Patents

Literature

80results about How to "Meet molding requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-magnesium ceramic fired at low temperature and manufacturing method thereof

The invention provides lithium-magnesium ceramic fired at low temperature and a manufacturing method thereof. A lithium-magnesium ceramic blank comprises 15-25wt% of lithium material, 60-70wt% of magnesium material and 10-20wt% of clay and is required to comprise the following chemical components in percentage by weight: 55-65% of SiO2, 1-5% of Al2O3, 15-25% of MgO, 1-4% of CaO, less than 1% of Na2O, less than 1.5% of K2O, 4-6% of Li2O4 and not more than 0.3% of Fe2O3, wherein ignition loss is 5-7%. Compared with the prior art, in the invention, the lithium material is used as a main fluxing agent capable of greatly reducing firing temperature, thereby reducing fuel cost and improving market competitiveness of products; the magnesium material is a main skeleton-forming constituent capable of preventing firing deformation; and the clay is used as main bonding constituent so as to ensure that a plasticity index meets a forming requirement.

Owner:QUANZHOU KUNDA GIFT

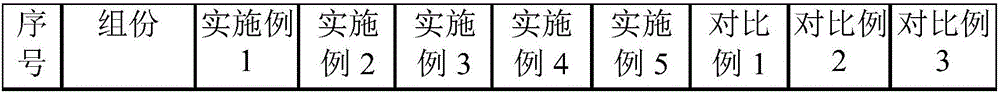

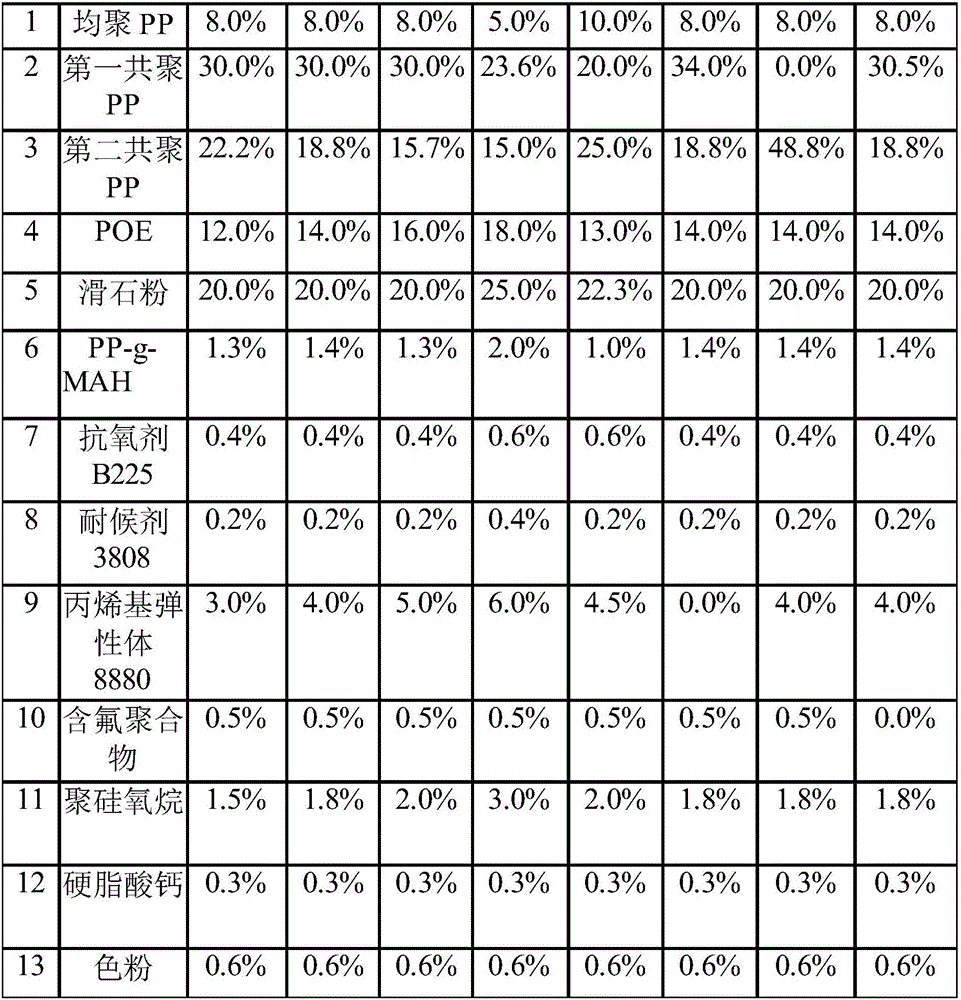

Modified polypropylene material for high-performance thin-wall automobile door panel and preparation method thereof

The invention belongs to the technical field of plastics modification and particularly relates to a modified polypropylene material for a high-performance thin-wall automobile door panel and a preparation method thereof. The material is prepared from, by mass, 5%-10% of homopolymerized PP, 20%-30% of first copolymerized PP, 15%-25% of second copolymerized PP, 12%-18% of toughening agent, 1%-2% of compatilizer, 0.4%-0.6% of antioxidant, 0.2-0.4% of weather resistance agent, 3%-6% of melting index regulator, 20%-25% of mineral enhancer, 1.5-3% of scratch resistant agent and 1-2% of other assistants. The preparation method of the modified polypropylene material comprises the steps of mixing, extrusion and granulation. The material prepared by adopting the preparation method has high liquidity, rigidity and toughness, can well meet the usage requirements of the thin-wall automobile door panel and is low in cost. Compared with the prior art, a high-liquidity allyl elastomer is used as the melting index regulator, the liquidity of the material is remarkably improved, and the thin-wall door panel forming requirements are met. In addition, high-liquidity polypropylene and a low surface energy polymer are used in a mixed mode, and the tiger skin stripe defects on the surface of the thin-wall door panel can be basically eliminated.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

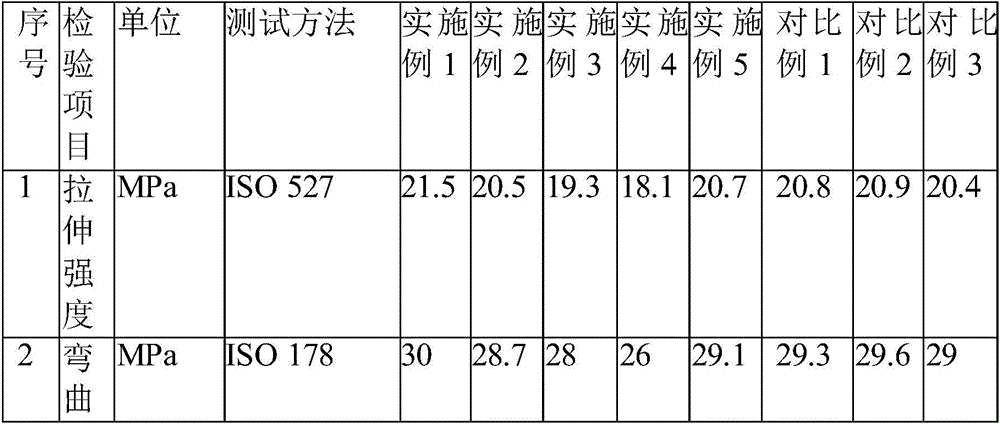

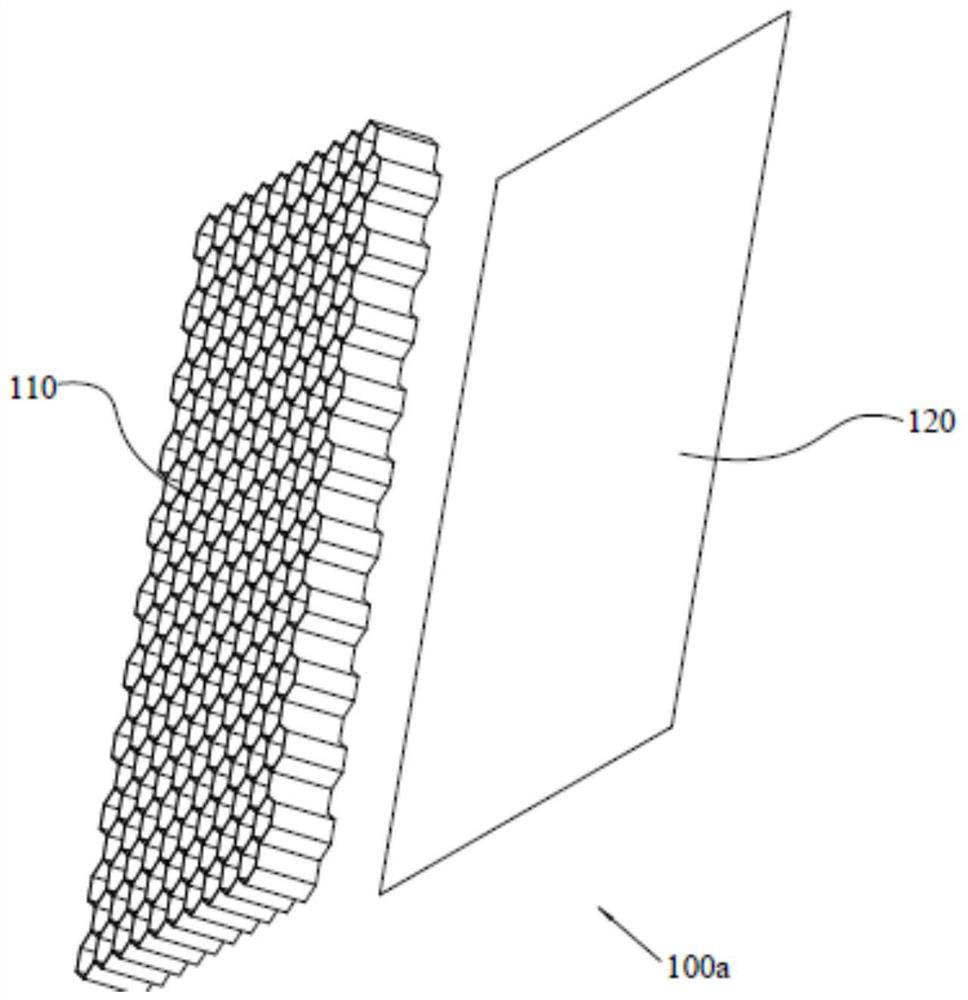

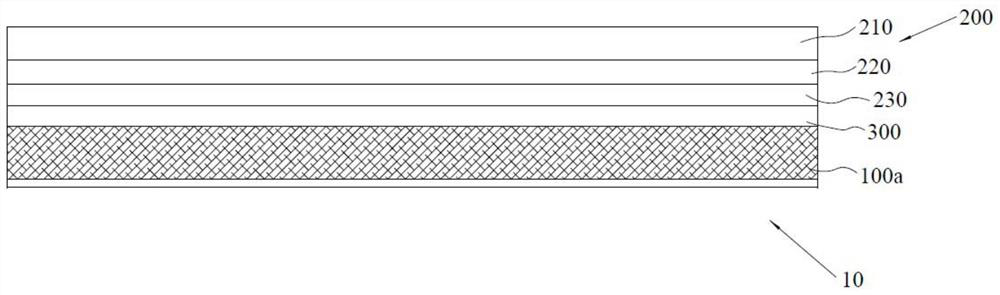

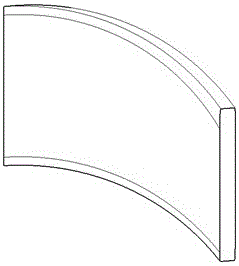

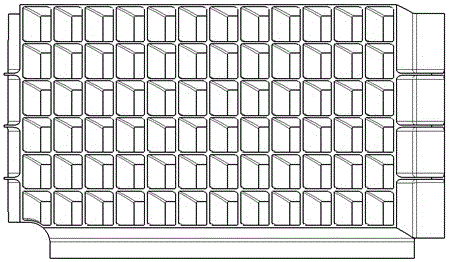

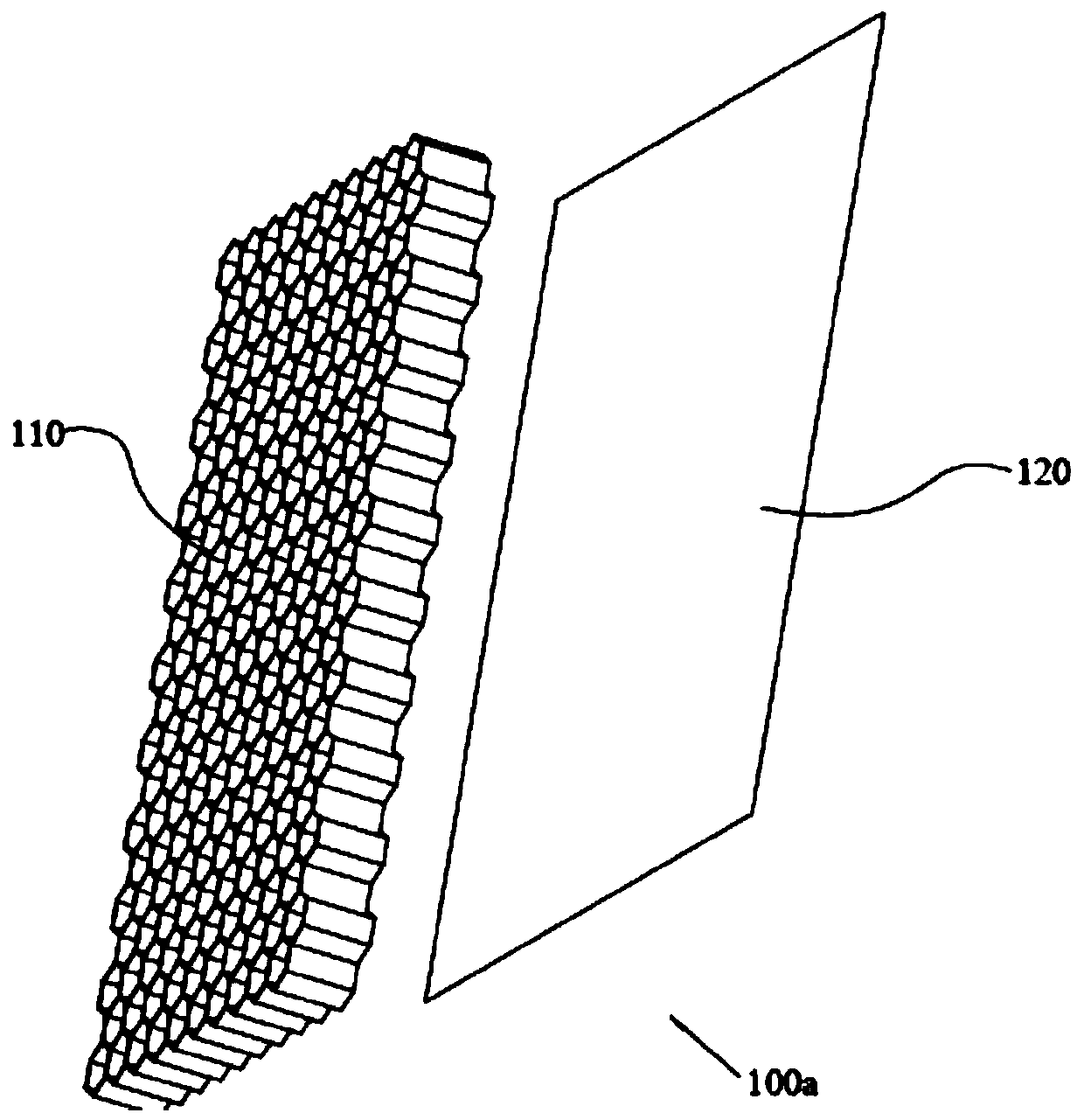

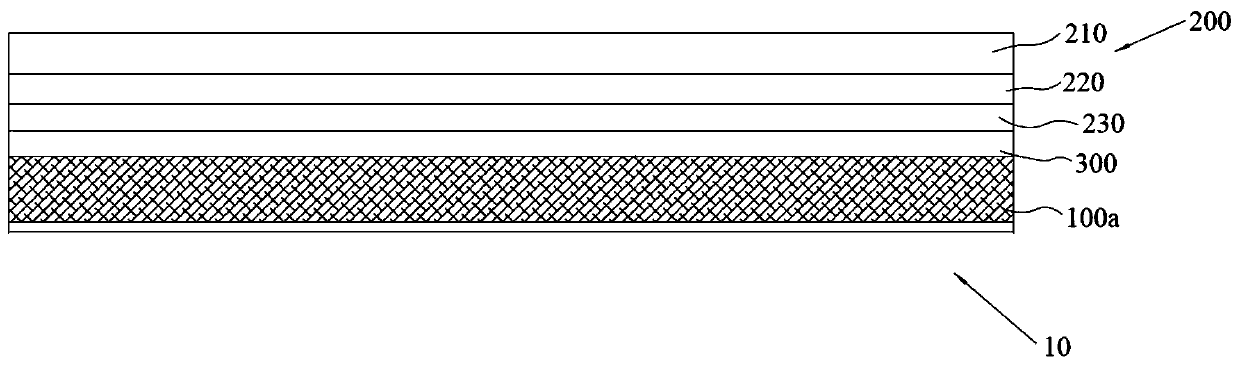

A continuous composite molding lightweight photovoltaic module and its continuous composite molding equipment

ActiveCN110491961BGuarantee the quality of laminationImprove yield rateFinal product manufacturePhotovoltaic energy generationBattery cellMaterials science

The invention discloses a continuous composite molding lightweight photovoltaic module, which includes a photovoltaic laminate and a lightweight photovoltaic backplane. The photovoltaic laminate includes a front flexible packaging layer, a battery sheet layer, and a back flexible packaging that are laminated and packaged as one. layer, the lightweight photovoltaic backplane includes at least a thermoplastic core layer in the shape of a honeycomb or porous foam and a first thermoplastic substrate layer, and the photovoltaic laminate and the lightweight photovoltaic backplane are composited into one body through a continuous composite molding process; The invention also discloses continuous composite molding equipment; the invention also has the advantages of light weight, safety and reliability, frameless design is not easy to accumulate dust and does not need to be grounded, and its layout can be flexible and changeable, avoiding the high burst problem of traditional double glass components, Moreover, the present invention will not cause problems such as bubbling, degumming, deformation and creep under the lightweight photovoltaic backplane scheme using the adhesive film layer structure, and will not be limited by the thickness of the light photovoltaic backplane, which fully meets the requirements of photovoltaic standards. , can realize real-scale promotion and application.

Owner:SUNMAN (ZHENJIANG) CO LTD

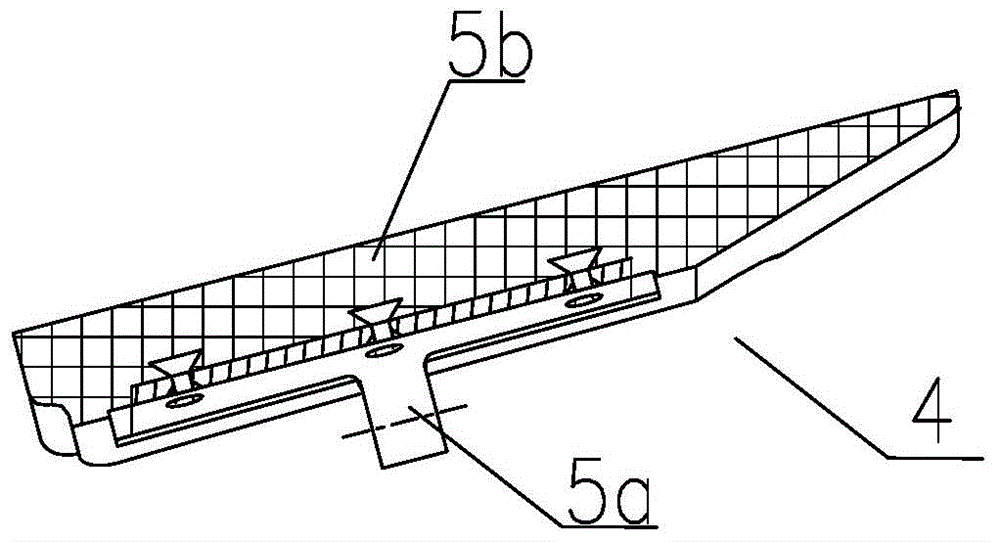

Forming method of carbon fiber composite material grille

InactiveCN106827585AGuaranteed straightnessSimplify the difficulty of demouldingDomestic articlesSurface finishFiber

The invention relates to a forming method of a carbon fiber composite material grille, the forming method of the carbon fiber composite material grille comprises the following steps: (1) core mold molding; (2) carbon fiber fabric paving; (3) mold assembly; (4) glue injection; (5) curing; (6) mold release, and mold core melting; (7) processing; on the basis of the existing method, the contradiction between the surface quality and demoulding difficulty is solved, the use requirements of pneumatic surface can be met; a low melting point alloy core mold used in the method can be repeatedly used, mold cost can be reduced, a RTM process is used for production, and the product is high in surface smooth degree, less in processing amount, and low in manufacturing cost.

