Polymetallic ultra-light covered wire

An ultra-light, double-wired technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of poor cold resistance of PVC, high density of galvanized steel wire, and large dielectric loss, etc., to meet mechanical properties, Effect of small outer diameter and improved environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

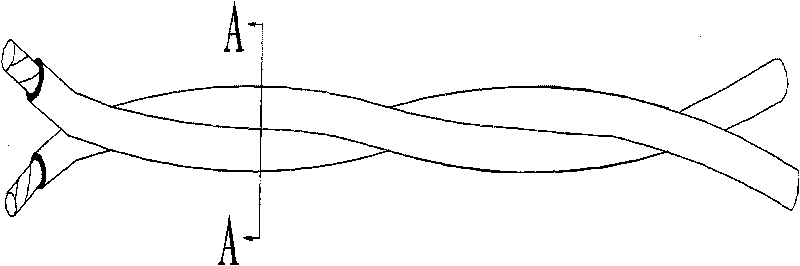

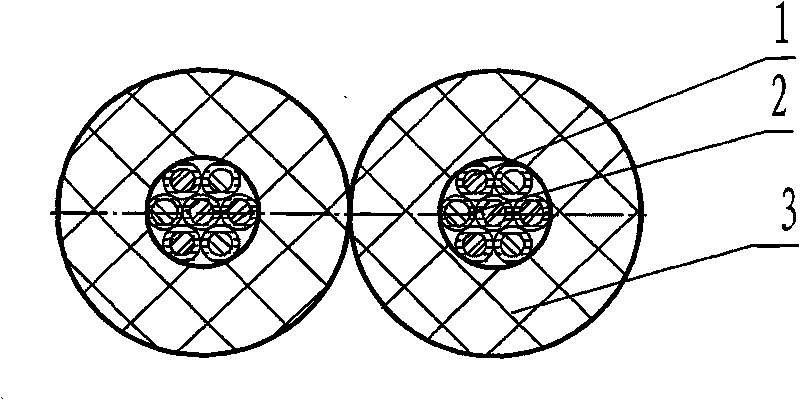

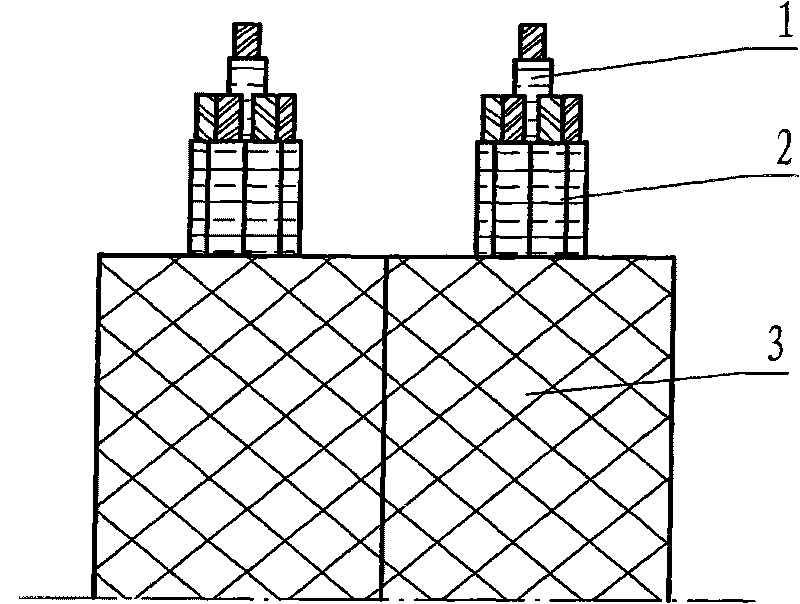

[0015] Embodiment 1: see attached figure 1 , 2 and 3.

[0016] A multi-metal ultra-light duplexed wire, which is composed of two insulated wire cores, each insulated wire core is composed of a conductive reinforced wire core and a protective insulating layer coated on the outside of the conductive reinforced wire core, the conductive reinforced wire core It is composed of three copper-clad aluminum wire conductive cores 2 and four copper-clad steel wire reinforcing cores 1;

[0017] Among the three copper-clad aluminum wire conductive cores 2 and the four copper-clad steel wire reinforcement cores 1, one copper-clad steel wire reinforcement core 1 is located in the center, and the other three copper-clad steel wire reinforcement cores 1 and three copper-clad aluminum wires Conductive wire cores 2 are alternately arranged around the copper-clad steel wire reinforcement core 1 in the center; that is, the connection line of the central axis of the cross-section of the four copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com