Patents

Literature

239results about How to "Solve technical difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

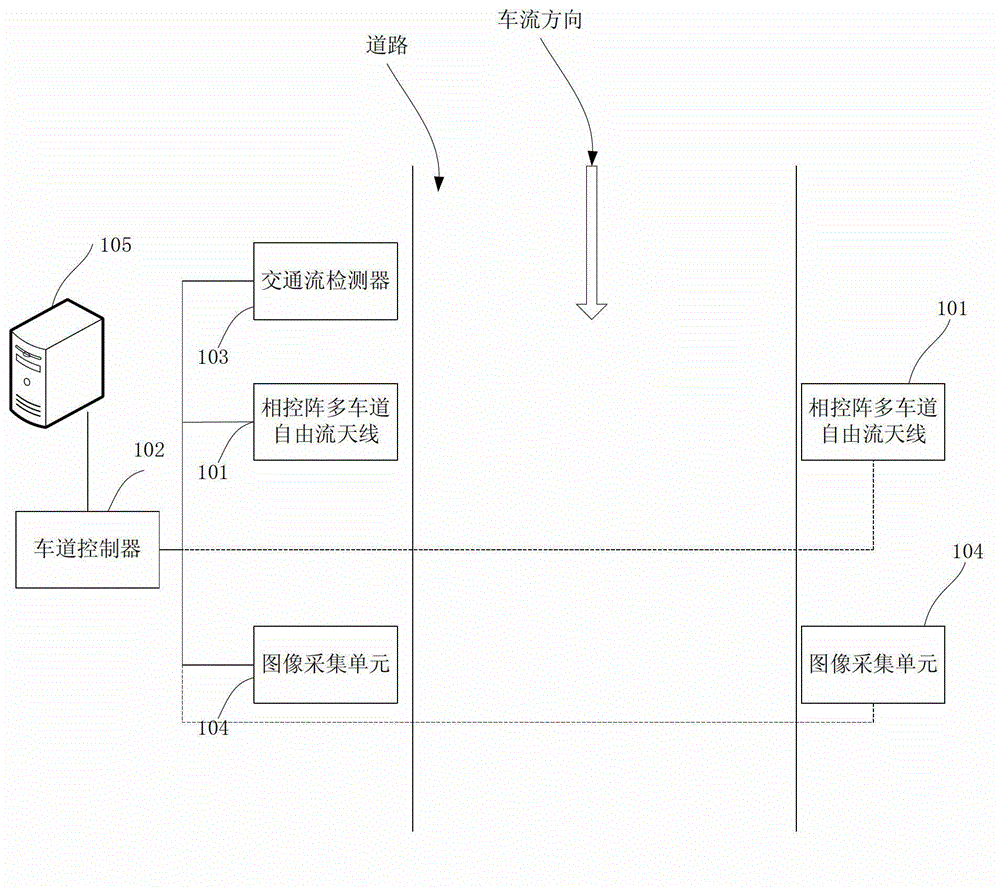

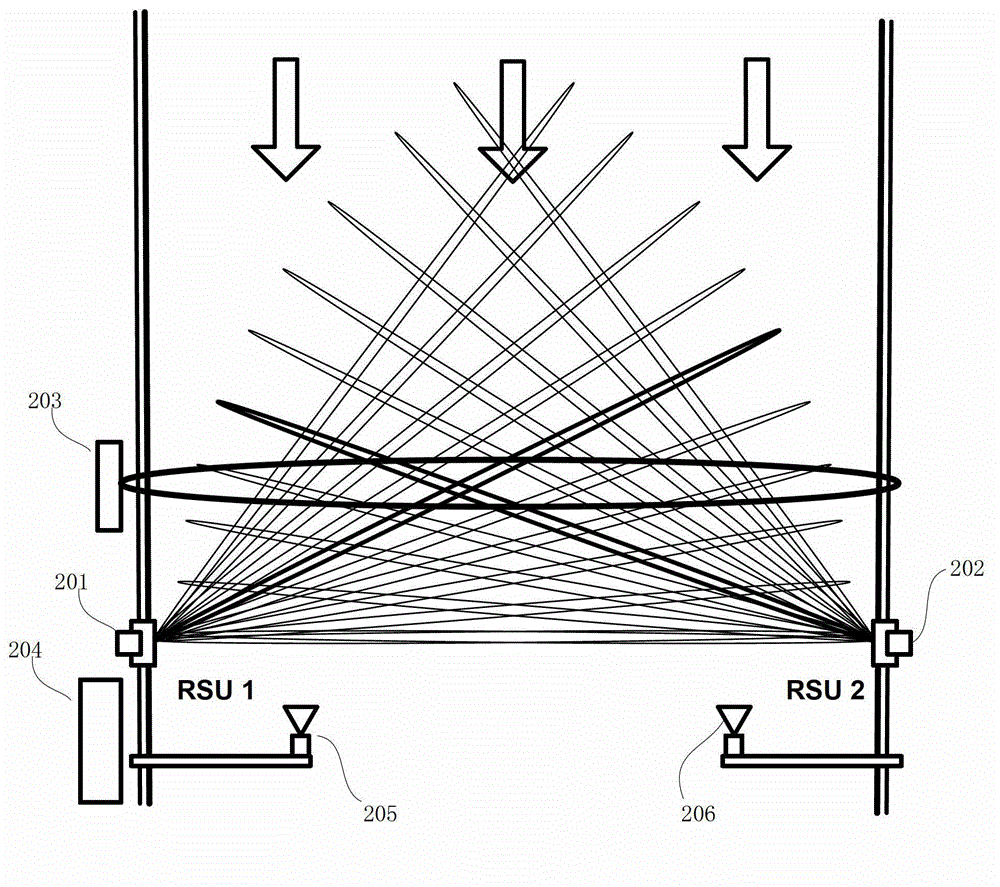

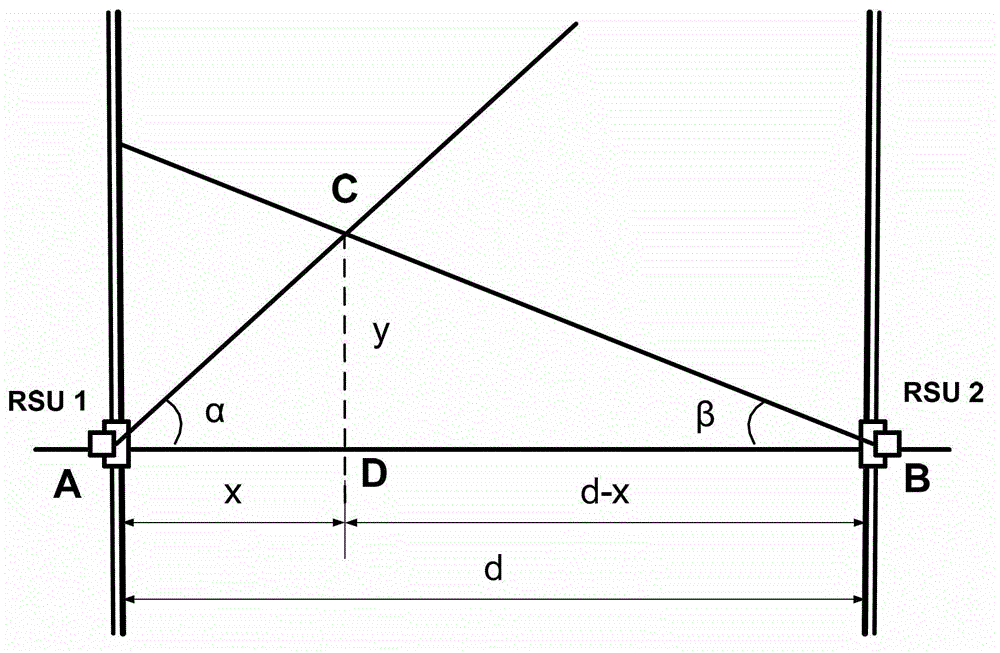

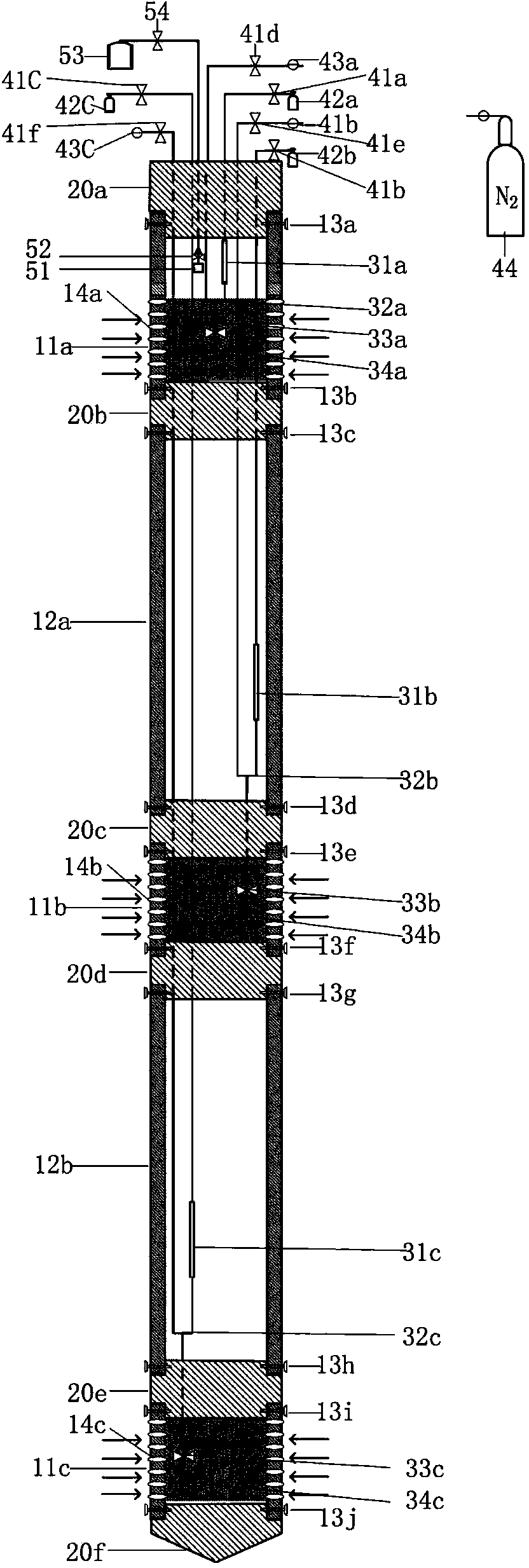

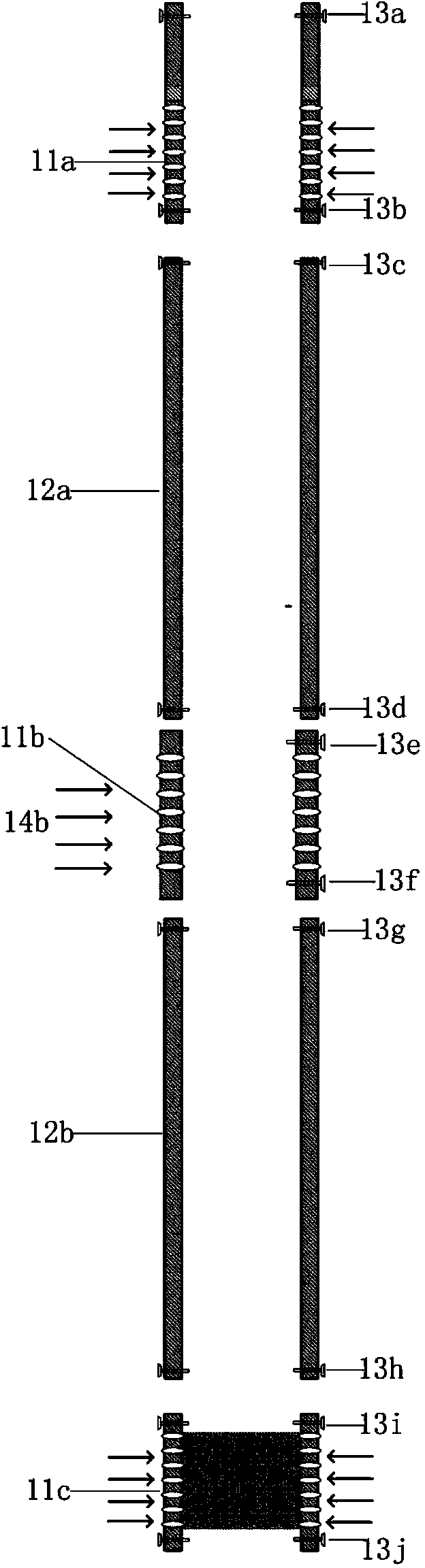

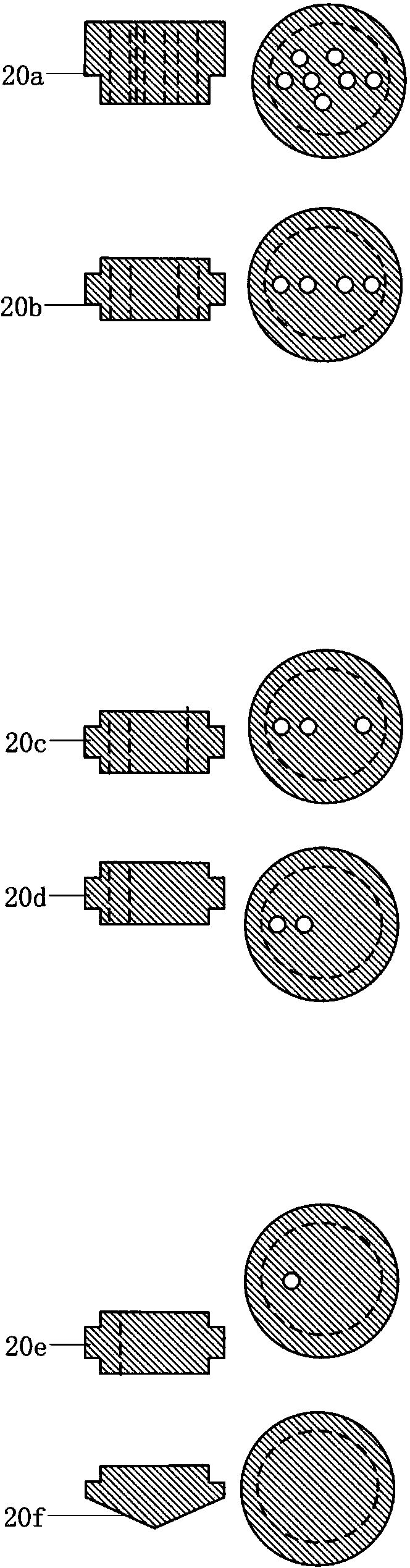

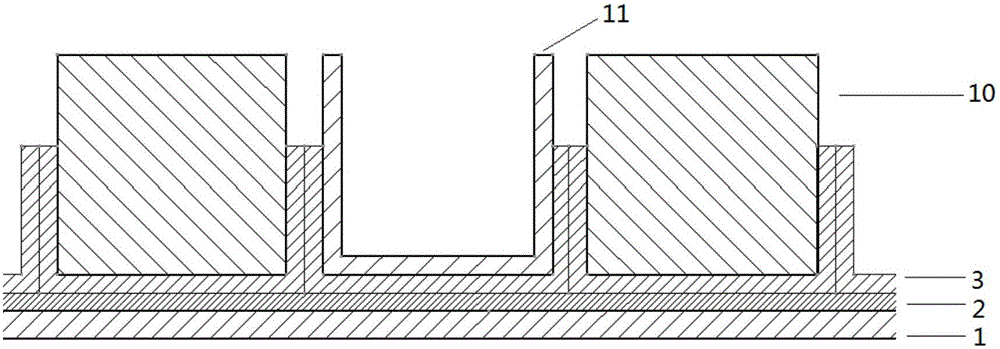

Multi-lane free flow electronic toll collection system arranged on side of road

InactiveCN103150772AReduce erection costSolve technical difficultiesTicket-issuing apparatusTime informationElectronic toll collection system

The invention relates to the field of an intelligent transportation system, in particular to a multi-lane free flow electronic toll collection system arranged on the side of a road. The multi-lane free flow electronic toll collection system comprises at least two phased array multilane free flow antennas arranged on the two sides of the road and used for measuring a vehicle electronic tag on a vehicle as well as angle information between the two phased array multilane free flow antennas respectively and transmitting the angle information as well as first time information during the measurement to a lane controller; and the lane controller is used for calculating according to the angle information between the two phased array multilane free flow antennas as well as self position information to obtain first position information of the vehicle, saving the first position information and the first time information of the vehicle and carrying out toll collection according to the first position information and the vehicle electronic tag of the vehicle. Through the system provided by the embodiment of the invention, the technical difficult problem that a transverse portal frame is erected above the wide road can be solved, so that the erection cost of the multi-lane free flow system is reduced.

Owner:北京速通科技有限公司

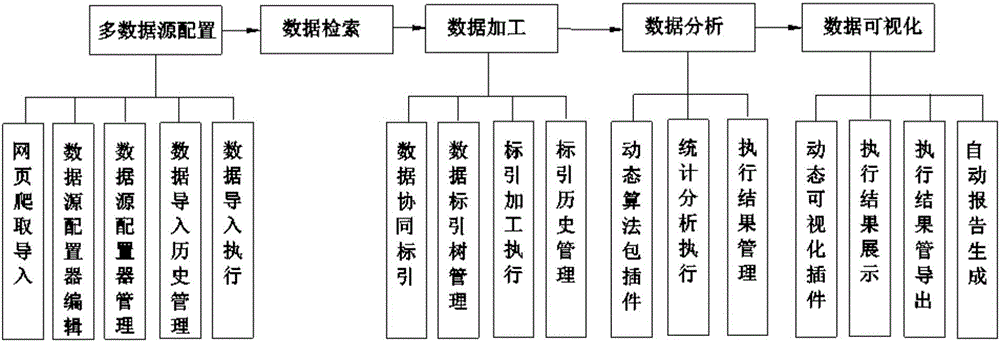

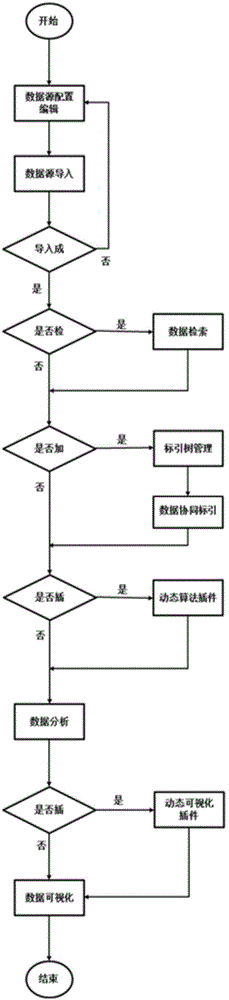

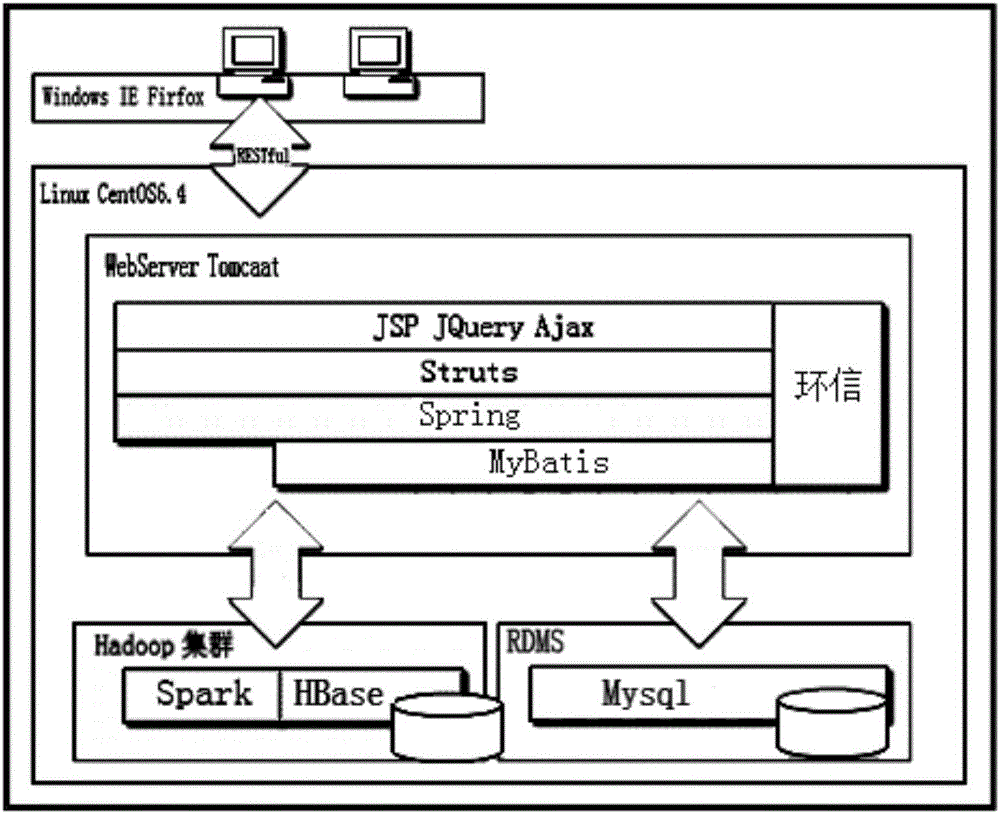

Big data collaborative analysis tool platform

InactiveCN106649773AOperation real-time collaborationProgress is clearly visibleOther databases queryingSpecial data processing applicationsStatistical analysisData modeling

The invention discloses a big data collaborative analysis tool platform. The big data collaborative analysis tool platform comprises a multi-data source configuration module, a data retrieval module, a data processing module, a data analyzing module and a data visualizing module, wherein the multi-data source configuration module is used for importing and crawling configurations of any data; the data retrieving module is used for establishing a full text segmenting index for imported data; the data processing module is used for realizing a collaborated data indexing and collaborated analyzing functions of team collaboration; the data analyzing module is used for customizing an algorithm template, analyzing algorithm freedom selection and customizing data modeling and algorithm realization; and the data visualizing module is used for realizing visualized display and automatic form reporting of an analyzing result. The platform disclosed by the invention has the beneficial effects that the defects of specialty, difficult technology, high cost and low efficiency in industry information researching work are overcome; a function integrated information research big data operating platform is provided, and multi-dimensional big data services such as multi-data source configurable importing and crawling of big data, big data storage, a big data search engine, big data online collaborative analysis, big data online real-time statistics, analysis and excavation and visualization are provided.