Owner:HENGSHEN

Halogen-free flame-retardant high-liquidity PC/ABS material used for shells of TV sets and preparation method of PC/ABS material

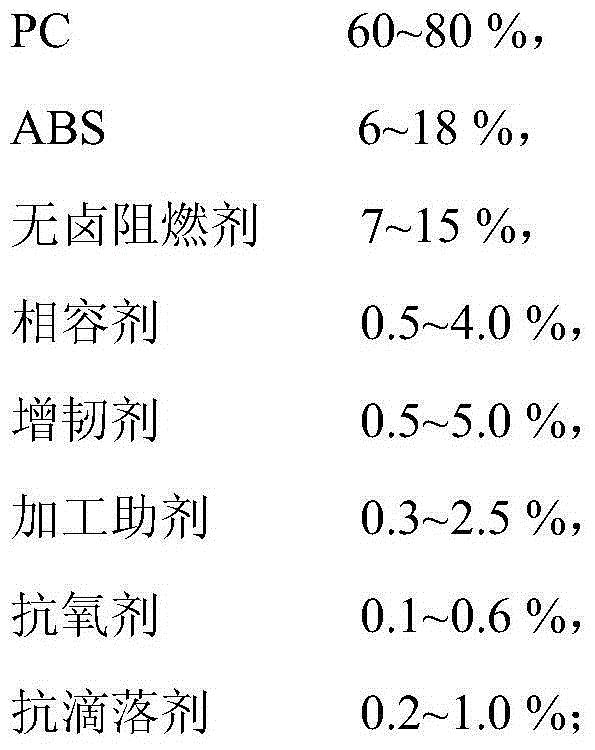

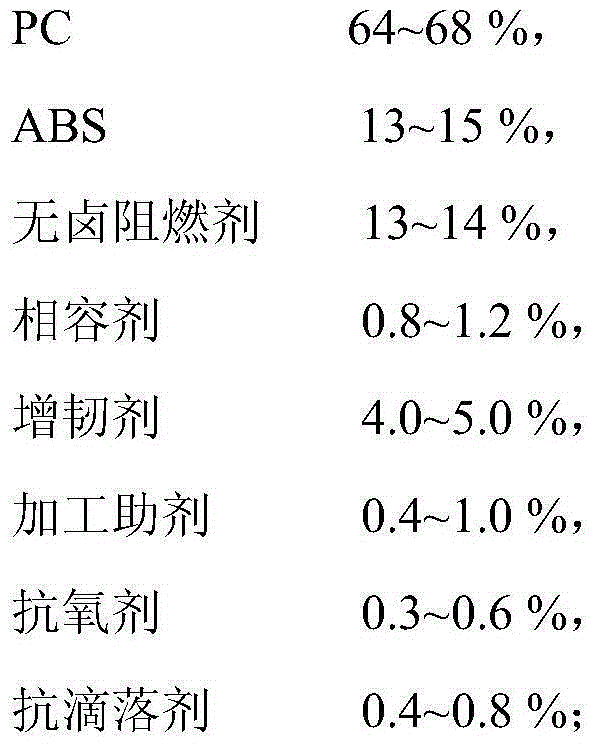

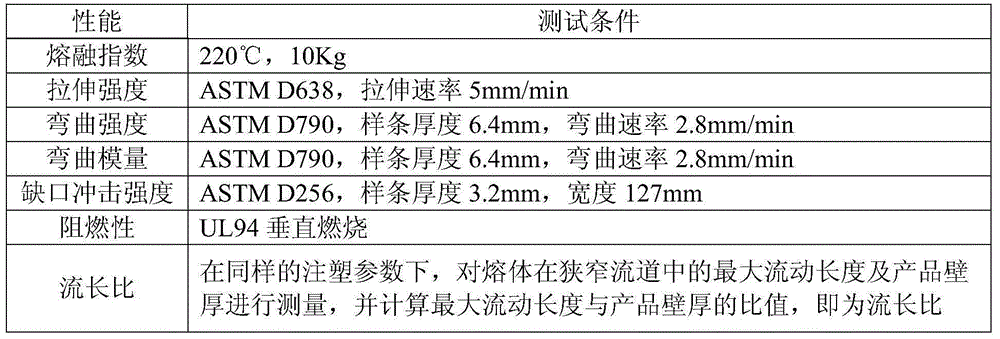

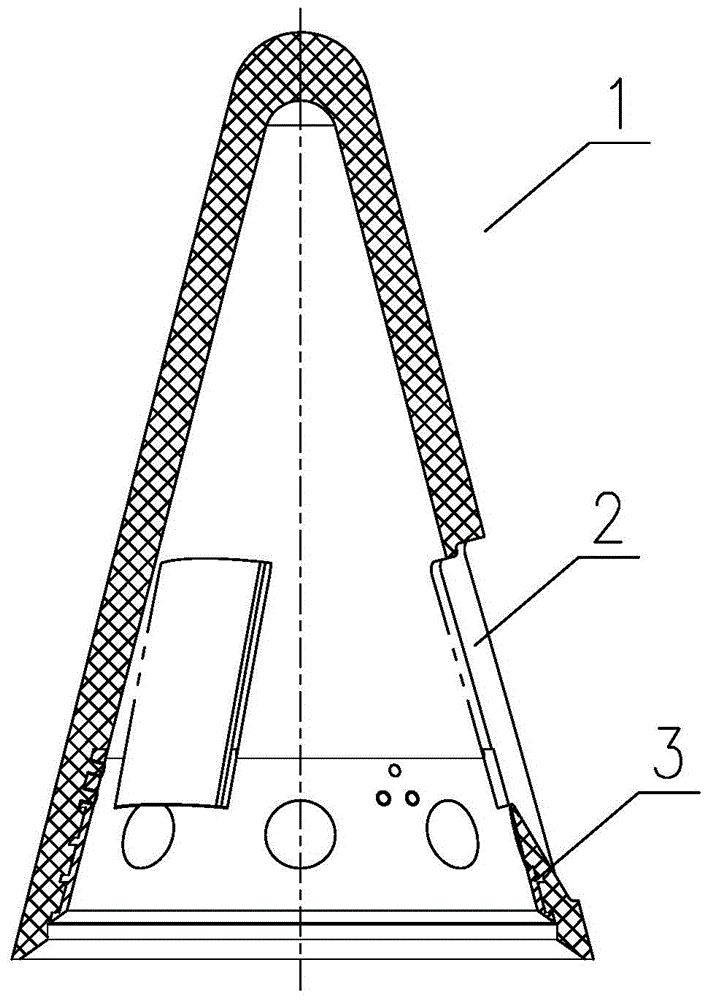

The invention provides a halogen-free flame-retardant high-liquidity PC / ABS material used for shells of TV sets and a preparation method of the PC / ABS material. The PC / ABS material is prepared from, by weight, 60-80% of PC, 6-18% of ABS, 7-15% of halogen-free flame retardants, 0.5-4.0% of compatilizers, 0.5-5.0% of toughing agents, 0.3-2.5% of machining auxiliaries, 0.1-0.6% of antioxidants and 0.2-1.0% of anti-dripping agents, wherein the PC is composed of polycarbonate with the molecular weight being 10,000-40,000 and the melt index being 20-30 g / 10min, and the ABS is acrylonitrile-butadiene-styrene copolymer with the liquidity being 20-40 g / 10min and the weight percent being 10-40%. According to the halogen-free flame-retardant high-liquidity PC / ABS material, due to the fact that the halogen-free flame retardants, the compatilizer, the toughing agents, the machining auxiliaries, the antioxidants and the anti-dripping agents are added in the selected PC and ABS base materials, the PC / ABS alloy material is good in liquidity and can meet the forming requirement of large thin-walled products, meanwhile, impacting toughness of the thin-walled products can be guaranteed, and the PC / ABS material is mainly applied to shells of TV sets, shells of printing machines and other large thin-walled electronic and electric products, can replace imported products such as Korea Sanyang PC / ABS NH-1000T and has large cost advantages.

Owner:FENGHUA XURI HONGYU

Formula and process of Li-Ti-Zn soft magnetic ferrite material with high frequency and high resistivity

The invention discloses a formula and process of a Li-Ti-Zn soft magnetic ferrite material with high frequency and high resistivity, relating to the physical technical field of soft magnetic ferrites. According to the formula, the Li-Ti-Zn soft magnetic ferrite material comprises 50-65mol% of Fe2O3, 1-4mol% of MnO, 10-20mol% of ZnO, 1-4mol% of TiO2, 0.1-0.5mol% of Co2O3, 15-28mol% of Li2CO3 and 0.2-0.8mol% of Bi2O3. The design originality of the formula is as follows: NiO in a nickel-zinc ferrite is replaced with LiCO3 on the premise that the performance of a product is unchanged, so that the production cost is greatly reduced, and the favorable economic benefit and social value are achieved.

Owner:绵阳市维奇电子技术有限公司

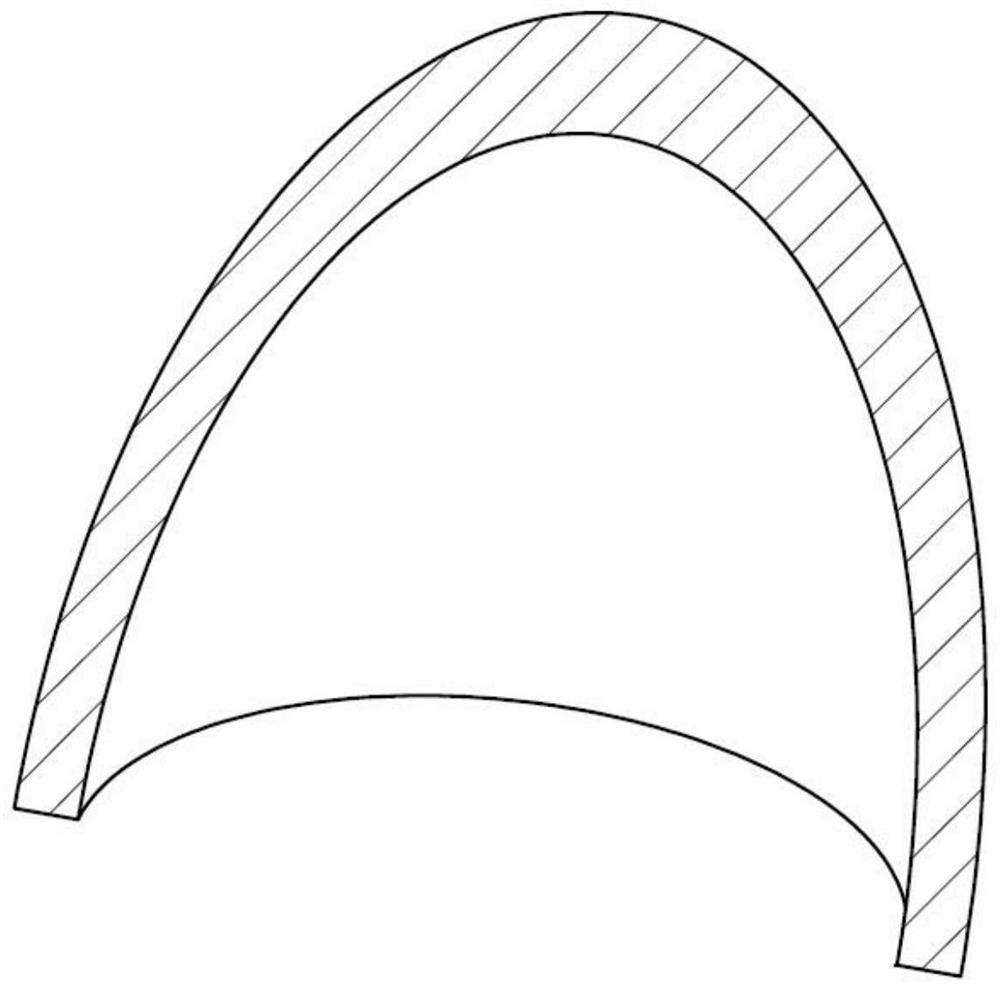

Shaping method of sealing gasket between windows and covering cap of cone-cylinder-shaped thermal shield

ActiveCN104875316AMeet molding requirementsSolve the sealing problemEngine sealsNumerical controlEngineering

The invention discloses a shaping method of a sealing gasket between windows and a covering cap of a cone-cylinder-shaped thermal shield. The shaping method of the sealing gasket between the windows and the covering cap of the cone-cylinder-shaped thermal shield includes following steps: using a numerical control machining method to process three windows on the thermal shield shaped through mould pressing, and using a near-net-shape forming method to shape the covering cap with a complex molding surface through mould pressing; performing repair so as to obtain matched intervals between the covering cap and the thermal shield windows so as to leave a space for manufacture of the sealing gasket; smearing the windows with prepared sealant, swearing the covering cap with a releasing agent, guaranteeing separation between the covering cap and the sealant, adhering the sealant to the thermal shield windows, and using a special shaping clamp matched with the thermal shield to tightly press the covering cap. The shaping method of the sealing gasket between the windows and the covering cap of the cone-cylinder-shaped thermal shield can guarantee seal performance of the thermal shield windows of a shield throwing system, and simultaneously can meet a downstream / upstream step increment between an external cone of the covering cap and an external cone of the thermal shield.

Owner:湖北三江航天江北机械工程有限公司

Retarded water-resistant gypsum block and preparation method thereof

InactiveCN101597937AImprove mobilityThe ratio of water to material dropsSolid waste managementMixing operation control apparatusSlagSlurry

The invention discloses a retarded water-resistant gypsum block and a preparation method thereof. The retarded water-resistant gypsum block is prepared from the following raw materials in percentage by weight: 80 to 90 percent of powdery gypsum, 5 to 15 percent of fly ash or blast furnace slag, 1 to 5 percent of excitant, and 0.5 to 2.5 percent of water reducing agent, wherein the water-solid ratio is between 0.3 and 0.4. The fineness of the raw materials reaches that an oversize product of a sieve with a size of 0.08 mm is not greater than 5 percent. The raw materials are added into a stirring tank according to the mixture ratio, an irrigation pump is used to pour mixed slurry into a forming die after the raw materials are stirred evenly, and the gypsum block is obtained after the demolding and constant-temperature drying. The gypsum block has retarding and water-resistant characteristics, reduces rejection rate, reduces drying time, and reduces the energy consumption during the drying.

Owner:贵州金三利科技建材有限公司

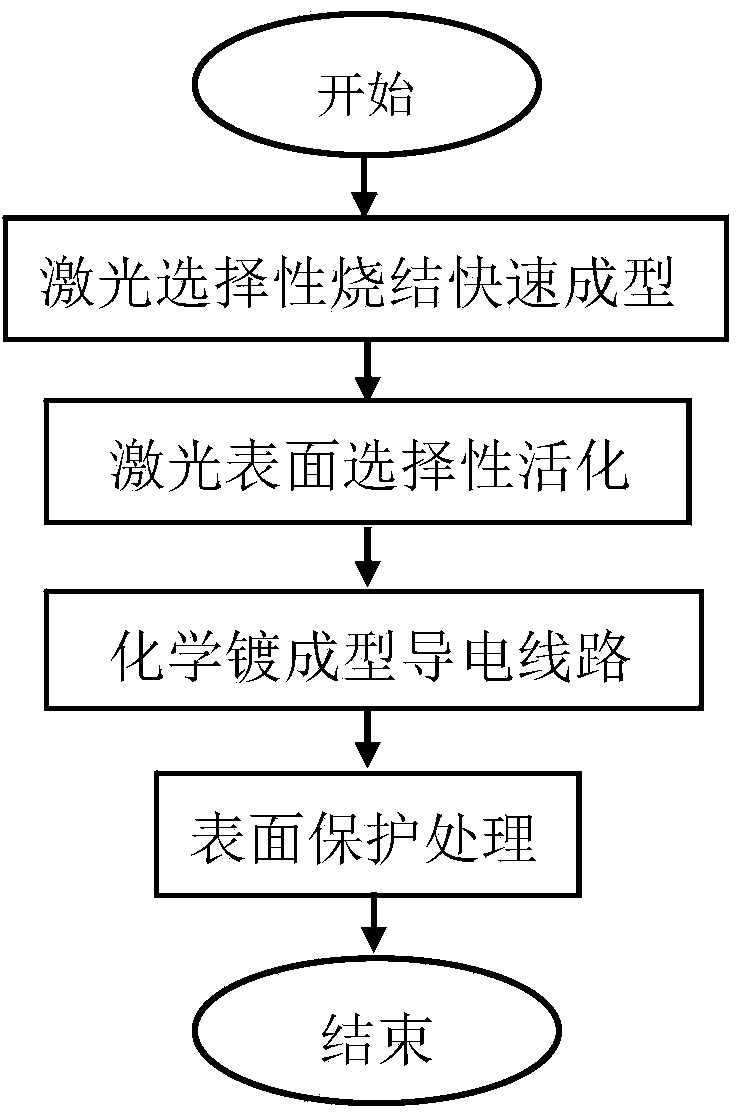

Three-dimensional circuit manufacturing method and modified laser sintering powder materials

ActiveCN104244588AFast preparationRapid Surface MetallizationConductive pattern formationSelective laser sinteringChemical plating

The invention discloses a three-dimensional circuit manufacturing method. The method comprises the steps that a prototype model is generated through a selective laser sintering method, wherein modified laser sintering powder materials comprising components suitable for laser surface activation are used as the raw materials for the prototype model; preset selective scanning is carried out on the surface of the prototype model through laser, so that a surface activation area is formed; a conductive circuit is formed in the surface activation area through chemical plating. The invention further discloses the modified laser sintering powder materials used for the three-dimensional circuit manufacturing method. According to the three-dimensional circuit manufacturing method and the modified laser sintering powder materials, the limitation brought by traditional SLS processing materials on the application is overcome, meanwhile, a matrix with the complex surface is formed, and the requirements for rapid manufacturing and forming of the conductive circuit and laser activation are effectively met.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

