Rapid manufacturing method of aluminum alloy cylinder block casting piece of embedded cylinder sleeve

A manufacturing method and technology of aluminum alloy, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of unstable aluminum-iron bonding rate, influence of cylinder liner positioning accuracy, uneven temperature drop, etc., and achieve temperature gradient control. Accurate range, guaranteed filling, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

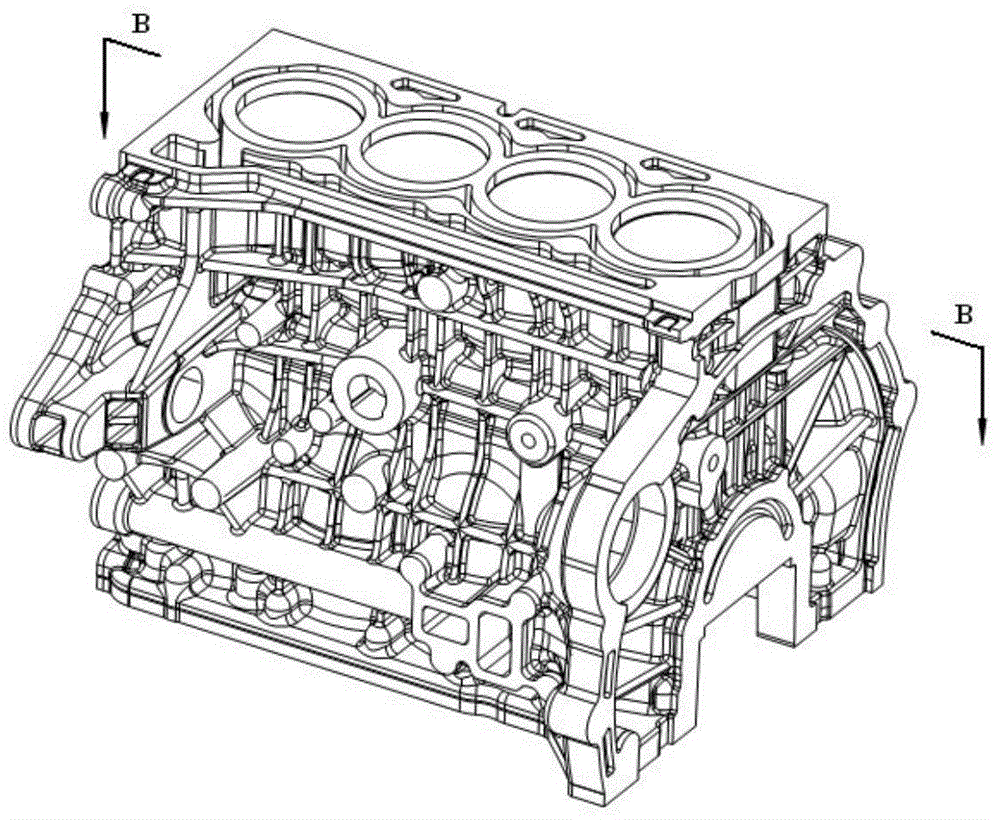

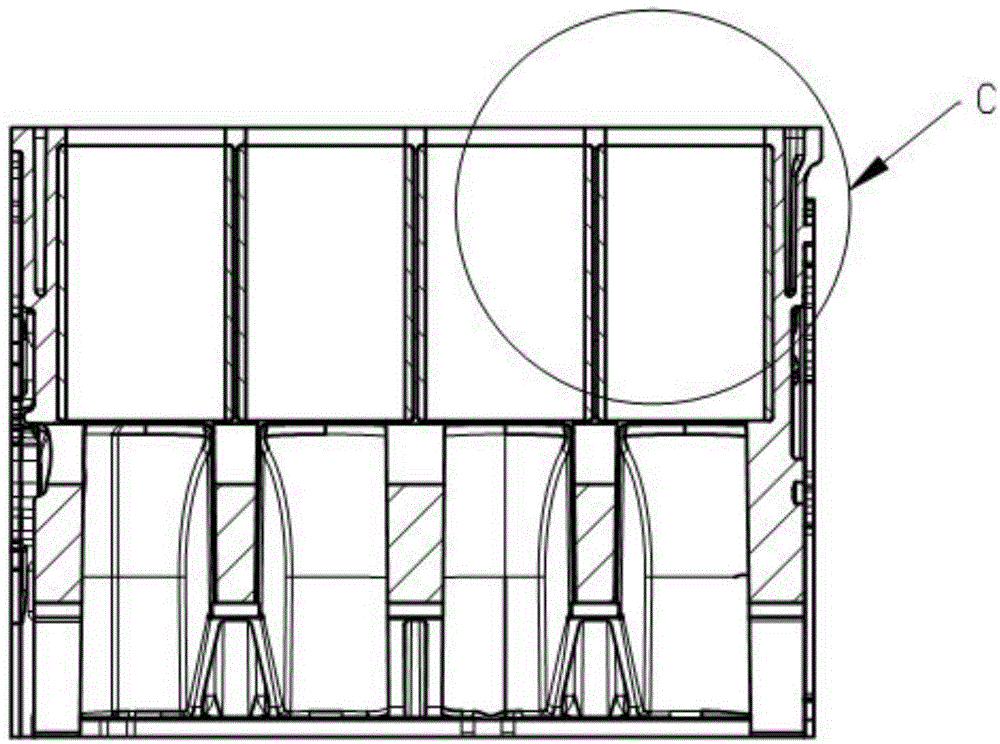

[0028] Embodiment one, see image 3 , Figure 4 , Figure 9 , a moldless rapid manufacturing method for aluminum alloy cylinder block castings with cylinder liners, comprising the following sequential steps: the first step is to obtain the 3D data of the aluminum alloy cylinder blocks with cylinder liners to be cast; the second step is to analyze the 3D data and determine the process Scheme; the third step, 3D data parting processing; the fourth step, the decomposition and manufacture of the core; the fifth step, the box pouring; the sixth step, cleaning and inspection of the casting. What is special is that in the third step of 3D data mold splitting process, the design of the aluminum alloy cylinder block with cylinder liner is divided into: a pair of sprue