Patents

Literature

41results about How to "Meet conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible material and method of manufacturing the same and use thereof

InactiveCN101108546AImprove corrosion resistanceImprove shielding effectVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceElectricity

The invention provides a soft material and the preparation method and use, which precede ion plating or magnetic control sputtering metal plating to the soft material, then precede vacuum metal steaming plating, the produced soft material product has good adhering capability, the resistance value is between 0.03 to 103 Omega, can ensure the vertical electricity conduction to the air permeability textile fabric. Or precede ion plating or magnetic control sputtering metal plating to the soft material, then proceed copper plating, and proceed vacuum steaming plating metal then. The resistance of the produced soft electricity conduction is between 0.005 to 0.03 Omega, the adhesive force is good, the erosion performance is better, the material shielding performance is larger than 70bB. The soft material can be used print the base material of circuit board , shielding clothes and various packaging material.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

Metallic material having chromate-free-treated surface excellent in corrosion resistance, heat resistance, anti-fingerprint property, conductivity, coating property and black deposit resistance during

ActiveCN101228294AMeet the corrosion resistanceMeet heat resistanceMetallic material coating processesThin material handlingAdditive ingredientMetallic materials

The present invention provides a metal material with a non-chromate surface treatment, which can satisfy the corrosion resistance, heat resistance, fingerprint resistance, electrical conductivity, paintability and processing requirements that were difficult to achieve with the conventional non-chromate technology. Anti-blackening and other properties. The non-chromate surface-treated metal material of the present invention forms a composite film containing various components by applying and drying a water-based metal surface treatment agent on the surface of the metal material. The water-based metal surface treatment agent contains one The organic silane coupling agent (A) of amino group and the silane coupling agent (B) containing 1 glycidyl group in the molecule are mixed according to the ratio of solid content mass ratio [(A) / (B)] of 0.5 to 1.7. A silicon compound (W), at least one fluorine compound (X) selected from titanium hydrofluoride or zirconium hydrofluoride, phosphoric acid (Y) and a vanadium compound (Z).

Owner:NIPPON STEEL CORP

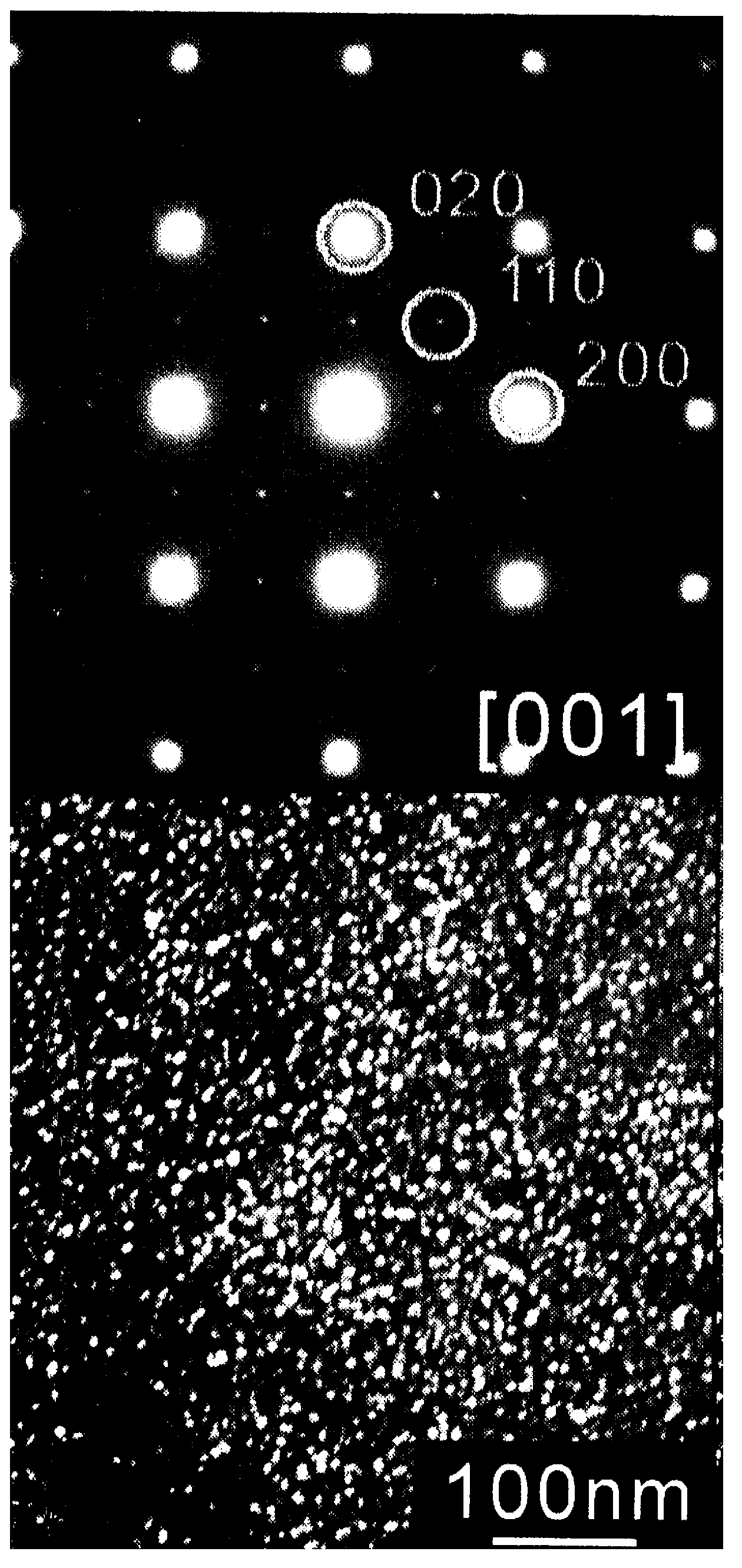

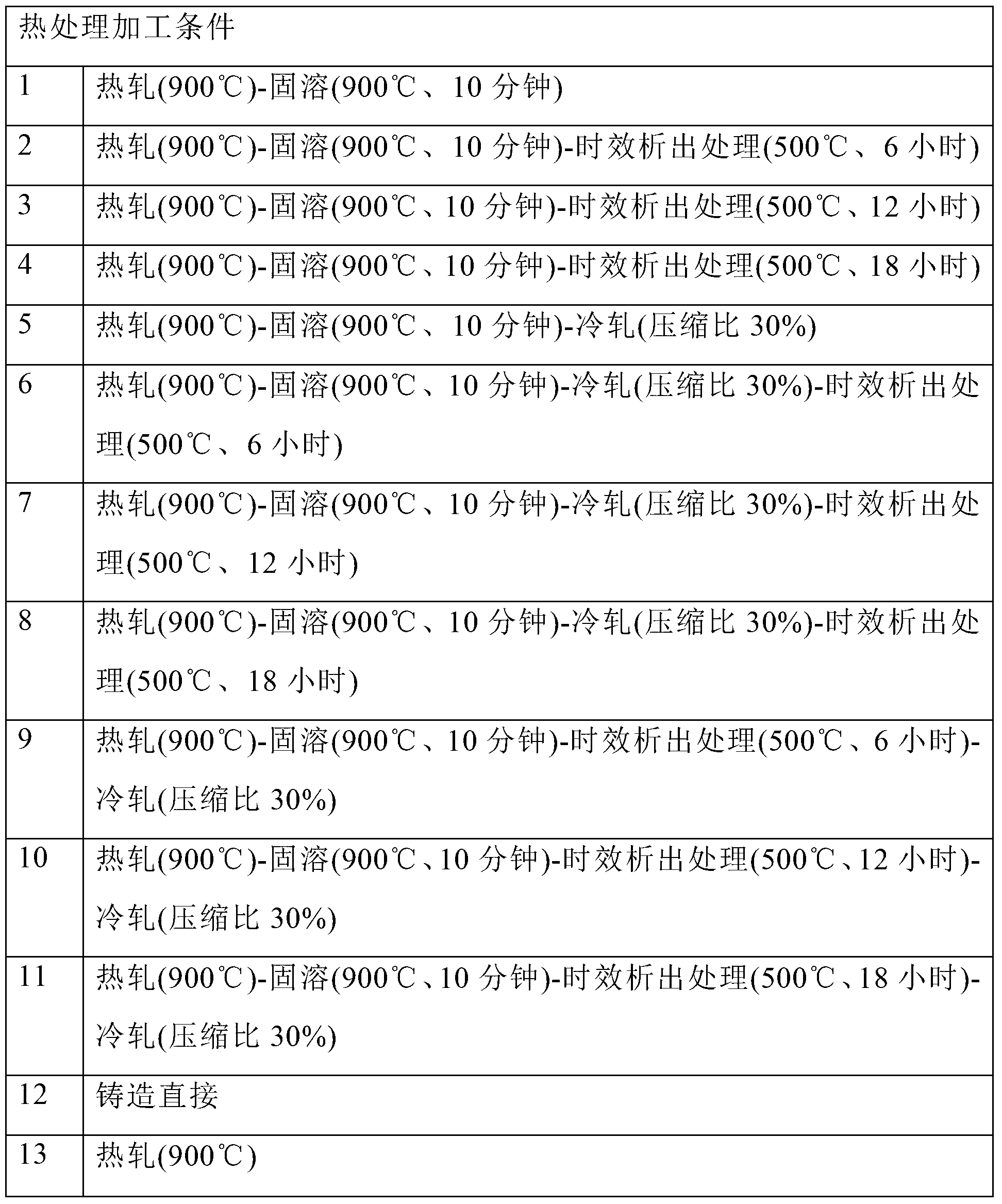

Copper alloy and method for producing copper alloy

ActiveCN103328665AImprove conductivityHigh strengthConductive materialMetal/alloy conductorsMetallurgyMaterials science

Provided is a copper alloy with an FCC structure, said copper alloy containing 3.0 to 29.5 mass% of Ni, 0.5 to 7.0 mass% of Al, and 0.1 to 1.5 mass% of Si, with the remainder comprising Cu and unavoidable impurities. By precipitating, at an average particle size of not more than 100 nm, an Si-containing L12-structured Gamma' phase in the parent phase of the copper alloy, the copper alloy is provided with excellent processability even at high temperatures, and is highly conductive. Furthermore, these characteristics can be controlled.

Owner:NIPPON SEISEN CO LTD +1

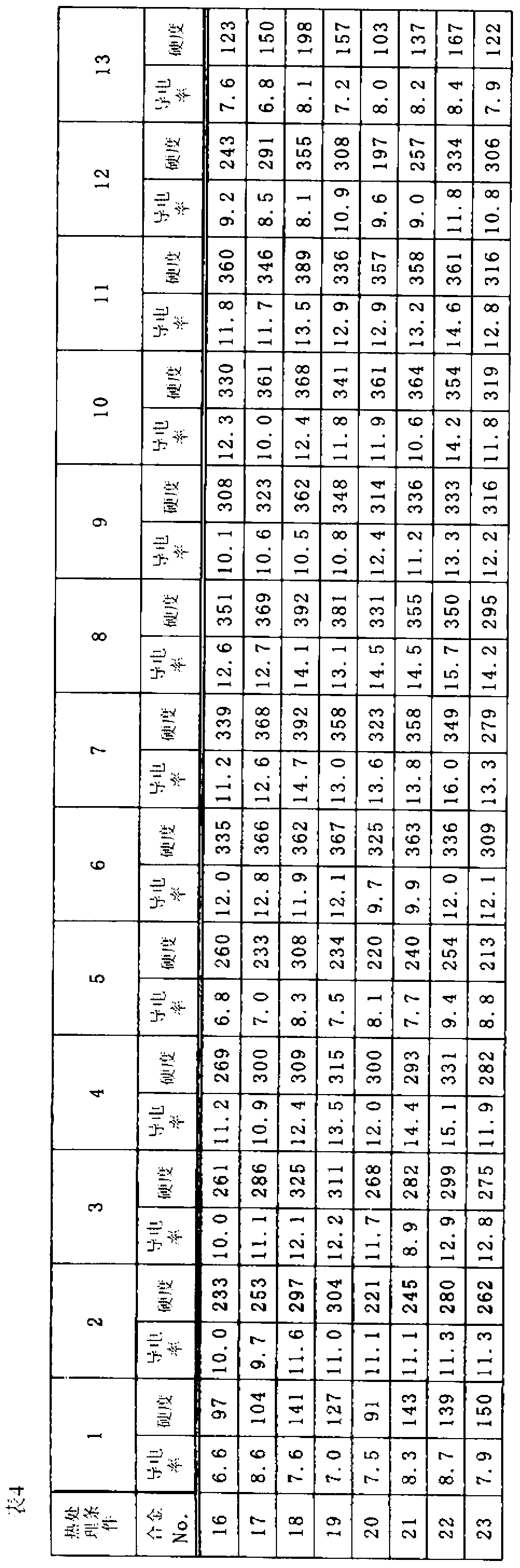

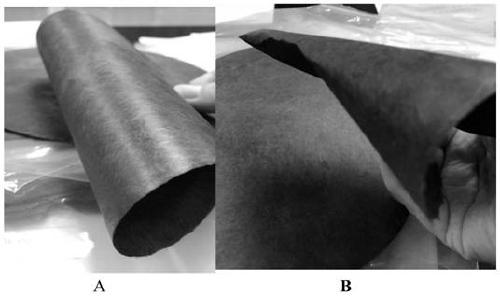

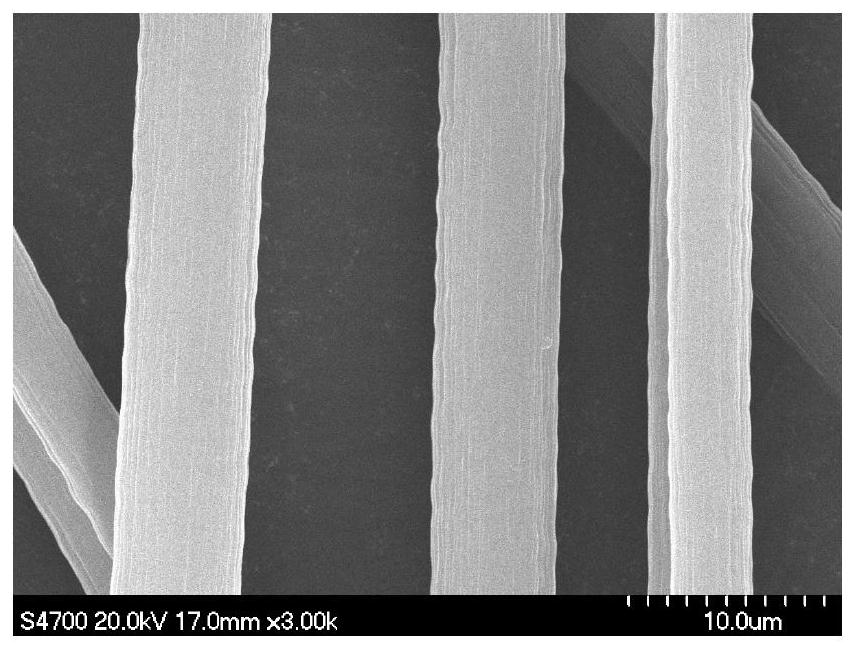

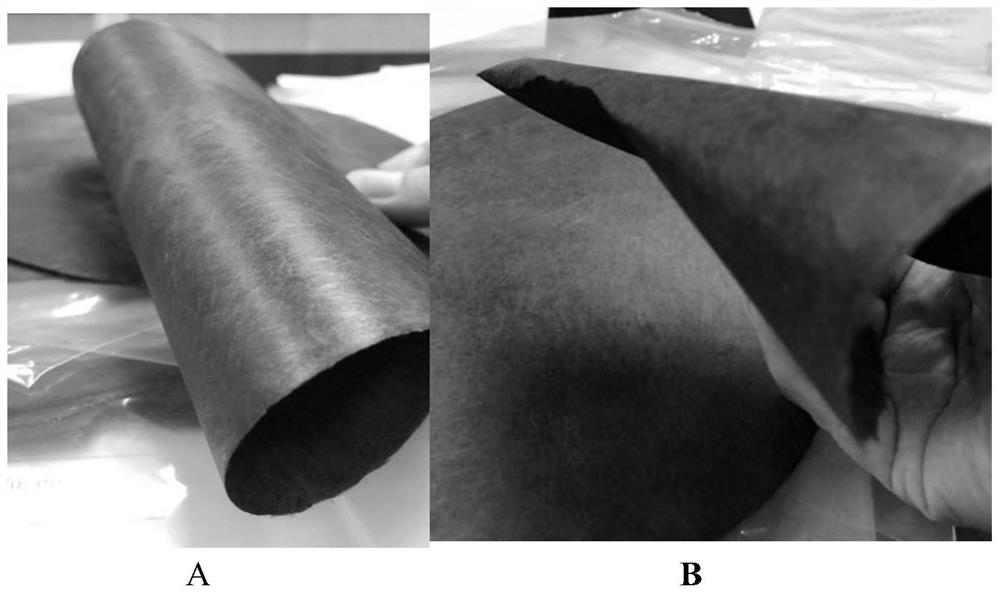

Low-diameter high-strength polyacrylonitrile-based carbon fibers and preparation method thereof

ActiveCN109402792ALow solid contentLow viscositySynthetic cellulose/non-cellulose material pulp/paperMonocomponent synthetic polymer artificial filamentCarbon fibersPolymer science

The invention relates to low-diameter high-strength polyacrylonitrile-based carbon fibers and a preparation method thereof. According to the method, acrylonitrile containing itaconic acid and methyl methacrylate is used as a ternary polymerization system, and an organic diol crosslinking agent is added in a polymerization process for polymerizing, so that a spinning stock solution which has a polymer content of 12.5-17.5% and a viscosity of 120-800 CP is obtained; due to the addition of the crosslinking agent, the spinnability and high drafting of the spinning solution with low polymer contentand low viscosity are improved; then, a wet spinning process is adopted and matched with reasonable solidification conditions and a spinning drafting process, so that low-diameter polyacrylonitrile precursor with surface grooves is prepared; the precursor is pre-oxidized, and is carbonized at a low temperature and a high temperature, so as to obtain the monofilament which has the equivalent diameter of 2-3 mum, the tensile strength of more than or equal to 3.5 GPa, and the tensile modulus of more than or equal to 230 Gpa; therefore, the low-diameter and high-strength polyacrylonitrile-based carbon fibers with a regular surface groove structure are obtained. The carbon fiber obtained by method can improve the flexibility of carbon fiber paper for fuel cells.

