Stirring device for chemical engineering

A stirring equipment and chemical technology, applied in the direction of mixer accessories, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve the problems of low technical content, short development time, poor manufacturing level, etc., to ensure the quality of mixing, Good drying effect and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

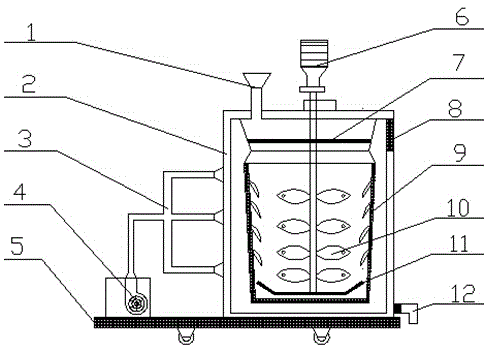

[0012] Such as figure 1 As shown, a mixing equipment for chemical industry includes a case body 2 and a stirring motor 6 arranged on the case body 2 , a material inlet 1 , and a material outlet 12 .

[0013] As a preferred solution of the present invention, one side of the outer wall of the chassis body 2 of the present invention is provided with three trumpet-shaped joints, and one end with a smaller diameter of the joints is connected to three outlets of the four-way pipe 3 through a connecting pipe, and the four-way pipe The other outlet of 3 is connected to the hot air blower 4 through a connecting pipe, and the other side of the outer wall of the chassis body 2 is provided with an air outlet 8; such a structural design can blow hot air into multiple pipes, and the drying effect is good, and at the same time, it can blow off the sticky air. The materials and impuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com