Owner:梁学东

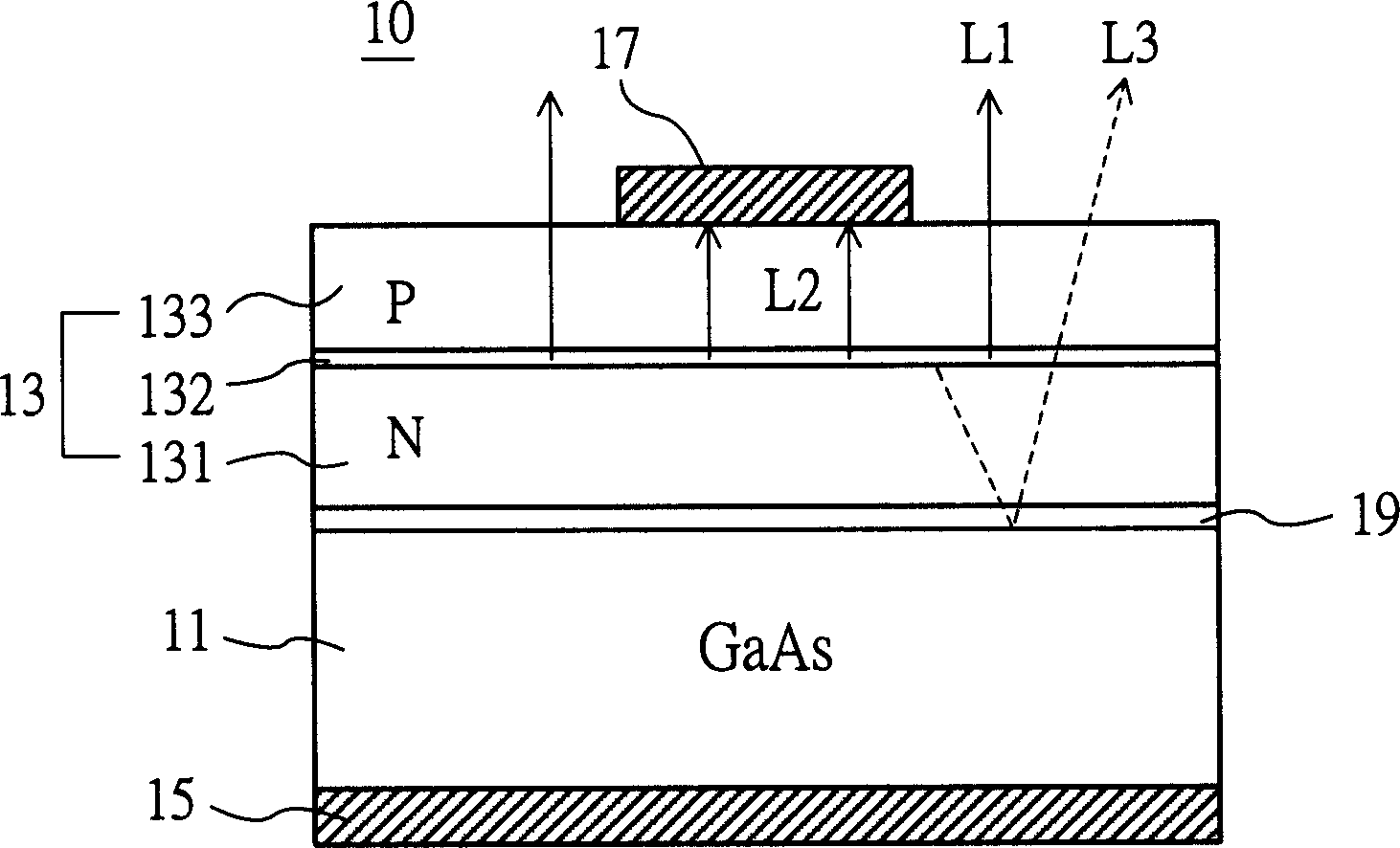

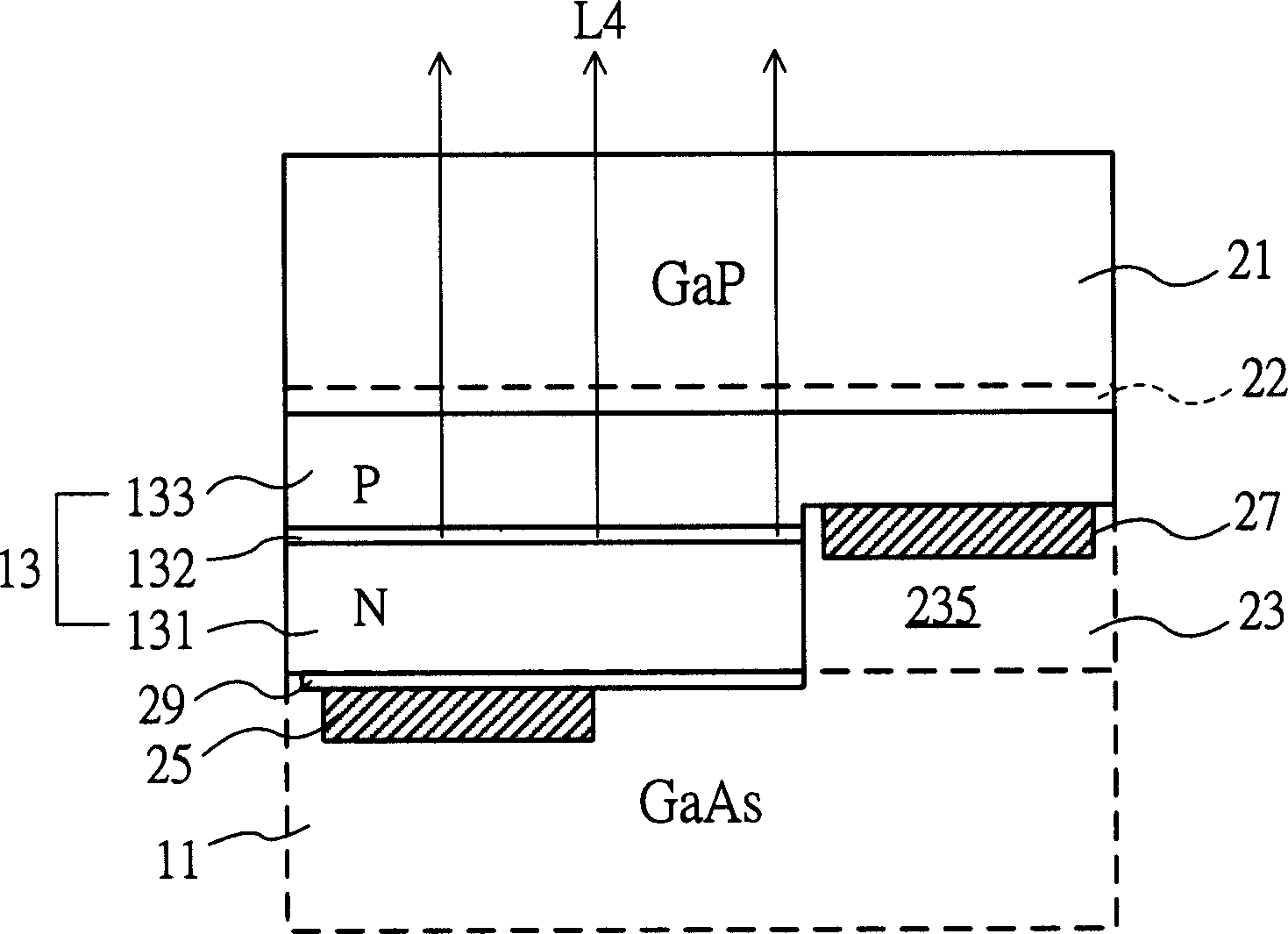

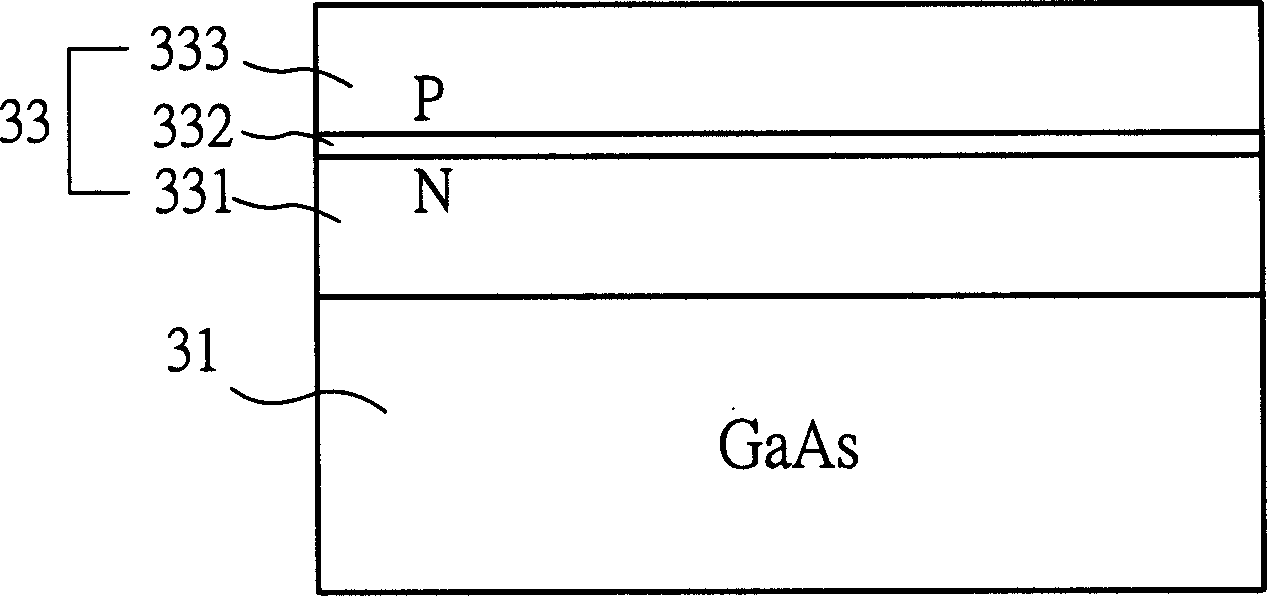

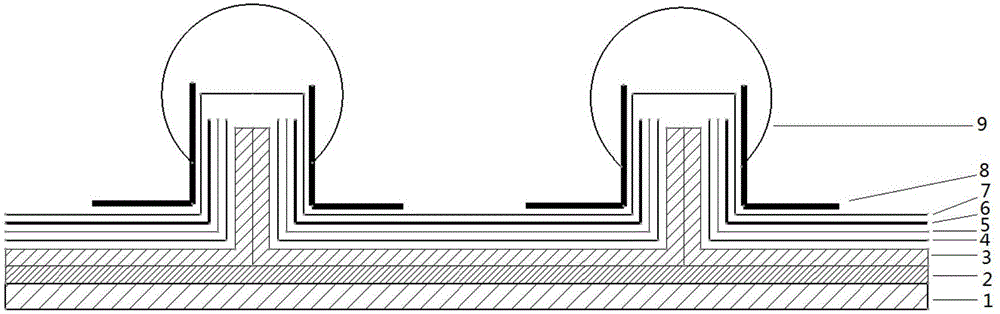

LED

InactiveCN1564333AUniform distribution of working current densityImprove efficiencySemiconductor devicesElectrical conductorEngineering

Quadreple epitaxial layer composed of first material layer, luminous layer and second material layer is formed on a semiconductor base plate. A euphotic base plate is fixed on surface of the second martial layer. With semiconductor base plate being removed, isolation groove and first extend groove are made under undersurface of first material to penetrate the first material layer and extend to part of volume of second material layer at least. First extend electrode is setup inside first extend groove. The first extend electrode is possible to connect with first electrode positioned at partial surface of the first material layer. Thus, the first electrode is located in nearly same level position to second electrode, which is on surface of other part of the first martial layer in order to carry out next processing easily. The invention increases luminescence are of PN interface, raises luminescence brightness and service life.

Owner:OPTO TECH

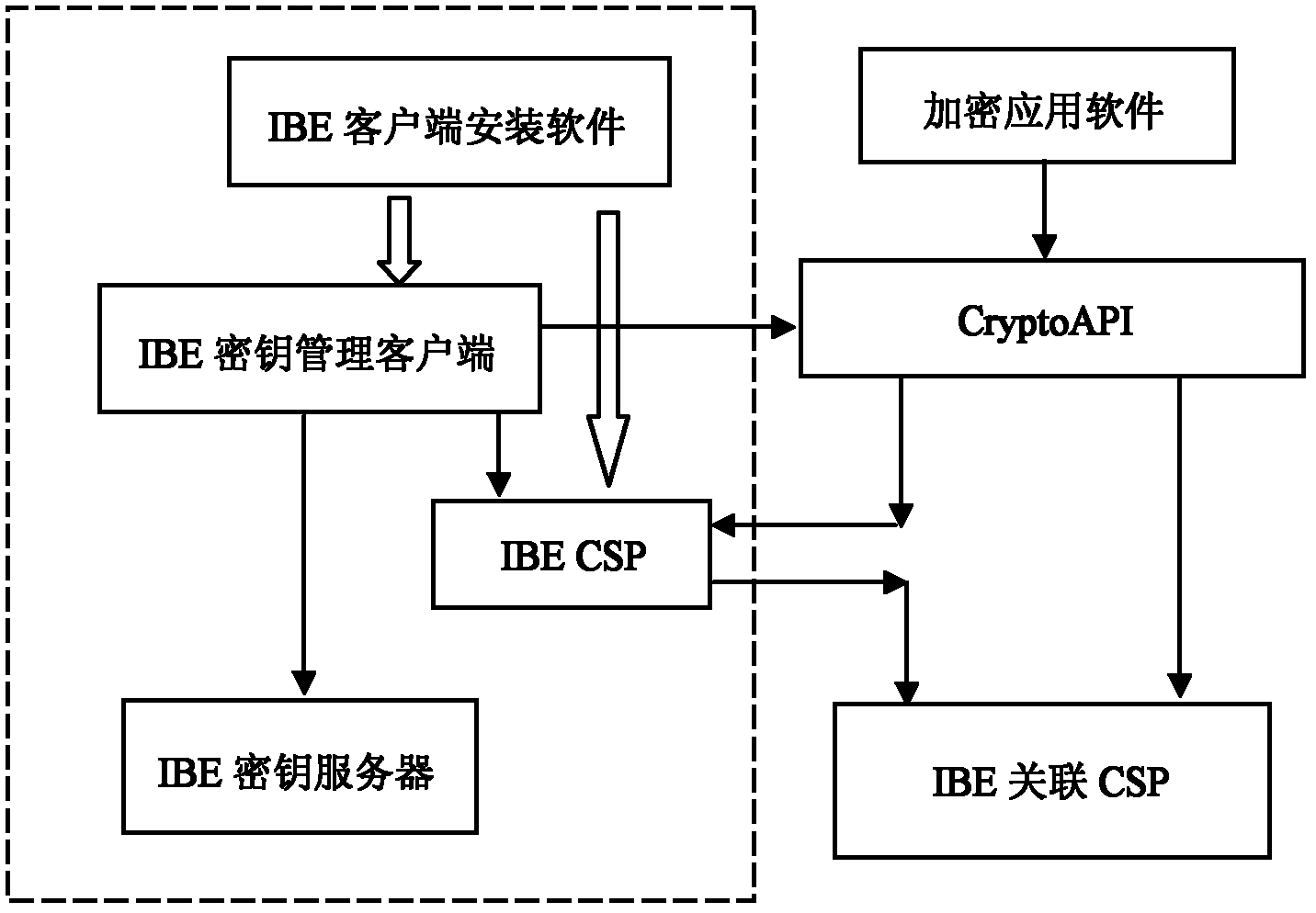

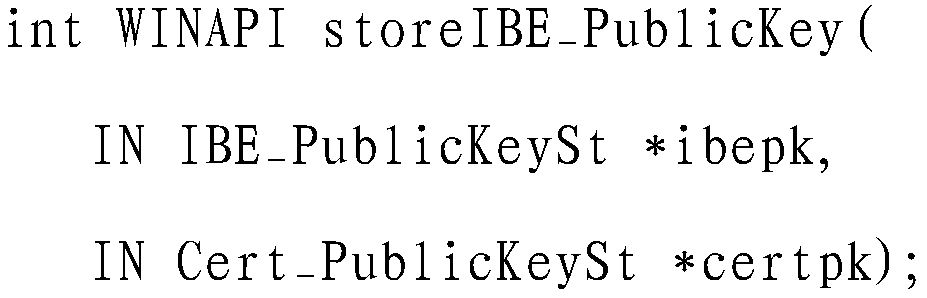

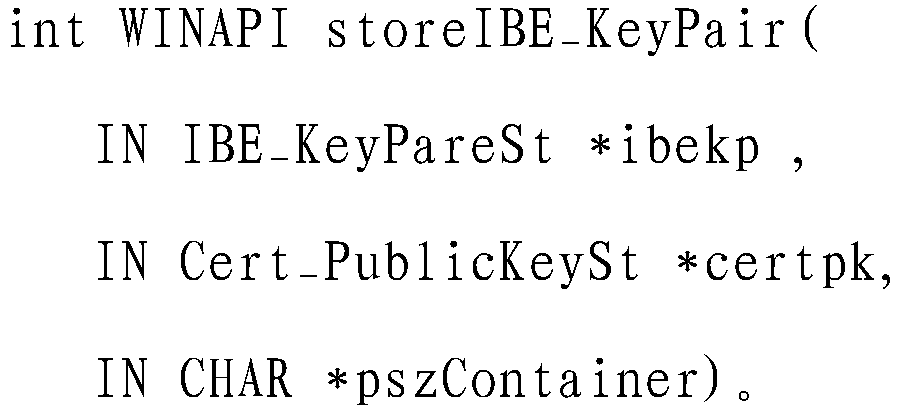

IBE (Internet Booking Engine) data encryption system based on medium digital certificate

InactiveCN102255729ASolve technical difficultiesPublic key for secure communicationUser identity/authority verificationThe InternetXML Encryption

The invention relates to an IBE (Internet Booking Engine) data encryption system based on a medium digital certificate, and comprises four components: an IBE CSP (Cryptographic Service Provider), an IBE key management client, an IBE key server and an IBE client installing software, wherein the IBE CSP is the core and key of the IBE data encryption system. The IBE data encryption system is used for enabling the system and the application which do not support an IBE encryption process to utilize the IBE process to encrypt and decrypt. In the IBE data encryption system, the medium digital certificate is taken as a bridge, an asymmetric key algorithm which is supported by RSA (Rivest Shamir Adleman), ECC (Elliptic Curves Cryptography) or other X509 certificate is provided by a register, but actually a Windows CSP of the IBE algorithm is realized, the data encryption and decryption operations based on the RSA, ECC or other asymmetric key algorithms are automatically converted into the corresponding data encryption and decryption operations based on the IBE algorithm.

Owner:WUHAN UNIV OF TECH +1

Method for preparing porous ceramics supported high activity nano titanium dioxide

InactiveCN1511630ASolve the shortcomings of poor firmness and uneven distributionSolve the shortcomings of easy crackingCatalyst activation/preparationWater vaporAdhesive

The present invention relates to the preparation of high activity TiO2 photocatalyst with porous ceramic base, and is especially the nano titania powder and titania sol combining process of preparing regenerable high activity nano titania carried in porous ceramic. The present invention prepares the high activity nano titania carried in porous ceramic through the combination of two carrying processes, titania powder sintering process and sol-gel process. The process includes preparing titania sol via sol-gel process, mixing titania sol and titania powder in certain ratio while stirring and adding dispersant and adhesive to form new solution, carrying the solution to the surface of porous ceramic, fumigating the carrying ceramic in water vapor atmosphere to eliminate most of the organic matters, and final sintering at high temperature for strong combination between nano titania and carrier and raised activity of titania.