Owner:BEIJING UNIV OF CHEM TECH

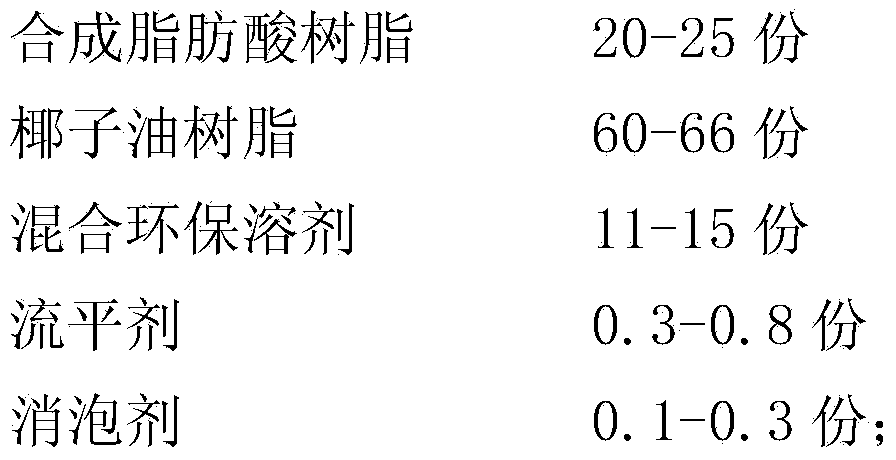

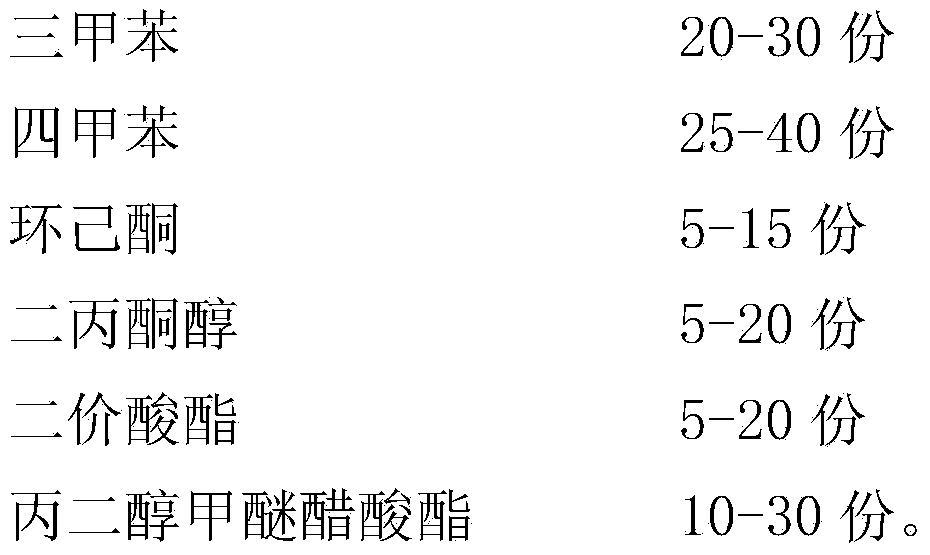

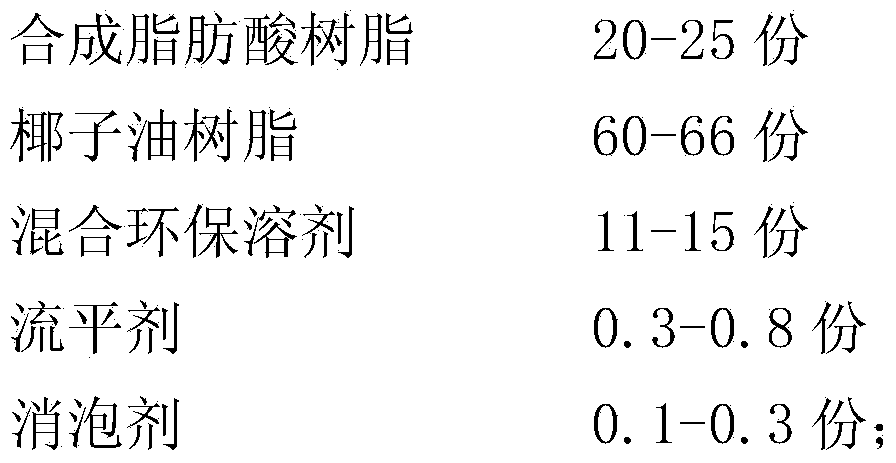

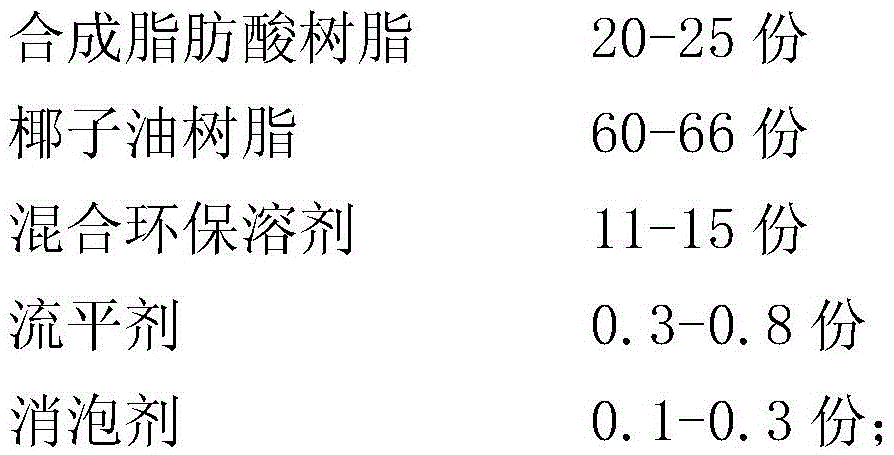

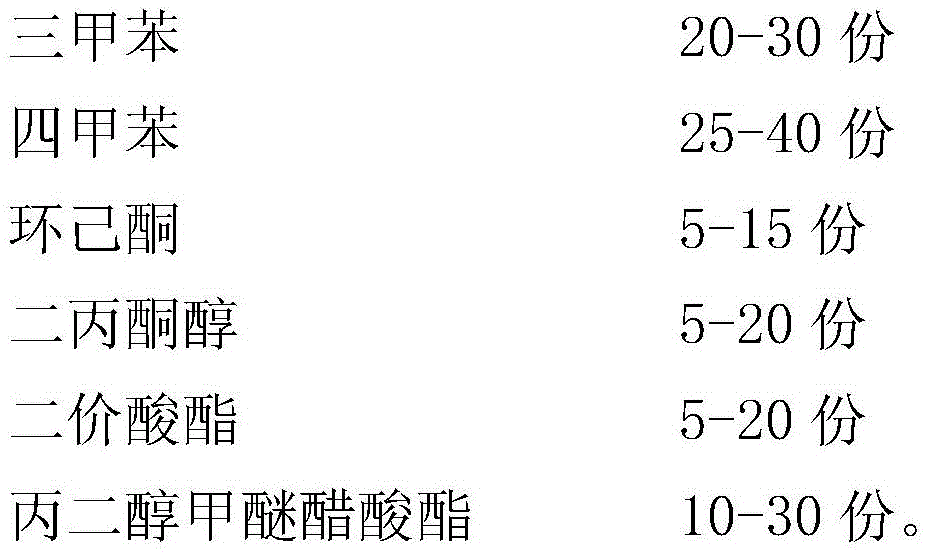

Polishable bright varnish for electrostatic spraying and preparation method thereof

The invention relates to a polishable bright varnish for electrostatic spraying and a preparation method thereof. The bright varnish is prepared from a main agent, a curing agent and a diluter in a ratio of (1-1.2):(0.8-1):(0.5-0.7), wherein the main agent is prepared from the following components in parts by weight: 20-25 parts of synthetic fatty acid, 60-66 parts of coconut oil, 11-15 parts of mixed environment-friendly solvent, 0.3-0.8 part of leveling agent and 0.1-0.3 part of defoaming agent; and the curing agent is an isocyanate curing agent. The polishable bright varnish for electrostatic spraying can be used for electrostatic spraying, and the coated film has the advantages of favorable leveling property and high hardness and is polishable.

Owner:SKSHU PAINT

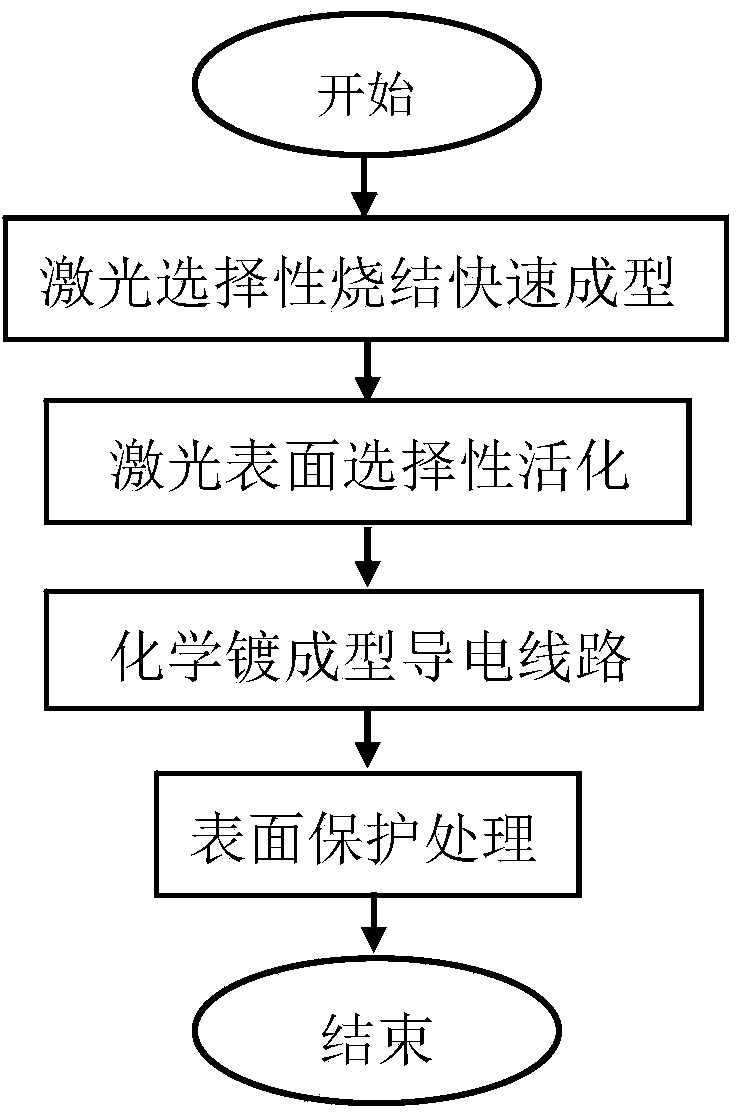

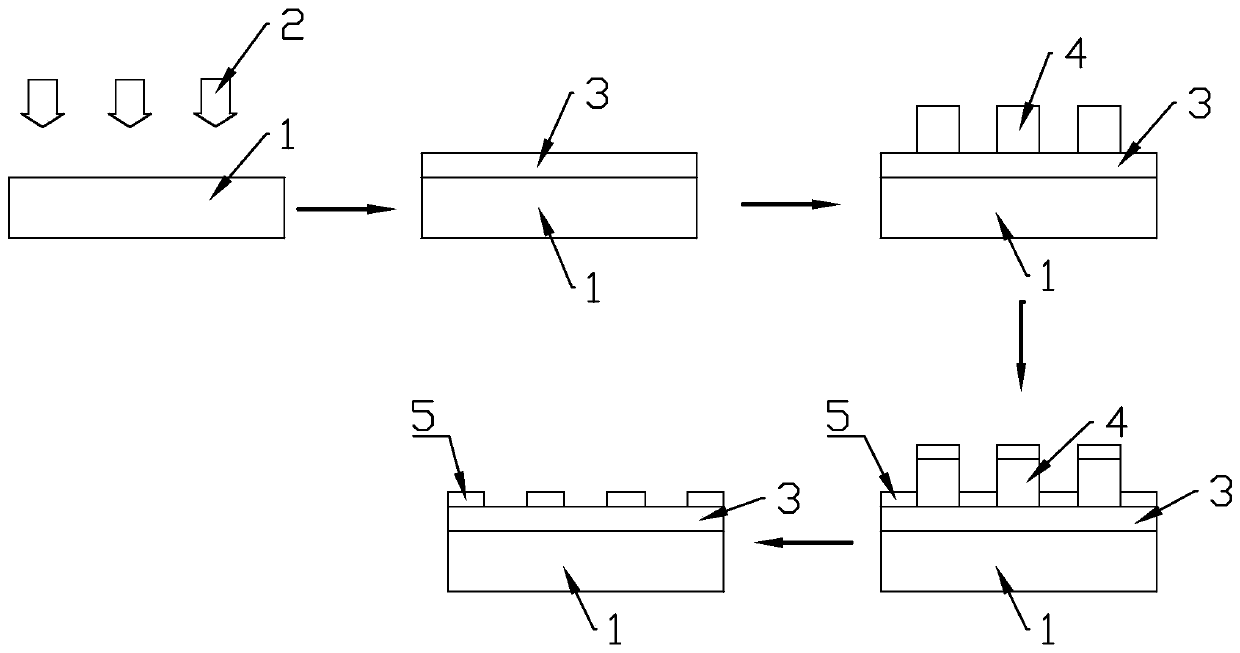

Three-dimensional circuit manufacturing method and modified laser sintering powder materials

ActiveCN104244588AFast preparationRapid Surface MetallizationConductive pattern formationSelective laser sinteringChemical plating

The invention discloses a three-dimensional circuit manufacturing method. The method comprises the steps that a prototype model is generated through a selective laser sintering method, wherein modified laser sintering powder materials comprising components suitable for laser surface activation are used as the raw materials for the prototype model; preset selective scanning is carried out on the surface of the prototype model through laser, so that a surface activation area is formed; a conductive circuit is formed in the surface activation area through chemical plating. The invention further discloses the modified laser sintering powder materials used for the three-dimensional circuit manufacturing method. According to the three-dimensional circuit manufacturing method and the modified laser sintering powder materials, the limitation brought by traditional SLS processing materials on the application is overcome, meanwhile, a matrix with the complex surface is formed, and the requirements for rapid manufacturing and forming of the conductive circuit and laser activation are effectively met.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

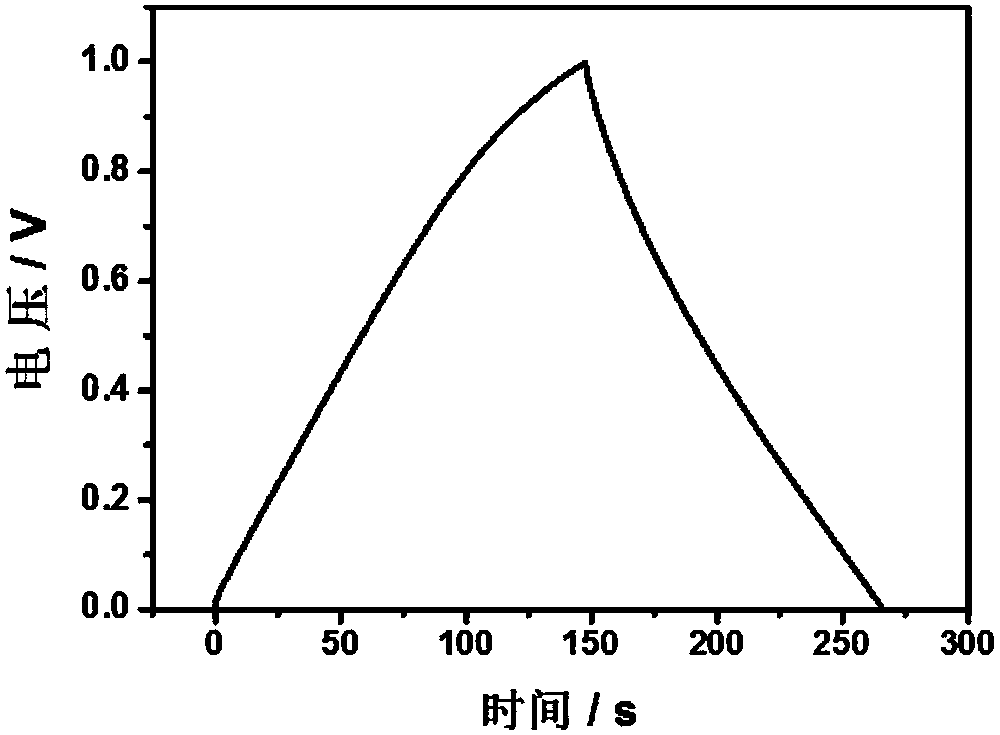

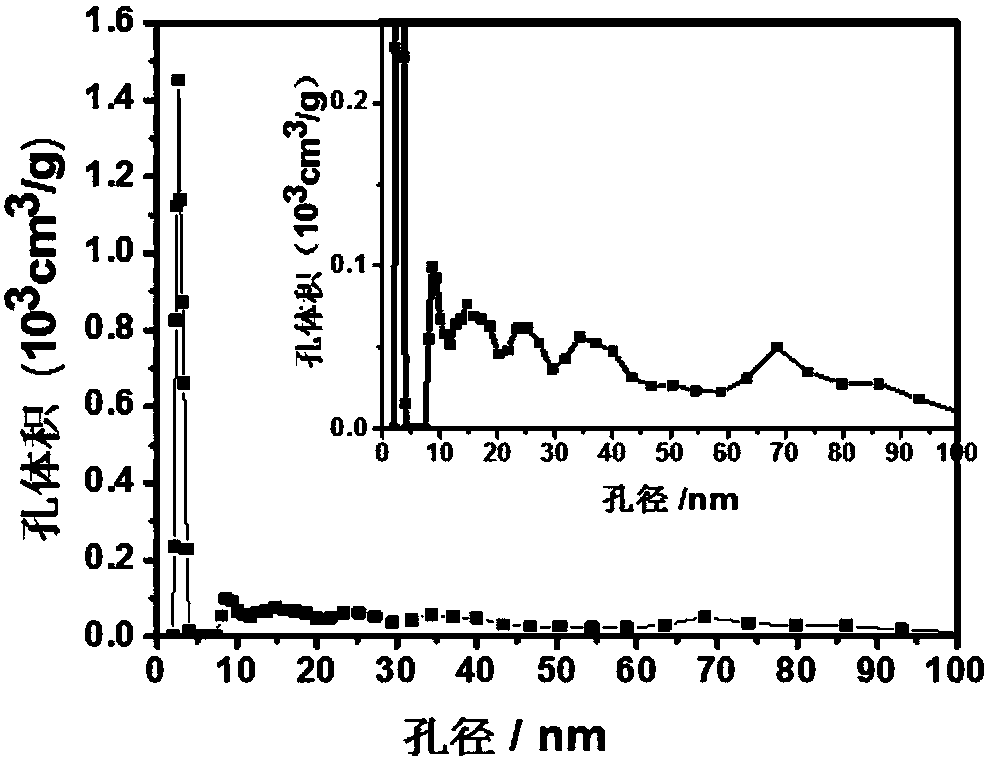

Graphene-asphalt based active carbon as well as preparation method and application thereof

