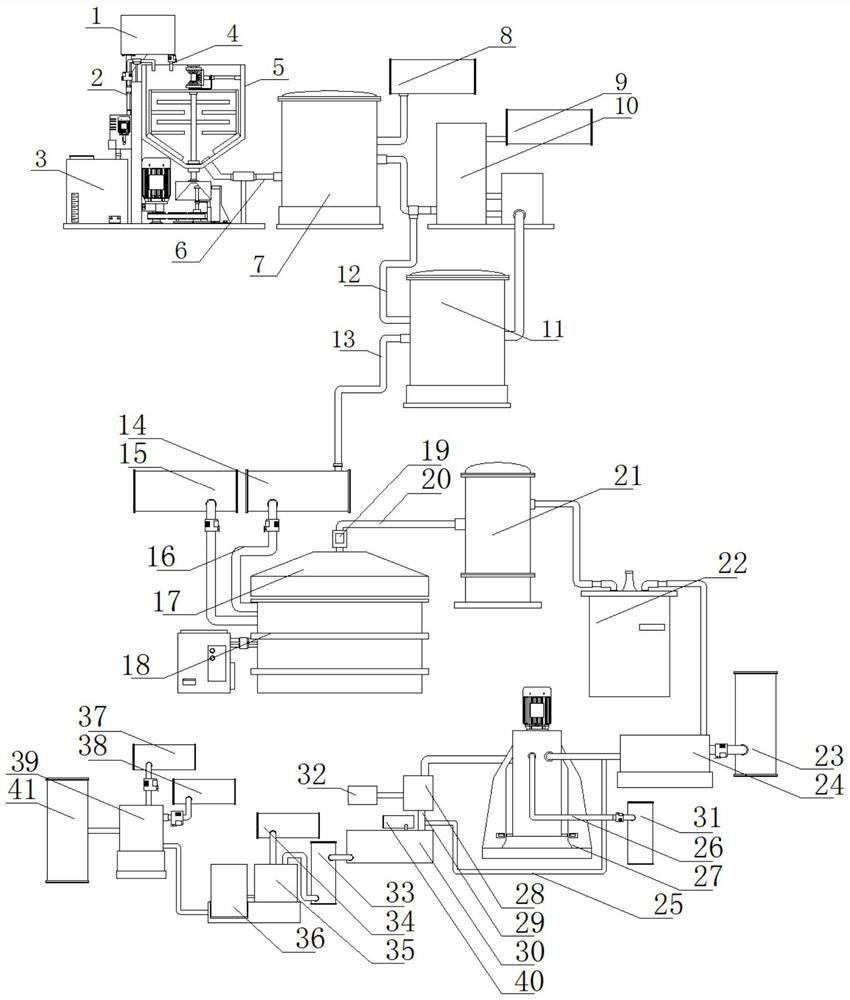

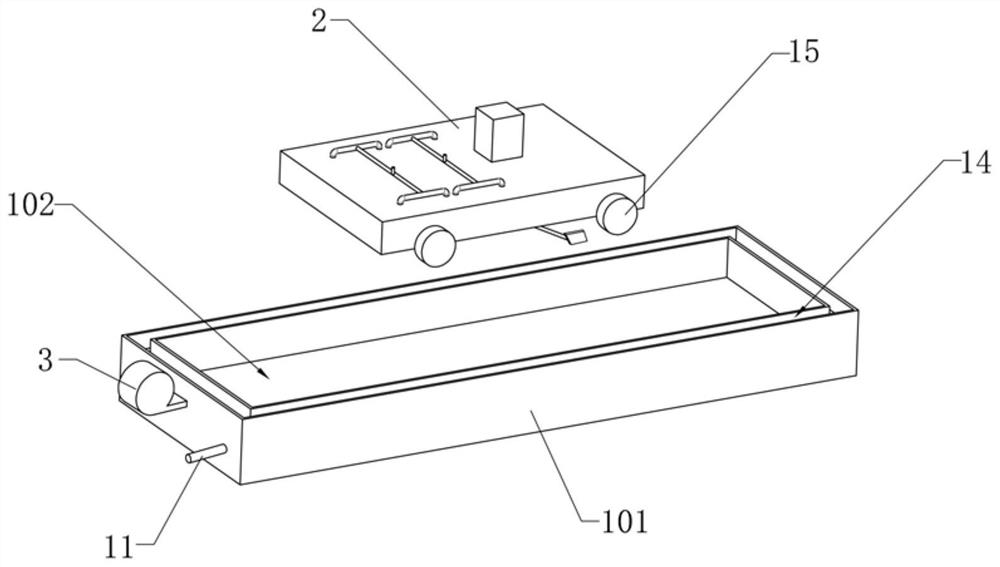

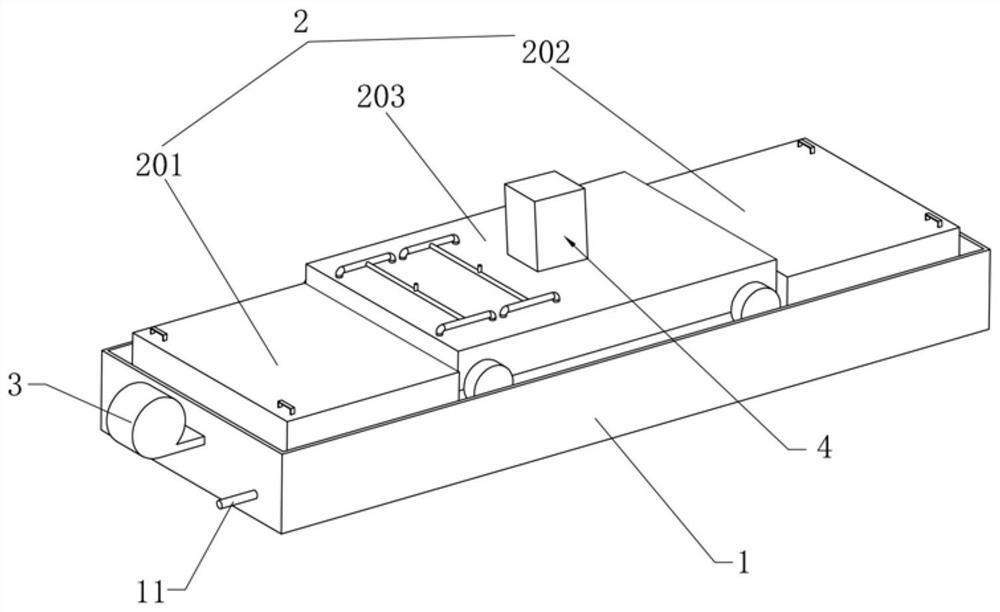

Multi-material ceramic photocuring printing system mechanism and rough blank preparation method

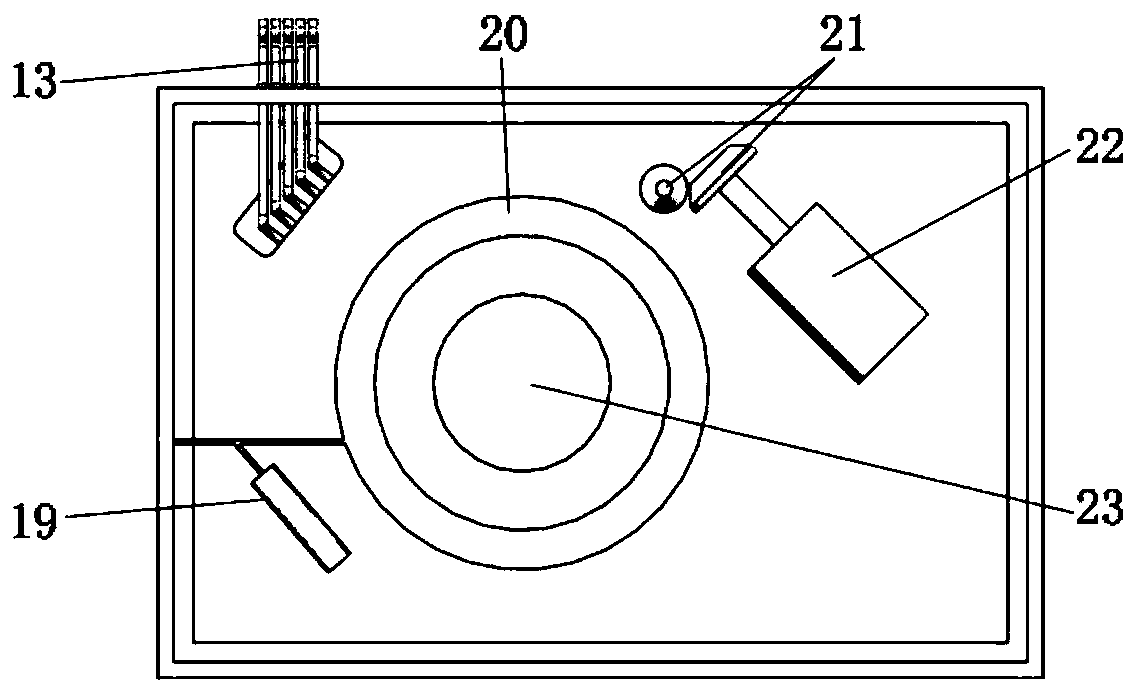

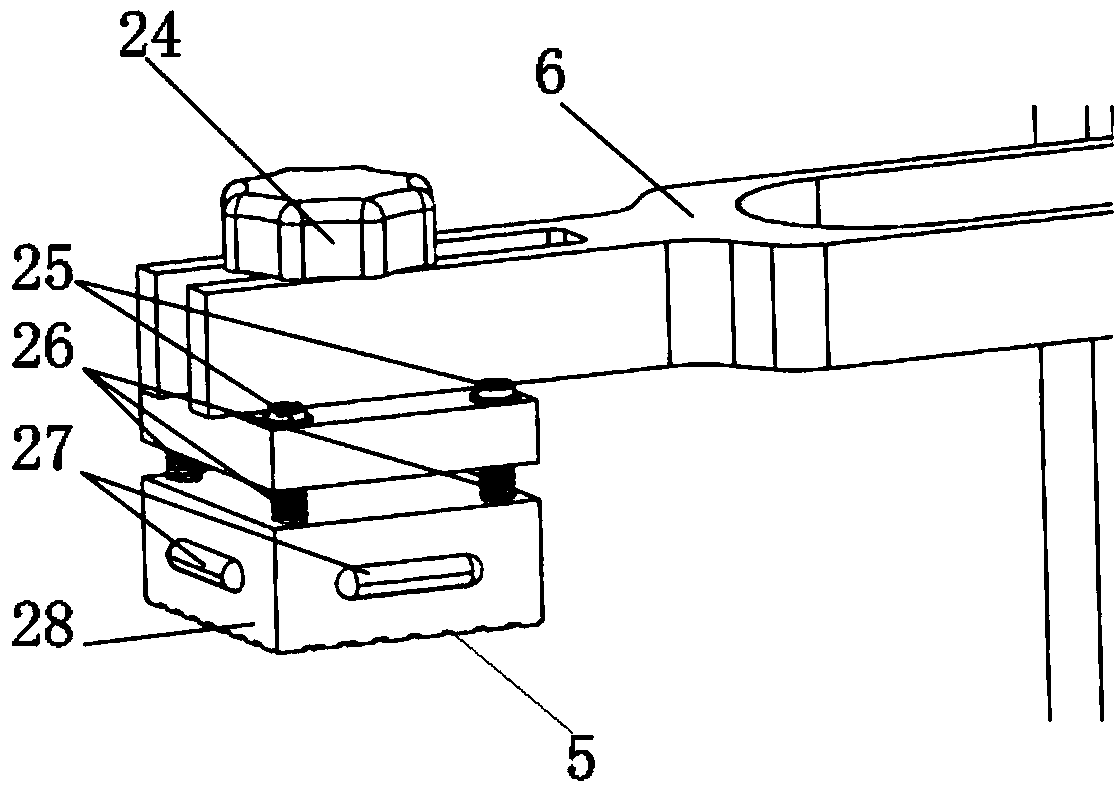

InactiveCN109676747AReduce supplyLow costAdditive manufacturing apparatusRotary stirring mixersMulti materialWorking temperature

The invention discloses a multi-material ceramic photocuring printing system mechanism and a rough blank preparation method. The multi-material ceramic photocuring printing system mechanism comprisesa photocuring printing system, forming equipment, stirring equipment, a clamping mechanism and a slicking device. The stirring equipment on the photocuring printing system works for stirring at the temperature of 30-35 DEG C for 1-2 h, the stirring speed is 60-100 r / min, a one-way stirring manner and a two-way stirring manner are combined, the needed constant and proper working temperature duringa polymerization reaction of photosensitive resin is guaranteed, excessive consumption of physical strength during manual stirring is omitted, the stirring quality of slurry is guaranteed, the slurryis more uniform, the action of extruding the slurry by extruding devices is achieved through a negative-pressure pump, the slurry made of different materials is conveyed by different pipelines, the extruding angle of an extruding device set is adjustable, and the acting positions of the extruding device set and the slicking device are harmonized. A temperature sensor is mounted on one side of a silicone rubber heating ring, both the silicone rubber heating ring and the temperature sensor are connected with a digital readout constant-temperature controller, the temperature of the slurry in a forming pond is at 30-35 DEG C, and the speed of the polymerization reaction of the photosensitive resin and the forming rate of rough blanks are increased.