sand molds 1 and 2, left sand mold 3, rear sand mold 5, bottom sand mold Sand mold 6, right sand mold 7, cylinder liner positioning tool 8, cylinder liner 9, water jacket core 10, crankcase core group 11, riser 12, fron...

Embodiment 2

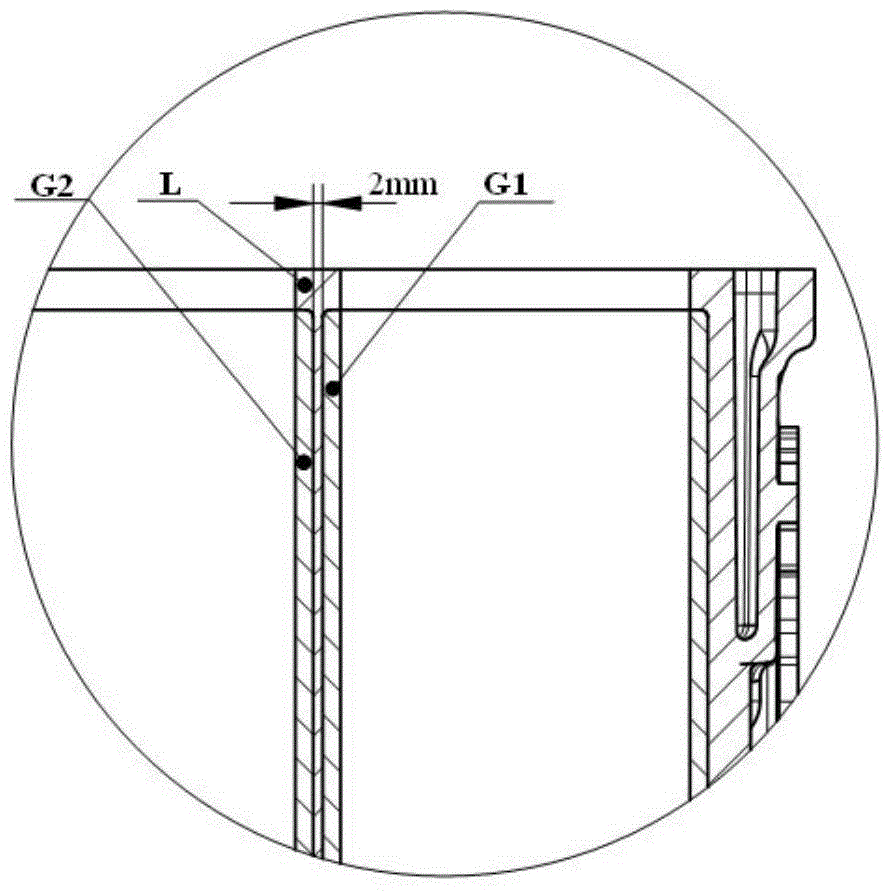

[0030] In the second embodiment, since the thickness of aluminum between the cylinder liners is 2mm, it is easy to produce cold shut and insufficient pouring; the positioning dimension accuracy of the cylinder liners is required to be high, and the bonding rate of aluminum and iron is required to be greater than 95%. In order to solve this technical difficulty, on the basis of Example 1, a set of auxiliary tooling is designed to ensure the position accuracy between them, and the size and position accuracy between them are guaranteed by processing metal profiles-assembly-three-coordinate detection, Auxiliary tooling such as Figure 5 — Figure 8 As shown, the auxiliary tooling is composed of a positioning post mounting seat 15, four sets of positioning posts 16, and four sets of induction coils 4. Each positioning post 16 is respectively connected with the positioning mounting seat 15 with a screw, and the positioning post 16 cooperates with the positioning post mounting seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com