ActiveCN108264046AGood electrical conductivityMeet conductivityHybrid capacitor electrodesGrapheneActive carbonAsphalt

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

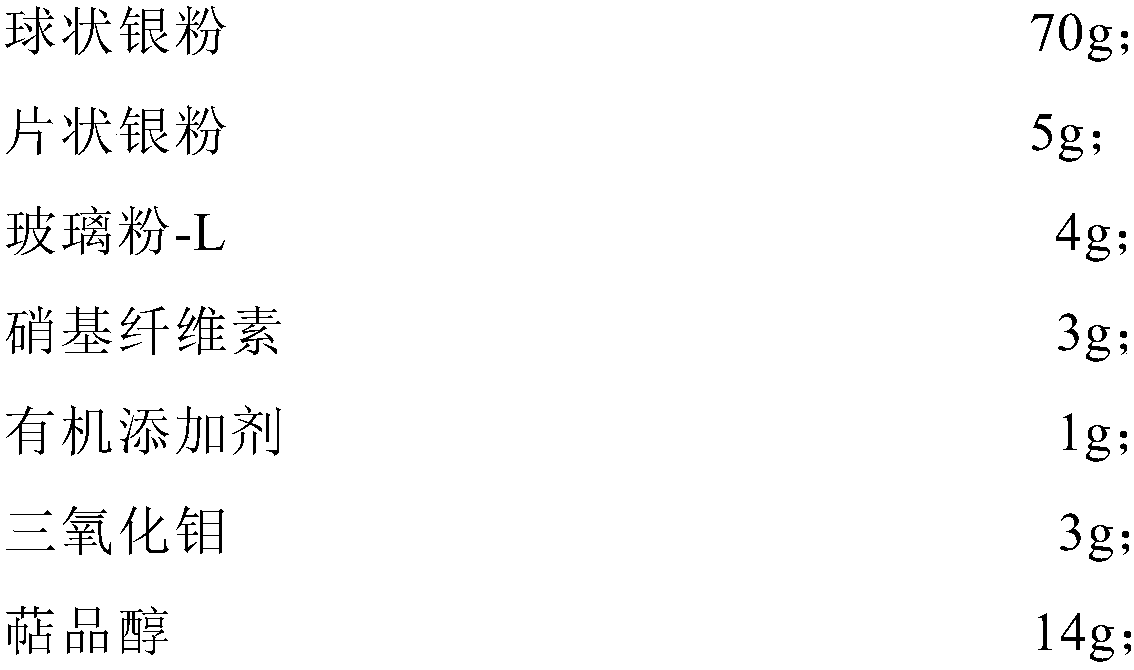

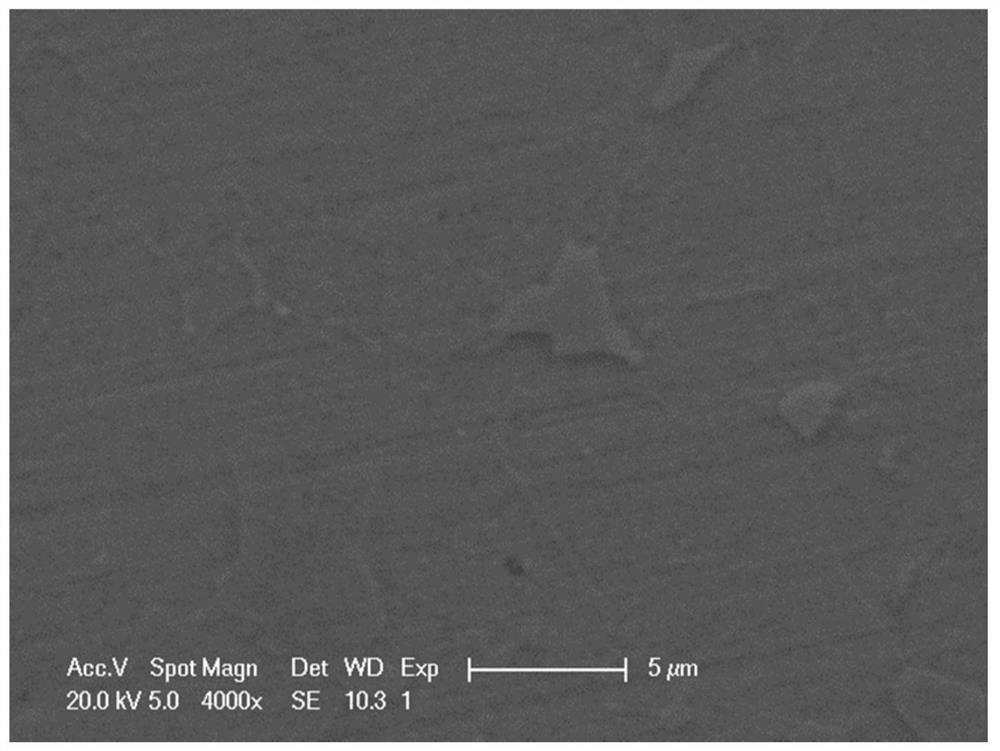

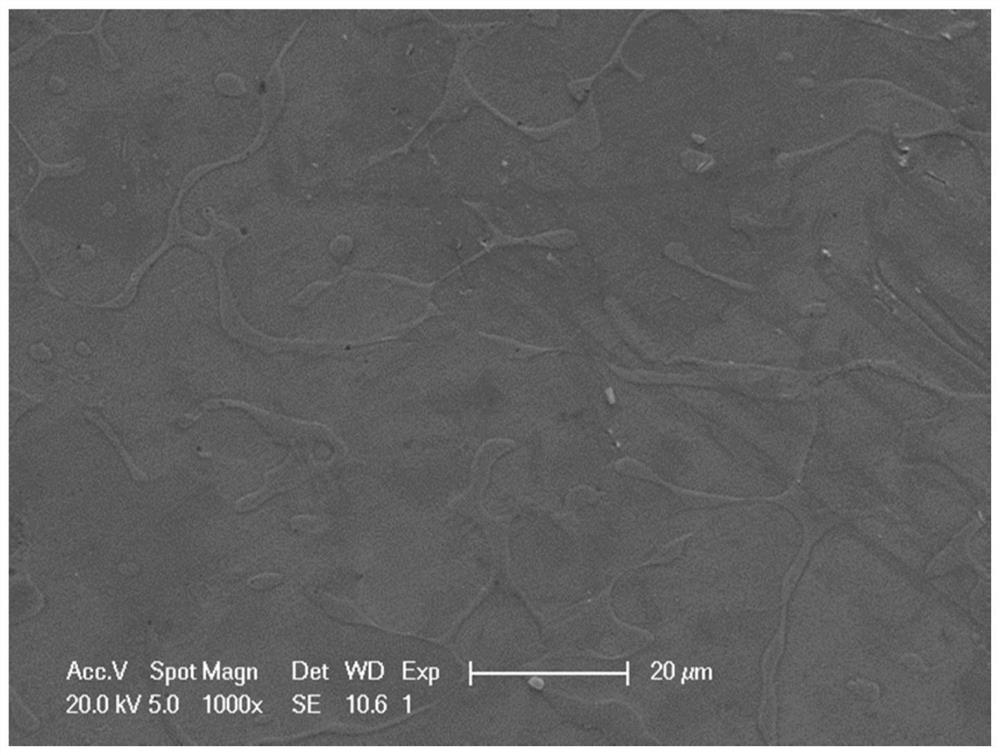

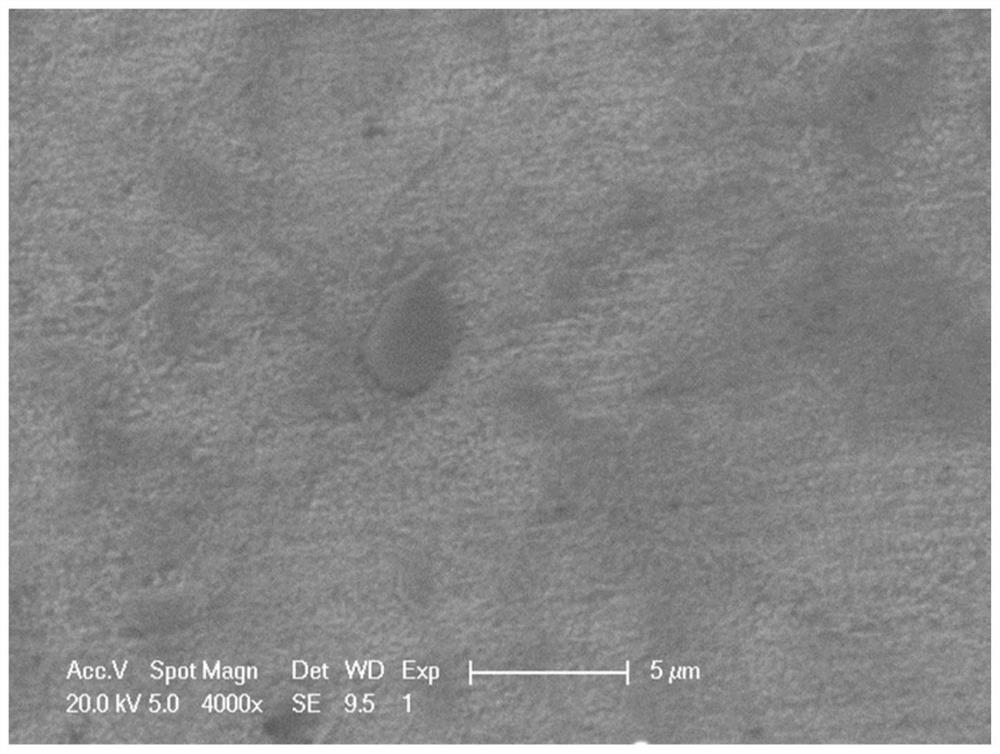

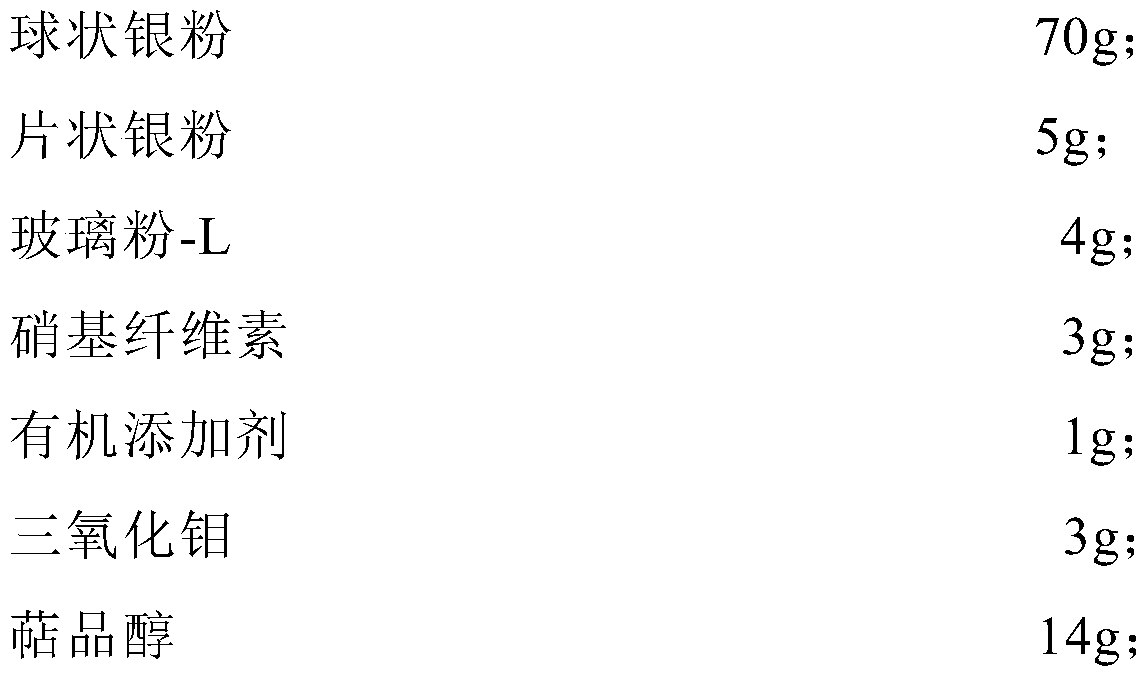

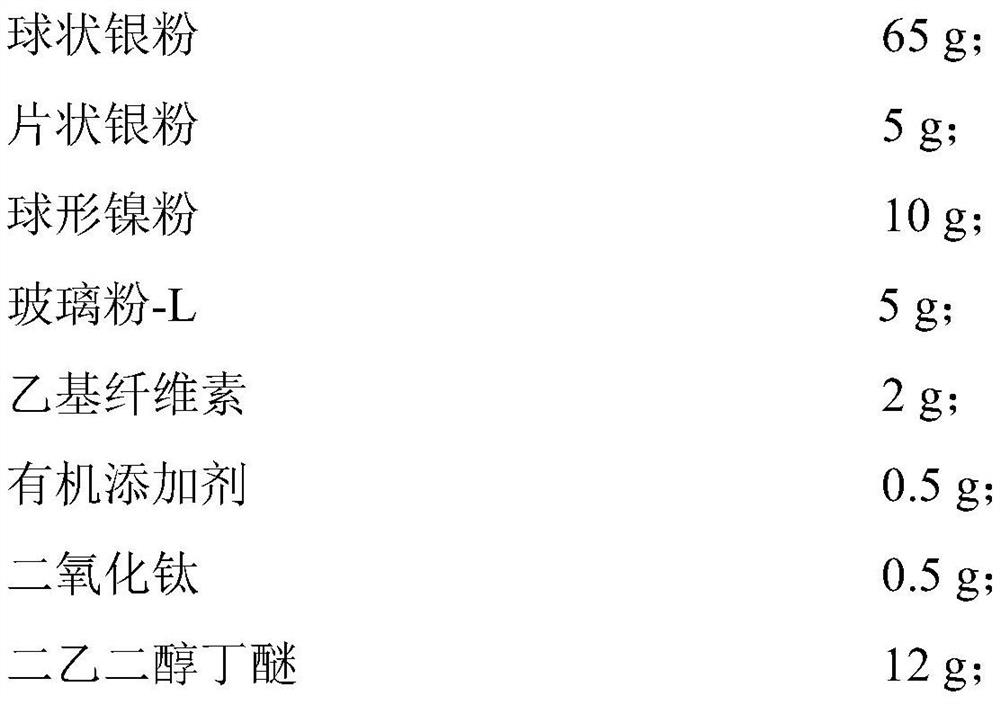

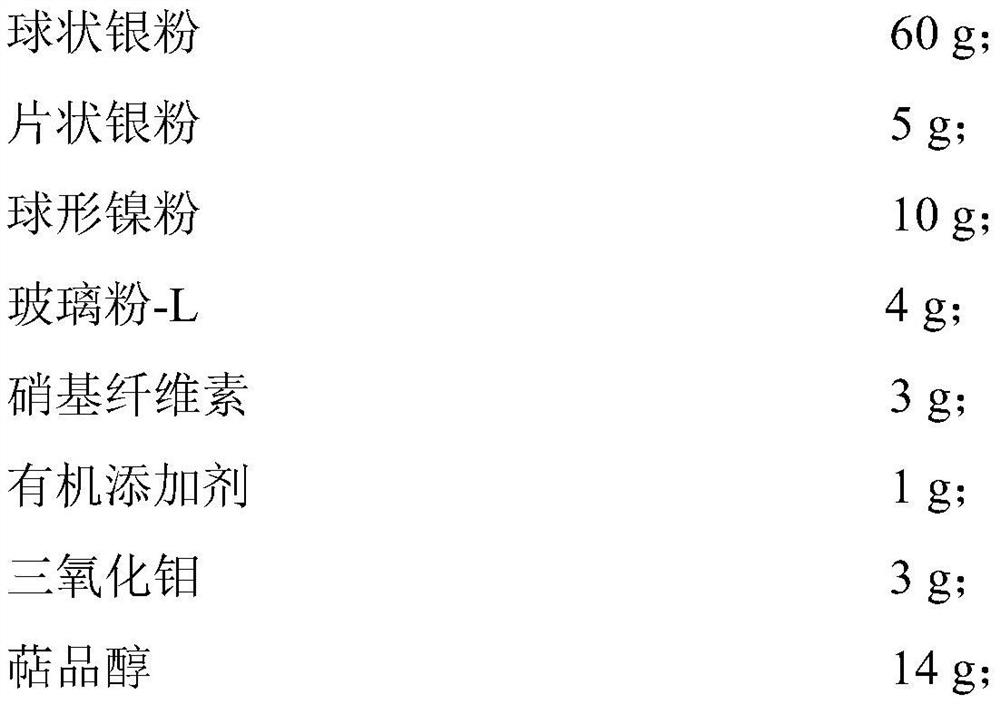

Anti-oxidation silver paste for car windshield glass and preparation method thereof

ActiveCN109785991AMeet conductivityMeet adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMaterials preparation

The invention relates to an anti-oxidation silver paste for car windshield glass and a preparation method thereof. A raw material adopts following components and weight percentage contents: 60-80% ofmetal silver powder; 3-6% of glass powder; 2-8% of polymer resin; 0.5-1.5% of organic additive; 0.5-4.5% of inorganic additive; and 10-30% of organic solvent. The anti-oxidation silver paste for the car windshield glass is obtained through steps of material preparation, preparation of a carrier, preparation of the silver paste, and production of the silver paste. Compared with the prior art, according to the prepared product, the requirement of technical indexes including conductivity, adhesion, the tin surface color and the matching property with black glaze can be satisfied, and the productalso has the advantage of anti-oxidation performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Copper-iron alloy material and preparation method and application thereof

The invention provides a copper-iron alloy material and a preparation method and application thereof. The copper-iron alloy material comprises, by weight, 5-20wt. % of iron, 0.002-0.05wt.% of RE and the balance copper. The copper-iron alloy material is easy to operate, the smelting temperature is greatly reduced, the smelting temperature in a crucible furnace is 1200-1250 DEG C, and compared withthe temperature of 1600 DEG C or above in a traditional method, energy consumption can be reduced; a vacuum smelting technology is adopted, oxidation in the high-temperature process can be avoided, the high purity of the material is guaranteed, and the oxygen element content can be lower than 150ppm; and the vacuum smelting technology is adopted, subsequent cold drawing deformation is combined, the structure components of a copper-iron alloy wire are uniform, the ductility of the copper-iron alloy wire can reach 24% or above, the wire breaking problem in electromagnetic shielding wire preparation can be reduced, the yield is increased, and the performance requirements for electric conduction and magnetic shielding of the electromagnetic shielding material can be met.