Owner:NANTONG INST OF TECH

Anti-blocking cement stirring device for building construction

ActiveCN107984614AQuality assuranceGood stirring functionCement mixing apparatusArchitectural engineeringBuilding construction

The invention discloses an anti-blocking cement stirring device for building construction. The anti-blocking cement stirring device comprises a first stirring tank, and the top of the first stirring tank is fixedly connected with a second stirring tank. The top of the second stirring tank is fixedly connected with a first motor, and the output shaft of the first motor is fixedly connected with a rotary rod. The bottom end of the rotary rod penetrates through the second stirring tank and extends to the inner chamber of the second stirring tank, and the two sides, extending to the inner chamberof the second stirring tank, of the rotary rod are fixedly connected with first stirring blades. The invention relates to the technical field of building construction. The anti-blocking cement stirring device can scrape cement remaining on the inner walls of the stirring tanks, greatly increases the use ratio of cement, reduces the labor intensity of workers, saves the cost, and is safe and reliable, so that the device has a good scraping function. The stirring quality of cement is ensured, so that the device has a good stirring function. The device is convenient and fast.

Owner:宁波裕龙光电科技有限公司

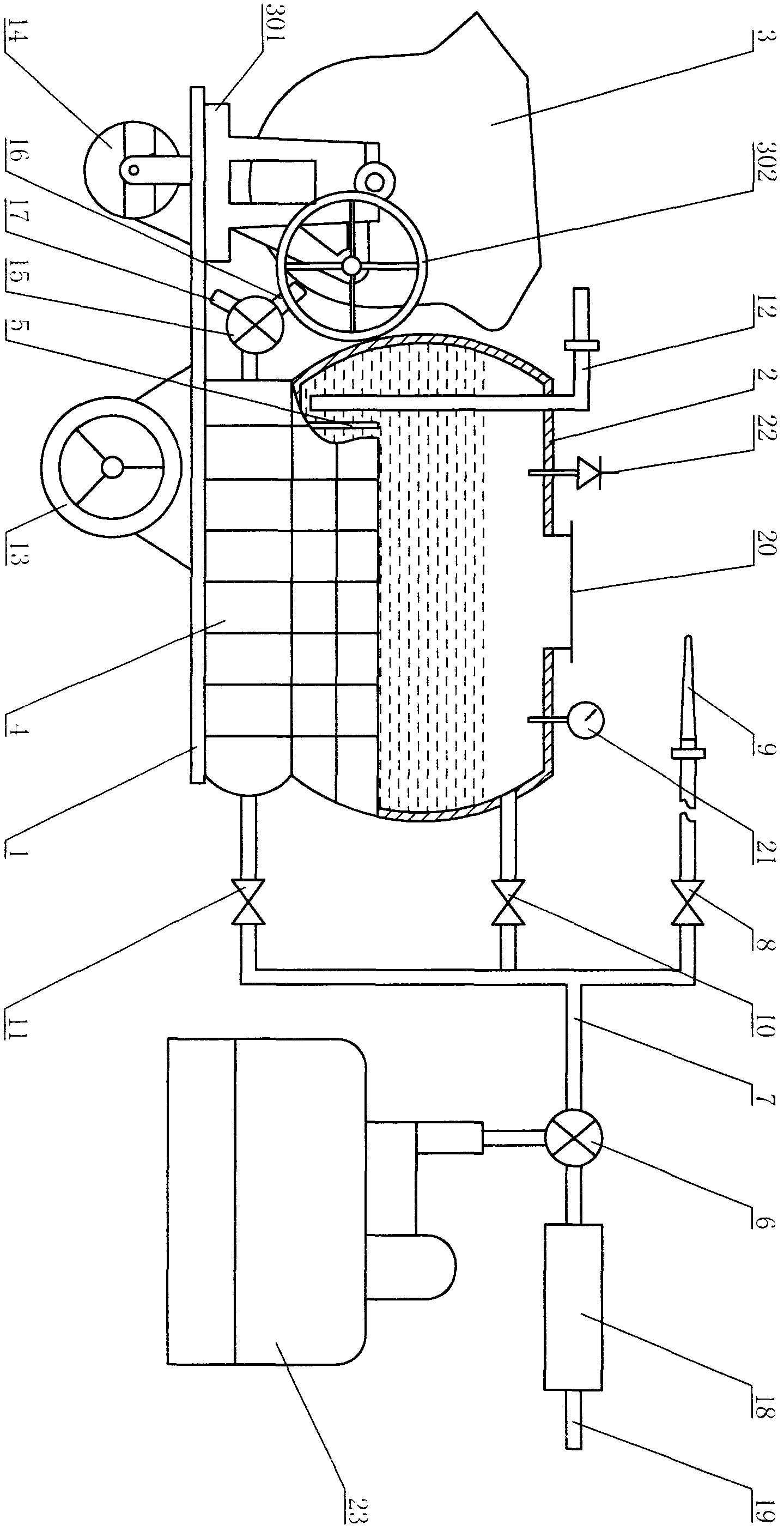

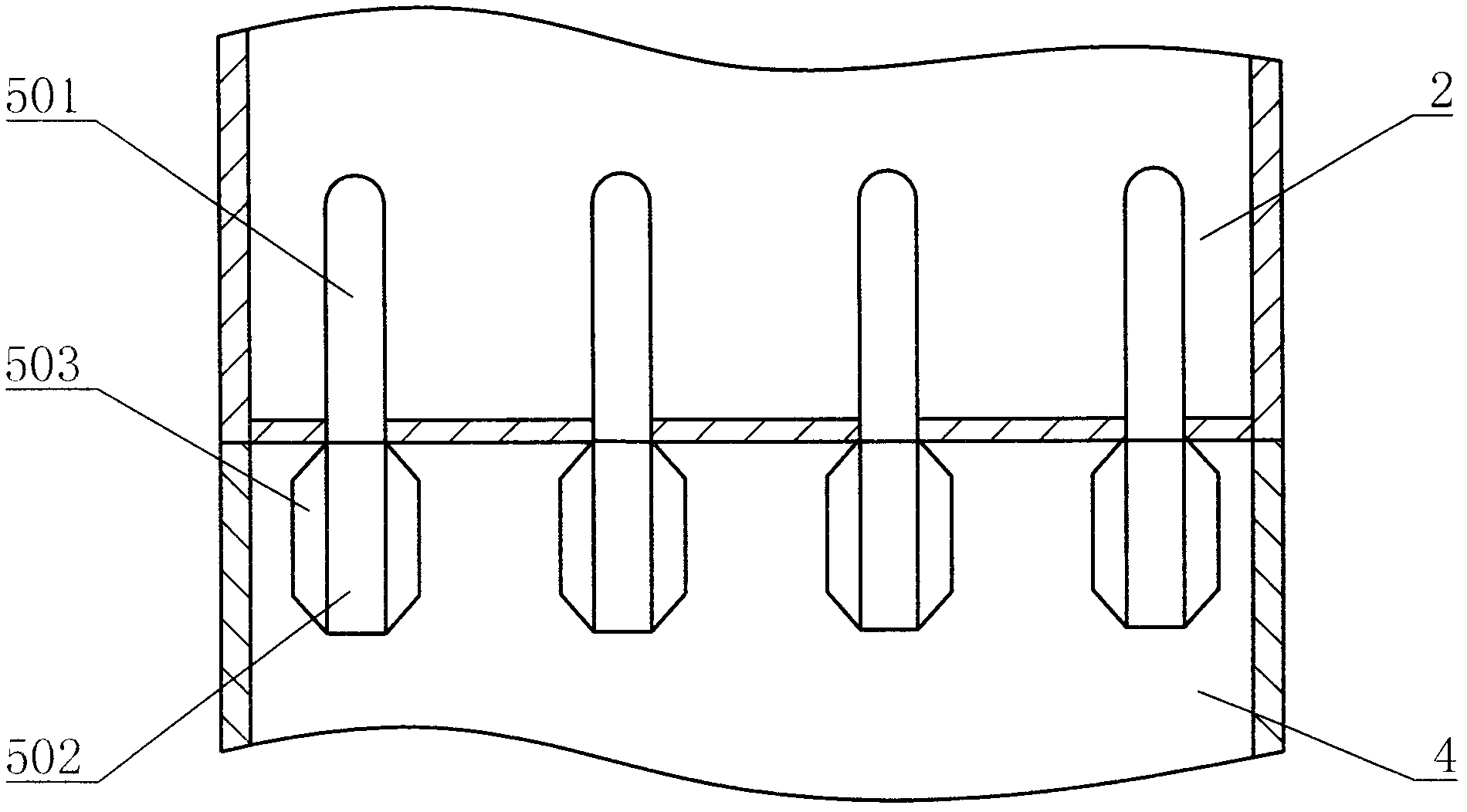

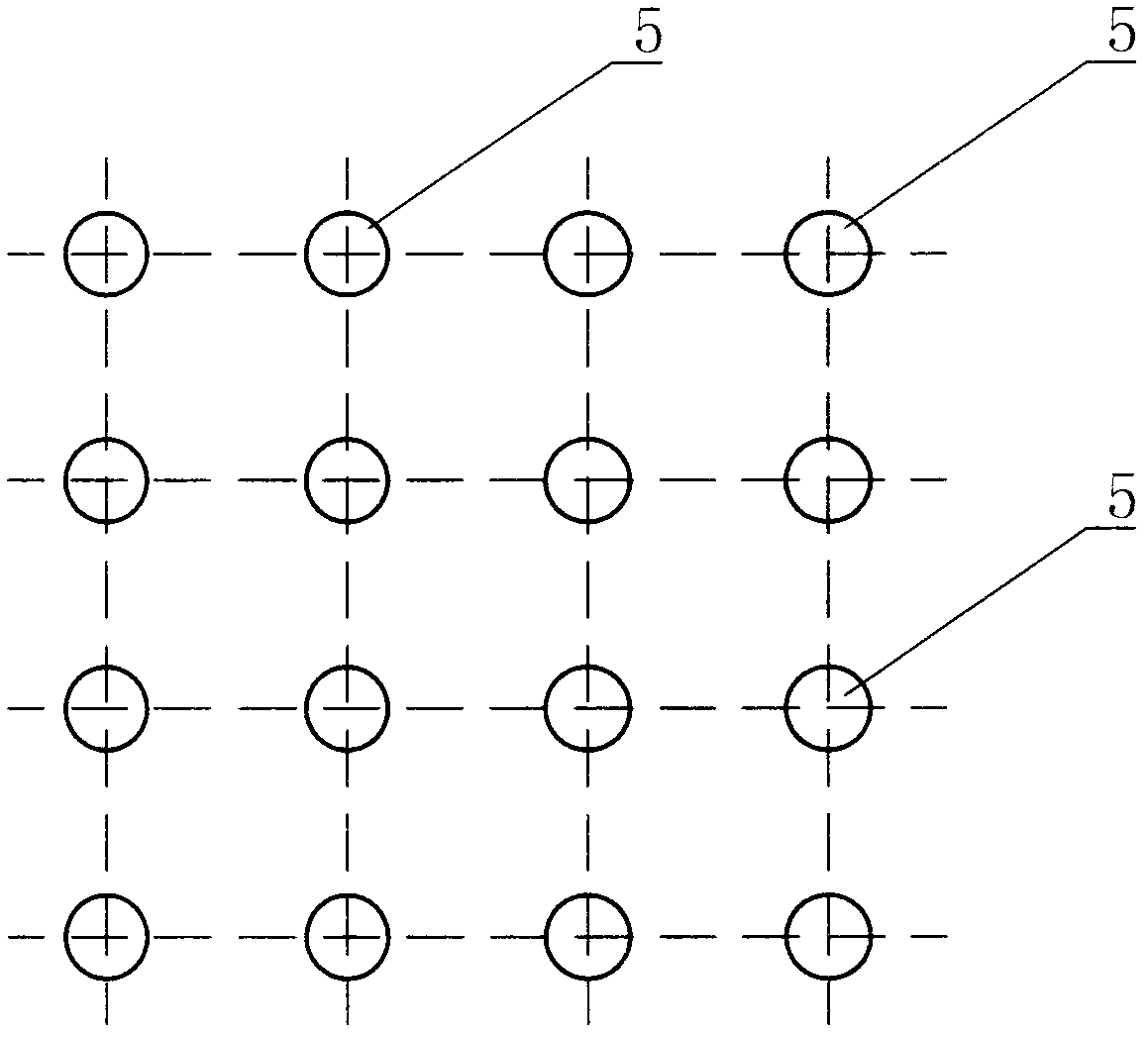