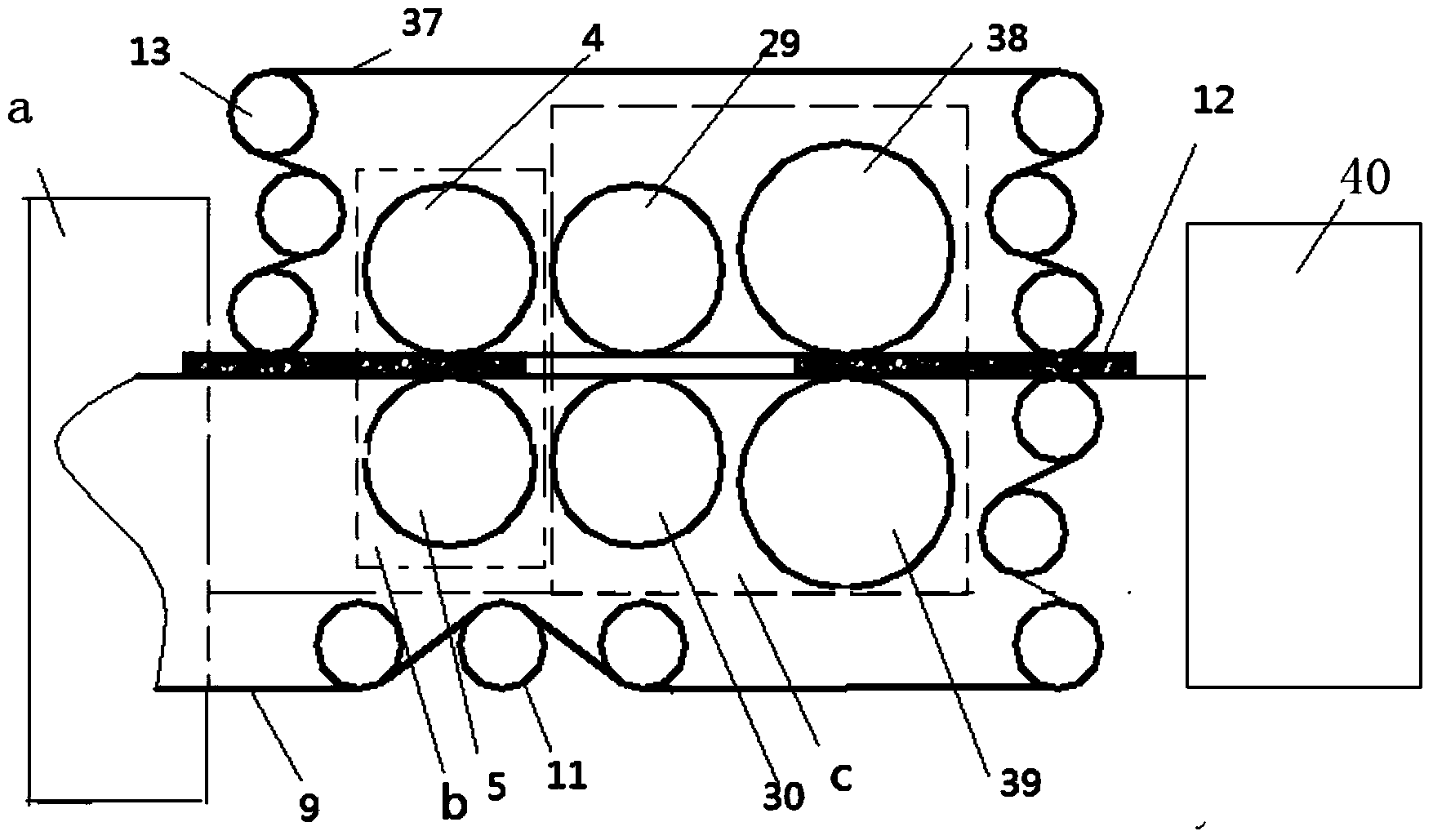

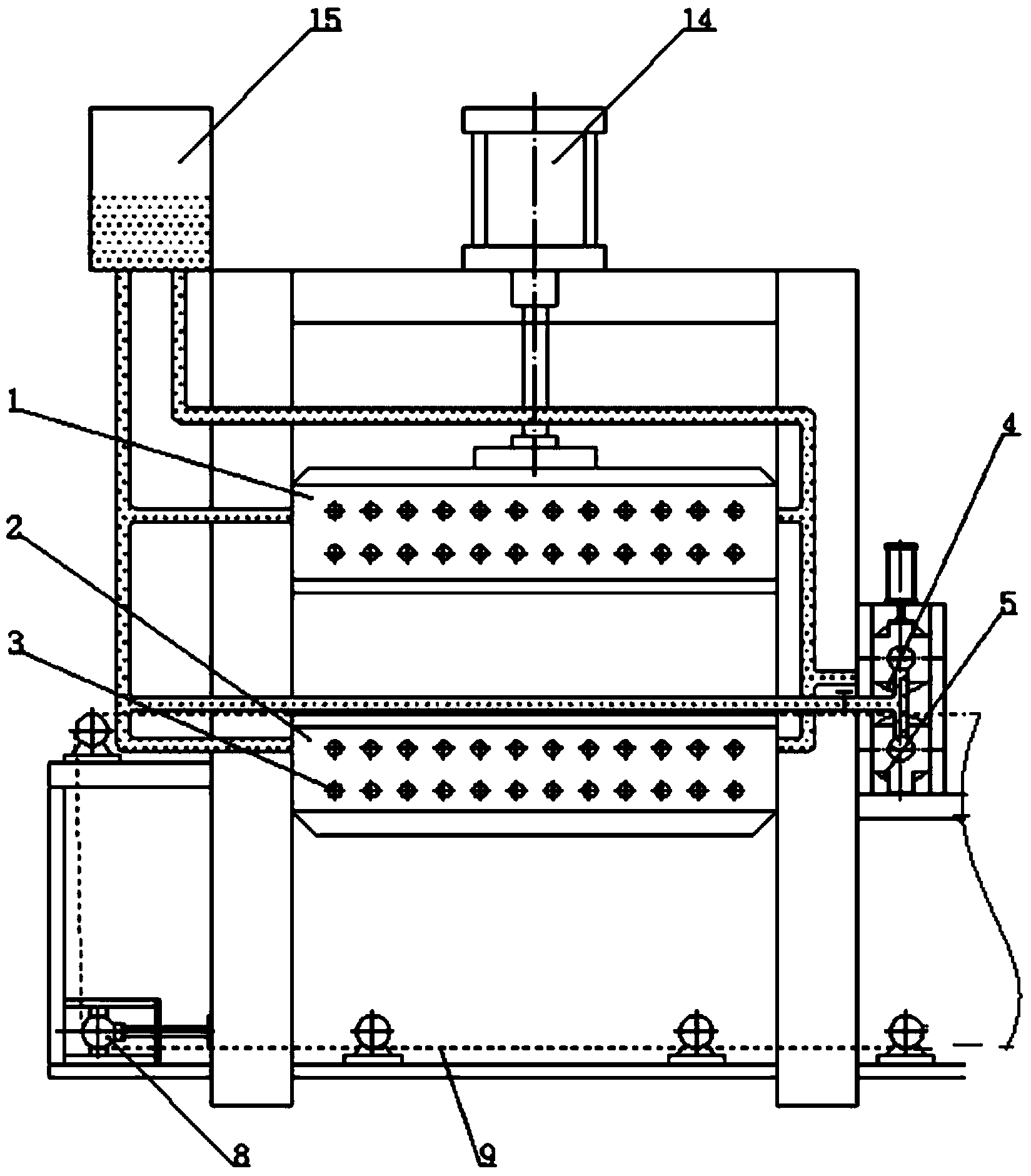

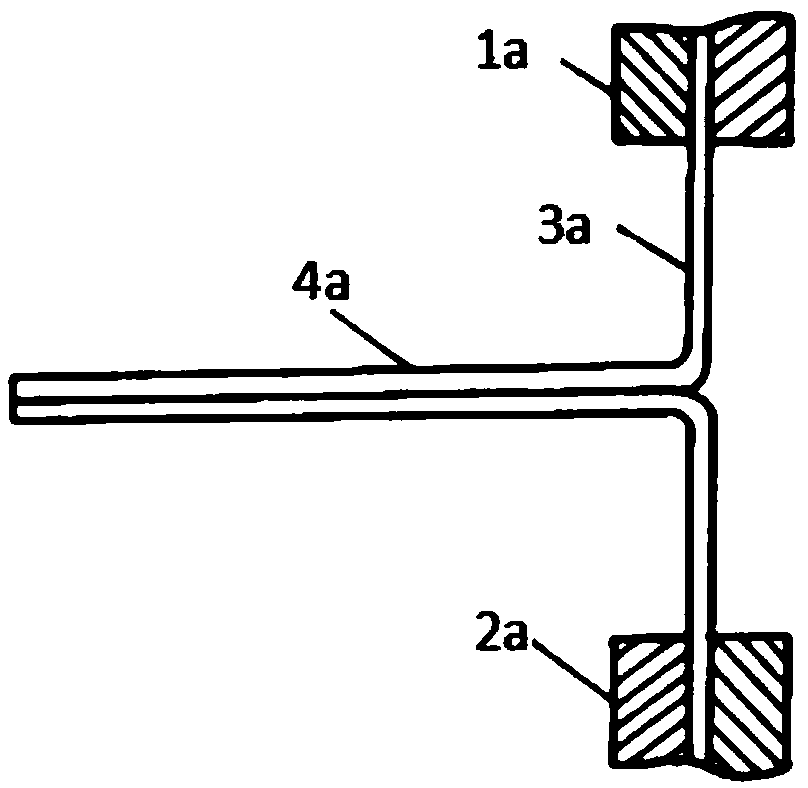

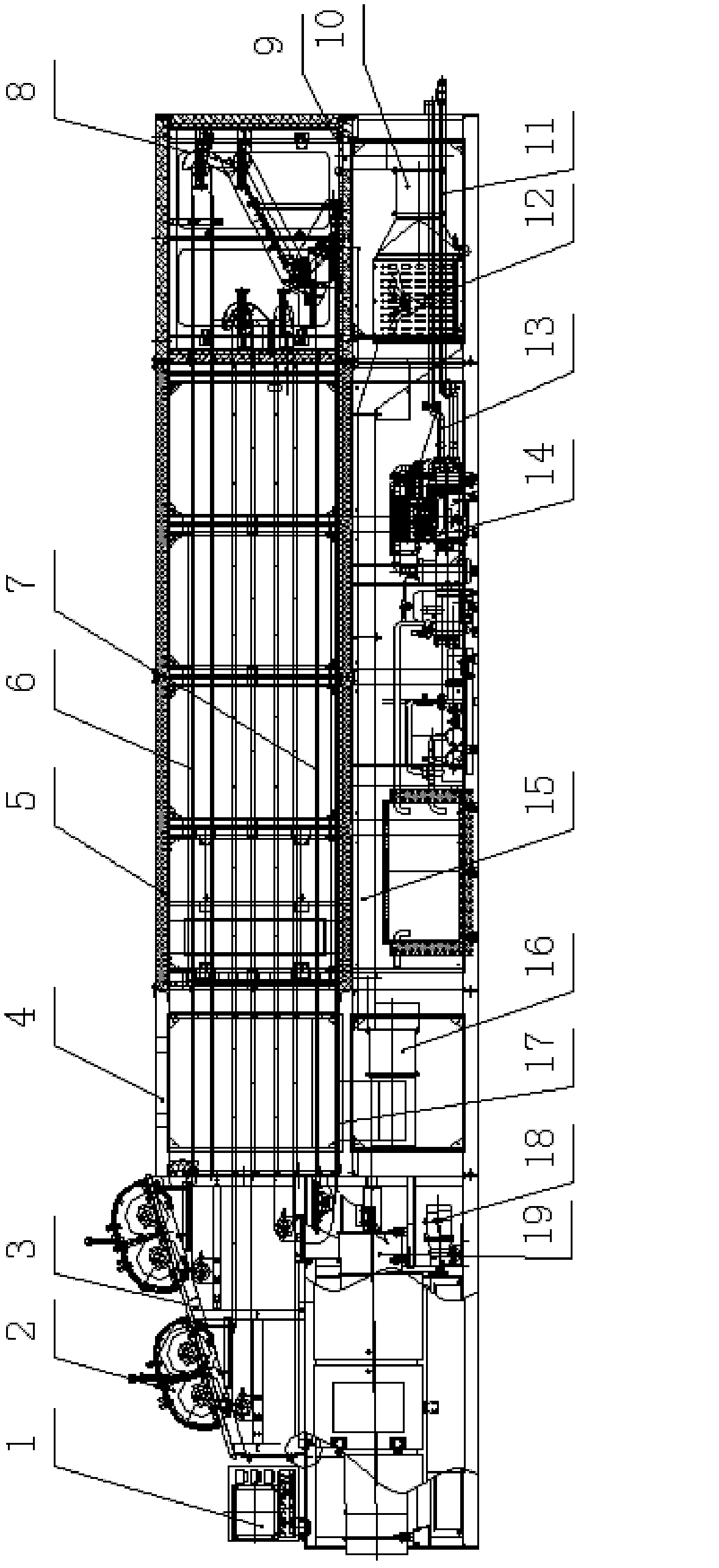

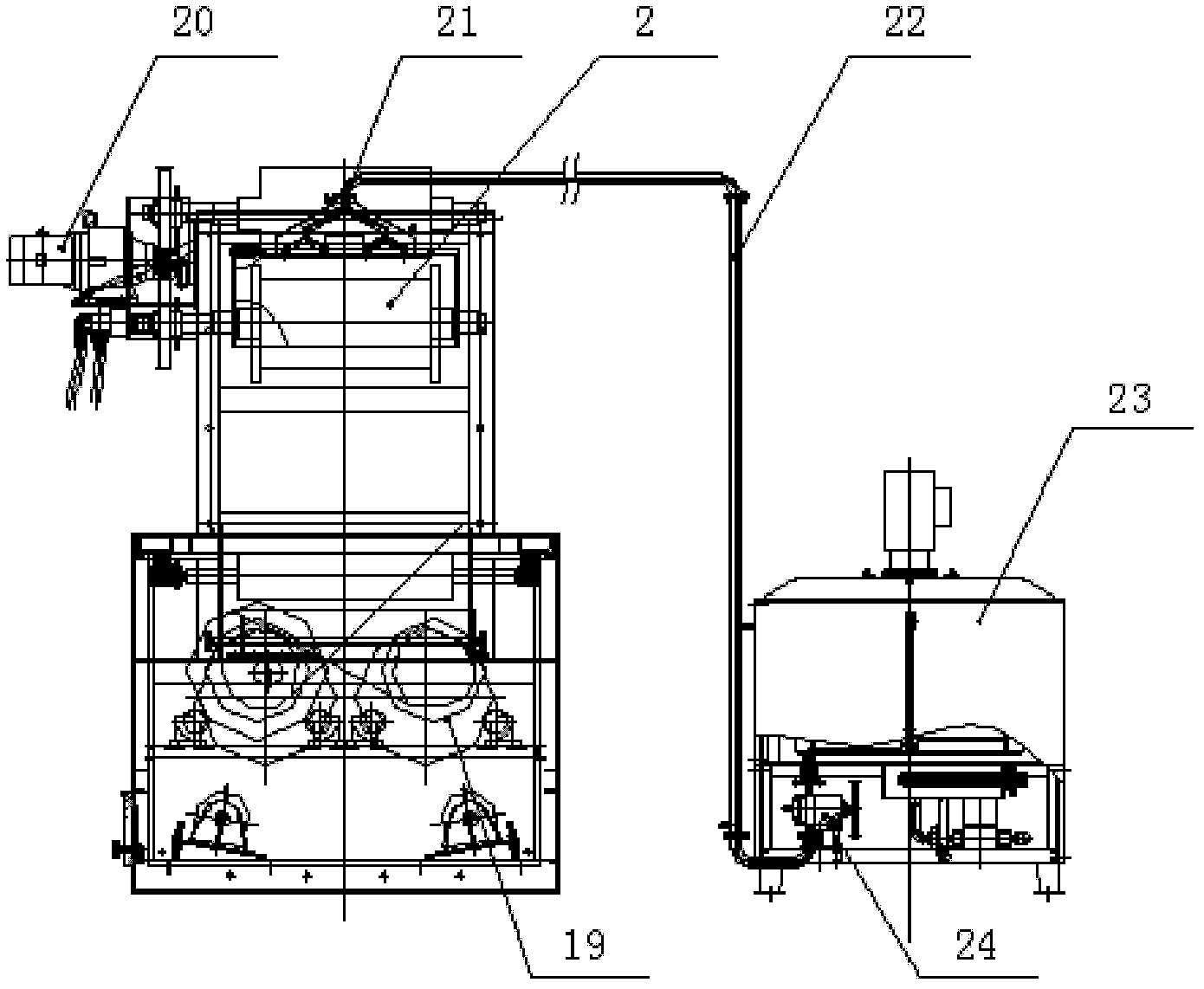

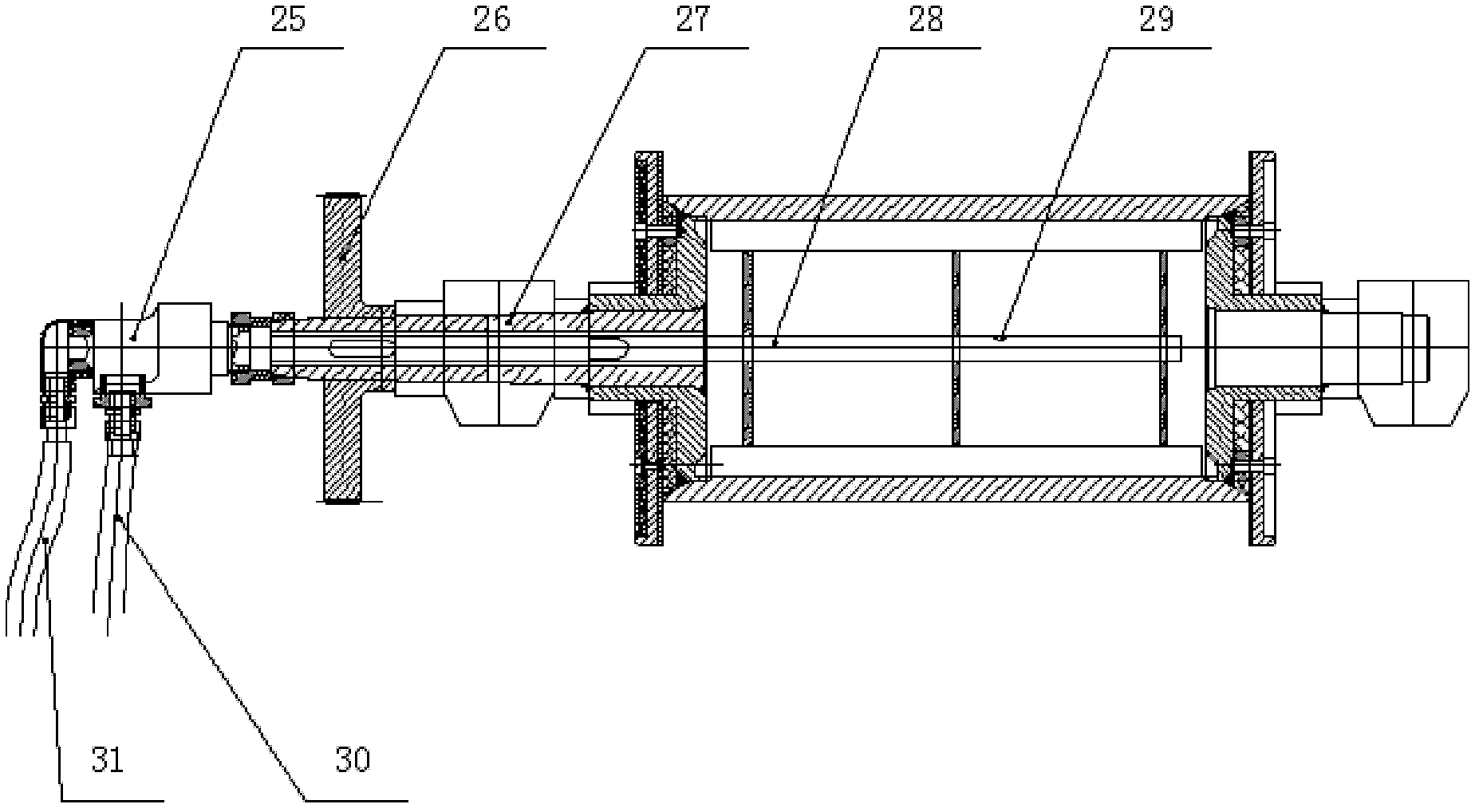

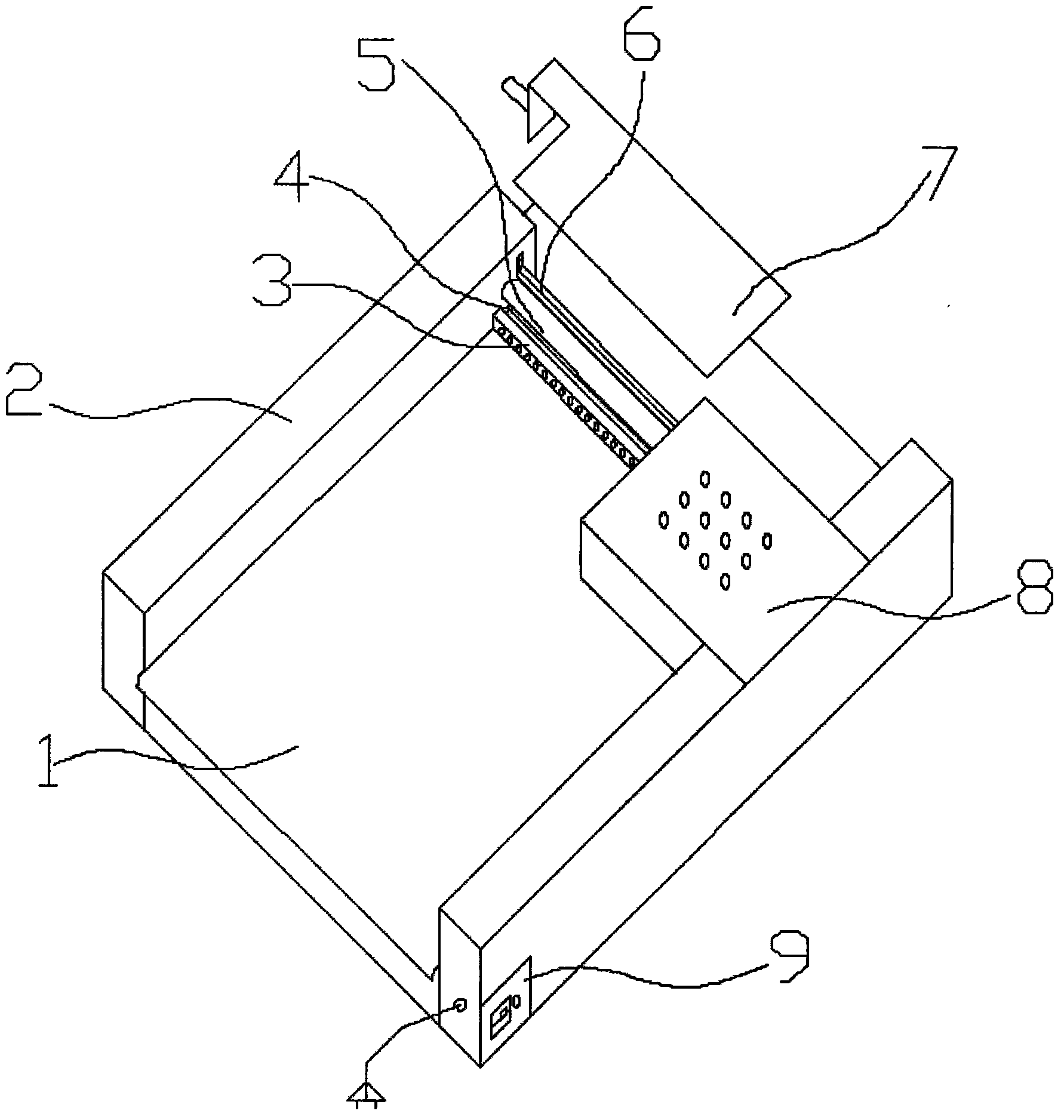

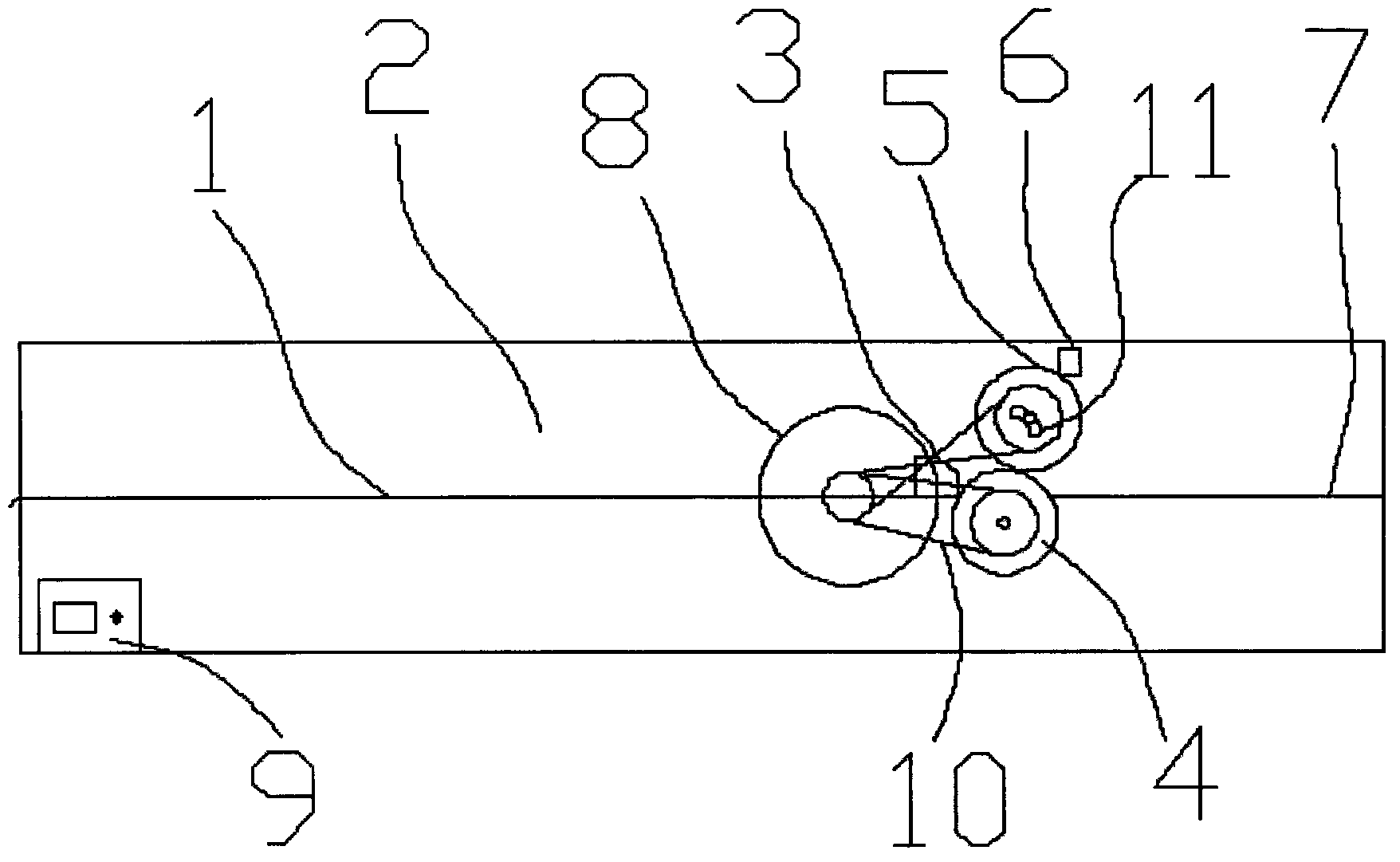

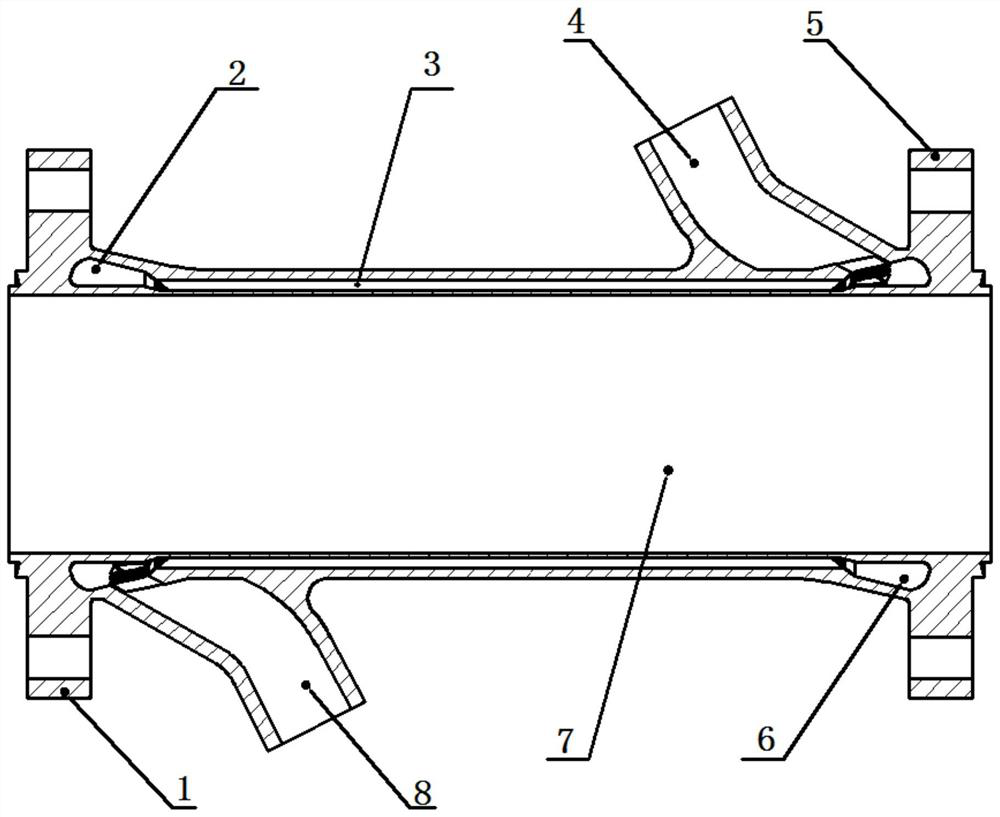

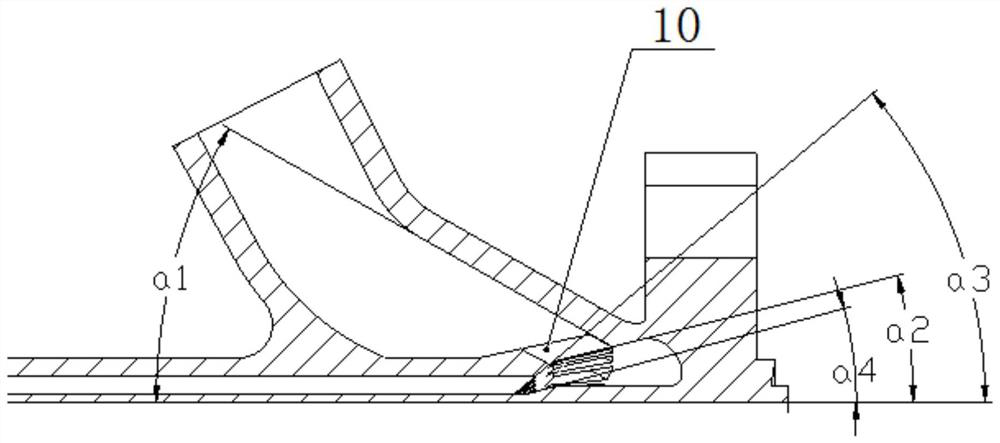

GMT sheet production system for teaching experiments

The invention discloses a GMT sheet production system for teaching experiments. The production system comprises a conveying system, a heating and baking system (a), a heating and dipping system (b) and a cooling and shaping system (c), wherein the conveying system is provided with a lower conveying belt (9), and the heating and baking system (a), the heating and dipping system (b) and the cooling and shaping system (c) are connected in sequence through the lower conveying belt (9); the heating and baking system comprises a heating oil tank (15) and a heating pressing plate assembly, and the heating pressing plate assembly is composed of an upper heating pressing plate (1) and a lower heating pressing plate (2); the heating and dipping system comprises at least one heating and dipping assembly, and each heating and dipping assembly is composed of an upper heating compression roller (4) and a lower heating compression roller (5); the cooling and shaping system comprises at least one cooling and shaping assembly, and each cooling and shaping assembly is composed of an upper cooling compression roller and a lower cooling compression roller. The production system is small in occupied area, low in cost, capable of achieving the effects of even heating and sufficient dipping and quite suitable for teaching research.

Owner:HUNAN UNIV

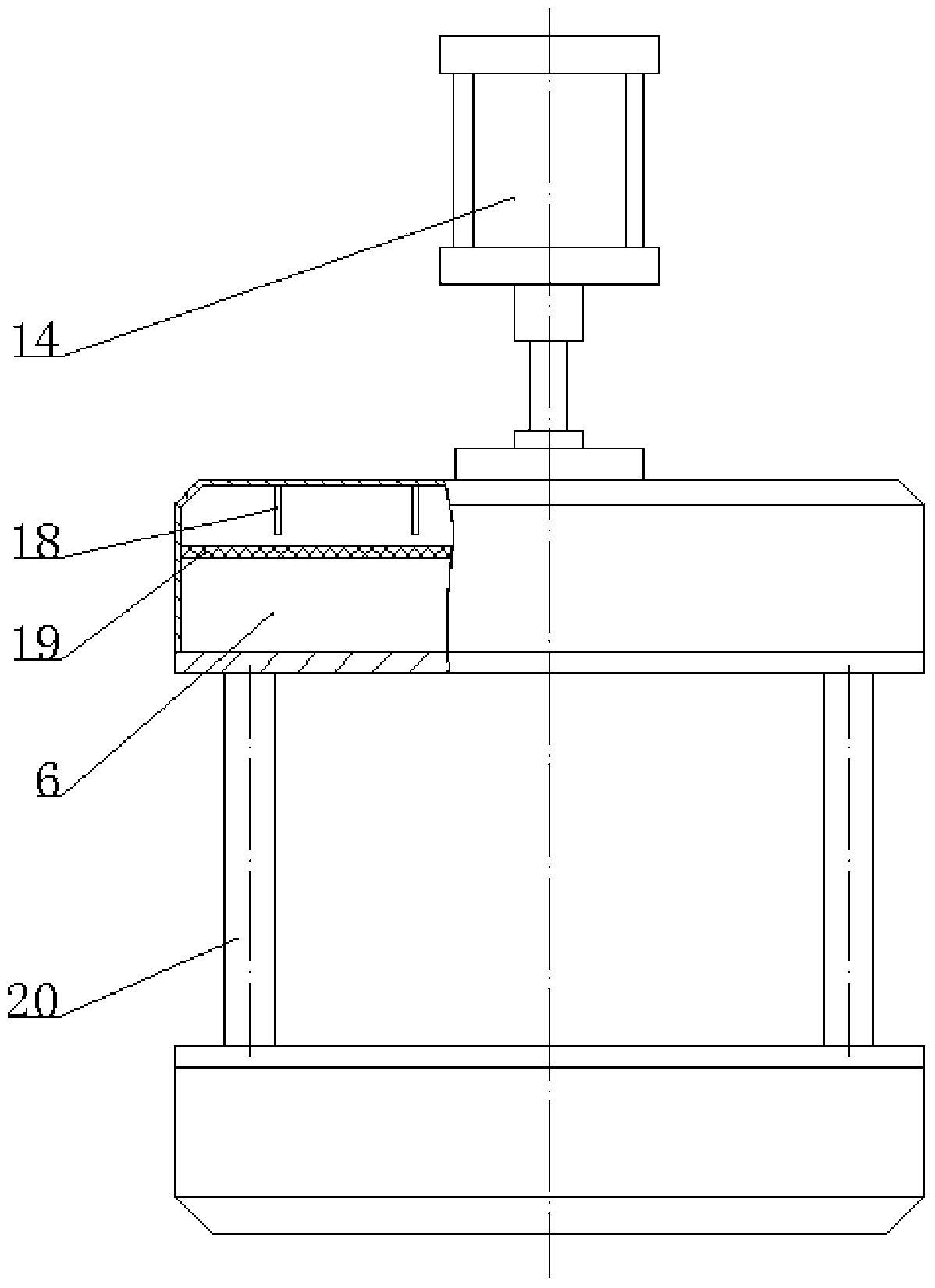

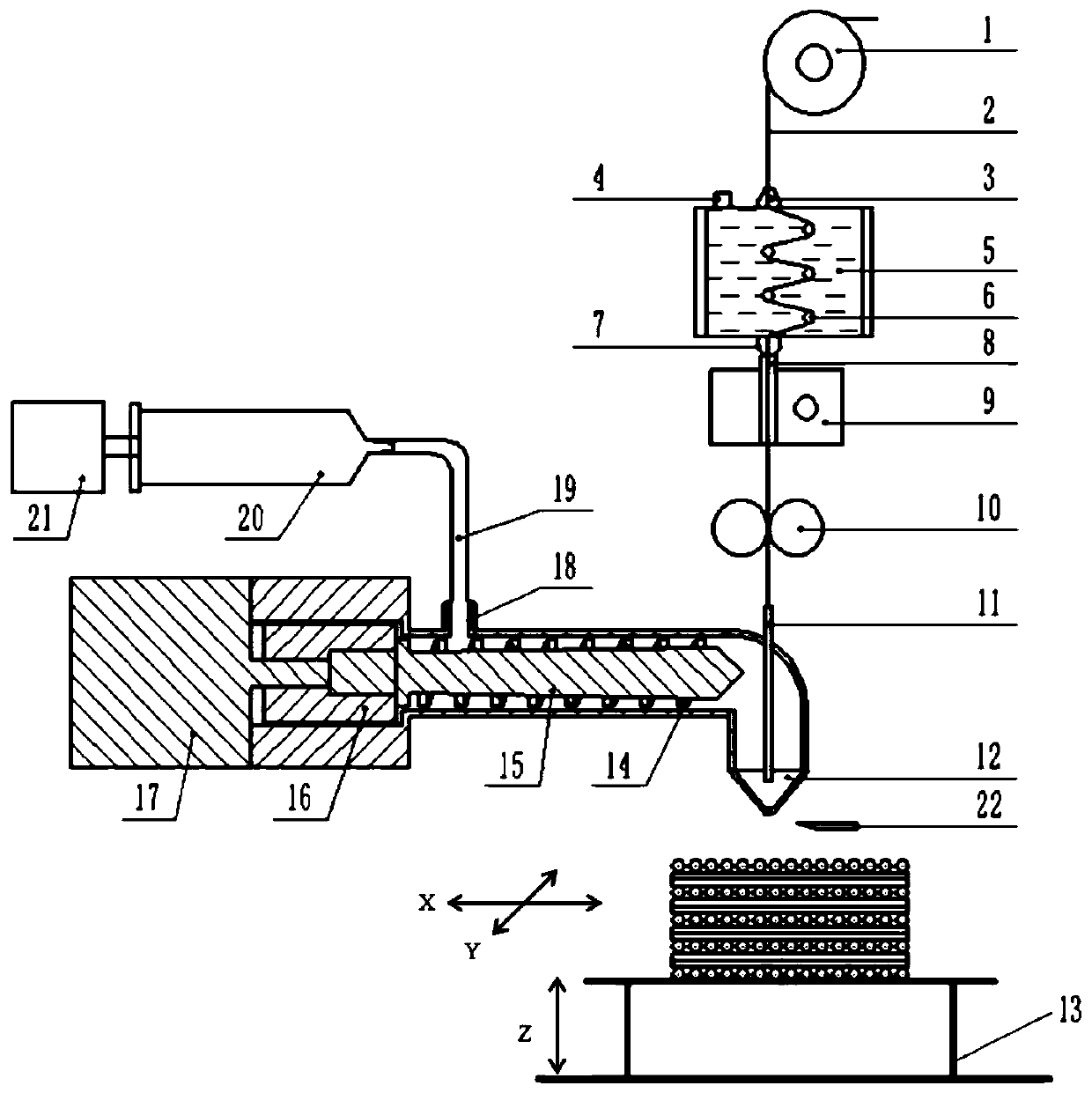

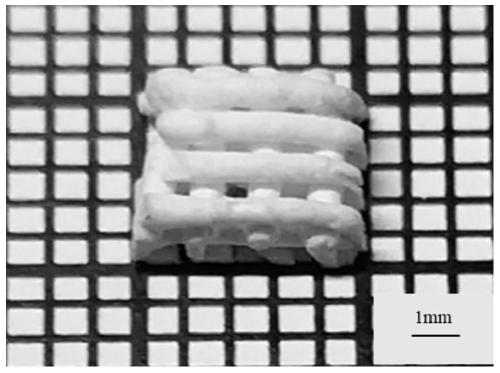

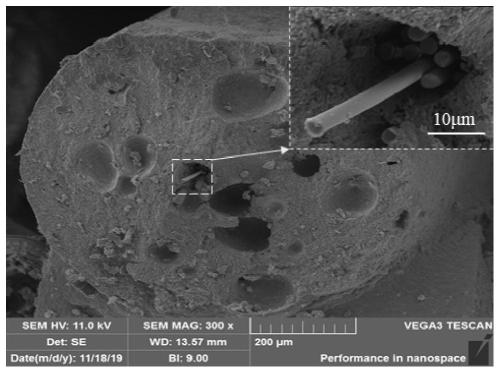

Three-dimensional (3D) printing device and method for bionic porous continuous carbon fiber reinforced ceramic bone scaffold

ActiveCN111168807ARealize integrated designAchieve extrusionAdditive manufacturing apparatusBathroom accessoriesCarbon fibersIntegrated design

The invention discloses a three-dimensional (3D) printing device and method for a bionic porous continuous carbon fiber reinforced ceramic bone scaffold. According to the device provided by the invention, a continuous fiber pretreatment device and a ceramic slurry extruding device are combined, so that the integrated design of the continuous fiber reinforced ceramic bone scaffold 3D printing device is realized. A fiber pretreatment material adopted by the method provided by the invention is a ceramic slurry which is the same as a base material but has lower solid content, and the ceramic slurry with lower solid content has better wettability and is not only capable of being adhered to the outer part of a carbon fiber multifilament and but also capable of permeating into the carbon fiber multifilament so as to realize adhesion, so that a biological performance of a composite material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