Owner:SOUTHEAST UNIV

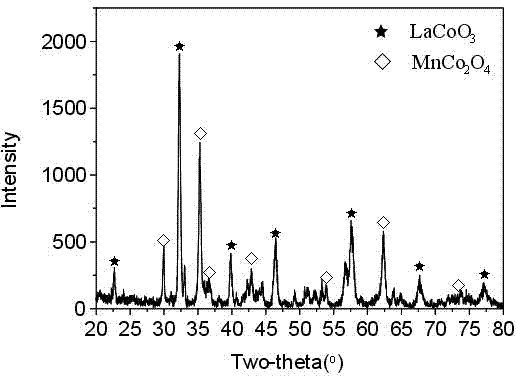

Preparation method of rare earth modified spinel coating

ActiveCN103695902ASolve the problem of weak bondingImprove corrosion resistanceMetallic material coating processesThermal dilatationManganese

The invention belongs to the field of metal surface modification, and particularly relates to a preparation method of a rare earth modified spinel coating. The preparation method specifically comprises the following steps: uniformly mixing cobalt powder, manganese dioxide powder and lanthanum oxide powder in proportion; preparing an electrode material by adopting a hot-pressing sintering method; then, depositing the electrode material on the surface of stainless steel by adopting a high-energy micro-arc alloying method under inert gas shielding to prepare a cobalt-based compound oxide coating which has good conductivity; and further placing the coating in an air or oxygen environment to heat and preoxidize to prepare a cobalt manganese spinel and lanthanum cobaltate compounded oxide coating. The cobalt manganese spinel and lanthanum cobaltate compounded oxide coating prepared by the process has good high temperature antioxidant and conductive performances, overcomes the problem that the prior spinel coating and metal interfaces are insecure to bind, and the coating is low in compactness and different in coefficient of thermal expansion and the like, and can satisfy the demands of anti-oxidation, conductivity, anti-Cr volatilization and the like on a ferritic stainless steel connector.

Owner:南通东湖国际商务服务有限公司

Refractory metal or stainless steel with electroplating layer on surface and refractory metal or stainless steel surface electroplating process

The invention provides a kind of refractory metal or stainless steel with an electroplating layer on the surface. The refractory metal or the stainless steel comprises a base material and the electroplating layer formed on the surface of the base material. The base material comprises a refractory metal base material or a stainless steel base material, wherein the refractory metal base material ismade of titanium, or tantalum, or niobium, or other alloy; the electroplating layer comprises a rhodium-ruthenium alloy layer. The electroplating layer has good adhesive force, corrosion resistance and weldability, the welding capability of a refractory metal product is improved, and the refractory metal or the stainless steel is beneficial to industrial application. The invention further providesa refractory metal or stainless steel surface electroplating process.

Owner:RAMBO TECH SHENZHEN LTD +1

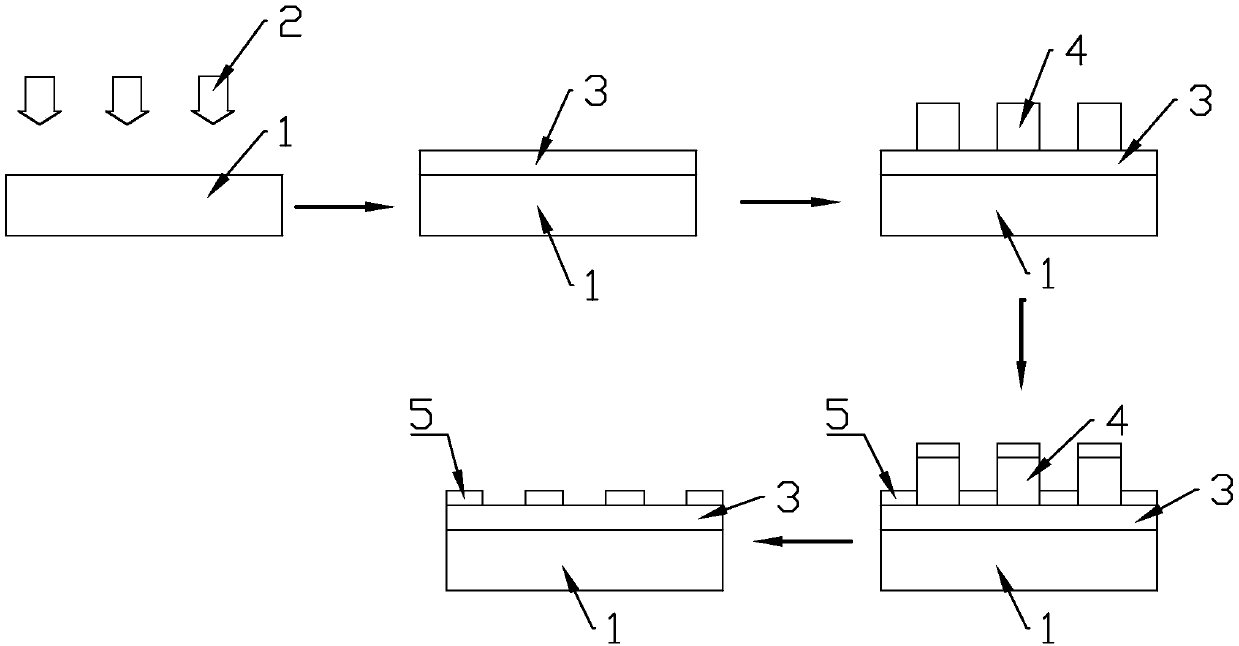

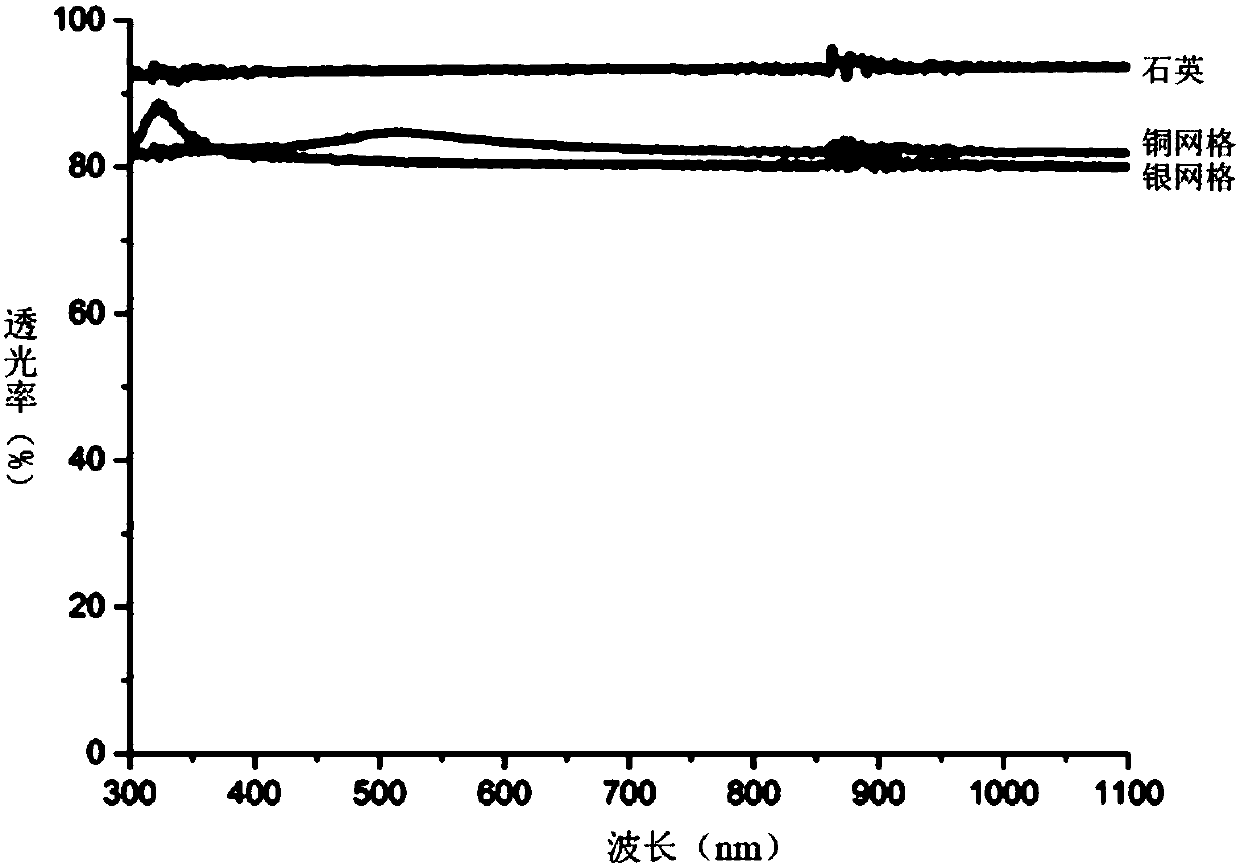

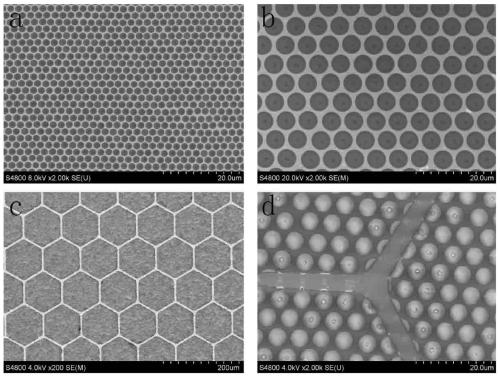

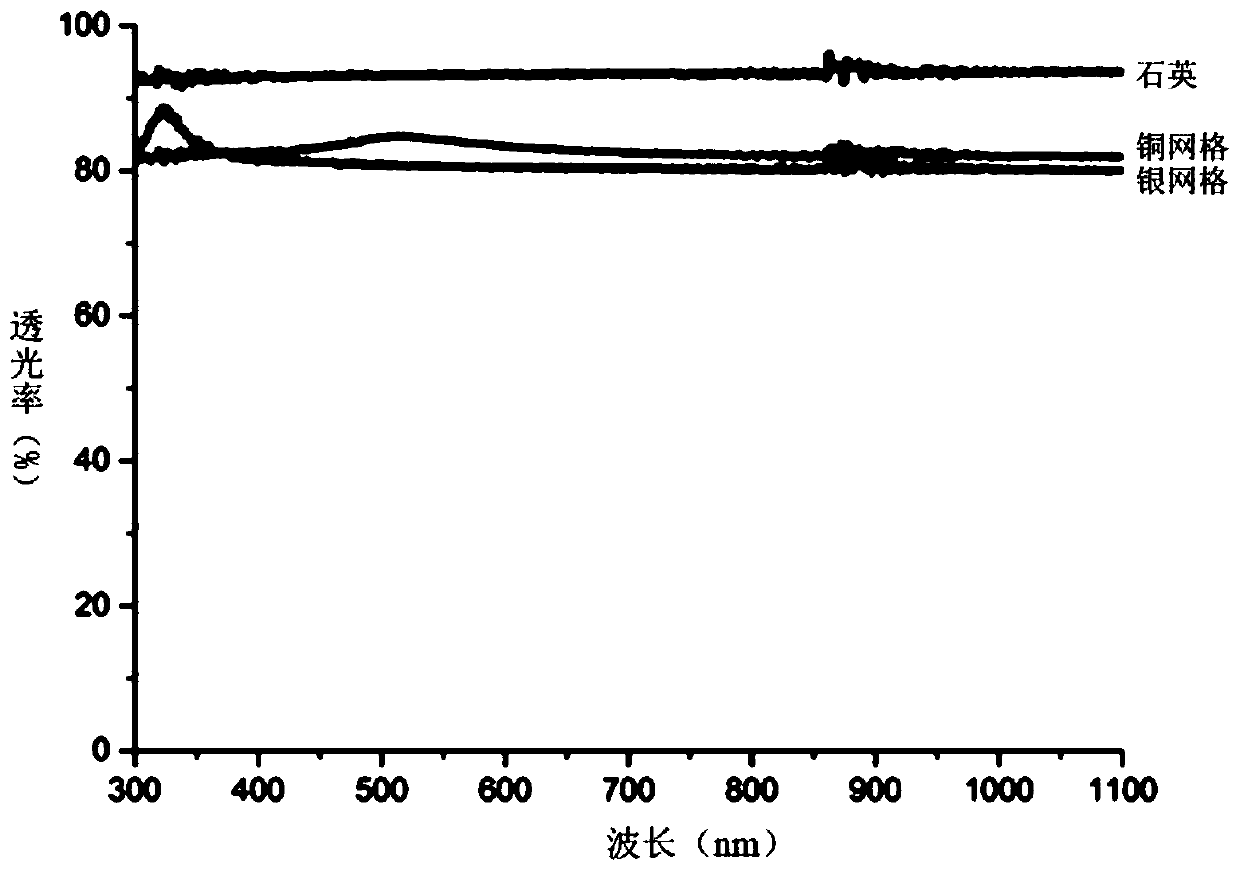

Ultra-thin metal grid-based transparent electrode and preparation method thereof

ActiveCN107610814AHigh light transmittanceGood electrical conductivityMaterial nanotechnologyConductive layers on insulating-supportsMetal gridSurface modification

The invention discloses an ultra-thin metal grid-based transparent electrode and a preparation method thereof, and relates to the technical field of a transparent electrode. The ultra-thin metal grid-based transparent electrode comprises a surface modified flexible transparent substrate; and a conductive metal grid layer with thickness of 1-10nm is deposited on the modified surface of the flexibletransparent substrate. The preparation method of the transparent electrode comprises the steps of grafting a layer of amino group on the surface of the substrate, forming a mask plate by photoresistor adhesive printing, depositing a metal layer with thickness of 1-10nm in the gap of the mask plate, and removing the mask plate to obtain the ultra-thin metal grid-based transparent electrode. By lowering the thickness of the metal grids, the light transmittance of the metal grids is improved; and meanwhile, the metal grids still have relatively high conductivity at the thickness of 1-10nm, so that the problem of "waxing and waning" between the conductivity and the light transmittance of the transparent electrode can be solved, and balance of the conductivity and the light transmittance is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Production method for medium-strength non-aging aluminum alloy electrotechnical round aluminum rod

The invention discloses a production method for a medium-strength non-aging aluminum alloy electrotechnical round aluminum rod. The production method comprises the steps of molten aluminum alloying, aluminum alloy melt homogenizing, primary purifying, secondary purifying and still standing, grain refining and filtering, third-time purifying and pouring, rolling and the like. According to the production method for the medium-strength non-aging aluminum alloy electrotechnical round aluminum rod, a certain content of copper, magnesium, boron and rare earth elements are added in electrolytic molten aluminum to improve the strength of an alloy, and meanwhile, the conductivity of the alloy is also met; and three times of the purifying and three times of the filtering are adopted in the production method, the purity of melt is improved, and meanwhile, the quality of the round aluminum rod is also guaranteed.

Owner:河南美雅德新材料有限公司

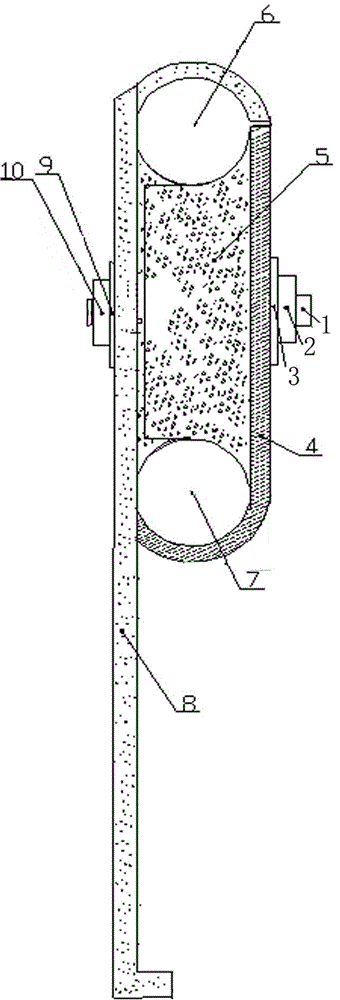

Manufacturing technology of bipolar plate

InactiveCN108666594ASolve penetrationMeet conductivityFuel cellsManufacturing technologyParaffin oils

The invention discloses a manufacturing technology of a bipolar plate. The manufacturing technology comprises the following steps: (1) selecting and using enough polyethylene paraffin, putting the polyethylene paraffin into a container, and heating until the polyethylene paraffin is completely fused; (2) immersing a graphite plate into the fused polyethylene paraffin, and taking out the immersed graphite plate until no bubble is emitted; and (3) hemming the graphite plate through paraffin immersing treatment to guarantee no weeping inside, and then connecting the hemmed graphite plate with theshell of a battery through PVC glue, wherein two sides of the graphite plate through paraffin immersing treatment are both connected with graphite felts as a positive electrode and a negative electrode of the battery; and (4) then after sealing, forming serially connected connecting points of the positive electrodes and the negative electrodes of two batteries on the graphite plate, namely the bipolar plate. According to the manufacturing technology, the polyethylene paraffin material is selected and used as a filler of the graphite plate, on one hand, the permeation problem of the graphite plate is solved, and on the other hand, the electrical conductivity of the graphite plate in a zinc-iodine battery is met; the bipolar plate with small volume and good electrical conductivity is formed; and the problem of filler fusion caused by the fat that the zinc-iodine battery is heated in the using process is also solved.

