Rotating speed adaptive frequency conversion control system and method for concrete mixer

A concrete mixer and frequency conversion control technology, which is applied in the direction of control devices, etc., can solve the problems of artificial cleaning of the mixer, inability to adapt to different raw material formulations, and poor mixing quality, etc., to improve mixing efficiency, reduce average power, and save energy. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

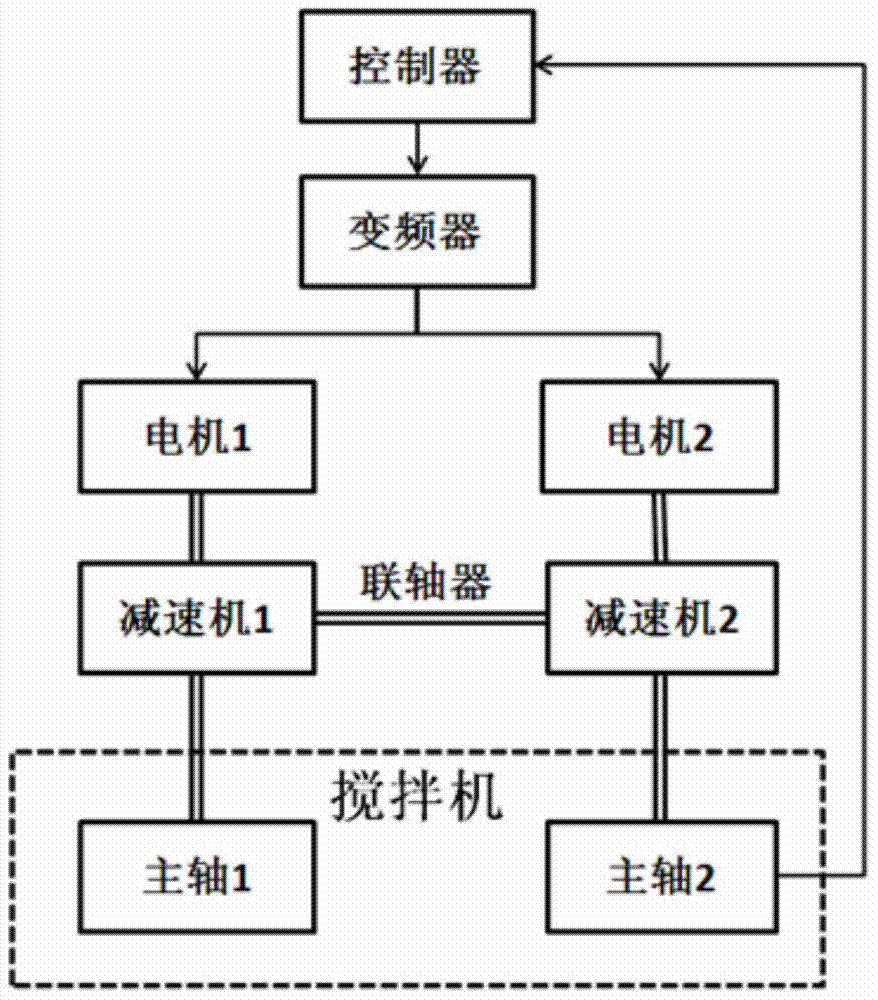

[0025] Please according to image 3 As shown, a rotational speed self-adaptive frequency conversion control system for a concrete mixer of the present invention includes a controller, a frequency converter, two motors and two reducers, wherein each of the two reducers is connected to a main shaft of the mixer, and the two motors are connected to Two reducers, the frequency converter is connected to the two motors through electrical connection, the controller is connected to the frequency converter, the controller has a parameter automatic optimization module, and the system also has a module that can adaptively control the stirring speed according to the load.

[0026] On the basis of the above, the present invention also has the following implementation modes, please continue to refer to image 3 as shown,

[0027] In a further embodiment of the present invention, the system uses vector control to perform frequency conversion control on the motor.

[0028] In a further embo...

Embodiment 2

[0041] like Figure 4 As shown, in this embodiment, the only difference from Embodiment 1 is that one frequency converter in Embodiment 1 controls two motors, and two separate frequency converters respectively control one motor, and other structures are the same as in Embodiment 1 The same, the specific working principle is the same as that of the first embodiment, and the achievable effect is also the same as that of the first embodiment, which will not be repeated here.

[0042] In summary, through the use of the present invention, the installed power of the motor can be reduced, the cost can be reduced, and energy consumption can be saved; the stirring speed and power can be adaptively controlled according to the load, the average power can be reduced, and energy consumption can be saved; automatic optimization according to different materials Control the parameters to ensure the mixing quality while improving the mixing efficiency; when the mixer is not mixing concrete, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com