Terylene FDY oil and preparation method thereof

An oil and polyester technology, applied in the field of polyester FDY oil and its preparation, can solve the problems of easy corruption, incomplete antistatic properties of oil, uneven oiling, etc., and achieves good storage and use stability, good resistance. Static effect, long-term use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

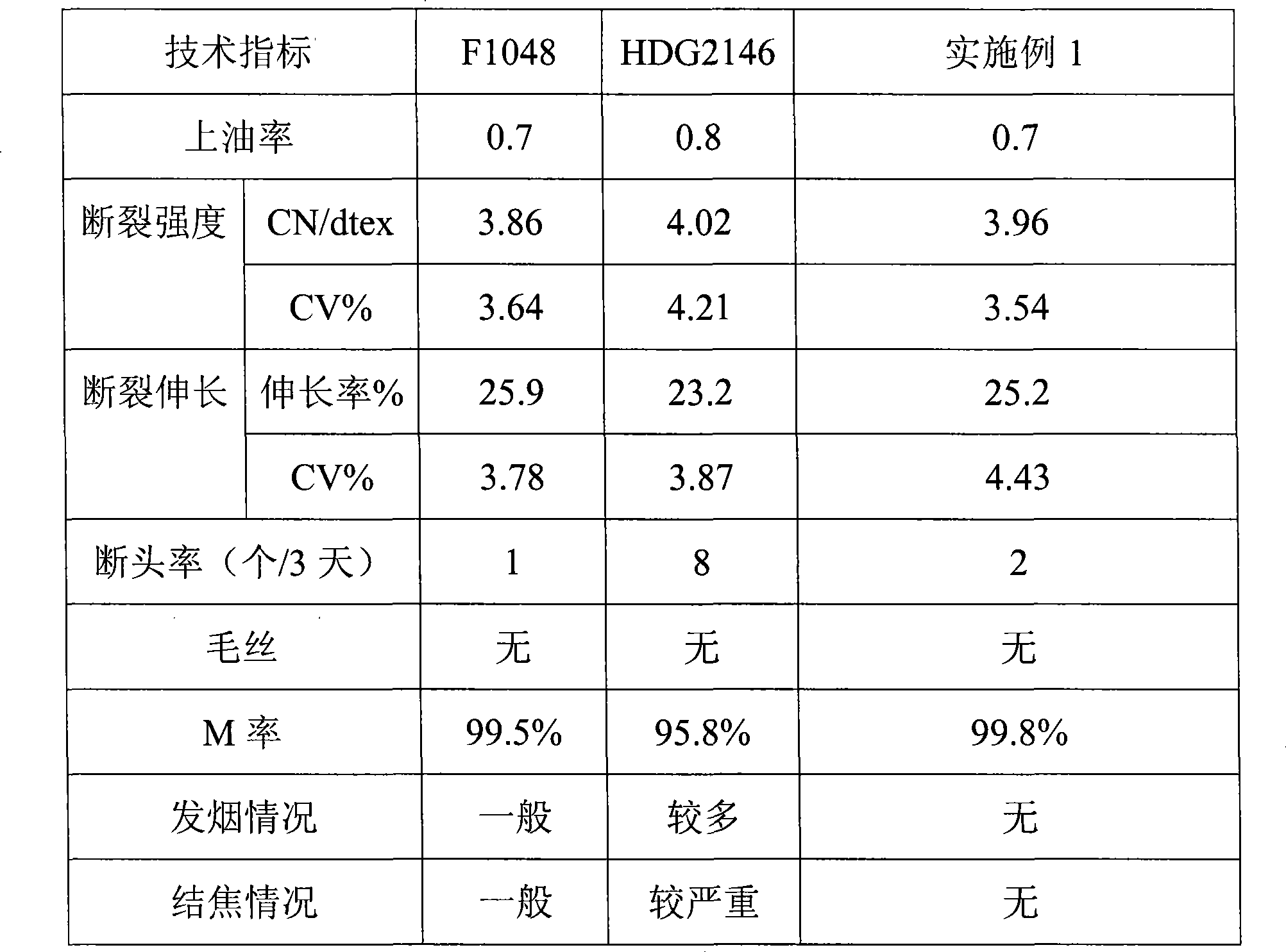

Embodiment 1

[0018] Each component and weight percentage of oil agent are as follows:

[0019] High temperature resistant smoothing agent 65%, including special polyether 30%, triol ester 25%, refined mineral oil 10%;

[0020] Environmentally friendly emulsifier 20%, of which isomerized alcohol polyoxyethylene ether 10%, polyoxyethylene laurate 6%, polyoxyethylene lauryl alcohol 4%;

[0021] 7% sizing agent, including 5% high molecular weight polyether and 2% oleic acid polyethylene glycol diester;

[0022] 5% composite antistatic agent, including 3% potassium salt of high-carbon alcohol polyoxyethylene ether phosphate, and 2% of β-alkyl sulfonate;

[0023] 3% additives, including 2% modified silicone oil and 1% preservative.

Embodiment 2

[0025] Each component and weight percentage of oil agent are as follows:

[0026] High temperature resistant smoothing agent 60%, including special polyether 35%, triol ester 25%;

[0027] Environmentally friendly emulsifier 20%, including isomeric alcohol polyoxyethylene ether 10%, random polyether 6%, fatty alcohol polyoxyethylene ether 4%;

[0028] 10% sizing agent, including 5% high molecular weight polyether and 5% polyoxyethylene laurate;

[0029] Composite antistatic agent 7%, of which isomerized alcohol polyoxyethylene ether phosphate potassium salt 5%, β-alkyl sulfonate 2%;

[0030] 3% additives, including 1% modified silicone oil, 1% higher alcohol and 1% preservative.

Embodiment 3

[0032] Each component and weight percentage of oil agent are as follows:

[0033] High temperature resistant smoothing agent 58%, including special polyether 25%, triol ester 20%, tetraol ester 13%;

[0034] Environmentally friendly emulsifier 25%, including isomeric alcohol polyoxyethylene ether 10%, random polyether 9%, fatty alcohol polyoxyethylene ether 6%;

[0035] 7% sizing agent, including 5% high molecular weight polyether and 2% polyoxyethylene laurate;

[0036] Composite antistatic agent 8%, including high carbon alcohol polyoxyethylene ether phosphate potassium salt 5%, β-alkyl sulfonate 3%;

[0037] 2% additives, including 1% modified silicone oil and 1% preservative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com