Owner:HUABENGUANG CATALYTIC TECH BEIJING

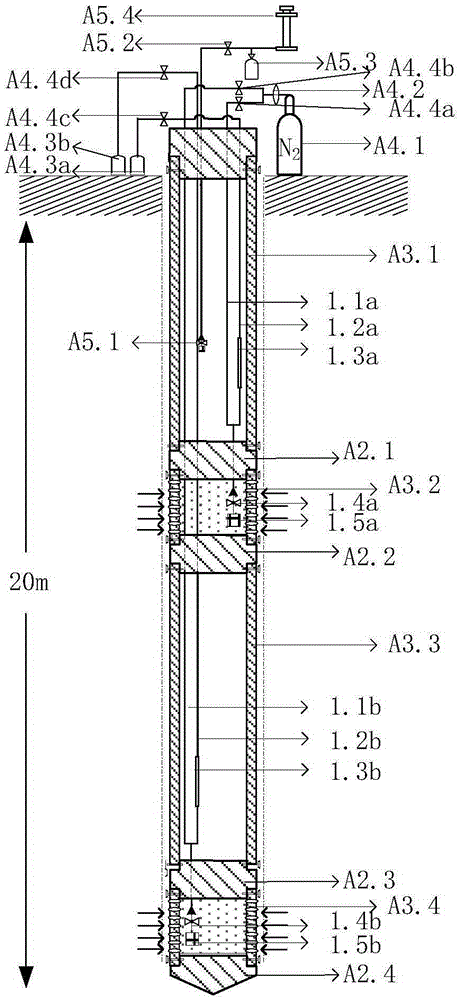

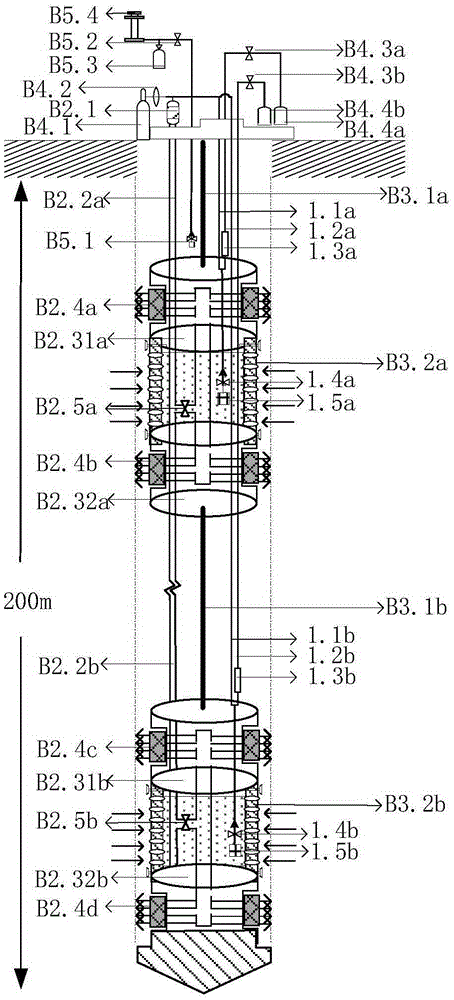

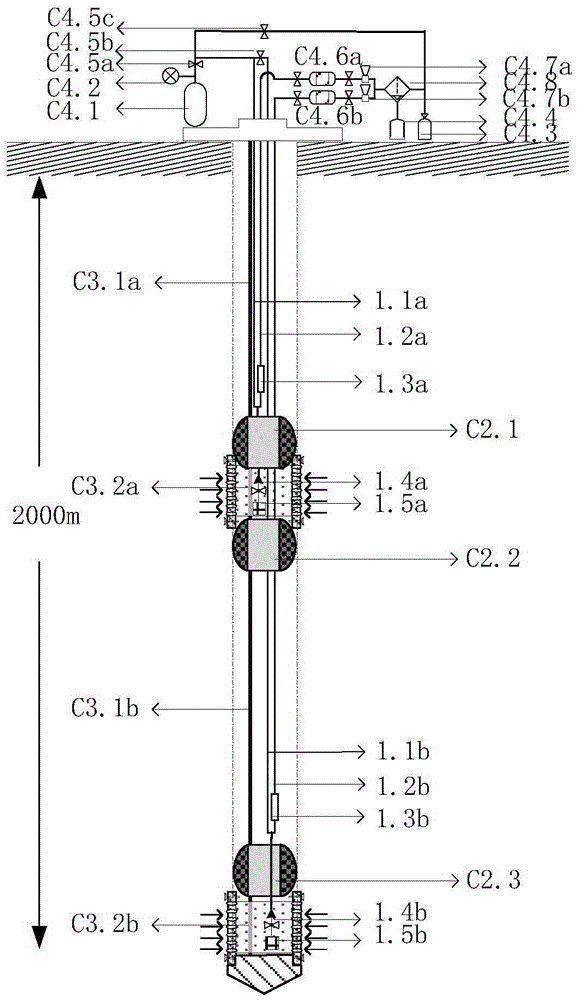

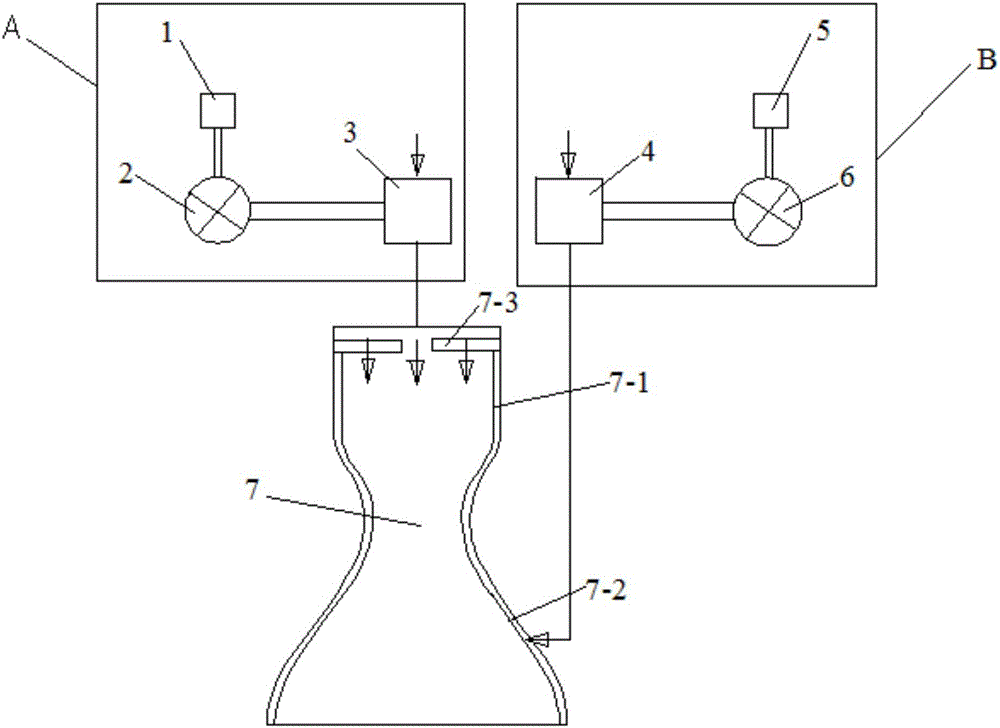

Underground fluid laminated sampling device and method based on U-shaped pipe technology

The invention discloses an underground fluid laminated sampling device based on a U-shaped pipe technology. The underground fluid laminated sampling device comprises an underground fluid sample injection subsystem, a packer subsystem, a chaining subsystem, a ground sampling subsystem and a soil gas sampling subsystem, wherein the underground fluid sample injection subsystem comprises a driving pipe, a sample discharging pipe, a fluid storage container, a liquid phase check valve and a filtering element; the soil gas sampling subsystem comprises a gas phase check valve arranged at a set position; the gas phase check valve is connected with a manual pump through a pneumatic ball valve and a gas sampling bag. The invention further discloses an underground fluid laminated sampling method based on the U-shaped pipe technology. The underground fluid laminated sampling device is novel in structural design; multiple technical difficulties are overcome; compared with a product of the original technology, the underground fluid laminated sampling device has the advantages that the working performance, the application range and the system stability are greatly improved, has higher competitiveness and industrial leading superiority, can be widely applied, is good in engineering demand, and has good application prospect and commercial value.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

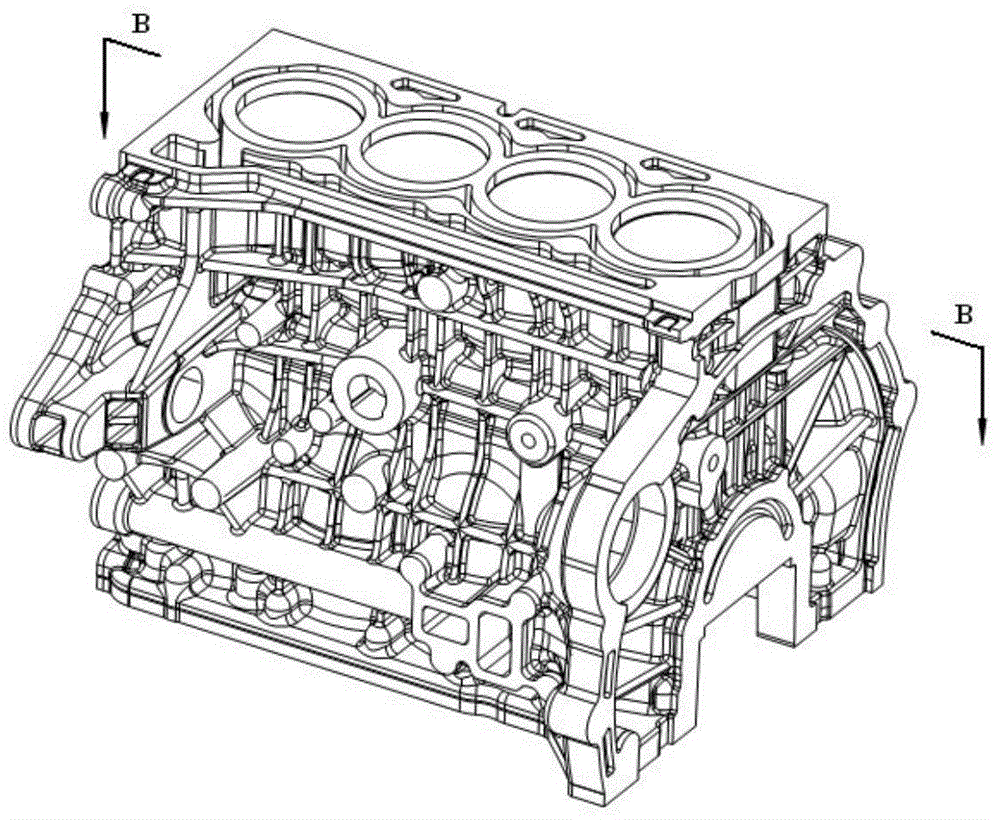

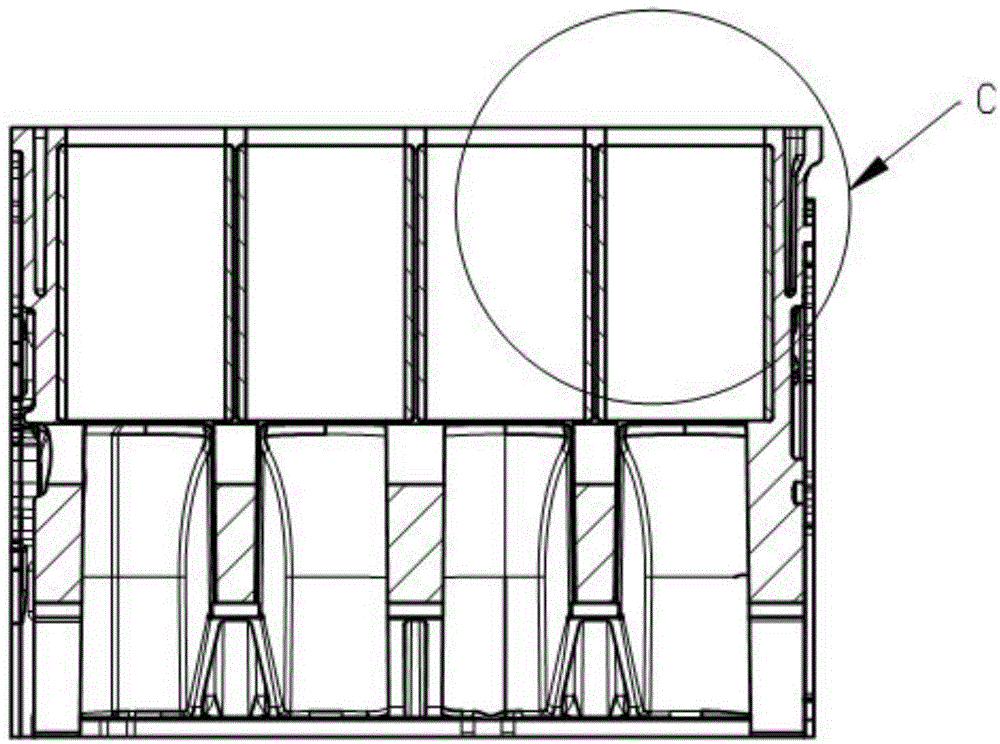

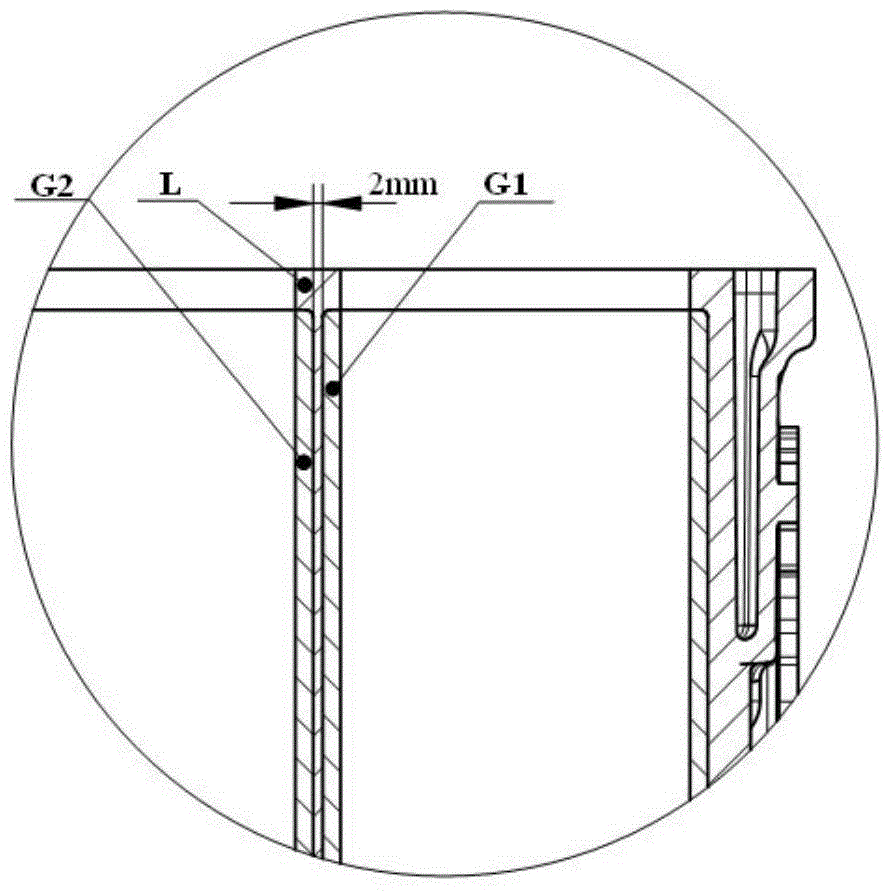

Rapid manufacturing method of aluminum alloy cylinder block casting piece of embedded cylinder sleeve

ActiveCN104550710APromote rapid developmentFast preparationFoundry mouldsFoundry coresManufacturing technologyCylinder block

The invention discloses a rapid manufacturing method of an aluminum alloy cylinder block casting piece of an embedded cylinder sleeve. The rapid manufacturing method comprises the following steps: obtaining 3D data of a to-be-cast aluminum alloy cylinder block of the embedded cylinder sleeve; analyzing the 3D data; determining a process scheme; carrying out parting processing on the 3D data; decomposing and manufacturing a mold core; casting in a manner of mold assembling to obtain a casting piece; cleaning the casting piece; and checking, wherein the design of an aluminum alloy cylinder block mold core of the embedded cylinder is divided into various sand molds and sand mold groups after the 3D data are subjected to parting processing; a left sand mold, a right sand mold, a front sand mold, a rear sand mold, a bottom sand mold, a dead head, a pouring cup and a sprue sand mold are fabricated by adopting a PDM model direct milling technology in the decomposing and fabricating processes of the mold core; and a water sleeve core and a crank case core assembly are fabricated by adopting a PCM patternless casting manufacturing technology. The method has the characteristics of being fast, accurate, efficient and economical, so that the high-quality aluminum alloy cylinder block of the embedded cylinder sleeve for an engine is manufactured; and the method is especially suitable for rapid manufacturing of one-piece, individual, small-batch and complicated products, new product development, and the like.

Owner:GUANGDONG FENGHUA ZHUOLI TECH CO LTD

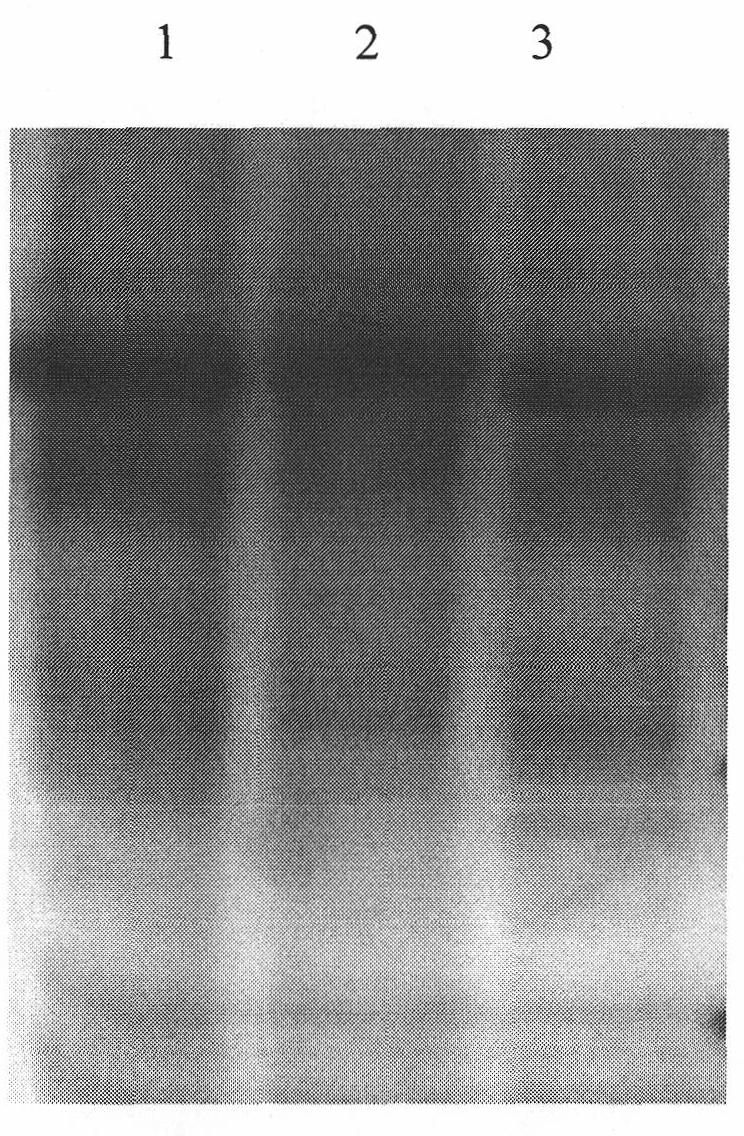

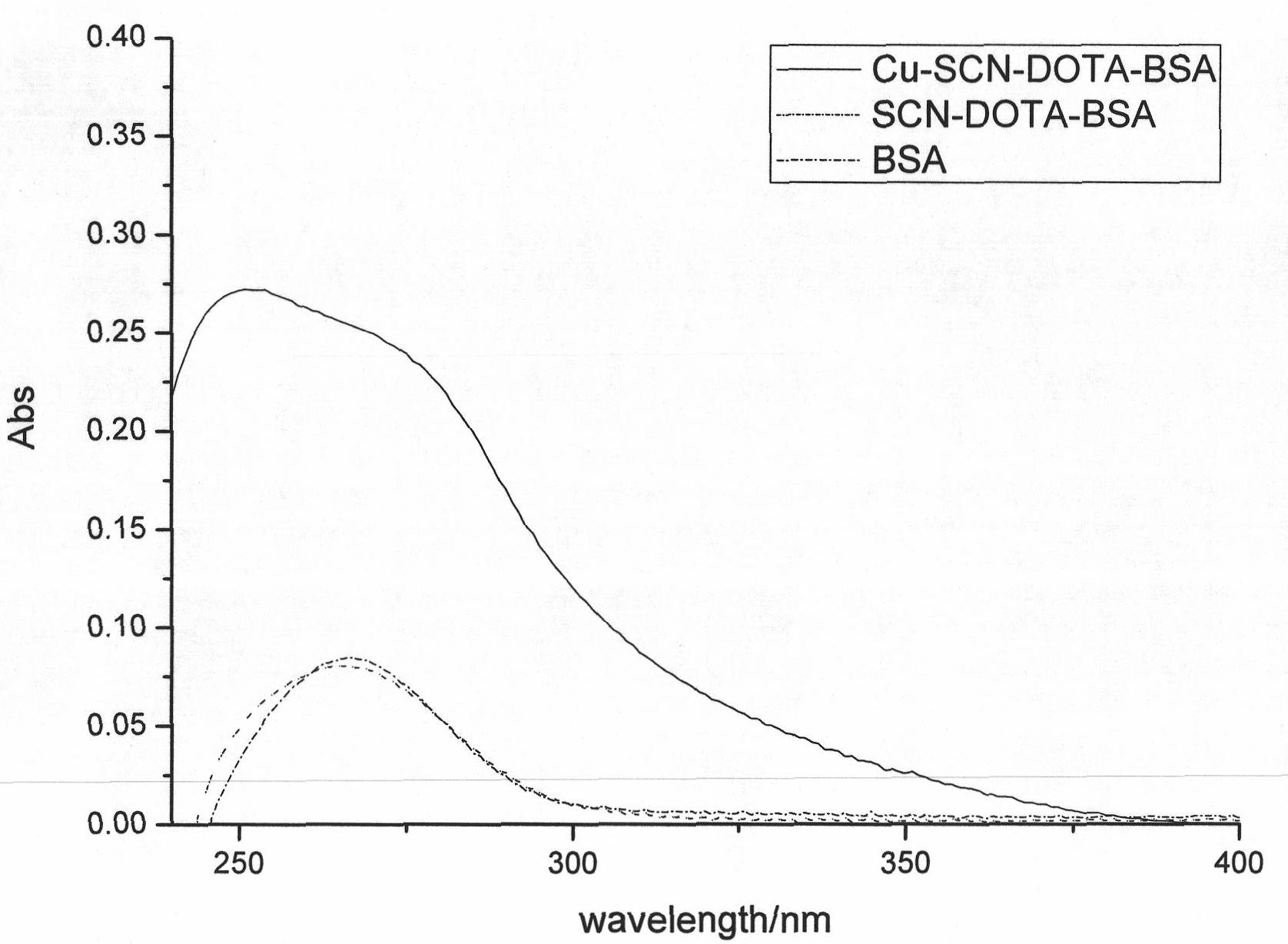

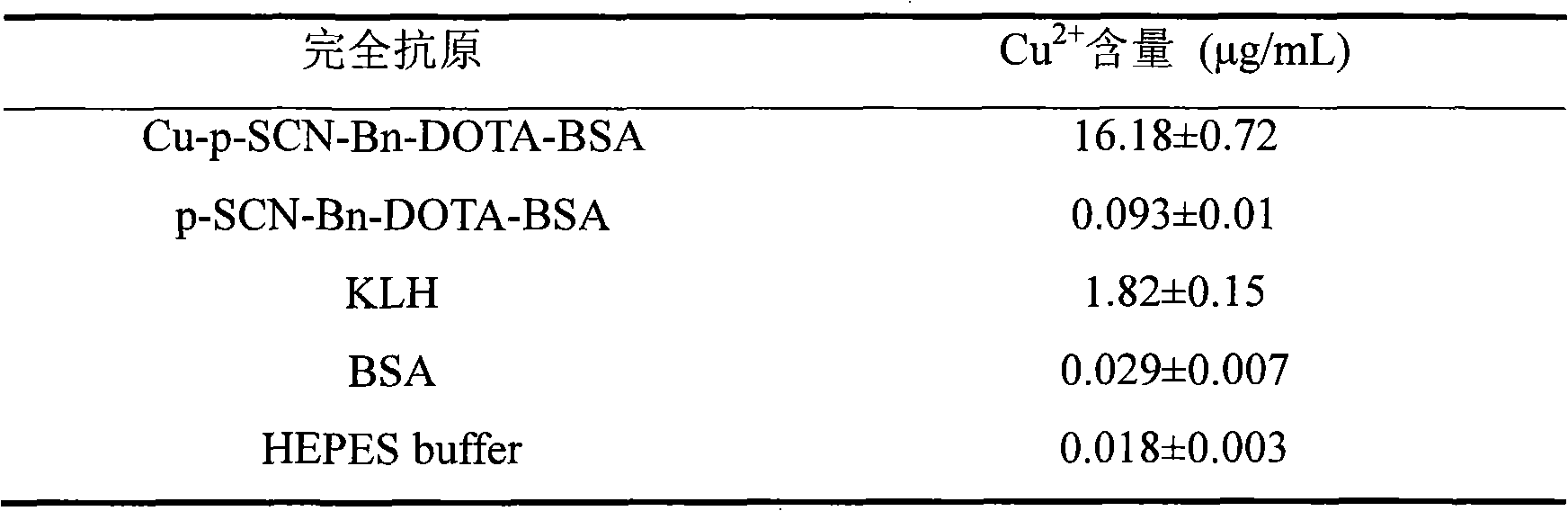

Heavy metal Cu<2+> complete antigen and preparation method thereof

InactiveCN101775074ASolve the technical difficulties of preparationSolve technical difficultiesOvalbuminSerum albuminSorbentMonoclonal antibody

The invention discloses a heavy metal Cu<2+> complete antigen and a preparation method thereof. The preparation method comprises the following steps: Cu<2+> is reacted with a bifunctional chelating agent to form a hapten; and a Cu<2+>-chelating agent hapten is reacted with a carrier protein to form a Cu<2+>-chelating agent-carrier protein complete antigen. The antigen has better immunogenicity; and an immune mice with the antigen can be used for preparing a Cu<2+> specific monoclonal antibody and further preparing a rapid Cu<2+> detection ELISA (enzyme-linked immuno sorbent assay) kit of various heavy metals and colloidal gold immunochromatography assay test paper.

