Patents

Literature

232 results about "Copper-clad steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-clad steel (CCS), also known as copper-covered steel or the trademarked name Copperweld is a bi-metallic product, mainly used in the wire industry that combines the high mechanical resistance of steel with the conductivity and corrosion resistance of copper.

A kind of solder and its igniter for exothermic welding of grounding body in grounding system

InactiveCN102267024AWelding/cutting media/materialsAlumino-thermic welding apparatusHigh resistanceExothermic welding

The invention discloses a solder for exothermic welding of a grounding body in a grounding system and an ignition agent of the solder, relates to the solder for the exothermic welding and the ignition agent of the solder and solves the technical problem of poor welding performance caused by impurities contained in a welding joint which is obtained by the conventional exothermic welding hot-melting soldering agent. The solder for the exothermic welding of the grounding body in the grounding system consists of copper oxide powder, copper powder, industrial pure aluminum powder, zinc powder, zirconium powder, silicon iron powder, fluorite powder, marble powder and lanthanum cerium alloy powder. The ignition agent of the solder for the exothermic welding of the grounding body in the groundingsystem consists of magnesium powder, the copper oxide powder, the industrial pure aluminum powder, potassium permanganate powder and red phosphorus powder. When the solder and the ignition agent are used, the mass ratio of the solder for the exothermic welding of the grounding body in the grounding system to the ignition agent is (78-82):1. All elements in the solder and rare-earth elements can purify the welding joint. The invention is applicable to welding of copper, copper alloy, steel, galvanized steel, copper-clad steel, stainless steel and high-resistance heating source materials.

Owner:HEILONGJIANG PATENT TECH DEV

High melting point exothermic welding flux for copper-clad steel/copper grounding grid

InactiveCN101637852ABalanced reliabilityUniform tissue formationWelding/cutting media/materialsSoldering mediaExothermic weldingCopper oxide

A high melting point exothermic welding flux for a copper-clad steel / copper grounding grid belongs to the metal welding field. The existing exothermic welding flux for welding copper-clad steel has the defects of lower melting point of the metal on a joint than the temperature of a base material, poor structural uniformity and the like. The exothermic welding flux comprises the following components by weight percent: 50-60% of copper oxide, 9-10% of aluminium metal powder, 20-35% of copper metal powder, 3-4% of fluorite powder, 2-3% of tin metal powder, 0-5% of nickel metal powder and the balance alloy powder. The exothermic welding flux has the melting temperature close to that of the base metal, and can assure that a grounding body formed by the joint and the base material has even reliability.

Owner:CHINA ELECTRIC POWER RES INST

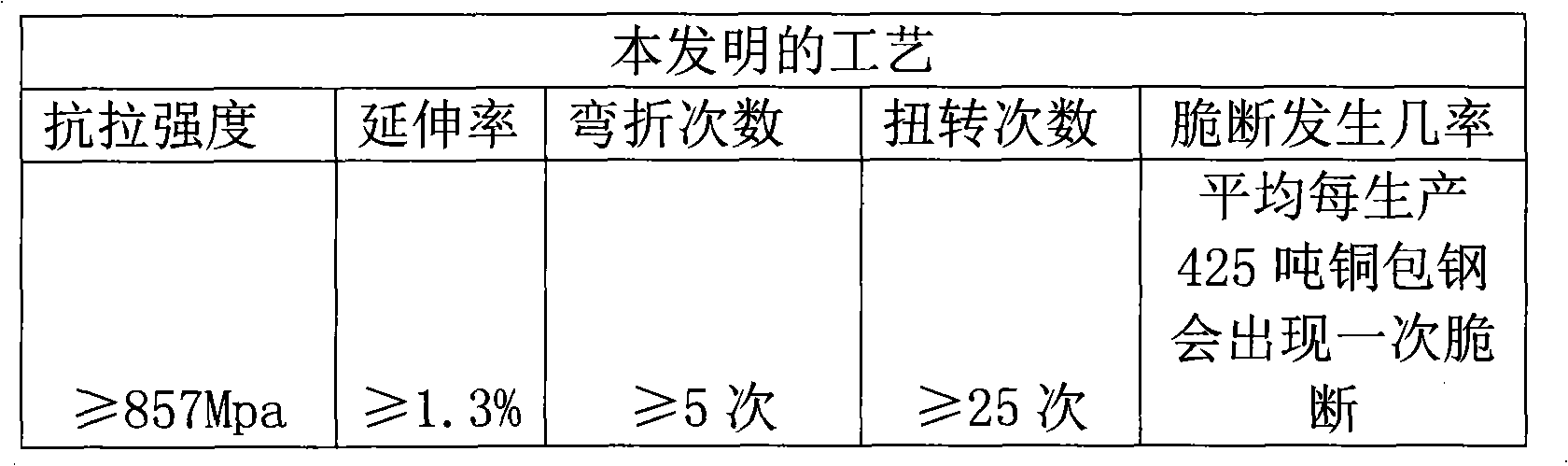

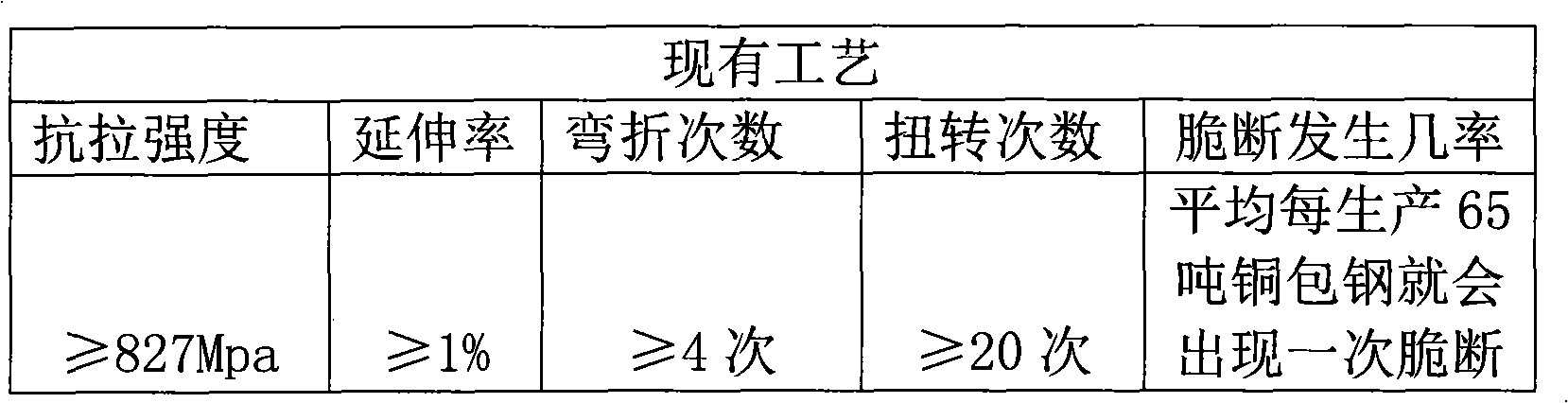

Technique for producing high-strength copper covered steel conductor for coaxial cable inner core wire

ActiveCN101303923AEliminate internal stressHigh tensile strengthMetal/alloy conductorsCable/conductor manufactureCoaxial cableElectrolysis

The invention relates to a high-strength copper-clad steel conductor. A production technique of a high-strength copper-clad steel conductor used for an inner core wire of a coaxial cable is characterized by comprising the following steps: rough drawing, medium temperature tempering, oxide layer removal, fine drawing, treatment before electro-deposition, acid electrolysis, washing, pretreatment of electro-deposition, washing, thick treatment of the electro-deposition, washing, oxidation protection, drying, tank wire drawing, washing, oxidation protection, drying and collecting lines and tray filling. Physical properties such as tensile strength, elongation, small reduction of area and bending times of the high-strength copper-clad steel conductor produced by the technique are enhanced.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Production method of tin-bismuth alloy coated copper clad steel wire

The invention discloses a production method of tin-bismuth alloy coated copper clad steel wires, which successively comprises acid pickling and rust protection treatment, first pullout treatment, first heat treatment, second pullout treatment, second heat treatment and tin electroplating. The tin electroplating means tin-bismuth alloy electroplating. The invention can effectively prevent tin pest, can substitute for leaded wires to be applied to lead wires, connecting wires and the like of electronic products, and can be widely applied to the field of the electronic products.

