Multifunctional air purification film and method for preparing same

An air purification and multi-functional technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as air pollution, and achieve the effect of long service life and long use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The first step is to prepare a nano-graphene oxide aqueous solution:

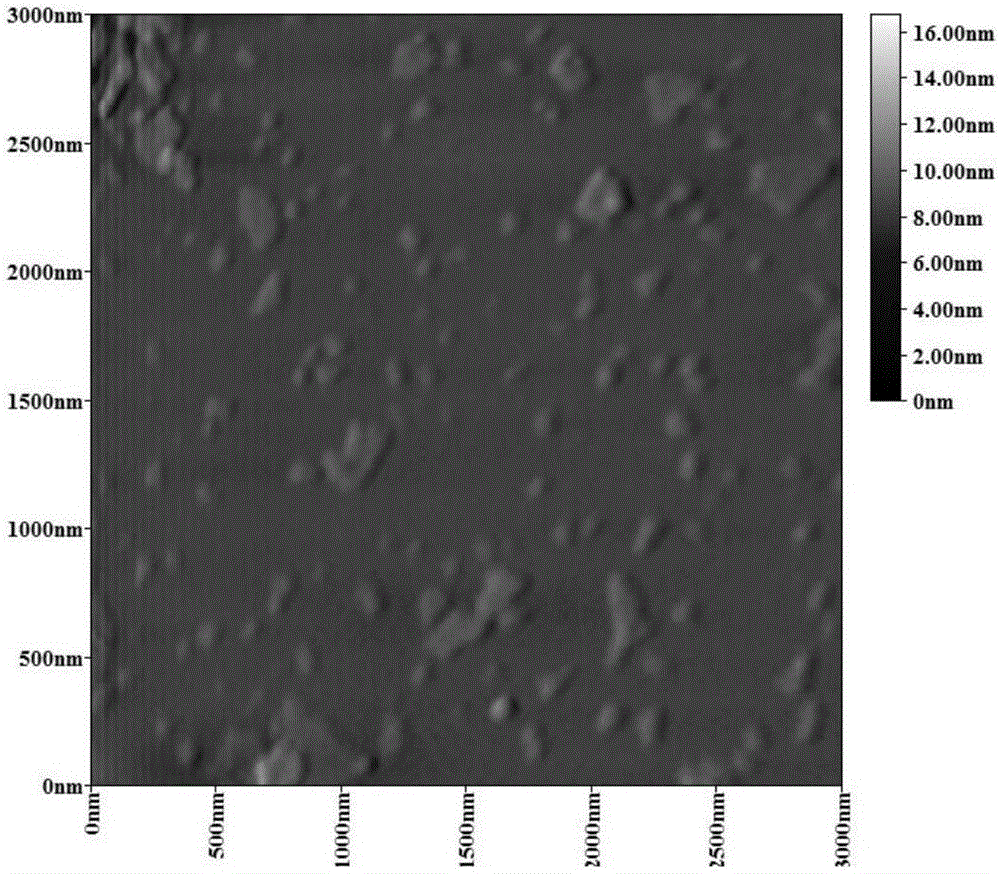

[0046] Dissolve graphene oxide and disperse it ultrasonically in an ice bath with ultrasonic power of 100W for 60 minutes. Graphene oxide with a size of about 350nm can be obtained, and the number of atomic layers is a single layer. Dry and set aside.

[0047] Take the 0.5g nano-graphene oxide obtained above, dissolve it in 1000mL ultrapure water, and obtain a 0.5mg / mL nano-graphene oxide aqueous solution;

[0048] The second step, conjugated polymer preparation:

[0049] Synthetic route of monomer (1) 3-(1,4-dioxa-6-hydroxy-hexyl)thiophene:

[0050] Add 45mL of pyridine, 15mL of diethylene glycol (16.75g, 157.8mmol), (5.6g, 49.9mmol), cuprous iodide (1.4g, 7.34mmol), stir for 30min and then add 3-bromothiophene (5.16g, 31.6mmol), raised to 100°C, and reacted for 24h. The reaction solution was cooled to room temperature, diluted with dichloromethane, filtered, and dried to obtain the product as ...

Embodiment 2-8

[0101] Other steps and test methods are the same as in Example 1, except that the fluorescent conjugated polymer used in step 3 is replaced by the aqueous solution of the fluorescent conjugated polymer in the third step in Example 1 to configure the following fluorescent conjugated polymers in sequence thing:

[0102] (a) Preparation of pyridine porphyrin TPP solution: 0.0068 g of pyridine porphyrin TPP was added into 20 mL of ultrapure water to obtain a 0.25 mM stock solution.

[0103] (b) Preparation of phenylporphyrin TP solution: 0.0076 g of phenylporphyrin TP was added to 20 mL of ultrapure water to obtain a 0.25 mM stock solution.

[0104] (c) Preparation of subblue M-B solution: Take 0.0016 g of subblue M-B and add 20 mL of ultrapure water to dissolve to obtain a 0.25 mM stock solution.

[0105] (d) Preparation of toluidine blue T-BO solution: Take 0.001 g of toluidine blue TBO and add 20 mL of ultrapure water to dissolve to obtain a 0.25 mM stock solution.

[0106] (...

