Forging technology for heavy disk forgings

A technology for forgings and processes, applied in the field of large-scale basic castings and forgings for major equipment, can solve the problems of refinement and dispersion of damaged inclusions, unqualified ultrasonic flaw detection, and increase in the area of inclusions, achieving excellent mechanical properties and solving technical difficulties. , the effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

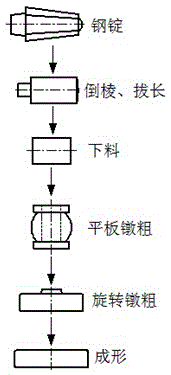

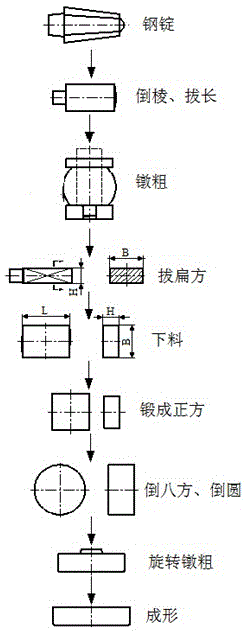

[0015] Existing flat upsetting forging process forging large-scale cake forging forming process, such as figure 1 As shown, the steel ingot is forged into a pie forging through the processes of chamfering, elongation, blanking, flat upsetting and rotary upsetting. Due to the limitations of the inherent defects of the traditional process, there are too many factors affecting the process parameters, it is difficult to master, and the quality of forgings fluctuates greatly. As a result, there are a large number of dense defects-inclusion cracks within a certain range from the center of the forged large cake forgings, and the pass rate of ultrasonic flaw detection is less than 50%. In order to overcome the problems in the above-mentioned prior art, the present invention provides a process route such as figure 2 The large cake forging forging p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com