Owner:JILIN UNIV

Gas pushing type underground fluid stratified sampling device

ActiveCN103967486ANovel structureEasy to operateBorehole/well accessoriesSoil gasClassical mechanics

The invention discloses a gas pushing type underground fluid stratified sampling device. The end port of a simple packer system is inserted into a pipe of a shaft system to perform embedding and fixedly riveted with the pipe through screws to form an integral cylindrical structure. The integral cylindrical structure is buried in the stratum through drilled holes, and a guide pipe in the integral cylindrical structure penetrates through small holes preserved in simple packers to be connected with a U-shaped pipe underground fluid sample feeding system. The guide pipe penetrates through the small hole preserved in a first simple packer to be connected with a gas phase filter and a gas phase check valve of a soil gas sampling system and penetrates through the first simple packer to be connected with a needle valve on the ground and a fluid sampling container. A gas pushing type ground fluid sampling system penetrates through the small hole preserved in the first simple packer to be connected with the U-shaped underground fluid sample feeding system. The gas pushing type underground fluid stratified sampling device is ingenious and novel in structure, low in cost, excellent in durability, strong in field adaptability, wide in application fields, strong in project demands and good in application prospect and commercial value.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

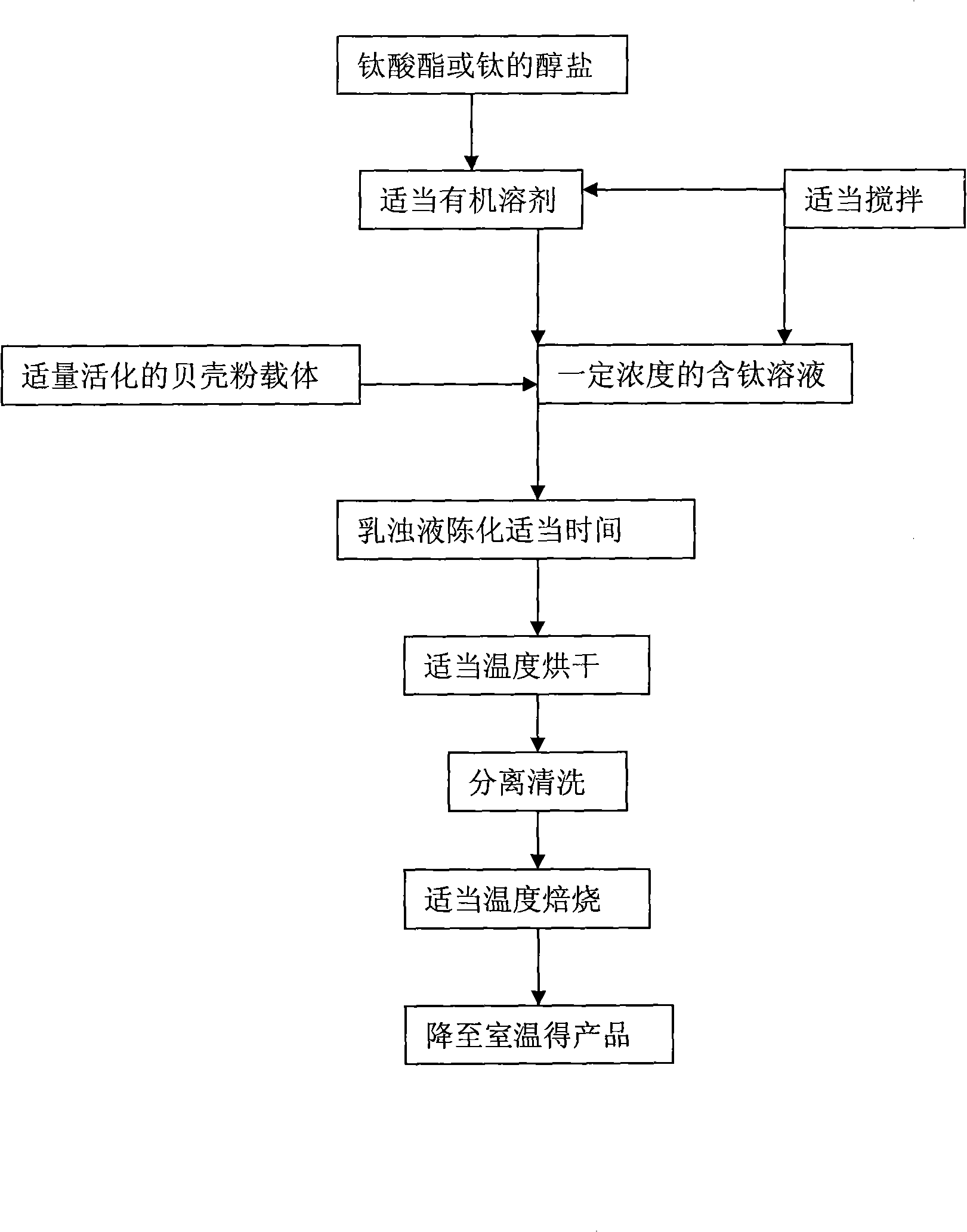

Nano titanic oxide impregnation preparation method using shell powder as carrier

InactiveCN101352674ASolve associativitySolve for uniformityCatalyst carriersCatalyst activation/preparationFiberTitanium oxide

The invention discloses an impregnation preparation method of nanometer titanium oxide which takes shell powder as a carrier, and in particular relates to a reproducible porous nanometer titanium oxide powder which takes the shell powder as the carrier and the preparation method thereof. In the method, titanium oxide is loaded on a shell powder carrier by impregnation; firstly, alkoxide solution of titanium ester or titanium with appropriate concentration is prepared, then an activated shell powder carrier with certain proportion is impregnated in the alkoxide solution, then the obtained solution is stirred and stayed for a certain time, and treated by low temperature and abstersion pretreatment and finally roasted at high temperature, so the nanometer TiO2 forms high-strength bond with the shell powder and promotes the catalytic activity of the nanometer TiO2 at the same time. Impregnation can be conducted for a plurality of times to increase load. The nanometer TiO2 is characterized by small particle size, good compatibility with materials, high catalytic efficiency, good stability, good regenerability, and the like, and can be applied to the fields of plastics, rubbers, fibers, coatings, home electronic appliances, paints, ceramics, water and environmental manipulation, pharmaceutical and hygienic articles, etc. In terms of sources of raw materials and production technology, the preparation method not only reduces the production cost of the nanometer TiO2 catalyst but also is helpful for disposal of the increasingly serious environmental problems, thus bearing great environmental protection significance.

Owner:GUANGDONG OCEAN UNIVERSITY

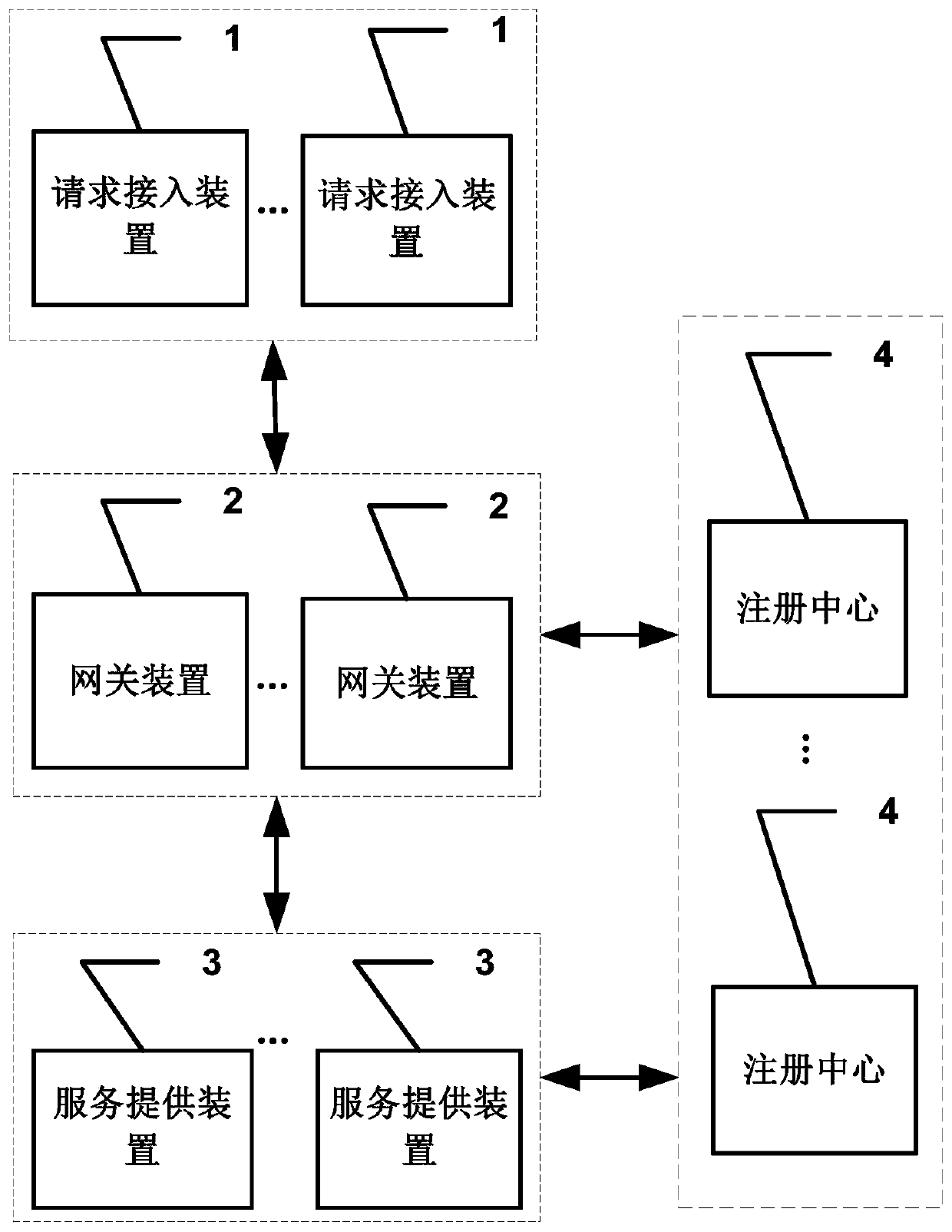

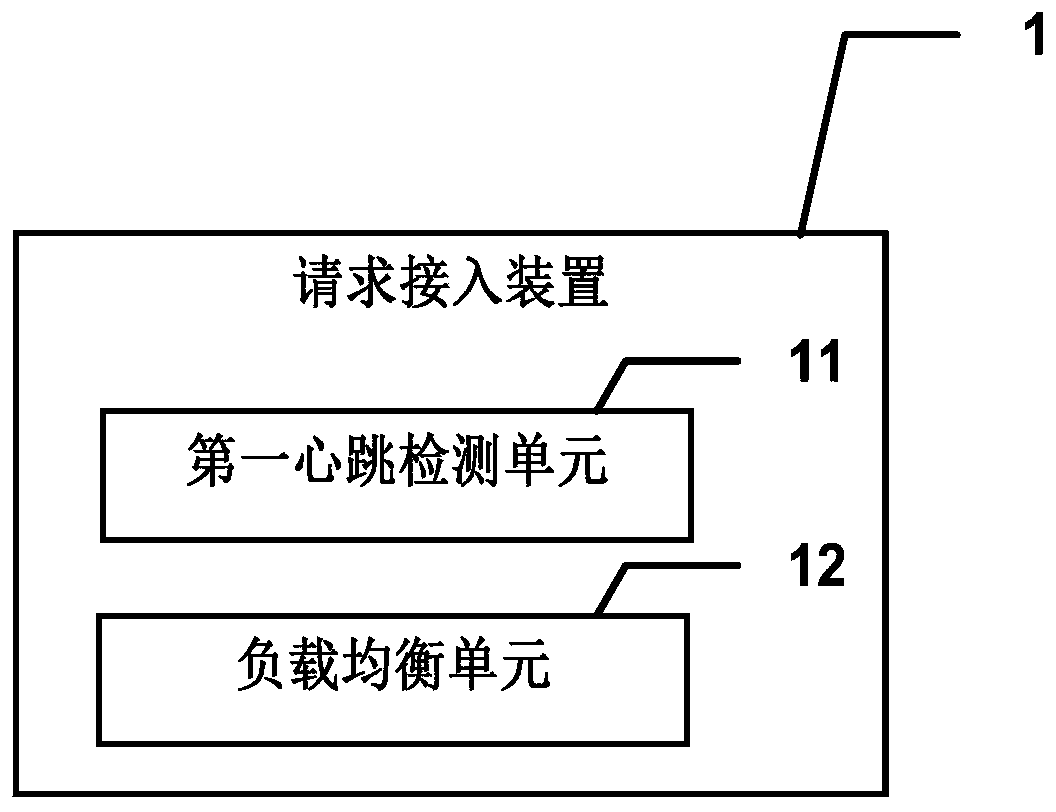

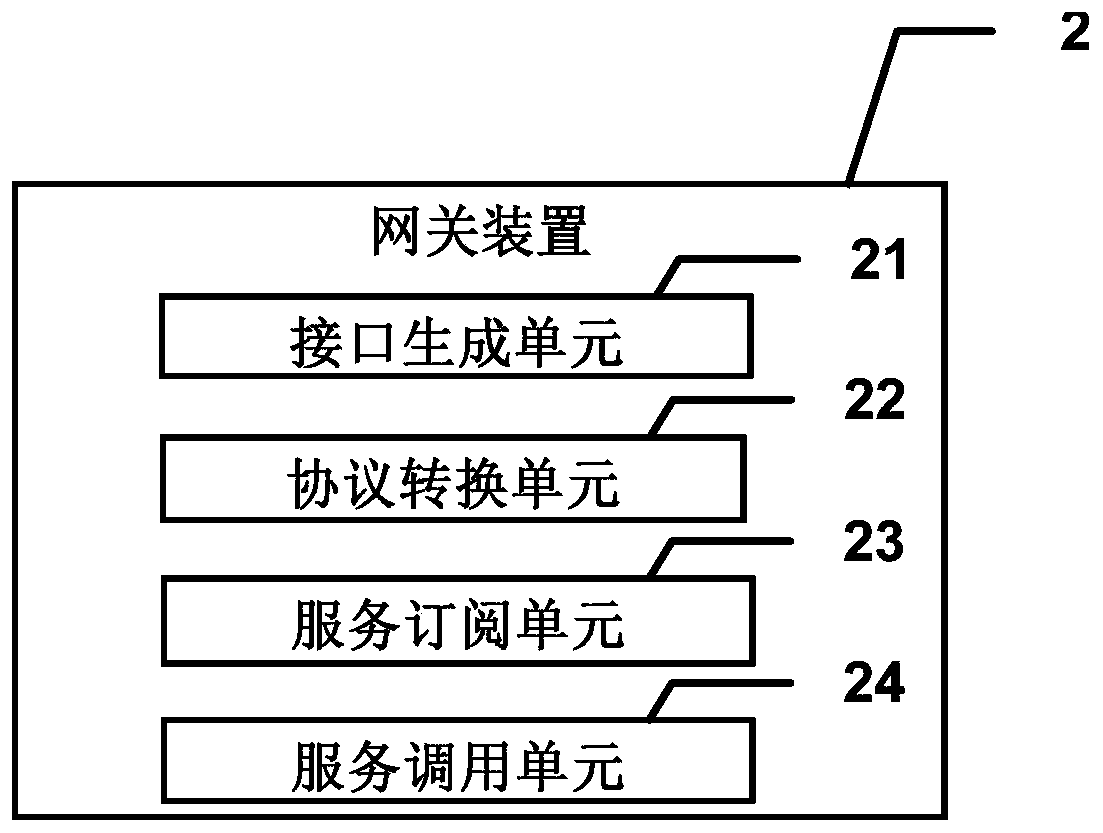

Distributed service access system and method

ActiveCN110191164AEasy to buildQuick buildData switching networksService gatewayDistributed services

The invention provides a distributed service access system and method. The system comprises the following steps: a request access device receives an Http request and sends the Http request to a gateway device; the gateway device analyzes the Http request to determine an interface name and a version number, judges whether the interface exposes the gateway or not according to the interface name, constructs an RPC consumer if the interface exposes the gateway, and converts the Http request into an RPC request; the gateway device obtains an address list of the service providing device through theregistration center and sends the RPC request to the service providing device; the service providing device returns a calling result according to the RPC request; and the gateway device converts the calling result into an Http message and sends the Http message to the service consumer. The system and method support the dynamic construction of the RPC consumer and the conversion of the Http protocol and the RPC protocol. Thesystem is simple in structure and easy to build, and supports building of the service gateway under the rapid landing Dubbo framework of an enterprise.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

