A construction method of pile foundation

A construction method and pile foundation technology, which is applied in the direction of infrastructure engineering, construction, etc., to achieve the effect of less efficiency loss, solving the problem of too much power, and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

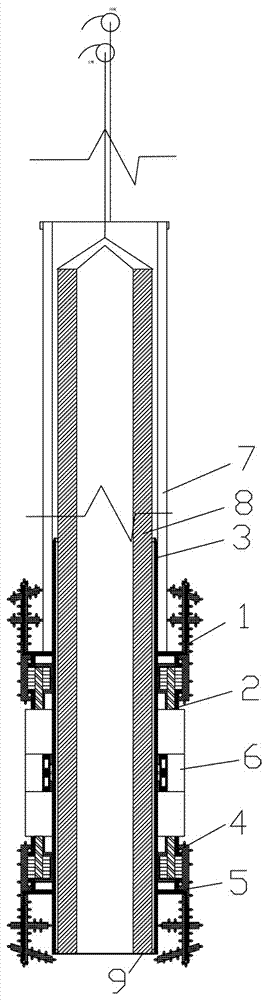

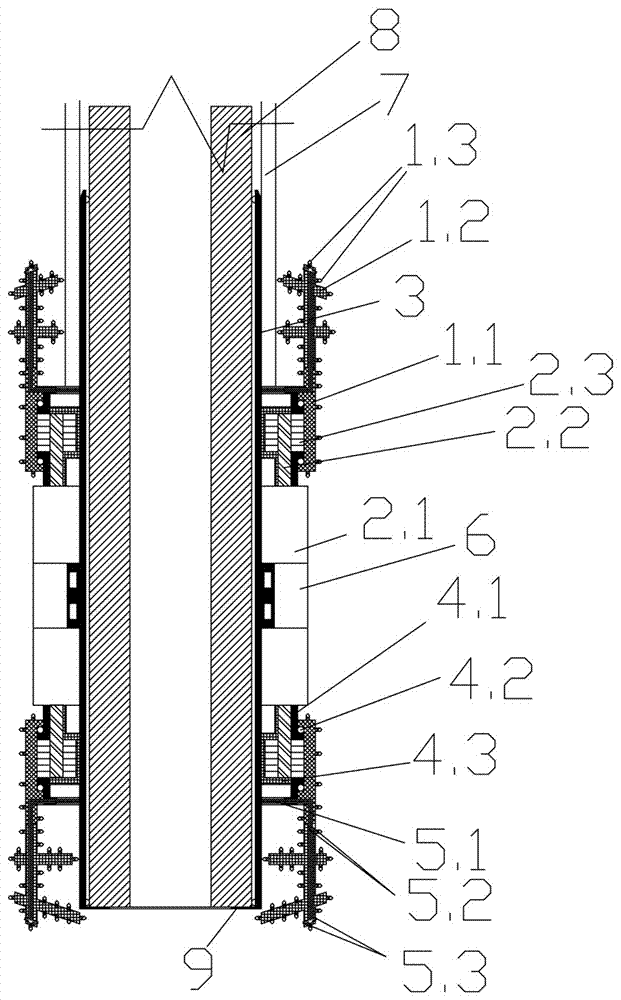

[0020] This embodiment provides a whole construction process of a rigid-flexible composite pile using the pile foundation construction method of the present invention.

[0021] 1. Install the equipment in place and start pile sinking

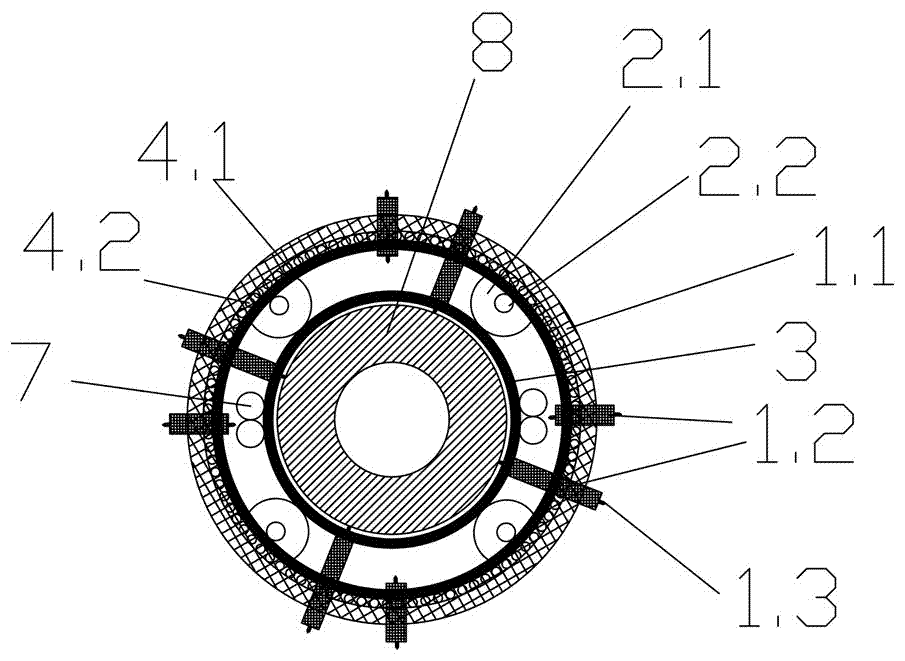

[0022] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, a set of special mechanical construction device with power is installed on the outside of the rigid pile. The function of surrounding foundation soil for replacement construction.

[0023] The special mechanical construction device includes one or several groups of ring turntable assembly 1, motor and transmission assembly 2, auxiliary and sealing assembly 4 for rotation and transmission, grouting assembly 5, vibrator 6 and rigid structural support 3. The ring turntable assembly 1 , the motor and transmission assembly 2 , the auxiliary and sealing assembly 4 for rotation and transmission, the grouting assembly 5 , and the vibrator 6 are fixed on the rigid structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com