Owner:NANTONG HONGYANG METAL PRODS

Thermofusion welding agent for welding copper covered steel grounded screen

ActiveCN101412167AHigh strengthReduce consumptionWelding/cutting media/materialsSoldering mediaDetonatorLow noise

The invention provides a hot-melt welding flux for copper-clad steel grounding net welding, which belongs to the field of metal welding. The prior hot-melt welding flux for copper-clad steel grounding net welding has the problems of violent reaction, huge heat release, high noise, poor corrosion resistance and the like. The hot-melt welding flux consists of hot-melt solder and detonator, wherein the hot-melt solder consists of the following materials in weight percentage: 30 to 40 percent of copper oxide powder, 8 to 11 percent of metal aluminum powder, 20 to 35 percent of metal copper powder, 5 to 10 percent of fluorite powder, 4 to 10 percent of tin powder and 5 to 10 percent of nickel powder. The hot-melt welding flux has the advantages of proper reaction speed, low heat release, low noise, good corrosion resistance and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

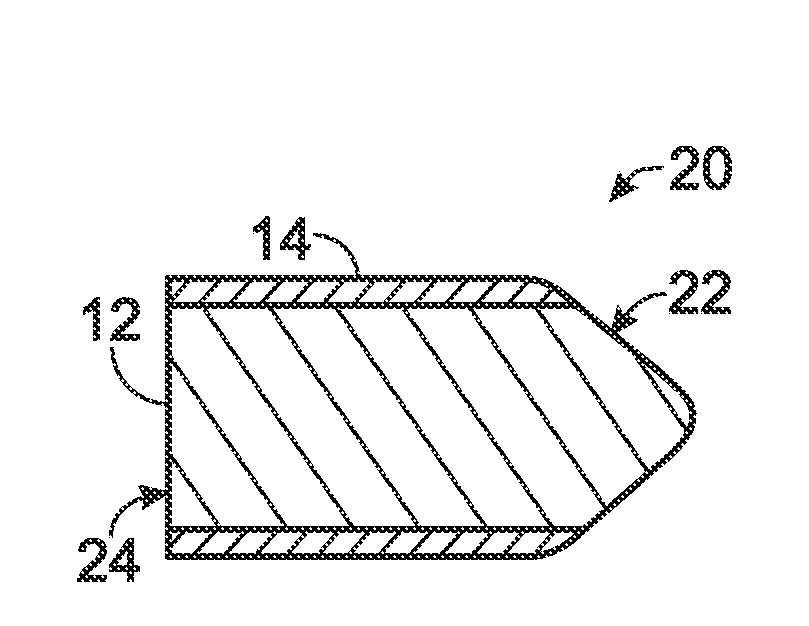

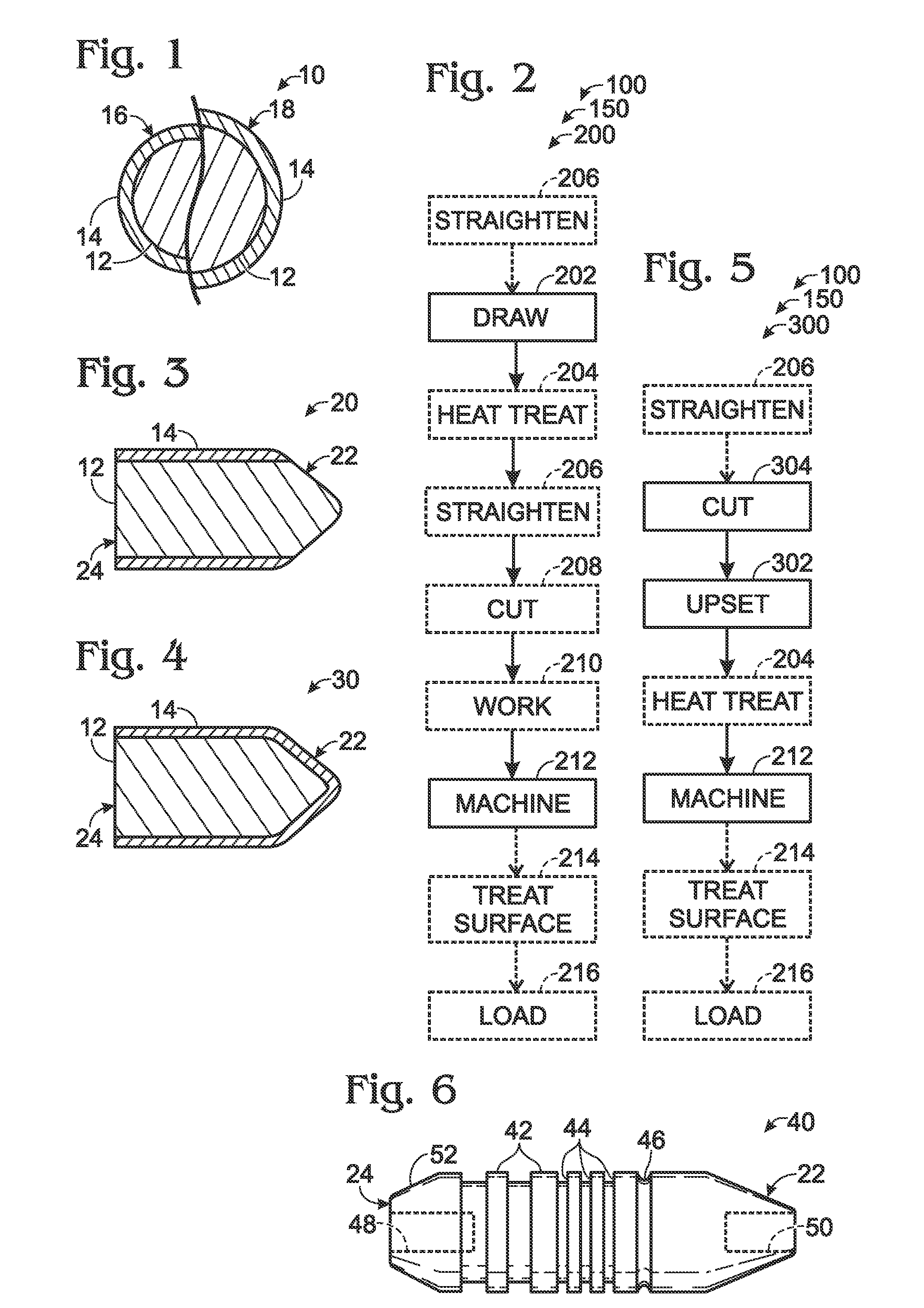

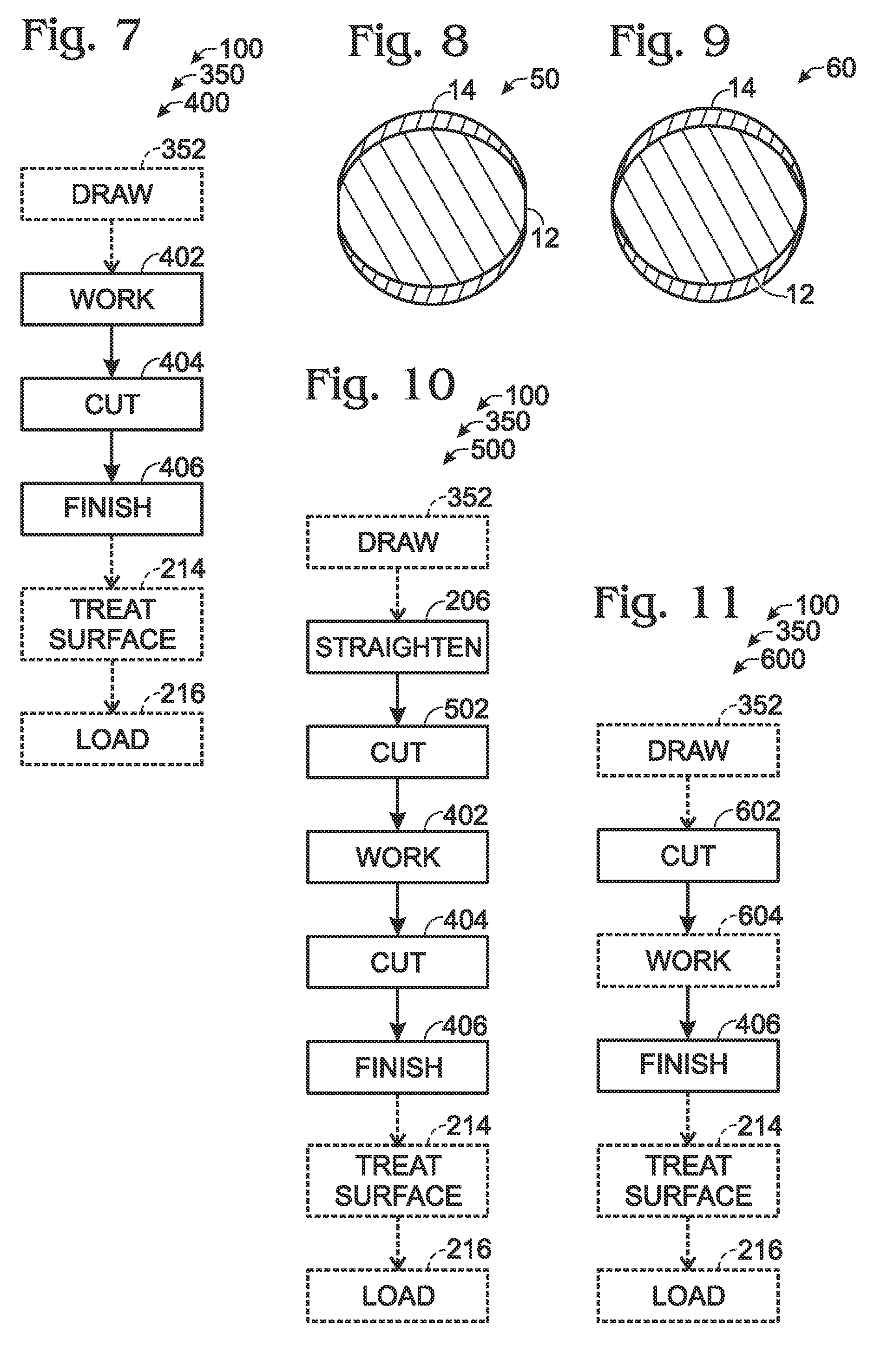

Firearm projectiles and cartridges and methods of manufacturing the same

InactiveUS20110203477A1Reduce the overall diameterIncrease the diameterAmmunition projectilesShotgun ammunitionEngineeringCopper-clad steel

Firearm projectiles and methods of manufacturing firearm projectiles from a supply of clad wire. In some embodiments, the clad wire is manufactured as electrical wire, such as copper-clad steel wire. Bullets and shot, as well as methods of forming bullets and shot, from clad wire are disclosed.