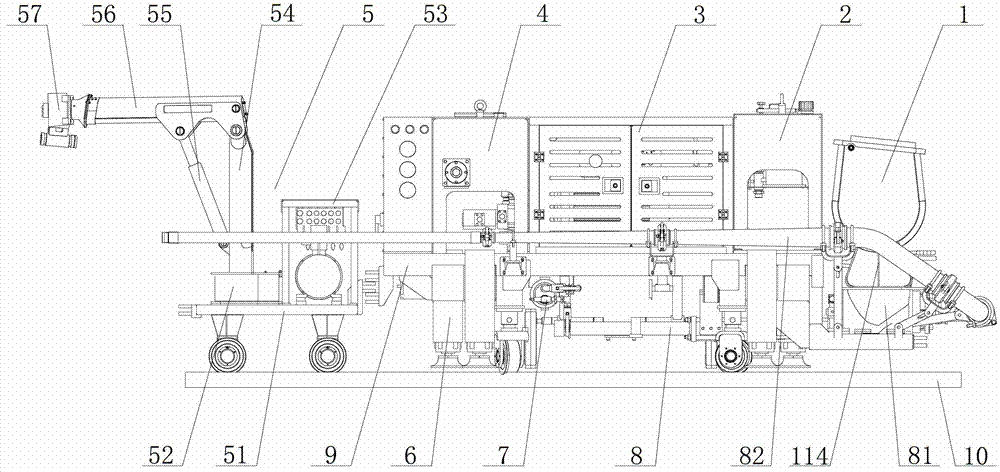

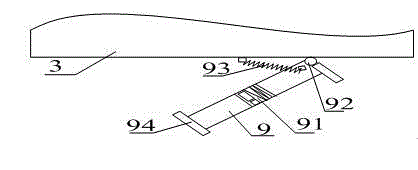

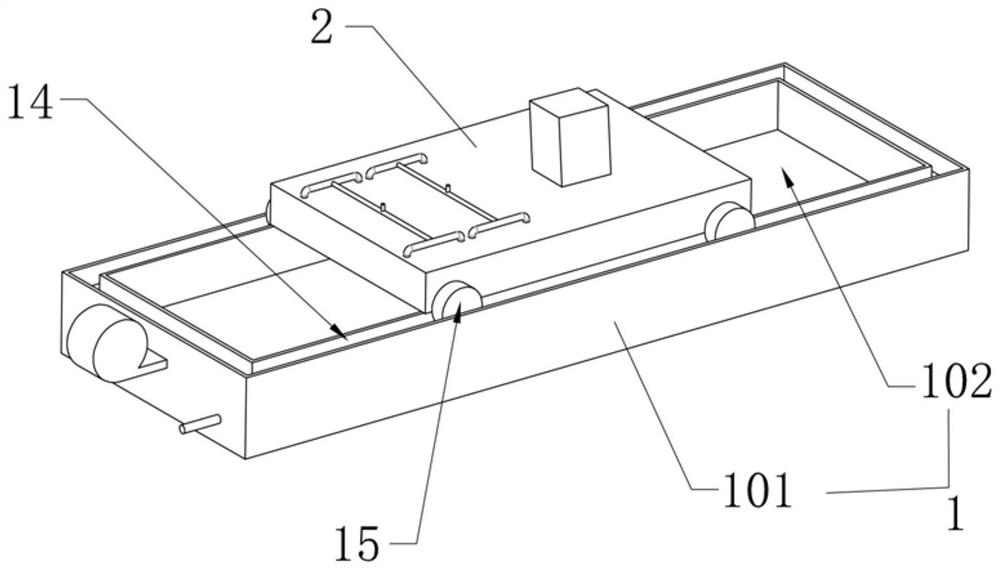

Pull-type asphalt highway maintenance vehicle

InactiveCN102561162AReduce consumptionSimple and fast operationRoads maintainenceFuel tankEngineering

The invention relates to highway maintenance and service equipment, in particular to a pull-type asphalt highway maintenance vehicle which has complete functions, saves energy, is environmentally friendly, and has low cost. The pull-type asphalt highway maintenance vehicle comprises a chassis (1), an oil storage tank (2), a mixer (3), a heating device arranged between the chassis (1) and the oil storage tank (2), and an exhaust gas recovery and distribution device, wherein the oil storage tank (2) and the mixer (3) are arranged on the chassis (1); the heating device comprises a heat collection box (4) and a heat pipe (5); the heat pipe (5) is arranged in the heat collection box (4); one end of the heat pipe (5) extends into the oil storage tank (2); the exhaust gas recovery and distribution device comprises a three-way valve (6) connected with an exhaust pipe of an internal combustion engine (23), and a gas pipeline (7) arranged by the three-way valve (6); the gas pipeline (7) is connected with a cleaning nozzle (9), the oil storage tank (2) and the heat collection box (4) respectively by a cleaning valve (8), a pressurization valve (10) and a heating valve (11); and an oil pipe (12) is arranged above the oil storage tank (2).

