Concrete stirrer

A concrete mixer and mixing drum technology, which is applied to cement mixing devices, clay preparation devices, mixing operation control, etc., can solve the problems of insufficient mixing of concrete mixers, inconvenient control of concrete usage, inability to guarantee building strength, etc. The effect of electric energy, material saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

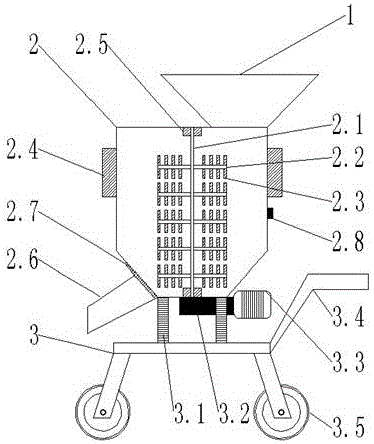

[0025] Such as figure 1 As shown, a concrete mixer includes a hopper 1, a mixing drum 2 and a car body 3, the lower end of the hopper 1 is connected to the mixing drum 2, and the hopper 1 and the mixing drum 2 are welded; the mixing drum 2 The bottom is provided with a feeding port 2.6, and the corresponding sealing cover 2.7 is arranged at the said feeding port 2.6; the inside of the mixing drum 2 is provided with a vertical stirring shaft 2.1, and the two ends of the stirring shaft 2.1 are provided with corresponding belts. A seat bearing 2.5, five stirring blades 2.2 are equidistantly arranged on the stirring shaft 2.1, 16 vertical stirring teeth 2.3 are equidistantly arranged on the stirring blade 2.2, and the stirring blades 2.2 and the stirring teeth 2.3 are welded; The bottom of the mixing drum 1 is provided with a shaft coupling 3.2 and a driving motor 3.3; the stirring shaft 2.1 is connected with the driving motor 3.3 through a shaft coupling 3.2, and the stirring sha...

Embodiment 2

[0030] Such as figure 1 As shown, a concrete mixer includes a hopper 1, a mixing drum 2 and a car body 3, the lower end of the hopper 1 is connected to the mixing drum 2, and the hopper 1 and the mixing drum 2 are detachable; the mixing The bottom of the barrel 2 is provided with a feeding port 2.6, and the corresponding sealing cover 2.7 is arranged at the said feeding port 2.6; the inside of the mixing drum 2 is provided with a vertical stirring shaft 2.1, and the two ends of the stirring shaft 2.1 are provided with corresponding Bearing 2.5 with a seat, five stirring blades 2.2 are equidistantly arranged on the stirring shaft 2.1, 20 vertical stirring teeth 2.3 are equidistantly arranged on the stirring blade 2.2, and the stirring blades 2.2 and the stirring teeth 2.3 adopt welding; the bottom of the mixing drum 1 is provided with a shaft coupling 3.2 and a driving motor 3.3; the stirring shaft 2.1 is connected with the driving motor 3.3 through a shaft coupling 3.2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com