Owner:AMICK FAMILY REVOCABLE LIVING TRUST

Production technology of copper-clad steel wire in soft state

ActiveCN102254629AAvoid crackingGuaranteed elongationCommunication cablesManufacturing extensible conductors/cablesElectricityElectrolysis

The invention relates to a production technology of a copper-clad steel wire in a soft state. The production technology successively comprises the following steps: drawing; tempering under high temperature; carrying out electro-deposition pretreatment; carrying out acid electrolysis; washing; carrying out pretreatment of electro-deposition; washing; carrying out electrodeposition thick treatment; washing; carrying out anti-oxidation processing; drying; drawing; washing; carrying out anti-oxidation processing; tempering under high temperature; polishing; carrying out anti-oxidation processing; and spooling to obtain a finished product. An advantage of the production technology of the copper-clad steel wire in the soft state is that an elongation rate of the produced copper-clad steel wire is greater than or equal to 8%, wherein the elongation rate, which is compared with an elongation rate of a copper-clad steel wire produced by a traditional tempering technology, can be enhanced by at least more than one time..

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Steel for copper-clad steel and method for producing the same

The invention relates to copper clad steel and a production method thereof. The copper clad steel comprises the following components by weight percent: less than or equal to 0.01% of C, less or equal to 0.009%of Si, 0.05-0.12% of Mn, 0.008-0.015% of Als, less than or equal to 0.015% of P, less than or equal to 0.010% of S and the balance of iron and inevitable impurities. The production method comprises the following steps: smelting, performing continuous casting to obtain a billet; heating the continuous casting billet; performing rough rolling on a high-speed line; performing finish rollingon another high-speed line; silking; performing delay chilling on a Stelmor line; and performing air cooling to the room temperature for standby. The production method solves the problems of the existing SWRM6 wire rod that the work hardening of the wire rod is easy to cause, the electrical conductivity is low and the requirements of the high-end copper clad steel can not be met. The invention provides the copper clad steel product which has good cold workability and high electrical conductivity and completely meets the user requirement.

Owner:武汉钢铁有限公司

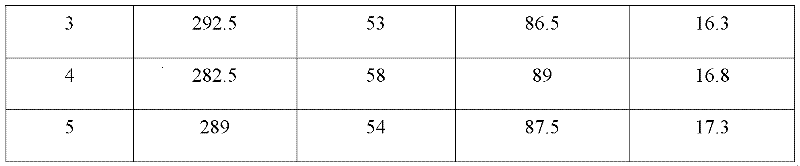

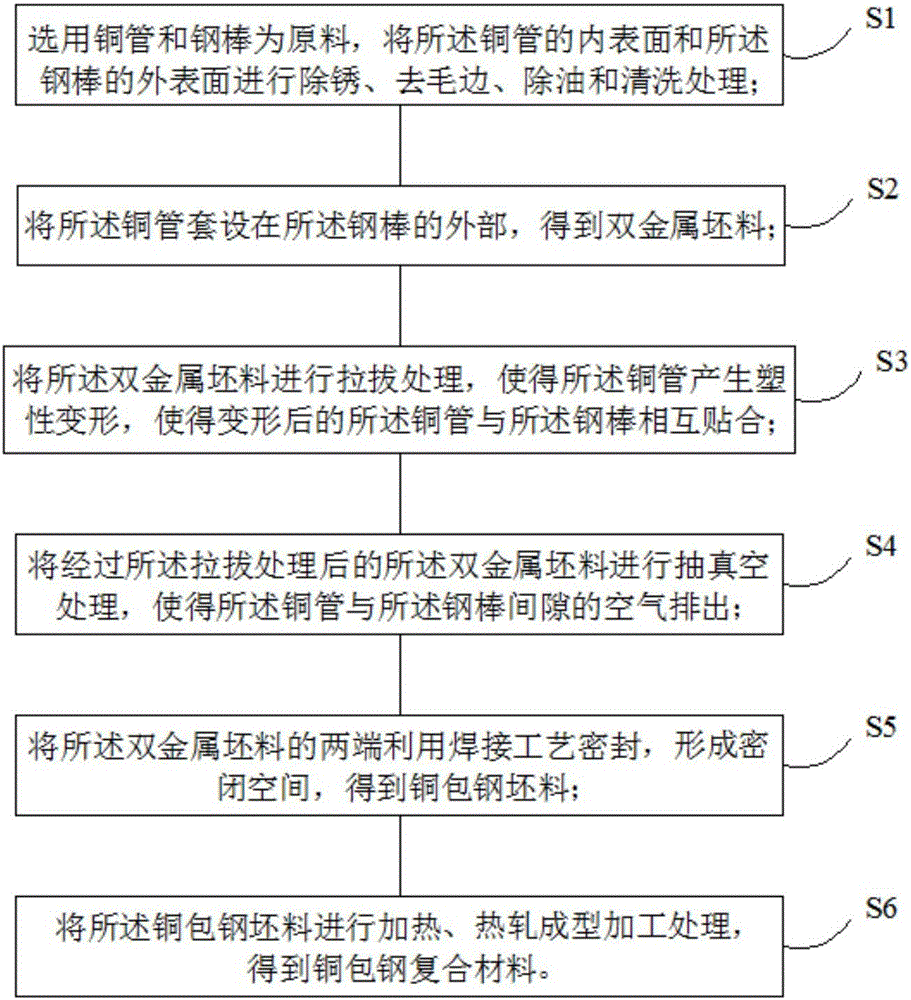

Method for preparing copper-clad steel composite material

InactiveCN106448932AImprove bindingGreat combination depthSingle bars/rods/wires/strips conductorsCable/conductor manufactureUltimate tensile strengthCopper-clad steel

The invention discloses a method for preparing a copper-clad steel composite material. The method comprises the following steps: performing treatment of rust removal, burr removal, oil removal and washing on the inner surface of a copper tube and the outer surface of a steel rod; sleeving the copper tube on the steel rod so as to obtain a double-metal blank; performing pull-drawing treatment on the double-metal blank so as to cause plastic deformation to the copper tube and clue the copper tube to the steel rod; performing vacuuming treatment on the double-metal blank so as to discharge air in the gap between the copper tube and the steel rod; sealing two ends of the double-metal blank by using a welding process so as to form a sealed space and thus obtain a copper-clad steel blank; performing treatment of heating and hot-rolling molding on the copper-clad steel blank, thereby obtaining the copper-clad steel composite material. According to the method disclosed by the invention, as procedures of vacuum sleeving, hot-rolling molding and the like are implemented, the copper tube and the steel rod can be mutually combined in a vacuum environment, then the copper-clad steel composite material can be prepared, and the method has the advantages of being high in combination strength, yield and capacity, adjustable in thickness of a copper layer, high in production efficiency, good in corrosion resistance and the like.

Owner:HUNAN 3T NEW MATERIAL

Wind energy cable and production method thereof

InactiveCN102568680AMeet the requirements of low temperature resistanceSo as not to damageClimate change adaptationInsulated cablesInsulation layerElectrical conductor

The invention discloses a wind energy cable, comprising an outer sheath layer and at least one insulation core, wherein the insulation core comprises a conductor and an insulation layer, a longitudinal covered slippage-resistance layer is arranged between the conductor and the insulation layer, the slippage-resistance layer is a Teflon band, the conductor comprises a composite oxygen-free copper wire and a copper-clad steel wire, the composite conductor increases the tensile property and torsion resistance performance of the wind energy cable. The longitudinal covered slippage-resistance layer is arranged between the conductor and the insulation layer, so as to make the most of the self-lubrication, high intensity, high temperature resistance and low temperature resistance features of the Teflon band, ensure that the slippage resistance layer can bear high temperature and high pressure during the extruded insulation process, the conductor and the insulation layer can completely slip during the use, the insulation can not be damaged during slippage, and the requirement of low temperature resistance can be satisfied.

Owner:四川川东电缆有限责任公司

Production method for copper-clad steel double-metal wire

ActiveCN101763916AMeet the qualityFulfil requirementsSingle bars/rods/wires/strips conductorsFurnace typesCopper-clad steelSolution treatment

The invention discloses a production method for a copper-clad steel double-metal wire, which includes the steps as follows: straightening a steel core, then removing rust, cleaning and mechanically polishing; heating and melting electrolytic copper, heating the steel core, then horizontally and continuously casting a coating copper layer; heating the copper-clad steel and implementing quick solid solution treatment; continuously pulling the copper-clad steel wire for a plurality of times to lead the diameter of a product to reach 4mm-26mm; annealing the pulled copper-clad steel wire and pulling a die to a specification needed by a finished product. The steel and copper in the product are connected in a melting way by malleable metallurgy and an interface can be completely and firmly combined to become a single compound. The pulling of the double-metal wire is just like pulling of a single metal wire. The invention can coat any products with different materials and different copper layer thicknesses, can meet the requirements of relevant industries on product quality and performances, can produce products with large diameter and long length, and does not pollute the environment. The production method for the copper-clad steel double-metal wire has the advantages of less equipment investment, quick effect and stable performance; moreover, the production method for the copper-clad steel double-metal wire can meet the high requirements on industries like war industry, high-speed railway, communications, electron and electric power, etc.

