Silver conductor slurry for back electrodes of solar energy battery

A technology of silver conductor paste and solar cells, applied to conductive materials dispersed in non-conductive inorganic materials, semiconductor devices, circuits, etc., can solve problems such as affecting photoelectric conversion efficiency and not dense network, and achieve products that are environmentally friendly, healthy, Excellent electrical conductivity, electrode solderability and strong solder resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

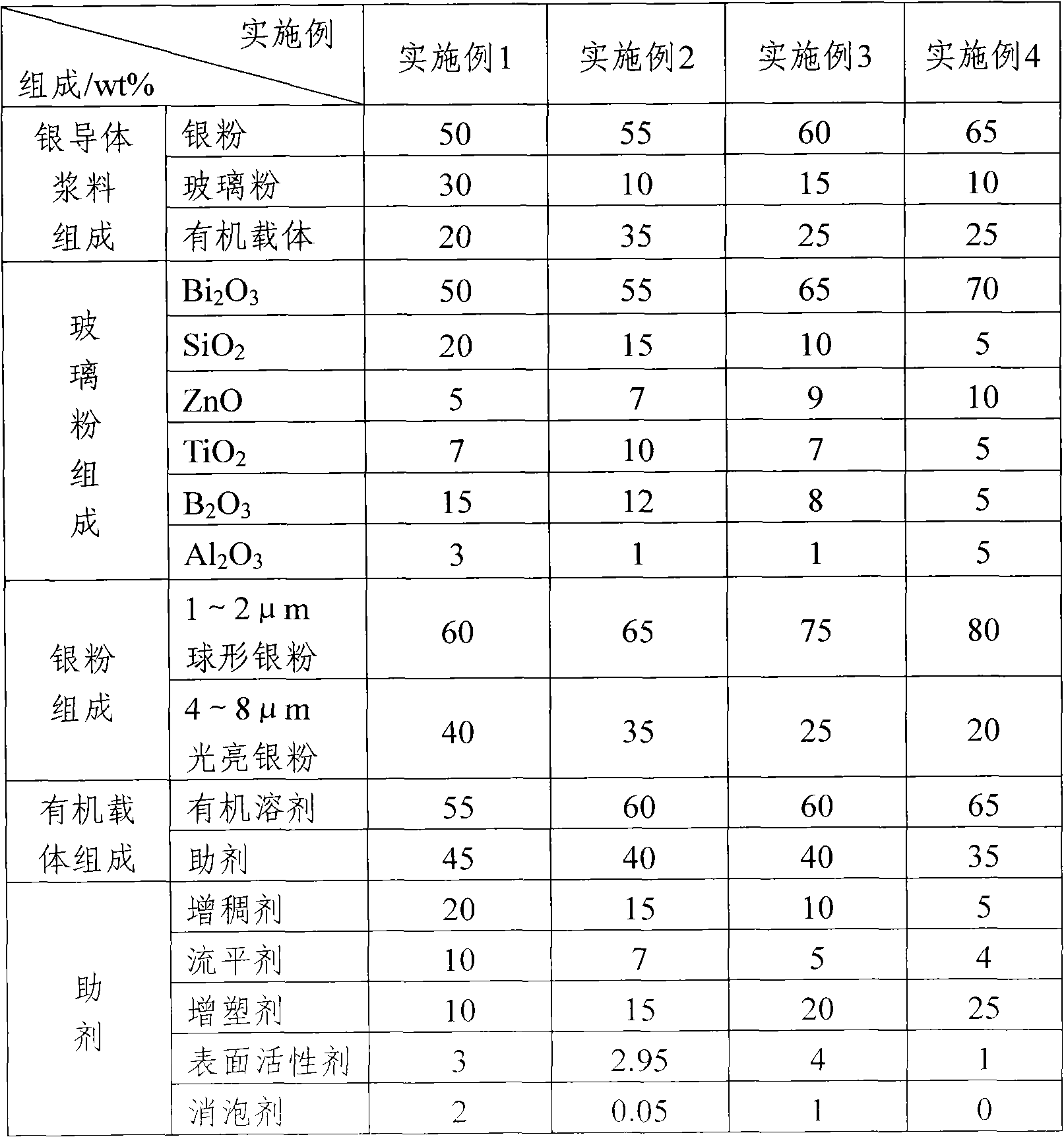

Embodiment 1

[0018] The invention is a silver conductor paste for solar back electrode, comprising: 50wt% silver powder, 30wt% glass powder and 20wt% organic vehicle, the composition of the glass powder includes 50% Bi 2 o 3 , 20wt% SiO 2 , 5wt% ZnO, 7wt% TiO 2 , 15wt% B 2 o 3 , 3wt% Al 2 o 3 .

[0019] Among them, 60% of spherical silver powder with a particle size of 1-2 μm and 40% of bright silver powder with a particle size of 4-8 μm are included.

[0020] Wherein, the composition of the organic vehicle is: 55wt% organic solvent and 45wt% auxiliary agent.

[0021] Wherein, the organic solvent is a combination of ethyl carbitol and terpineol, and the weight ratio is 1:1.

[0022] Wherein, the auxiliary agent and the weight percentage of the auxiliary agent occupying the organic carrier respectively include: 20wt% of thickener, 10wt% of leveling agent, and 10wt% of plasticizer.

[0023] Wherein, the thickener is hydroxyethyl cellulose.

[0024] Wherein, the leveling agent is po...

Embodiment 2

[0029] The invention is a silver conductor paste for solar back electrode, comprising: 55wt% silver powder, 10wt% glass powder and 35wt% organic vehicle, the composition of the glass powder includes 55wt% Bi 2 o 3 , 15wt% SiO 2 , 7wt% ZnO, 10wt% TiO 2 , 12wt% B 2 o 3 , 1wt% Al 2 o 3 .

[0030] Wherein, the silver powder contains 65 wt% spherical silver powder with a particle diameter of 1-2 μm and 35 wt% bright silver powder with a particle diameter of 4-8 μm.

[0031] Wherein, the composition of the organic vehicle is: 60wt% organic solvent and 40wt% auxiliary agent.

[0032] Wherein, the organic solvent is terpineol.

[0033] Wherein, the weight percentages of the additives occupying the organic carrier include: 15wt% of thickener, 7wt% of leveling agent, and 15wt% of plasticizer.

[0034] Wherein, the thickener is ethyl hydroxyethyl cellulose.

[0035] Wherein, the leveling agent is silicone-modified polyacrylate, and the plasticizer is a combination of diethylene...

Embodiment 3

[0040] The invention is a silver conductor paste for solar back electrode, comprising: 60wt% silver powder, 15wt% glass powder and 25wt% organic vehicle, the composition of the glass powder includes 65wt% Bi 2 o 3 , 10wt% SiO 2 , 9wt% ZnO, 7wt% TiO 2 , 8wt% B 2 o 3 , 1wt% Al 2 o 3 .

[0041] Wherein, the silver powder contains 75 wt% spherical silver powder with a particle diameter of 1-2 μm and 25 wt% bright silver powder with a particle diameter of 4-8 μm.

[0042] Wherein, the composition of the organic vehicle is: 60wt% organic solvent and 40wt% auxiliary agent.

[0043]Wherein, the organic solvent is a combination of terpineol and butyl carbitol, and the weight ratio is 1:2.

[0044] Wherein, the auxiliary agent and the weight percentage of the auxiliary agent occupying the organic carrier respectively include: 10wt% of thickener, 5wt% of leveling agent, and 20wt% of plasticizer.

[0045] Wherein, the thickener is hydroxyethyl cellulose.

[0046] Wherein, the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com