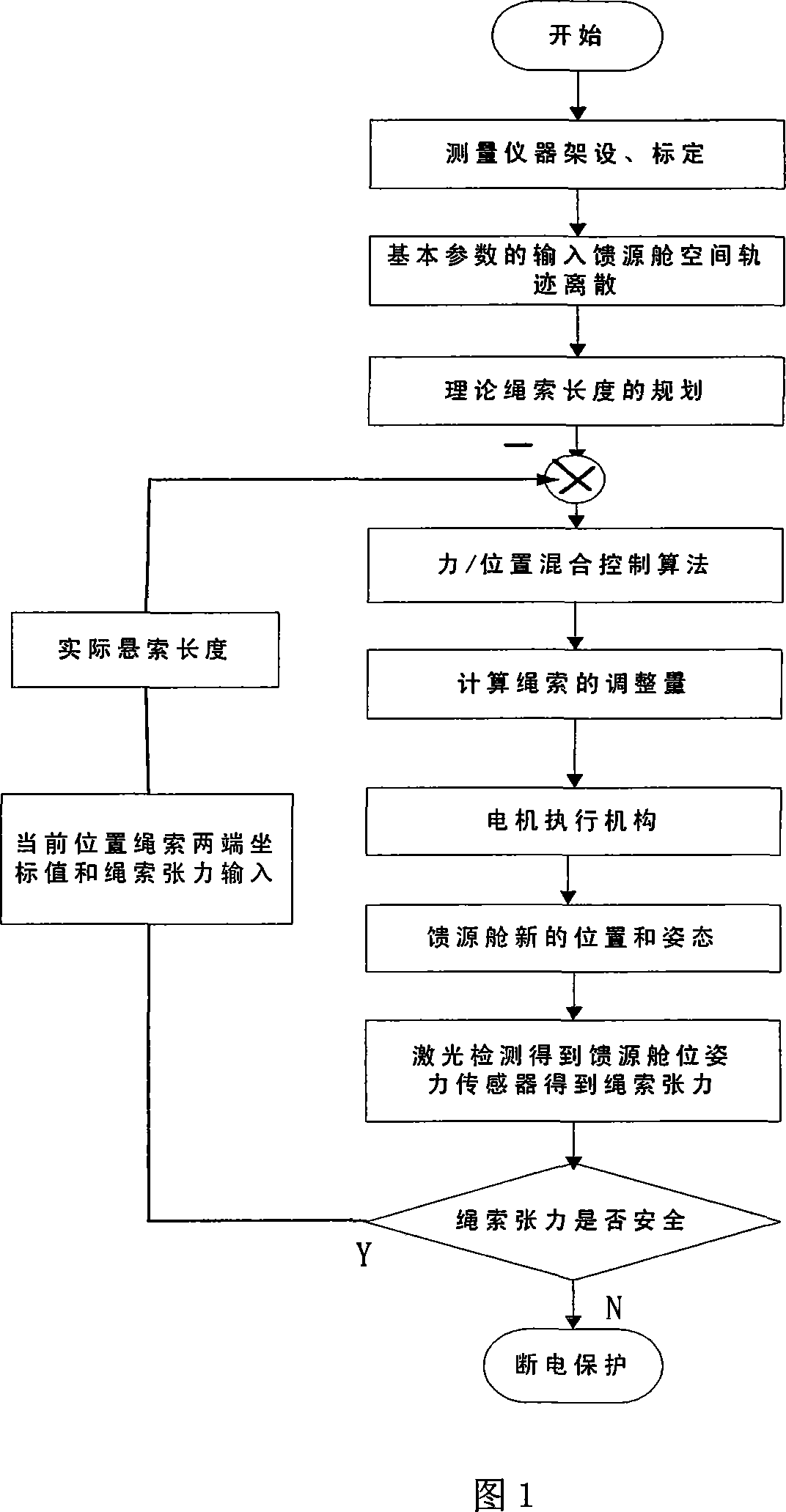

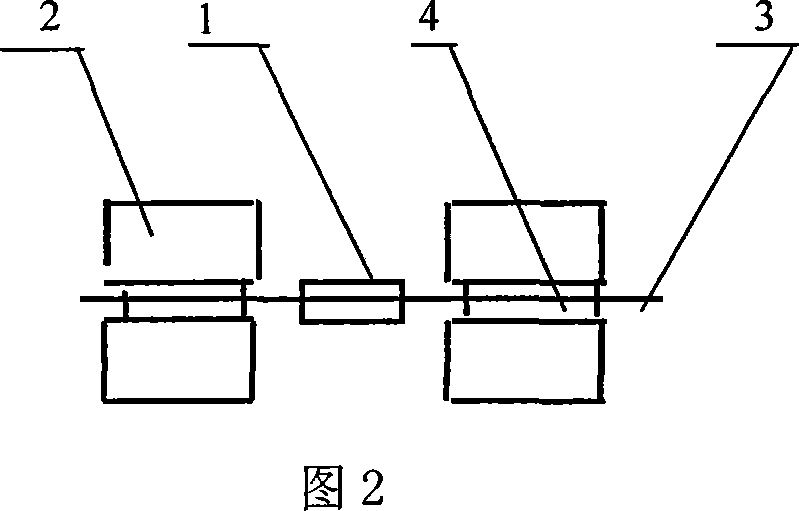

Cable length/force-based large-size cables structure parallel robot cable regulating method

InactiveCN101060196AReduced measurement accuracyMeet the needs of process force controlAntenna supports/mountingsCatenaryCable tension

The disclosed cable adjustment method for giant cable parallel robot cable based on cable length / force comprises: scaling the station coordinate and peak coordinate by measuring apparatus, determining the theoretical attitude angle of feeding cabin; taking cable space shape as the catenary, and solving the theoretical length of cable at every discrete point; detecting the cable tension by sensor, calculating current real length, comparing the real and theoretical lengths to obtain the adjust quantity; finally, sending the adjust quantity into actuator for dragging the feeding cabin. With 2cm / s space scanning speed, this invention introduces position precision less than 3cm, and special fit to giant cable-system parallel robot.

Owner:XIDIAN UNIV

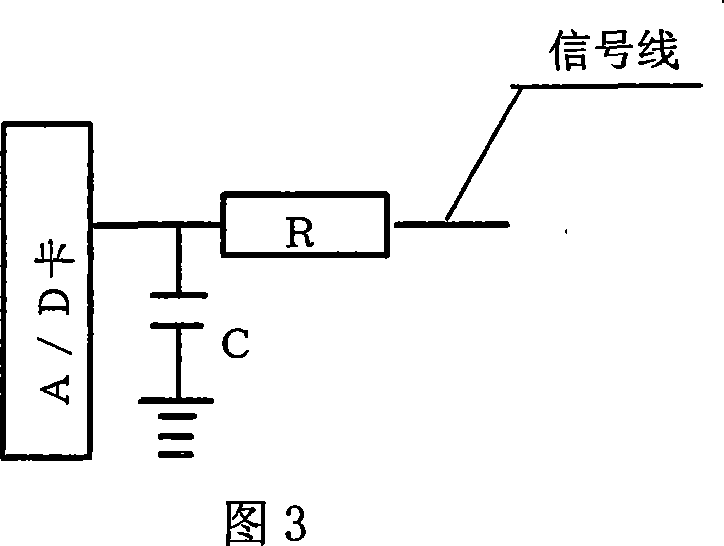

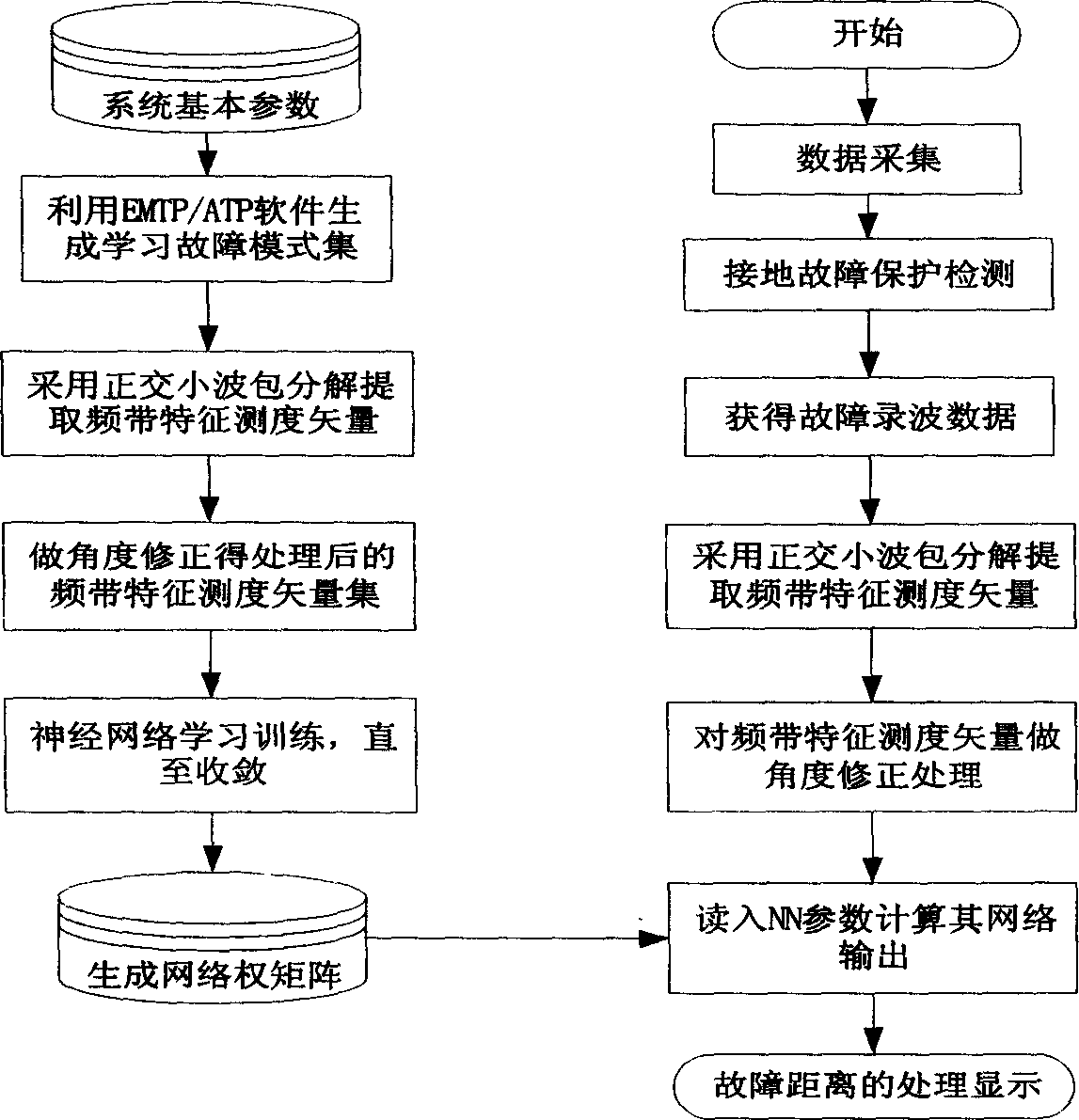

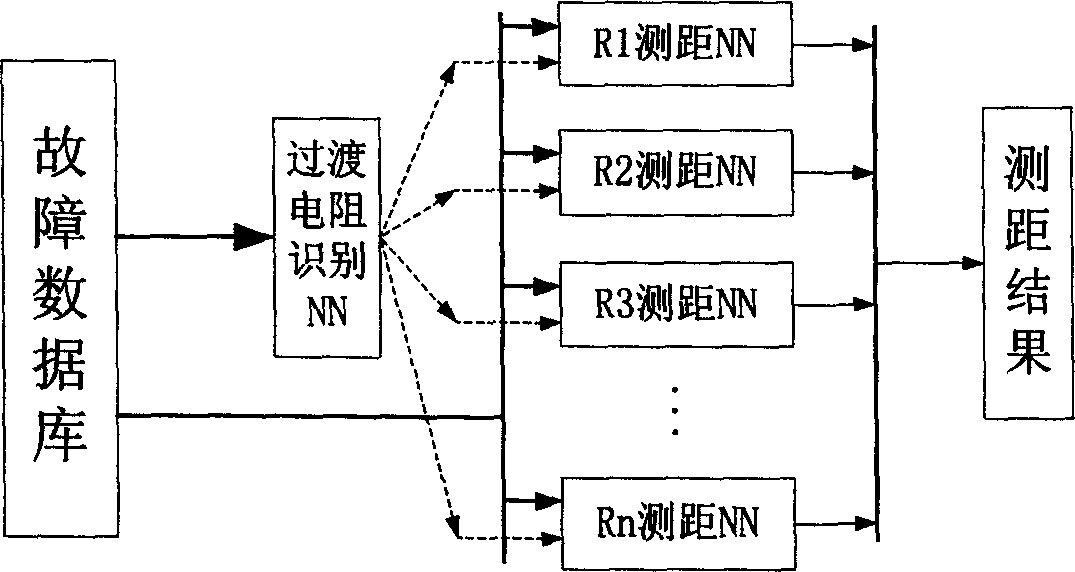

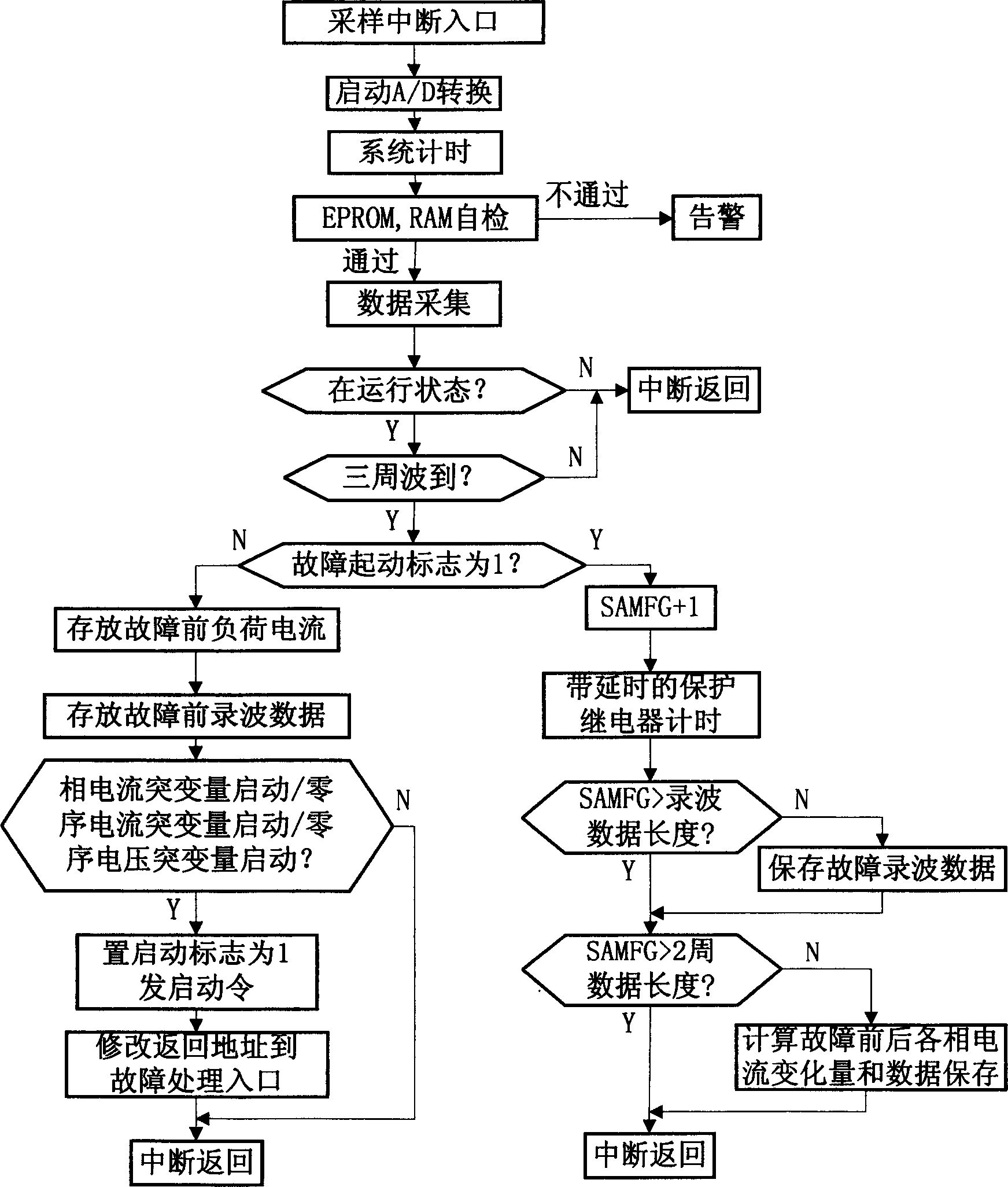

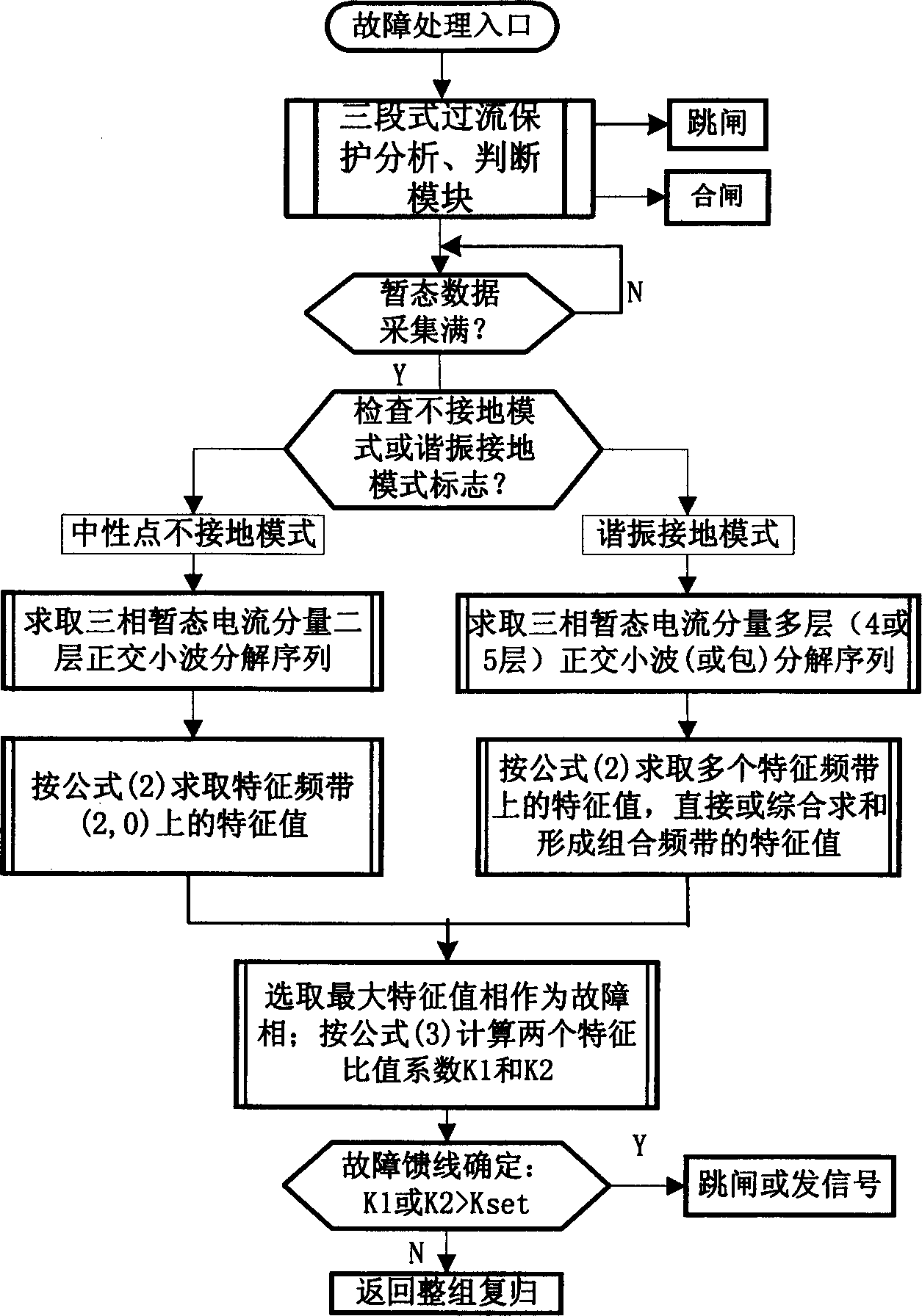

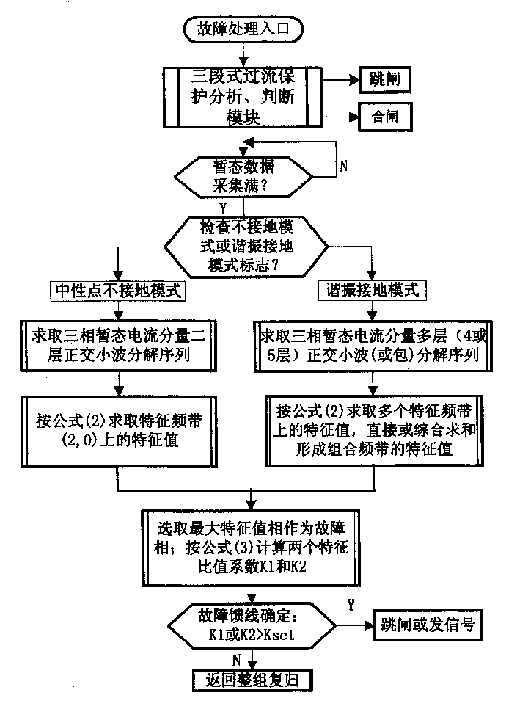

Feeder line singlephase fault and multiphase fault distance measuring method based on wavelet decomposition frequency band feature

InactiveCN1605878AFind quicklyOvercome and suppress the influence of uncertain factorsFault locationDecompositionData acquisition

The invention discloses a feeder line single phase fault and multiphase fault distance measuring method based on wavelet decomposition frequency band feature, wherein the single phase fault distance measuring method consists of using non-fault phase transient current composition as the fault distance measurement information, and carrying out data acquisition, earth connection error protection detecting, obtaining fault recording wave data, extracting frequency band characteristic measurement vector by using orthogonal wavelet packet decomposition, angular correction treatment to the frequency band characteristic measurement vector and neural net computation. The multiphase fault distance measuring method utilizes the failure current information as the fault distance measurement basis.

Owner:TIANJIN UNIV

Economic and environment-friendly polymer-based cable bridge

InactiveCN102964725AImprove performanceIncrease coefficient of frictionChemical industryParaffin wax

The invention discloses an economic and environment-friendly polymer-based cable bridge which comprises the components with the content as follows: 100phr of polyvinyl chloride (PVC), 5phr of Ca-Zn compound stabilizer, 10phr of chlorinated polyethylene (CPE), 3phr of P83, 0.5phr of paraffin wax, 0.3phr of polyethylene (PE) wax, 0.4phr of acrylic acid (ACR), 10phr of calcium carbonate whisker, 8phr of DBDPE, 5phr of nano antimonous oxide, 2phr of compound zinc borate, 5phr of titanium dioxide, 0.5phr of 1010 and 0.2phr of UV-531. The economic and environmentally friendly polymer-based cable bridge breaks through the key technology of strength and water resistance of fire-proof and environment-friendly multi-element composite material, and has the characteristics of being environment-friendly, attractive, light in mass, flame retardant, corrosion-resistant, low in manufacturing cost, convenient in field installation, long in service life and the like, thus being widely applied to industries such as chemical industry, petroleum and the like and being more suitable for being used in the environmental conditions such as dampness, salt mist and chemical gas.