Owner:GANSU TINTO METALLURGICAL SCI & TECH

Production technology of preprocessing copper-clad steel wire matrix

ActiveCN102719785AImprove anti-corrosion performanceSmall difference in tensile strengthSolid state diffusion coatingGrinding machinesSurface oxidationDecomposition

The invention, relating to a production technology of copper-clad steel, particularly discloses a production technology of preprocessing a copper-clad steel wire matrix, successively comprising the following steps: husking, derusting with a wire brush, pickling, washing, boronizing, drawing, secondary washing, drying and spooling, and ammonia decomposition tempering. The technology has the following advantages: little pollution in the production process, complete treatment of the surface oxidation layer of the steel wire, bright surface of the steel wire, good anti-oxidation effect, and good binding force between the processed steel wire and the copper layer in the subsequent electroplating process.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

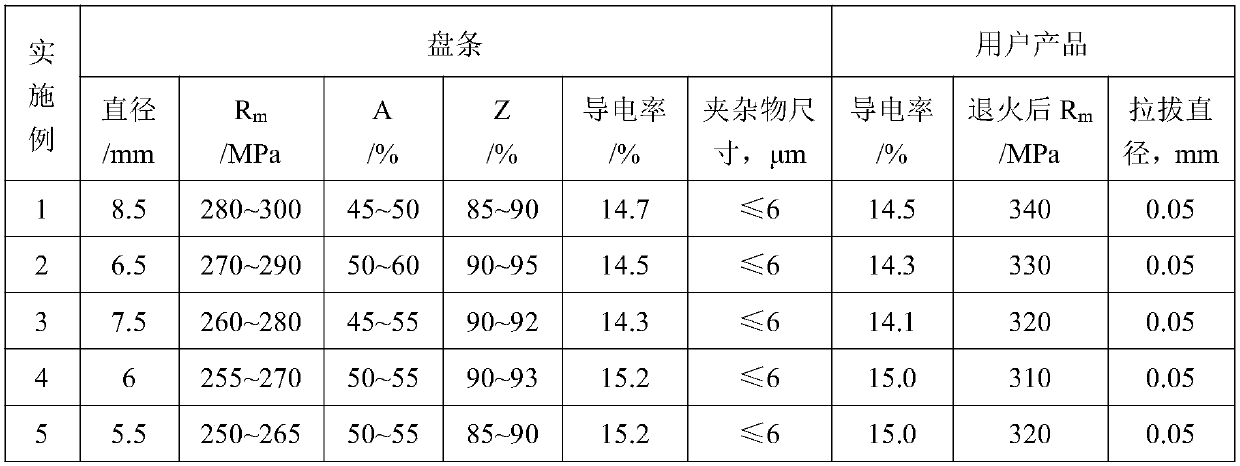

Steel wire rod for copper clad steel composite shielded wire and production method of steel wire rod

ActiveCN108062992AExcellent drawing performanceReduce thicknessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsWire rodChemical composition

The invention relates to a steel wire rod for a copper clad steel composite shielded wire and a production method of the steel wire rod and belongs to the technical field of steel for communication cables. The chemical components of the steel wire rod include C, Si, Mn, P, S, Al, Ti and B; the balance of the steel wire rod includes Fe and unavoidable impurities; the mass percentage of C is smallerthan or equal to 0.010%; the mass percentage of Si is smaller than or equal to 0.010%; the mass percentage of Mn is smaller than or equal to 0.07%; the mass percentage of P is smaller than or equal to 0.010%; the mass percentage of S is smaller than or equal to 0.010%; the mass percentage of Al is smaller than or equal to 0.004%; the mass percentage of Ti is smaller than or equal to 0.003%; and the mass percentage of B ranges from 0.0060 to 0.0120%. The production method includes a billet smelting process, a billet heating process, a wire rod rolling process and a wire rod cooling process. According to the heating process, continuous casting billet heating and hot billet secondary heating are adopted, and the temperature of a heating furnace ranges from 1140 to 1160 DEG C. According to the wire rod cooling process, a slow cooling technique is adopted. The steel wire rod for the shielded wire has excellent drawing performance and excellent conductive performance; the steel wire rod canbe drawn to 0.08 mm with wire fracture avoided; and the conductivity of the steel wire rod can reach 16.3% or more.

Owner:XINGTAI IRON & STEEL

Preparation method of copper-clad steel bimetal composite rod

The invention relates to a preparation method of a copper-clad steel bimetal composite rod, belonging to the technical field of bimetal composite material preparation. The preparation method comprises the following steps of: (1) using a steel rod and a copper tube as raw materials; (2) carrying out the pretreatment of deoiling, derusting and drying on the steel rod and the copper tube; (3) rolling the head of the steel bar by a head rolling machine; (4) inserting the steel bar into the copper tube, carrying out the composite head rolling treatment by the head rolling machine; and (5) carrying out 2-3 passes of composite drawing to obtain the copper-clad steel bimetal composite rod. The method has the characteristics of simple process, high efficiency and low cost. The copper-clad steel bimetal composite rod prepared with the method has stable bonding performance in the copper-steel surface and great surface quality.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Production method of steel wire rod for very fine copper-clad steel wire

InactiveCN107675068AKeep Steel PureComply with chemical composition requirementsSteelmakingManganese

The invention discloses a production method of a steel wire rod for a very fine copper-clad steel wire. The production method comprises the following steps of a steelmaking procedure and a controlledrolling procedure, wherein the steelmaking procedure comprises the following steps of 1) molten iron pretreatment; 2) converter steelmaking; 3) argon blowing; 4) RH refining: controlling the mass content of carbon in molten steel to be smaller than or equal to 0.003 percent, the mass content of free oxygen to be smaller than or equal to 15ppm and the mass ratio of manganese and sulfur to be Mn / S larger than or equal to 10; and 5) continuous casting; and the controlled rolling procedure comprises the following steps of 6) heating, wherein a temperature of a heating section is 1050-1150 DEG C, atemperature of a heat balance section is 1150 plus / minus 50 DEG C, and a section temperature difference is smaller than or equal to 30 DEG C; 7) roughing; 8) finishing: a temperature of an inlet of afinishing mill is 900 plus / minus 15 DEG C, and a temperature of an inlet of a reducing sizing mill is 890 plus / minus 10 DEG C; and 9) cooling control: controlling cooling on a Stelmor cooling controlline, wherein a laying temperature of a laying machine is 890 plus / minus 10 DEG C, and the average cooling rate is 0.5-1.5 DEG C / s. The steel wire rod produced by the method has especially good colddrawing performance and higher conductivity and meets the requirements for the steel wire rod for the very fine copper-clad steel wire by electronic products including mobile phones.

Owner:武汉钢铁有限公司

Copper-clad steel/copper grounding grid heat release welding flux with high safety

InactiveCN101637853AImprove securitySplash noWelding/cutting media/materialsSoldering mediaGrounding gridAluminium powder

Owner:CHINA ELECTRIC POWER RES INST

Ignition powder for copper-clad steel/copper grounding grid exothermic welding

InactiveCN101637851AEasy to storeEasy to transportWelding/cutting media/materialsSoldering mediaExothermic weldingGrounding grid

An ignition powder for copper-clad steel / copper grounding grid exothermic welding belongs to the metal welding field. The existing ignition powder for exothermic welding has the problems of poor safety, no environmental protection, complex components, high reaction brightness and the like. The ignition powder for exothermic welding comprises the following components by weight percent: 20-70% of copper oxide powder with granularity of 40-80 meshes and 85% of oxidation degree; 0-50% of copper oxide powder with granularity of 200-300 meshes and 99.9% of oxidation degree; 10-15% of aluminium metalpowder with granularity of 200-300 meshes and 99.9% of purity; and 15-35% of magnesium metal powder with granularity of 40-100 meshes and 99.9% of purity. The ignition powder has the advantages of simple components, environmental protection, good safety, even reaction speed, moderate brightness and the like.

Owner:CHINA ELECTRIC POWER RES INST

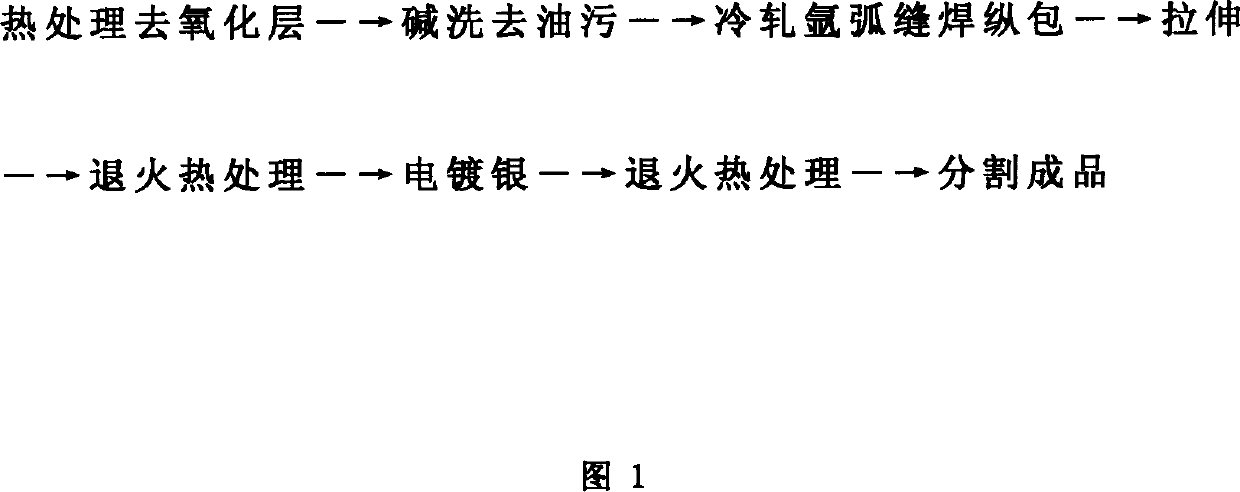

Method for producing silver-copper plated steel clad wire for coated electronic product

InactiveCN1822246AHigh strengthLower resistanceWire articlesSingle bars/rods/wires/strips conductorsElectrical resistance and conductanceHigh intensity

Present invention discloses a silver-copper plated steel-clad wire manufacturing method for electronic products. It contains heat treatment, soda wash, cold rolling copper strip, argon arc seam welding, longitudinal coated on steel wire, stretching, annealing heat treatment, plating silver on copper clad steel wire, annealing heat treatment, and cutting finished product etc steps. Said invented cam draw copper clad steel wire to thin wire with diameter lees than o.10mm without broken layer, ensured high strength of copper steel thermometal composite material, with low resistance and high corrosion resistance.