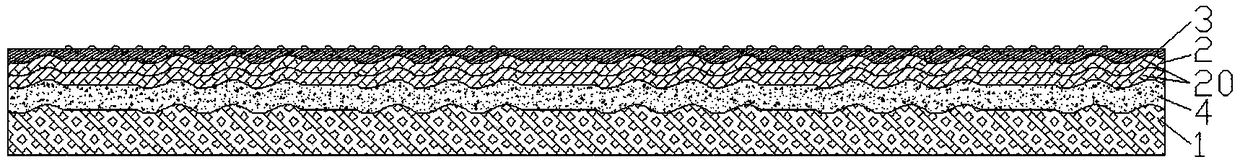

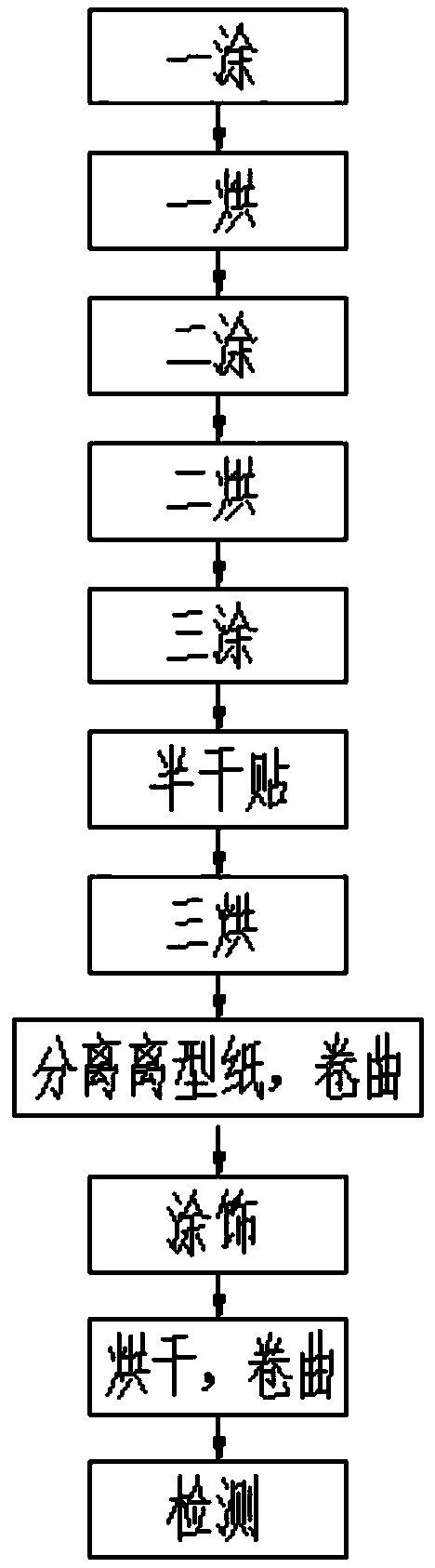

High laminating degree PU leather, and preparation method thereof

InactiveCN109109419ACompact structureHierarchical stabilityLamination ancillary operationsSynthetic resin layered productsAdhesiveIn vehicle

The invention discloses a high laminating degree PU leather. The high laminating degree PU leather comprises a base cloth layer, a PU layer, and a coating decorative layer successively; an adhesive layer is arranged between the base cloth layer and the PU layer; the adhesive layer is prepared from a solvent-free PU adhesive; the coating decorative layer is a water- based coating decorative layer;the PU layer comprises two PU single layers; the PU layer comprises, by weight, 90 to 105 parts of PU resin, 62 to 72 parts of DMF, 12 to 16 parts of ethyl acetate, and 19 to 25 parts of color paste;the coating decorative layer comprises, by weight, 4 to 6 parts of a semi-bright delustering surface treatment agent, 4.5 to 6 parts of a delustering surface treatment agent, 0.5 to 0.8 part of a dryslide handfeel wear resisting agent, 0.6 to 0.75 part of a wet slide handfeel wear resisting agent, 0.6 to 0.85 part of a antifouling agent, 0.25 to 0.32 part of a levelling agent, 0.6 to 0.85 part ofa cross-linking agent, and 2.5 to 4 parts of industrial distilled water. A preparation method of the high laminating degree PU leather is capable of avoiding layering phenomenon after material heating force loading in coating moulding process of the PU material, and satisfying moulding requirements of irregular interior decorative parts in vehicles; and extremely excellent durability and fastnessare achieved.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

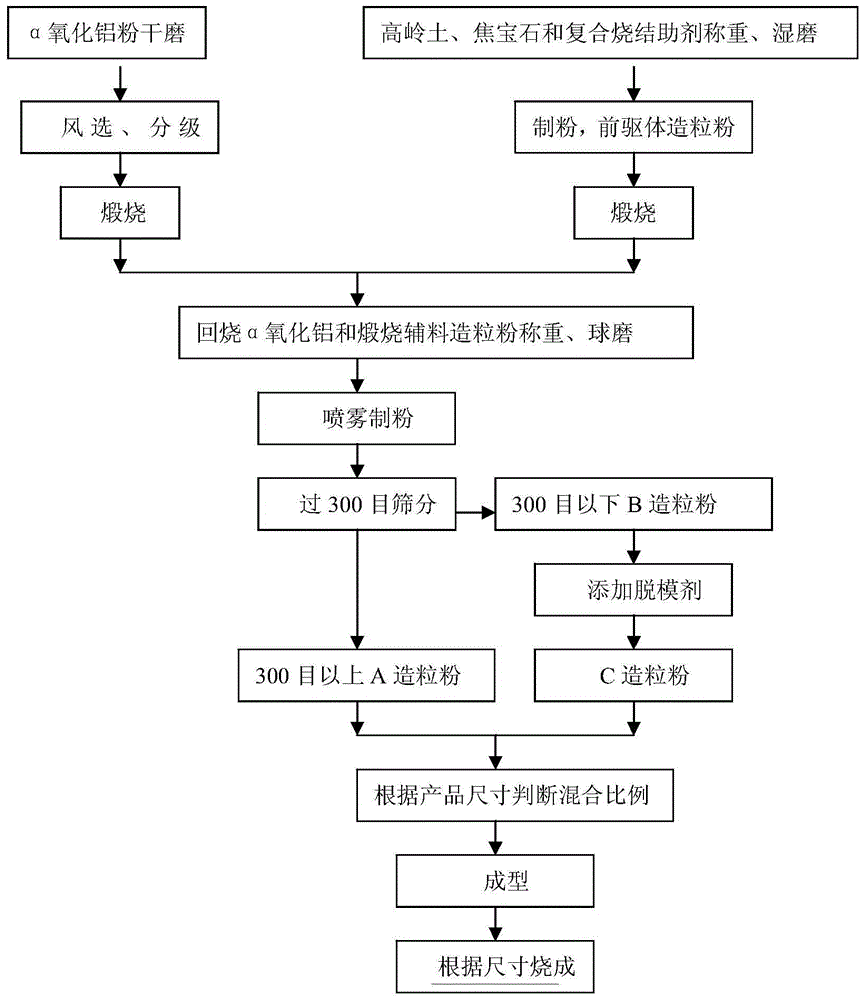

Method for preparing aluminum oxide ceramic sphere without fingernail line defect

The invention discloses a method for preparing aluminum oxide ceramic spheres without fingernail line defect. The method comprises the following steps: performing dry grinding and air separation on alpha-aluminum oxide powder, and reburning alpha-aluminum oxide powder with D90 of 3-6 micrometers; carrying out wet grinding, powdering and calcining other assistant materials; mixing the treated main material and assistant materials, performing wet grinding, and powdering; separating the pelleting powder with a sieve of 300 meshes so as to obtain pelleting power A and pelleting powder B; adding additives into the pelleting powder B so as to obtain pelleting powder C; mixing the pelleting powder A and the pelleting powder C in different ratios according to sizes of half-finished products, and performing compression molding; performing firing molding by using different firing processes according to the sizes of the half-finished products. By adopting the method, the aluminum oxide ceramic sphere production process can be comprehensively improved in multiple ways and aspects, and the purposes of reducing or eliminating fingernail line defect of aluminum oxide ceramic spheres can be achieved.

