Production method of cyperus esculentus oil and cyperus esculentus flour

A technology of oily bean powder and oily bean, which is applied in the fields of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc., to achieve the effects of high raw material utilization rate, simple process and high oil extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

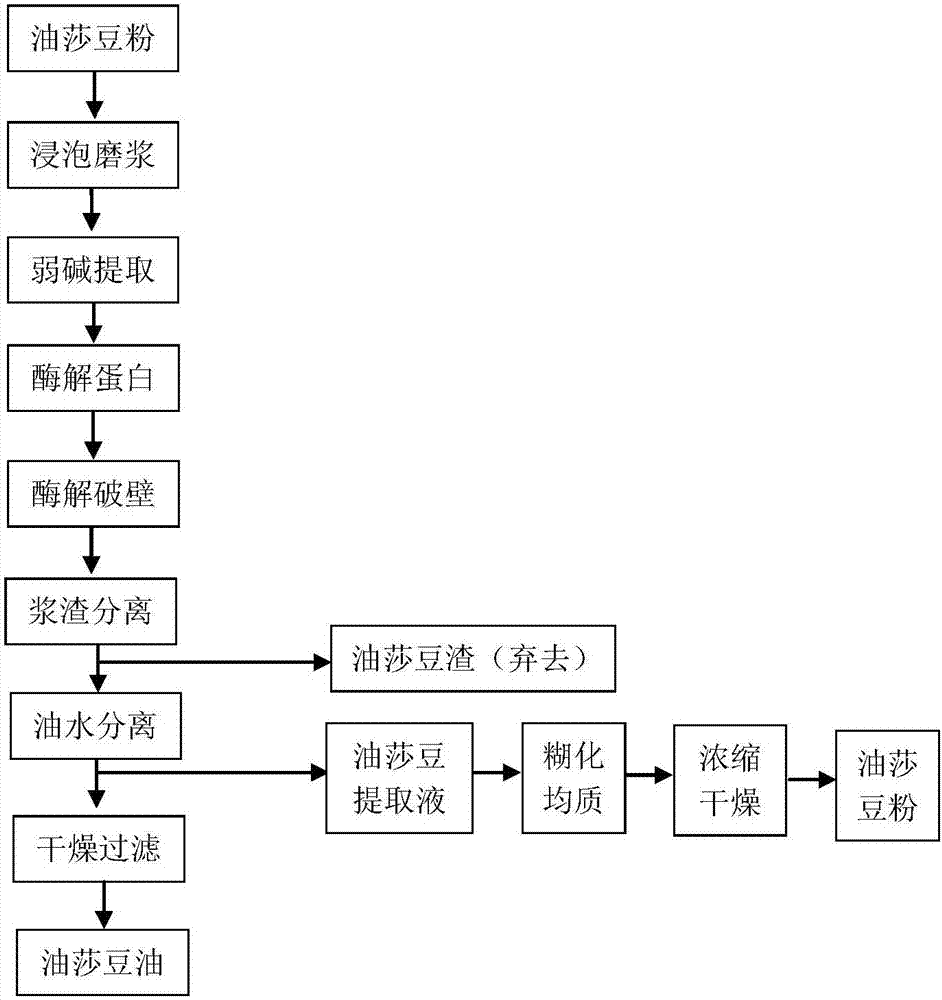

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of oily bean oil and oily bean powder, the steps are:

[0041] (1) Crushing, sifting and soaking and refining: Take 25.6kg of peeled oily bean powder crushed by a stainless steel grinder and sieved through a 100-mesh standard sieve; add water 5 times its mass to the peeled oily soybean powder to adjust the mixture Raise the material temperature to 40° C., stir for 1 hour to make the peeled oily bean powder fully absorb water and expand, and use a refiner to grind to obtain a mixed material of oily bean milk and residue. The stirring speed of this step is controlled to be 140 rpm.

[0042] (2) Weak base extraction and enzymatic protein hydrolysis: under the condition of constant stirring, adjust the temperature of the mixed material of Yousha and soybean milk dregs obtained in step (1) to 55°C and maintain it at 55°C, and use a potassium hydroxide solution with a concentration of 10% by mass Adjust the pH to 9.4 or 9.5 or 9.6, and continue stirring ...

Embodiment 2

[0048] A preparation method of oily bean oil and oily bean powder, the steps are:

[0049](1) Crushing, sieving and soaking and refining: Take 595kg of peeled oily bean powder crushed by a stainless steel grinder and sieved through a 120-mesh standard sieve; add 5.5 times its mass of water to the peeled oily soybean powder, and stir for 2 hours The dehulled oily bean powder is fully swollen by water absorption, and is refined with a refiner to obtain a mixed material of oily soybean milk and residue. The stirring speed of this step is controlled to be 135 rpm.

[0050] (2) Weak base extraction and enzymatic protein hydrolysis: under the condition of constant stirring, adjust the temperature of the mixed material of Yousha and soybean milk dregs obtained in step (1) to 50°C and maintain it at 50°C, and use 10% by mass concentration of sodium hydroxide solution Adjust the pH to 9.9 or 10.0 or 10.1, and continue stirring for 2.5 hours to dissolve protein, pectin and other polysa...

Embodiment 3

[0056] A preparation method of oily bean oil and oily bean powder, the steps are:

[0057] (1) Crushing, sieving and soaking and refining: Take 1254kg of peeled oily bean powder crushed by a stainless steel pulverizer and sieved through a 100-mesh standard sieve; add water 6 times its mass to the peeled oily soybean powder to adjust the mixed material Temperature to 25°C, stirring for 3 hours to make the peeled oily bean powder fully absorb water and swell, and use a refiner to grind to obtain a mixed material of oily bean milk and residue. The stirring speed of this step is controlled to be 125 rpm.

[0058] (2) Weak base extraction and enzymatic protein hydrolysis: under the condition of constant stirring, adjust the temperature of the mixed material of Yousha and soybean milk dregs obtained in step (1) to 50°C and maintain it at 50°C, and use a potassium hydroxide solution with a concentration of 10% by mass Regulate pH to be 9.4 or 9.5 or 9.6, continue stirring for 3 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gelatinization degree | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com