Owner:吴江南方电缆有限公司

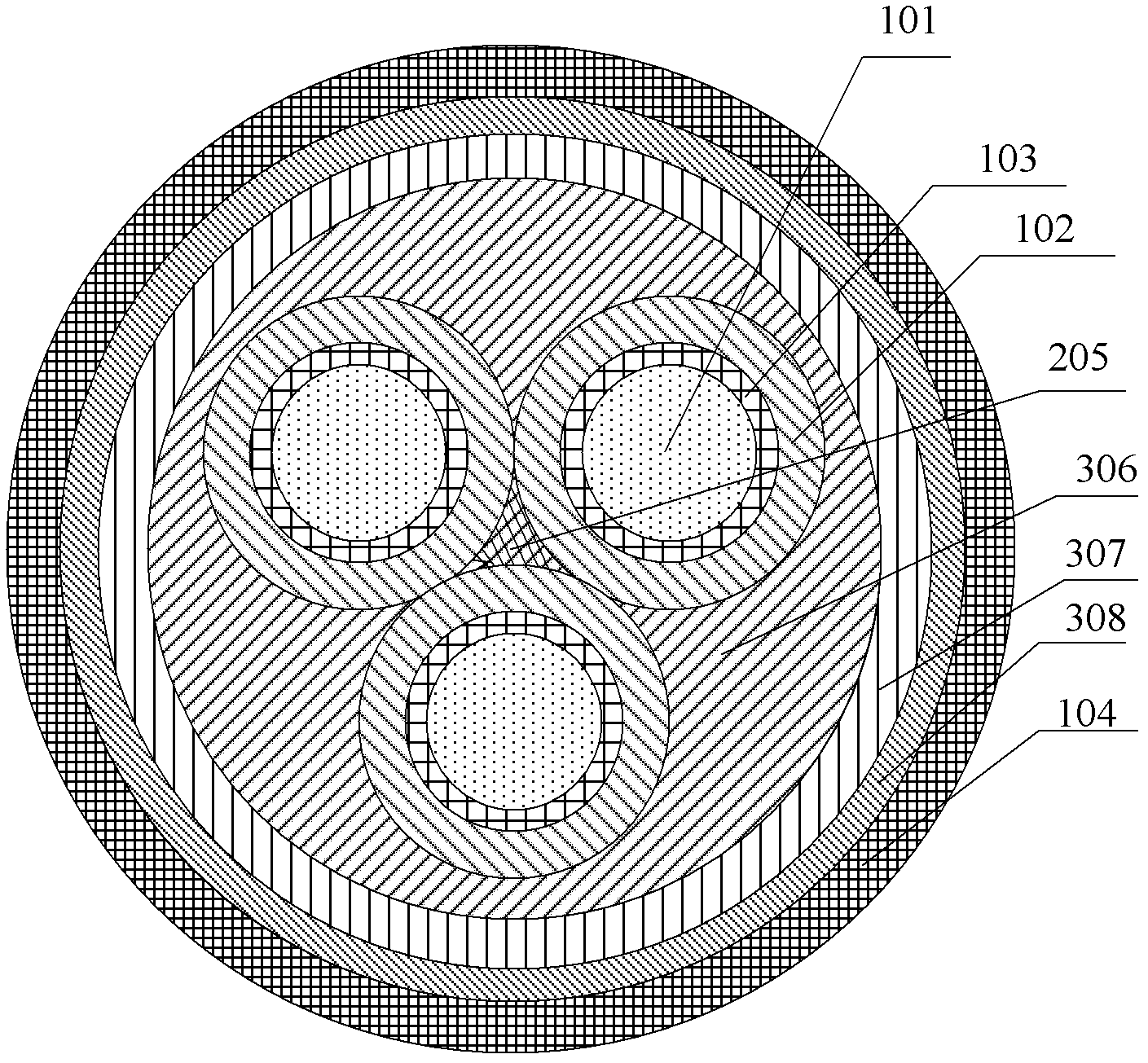

Semi-flexible low loss coaxial radio frequency cable for mobile base station

InactiveCN101752639ALow costReduce lossCoaxial cables/analogue cablesWaveguidesUltrasound attenuationElectrical conductor

The invention discloses a semi-flexible low loss coaxial radio frequency cable for a mobile base station. The invention is characterized in that: an inner conductor is a copper wire or a copper clad steel wire; and the inner conductor is coated with a composite insulating layer consisting of a first insulating layer and a second insulating layer, a shielding insulating layer, an outer conductor and an outer sheath layer from inside to outside sequentially. The invention has the advantages that expensive gold and silver are saved; the usage of polyfluortetraethylene ten times more expensive than polyethylene is greatly reduced; the cost is obviously reduced; and the cable has good shielding property, high using frequency, low loss, small attenuation and standing-wave ratio and long transmitting distance, can reduce the amount of the base stations in the coverage area and reduce the transmitting cost, and has obvious economic benefit.