Owner:王琰

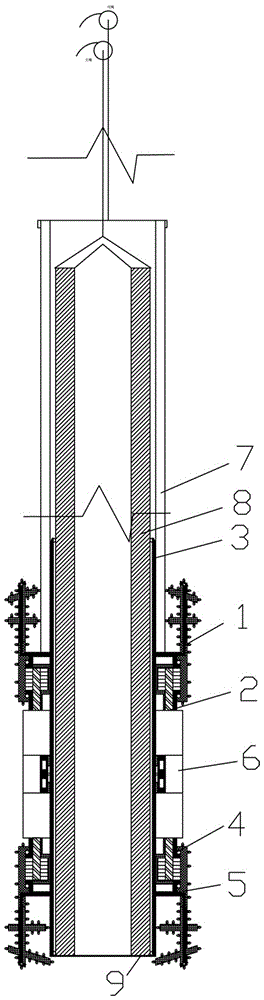

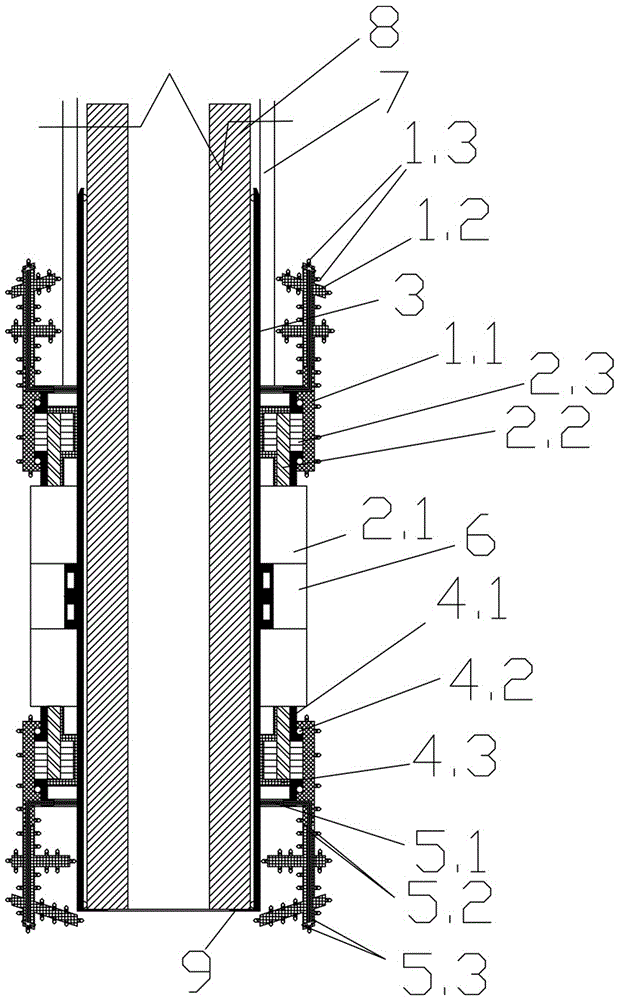

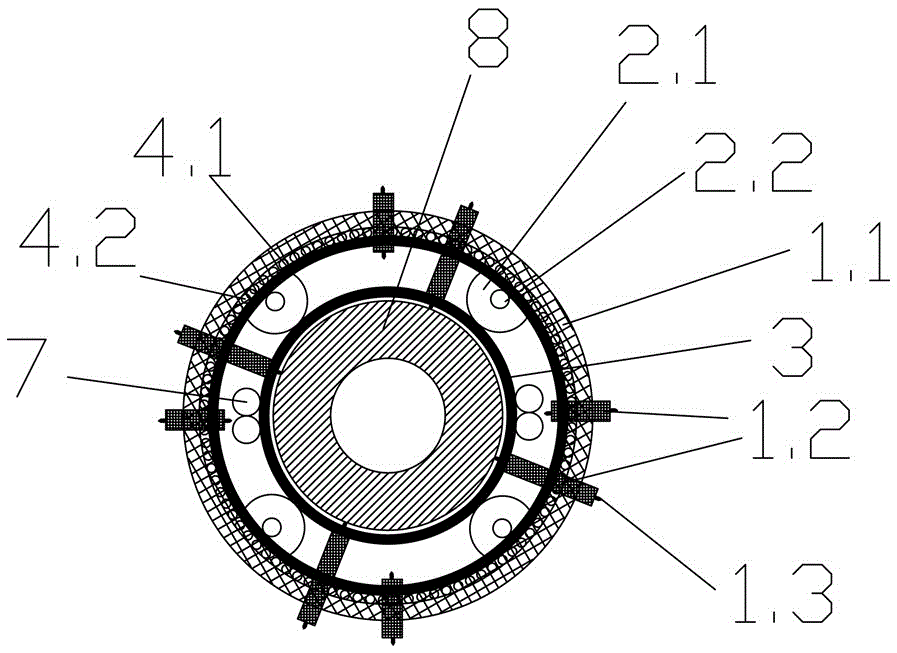

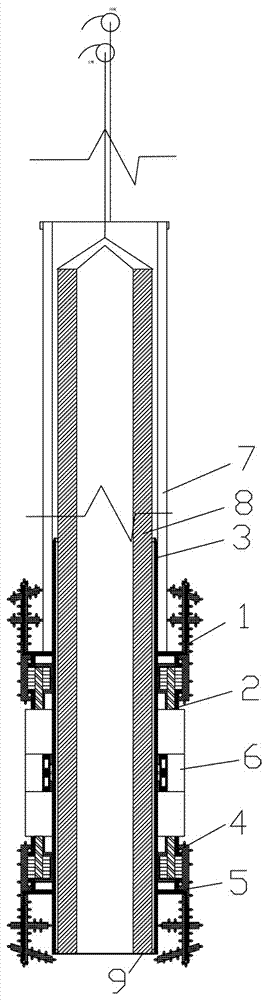

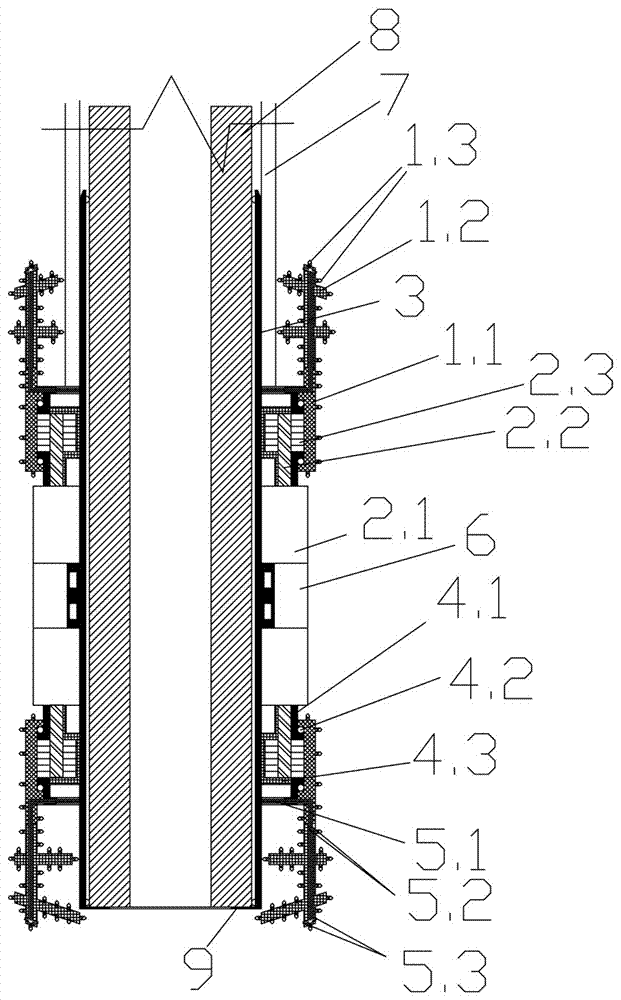

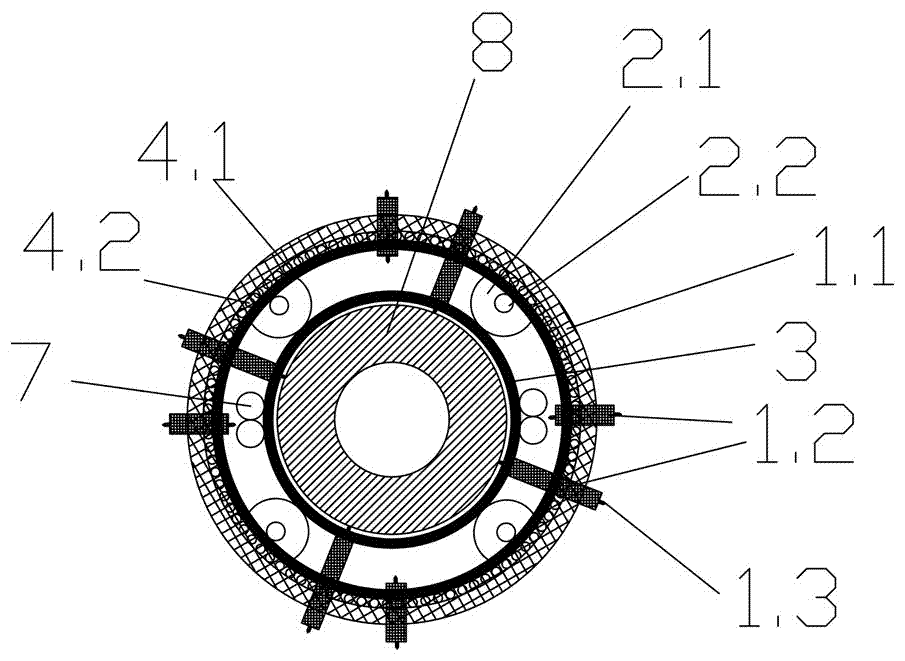

Construction method for pile foundation

ActiveCN105544579AGuaranteed same coreImprove efficiencyFoundation engineeringBuilding constructionMechanical construction

The invention discloses a construction method for a pile foundation. The construction method for the pile foundation comprises the steps that a set of special mechanical construction device having power is installed on the outer side of a rigid pile; after the rigid pile with the special mechanical construction device installed on the outer side is placed in place, sinking of the rigid pile is started by means of a ground pile frame, the pile sinking process is controlled, and the special mechanical construction device having power sinks underground on the outer side of the rigid pile along with the rigid pile after sinking of the rigid pile is started; and in the sinking process of the rigid pile or in the pulling process of the special mechanical construction device, the special mechanical construction device is used for conducting drilling construction on foundation soil around the pile or conducting modification construction on the foundation soil around the pile or conducting replacing construction on the foundation soil, so that sinking of the rigid pile is achieved under the condition that small force is exerted on the ground pile frame, and modified soil including cemented soil or replacement soil containing concrete or mortar can be formed around the rigid pile.

Owner:黄国庆

Lift-type architectural coating stirring device

InactiveCN105536615AEasy to adjustQuality improvementRotary stirring mixersTransportation and packagingBiochemical engineeringCooling coil

The present invention discloses a lift-type architectural coating stirring device including a tank body, a first motor and a stirring shaft; the bottom side wall of the tank body is provided with a material discharge hole, a filter net is arranged on the material discharge hole, the stirring shaft is provided with a stirring blade, the stirring blade is placed inside the tank body, the tank body comprises an inner layer and an outer layer, a cooling coil is arranged between the inner layer and the outer layer, a water inlet end of the cooling coil is communicated with an external water pump, a water outlet end of the cooling coil and the water pump are communicated with an external water pool, the bottom of the tank body is fixed onto a rotating lifting mechanism through a connecting plate, in use, by additional arrangement of the cooling coil and the water pump, the stirring tank always maintains at right stirring temperature, stirring quality can be guaranteed, by use of a stirring column structure and the rotating lifting mechanism on the bottom of the tank body, the tank body is very easy to adjust in stirring process, and coating stirring quality is significantly improved.

Owner:李秋芬

Construction method of large-volume concrete in severe cold areas

InactiveCN108999405AEnsure mixing qualityReduce freezingBuilding material handlingElectric heatingCold area

The invention discloses a construction method of large-volume concrete in severe cold areas, which comprises the steps of 1, mix proportion design of concrete raw materials; 2, heat preservation storage of the concrete raw materials, wherein the step further comprises the sub-steps of 2.1, heat preservation storage of gravel aggregates, and 2.2, storage and heating of water by adopting an electricheating water tank; 3, mixing of the concrete raw materials; 4, concrete transportation; 5, concrete pouring; and 6, concrete maintenance. According to the construction method of large-volume concrete in the severe cold areas, heat preservation can be performed on the concrete forming process through setting the measures of performing heat preservation on the concrete raw materials, performing heat preservation on the raw material mixing process, performing heat preservation on concrete transportation and pouring and performing heat preservation on concrete maintenance, thereby ensuring the mixing quality, the pouring quality and the forming quality of the concrete.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Concrete stirrer

InactiveCN106626065AReduce the presence of air bubblesEnsure mixing qualityDischarging apparatusMixing operation control apparatusCouplingPulp and paper industry

Owner:唐健发 +1

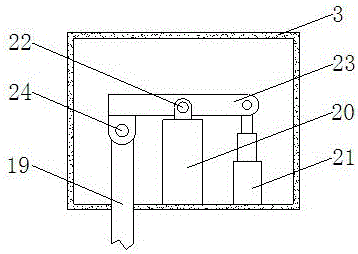

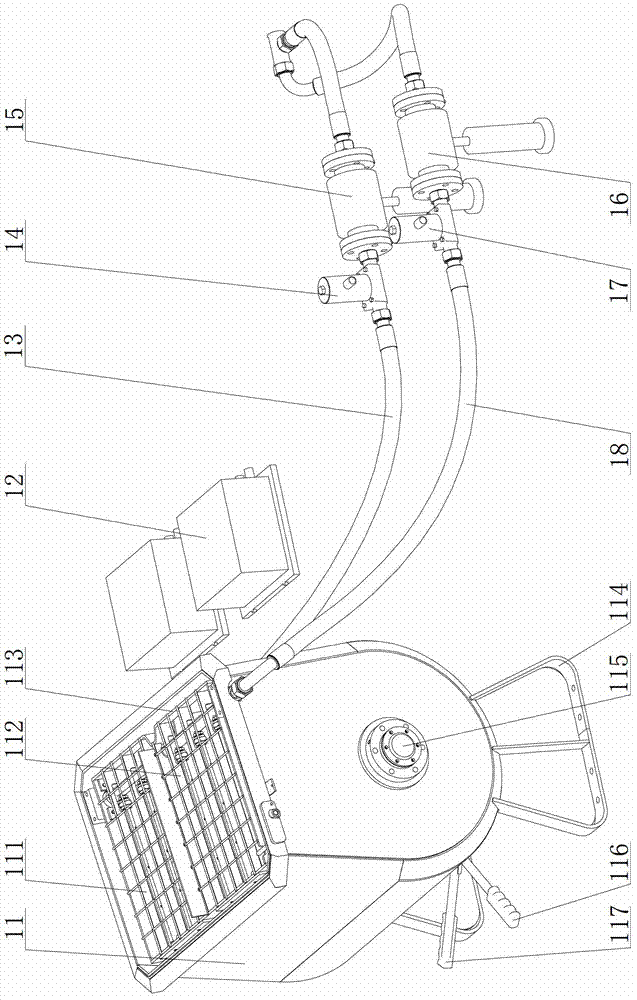

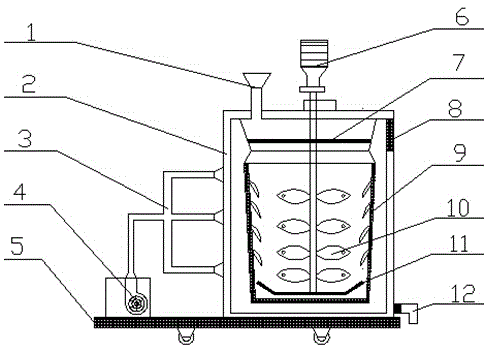

Pre-agitating system and wet spraying machine

InactiveCN102828757AEnsure mixing qualityHigh precisionUnderground chambersCement mixing apparatusEngineeringMechanical engineering

The invention discloses a pre-agitating system and a wet spraying machine. The pre-agitating system comprises an agitating hopper, a water inlet pipeline, an electromagnetic valve, a flow meter and a control device. A discharging valve is arranged at the bottom of the agitating hopper, and the electromagnetic valve and the flow meter are serially arranged on the water inlet pipeline which is communicated with the agitating hopper. The control device is in signal connection with the electromagnetic valve and the flow meter, and used for setting the water feeding volume of the agitating hopper, determining whether the volume of water fed by the water inlet pipe into the agitating hopper reaches the water feeding volume or not according to information fed back by the meter flow, and controlling the electromagnetic valve to close when the water feeding volume is reached. The electromagnetic valve and the flow meter on the water inlet pipeline are controlled in real time by the control device to supply the water feeding volume in corresponding proportion to the drying material feeding volume to the agitating hopper, namely automatic precise water feeding is realized, and accordingly concrete agitating quality can be guaranteed. The invention further provides the wet spraying machine with the pre-agitating system.