Owner:EAST CHINA NORMAL UNIV

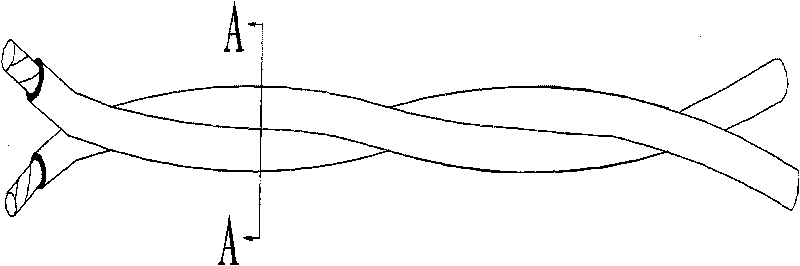

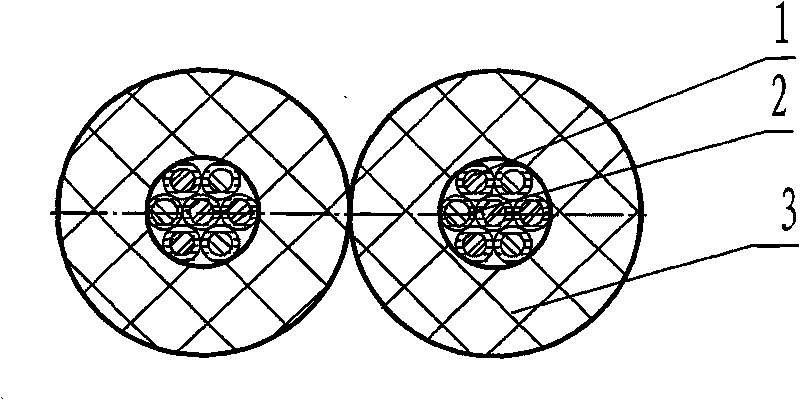

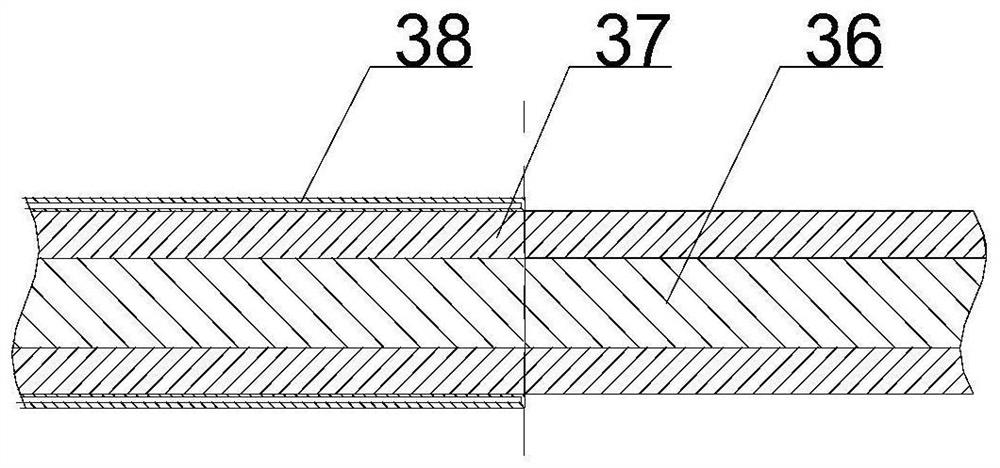

Polymetallic ultra-light covered wire

InactiveCN101699569AMeet conductivityMeet the mechanical propertiesNon-insulated conductorsPlastic/resin/waxes insulatorsLow-density polyethyleneHigh humidity

The invention discloses a polymetallic ultra-light covered wire, which consists of two insulated wire cores stranded. Each insulated wire core consists of a conductive reinforced core and a protective insulating layer covered outside the conductive reinforced core, wherein the conductive reinforced core consists of three copper-clad aluminum conductor conductive cores and four copper-clad steel conductor reinforced cores which are mixed and stranded; and linear polyethylene with low density is adopted as the insulating layer. The polymetallic ultra-light covered wire can simultaneously meet conductivity and mechanical performance and reduce the weight of a product, adopts the linear polyethylene with the low density as the insulating layer so as to meet the insulating performance, reduce the weight of the product and also improve the environment resistance of the product; The polymetallic ultra-light covered wire can work under the conditions of high temperature, high humidity and low temperature for a long time, has the advantages of good mechanical performance, light weight, small outer diameter, stable transmission quality, and quick and convenient succession, and is applied to engine-driven quick stretching and releasing operations.

Owner:SICHUAN JIUZHOU WIRE & CABLE

Plastic bipolar plate and preparation method thereof

InactiveCN108134105AMeet the tensile strengthMeet bending strengthFinal product manufactureCollectors/separatorsCompression moldingMixed materials

The invention relates to the field of the preparation of bipolar plates for power supplies, and particularly relates to a plastic bipolar plate and a preparation method thereof. The bipolar plate is prepared from three parts of a conducting material, a resin material and a functional material. The preparation method comprises the following main steps of forcibly mixing the conducting material, theresin material and the functional material, which are in a certain proportion, in a high speed ball mill, and carrying out compression molding on the uniformly mixed materials in a mold at a high temperature, so as to obtain the novel plastic bipolar plate. The plastic bipolar plate can be used for resolving the contradiction between the conductivity and the mechanical performance of a conventional plastic bipolar plate; while the strength and the corrosion resistance of the bipolar plate are improved, the conductivity of the bipolar plate is further ameliorated; further, the bipolar plate prepared by the method has the characteristics of being simple in process and low in raw-material and equipment cost, and the large-scale industrialized production is easily realized.

Owner:SHENZHEN JINGTE INTELLIGENT MFG TECH CO LTD

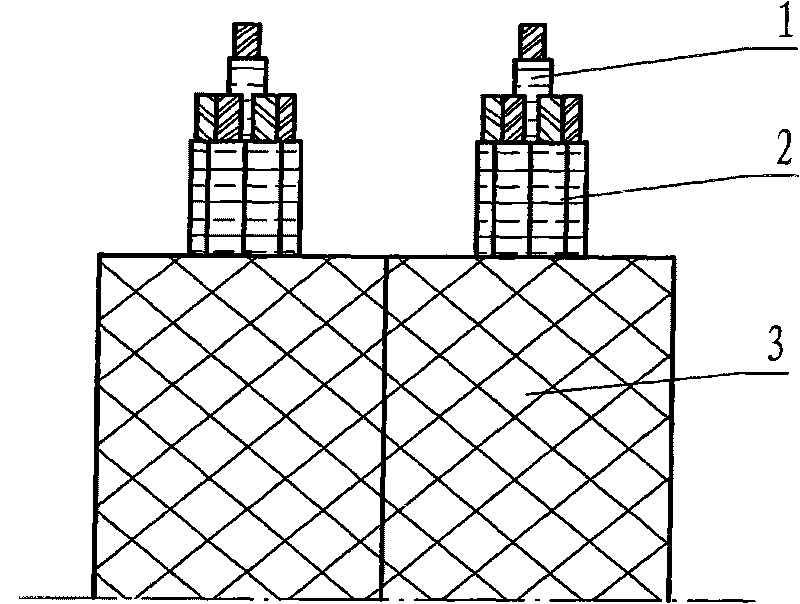

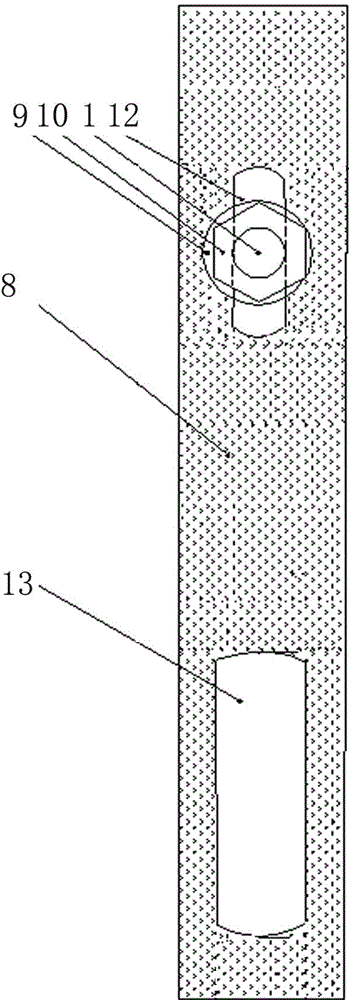

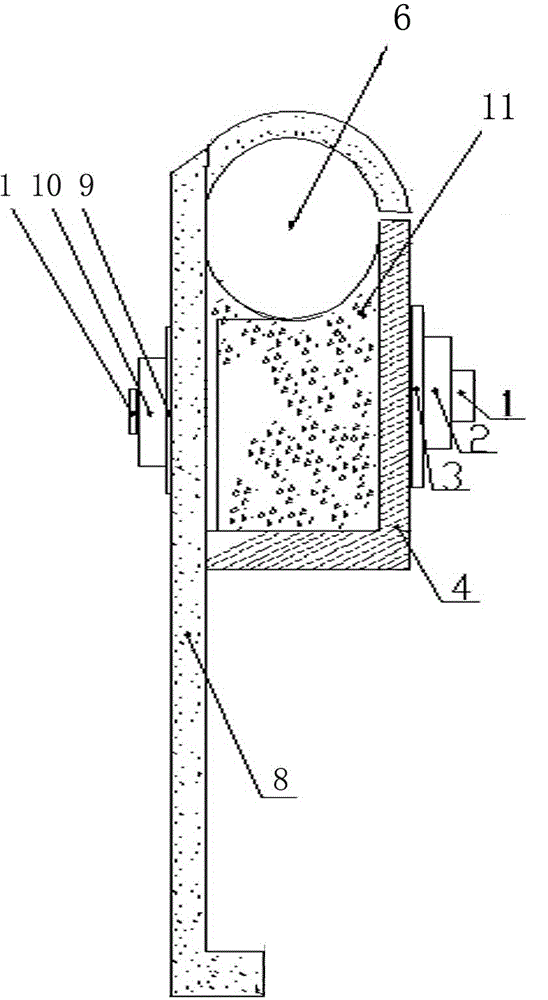

Span adjustable grounding wire head clamp device

ActiveCN102683922BMeet conductivityMeet heat resistance requirementsElectric connection structural associationsClamped/spring connectionsHeat resistanceGrounding line

The invention relates to the technical field of a span adjustable grounding wire head clamp device. The device is characterized in that an upper retaining ring, a concave pillar and a lower retaining ring and a wire hanging plate thereof are connected by screws; and an adjustable retaining hole and a ground wire hanging groove are also arranged at the bottom of the lower retaining ring and the wire hanging plate thereof. The device has the following beneficial effects that the problem of installation of grounding wires of overhead single conductors with current-carrying capacities being above 879A and wire diameter areas being above 400mm<2> and overhead composite conductors with current-carrying capacities being above 1620A and wire diameter areas being above 400mm<2>*2 and the problem that the grounding wires are difficult to install in the places needing installation of the grounding wires due to various reasons are solved; and the device meets the requirements of electrical conductivity and heat resistance, has simple structure and can not only appropriately adjust the span to meet the installation requirement according to the overhead wire diameters on the site but also be suitable for various grounding wire conductor terminal joints.