Owner:江苏通光电子线缆股份有限公司

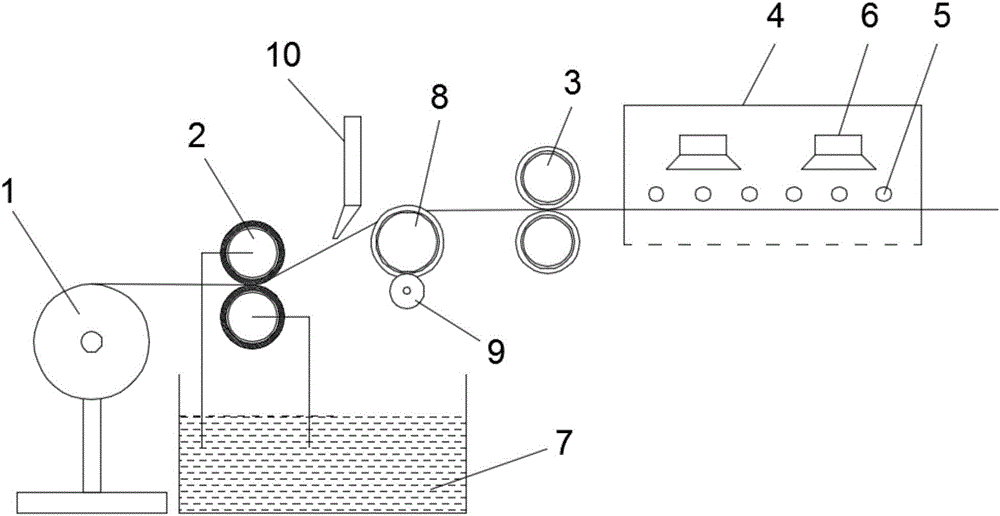

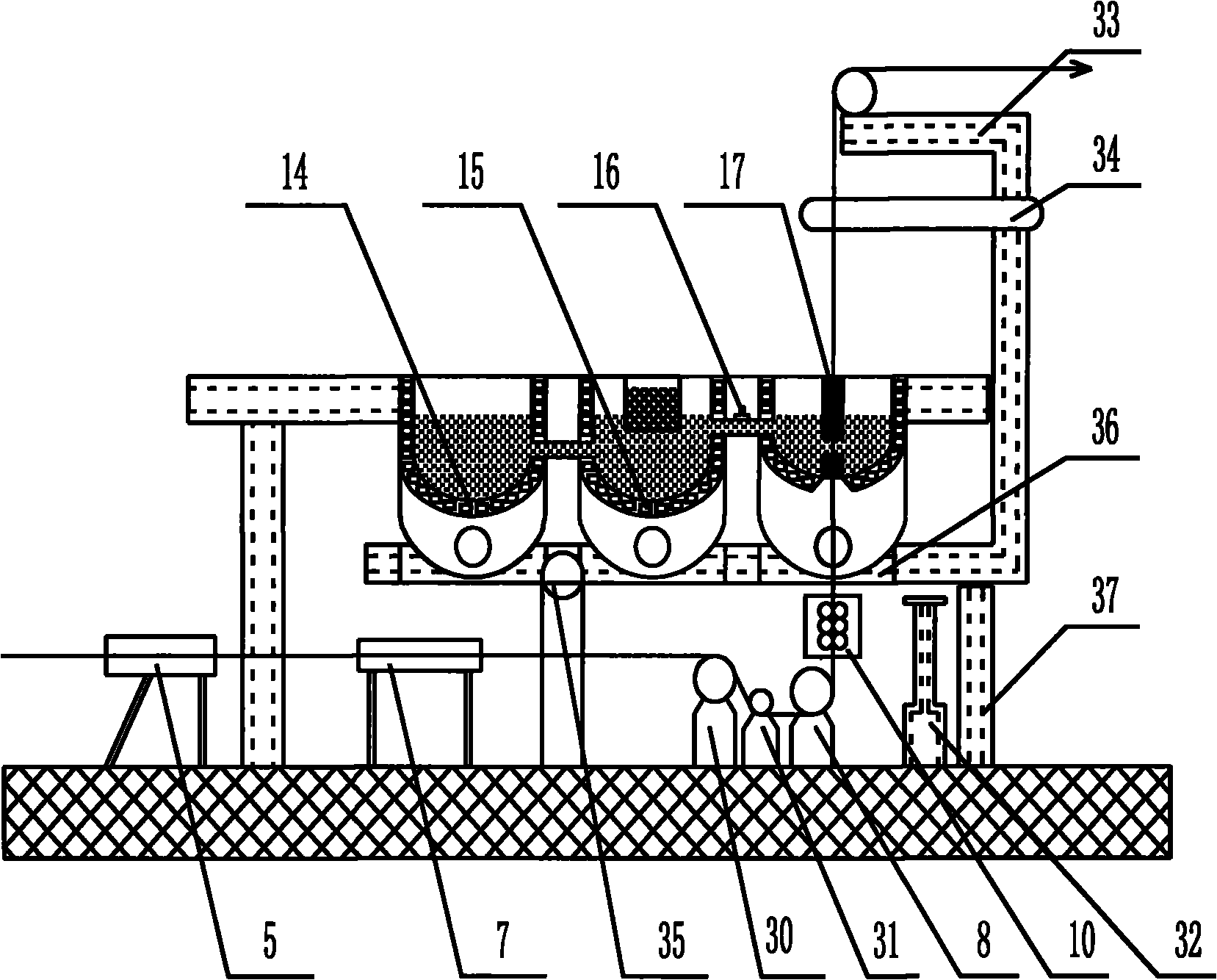

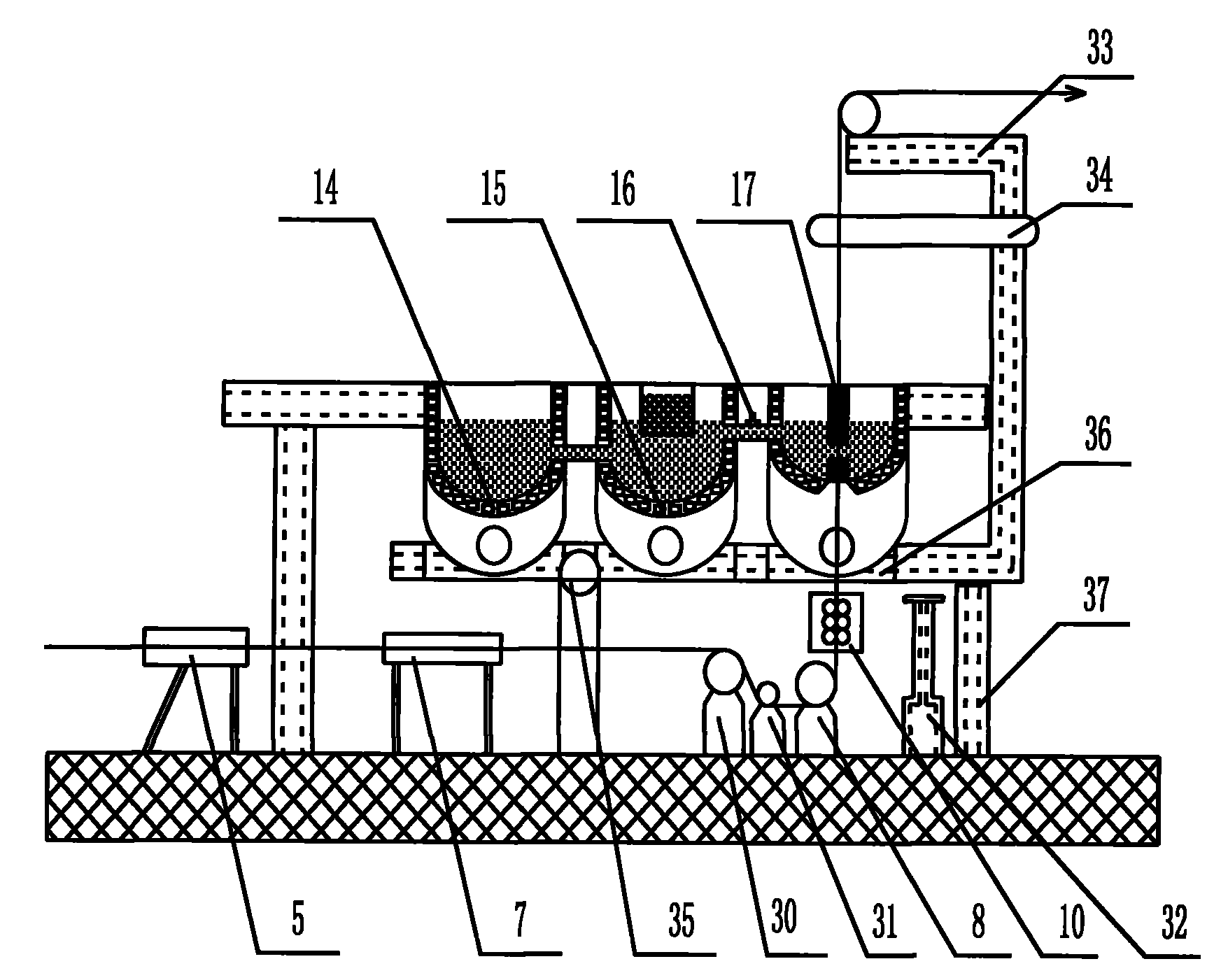

Cleaning mechanism of copper clad steel wire

InactiveCN106238365AEfficient removalImprove conductivityCleaning using toolsCleaning using liquidsEngineeringCopper-clad steel

The invention relates to a cleaning mechanism of a copper clad steel wire. According to the cleaning mechanism of the copper clad steel wire, a wire unwinding device, steel brush double rollers, a wire drawing device and a drying device are arranged in sequence from left to right; a cleaning fluid tank is arranged below the steel brush double rollers; a cleaning fluid enters the steel brush double rollers from the cleaning fluid tank through a pipeline; a sponge roller is arranged above the upper right part of the steel brush double rollers, so that the steel wire between the steel brush double rollers and the sponge roller is inclined upwards; a squeeze roller is arranged on the bottom side of the sponge roller; the squeeze roller is located above the cleaning fluid tank; and a water blowing fan is arranged above the steel wire between the steel brush double rollers and the sponge roller. According to the cleaning mechanism, high-speed scraping is performed by the steel brush rollers and the cleaning fluid, so that impurities such as oil stains and the like can be effectively removed from the surface of the steel wire, and then the cleaning fluid is sucked by the sponge roller and then is squeezed to the cleaning fluid tank by using the squeeze roller so as to be dried; in the whole process, the cleaning efficiency is high, and the cleaning effect is good, so that the copper cladding quality in the next step is guaranteed, and the conductivity of a finished product of the copper clad steel wire is increased.

Owner:ZHANGJIAGANG XINBANG ELECTRIC POWER TECH CO LTD

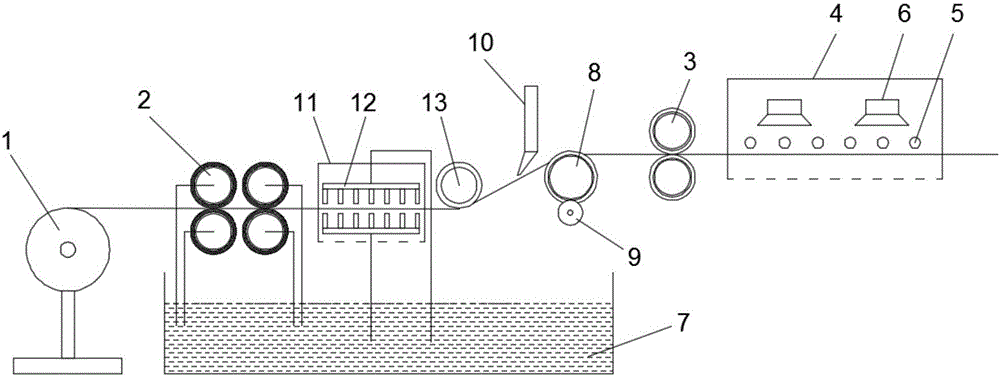

Surface cleaning system for copper-clad steel wire

InactiveCN106269611AEfficient removalImprove conductivityDrying gas arrangementsCleaning using toolsSurface cleaningEngineering

The invention relates to a surface cleaning system for a copper-clad steel wire. According to the surface cleaning system for the copper-covered steel wire, a pay-off device, steel brush double rollers, a wire tensioning device and a drying device are arranged in sequence from left to right; a cleaning liquid tank is arranged below the steel brush double rollers; a spraying cleaning device, a tension control roller and a sponge roller are arranged between the steel brush double rollers and the wire tensioning device, and the sponge roller is located on the upper right of the tension control roller; a water squeezing roller is arranged at the bottom side of the sponge roller and located above the cleaning liquid tank; a water blowing fan is arranged above the position, between the tension control roller and the sponge roller, of the steel wire. Oil stains and other impurities on the surface of the steel wire can be effectively removed through high-speed scraping of the steel brush rollers and cleaning liquid and high-pressure spraying of the spraying cleaning device, the cleaning liquid is sucked away through the sponge roller and then squeezed back into the cleaning liquid tank through the water squeezing roller, and then drying is carried out; the cleaning efficiency is high, and the cleaning effect is good. Thus, the quality of a next step of copper cladding is guaranteed, and the conductivity of a copper-clad steel wire finished product is improved.