Owner:SANY HEAVY IND CO LTD (CN)

Neutron radiation resisting barite low hydration heat concrete construction technology

ActiveCN104712144AGuarantee the construction qualityImprove workabilityBuilding material handlingSlagNeutron radiation

The invention relates to the technical field of building construction, in particular to a neutron radiation resisting barite low hydration heat concrete construction technology. According to the neutron radiation resisting barite low hydration heat concrete construction technology, raw materials of concrete are iron sand, glass dust, heavy crystal sand, iron ore, barite, cement, mineral powder, water and a water reducing agent; the construction technology comprises the following steps of A, calculating working mix proportion; B, feeding; C, stirring; D, transporting; E, pouring; F, maintaining. The technical scheme can effectively guarantee the construction quality of the concrete, good workability, no bleeding and good mobility in concrete pouring are guaranteed, and the requirements for radiation resistance, low shrink, high density, high uniformity and the like are satisfied. When a mass concrete structure with the minimum geometric dimensioning larger than 1.2m is subjected to construction by the adoption of the technical scheme provided by the neutron radiation resisting barite low hydration heat concrete construction technology, low hydration heat of the concrete construction can be guaranteed, the temperature difference between inside and outside is lower than or equal to 20 DEG C, the adiabatic temperature rise is lower than or equal to 55 DEG C, the phenomena of honeycombs, holes, slag inclusion and cracks do not occur on the surface of the concrete, and therefore higher pouring and vibrating quality can be guaranteed.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR +1

Jacketed pan for food production

ActiveCN110693317AEasy to tiltTilt not requiredCooking vesselsFood shapingElectric machineEngineering

The invention relates to the technical field of jacketed pans, specially relates to a jacketed pan for food production. The jacket pan comprises a lower unit bracket, a rotating shaft, a pan body andan upper unit bracket; the upper end face of the lower unit jacket is fixedly connected with the upper unit bracket. The upper end surface of the upper unit bracket is fixedly connected with a rotating motor; steam absorption devices are arranged on the left side and the right side of the rotating motor, the lower end faces of the steam absorption devices are fixedly connected with the upper unitbracket, a connecting device is fixedly connected to the tail end of a main shaft of the rotating motor, a stirring device is fixedly connected to the lower end face of the connecting device, and thepan body is arranged below the stirring device. According to the jacketed pan, through the arrangement of the connecting shaft, a connecting spring, a sliding ring and a limiting frame, the sliding ring is pushed upwards, then the limiting frame is separated from a stirring shaft; it is guaranteed that the rotating motor does not need to incline through the arrangement, and therefore the problem that products in the jacketed pan are prone to splashing when poured out is solved.

Owner:湖南恒森农业科技股份有限公司

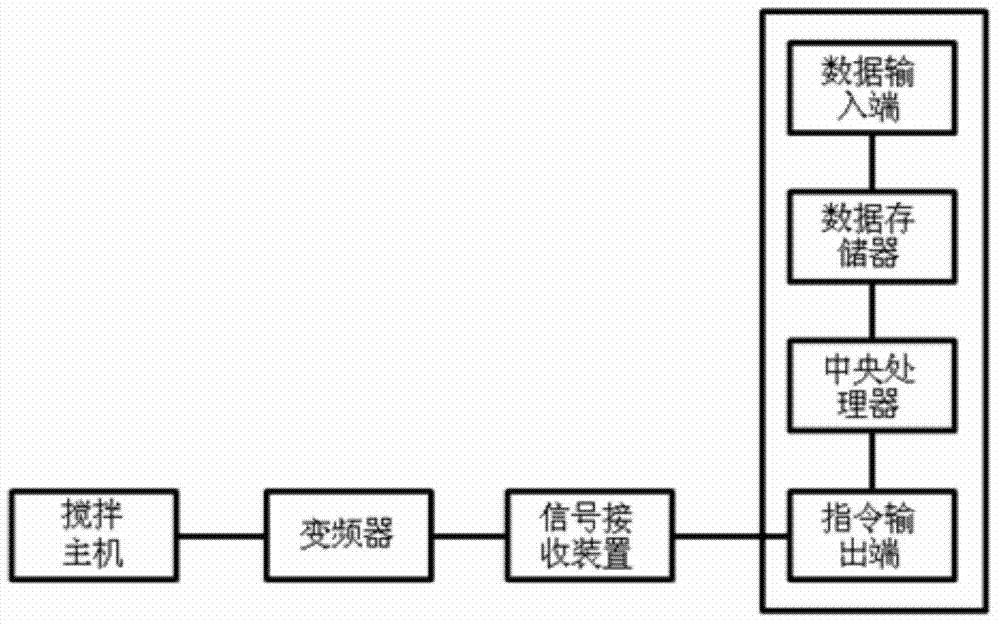

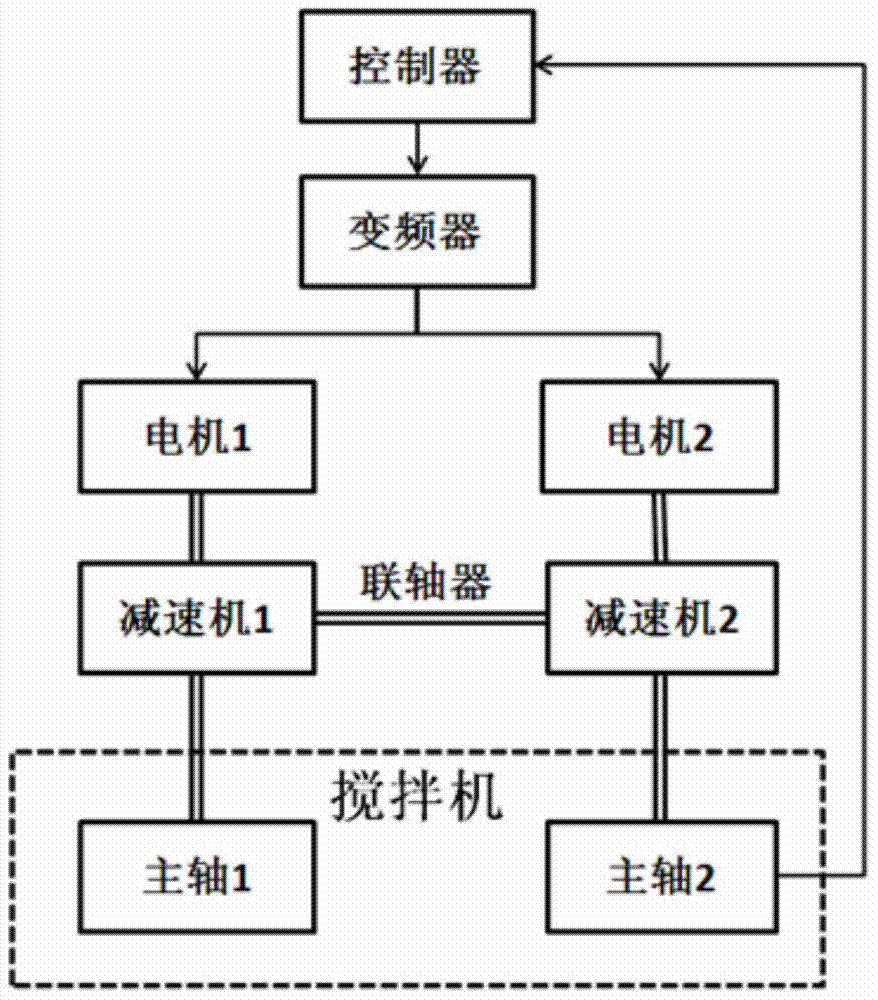

Rotating speed adaptive frequency conversion control system and method for concrete mixer

InactiveCN103786259AReduce installed powerLow costControl apparatusFrequency changerFrequency conversion

The invention discloses a rotating speed adaptive frequency conversion control system and a rotating speed adaptive frequency conversion control method for a concrete mixer. The system comprises a controller, a frequency converter, two motors and two speed reducers; each of the two speed reducers is connected with a main shaft of the mixer; both the two motors are connected with the two speed reducers; the frequency converter is electrically connected with the two motors; the controller provided with a parameter automatic optimizing module is connected with the frequency converter. The system further comprises a module which can adaptively control the rotating speed in mixing according to the load so as to increase the rotating speed to clean a mixing shaft and blades when concrete is not mixed. With the adoption of the rotating speed adaptive frequency conversion control system and method for the concrete mixer, the installed power of the motors can be reduced, the cost can be decreased, and the energy consumption can be saved; the mixing speed and power of mixing can be adaptively controlled according to the load, thus the average power can be reduced, and the energy consumption can be saved; the parameters are automatically and optimally controlled according to different materials, so as to ensure the mixing quality while improving the mixing efficiency; when concrete is not mixed, the mixer can be cleaned by running at high speed.

Owner:SANYI ROBOT TECH CO LTD

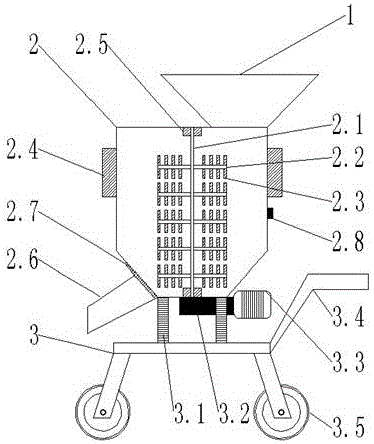

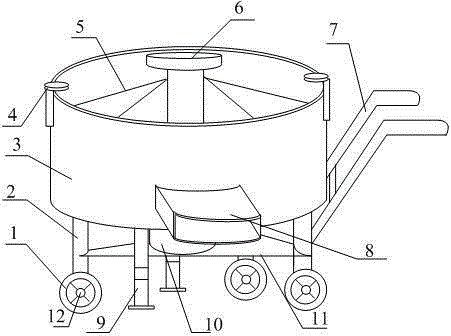

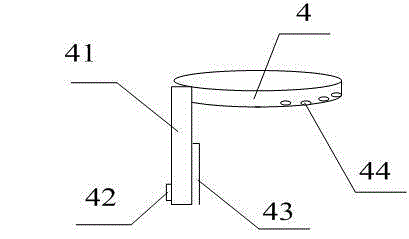

Novel small concrete mixer

InactiveCN105773836AAdd water evenlyImprove efficiencyCement mixing apparatusLiquid ingredients supply apparatusEngineeringCylinder block

The invention provides a novel small concrete mixer. The novel small concrete mixer comprises movable wheels, a support, a cylinder block, sprayers, mixing rods, a rotary shaft, a hand-pushing handle, a discharging outlet, balancing legs, a motor, a motor base and wheel shafts. The movable wheels are fixed to the lower portion of the support through the wheel shafts. The cylinder block is arranged on the upper portion of the support. The sprayers are fixed to the left side edge and the right side edge of the cylinder block through jack catches. The mixing rods are fixed to the rotary shaft. The hand-pushing handle is welded to the right side of the support. The discharging outlet is formed in the front side face of the cylinder block. The balancing legs are connected to the lower portion of the cylinder block through collapsible shafts. The motor is arranged on the lower portion of the cylinder block. The motor base is arranged on the lower portion of the motor. Through the arrangement of the sprayers, the balancing legs and the movable wheels, the mixing quality is improved, the equipment service life is prolonged, the mixer is convenient to move, manpower is saved, operation is simple, the efficiency is improved, and the mixer is convenient to apply and popularize.

Owner:天津天成昇科技有限公司

Stirring device for chemical engineering

InactiveCN104815576AGuaranteed post storageEnsure mixing qualityRotary stirring mixersMixer accessoriesFilter materialChemical engineering

The invention discloses a stirring device for chemical engineering. The stirring device comprises a tank body, a stirring motor, a feed inlet and a discharge outlet, one side of the outer wall of the tank body is provided with three joints, the other ends of the joints are converged in three outlets of a four-way pipe via connecting pipes, and the other outlet of the four-way pipe is connected with a hot air fan via a connecting pipe. The feed inlet is communicated with a stirring chamber arranged in the tank body, the upper end of the stirring chamber is provided with a primary filter screen close to the feed inlet, and a secondary filter screen is fixedly arranged on the periphery of the stirring chamber. The stirring device is convenient to operate, uniform in stirring, high in stirring efficiency and capable of automatically filtering materials. Meanwhile, the materials can be automatically dried and quality of the materials can be ensured.