Owner:SHENYANG POWER SUPPLY LIAONING POWER +1

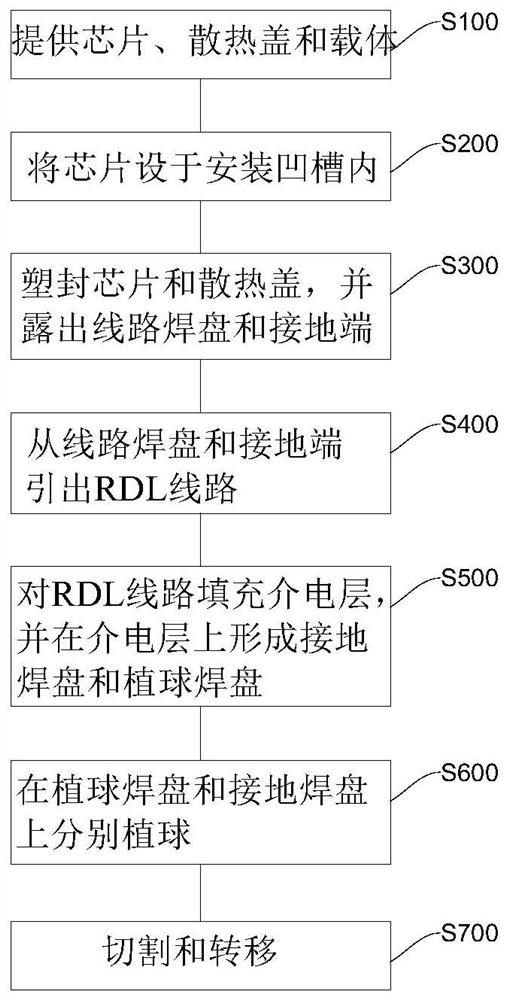

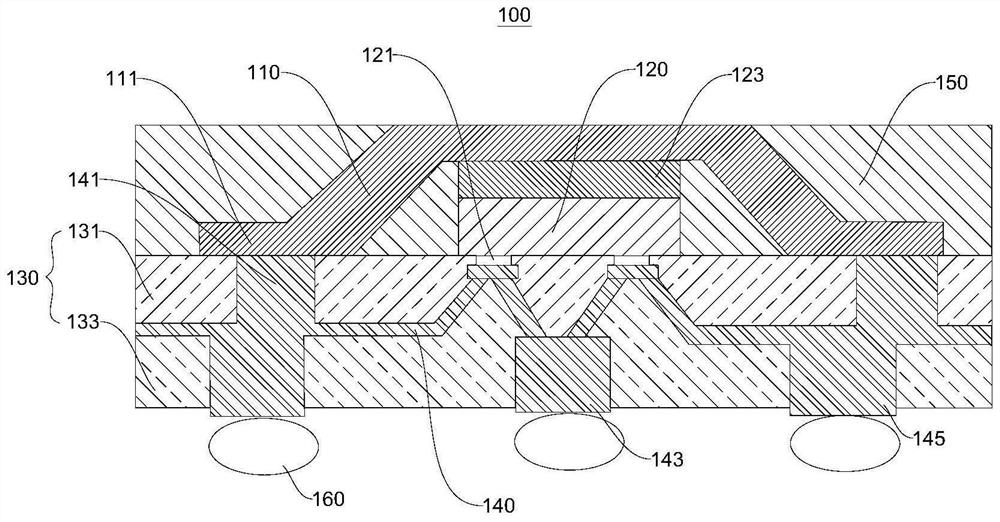

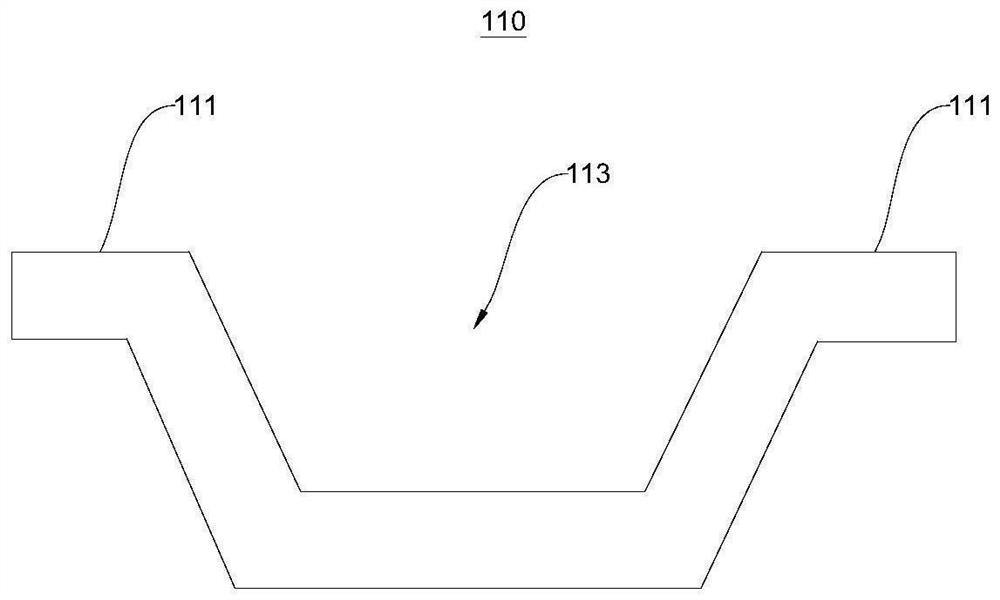

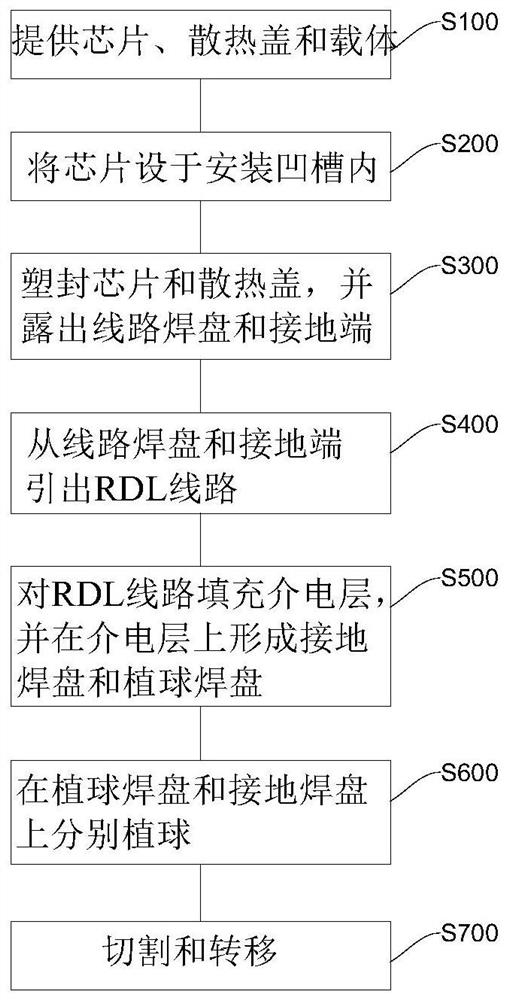

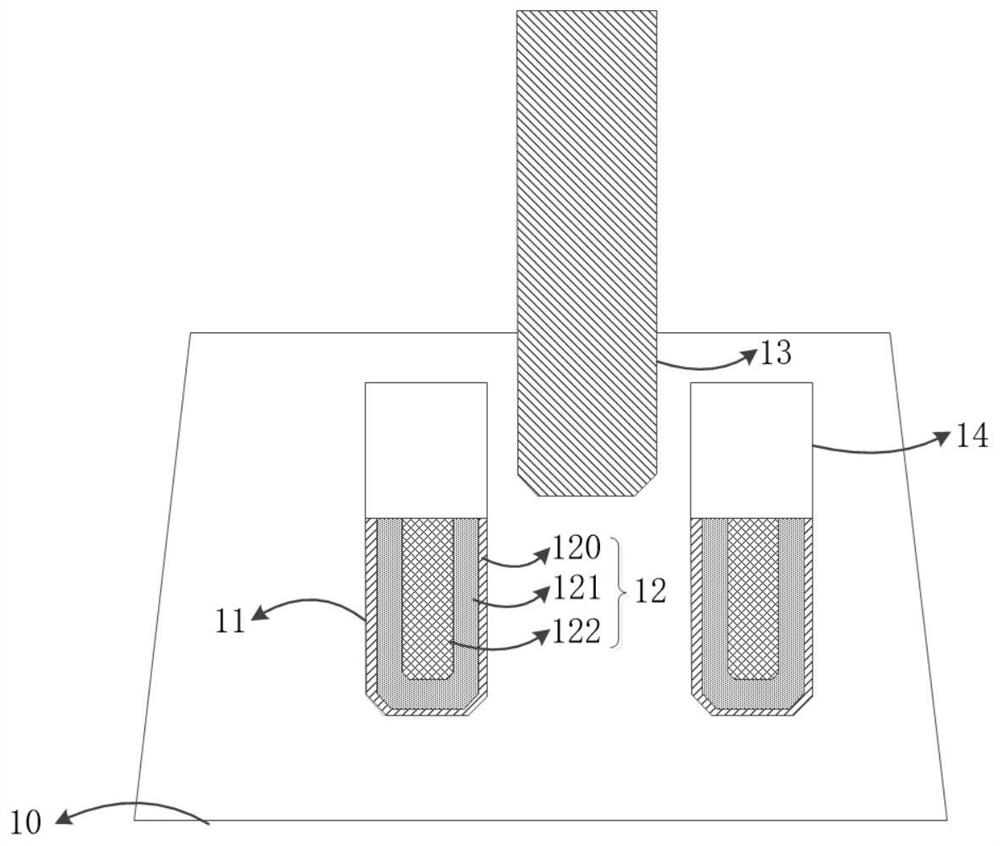

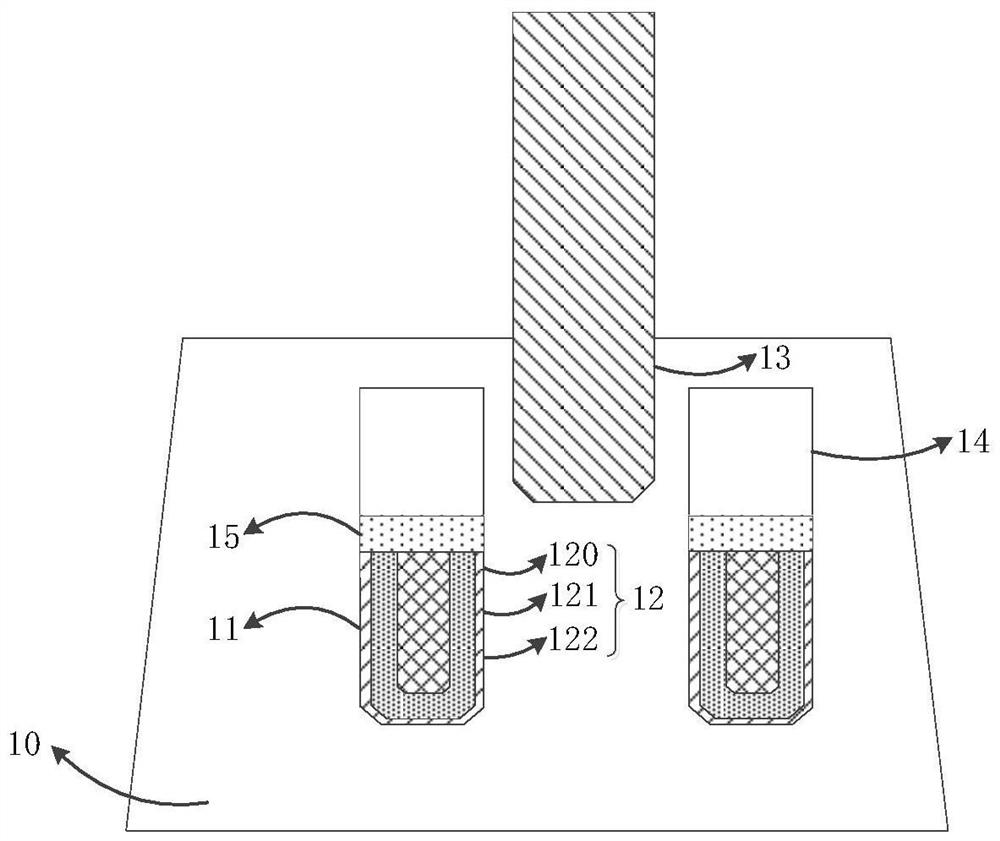

Packaging structure manufacturing method and packaging structure

ActiveCN111755350AMeet conductivityReduce ground resistanceSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringGrounding resistance

The embodiment of the invention provides a packaging structure manufacturing method and a packaging structure, and relates to the technical field of packaging. The manufacturing method of the packaging structure comprises the following steps: providing a chip and a heat dissipation cover, wherein the chip is provided with a circuit bonding pad, and the heat dissipation cover is provided with a grounding end and a mounting groove; arranging the chip in the mounting groove; plastically packaging the chip and the heat dissipation cover, and exposing the circuit bonding pad and the grounding end;leading out an RDL circuit from the circuit bonding pad and the grounding end; and filling the RDL circuit with a dielectric layer, and forming a grounding bonding pad and a ball mounting bonding padon the dielectric layer, wherein the grounding bonding pad is connected with the grounding end, and the ball mounting bonding pad is connected with the circuit bonding pad. Because the RDL line is directly led out from the grounding end and the line bonding pad, that is, the heat dissipation cover is directly connected with the RDL line, the reduction of grounding resistance is facilitated, and the service life of the packaging structure is prolonged.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

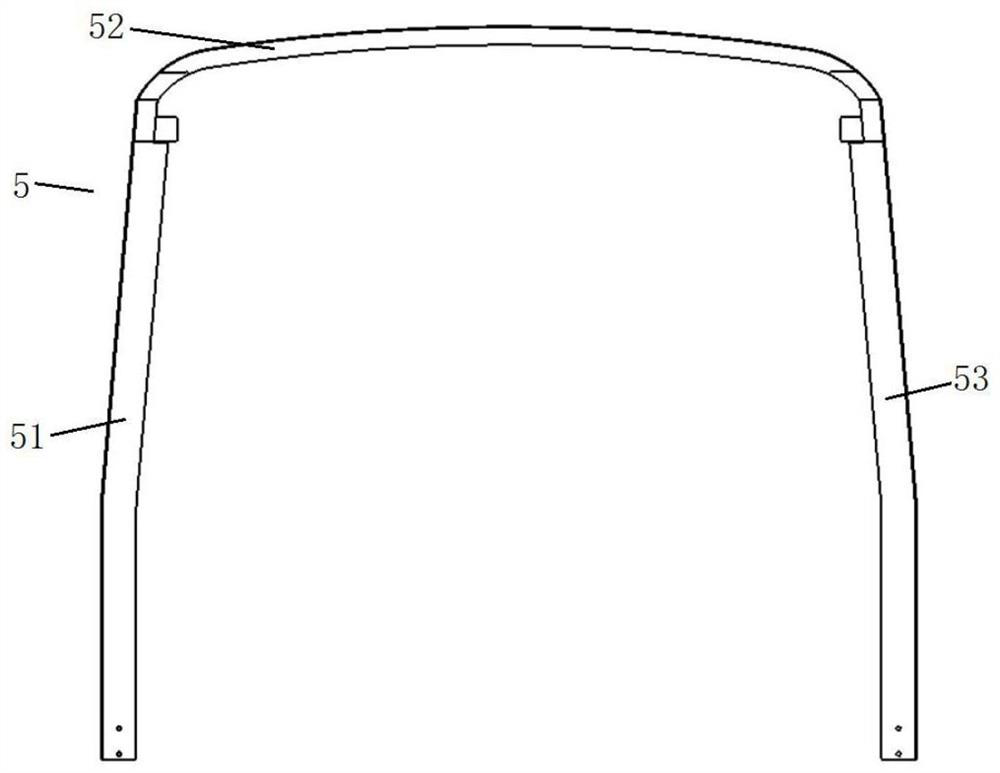

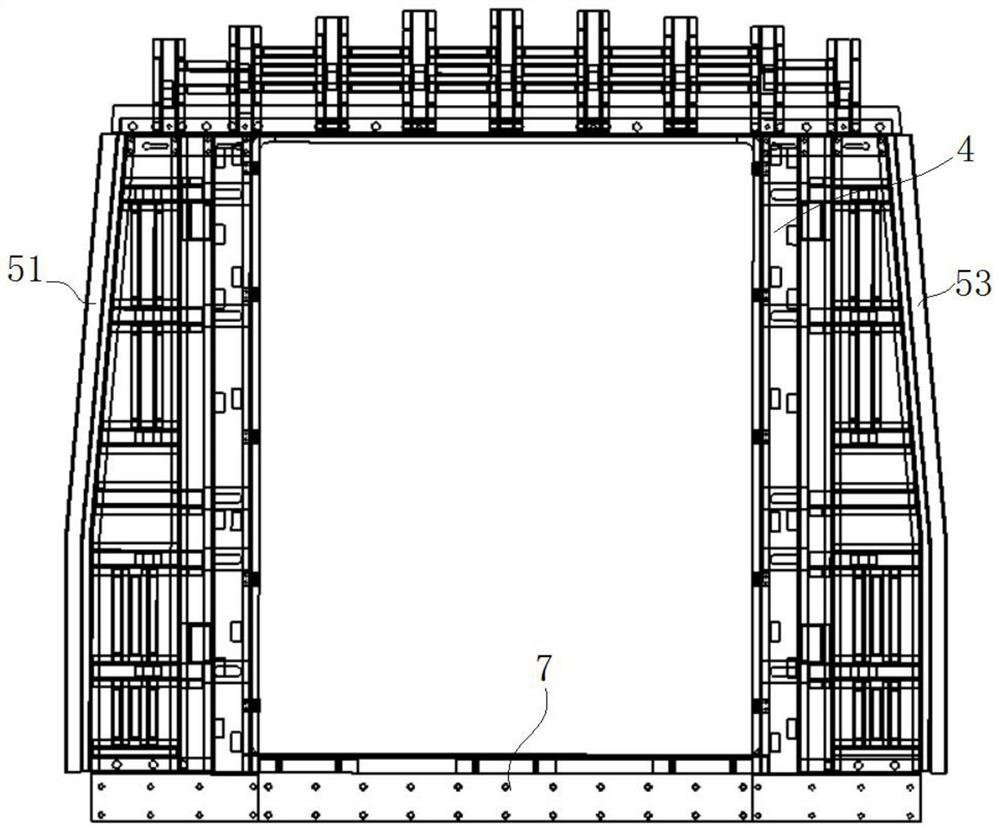

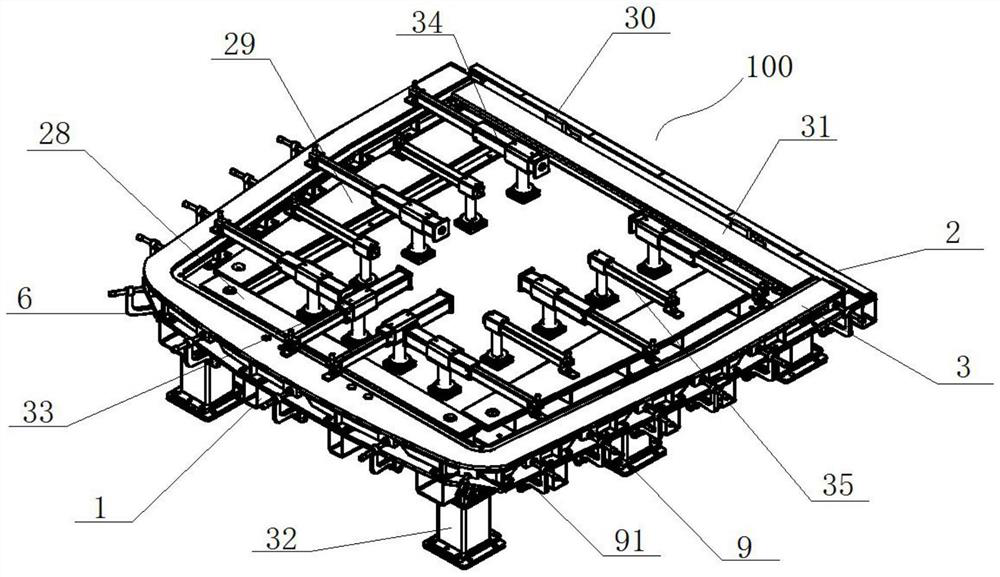

Vehicle body end wall synthesis tool and process

PendingCN113953755ANovel and reasonable structureSmall amount of deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a vehicle body end wall synthesis tool and a process. The vehicle body end wall synthesis tool comprises a tool platform, a supporting copper table and a pressing assembly, and an auxiliary electrode is arranged on the tool platform; the supporting copper table is arranged on the tool platform, used for loading an end wall auxiliary plate and an end wall assembly, and can form continuous surface support for a to-be-welded part between the end wall auxiliary plate and the end wall assembly; the supporting copper table is electrically connected with the auxiliary electrode; and the pressing assembly is arranged on the tool platform and used for pressing the end wall auxiliary plate and the end wall assembly on the tool platform. The tool is reasonable in structural design, and through the arrangement of the supporting copper table, the problems that in the prior art, due to the fact that part of end wall auxiliary plate faces are not supported, the flatness is poor, welding point indentations are deep due to the welding mode, the welding difficulty between the end wall assembly and the end wall auxiliary plate is increased, and the welding quality is reduced are solved; and in addition, the invention further provides the vehicle body end wall synthesis process based on the vehicle body end wall synthesis tool, operation steps are simple, and practicability is high.

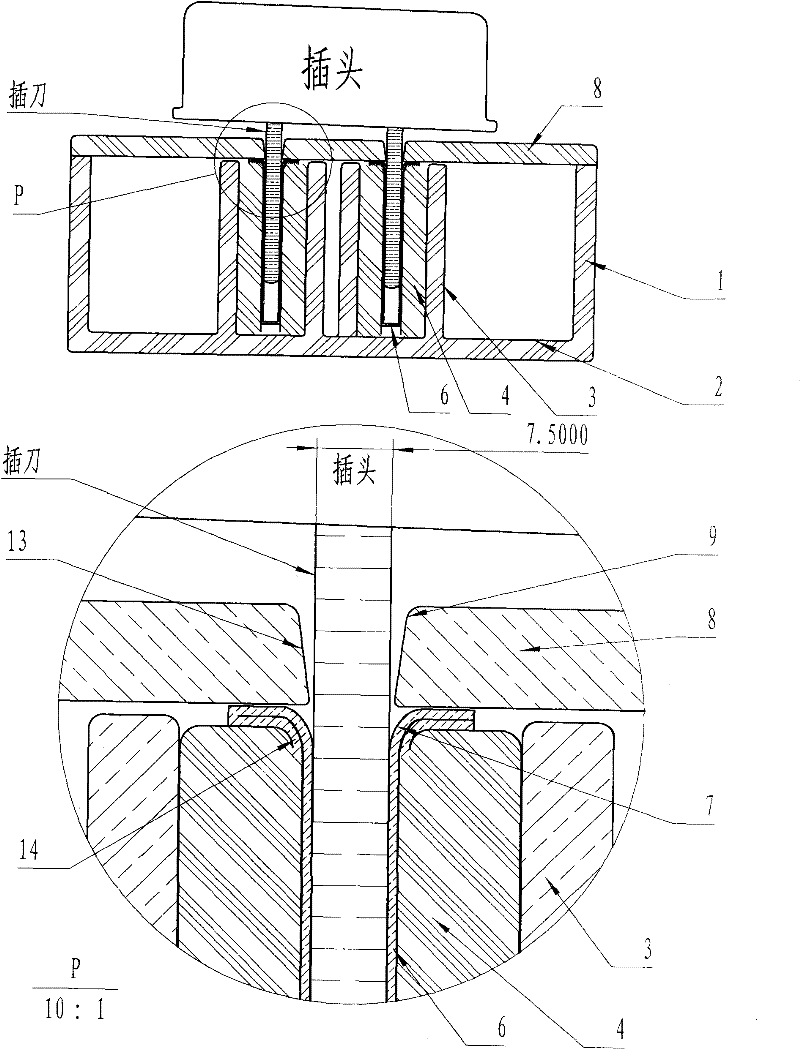

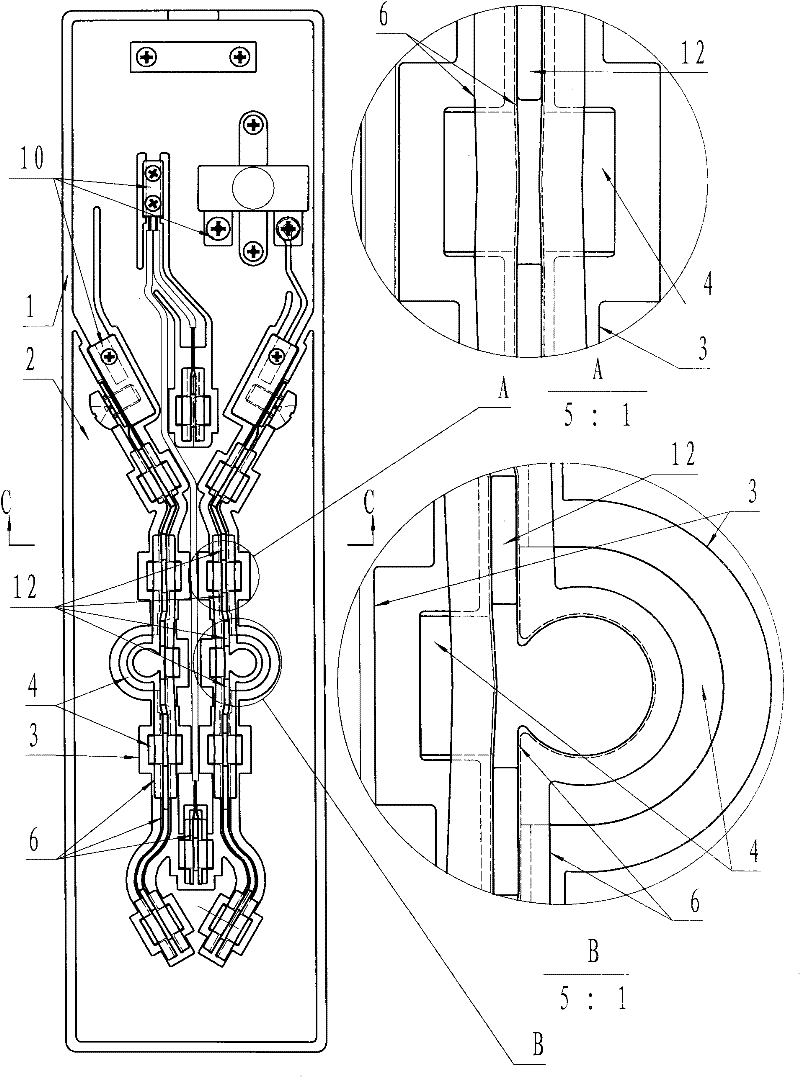

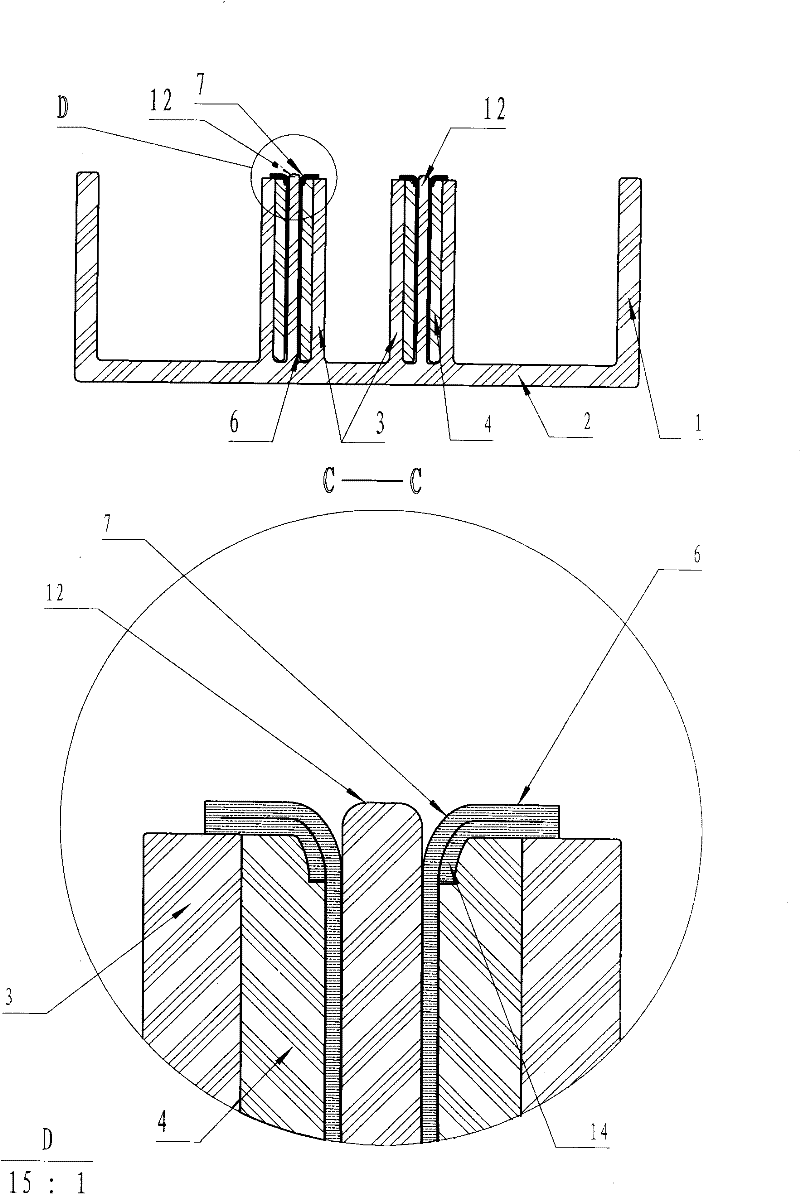

Electric socket

InactiveCN102231458AReduce thicknessEnough pressureCoupling contact membersContact pressureThermal insulation