Owner:ZHANGJIAGANG XINBANG ELECTRIC POWER TECH CO LTD

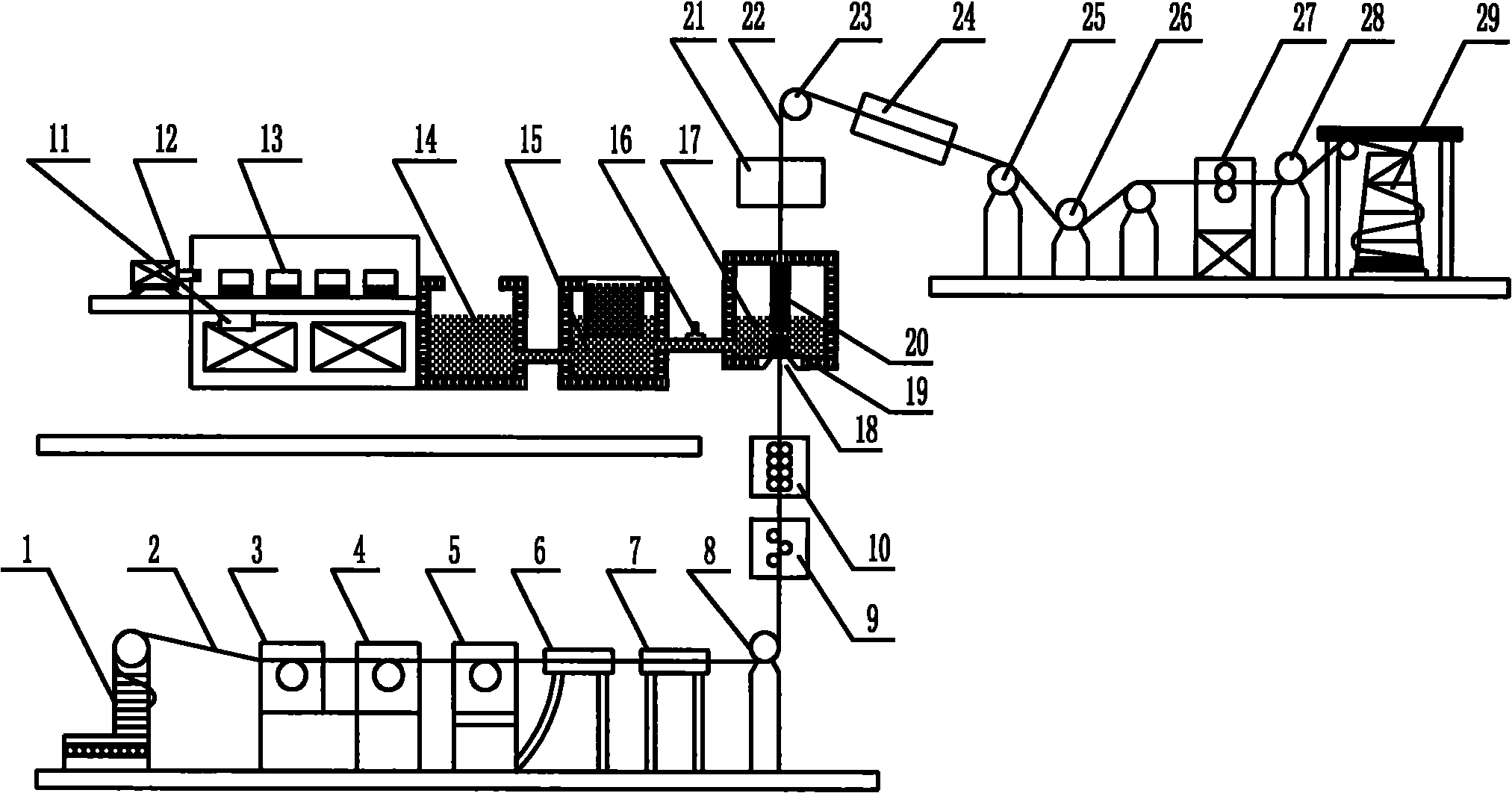

Method and device for continuous up-casting of copper-clad steel

InactiveCN101804448AGood constant temperature effectEasy transferTemperature controlCopper-clad steel

The invention discloses a method and a device for the continuous up-casting of copper-clad steel. The method comprises the key points that: a preheated steel core wire enters from the bottom of a continuous casting furnace, and then is vertically dragged out of the upper part of the continuous casting furnace after continuous casting and cladding in melted copper in the furnace in sequence. The preheating temperature of the steel core wire is between 600 and 700 DEG C; the temperature of the melted copper is controlled to between 1,150 and 1,110 DEG C; the cladding distance of the steel core wire in copper liquid is controlled to between 8 and 17cm; and the speed at which the copper-clad steel core wire after the continuous casting is extracted from the furnace is between 100 and 120m / min. Meanwhile, the device makes the continuous casting furnace keep constant temperature and ensures the quality of products because a melting furnace, a heat preserving furnace and the continuous casting furnace are connected with one another; and moreover, because the device is provided with a furnace body lifting device, the device can conveniently transfer the melted copper in the continuous casting furnace so as to facilitate maintenance.