Owner:DONGZHI TIANFU CHEM

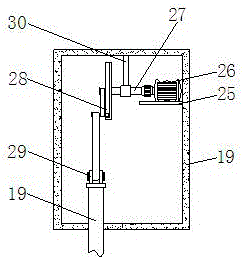

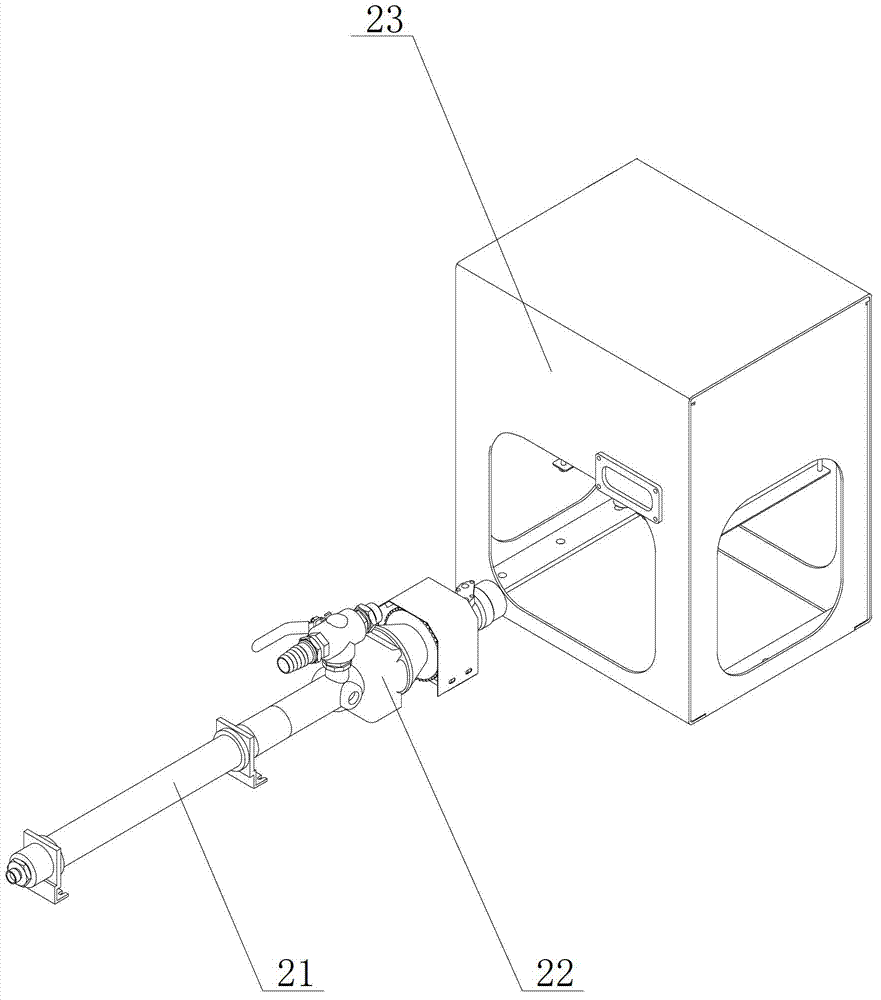

Anti-blocking gypsum mortar spraying machine

InactiveCN107584664AStir wellImprove fluencyDischarging apparatusCement mixing apparatusPulp and paper industryAir compressor

The invention discloses an anti-blocking gypsum mortar spraying machine. The machine comprises a rack, a motor, a stirring device and a discharging device, wherein the motor is located above the rack;a primary stirring device and a secondary stirring device are correspondingly mounted at the upper part and the lower part of the rack respectively; the primary stirring device comprises a primary stirring barrel, a primary stirring shaft and primary stirring bars, the primary stirring barrel is fixedly mounted at the upper part of the rack, a feeding port is formed in the upper left part of theprimary stirring barrel, and a control valve is arranged at the bottom of a secondary stirring barrel; a spraying mechanism comprises an air compressor, an extruding mechanism, a screw conveyor, a mortar spraying pipe, a spiral steel wire, a two-way water ring and a mortar spraying head. The anti-blocking gypsum mortar spraying machine is convenient to use, low in construction cost, safe and efficient; the raw materials are subjected to coarse stirring and fine stirring, all stages of stirring are non-interfering, not only can the raw materials be sufficiently stirred, but also stirring efficiency and stirring quality are guaranteed; smoothness of mortar spraying is improved, blockage is reduced, and work efficiency is improved.

Owner:金晶

Trifluoromethanesulfonic acid production device and method

PendingCN112679392APut an end toImprove efficiencyCellsOrganic compound preparationPotassium fluorideTriflic acid

The invention relates to a trifluoromethanesulfonic acid production device and method, and belongs to the technical field of organic chemical engineering. The method comprises the following steps: reacting a methanesulfonyl chloride aqueous solution with potassium fluoride to obtain a methanesulfonyl fluoride crude product, carrying out reduced pressure distillation and phase separation, carrying out reduced pressure distillation again, electrolyzing the obtained methanesulfonyl fluoride pure product and anhydrous hydrogen fluoride in an electrolyzer, cooling the electrolyzed gas, introducing the cooled gas into a sodium fluoride tower, collecting the cooled gas by using a cold trap device, carrying out hydrolysis reaction on the obtained trifluoromethanesulfonyl fluoride and a potassium hydroxide solution, carrying out extraction separation on a reaction product, and recrystallizing to obtain potassium trifluoromethanesulfonate; and carrying out acidolysis reaction on potassium trifluoromethanesulfonate and excessive concentrated sulfuric acid to obtain a trifluoromethanesulfonic acid crude product, and distilling the trifluoromethanesulfonic acid crude product to obtain purified trifluoromethanesulfonic acid. Methylsulfonyl fluoride can be rapidly prepared and purified, unqualified products generated in the preparation process can be fluorinated again, and the production efficiency and quality are effectively improved.

Owner:PERIC SPECIAL GASES CO LTD

Preparation device of Q235 steel template anticorrosive coating for ship

ActiveCN112675761AIncrease contact areaGuaranteed uniformityShaking/oscillating/vibrating mixersMixer accessoriesElectric machineryEngineering

The invention discloses a preparation device of an anticorrosive coating based on a marine Q235 steel template. The preparation device comprises a stirring tank body and a stirring assembly arranged in the stirring tank body, an upper cover is arranged at the top of the stirring tank body in a sealing manner, a feeding opening is formed in the top of the upper cover, a discharging opening is formed in the top of the stirring tank body, and the output end of a stirring motor arranged in the center of the top of the upper cover downwards extends into the stirring tank body and is in driving connection with the stirring assembly. A first stirring blade and a second stirring blade on the stirring assembly can rotate oppositely or oppositely while rotating with the stirring shaft as the center, the unfolding and folding functions are achieved, the contact area between the stirring blades and ingredients can be increased when the first stirring blade and the second stirring blade are unfolded, the stirring time can be shortened while the stirring quality is guaranteed, and when the first stirring blade and the second stirring blade are folded together, the first stirring blade and the second stirring blade interact with each other to extrude ingredients, so that the stirring uniformity of the ingredients is guaranteed.

Owner:YINGKOU INST OF TECH

Industrial stirring machine

InactiveCN104815579ASimple and efficient operationStir wellRotary stirring mixersMixer accessoriesImpellerFilter material

The invention discloses an industrial stirring machine. The industrial stirring machine comprises a stirring machine body, a stirring mechanism, a feed inlet and a discharge outlet. The stirring mechanism, the feed inlet and the discharge outlet are arranged on the stirring machine body. An observation window is arranged at the upper end of a shell of the stirring machine body. Air hammers are arranged on two sides of the shell of the stirring machine body symmetrically. The feed inlet is connected to a feed barrel arranged in the stirring machine body, the feed barrel is positioned at the top and a bottom framework is fixed to the lower side of the feed barrel. A filter net is arranged on the periphery of the bottom framework. Scrapers of arc-shaped structures are arranged on the inner side of the bottom framework and correspond to stirring impellers. The industrial stirring machine is simple and convenient to operate, uniform in stirring, high in stirring efficiency, capable of filtering materials automatically and allowing operators to observe stirring progress of the materials anytime and not easy to block during stirring.

Owner:ANHUI YANGZI CHEM

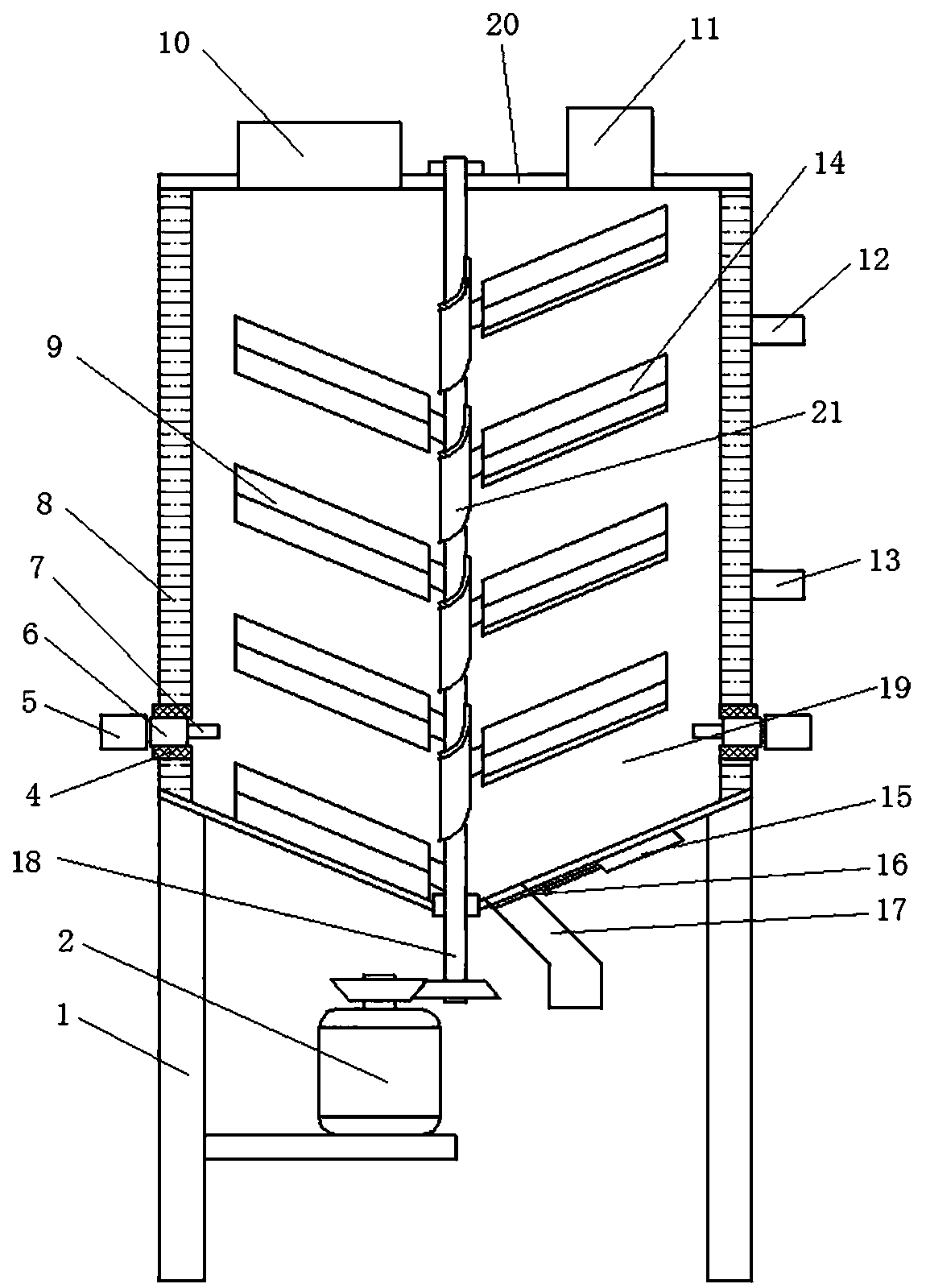

Stirring device for culture materials of edible fungi

InactiveCN105396486AAvoid touchingEnsure mixing qualityRotary stirring mixersMixer accessoriesEngineeringFungi culture

The invention belongs to the field of edible fungi culture medium processing devices and particularly discloses a stirring device for culture materials of edible fungi. The stirring device comprises a rack, a stirring kettle and a heating tank, wherein the stirring kettle comprises a kettle body, a stirring shaft, a stirring blade and a stirring motor; the kettle body is obliquely fixed on the rack, is cylindrical and comprises a side wall, a sealing ring, an inner wall and an outer wall; a hollow interlayer is arranged between the inner wall and the outer wall which are connected via the sealing ring; a water outlet pipe is arranged on the sealing ring at the relatively low end of the kettle body; steam outlets are uniformly formed in the inner wall; a steam inlet pipe is arranged on the sealing ring at the relatively high end of the kettle body; the stirring blade is spirally wound and fixed on the stirring shaft; the stirring shaft is hinged to the side wall; a belt plate connected with the stirring motor via a belt is arranged on the stirring shaft. The stirring device provided by the invention can not only uniformly stir a culture medium but also effectively protect the culture medium from mould and bacterial contamination.