Owner:JINGANG NEW MATERIALS

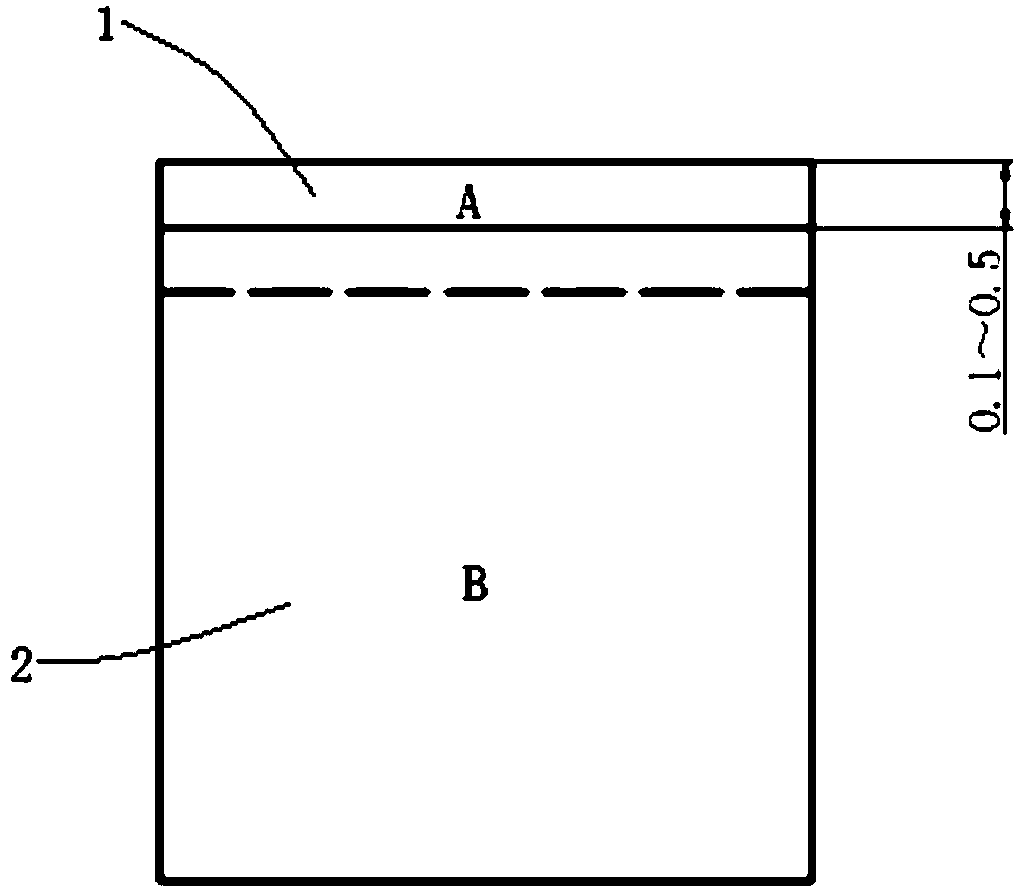

Arc angle laser welding forming method of angle seam joints

InactiveCN108326420AHigh heat input efficiencyLow heat inputLaser beam welding apparatusEngineeringFusion welding

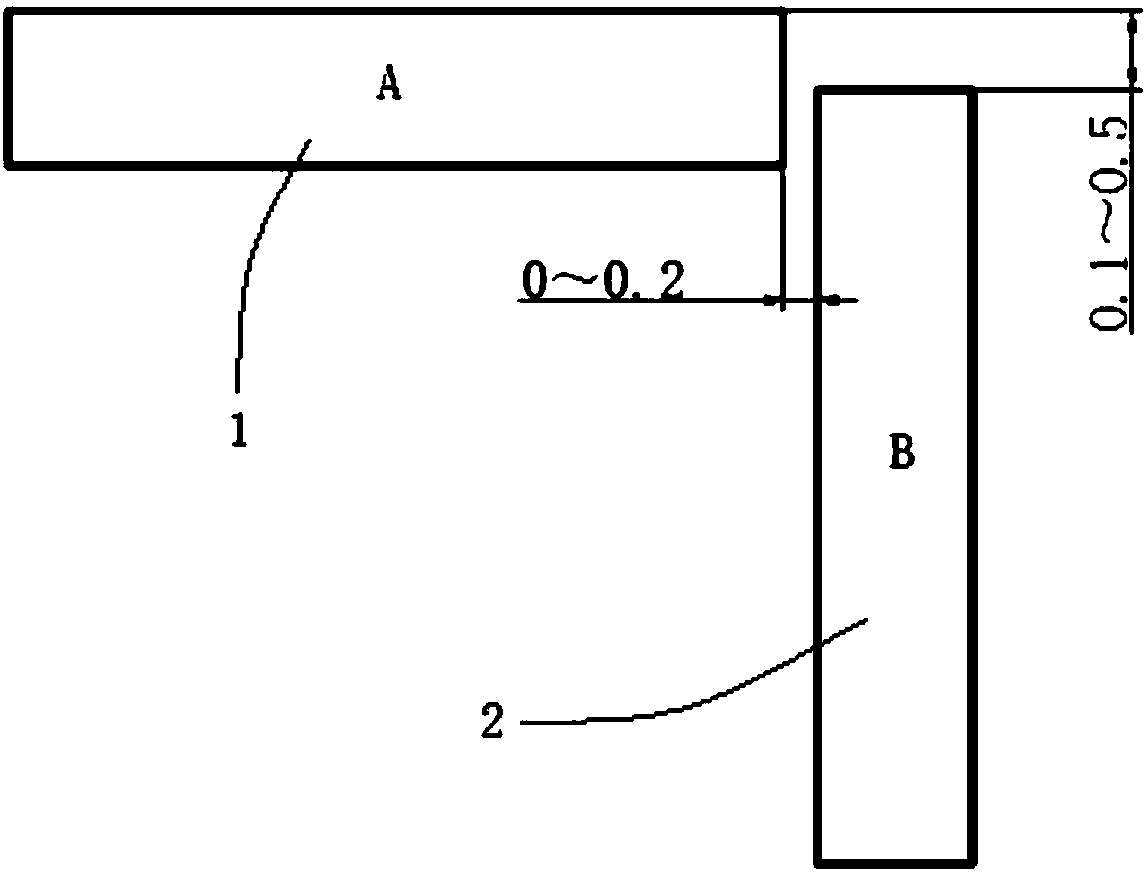

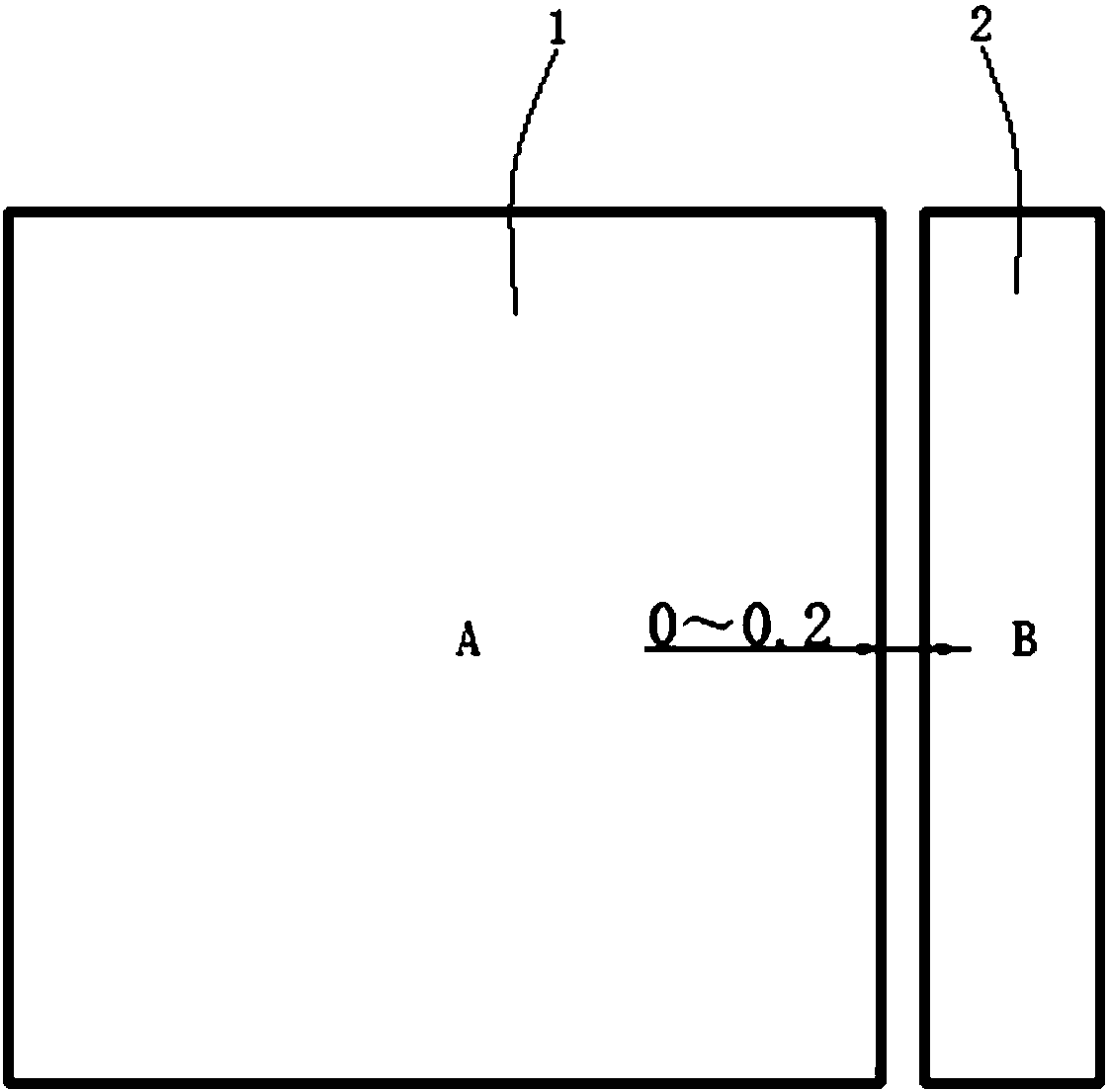

The invention relates to an arc angle laser welding forming method of angle seam joints. The method comprises the steps as follows: two plates are positioned, the plate A and the plate B are perpendicular, the distance between the two plates is controlled within the range of 0-0.2 mm, the to-be-welded end surface of the plate B is located between two plate surfaces of the plate A, and the distancebetween the to-be-welded end surface of the plate B and the outer side plate surface of the plate A is in a range of 0.1-0.5 mm; a laser self-fusion welding manner is adopted for welding forming, andthe focus spot diameter of laser beams is 1.5-2.2 mm. A special welding joint splicing form is adopted, the space occupied by surplus height of appropriate weld seams is reserved, the weld seams haverelatively flat surfaces after welding and form smooth arc angle seams, the weld seam appearance requirement is guaranteed, and the weld seam arc angle forming requirement can be better met; a large-focus spot diameter laser welding technology is adopted, welding seam forming can meet the product requirement, simple polishing treatment is needed only in the later period, and stable production with high quality, efficiency and benefits is realized.

