Long pumping distance machine-made sand concrete

A technology for machine-made sand and concrete, applied in the field of concrete, can solve the problems of wasting resources, increasing engineering costs, and limiting the scope of application of mountain sand concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

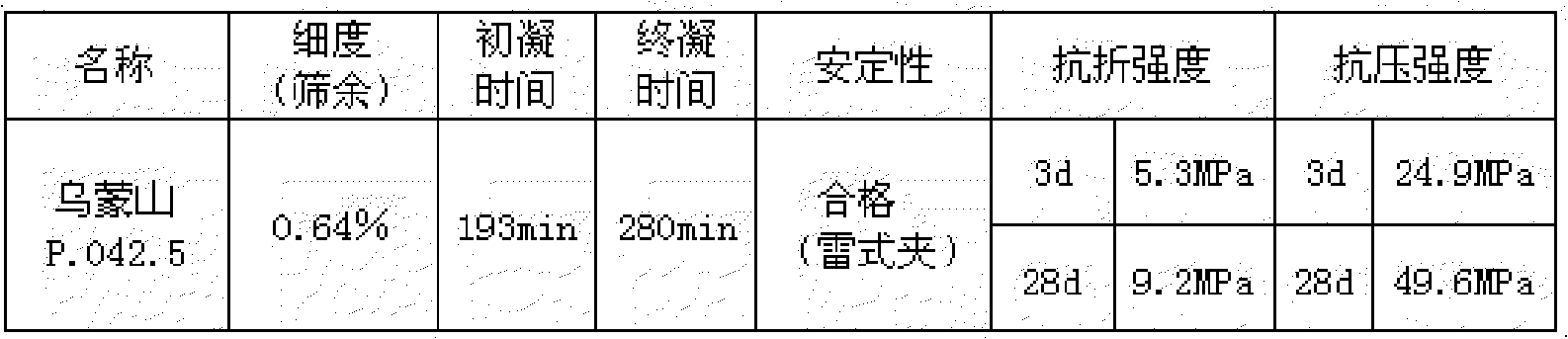

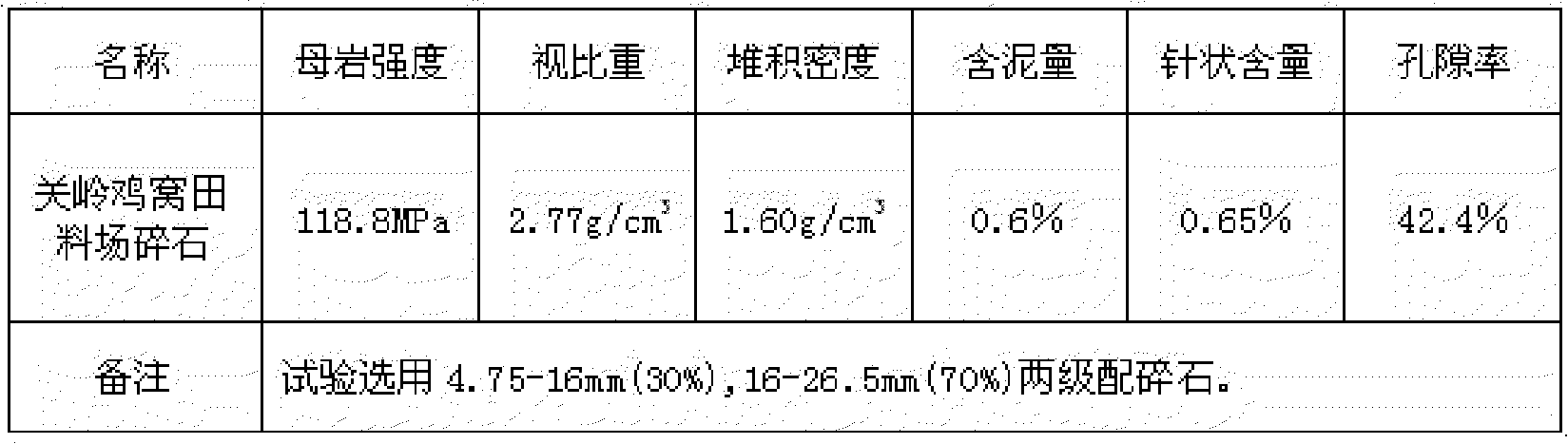

[0191] Embodiment 1 of the present invention: by weight, adopt Guizhou Shuicheng Cement Plant Wumengshan P.O42.5 cement 400, machine-made sand 800 produced by Guanling Jiwo field stockyard, the requirement of machine-made sand is, fineness modulus 3.05, dust content less than 7%, 5-16mm particle size crushed stone 310, 16-25mm particle size crushed stone 720, tap water 160, Guizhou Anshun Power Plant Class I fly ash 75, Guangdong Zhanjiang FDN-5 high-efficiency water reducer 18. The water-reducing rate of the water-reducing agent can reach 20-30%. Mix and stir various raw materials to prepare concrete. When in use, concrete can be pumped to a height of more than 200 meters at a time.

Embodiment 2

[0192] Embodiment 2 of the present invention: by weight, adopt Guizhou Shuicheng Cement Plant Wumengshan P.O42.5 cement 425, machine-made sand 780, 5-16mm grain size crushed stone 300, 16 of Guanling Jiwo field stockyard production -25mm particle size crushed stone 700, tap water 155, Guizhou Anshun Power Plant Class I fly ash 80, Guangdong Zhanjiang FDN-5 type high-efficiency water reducer 24, mix and stir various raw materials to prepare concrete.

Embodiment 3

[0193] Embodiment 3 of the present invention: By weight, adopt P.O42.5 cement 407, machine-made sand 791, 5-16mm particle diameter crushed stone 307, 16-25mm particle diameter crushed stone 714, tap water 157.6, I grade fly ash 77.6, superplasticizer 19.4, mix and stir various raw materials to prepare concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com