Owner:CHONGQING ZUIBASHI AGRI PROD

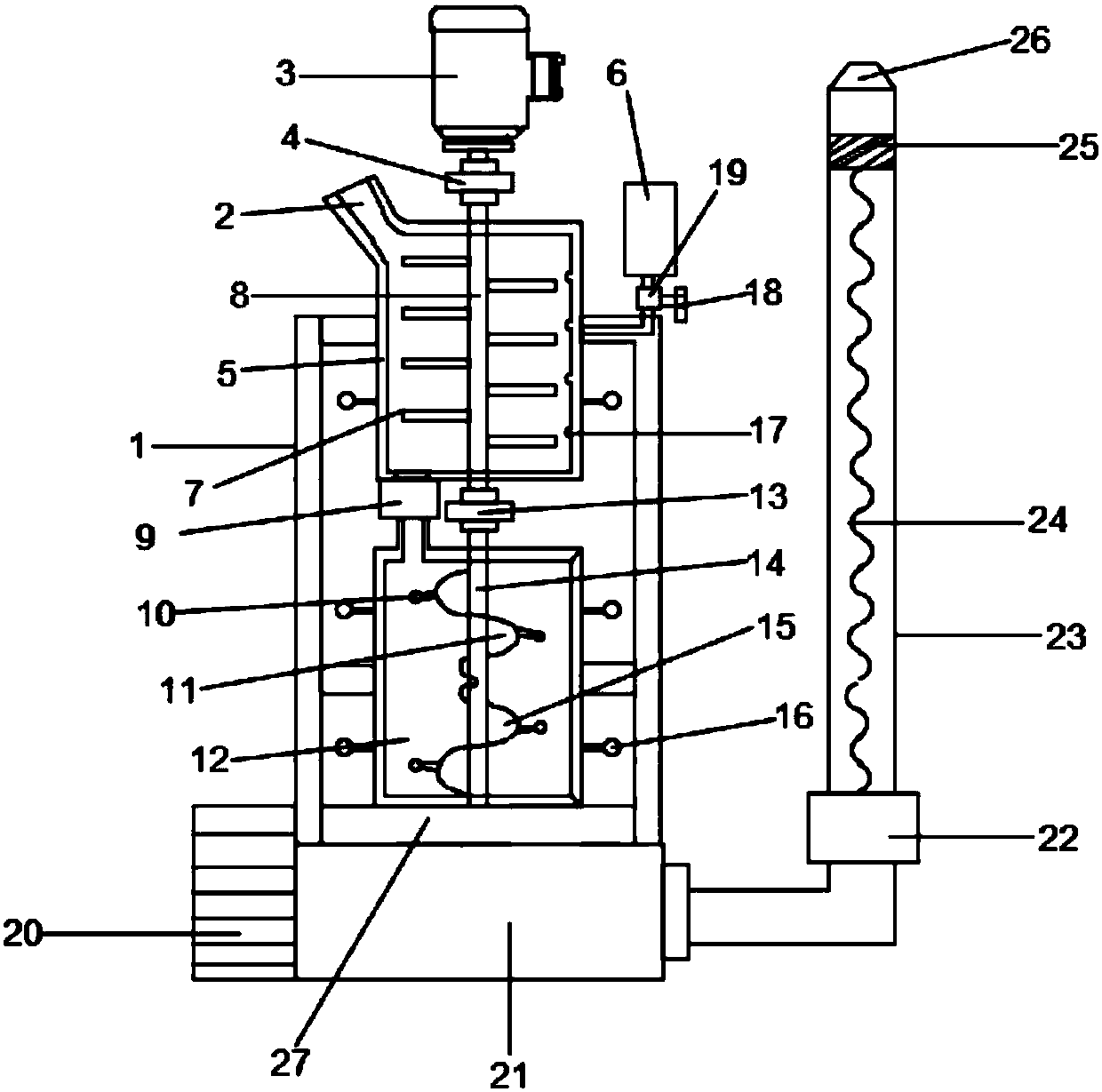

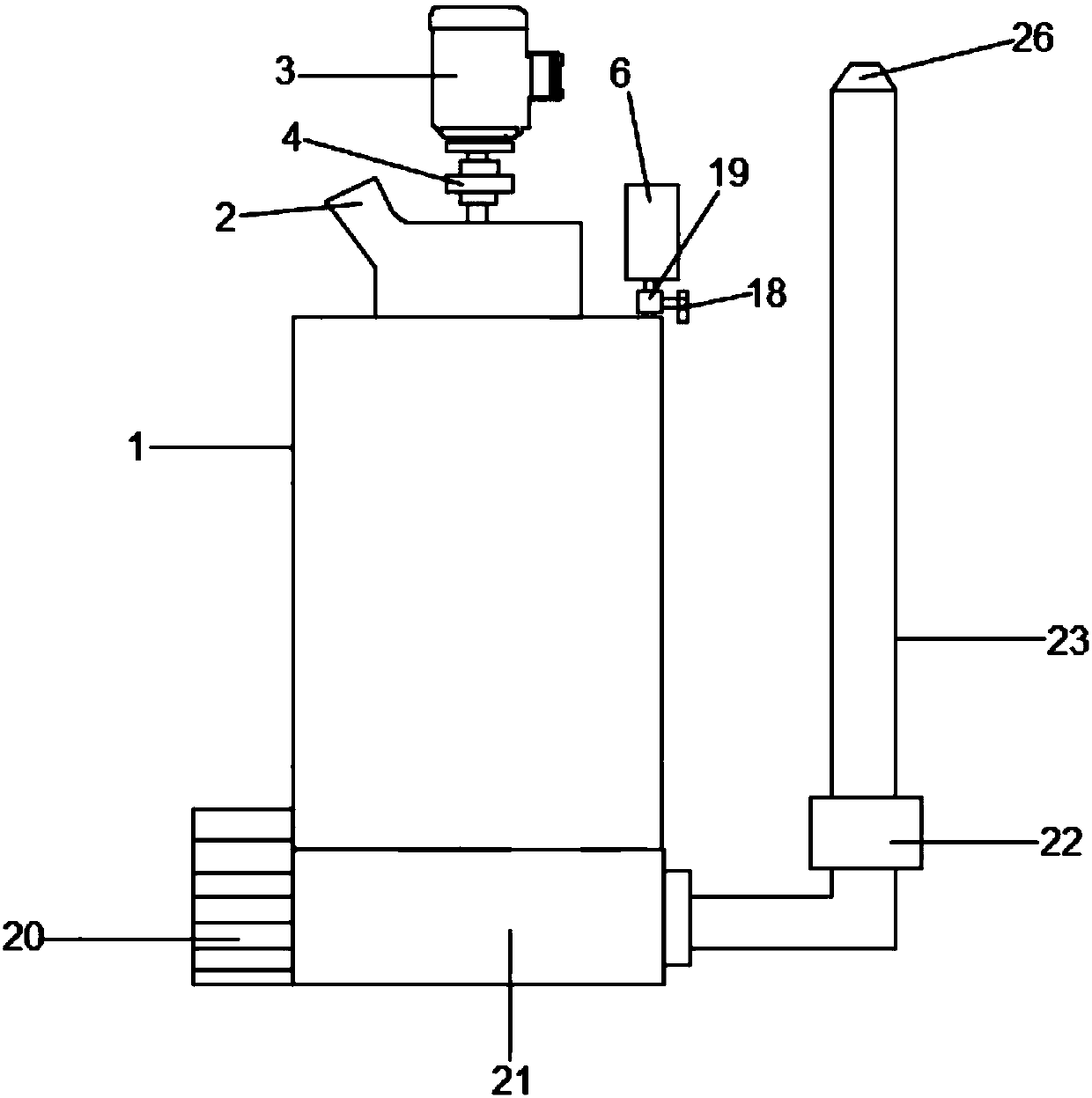

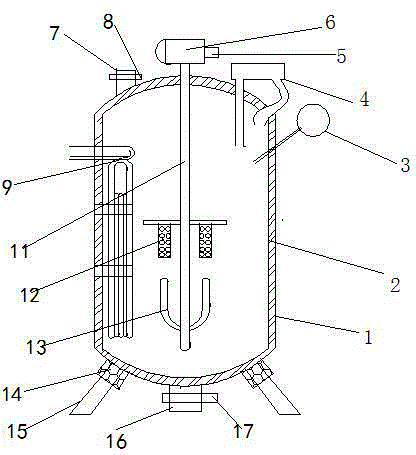

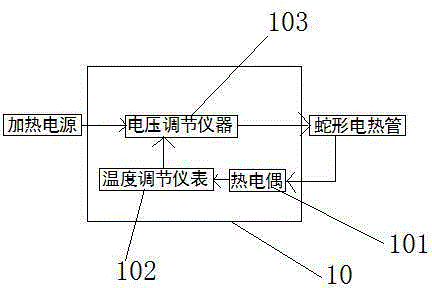

Chemical reactor

InactiveCN105727865AIncrease contact areaImprove heating efficiencyRotary stirring mixersMixer accessoriesAutomatic controlVoltage regulation

The invention discloses a chemical reactor. The chemical reactor comprises a tank, an electric motor and a temperature control system; the temperature control system comprises a thermocouple, a temperature control instrument and a voltage regulator; a mixing shaft is vertically arranged in the tank; a U-shaped mixer and a plate are connected to the mixing shaft; the mixing shaft is connected to the electric motor; a frequency converter is connected to the electric motor; a serpentine heating tube is arranged in the tank; the serpentine heating tube is connected to the temperature control system; an anti-corrosion layer is arranged on an inner wall of the tank; a material inlet and a material outlet are respectively arranged at a top and a bottom of the tank; a condenser reflux is further arranged at the top of the tank; a barometer is arranged on one outer side of the tank; support legs are arranged under the bottom of the tank; and vibration absorbers are arranged on the support legs at the joints of the support legs and the tank. The invention has the following beneficial effects: the chemical reactor is simple and compact in structure and practical in functions; and the chemical reactor is capable of heating rapidly and controlling heating temperature automatically; moreover, the chemical reactor is capable of adjusting rotation speed of the electric motor by itself, so that operation time of the chemical reactor is reduced and work efficiency and quality of the chemical reactor are improved.

Owner:天津天成昇科技有限公司

Pyrolysis stirring apparatus for treating contaminated soil

InactiveCN110142288AImprove stirring efficiencyFully heatedContaminated soil reclamationAgricultural engineeringUltrasonic vibration

The invention discloses a pyrolysis stirring apparatus for treating the contaminated soil. The apparatus comprises a machine frame and a pyrolysis tank welded on the machine frame, wherein the top ofthe pyrolysis tank is connected with a top cover by bolts, the top cover is provided with a material inlet and a gas discharge port, a jacket is disposed at the outer side of the side wall of the pyrolysis tank, the jacket is provided with an oil inlet and an oil outlet, the side wall of the pyrolysis tank is provided with at least one set of ultrasonic vibration components, the bottom of the pyrolysis tank has a funnel shape, a stirring component is arranged at the center of the bottom of the pyrolysis tank, and a material discharge component is further arranged at the bottom of the pyrolysistank. The apparatus can fully stir the soil to ensure that the soil can be uniformly heated.