Owner:WUHAN HGLASER ENG CO LTD

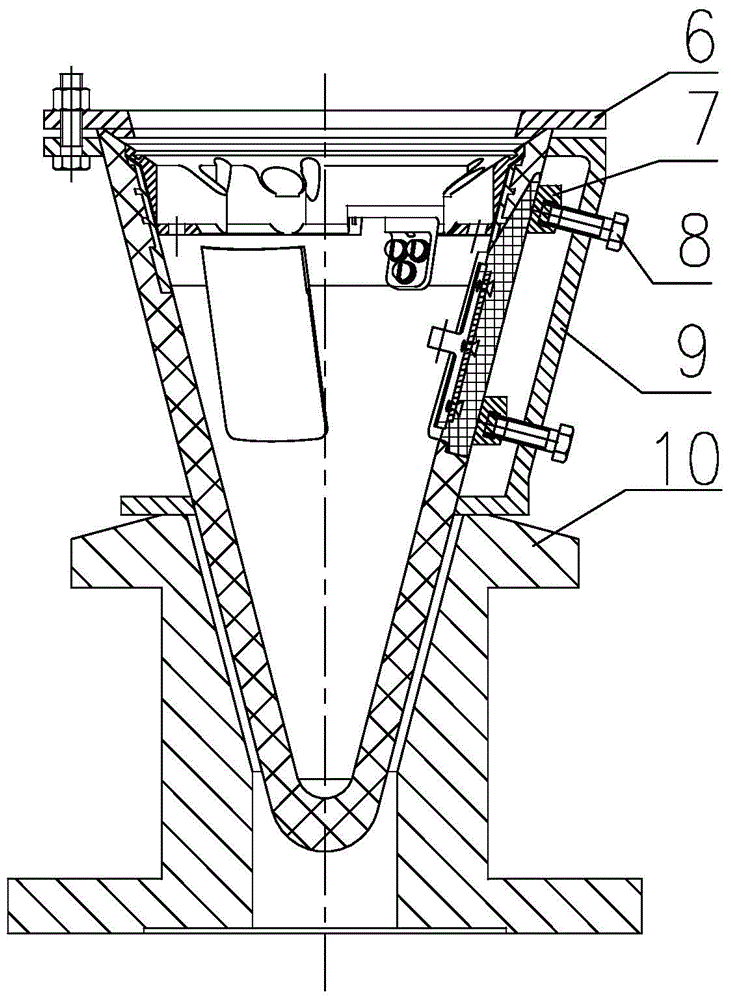

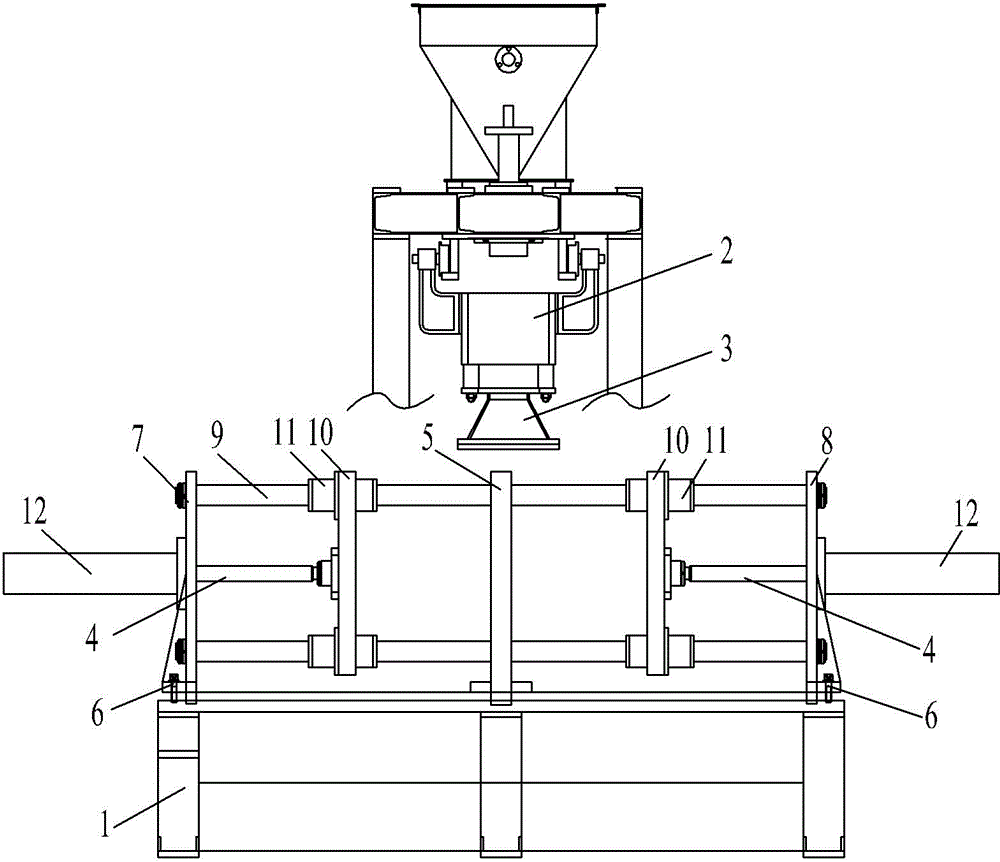

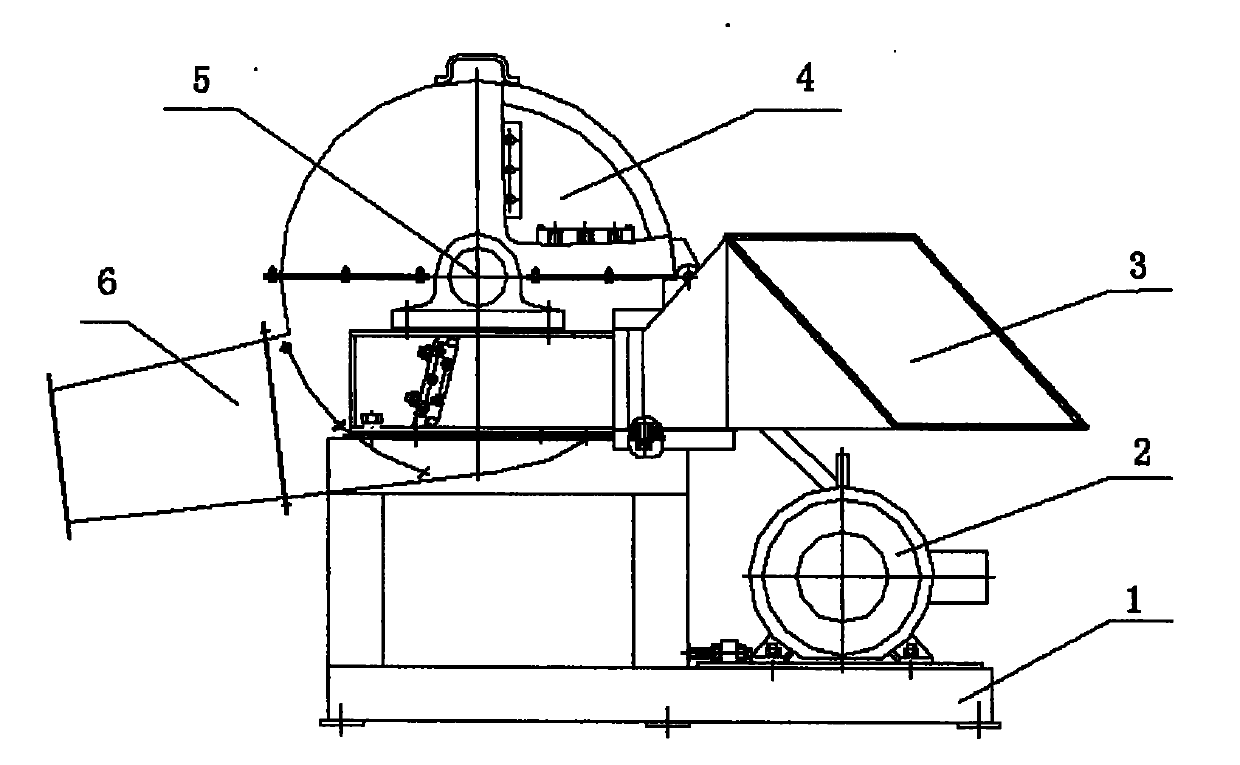

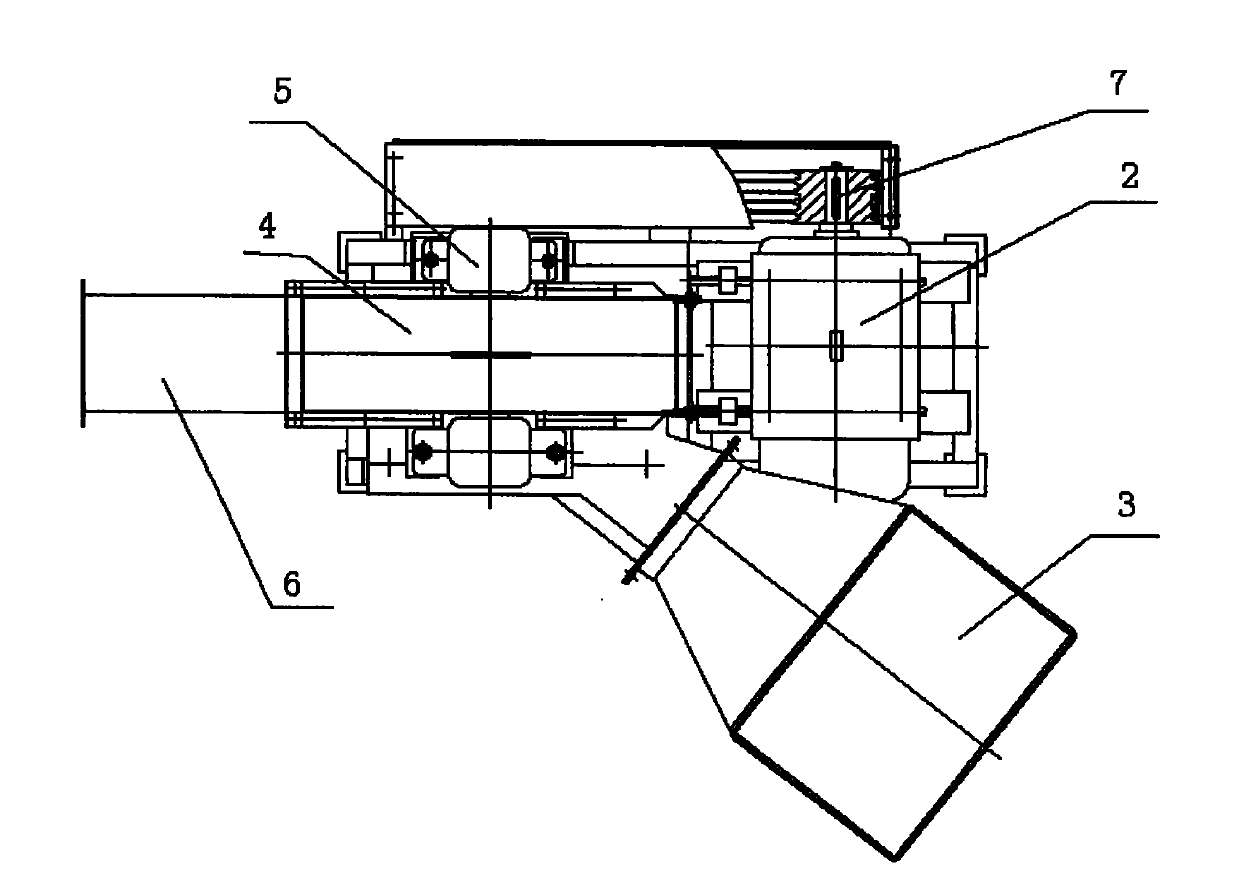

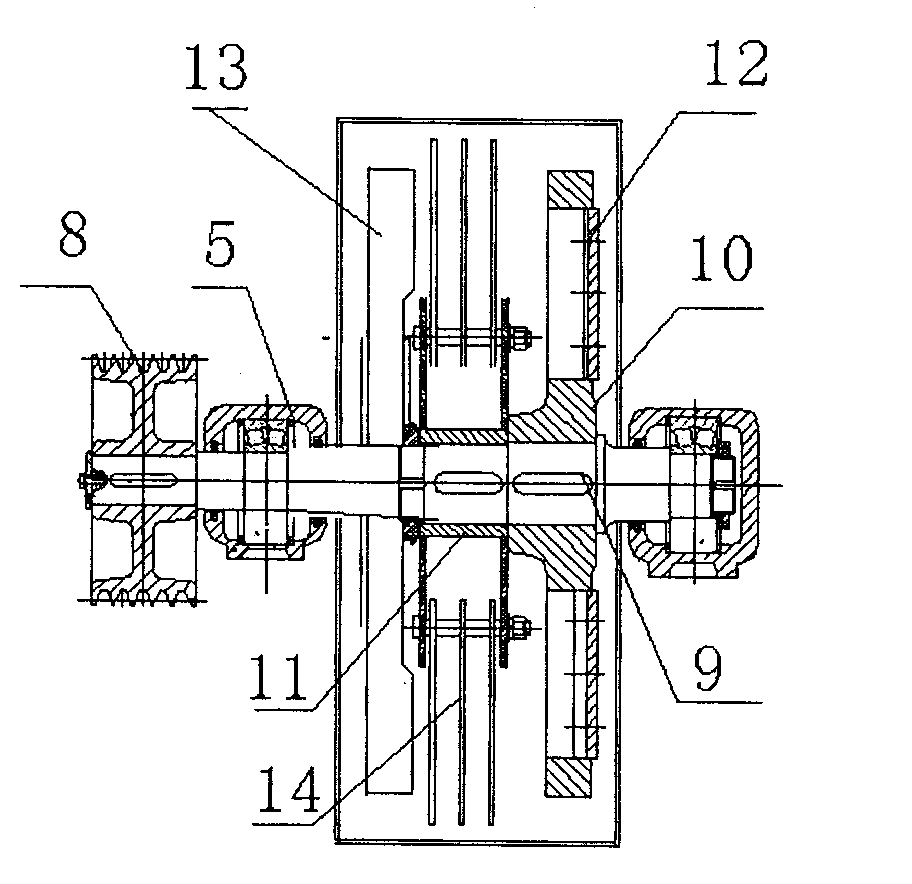

Vertical-parting core shooting machine

The invention provides a vertical-parting core shooting machine. The vertical-parting core shooting machine can be operated simply, can be used conveniently, and has low cost and high production efficiency. The vertical-parting core shooting machine comprises a base, wherein a sand shooting barrel is arranged on the base, a shooting head is arranged under the sand shooting barrel, a fixed mold plate is fixed at the center of the end surface of the base, a left side plate and a right side plate are fixed at the left end and the right end of the base correspondingly and respectively by bolts, the upper end and the lower end of each of the left side plate and the right side plate are connected with the fixed mold plate by guide posts, a movable mold plate adaptive to the fixed mold plate is fixed by a sliding sleeve on the guide post and is arranged between the left side plate and the fixed mold plate and between the right side plate and the fixed mold plate, a mold closing cylinder is arranged outside the left side plate and the right side plate, and an ejector rod of the mold closing cylinder penetrates through the left side plate and the right side plate to be connected with the movable mold plate.

Owner:WUXI SHUANGQUAN MECHANICAL FACTORY

Full automatic chocolate button forming machine

The invention relates to a full automatic chocolate button forming machine which is composed of a feed system, a cooling conveying system, a cooling button rolling system, a rotary screen system and a cooling system, wherein the feed system is composed of an agitator tank, a rotor pump and a pouring head; the rotor pump is arranged on the agitator tank, and connected to the pouring head through a pipeline; the cooling conveying system is composed of a conveying chamber and a conveyer belt mounted inside the conveying chamber; the cooling button rolling system is composed of a roller die and a drive motor thereof, the roller die is installed in the feed position of the conveyer belt, and the upper part of the roller die is provided with the pouring head; the cooling system is composed of a condenser, a refrigerator, a fan and an air duct; and the rotary screen system is composed of a rotary screen and a drive motor thereof, and the rotary screen is installed on the lower part of the discharge position of the conveyer belt. The invention can implement full automatic production of chocolate buttons, and has the advantages of simple technique, integrated equipment, good sanitation performance, high yield and low labor intensity.

Owner:TIANJIN CENTURY MAOYUAN MACHINERY +1

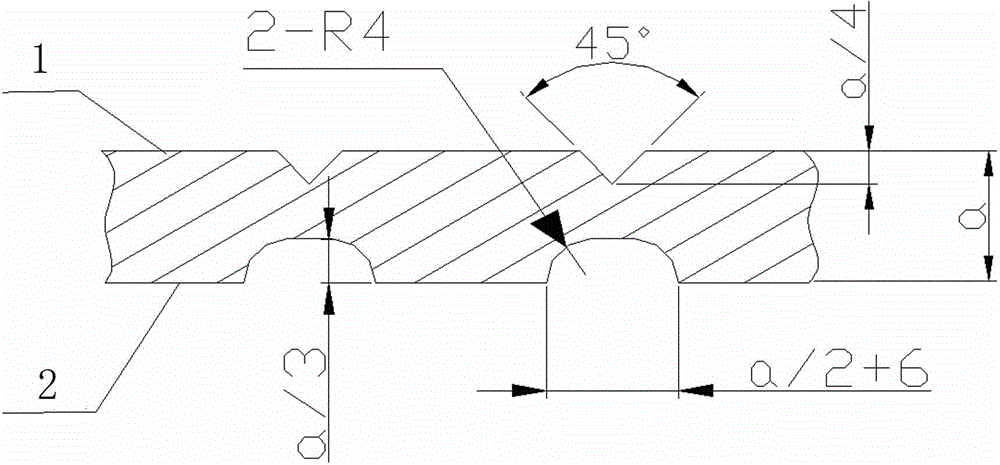

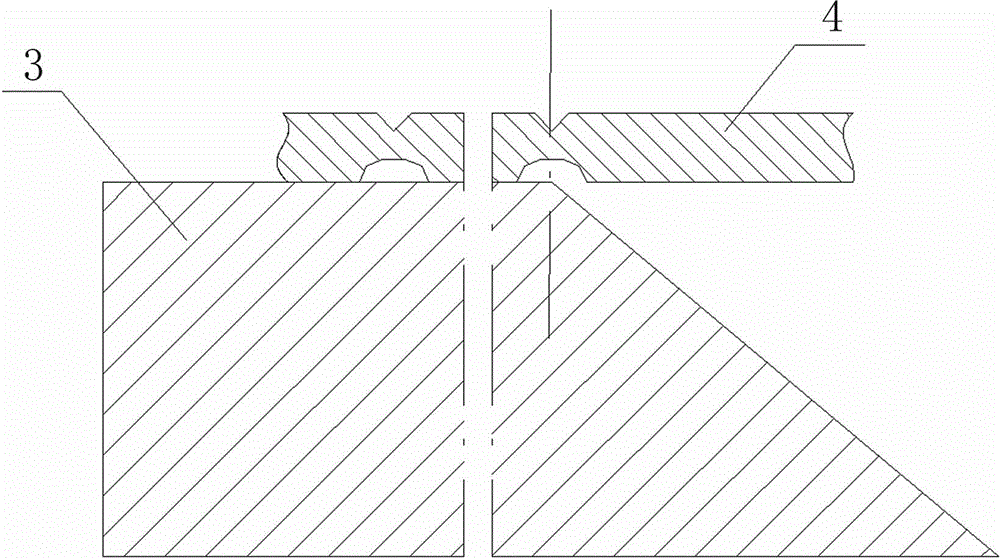

Method for sinking formation of composite material wallboard tool

ActiveCN104942554AMeet molding requirementsAvoid dependence on processing capacityNumerical controlSheet steel

The invention relates to a method for sinking formation of a composite material wallboard tool. The method comprises the following steps: (1) causing the blanking thickness to be a according to the overall unfolded dimension of the wallboard tool and setting a basic hole; (2) respectively forming open grooves at the sunk upper edge position and the sunk lower edge position of the wallboard tool; (3) arranging an inclined plane at the end of a forming die; (4) respectively performing alignment on center lines of central V-shaped 45-degree grooves of the upper edge and the lower edge, performing heating to 500-550 DEG C, and under the gravity effect after the heating, enabling the suspended wallboard tool to sink naturally and completely adhere to the forming die; (6) using welding rods to fill a wallboard tool process groove; (7) performing destressing heat treatment; and (8) performing numerical control processing of the wallboard tool, so that the sinking formation is finished. The method can remarkably improve forming accuracy of an overall steel plate of a large curved surface composite material tool and steel plate surface streamline, reduce working strength and avoid the dependence on mechanical equipment and workers' processing capabilities, and a standardized forming process can be established.

Owner:SHENYANG AIRCRAFT CORP

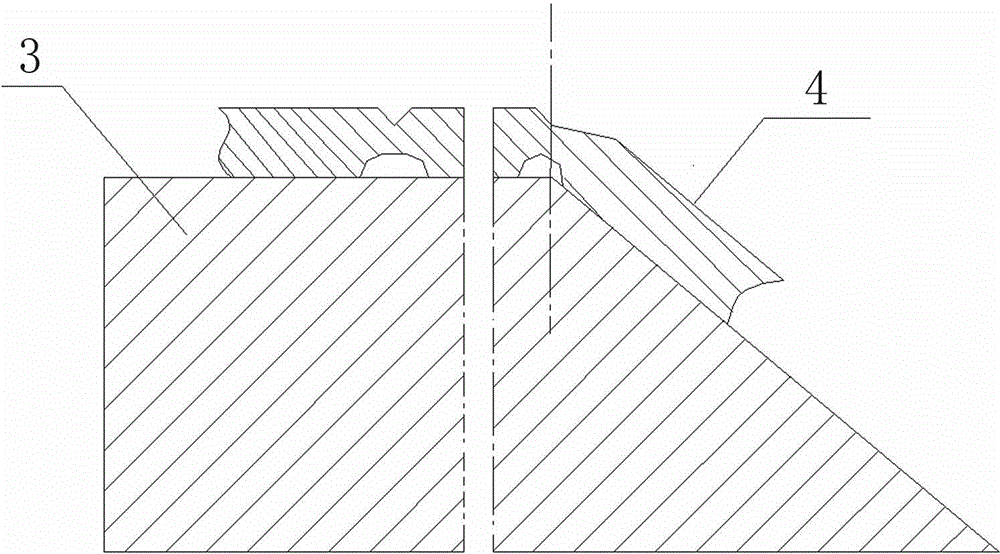

Mold for manufacturing glass container

InactiveCN103351097AAvoid cooling rateMeet molding requirementsGlass blowing apparatusCavity wallGlass container

The invention relates to a mold for manufacturing a glass container and belongs to the technical field of glass molds. The mold comprises a pair of prototype half molds in the same shape and structure, wherein the prototype half molds are opposite to each other, and each prototype half mold is provided with a glass container rudiment forming cavity and a glass container rudiment mouth forming cavity formed by coarctation of one end of the glass container rudiment forming cavity. The mold is characterized in that a group of heat preservation holes in parallel to the glass container rudiment mouth forming cavity are formed in the prototype half molds and around cavity walls of the glass container rudiment mouth forming cavities at intervals, and heat preservation hole caps are arranged at orifices of the heat preservation holes. Since the heat preservation holes are formed in the prototype half molds and around the cavity walls of the glass container rudiment mouth forming cavities at intervals, the cooling speed of glass melt in a mouth of the glass container can be reduced, and the forming requirement of the high glass container with a small mouth size is met.

Owner:CHANGSHU JIANHUA MOLD TECH

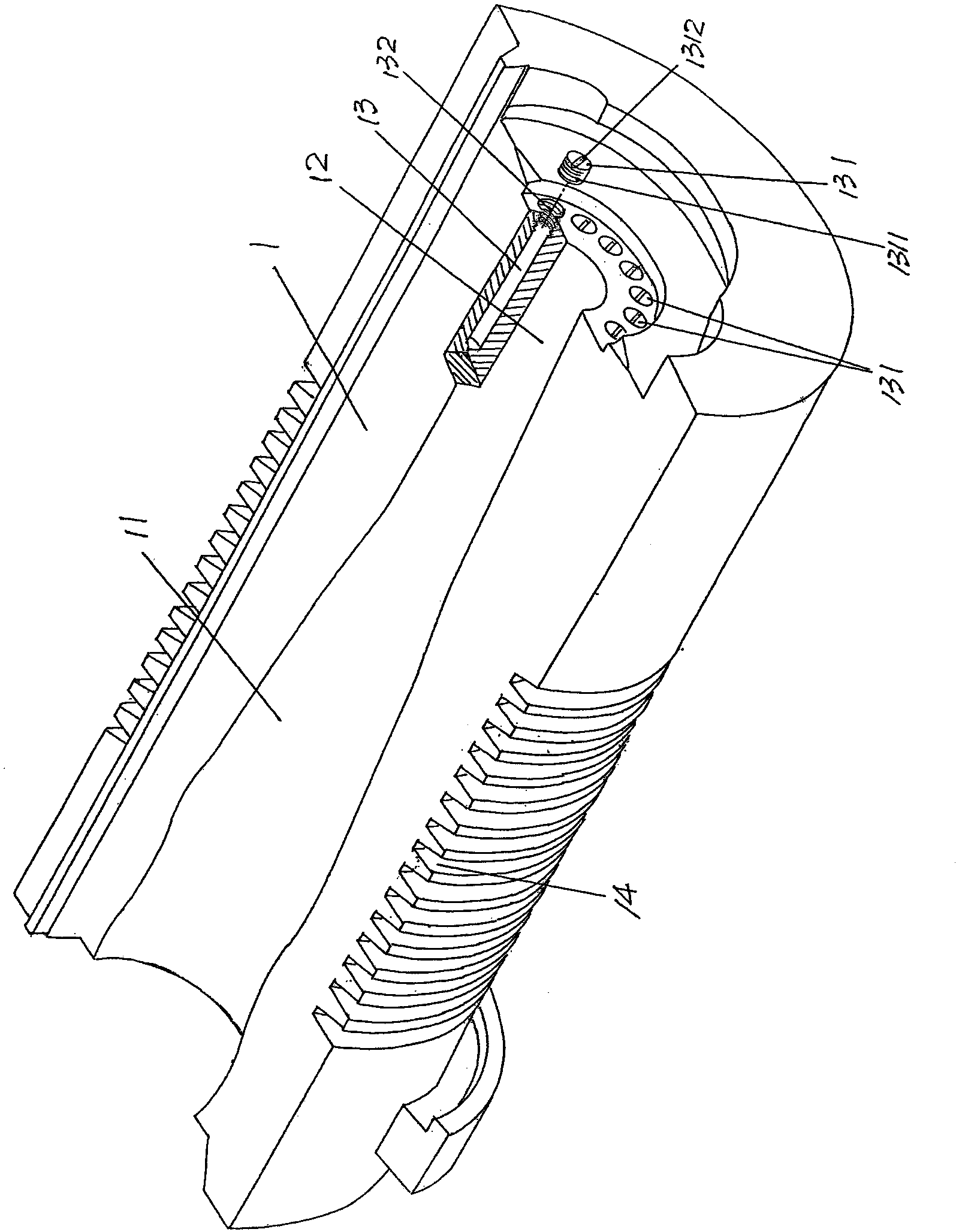

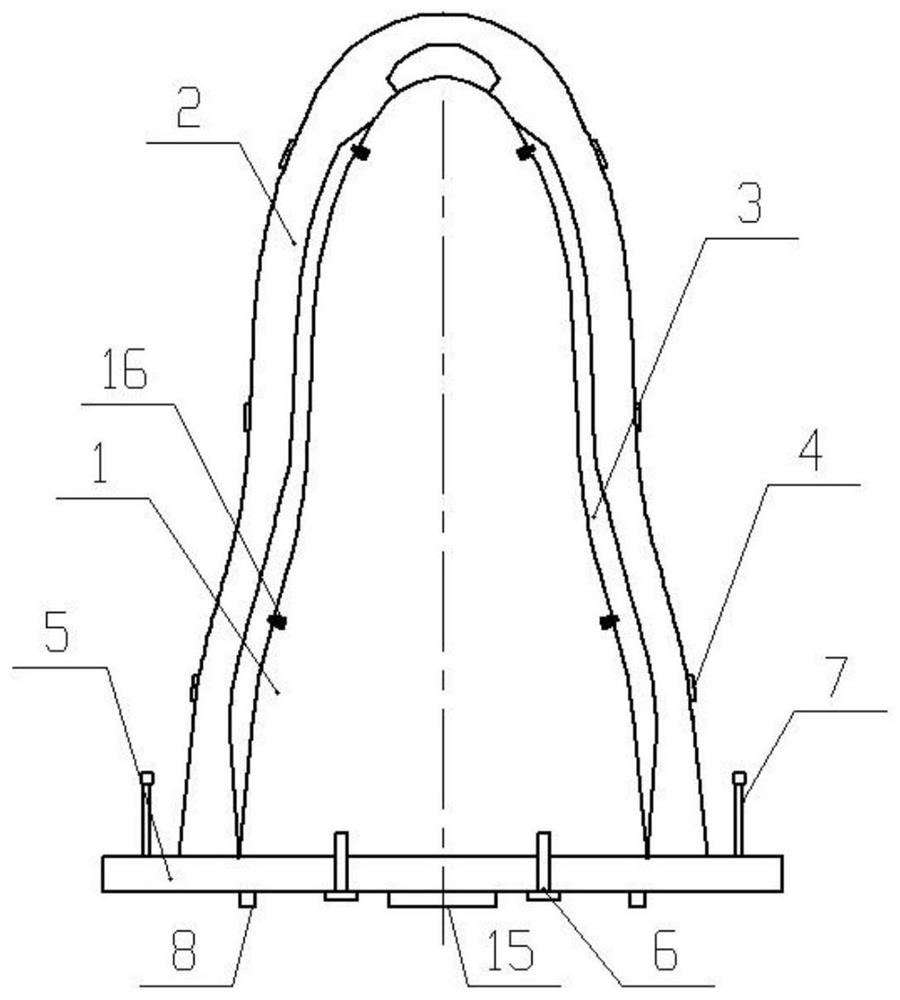

Pretreatment device for solid biomass fuels

InactiveCN101791582ASolve the crushing problemMeet molding requirementsGrain treatmentsEngineeringPre treatment