The invention discloses an electric socket. The electric socket comprises a pedestal, a top cover, a spacing groove, an elastomer, a heat spacer, a conducting strip, a pressure block, a stop block and a wiring apparatus, wherein the inner-side plane of the spacing groove is parallel or vertical to the axisymmetric plane of the top cover slit, the elastomer is placed in the spacing groove and the conducting strip is placed on the side surface of the axisymmetric plane of the top cover slit. The electric socket also comprises a stop block which can control the position of the conducting strip, a thermal insulation layer which can isolate the conducting strip and a pressing piece which can separate the elastomer and the conducting strip. Compared to an electric socket in the prior art, when the electric socket provided in the invention is used, the contact pressure between the sleeve and the slotting tool is lasting, the contact area is large and a certain high temperature can be resisted. Therefore, faults, damages and inconveniences which are caused by too large inserting and plugging forces, large contact resistor and too high temperature rise can be prevented. The costs can be reduced and the invention can be widely applied to many places.

Owner:杜兴喜 +1

A kind of transparent electrode based on ultra-thin metal grid and preparation method thereof

ActiveCN107610814BHigh light transmittanceImprove conductivityMaterial nanotechnologyConductive layers on insulating-supportsThin metalPhotoresistor

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

A polishable bright varnish for electrostatic spraying and preparation method thereof

ActiveCN103484003BImprove the level ofHigh glossPolyurea/polyurethane coatingsEnvironmental resistanceCoconut oil

The invention relates to a polishing varnish for electrostatic spraying and a preparation method thereof. The varnish is prepared from a main agent, a curing agent and a diluent at a ratio of 1-1.2:0.8-1:0.5-0.7, wherein the main The agent components and parts by weight are as follows: 20-25 parts of synthetic fatty acid, 60-66 parts of coconut oil, 11-15 parts of mixed environmental protection solvent, 0.3-0.8 part of leveling agent, 0.1-0.3 part of defoamer; The curing agent is an isocyanate curing agent. The polishing varnish for electrostatic spraying of the present invention can be electrostatically sprayed, and the coating film after spraying has good leveling property and high hardness and can be polished.

Owner:SKSHU PAINT

Anti-oxidation silver paste for passenger car front windshield and preparation method thereof

ActiveCN109785991BMeet conductivityMeet adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePolymer resin

The invention relates to an anti-oxidation silver paste for car windshield glass and a preparation method thereof. A raw material adopts following components and weight percentage contents: 60-80% ofmetal silver powder; 3-6% of glass powder; 2-8% of polymer resin; 0.5-1.5% of organic additive; 0.5-4.5% of inorganic additive; and 10-30% of organic solvent. The anti-oxidation silver paste for the car windshield glass is obtained through steps of material preparation, preparation of a carrier, preparation of the silver paste, and production of the silver paste. Compared with the prior art, according to the prepared product, the requirement of technical indexes including conductivity, adhesion, the tin surface color and the matching property with black glaze can be satisfied, and the productalso has the advantage of anti-oxidation performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

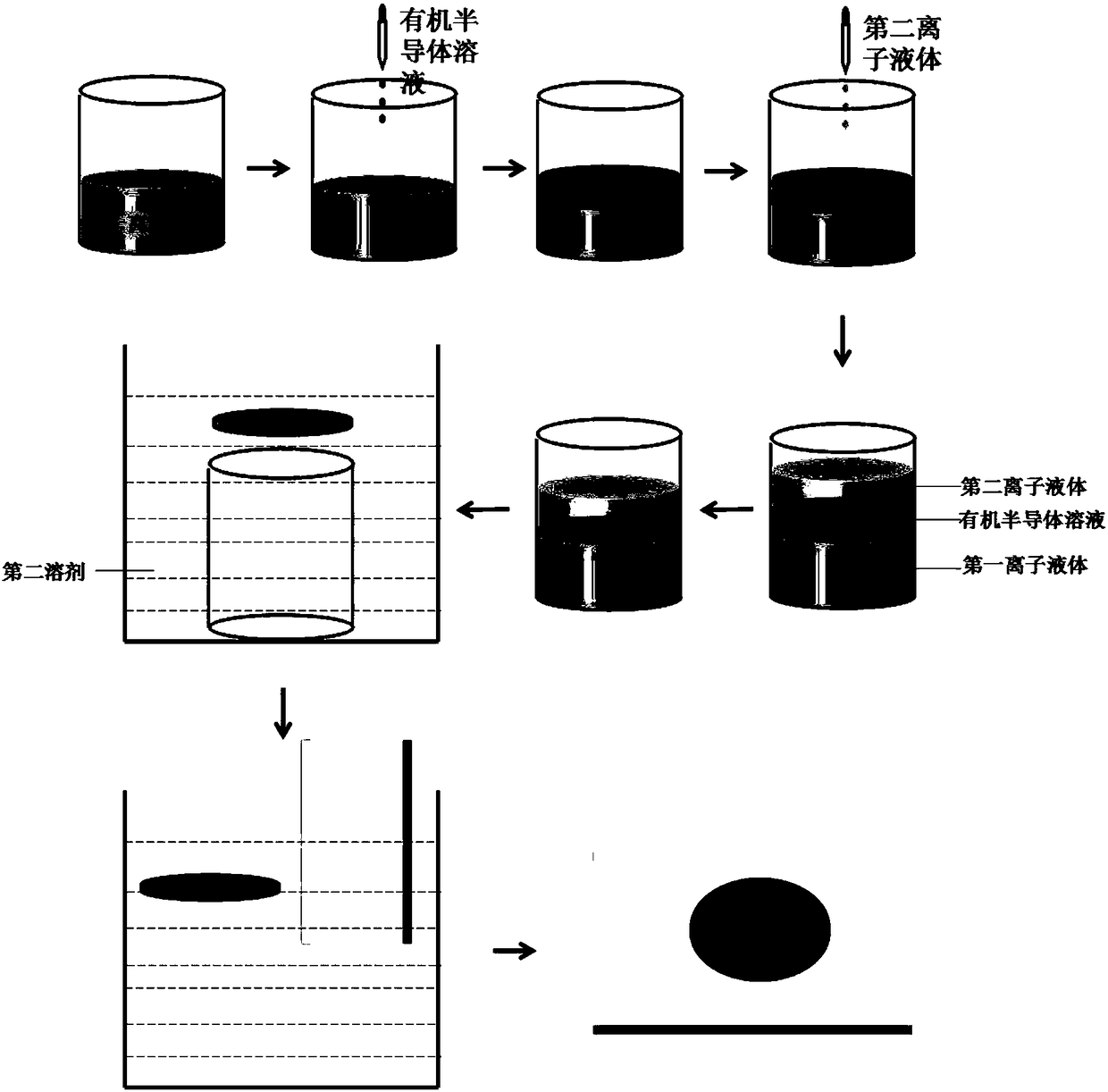

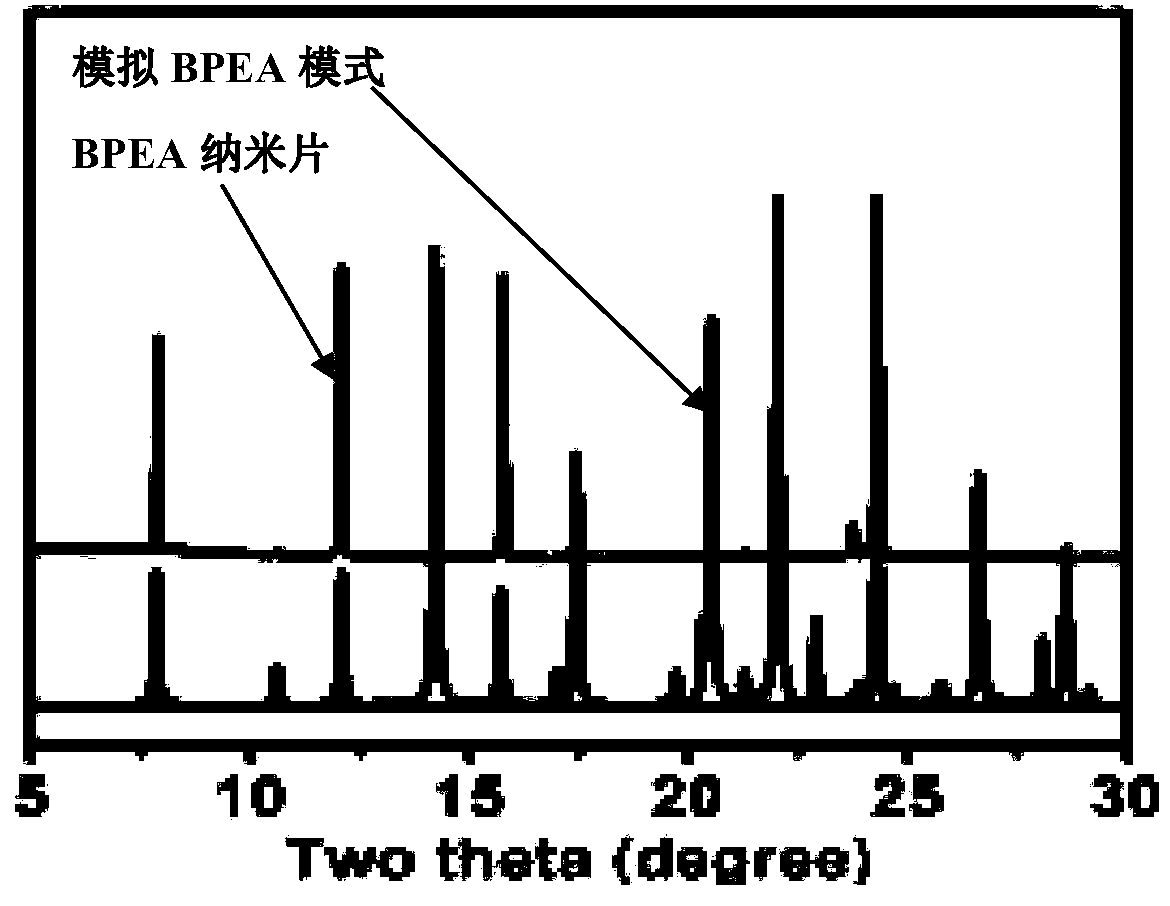

Organic self-supporting single crystal film and preparation method and application thereof

ActiveCN108735901AEasy to operateReduce energy consumptionSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalOrganic semiconductor

The invention discloses an organic self-supporting single crystal film and a preparation method and application thereof. The organic self-supporting single crystal film is composed of large two-dimensional flaky organic semiconductor single crystals. The preparation method comprises the steps that a sandwich structure formed by an organic semiconductor solution and two ion liquids is provided, wherein the first ion liquid does not mix with the organic semiconductor solution, the second ion liquid slightly mixes with the organic semiconductor solution, the density of the first ion liquid is higher than that of the organic semiconductor solution, and the density of the second ion liquid is lower than that of the organic semiconductor solution; and a solvent in the organic semiconductor solution is slowly dissolved with the second ion liquid and penetrates through the second ion liquid to volatize, so that the organic semiconductor material is slowly self-assembled between the two ion liquids to form the organic self-supporting single crystal film. The organic self-supporting single crystal film has the advantages of solubilized preparation, large-size two-dimensional single crystals,high flexibility and the like, and the preparation method is easy to operate.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

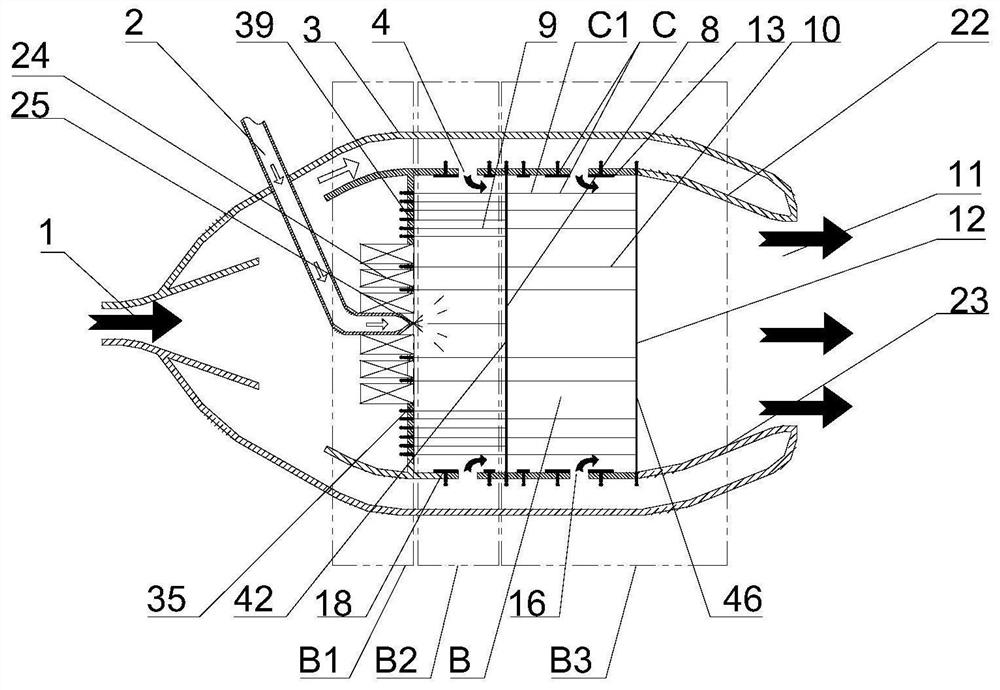

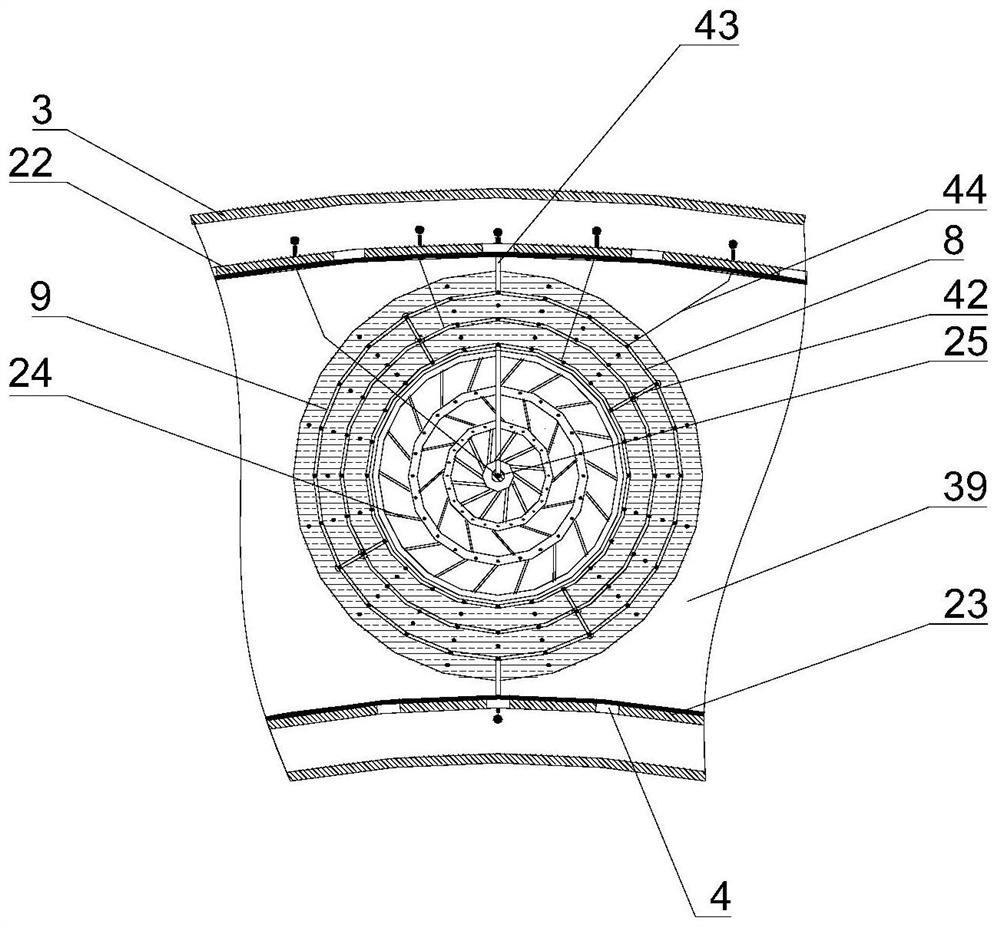

Aero-engine electrode and aero-engine comprising same

ActiveCN113107684AControllable electric fieldMeet conductivityEfficient propulsion technologiesGas turbine plantsCombustion chamberEngineering

The invention discloses an aero-engine electrode and an aero-engine comprising the same. The electrode comprises a temperature-resistant conductive electrode inner core and a temperature-resistant corrosion-resistant electrode outer wall, wherein the electrode outer wall wraps the exposed surface of the electrode inner core. A plurality of the electrodes are mounted in a combustion chamber of the engine and can generate electric fields in the combustion chamber. The electrodes can be mounted in the combustion chamber and are controlled by an external electric field control device to output different voltages, so that the electric fields can be generated between the different electrodes; and the electrodes are arranged at different positions in the combustion chamber of the engine and can generate axial, radial or oblique electric fields, the external electric field control device outputs voltages and controls voltage changes, and therefore the electric fields between the electrodes can be controlled.