Owner:HUNAN CITY UNIV

A dry-mixed mortar mixing device

ActiveCN112895135BImprove the mixing effectStir wellDischarging apparatusCement mixing apparatusCouplingElectric machinery

Owner:深圳市世展建设有限公司

Long pumping distance machine-made sand concrete

ActiveCN101164959BEnsure mixing qualityQuality assuranceSolid waste managementCrushed stoneWater reducer

Owner:GUIZHOU BRIDGE CONSTR GROUP

3D printing precoated sand and preparation method thereof

InactiveCN108296477AEnsure mixing qualityGuaranteed dimensional accuracyAdditive manufacturing apparatusFoundry mouldsNitrile rubberChemical composition

The invention relates to precoated sand and a preparation method thereof, in particular to 3D printing precoated sand and a preparation method thereof. The 3D printing precoated sand is prepared fromthe following raw materials in parts by weight: 80-90 parts of silica sand, 50-60 parts of graphite powder, 10-15 parts of lignin, 1.2-1.6 parts of sodium hexametaphosphate, 3-5 parts of pyrethroids compound, 3-5 parts of nitrile rubber, 3-5 parts of maltose, 10-20 parts of silica sol and 20-25 parts of phenolic resin. The 3D printing precoated sand provided by the invention is excellent in mechanical property, high in curing speed and good in high-temperature resistance, and addition of chemical components is reduced. The preparation method of the 3D printing precoated sand provided by the invention is simple to operate, and the process parameters are strictly controlled, so that the product quality of the precoated sand is finally guaranteed.

Owner:LIUZHOU LIUJING TECH CO LTD

A construction method of pile foundation

ActiveCN105544579BGuaranteed same coreImprove efficiencyFoundation engineeringEngineeringBuilding construction

Owner:黄国庆

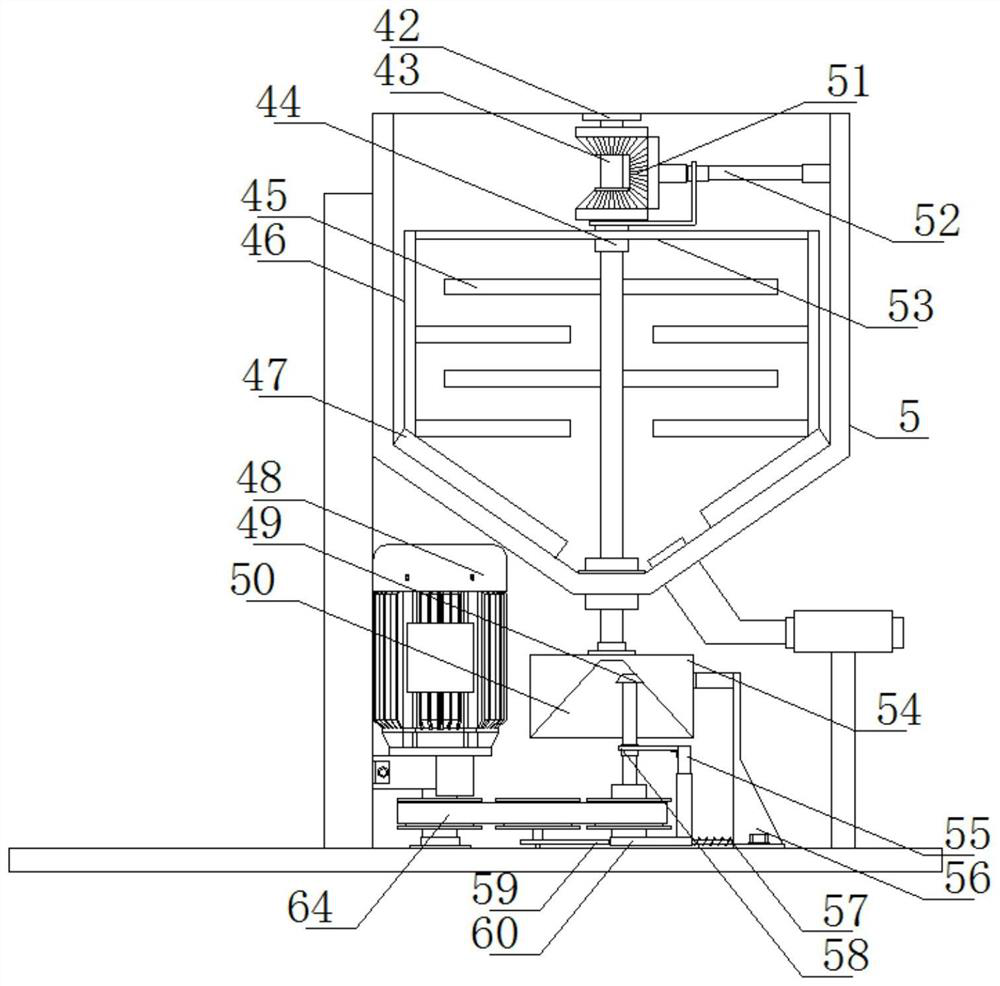

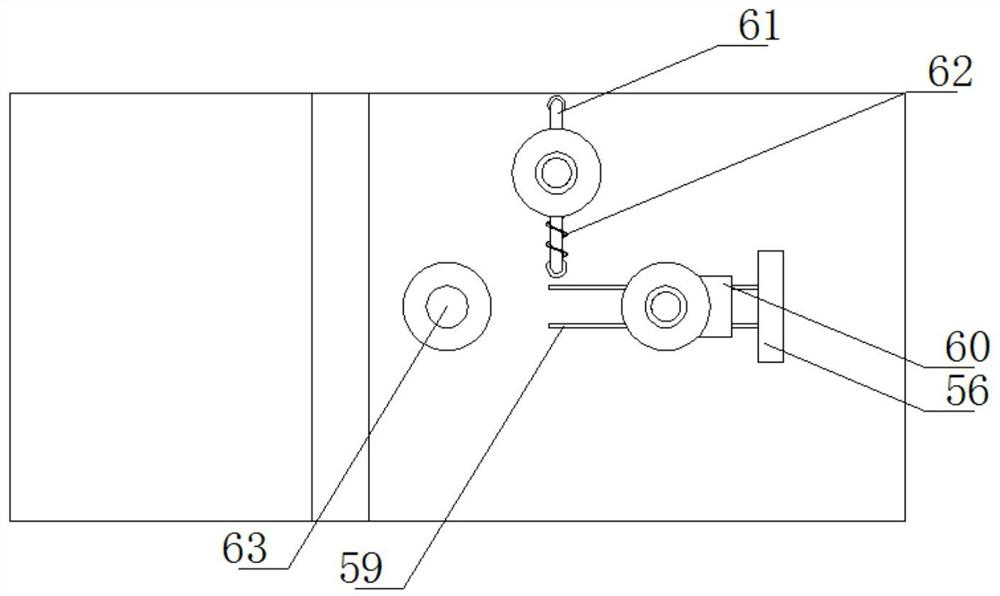

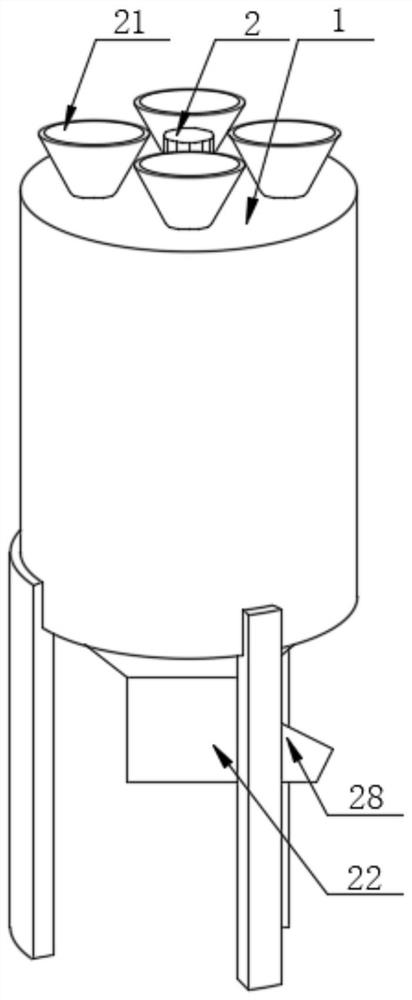

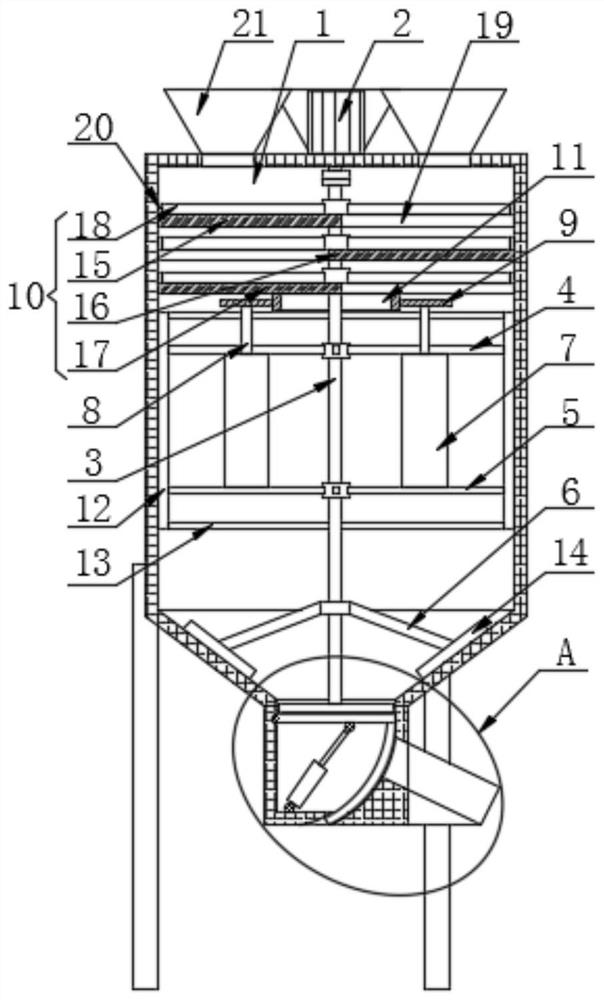

Automatic rice-steaming, spreading-cooling and automatic-stirring integrated machine for brewing wine and rice-steaming, spreading-cooling and stirring process

PendingCN111826250AQuick coolingImprove work efficiencyRotary stirring mixersTransportation and packagingProcess engineeringCereal grain

The invention relates to the technical field of wine-brewing equipment and methods, and particularly relates to an automatic rice-steaming, spreading-cooling and automatic-stirring integrated machinefor brewing wine and a rice-steaming, spreading-cooling and stirring process. The integrated machine comprises a rice-steaming bin, a bin cover and a cooling device, wherein the bin cover is used forsealing the rice-steaming bin, the cooling device is used for carrying out cooling in the rice-steaming bin, and the bin cover is provided with a stirring device. By virtue of cooperation of the bin cover and the rice-steaming bin, distillation of cereals is realized; by virtue of the cooling device and the stirring device, rapid spreading cooling of the cereals in the rice-steaming bin can be realized, so that the working efficiency of wine brewing is improved; and meanwhile, the stirring device is capable of uniformly stirring the cereals without grinding the cereals, so that the integrity of the cereal grains is guaranteed, the problem that the cereals are soured due to manual operation is solved, the stability of brewed wine is improved, the quality of the brewed wine is improved, andthe mellow degree of the brewed wine is guaranteed. The invention further provides a rice-steaming, spreading-cooling and stirring method, thereby improving the quality of the brewed wine.

Owner:许绍星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com