Owner:QINGDAO XINWANTONG PLASTIC IND

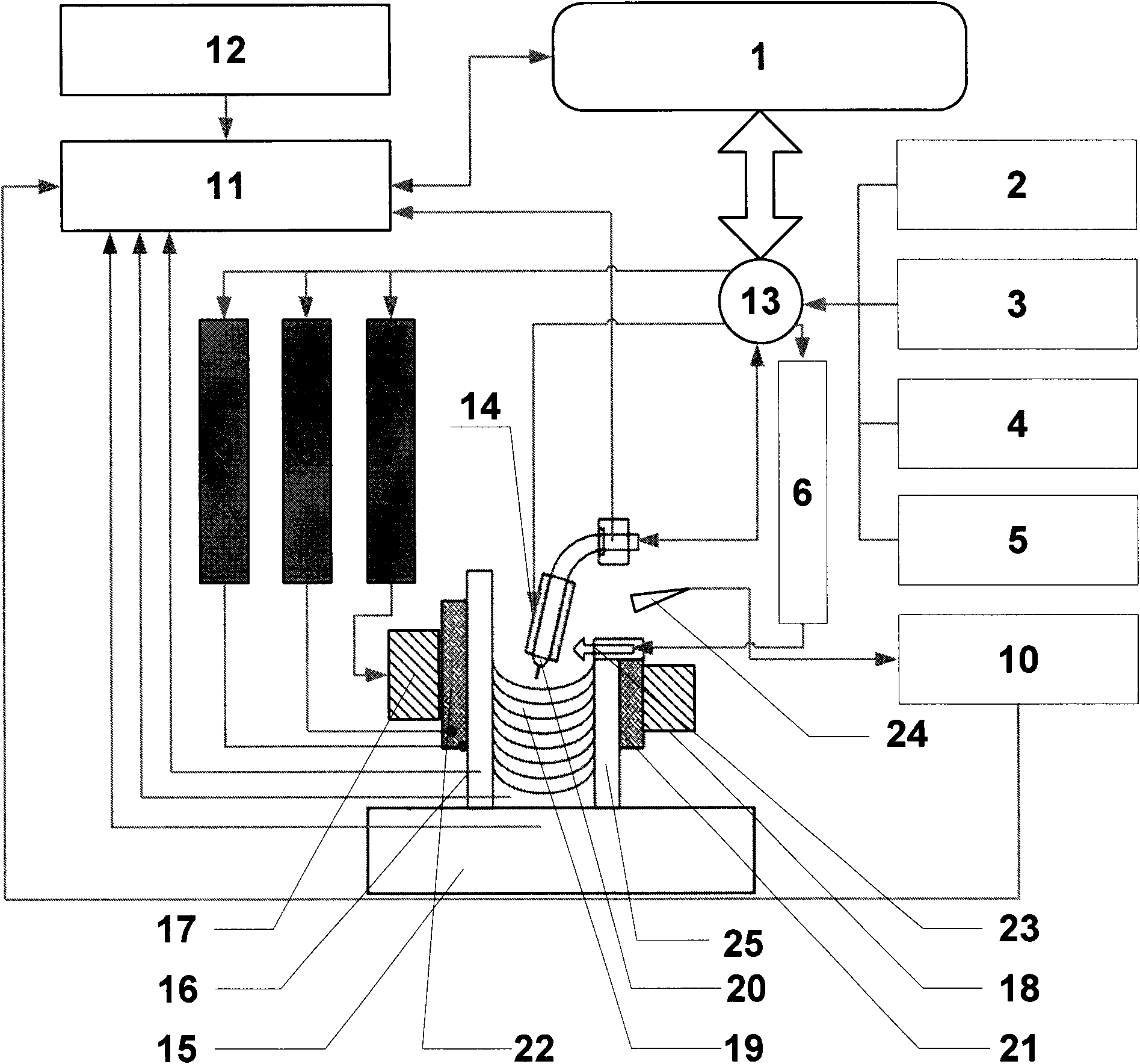

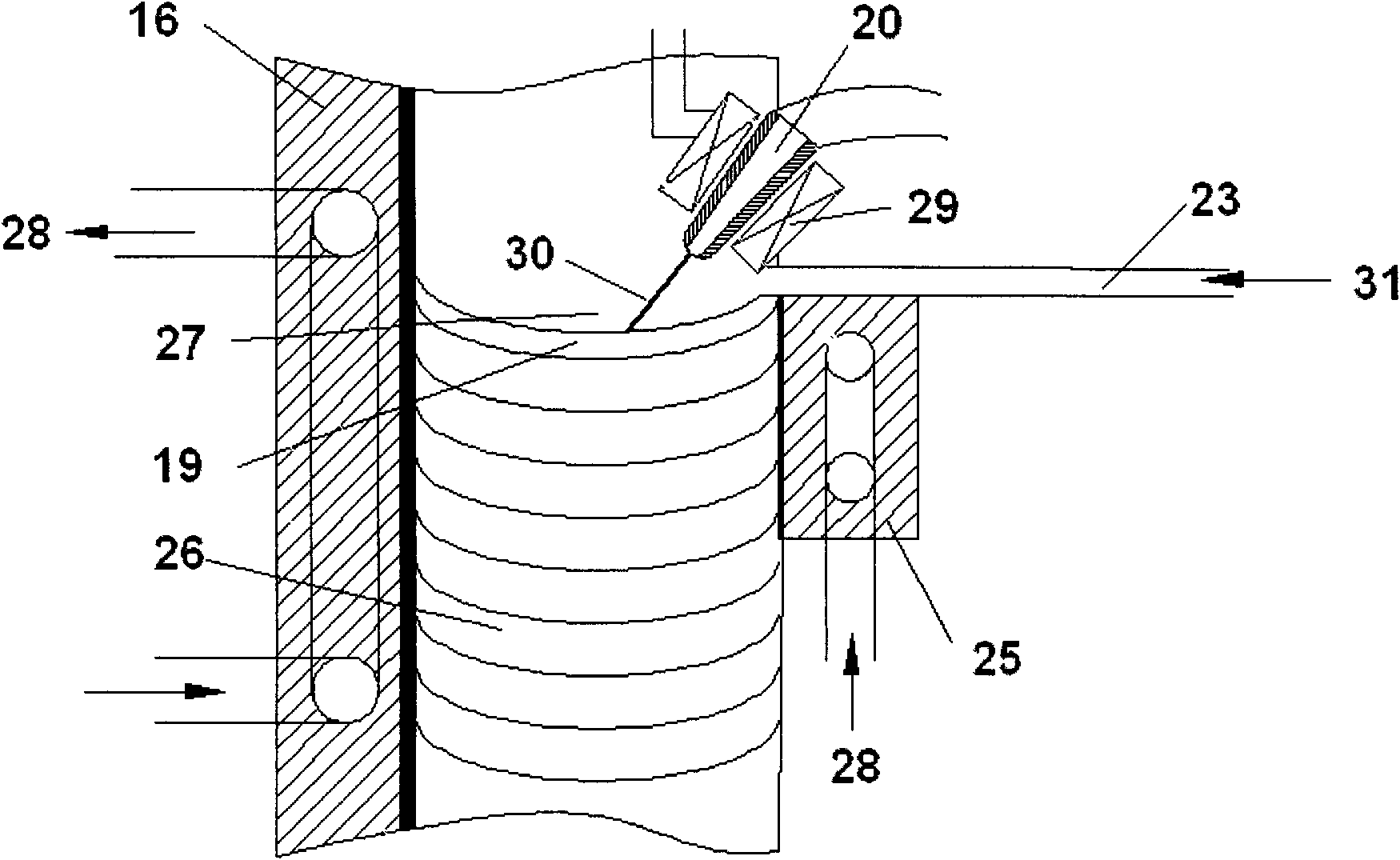

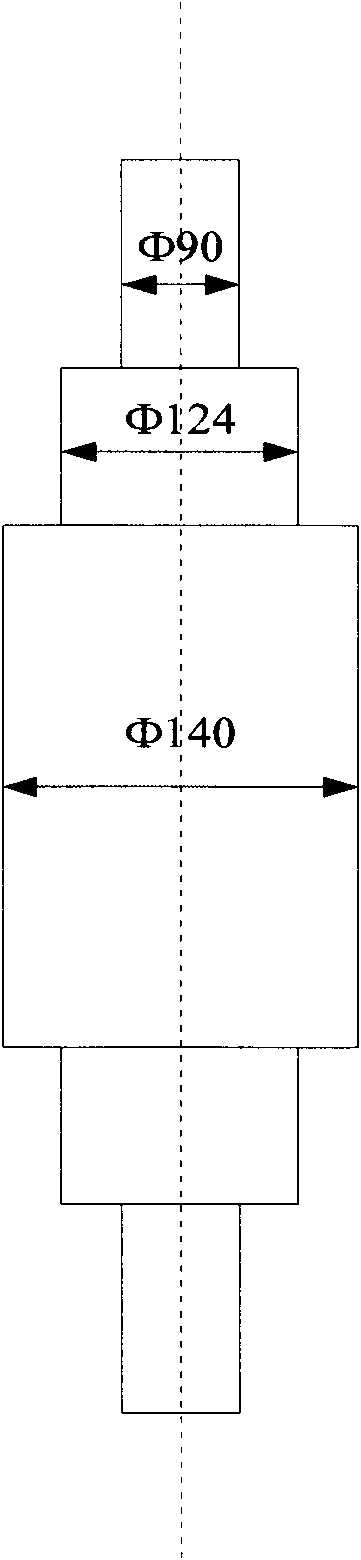

Method and equipment for manufacturing gradient functional structure

InactiveCN102240861AAvoid defectsMeet the needs of high-performance componentsWelding accessoriesNon-electric welding apparatusTemperature controlControl system

The invention relates to a method and equipment for manufacturing a gradient functional structure through arc welding and quick forming. By adopting the technology of outer-field compounding, molding, forcible temperature control, sequential growth, and whole welding forming, a double metal gradient material is subjected to in-situ alloying, and the gradient functional structure is manufactured in a near net way; and in the method, an electromagnetic stirring action, an electromagnetic metallurgical action and an ultrasonic welding action are adopted, the large-volume welding pool liquid metal solidification process is comprehensively controlled, and the gradient functional structure is manufactured by matching a high-speed wire feed system, a mould forcible temperature control system, a near net forcible sequential growth whole forming system, and an in-situ alloying gradient material. The equipment is formed by integrating and combining an electromagnetic welding system, an ultrasonic welding system, and an efficient welding system. By the method and the equipment for quickly manufacturing the gradient functional structure by a non-layered welding structure in a low-cost way, a manufacturing period is reduced, production efficiency is improved, and the high reliability and the long service life of the gradient functional structure are guaranteed.

Owner:CHONGQING UNIV

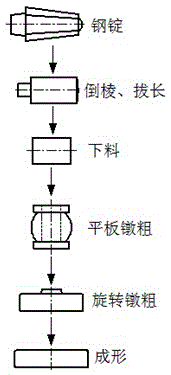

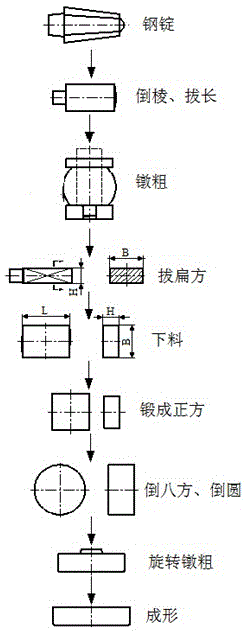

Forging technology for heavy disk forgings

InactiveCN106475500ASolve technical difficultiesSimple process routeMetal-working apparatusWheelsWidth ratioReduction rate

The invention relates to a forging technology for heavy disk forgings. The forging technology includes the steps of heating steel ingots to be forged, preserving the temperature, enabling the temperature of the center parts of the steel ingots and the temperature of the exteriors of the steel ingots to be identical and heating the steel ingots uniformly and thoroughly; drawing the steel ingots through an existing forging method, wherein the anvil width ratio is 0.8-0.9; drawing the steel ingots at a time with the reduction rate being at least 20% each time; in the square stage, adopting a WHF forging method, an SUF forging method or a TER forging method and adopting an anvil staggering and drawing technology; carrying out forging flatly and squarely in the height direction through a wide anvil forging method to form blanks; enabling the value of the ratio of the length of blanked work-blanks to the width of the blanks to be smaller than or equal to 1.5; and carrying out square forging, octagon chamfering, rounding and forging forming through an existing forging method to obtain the heavy disk forgings. According to the forging technology, compaction and forging penetration are carried out on the blanks in the drawing process, previous forging structures and streamlines are basically maintained after upsetting formation and are prevented from being damaged, the technical problems of tube plate forging are solved, the ultrasonic flaw detection qualification rate is close to 100%, the mechanical property is excellent, and the requirements of product performance can be completely met.

Owner:LANZHOU LS GRP

Preparation method of heavy metal mercury monoclonal antibody

InactiveCN101139398AFast pushStrong antigenicityImmunoglobulins against animals/humansBiological testingBALB/cSpleen cell

The present invention relates to a preparation method of heavy metal mercury monoclonal antibody, which belongs to the field of biotechnology. The present invention is particularly used in the preparation of specificity-recognition heavy metal mercury monoclonal antibody and in the fast mercury high-sensitivity measurement remained in the agricultural production and the agricultural production environment. The heavy metal mercury ion and the carrier albumen are coupled into full antigens through bifunctional metal chelate 1-(4-separate-cyano phenyl)-EDTA; the full antigens are used on Balb / C mouse and the spleen cells and the Sp2 / 0 myeloma cells are used to prepare hybridoma cells through the hybridoma technology. And monoclonal antibody which can stably excrete anti-Hg-EDTA is generated. The preparation technology in the present invention is easy and practical: the whole preparation process of the antigen requires no special instrument. The present invention is suitable for factory-scale production.

Owner:NANJING AGRICULTURAL UNIVERSITY

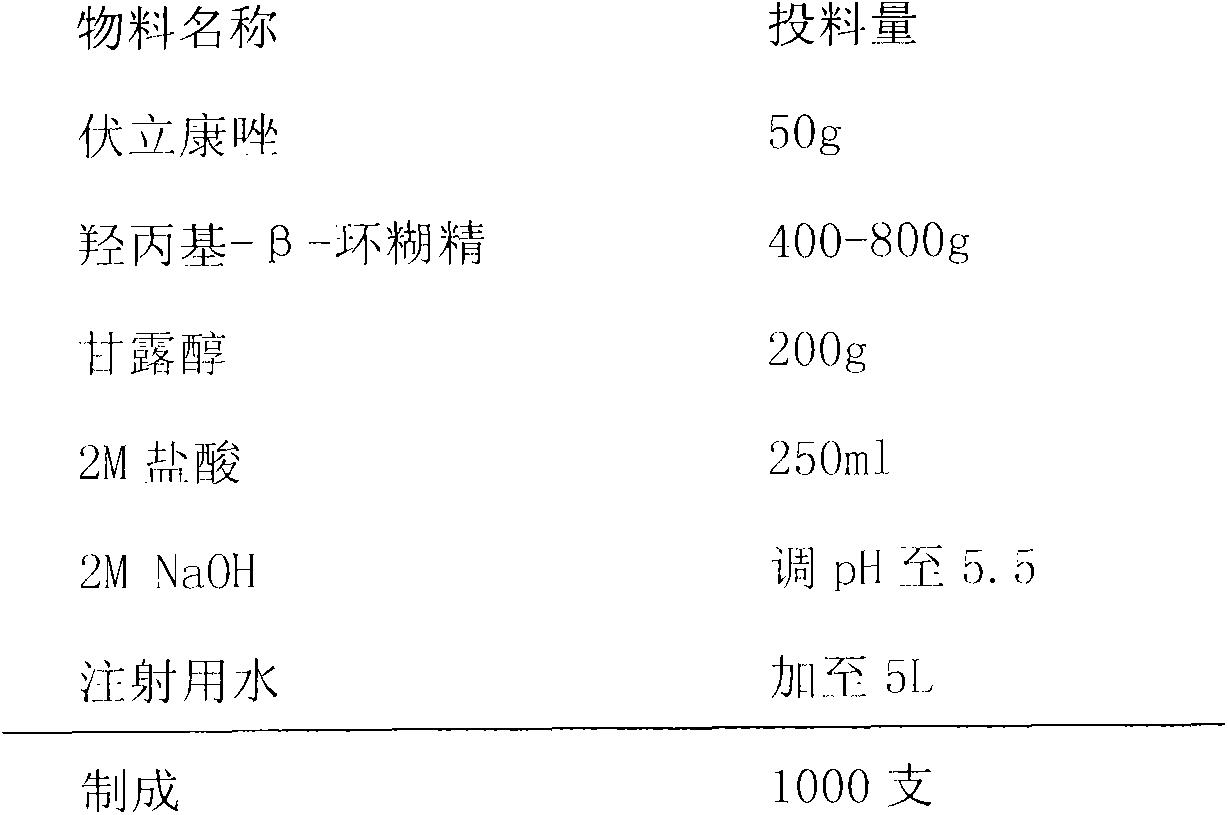

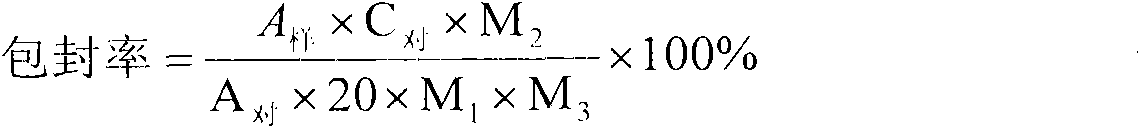

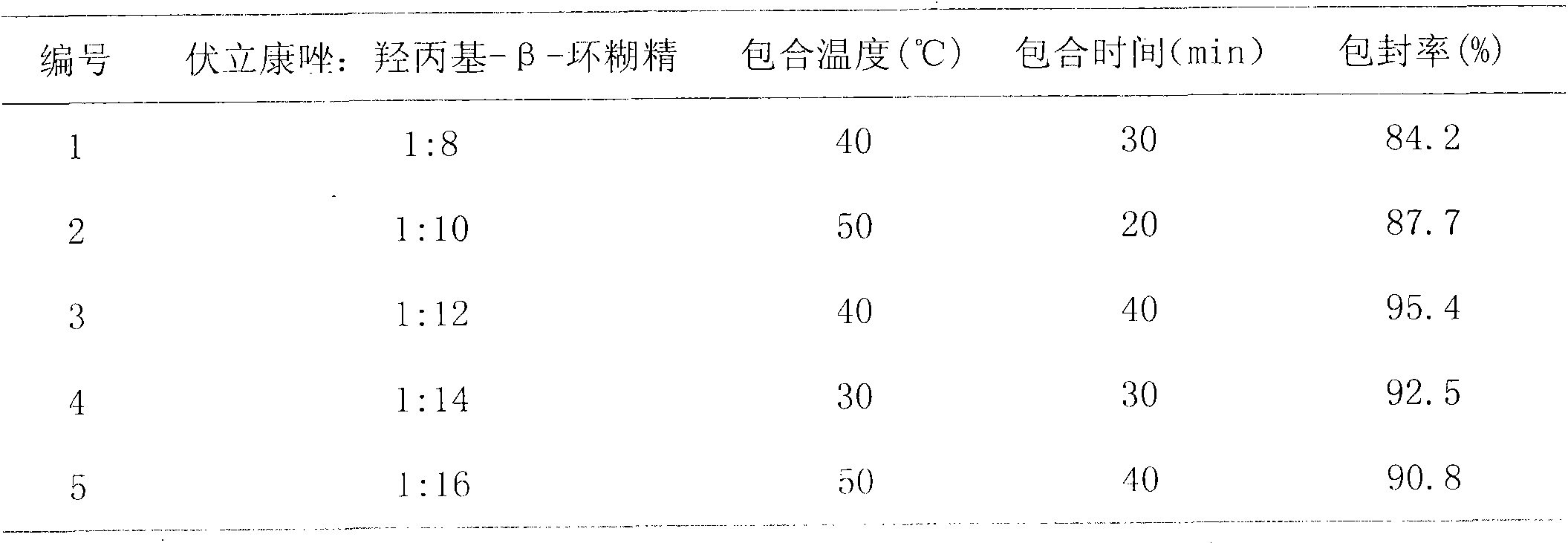

Voriconazole freeze-dried powder injection for injection and preparation method thereof

InactiveCN103251565AImprove solubilityImprove stabilityPowder deliveryOrganic active ingredientsFiltrationFreeze-drying

Belonging to the technical field of drug preparation, the invention relates to a voriconazole freeze-dried powder injection for injection and a preparation method thereof. The invention provides a pharmaceutical preparation that treats invasive fungal infections and has good solubility and high stability for clinical practice. According to a prescription, the voriconazole freeze-dried powder injection for injection provided in the invention is composed of voriconazole, hydroxypropyl-beta-cyclodextrin, mannitol, hydrochloric acid, sodium hydroxide, and water for injection. The preparation process includes: subjecting an aqueous solution of hydroxypropyl-beta-cyclodextrin and an acid solution of voriconazole to clathration, adding mannitol, then conducting stirring dissolving, using a sodium hydroxide solution to adjust the pH value, carrying out activated carbon adsorption, decarbonization, fine filtration by a microfiltration membrane and semi-finished product inspection, if the semi-finished product is qualified, performing subpackaging, freeze-drying, and conducting complete inspection. The cruxes of the preparation method are proportioning of voriconazole and hydroxypropyl-beta-cyclodextrin in the prescription, control of clathration temperature and time, charging sequence and other technical parameters. At the same time, the invention also provides a method for determination of the inclusion encapsulation efficiency.