The invention discloses a pretreatment device for solid biomass fuels, and belongs to the technical field of agricultural machinery. The technical scheme is that: the pretreatment device comprises a motor (2) and a smashing device (4) arranged on a stand (1), and a cutter disc (10) and a smashing device (11) arranged in the cutting and smashing device (4); and the pretreatment device is characterized in that: cutters (12) with different combinations are distributed on ring holes of the cutter disc (10) along the periphery, and form a closed cutting and smashing chamber together with a side knife (15) and a bottom knife (16); and blades (13) and hammers (14) are peripherally arranged on the smashing device (11) to form a smashing chamber and a discharge chamber. The pretreatment device for the solid biomass fuels can cut and smash biomass materials, such as crop stalks, forestry remainders and the like by adjusting the combinations of the smashing cutters, effectively solves the smashing problem of various raw materials before the formation, and can provide a technical support for the formation of the solid biomass fuels.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

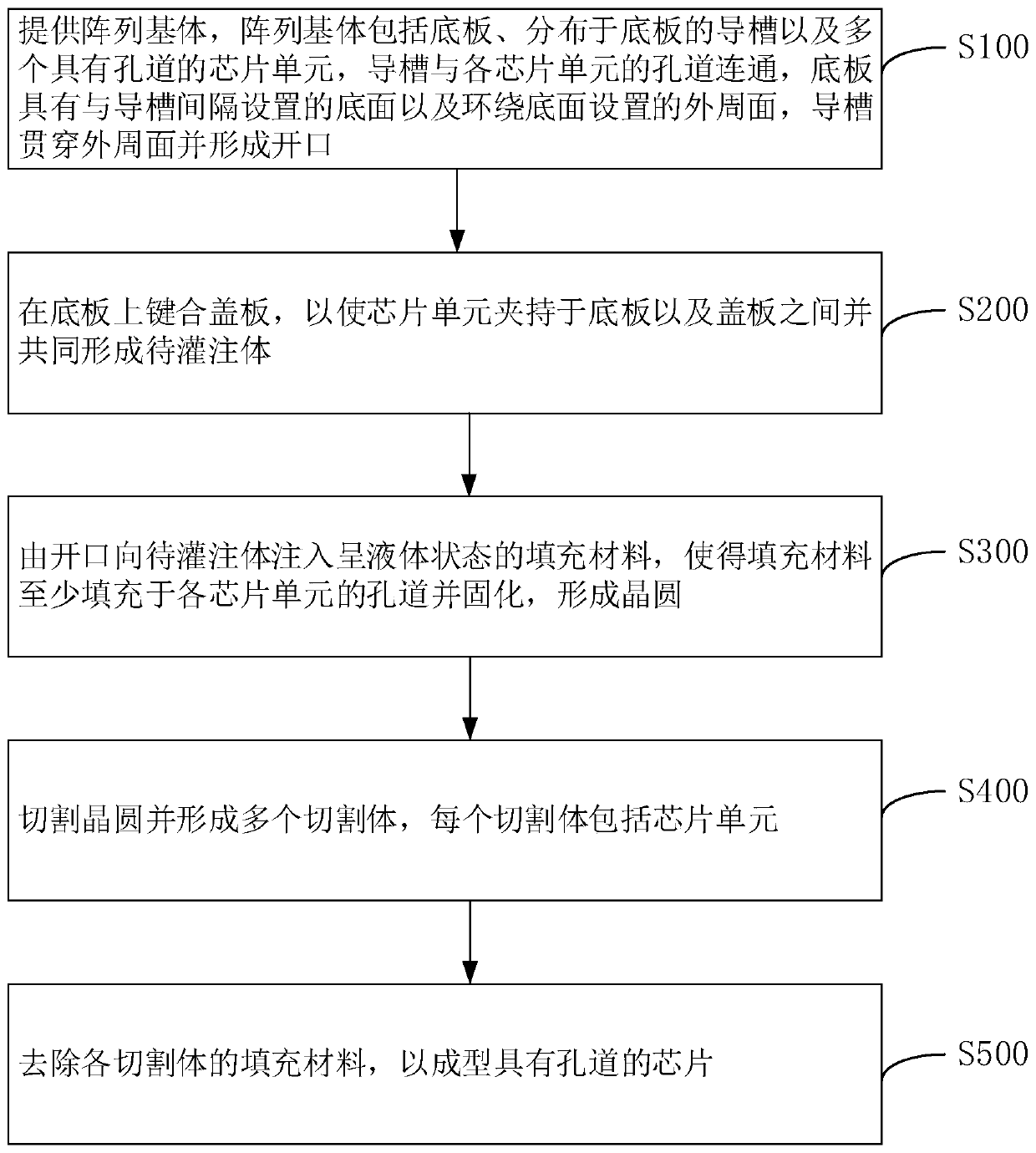

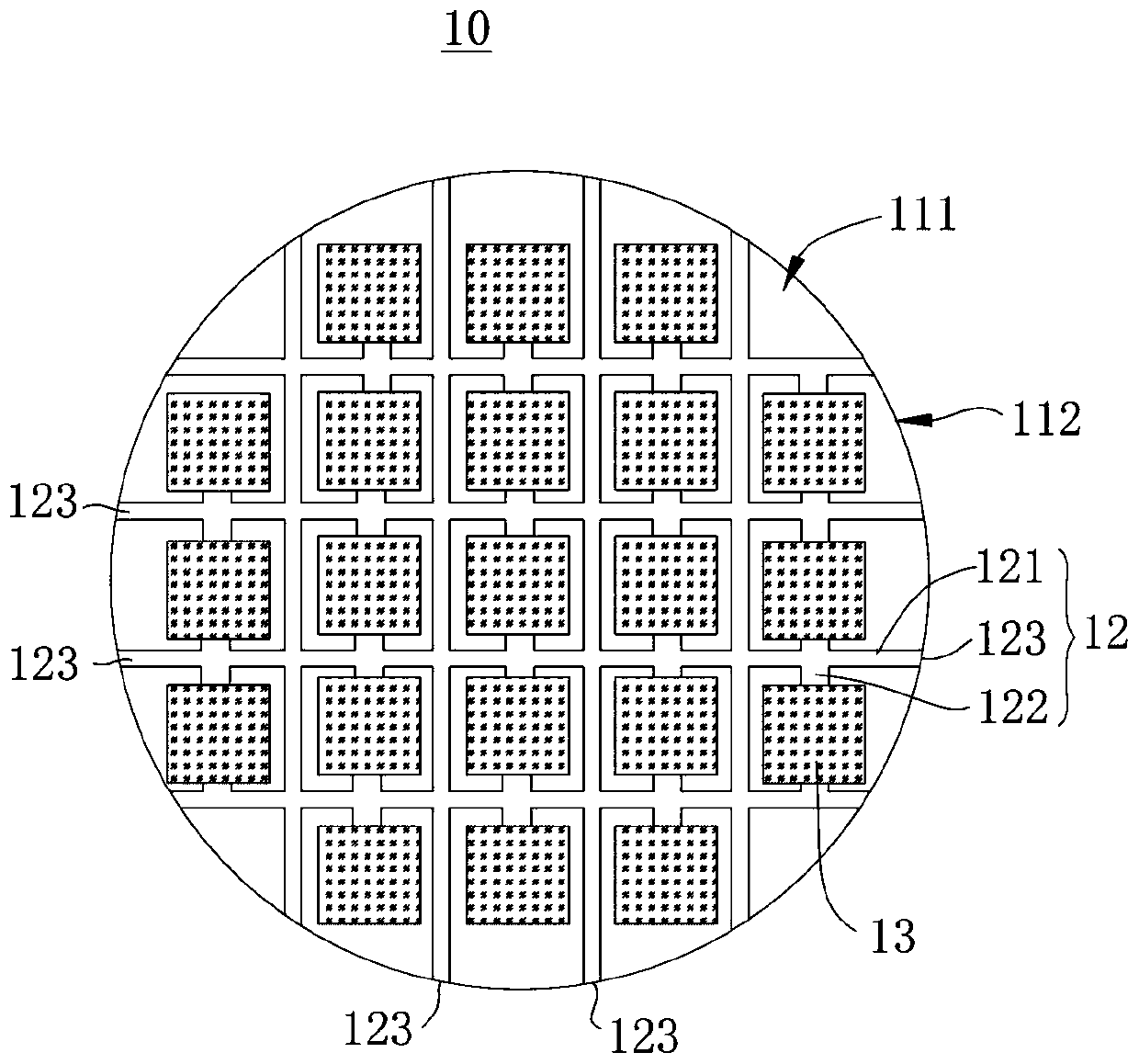

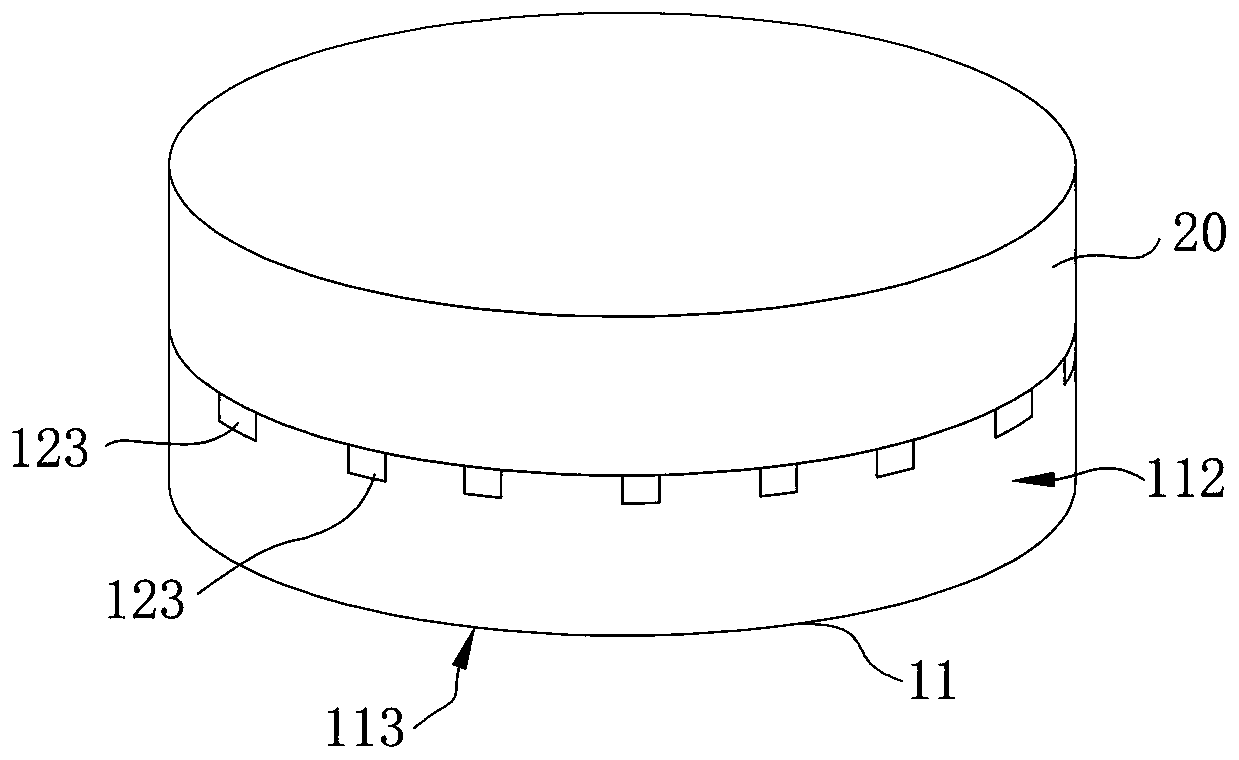

Chip cutting forming method and wafer

ActiveCN111298853AMeet molding requirementsImprove performanceDecorative surface effectsLaboratory glasswaresWaferLiquid state

The invention relates to a chip cutting forming method and a wafer. The chip cutting forming method comprises the following steps that an array substrate is provided and comprises a bottom plate, guide grooves distributed in the bottom plate and a plurality of chip units with hole channels, the guide groove communicates with the hole channels of the chip units, the bottom plate is provided with abottom face spaced from the guide groove and a peripheral face surrounding the bottom face, the guide groove penetrates through the peripheral face and forms an opening and bonds a cover plate on thebottom plate to form a to-be-perfused body together, a filling material in a liquid state is injected into the to-be-filled body from the opening of the guide groove, so that the filling material at least fills the pore channels of the chip units and is cured to form a wafer, and the wafer is cut to form a plurality of cutting bodies, and the filling material of each cutting body is removed to form the chip with the pore channels. According to the chip cutting and forming method and the wafer provided by the embodiment of the invention, the cutting and forming requirements of the chip can be met, chippings can be prevented from entering the pore channels of the chip, and the performance of the chip is ensured.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

Continuous composite molding light photovoltaic module and continuous composite molding equipment thereof

ActiveCN110491961AGuaranteed lamination qualityImprove yield rateFinal product manufacturePhotovoltaic energy generationHoneycombBackplane

The invention discloses a continuous composite molding light photovoltaic module that comprises a photovoltaic laminated piece and a light photovoltaic back plate, wherein the photovoltaic laminated piece comprises a front flexible packaging layer, a battery piece layer and a back flexible packaging layer which are laminated and packaged into a whole; the light photovoltaic back plate at least comprises a thermoplastic core layer and a first thermoplastic substrate layer which are honeycomb-shaped or porous foaming-shaped, and the photovoltaic laminated piece and the light photovoltaic back plate are compounded into a whole through a continuous composite molding process; the invention further discloses continuous composite molding equipment. The module and equipment have the advantages oflight weight, safety, reliability, no frame design, low possibility of dust accumulation, no need of grounding, and flexible and changeable model; the problem of high burst of a traditional double-glass assembly is avoided, the problems of bubbling, degumming, deformation, wriggling and the like cannot occur under the scheme of using the light photovoltaic back plate of an adhesive film layer structure, meanwhile, the limitation of the thickness of the light photovoltaic back plate is avoided, the photovoltaic standard requirement is completely met, and real-scale application and popularization can be achieved.

Owner:SUNMAN (ZHENJIANG) CO LTD

Tea leaf forming machine

InactiveCN103564069AReduce volumeDoes not reduce work efficiencyPre-extraction tea treatmentFailure rateEngineering

The invention mainly relates to the technical field of tea leaf processing machines, and especially relates to a tea leaf forming machine. The tea leaf forming machine comprises a frame, a feeding platform, an upper pressure roller, a lower pressure roller, a baffle plate, a driving device, an adjustment controller and a pressure adjustor. The machine simplifies and reduces the work mechanism, so the overall volume is reduced, and the work efficiency is not reduced; the pressing effect is realized through the extrusion of the pressure rollers to realize tea leaf forming requirements comprising a good press forming effect and a uniformed product shape; the pressing thickness can be flexibly controlled by adjusting the spacing the pressure rollers; and a manual feeding or conveyor belt feeding double mode can be adapted to production requirements under different worker numbers. The forming machine has the advantages of simple structure, flexible use, high production efficiency, low cost and low work failure rate.

Owner:杨成君

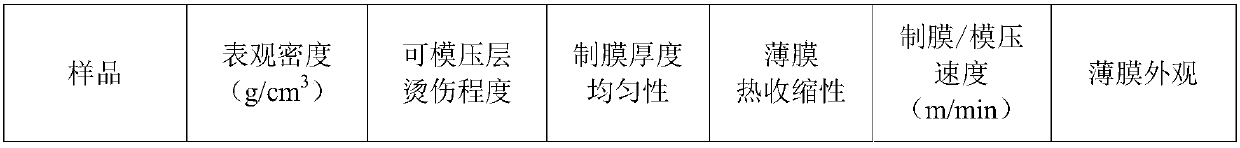

Moldable two-way stretch polypropylene film as well as preparation method and application thereof

ActiveCN109532173AImprove thickness uniformityAvoid burnsLamination ancillary operationsSynthetic resin layered productsSurface layerPolypropylene

The invention discloses a moldable two-way stretch polypropylene film as well as a preparation method and application thereof. The moldable two-way stretch polypropylene film comprises a first moldable layer, a second moldable layer, a polypropylene core layer and a polypropylene surface layer; the moldable two-way stretch polypropylene film is prepared by the first moldable layer, the second moldable layer, the polypropylene core layer and the polypropylene surface layer through a coextrusion two-way stretch process. Compared with a traditional moldable two-way stretch polypropylene film, themoldable two-way stretch polypropylene film has the advantages that the appearance is good, surface scalding cannot be generated in film preparation and laser mold pressing processes, the film preparation and mold pressing speed is higher, the film heat shrinkage is lower, and the thickness uniformity is higher.

Owner:GUANGDONG DECRO PACKAGE FILMS

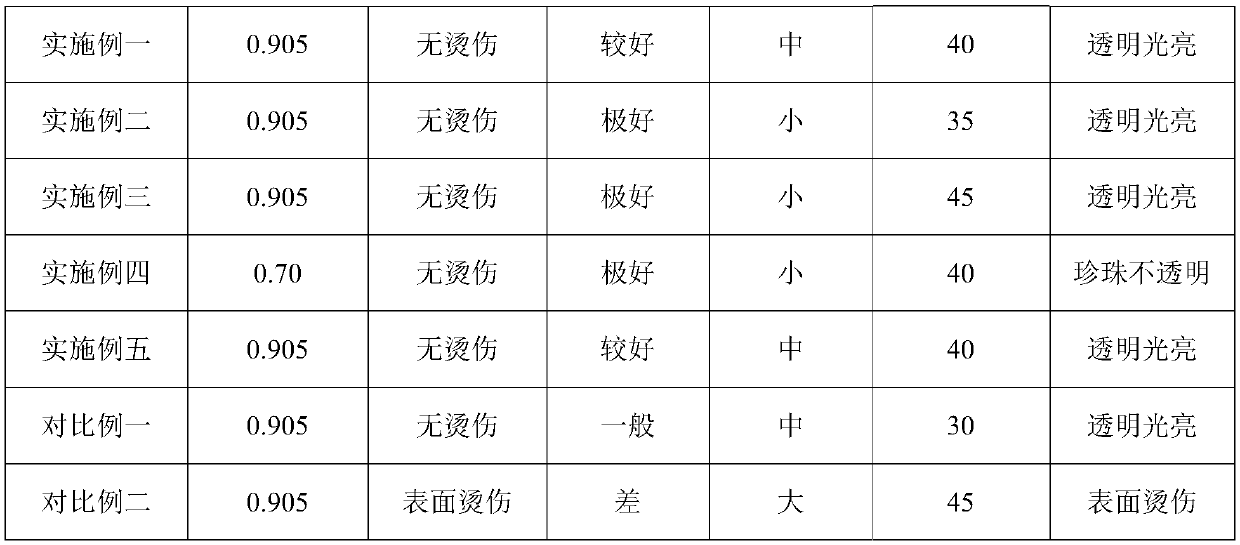

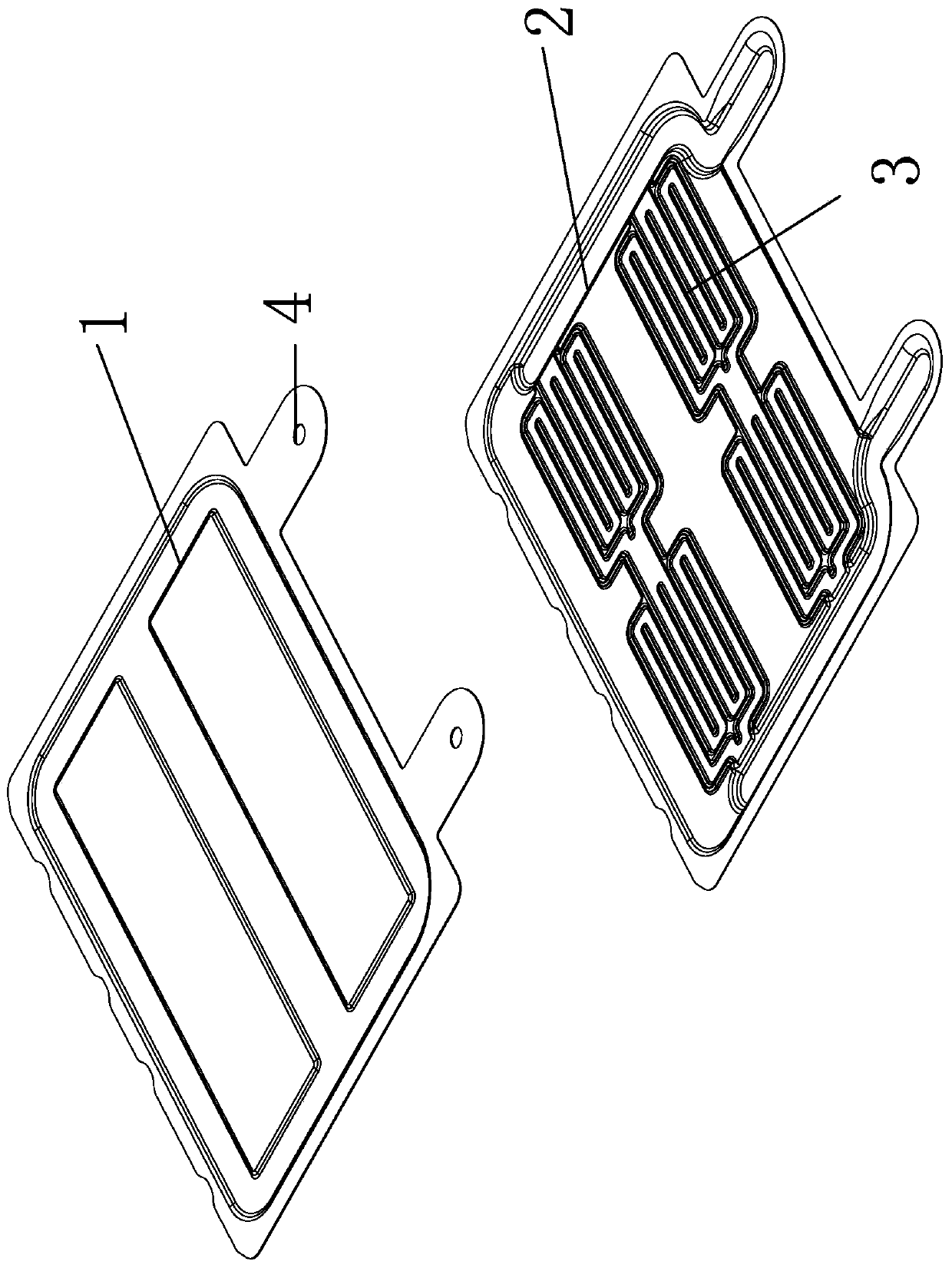

Battery box aluminum alloy blowing expanding type water cooling plate production process

InactiveCN109807247AHigh heat conversion efficiencyExtended service lifeWork treatment devicesSecondary cellsThermoplasticLow speed

The invention belongs to the technical field of new energy batteries and provides a battery box aluminum alloy blowing expanding type water cooling plate production process. A lower-layer aluminum plate is firstly subjected to pre-treatment of grinding, oil removing and the like and then is coated with an isolating agent; after the lower-layer aluminum plate is coated with the isolating agent according to an actual pipeline pattern, silk-screen printing of an upper liquid passing channel is performed; two layers of aluminum plates are fixed together through an edge and corner stamping technology; then, the aluminum plates are placed into a rolling roller to be subjected to hot rolling bonding; and then blowing expanding gas is introduced through a gas blowing hole in the upper-layer aluminum plate, and low-speed thermoplastic blowing expanding forming is performed on the aluminum plate. The battery box aluminum alloy blowing expanding type water cooling plate production process has thebeneficial effects that after rolling bonding of the two layers of aluminum plates for a battery pack of an electric automobile, then a water cooling board manufacturing process through superplasticprocess blowing expanding is performed, an aluminum water cooling board manufactured by depending on an superplasticity forming process can extend uniformly in the wall thickness direction, a very small thickness is achieved, breakage is not caused, and the manufactured water cooling board is high in precision, good in whole forming performance, high in automation degree of production, and capableof meeting the forming requirements of various complicated parts.