Embodiment 9

[0112] The first step is to make a purification membrane:

[0113] Melt organic polymer polypropylene at 140°C;

[0114]Then add nano-graphene oxide solution and fluorescent conjugated polymer (poly3-(1,4-dioxa-6-bromotrimethylamino-hexyl)thiophene-co-3-(1,4,7 -trioxa-octyl)thiophene (PT)) solution, stirred evenly, wherein, the concentration of the nano-graphene oxide aqueous solution is 0.5mg / mL, 600mL, the concentration of the aqueous solution of the fluorescent polymer is 1.0mg / mL, 100mL ; The mass ratio is organic polymer material: nano-graphene oxide: fluorescent conjugated polymer=200:3:1;

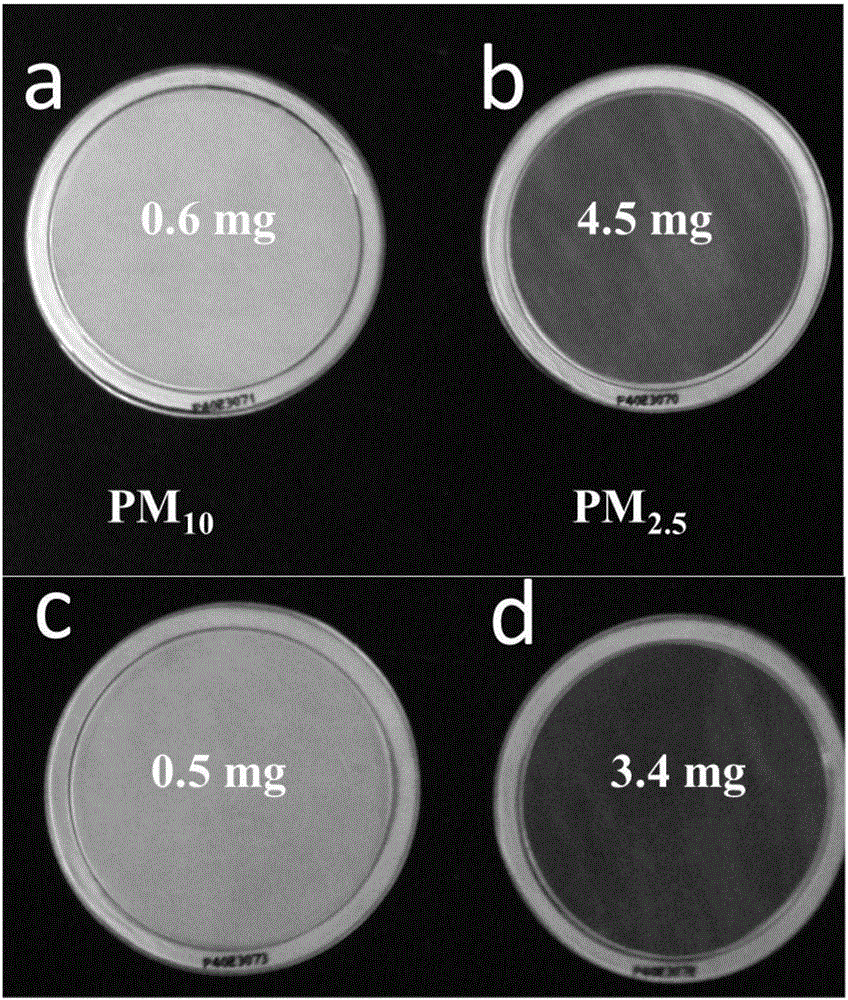

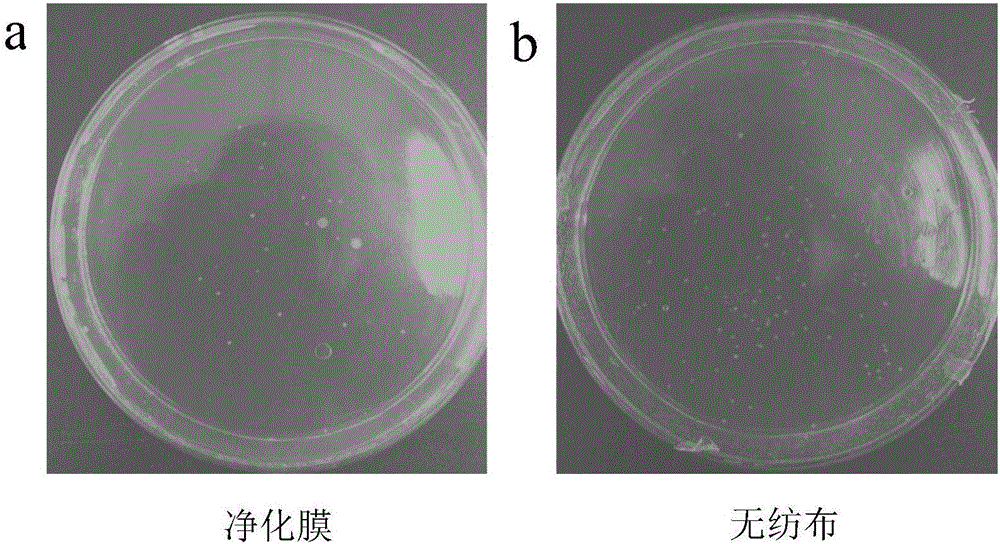

[0115] The above-mentioned mixture is made into a film by the melt-blowing method, and the aperture of the film is 1 μm; the thickness of the film is 2000 μm; wherein: Melt-blown equipment: Wuxi AJMS Machinery Co., Ltd. Spinning hole diameter 0.3mm, hole depth 3mm. Process conditions: air pressure: 0.15-0.3MPa; receiving distance: 5-9cm; metering pump speed: 45-60Hz, optimal proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com