Owner:AERO ENGINE ACAD OF CHINA

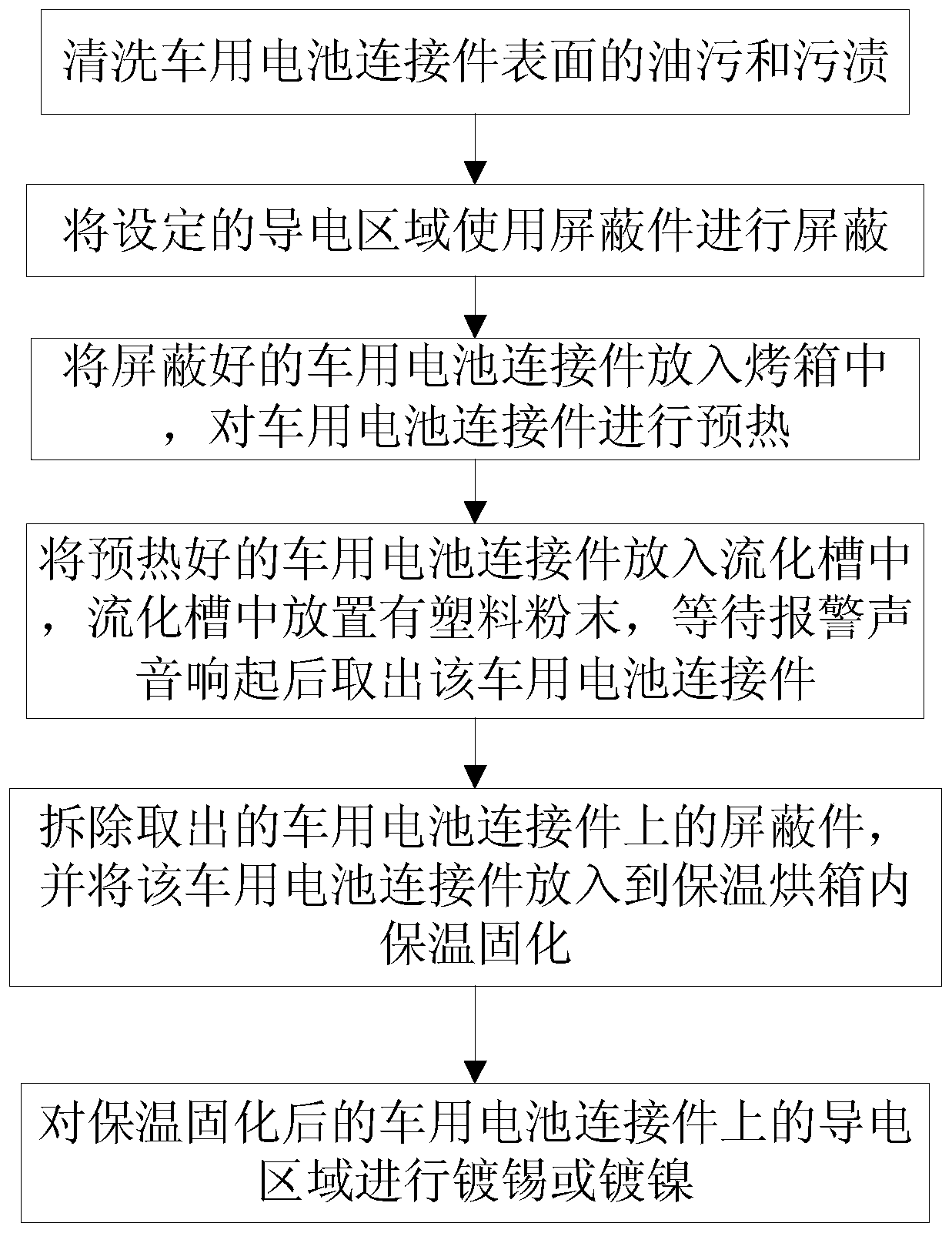

Processing technology of vehicle battery connector

The invention provides a processing technology of a vehicle battery connector. The processing technology comprises the following steps: step 1, cleaning oil stain and stains on the surface of the vehicle battery connector; step 2, shielding the conductive region set on the vehicle battery connector by a shielding member; step 3, putting the shielded vehicle battery connector into an oven and preheating the vehicle battery connector; step 4, placing the preheated vehicle battery connector into a fluidization tank, wherein plastic powder is placed in the fluidization tank and the vehicle batteryconnector is taken out after waiting for an alarm sound; step 5, dismantling the shielding member on the taken-out vehicle battery connector and putting the vehicle battery connector into an heat insulation oven for insulation and solidification; and step 6, performing tin or nickel plating on the conductive region on the vehicle battery connector after heat insulation and solidification. According to the method, tinning or nickel plating only needs to be performed on the region needing conduction, thereby reducing the production cost and meeting the conduction and insulation requirements ofthe existing battery connectors.

Owner:宁波市叶兴汽车零部件有限公司

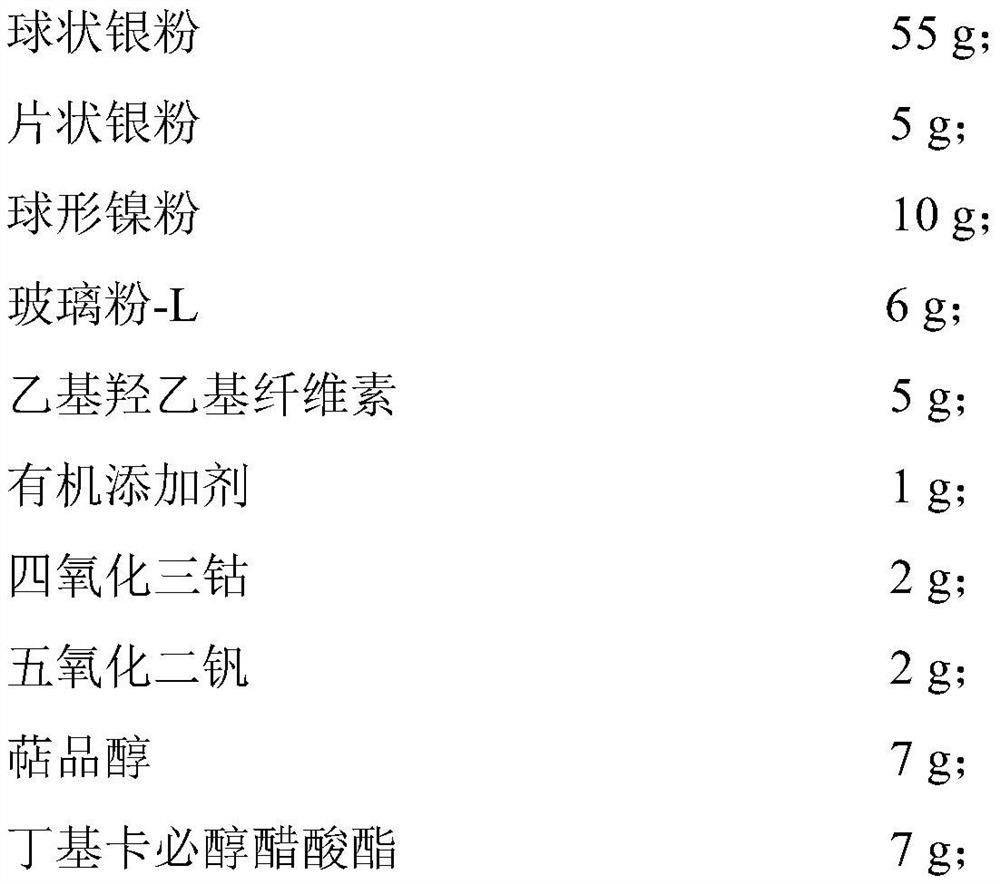

Grey conductive silver paste for automobile glass and preparation method thereof

ActiveCN113539545AImprove acid resistanceImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteOrganic solvent

The invention relates to gray conductive silver paste for automobile glass and a preparation method of the gray conductive silver paste. The raw materials of the conductive silver paste comprise the following components in parts by weight: 50-70 parts of metal silver powder, 10 parts of metal nickel powder, 3-6 parts of glass powder, 2-8 parts of macromolecular resin, 0.5-1.5 parts of an organic additive, 0.5-4.5 parts of an inorganic additive and 10-30 parts of an organic solvent. The silver paste is obtained through the following steps: (1) carrier preparation; (2) preparation of silver paste; (3) production of silver paste production. Compared with the prior art, the invention not only can meet the technical index requirements of conductivity, adhesive force, tin surface color, matching with black glaze and the like of the front windshield of the passenger car, but also has oxidation resistance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

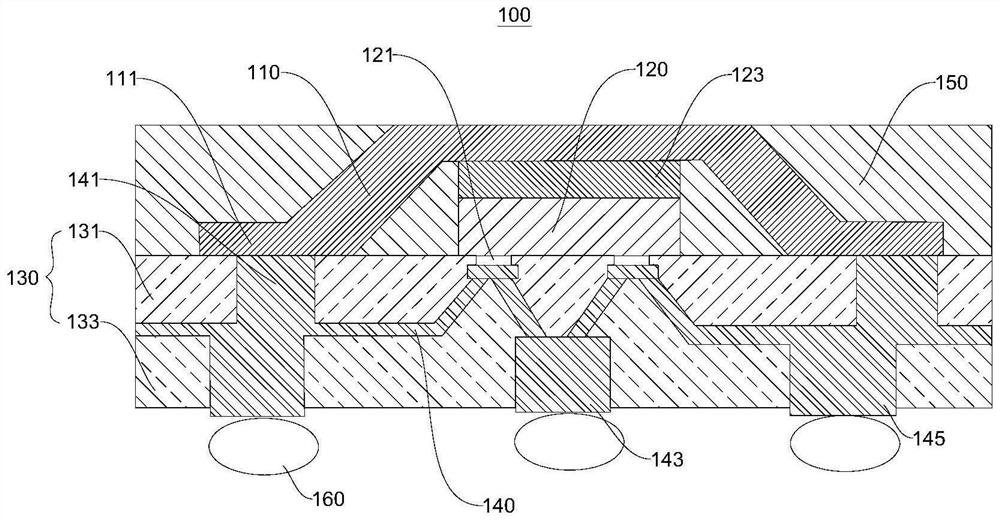

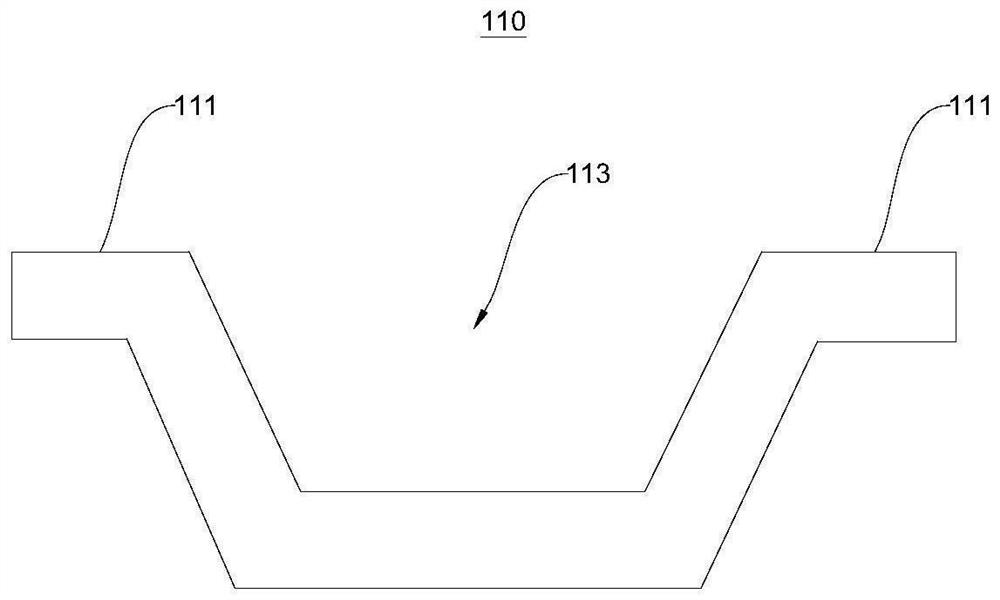

Packaging structure manufacturing method and packaging structure

ActiveCN111755350BMeet conductivityReduce ground resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringGrounding resistance

Embodiments of the present invention provide a method for manufacturing a package structure and a package structure, which relate to the technical field of packaging. The manufacturing method of the package structure includes providing a chip and a heat dissipation cover; wherein, the chip is provided with a circuit pad, and the heat dissipation cover is provided with a ground terminal and a mounting groove. Set the chip in the mounting groove; plastic-encapsulate the chip and the heat dissipation cover, and expose the circuit pad and the ground terminal; lead the RDL circuit from the circuit pad and the ground terminal; fill the RDL circuit with a dielectric layer, and form on the dielectric layer A ground pad and a ball-mounting pad; wherein, the ground pad is connected to the ground terminal, and the ball-mounting pad is connected to the circuit pad. Since the RDL line is directly drawn from the ground terminal and the line pad, that is, the heat dissipation cover is directly connected to the RDL line, it is beneficial to reduce the grounding resistance and prolong the service life of the package structure.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

A kind of low-diameter high-strength polyacrylonitrile-based carbon fiber and preparation method thereof

ActiveCN109402792BLow solid contentLow viscositySynthetic cellulose/non-cellulose material pulp/paperMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The invention relates to low-diameter high-strength polyacrylonitrile-based carbon fibers and a preparation method thereof. According to the method, acrylonitrile containing itaconic acid and methyl methacrylate is used as a ternary polymerization system, and an organic diol crosslinking agent is added in a polymerization process for polymerizing, so that a spinning stock solution which has a polymer content of 12.5-17.5% and a viscosity of 120-800 CP is obtained; due to the addition of the crosslinking agent, the spinnability and high drafting of the spinning solution with low polymer contentand low viscosity are improved; then, a wet spinning process is adopted and matched with reasonable solidification conditions and a spinning drafting process, so that low-diameter polyacrylonitrile precursor with surface grooves is prepared; the precursor is pre-oxidized, and is carbonized at a low temperature and a high temperature, so as to obtain the monofilament which has the equivalent diameter of 2-3 mum, the tensile strength of more than or equal to 3.5 GPa, and the tensile modulus of more than or equal to 230 Gpa; therefore, the low-diameter and high-strength polyacrylonitrile-based carbon fibers with a regular surface groove structure are obtained. The carbon fiber obtained by method can improve the flexibility of carbon fiber paper for fuel cells.

Owner:BEIJING UNIV OF CHEM TECH

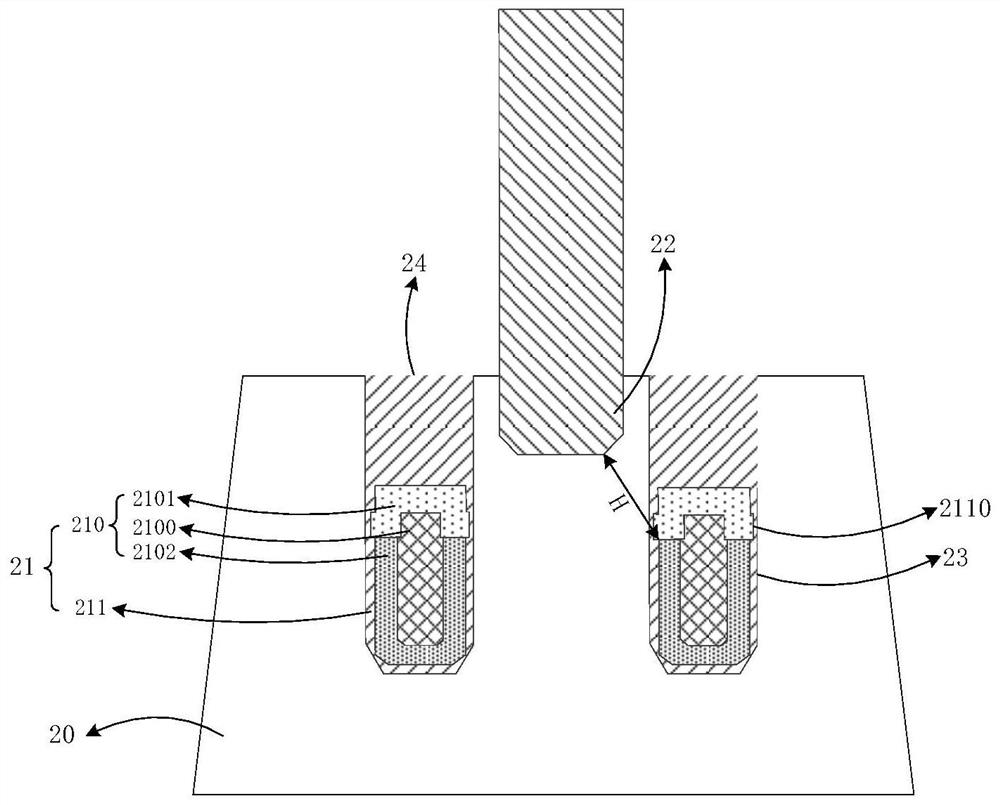

Semiconductor device, manufacturing method thereof and electronic equipment

PendingCN113782605AImprove refresh effectAdjust resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialGate stack

The invention discloses a semiconductor device, a manufacturing method thereof and electronic equipment, relates to the technical field of semiconductor manufacturing, and aims to control the resistance value of a gate electrode, suppress the generation of leakage current and improve the refresh performance of the semiconductor device. The semiconductor device includes a substrate and a gate stack embedded in the substrate, wherein a gate electrode of the gate stack including an upper gate, a lower gate, and a peripheral gate; the upper gate is of an n-shaped structure, the peripheral gate is of a U-shaped structure, the upper gate covers the top surface and the upper portion of the side surface of the lower gate, and the peripheral gate covers the bottom surface and the lower portion of the side surface of the lower gate; and the bottom surface of the upper gate is connected with the top surface of the peripheral gate. The invention also provides a manufacturing method of the semiconductor device. The semiconductor device provided by the invention is applied to electronic equipment.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com