Owner:ZHUHAI EBANG PHARMA +1

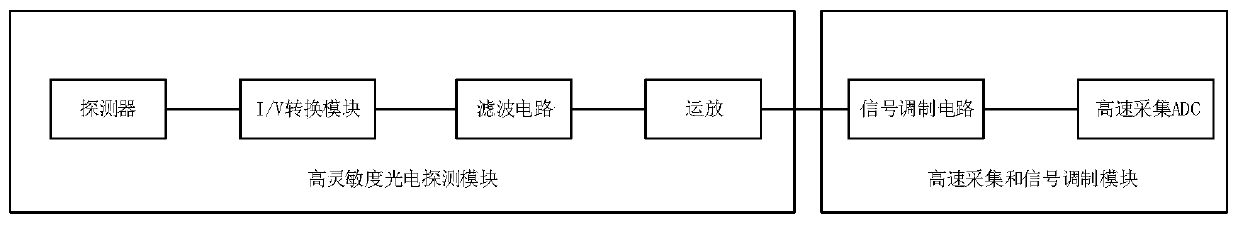

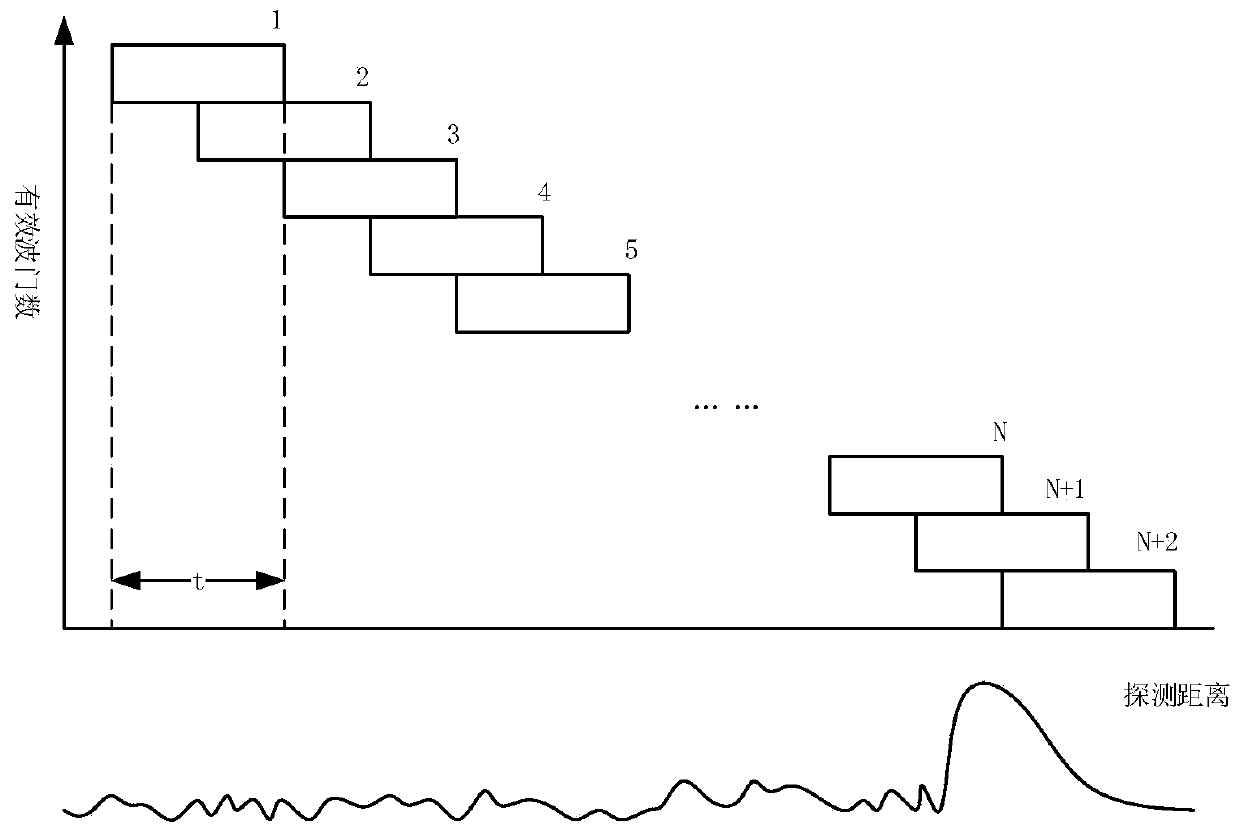

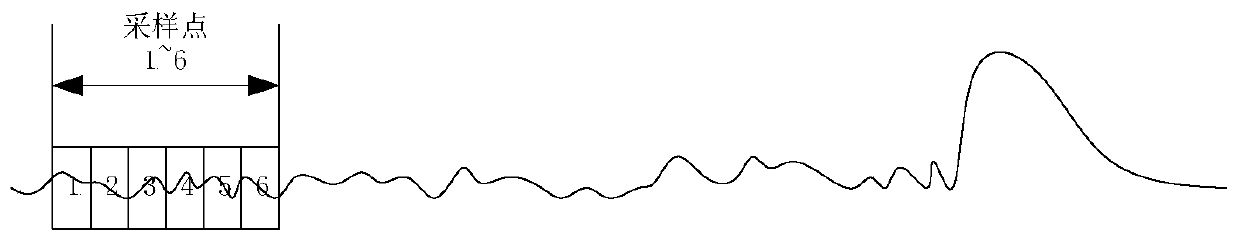

Vehicle obstacle avoidance laser radar waveform extraction method, laser radar and medium

ActiveCN110031821AAchieving Ranging AccuracySolve technical difficultiesElectromagnetic wave reradiationPhotodetectorFull waveform

The invention discloses a vehicle obstacle avoidance laser radar waveform extraction method, a laser radar and a medium. The method comprises the following steps of receiving an optical signal at a focal plane through a photodetector, and performing photoelectric conversion to obtain a laser radar electrical analog signal; converting the analog signal into an echo digital waveform by a high speedAD and a modulation circuit; storing the digital waveform online, and acquiring an echo interval of the effective waveform online by sliding window filtering; and integrating the effective waveform toobtain a target center-of-mass position. The invention relates to a vehicle obstacle avoidance laser radar waveform extraction method which can analyze the information of all the sampling points on afull waveform data channel by acquiring all laser echo signals on a laser transmission channel during single collection based on a laser echo full waveform collection technology system to obtain multi-pulse multi-center-of-mass positions, thus achieving centimeter-level ranging accuracy.

Owner:白犀牛智达(北京)科技有限公司

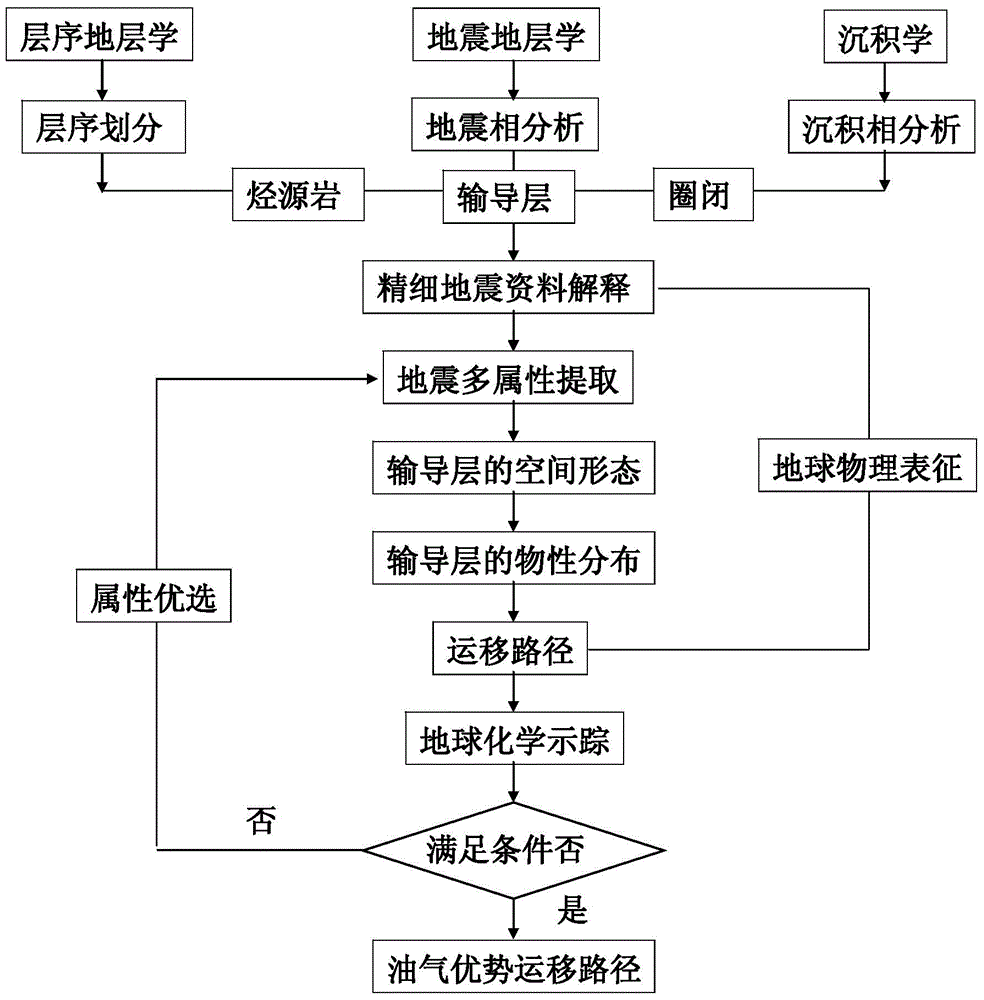

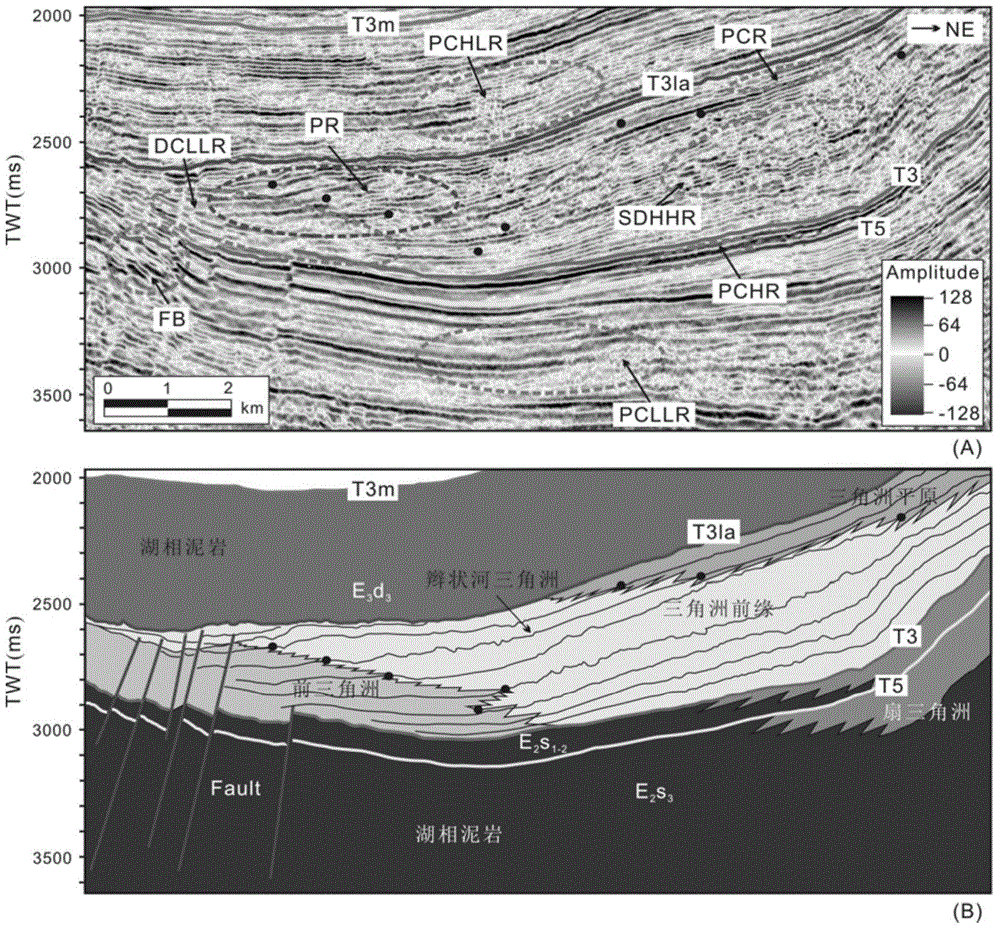

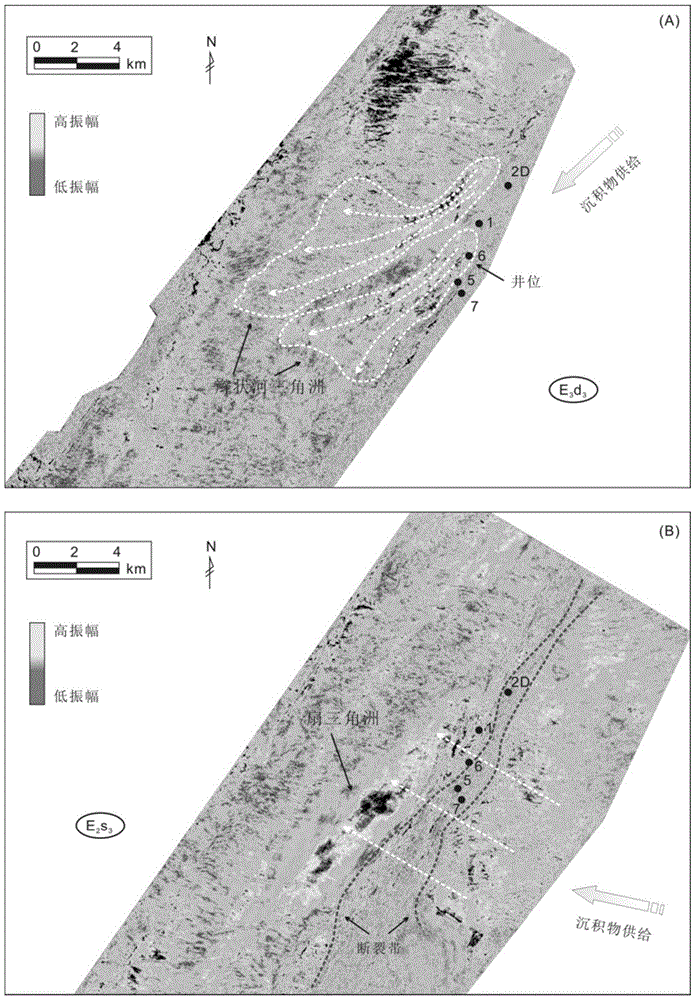

Oil-gas migration route tracing method through geology, geophysics and geochemistry methods

InactiveCN104389590ASolve technical difficultiesSelf-testingConstructionsSource rockSpatial distribution

The invention provides an oil-gas migration route tracing method through geology, geophysics and geochemistry methods. The oil-gas migration route tracing method through the geology, geophysics and geochemistry methods comprises the following steps of (1) performing geologic study of a carrier bed to determine the configuration relation between the carrier bed and source rock; (2) determining geophysics characterization of the carrier bed to determine spatial distribution and petrophysical distribution of the carrier bed to predict an oil-gas migration route; (3) tracing and checking the predicted oil-gas migration route in step (2) through a geochemistry method. According to the oil-gas migration route tracing method through the geology, geophysics and geochemistry methods, the geology, geophysics and geochemistry methods are comprehensively used for studying the oil-gas migration route. The oil-gas migration route tracing method through the geology, geophysics and geochemistry methods aims at effectively determining oil source relationship, establishing a transportation frame and tracking the oil-gas migration route and serving oil-gas exploration.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

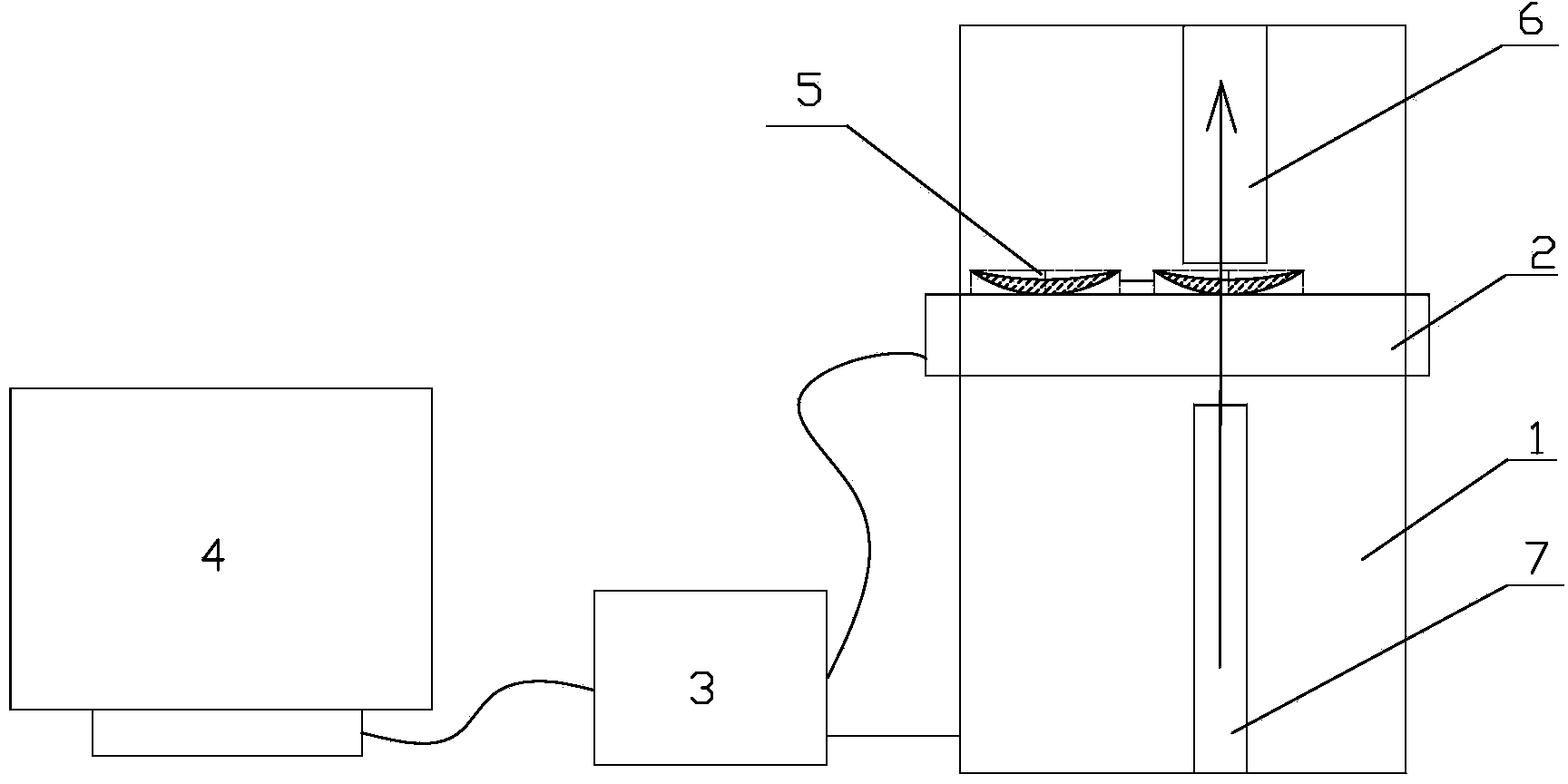

Full-automatic self-serviced assembled spectacles parameter test device and measuring method

ActiveCN103412415ABreak through technical difficultiesGood vision correctionSpectales/gogglesTesting optical propertiesEngineeringReal-time computing

The invention discloses a full-automatic self-serviced assembled spectacles parameter test device. The test device comprises a lensometer, a two-dimensional mobile platform and a controller, a pair of to-be-measured spectacles is fixed on the two-dimensional mobile platform, the two-dimensional mobile platform is arranged between an upper measuring sensor and a lower measuring sensor of the lensometer so as to measure the spectacles on the two-dimensional mobile platform through the upper measuring sensor and the lower measuring sensor, the lensometer and the two-dimensional mobile platform are respectively communicated with the controller, and the controller is used for controlling the movement of the two-dimensional mobile platform through a signal transmitted by the lensometer. The invention further discloses a full-automatic spectacles parameter measuring method. The device disclosed by the invention is capable of automatically computing the optical centre position of the lens and precisely positioning and measuring the lens, the measurement precision is high, and the operation is simple.

Owner:江苏兴洋光学科技有限公司

Long pumping distance machine-made sand concrete

ActiveCN101164959AEnsure mixing qualityQuality assuranceSolid waste managementCrushed stoneWater reducer

This invention relates to a high delivery lift type machine-finished sands concrete. The raw materials are (by weight ratio): cement 400-425, machine-finished sands 780-800, broken stone (grain size=5-16mm)300-310, broken stone (16-25mm) 700-720, water 155-160, coal ash 75-80, water reducing agent 18-24. This inventive concrete has better working properties, its delivery lift can be up to 200m. It can make the equipment being at normal operation.

