Electro-hydraulic synchronous uniform loading cutter driving system of tunneling machine

A technology of electro-hydraulic mixing and driving system, which is applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., to reduce system overflow loss, improve operating efficiency, and improve the maximum escape ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

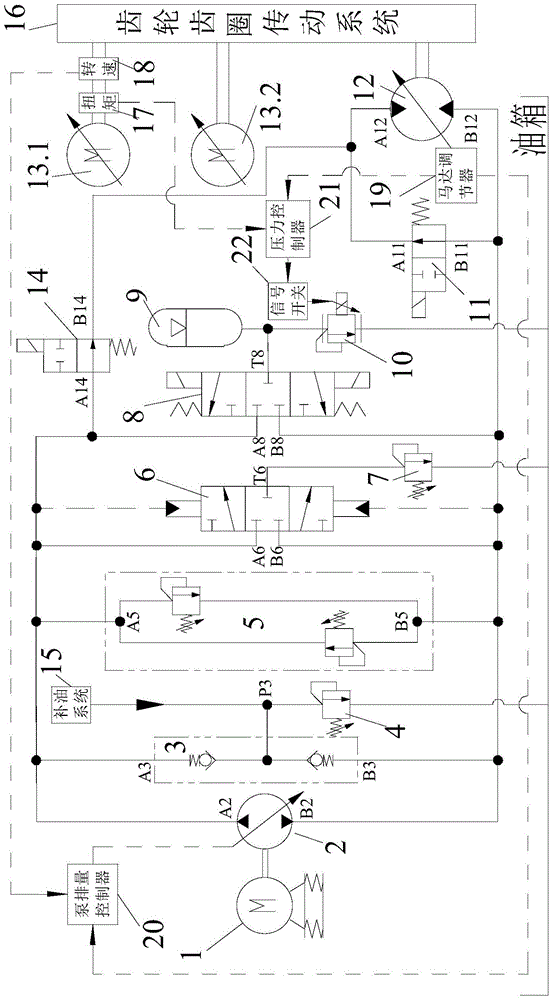

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] like figure 1 As shown, the present invention includes an ordinary motor 1, a two-way proportional variable pump 2, an oil supply one-way valve group 3, an oil supply pressure limiting valve 4, a closed circuit safety valve group 5, a flushing valve 6, a flushing pressure limiting valve 7, a replacement Directional valve 8, accumulator 9, electromagnetic proportional relief valve 10, large diameter switch valve 11, bidirectional proportional variable motor 12, main frequency conversion motor 13.1, slave frequency conversion motor 13.2, torque sensor 17 and speed sensor 18.

[0020] Ordinary motor 1 is connected to bi-directional proportional variable pump 2, oil supply check valve group 3 composed of two check valves installed backwards, closed circuit safety valve group composed of two overflow valves installed in reverse parallel connection 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com