Owner:NINGBO XINTAI MACHINERY

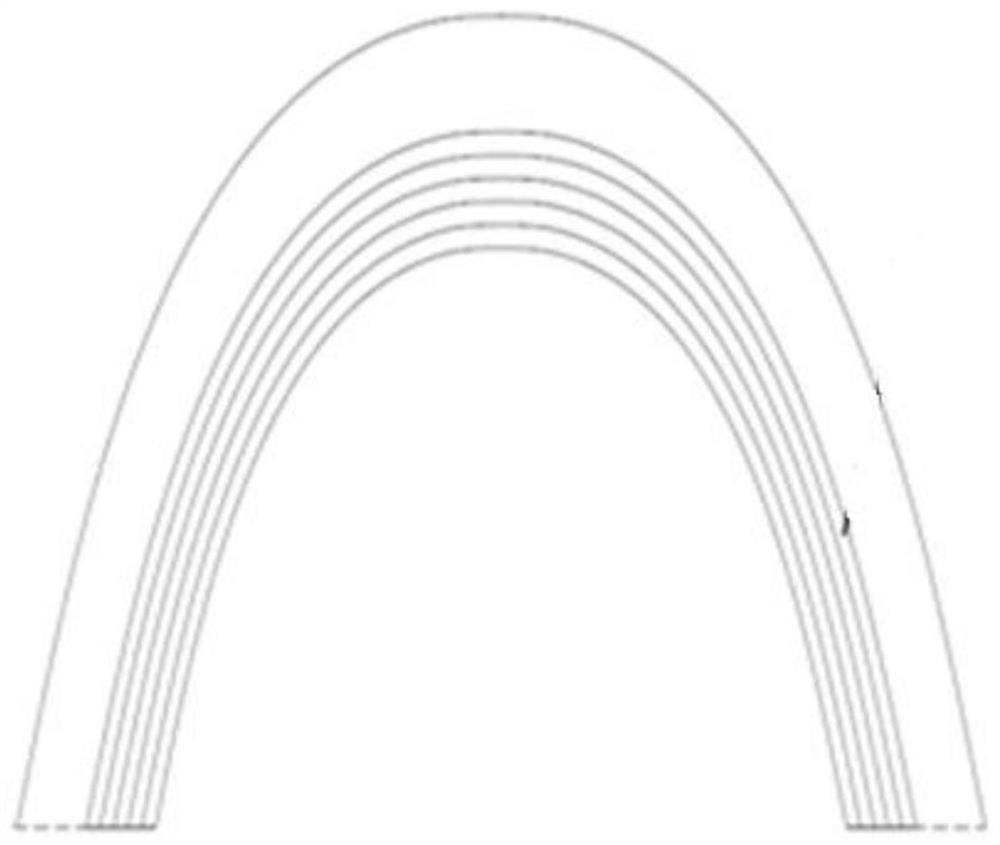

Planar profiling fabric and forming process thereof

ActiveCN111910319AAddress capacity limitationsRealize mechanized productionPattern making devicesMulti-ply fabricsTotal thicknessForming processes

The invention discloses a planar profiling fabric and a forming process thereof. The forming process includes the following steps that 1, the planar profiling fabric is decomposed into fabric bodies of n unit sleeves in the thickness direction, the thicknesses of the n unit sleeves are d1, d2... dn respectively, and the total thickness D of the planar profiling fabric is equal to the sum of d1, d2... dn; 2, plane unfolding and profiling design are carried out on the fabric body of each unit sleeve, and the fabric bodies of the n unit sleeves are woven by adopting a multi-piece forming method;and step 3, the fabric bodies of the n unit sleeves are sequentially arranged outside a core mold in a sleeving manner, and conversion into a three-dimensional form is carried out so as to obtain theplanar profiling fabric. According to the planar profiling fabric and the forming process, a grouped parallel warp arrangement manner and a reciprocating weft insertion manner are adopted, profiling weaving of large-size and large-diameter fabrics can be realized, the problem of equipment capacity limitation is solved, a three-dimensional profile fabric flattening technology is adopted for design,planar profiling weaving is performed in an offline manner, mechanical production can be achieved by means of existing common textile equipment, and the advantages of being efficient and low in costare achieved.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Unsymmetrical-cross section special-shaped line production machining technique for bicycle transmissions

InactiveCN106734272AHigh precisionGood dimensional stabilityDrawing diesEconomic benefitsWork in process

The invention discloses an unsymmetrical-cross section special-shaped line production machining technique for bicycle transmissions. The technique comprises the following steps: (1) materials are selected, wherein a material with the model of SCM415 which is produced abroad is selected as a base material; (2), moulding is performed; a technique combining roller drawing and mould drawing is used; firstly a roller drawing technique is used for producing a semi-product; then a mould drawing technique is used for determining a final finished product; roller drawing speed is controlled to be 0.8-1.2 m / s; and mould drawing speed is controlled to be 1.8-2.4 m / s. After being processed with the technique, the special-shaped line product has higher precision, is good in size stability, and is basically fluctuation-free; the special-shaped line product is good in surface lubrication, so that the moulding requirement of a customer is met, and subsequent machining requirement of the customer is met; and the special-shaped line product is good in linearity and is twisting-free. According to the above indexes, the properties of the product are obviously superior to similar products in a current market; the unsymmetrical-cross section special-shaped line production machining technique can be well applied to the bicycle transmissions, has a good market prospect, and can create considerable economic benefit for a company.

Owner:DONGGUAN KELEE STEEL WIRE

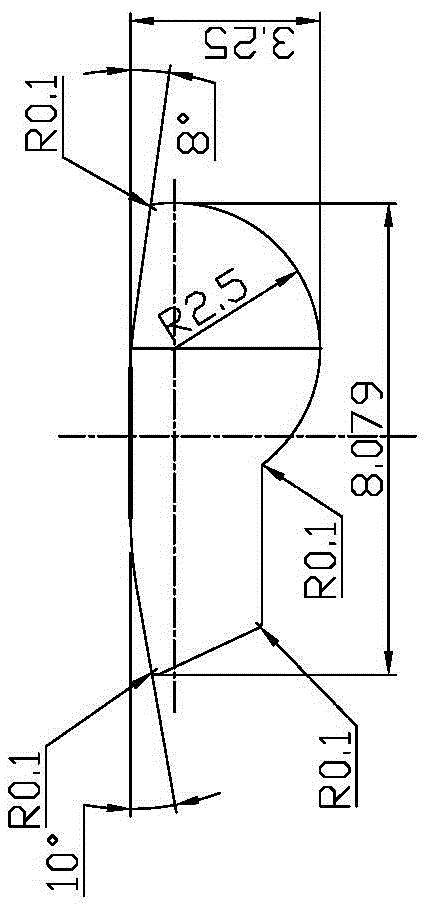

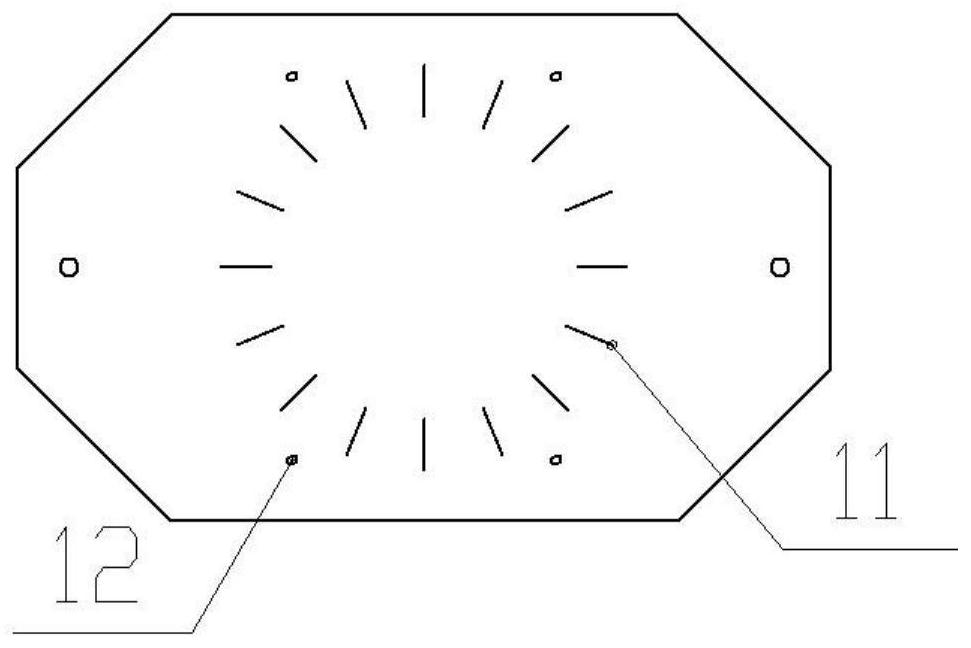

Bending radius-adjustable corrugated steel web mould pressing die

InactiveCN104353714AMeet market requirementsMeet molding requirementsShaping toolsBend radiusStamping press

The invention discloses a bending radius-adjustable corrugated steel web mould pressing die comprising a punching machine head and a base, wherein the punching machine head is connected with a top seat; the base is arranged below the top seat corresponding to the punching machine head; top seat pressing plates are fixed on both sides of the punching machine head on the top seat by bolts; the tail of the punching machine head is welded with the top seat to be fixed and the head is connected with an upper stamping die; the base is provided with a lower stamping die. By adopting the bending radius-adjustable corrugated steel web mould pressing die to carry out mould pressing on a steel plate, groove moulds of the stamping dies can be quickly replaced according to needs, and corrugated steel webs with different thickness ranges can be processed to meet market requirements of products. The stamping dies are arranged in a separated manner, so as to meet the mould pressing requirements of different types of steel plates within the thickness range of (10mm-30mm), the device cost is reduced, operation steps are simplified, the accuracy of manufacture of the products is improved, the production efficiency is improved, large-scale production is facilitated, and competitiveness of business market is strengthened.

Owner:HENAN DAJIAN BRIDGE STEEL STRUCTURE

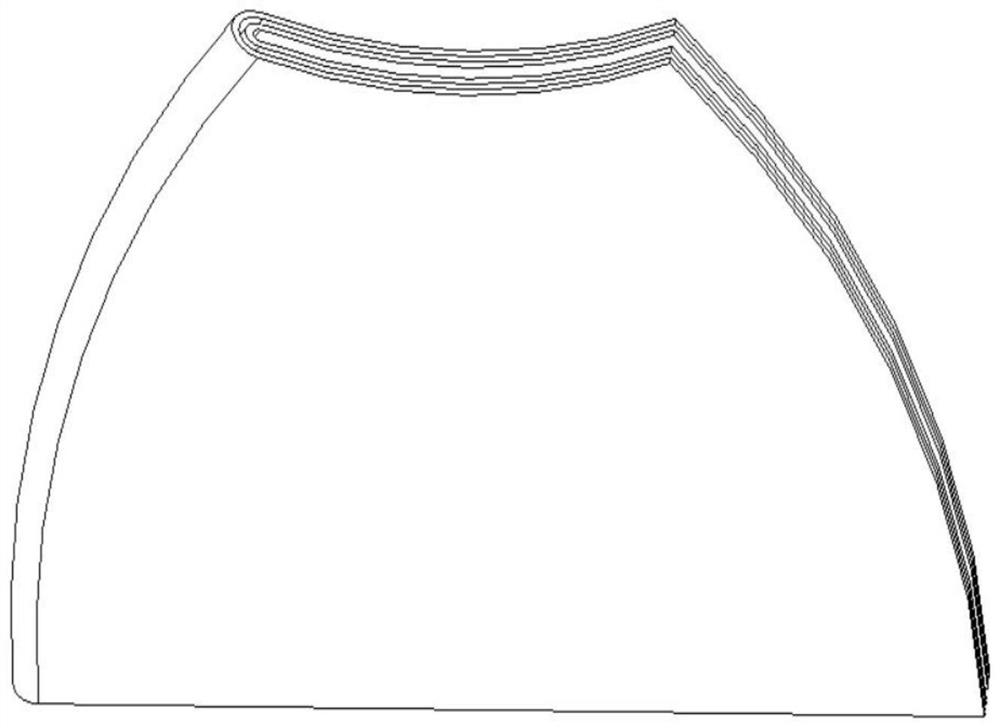

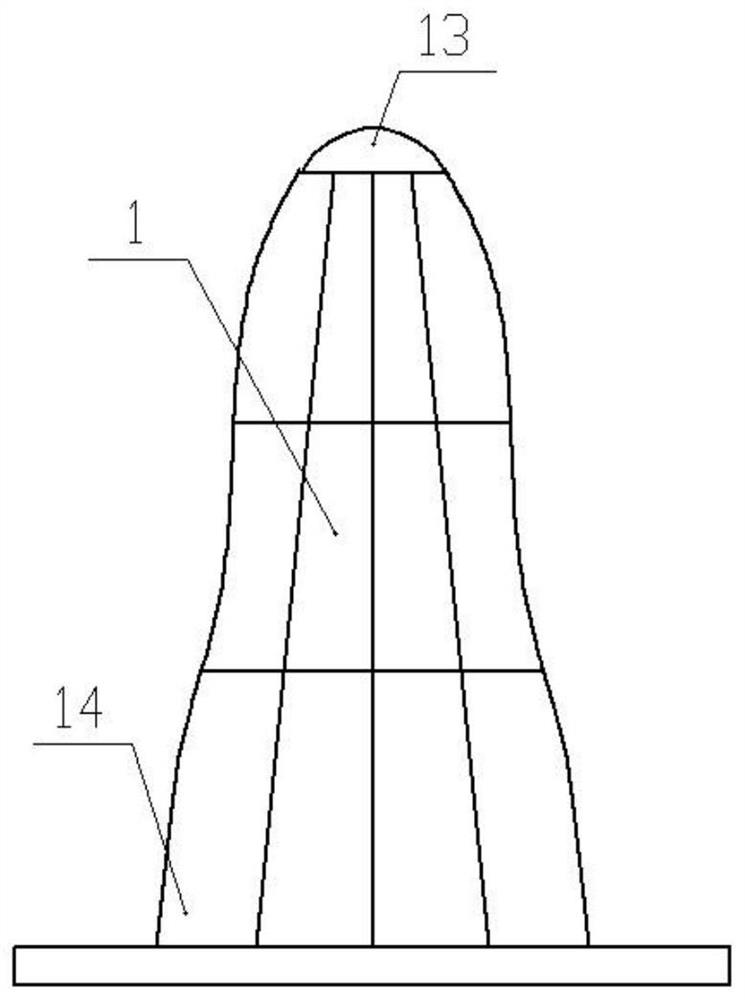

Fabric profiling mold

ActiveCN113715416AReduce weightImprove profilabilitySynthetic resin layered productsNeedling machinesRigid coreEngineering

The invention discloses a fabric profiling mold which comprises an inner-layer rigid core mold (1), an outer-layer flexible cushion layer (2), a middle-layer variable-rigidity cushion layer (3) and a stable base plate (5), the bottom of the inner-layer rigid core mold (1) is fixedly connected with the stable base plate (5), and the middle-layer variable-rigidity cushion layer (3) is arranged between the inner-layer rigid core mold (1) and the outer-layer flexible cushion layer (2). The middle layer variable-rigidity cushion layer adopts a layered design, the rigidity is gradually improved from inside to outside, the rigidity is continuously adjustable within a certain range by adjusting the proportion of middle layer filler, and a heating resistance wire is arranged in the middle layer variable-rigidity cushion layer so that the mold is heated in the preparation process, and it is guaranteed that the fabric forming requirement is met. The mold is high in profiling precision, high in reusability, low in cost and beneficial to improving the working efficiency.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

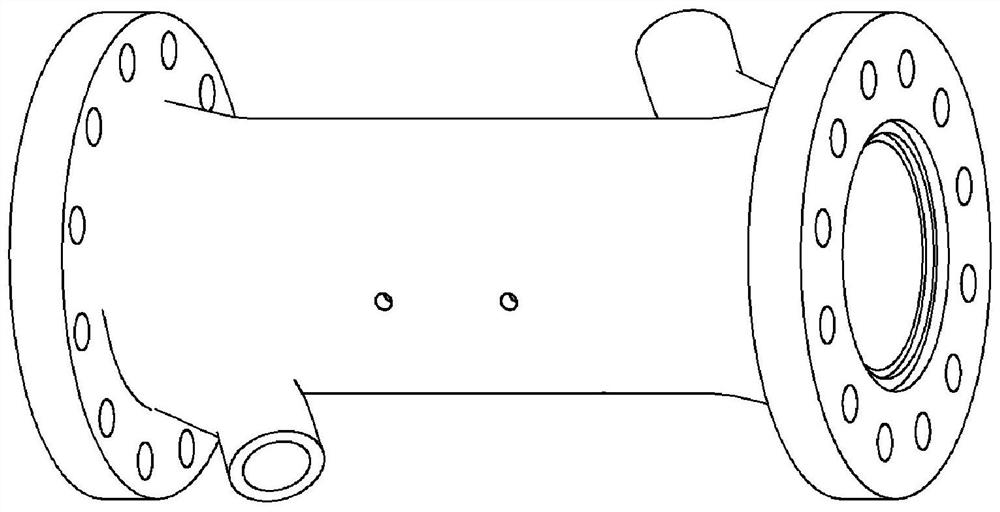

Gas pipeline integrated with cooling channel

ActiveCN112253334AMeet the requirements of one-time moldingSimple processRocket engine plantsButt weldingQuality control

In order to solve the technical problems that an existing gas pipeline with a cooling structure is long in machining period, complex in procedure, high in cost, difficult in quality consistency control and low in integration level, the invention provides a gas pipeline integrated with a cooling channel. The cooling channel is integrated in the side wall of a gas channel, so that the process is simplified, and the integration level of the product is improved. The structure design oriented to a 3D printing process is adopted, a cooling working medium inlet pipe connector, a cooling working medium inlet liquid collecting cavity, a cooling channel and the like and the gas pipeline are integrally designed without supports, the structure can meet the requirement for integral one-time forming ofthe 3D printing technology, and multiple machine frame, brazing, butt welding and other working procedures in traditional process links are not needed. Product machining and turnover periods are greatly shortened, product consistency, connection strength and rigidity are good, quality control is more effective, and development cost is greatly reduced.

Owner:XIAN AEROSPACE PROPULSION INST

Preparation method of lotus leaf tea

InactiveCN107410617AKeep the original fragranceDoes not affect appearance and colorTea substituesWaxCooking & baking

The invention relates to a preparation method of lotus leaf tea. The preparation method comprises the steps of: selecting materials, picking leaves, soaking, steaming, carrying out microwave expansion and quick drying, spreading, twisting and slow-fire baking. The preparation method has the beneficial effects that firstly wax layers on the surfaces of lotus leaves are damaged by steaming, so that the lotus leaves are softened, and the astringency is removed; the lotus leaves are quickly dried by microwave expansion, since the heating speed of the microwave expansion is fast, and the heating time for the lotus leaves is short; the microwave heating is carried out from the inner parts of the lotus leaves, and in the process of drying the lotus leaves, the inner tissues of the lotus leaves are bulky, and simultaneously the toughness of inner fibers of the lotus leaves is maintained, so that the forming requirements of the lotus leaf tea can be met and the quality of the lotus leaf tea is effectively improved.

Owner:HUBEI YOUHUA XUN TEA FLORICULTURE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com