Owner:GUIZHOU BRIDGE CONSTR GROUP

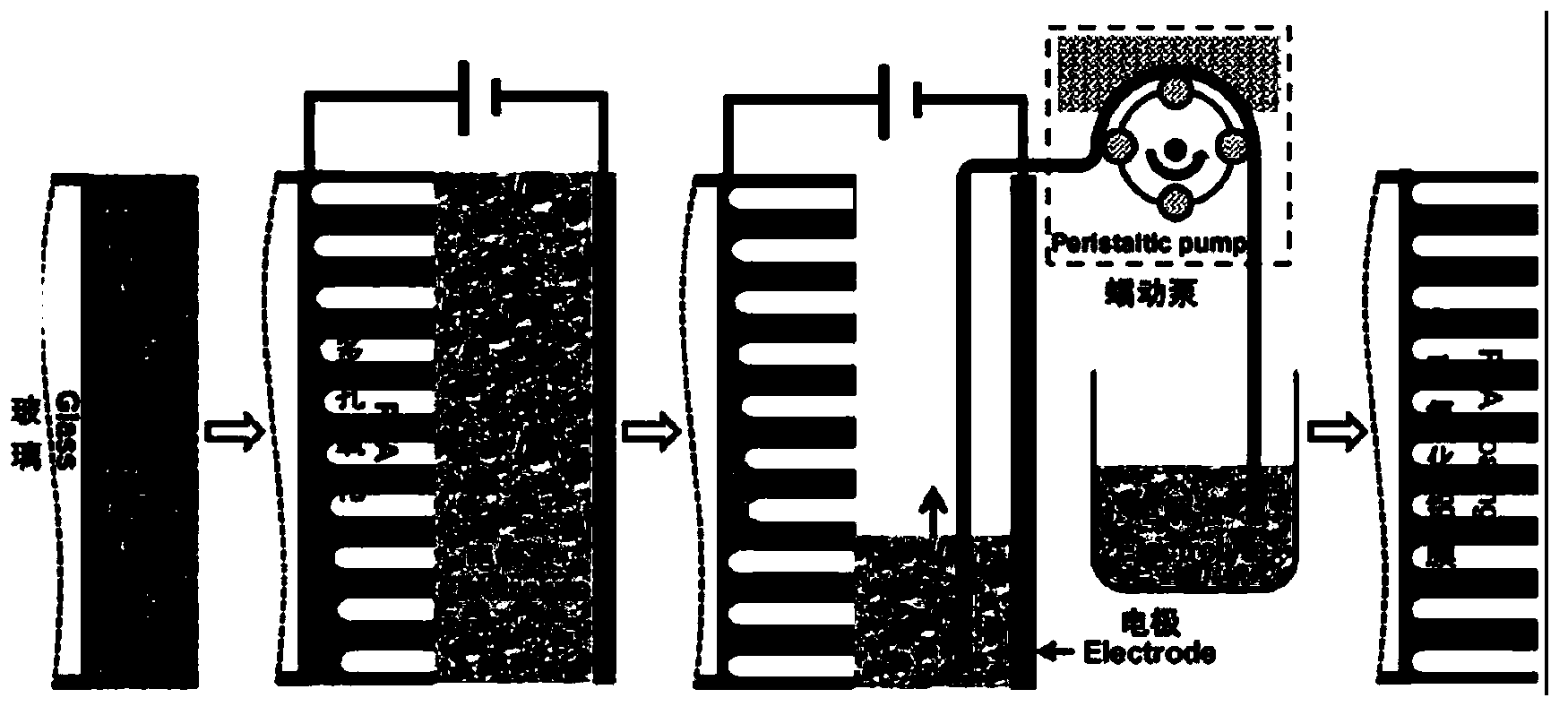

Method for preparing in-situ porous aluminum oxide membrane on insulated substrate

ActiveCN103668381ASolve technical difficultiesSimple preparation processAnodisationVacuum evaporation coatingPeristaltic pumpPhysical chemistry

The invention relates to a method for preparing an in-situ porous aluminum oxide membrane on an insulated substrate. The method is characterized by comprising steps of (1) plating a layer of 100nm-10mu m thick smooth aluminum membrane on the insulated substrate; (2) steeping the substrate plated with aluminum membrane obtained in step (1) in oxalic acid electrolyte for anodic oxidation in advance; (3) carrying out anodic oxidation through scanning, namely, taking the substrate anodized in advance in step (2) out of an electrolytic cell, removing adsorbed oxalic acid electrolyte through washing, shifting the oxalic acid electrolyte in the electrolytic cell out, putting the washed substrate back into the electrolytic cell, then pumping the oxalic acid electrolyte shifted out back to the electrolytic cell by a peristaltic pump at constant speed, keeping the liquid level of the electrolytic cell rising at constant speed, after the liquid level of the electrolyte sweeps over the whole pre-oxidized substrate from the bottom of the substrate at constant speed, sequentially anodizing unoxidized residual aluminum layer on the substrate in the pre-oxidizing step along with rising of the electrolyte at constant speed so as to obtain uniform high-quality in situ porous anodized aluminum membrane on the insulated substrate; and (4) oxidizing annealing. The method is simple and low in manufacture cost, and can be used for plating a large area of the in-situ porous anodized aluminum membrane on insulated substrates of various appearances.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Electromagnetical multi-circle absolute value encoder

InactiveCN101493342AReduce usageRealize multi-turn position valueConverting sensor output electrically/magneticallyEngineeringFlange

The invention relates to an electromagnetic multi-turn absolute encoder. The encoder comprises a main encoder measuring spindle (1), a magnetic detection chip (4), a magnet (6), an encoder flange base (9) as well as a multi-turn gear set (2) arranged below the magnetic detection chip (4); the multi-turn gear set (2) is connected with a magnetic base (7) housing the magnet (6) by a gear connection mechanism (8); the encoder flange base (9) and the main encoder measuring spindle (1) passing through the encoder flange base (9) are arranged below the multi-turn gear set (2); the magnetic detection chip (4) is provided with a circuit board (5) with the functions of DSP data processing, CPU computation, memory cell EEROM and signal output; and a data connecting wire (3) connects the multi-turn gear set (2) with the circuit board (5). The electromagnetic multi-turn absolute encoder can effectively realize normal encoder use in severe environmental conditions such as vibration, smoke and dust and the like on the one hand, and realize multi-turn location value of a measured object on the other hand.

Owner:上海精浦机电有限公司

Method for realizing theoretical criterion protection of distribution network feed line single phase earth fault

InactiveCN1458725AGood for driving automationSimple structureEmergency protective circuit arrangementsTransient stateEffect factor

This invention discloses a method for protecting distributing network feed line single-phase grounding fault for providing a protection method applying three-phase transient current component orthogonal wavelength resolution or improved wavelet packet resolution algorithm to extract the character value of single or combined character frequency bands of phase transient components, utilizing the judgement principle of fixed theory between frequency band character values of fault or unfault phases to distinguish the two phases. Combined start mode is applied to protection.

Owner:TIANJIN UNIV

Electric drive propellant feeding system liquid-propellant rocket engine

InactiveCN106555707AEasy to controlSolve technical difficultiesRocket engine plantsElectricityThrust chamber

The invention discloses an electric drive propellant feeding system liquid-propellant rocket engine which comprises an oxidizing agent conveying system, a fuel conveying system and a thrust chamber. The oxidizing agent conveying system and the fuel conveying system are independently communicated with the thrust chamber, so that an oxidizing agent and fuel are correspondingly fed into the thrust chamber, are mixed in the thrust chamber and burn in the thrust chamber, and reaction thrust is generated. The oxidizing agent conveying system comprises an oxidizing agent battery, an oxidizing agent motor and an oxidizing agent pump which are sequentially connected, and the oxidizing agent pump is used for being connected with an oxidizing agent storage tank and a thrust chamber pipe. The electric drive propellant feeding system liquid-propellant rocket engine is simple in structure, high in reliability and miniaturized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Zenia insignis and dalbergia odorifera mixed afforestation method in stony desertification region

ActiveCN105393892AImprove the ecological landscape effectReduce cost inputClimate change adaptationAfforestationSoil conservationRevegetation

The invention discloses a Zenia insignis and dalbergia odorifera mixed afforestation method in stony desertification regions. The method comprises cleaning a mountain and preparing land, processing seedlings, afforesting in a mixed manner, and performing tending management. The method specifically comprises: in autumn in the previous year of afforestation, performing manual cave-shaped land preparation, selecting Zenia insignis container seedlings of 5-8 months and dalbergia odorifera container seedlings which are older than or equal to one year old to afforest, using a star-like uneven-aged mixed plantation method, plantation density of a mingled forest being 1900-2600 plants / hm2, after afforestation, weeding, applying fertilizer, and tending. The method breaks a problem that a Zenia insignis pure forest has stony desertification in a seasonal manner because of fallen leaves in winter, and makes Zenia insignis and the dalbergia odorifera muturally promote growth, so as to improve vegetation coverage of stony desertification mountain areas, improve soil, and enhance water and soil conservation effect. The method maintains soil fertility, promotes growth of rare tree dalbergia odorifera trees in height and improves trunk quality, reduces investment in manual trimming of the dalbergia odorifera and arranging trunk auxiliary supports, accelerates vegetation recovery process in the stony desertification regions, and increases income of mountainous area people. The method has good social benefit and ecological benefits.

Owner:GUANGXI FORESTRY RES INST

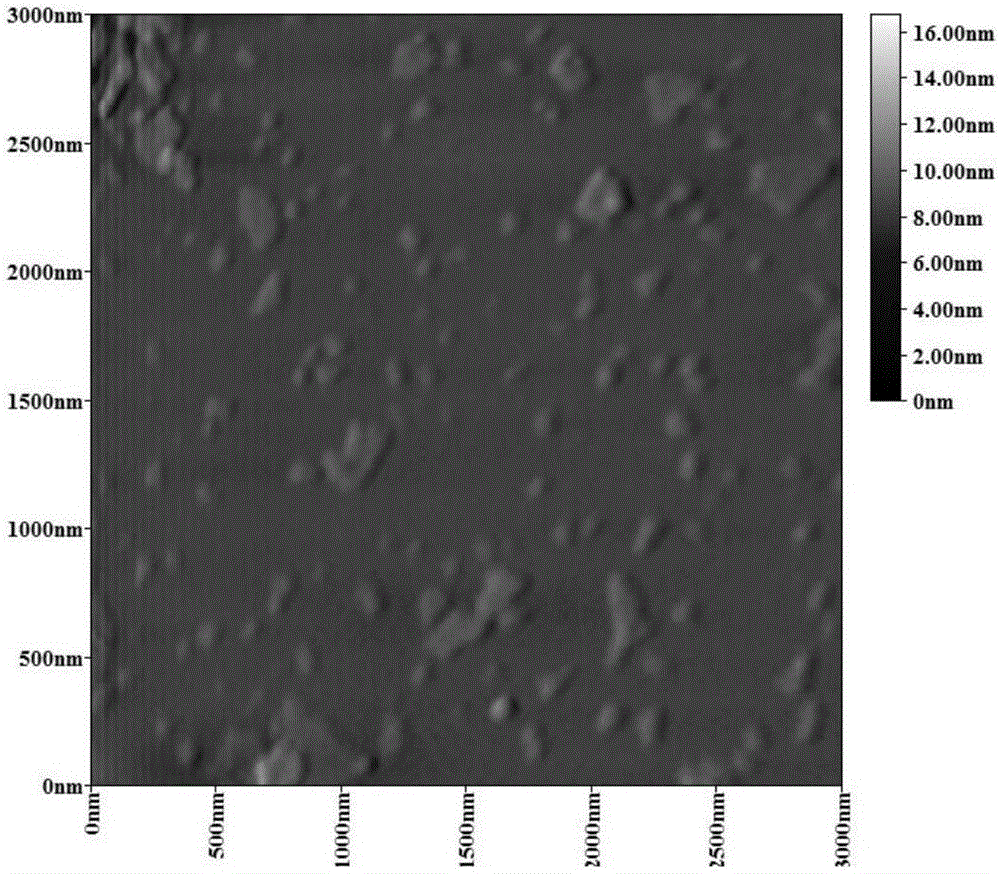

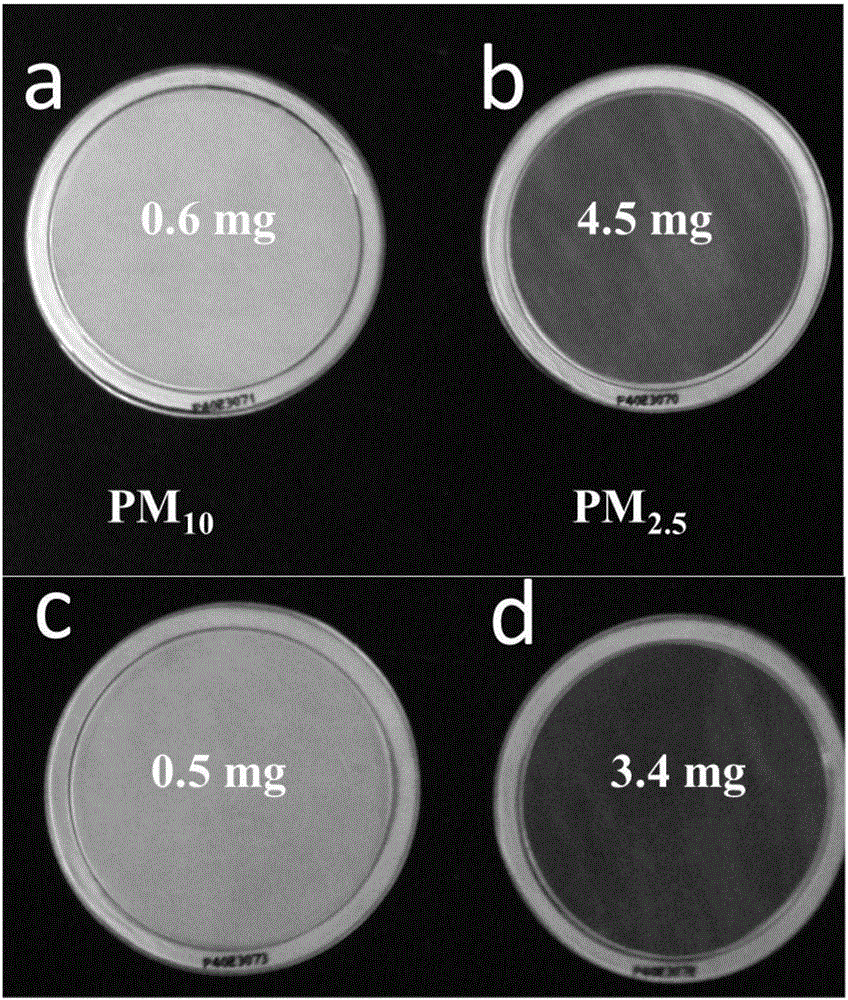

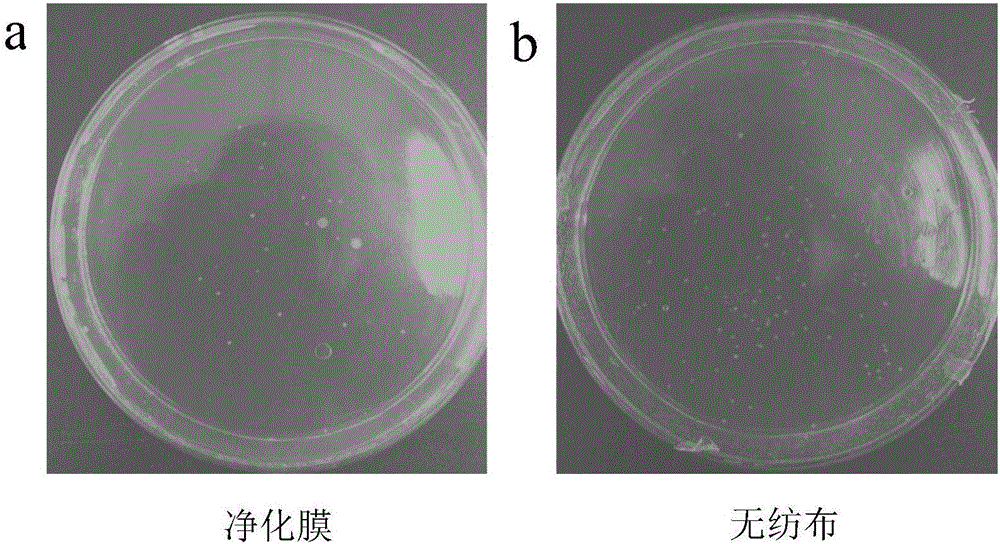

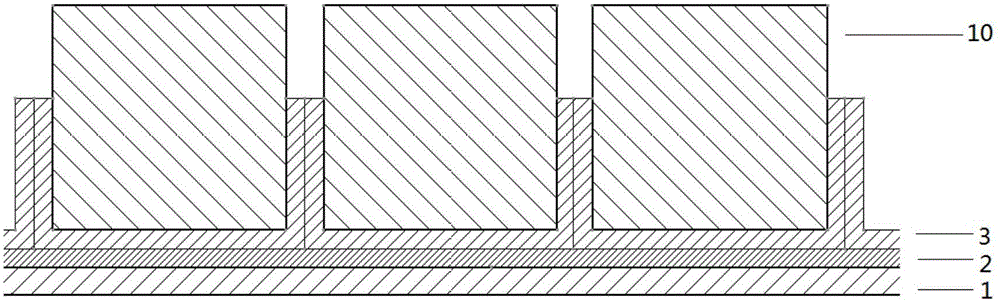

Multifunctional air purification film and method for preparing same

ActiveCN106268705AExtended use timeHigh removal rateOther chemical processesDispersed particle separationMolecular materialsNonwoven fabric

The invention relates to a multifunctional air purification film and a method for preparing the same. The multifunctional air purification film is one of the following two types: a first type of air purification film which comprises a base film and a multifunctional layer coated on the base film, wherein the multifunctional layer is mixture of nanometer graphene oxide and a fluorescent conjugated polymer, and the base film is a nonwoven fabric; a second type of air purification film which is obtained through spray melting after mixing an organic high-molecular material, nanometer graphene oxide and a fluorescent conjugated polymer, wherein the aperture of the used purification film is 0.2mu m to 12mu m, and the thickness is 500mu m to 5000mu m. As compared with a traditional antibacterial film, the antibacterial air purification film which is obtained by the invention and can eliminate PM2.5 has the characteristics such as high efficiency, good antibacterial performance and long service life.

Owner:河北凯尔威生物技术有限公司

Mandrel-free autoclave integral molding method for U-shaped unit stiffened wallboards

ActiveCN105729830ASatisfy molding qualityMeet molding requirementsFlat articlesEngineeringMechanical engineering

The invention belongs to the technical field of composite molding and relates to a mandrel-free autoclave integral molding method for U-shaped unit stiffened wallboards. According to the mandrel-free autoclave integral molding method for U-shaped unit stiffened wallboards, designed by the invention, a mandrel-free molding method is adopted to meet the requirements of part inner molding quality and vertical rib perpendicularity; and at the same time, the temperature field evenness of dies is improved, multi-die autoclave feeding is realized, and production cost is reduced. A molding device in a molding technology is on the outer side of a vacuum bag, so that the profile precision requirement is not high. U-shaped unit laying dies are only used as laying dies and are not fed into the autoclave with parts, so that the precision requirement is relatively lower. Besides, a pressurization heating process is not carried out, dies are not placed on the parts, fit clearances are not available, pressure is directly applied on the parts, and the inner quality of the parts is great. Compared with a traditional method, the method has the advantages that the molding technology is simple, the manufacture cycle is short, the heat conductivity is great, the temperature rise evenness of the parts is great, and the solidifying of a plurality of components in the large autoclave at a time can be ensured.

Owner:AVIC COMPOSITES

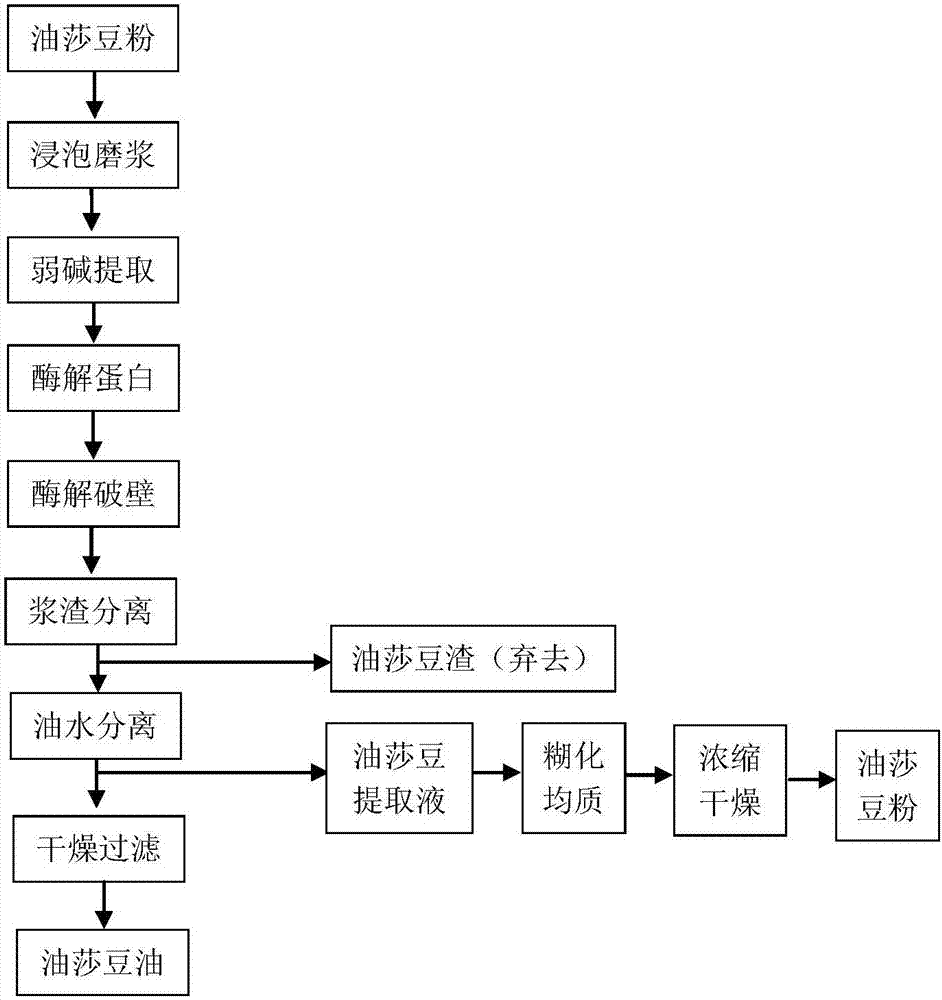

Production method of cyperus esculentus oil and cyperus esculentus flour

ActiveCN107099375AFully extractedHigh extraction rateFatty-oils/fats refiningFatty-oils/fats productionCelluloseSolubility

The invention discloses a production method of cyperus esculentus oil and cyperus esculentus flour. Water-soluble characteristics of water-soluble components of cyperus esculentus and properties that starch can form starch milk dispersing in water, protein is soluble in water under alkaline conditions and can be enzymed and the cyperus esculentus oil exists in cells and can break through walls to be released are utilized, the cyperus esculentus is smashed and soaked with water prior to being ground into thick liquid, protein, pectin and cellulose are sequentially enzymed to break through the walls to release the oil, an oil-water mixture is obtained after mixed materials are separated through pulp residues, and the oil-water mixture is subjected to oil-water separation to obtain cyperus esculentus crude oil and cyperus esculentus extract; the cyperus esculentus crude oil is dried and filtered to obtain the cyperus esculentus oil; the cyperus esculentus extract is subjected to heating and gelatinizing into starch, homogenizing, concentrating and spray drying to obtain the cyperus esculentus flour. The method is easy to implement, convenient in operation, low in cost, free from organic solvents, free from refining of oil, high in utilization rate of raw materials, sufficient in extraction of active ingredients and nutrient substances, good in solubility property, remarkable in healthcare function, good in taste and mechanized.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com