Three-dimensional circuit manufacturing method and modified laser sintering powder materials

A production method, laser sintering technology, applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems that cannot meet the requirements of laser surface activation, integrate SLS technology, and cannot manufacture plastic parts, etc., to meet laser activation and Conductive circuit forming requirements, not limited by shape, and the effect of eliminating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

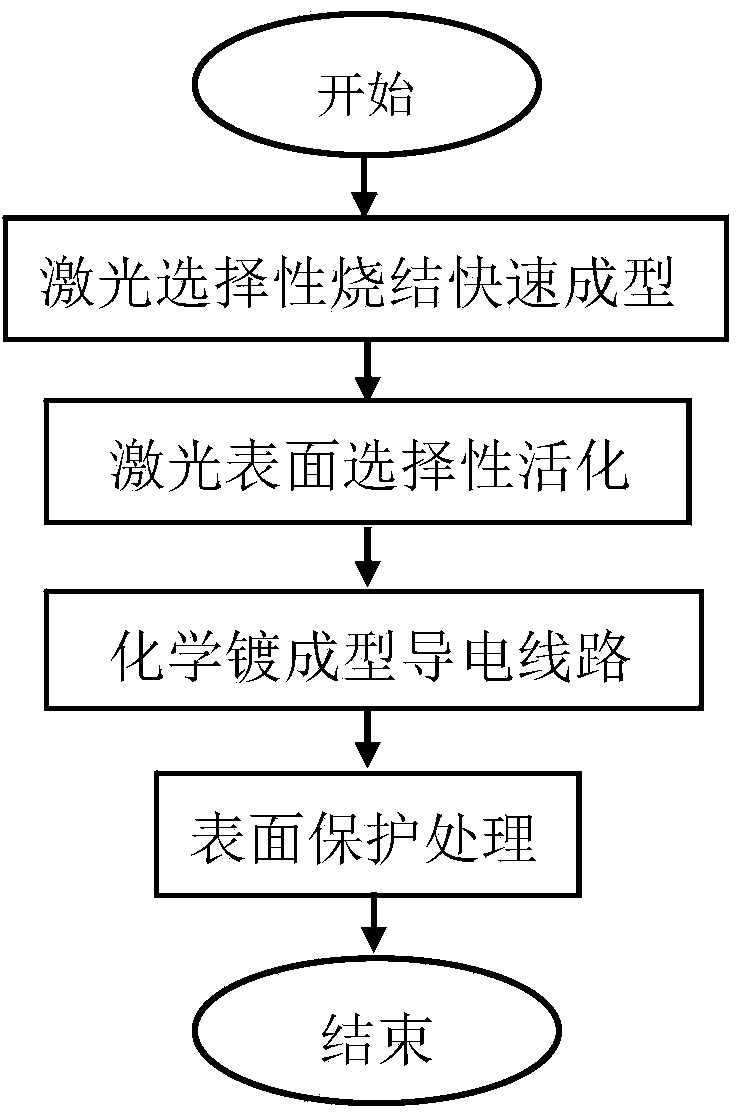

[0029] In some embodiments, a method for manufacturing a three-dimensional circuit is as figure 1 shown, including the following steps.

[0030] step one , Generating prototypes by selective laser sintering (SLS) method.

[0031] The modified SLS powder raw material suitable for laser surface activation is used. The plastic base material can be polyamide (ie nylon). Specifically, nylon base materials commonly used in the market such as PA66 and PA12 can be used. Metal complexes are added to the above base materials. compound, and the metal complex compound is coated with silica. In a preferred embodiment, the total amount of modified SLS powder raw materials is calculated as 100 parts by mass, the plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com