Owner:秦志春 +1

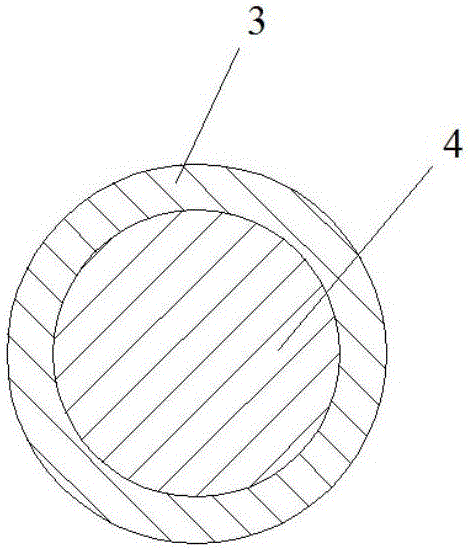

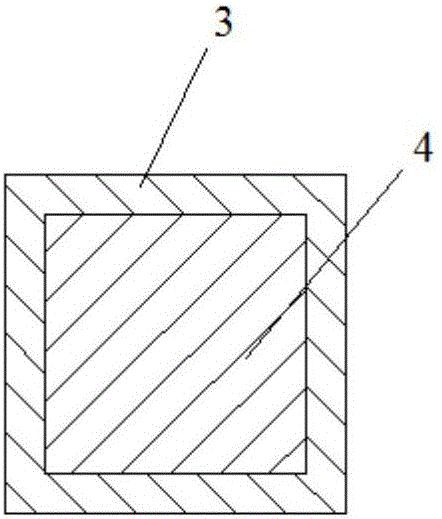

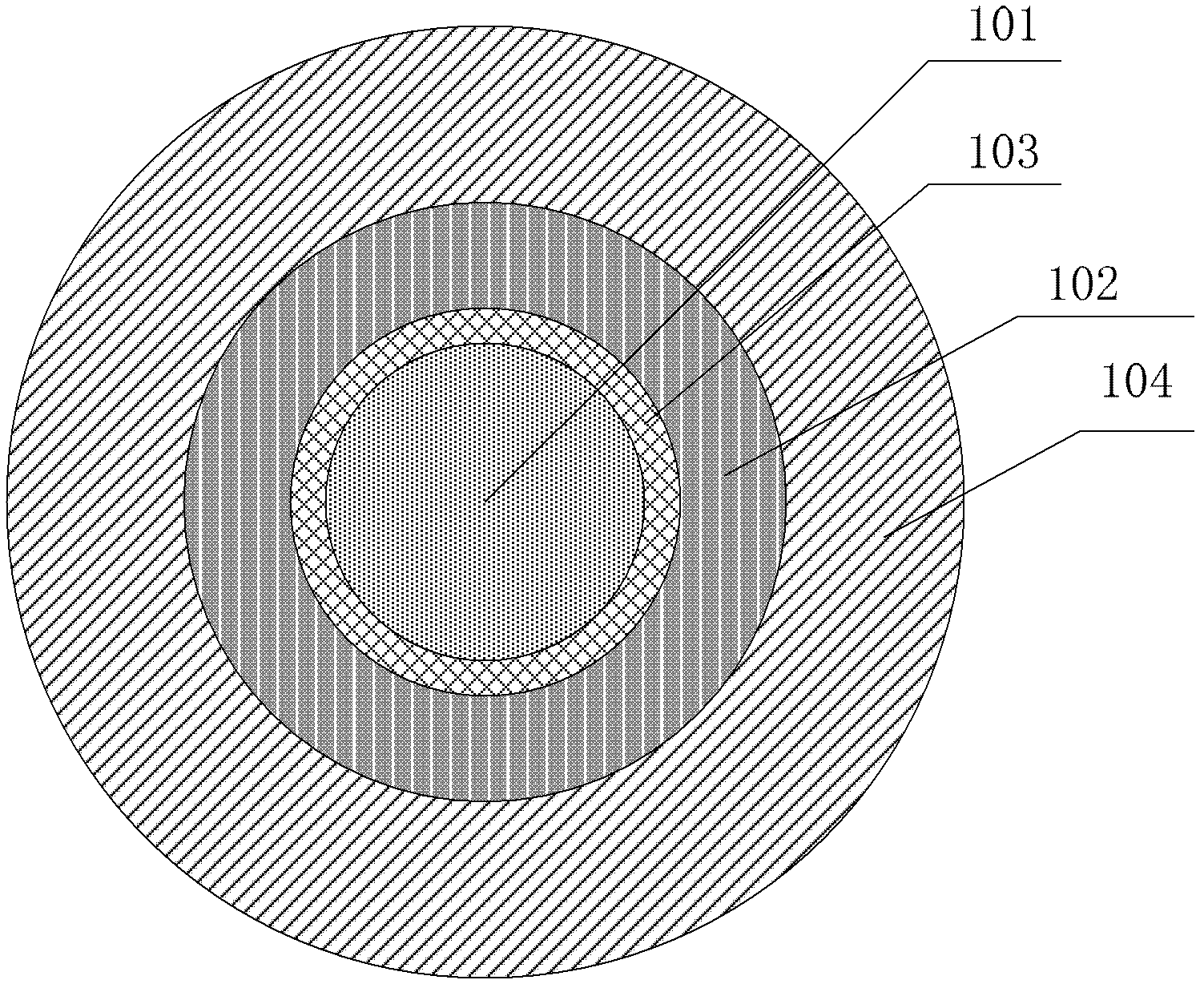

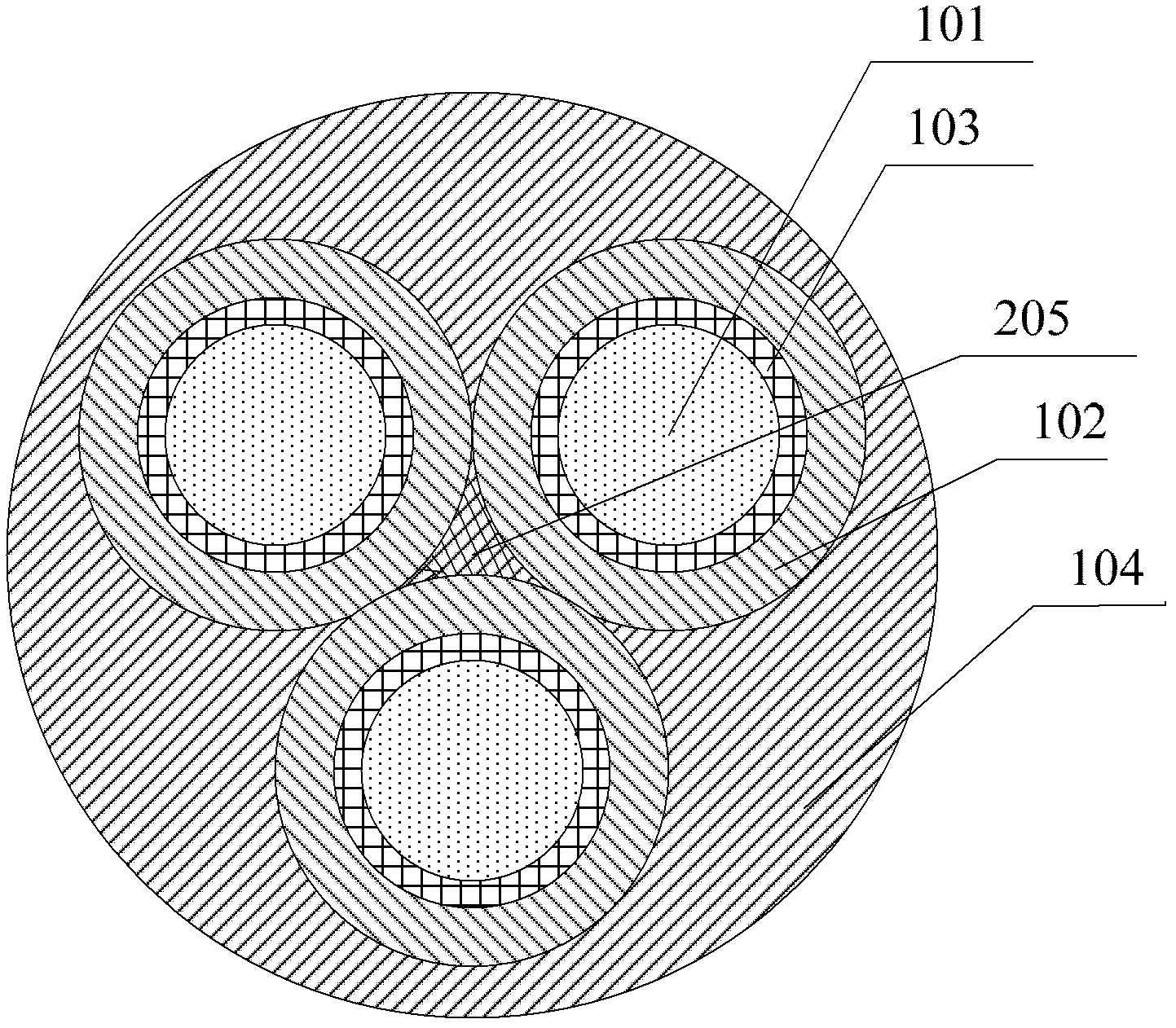

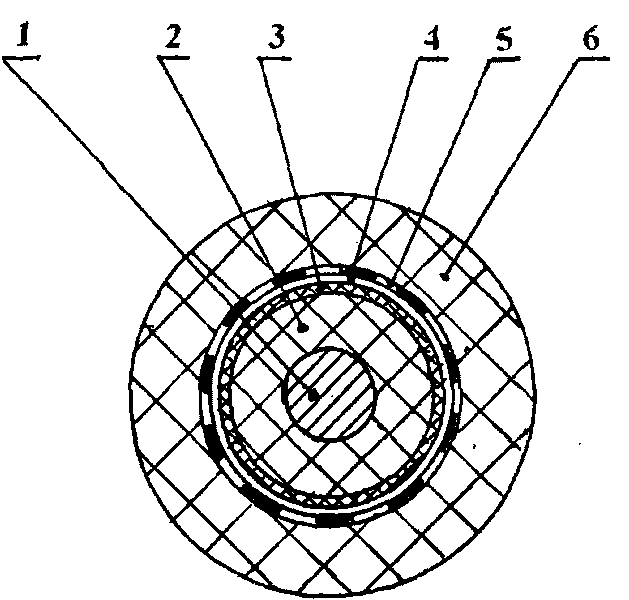

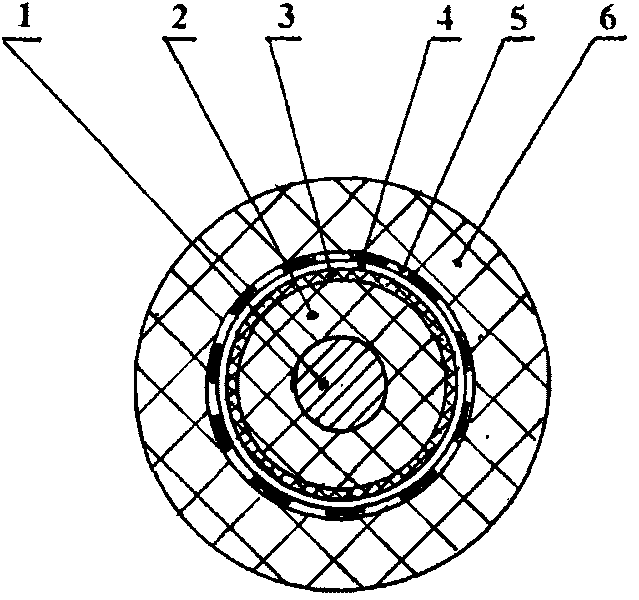

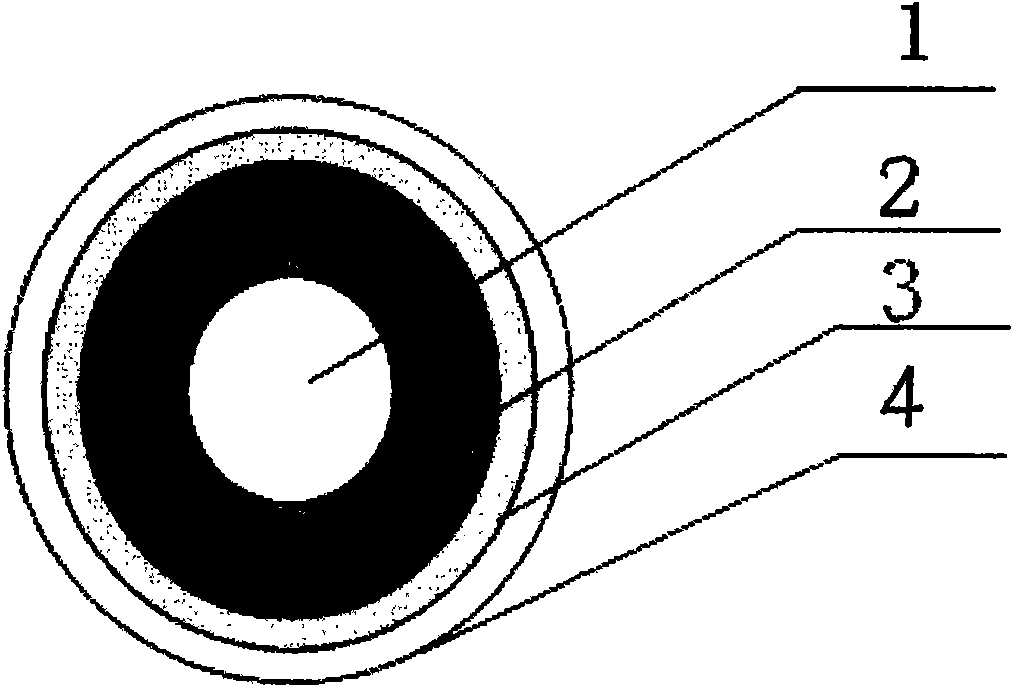

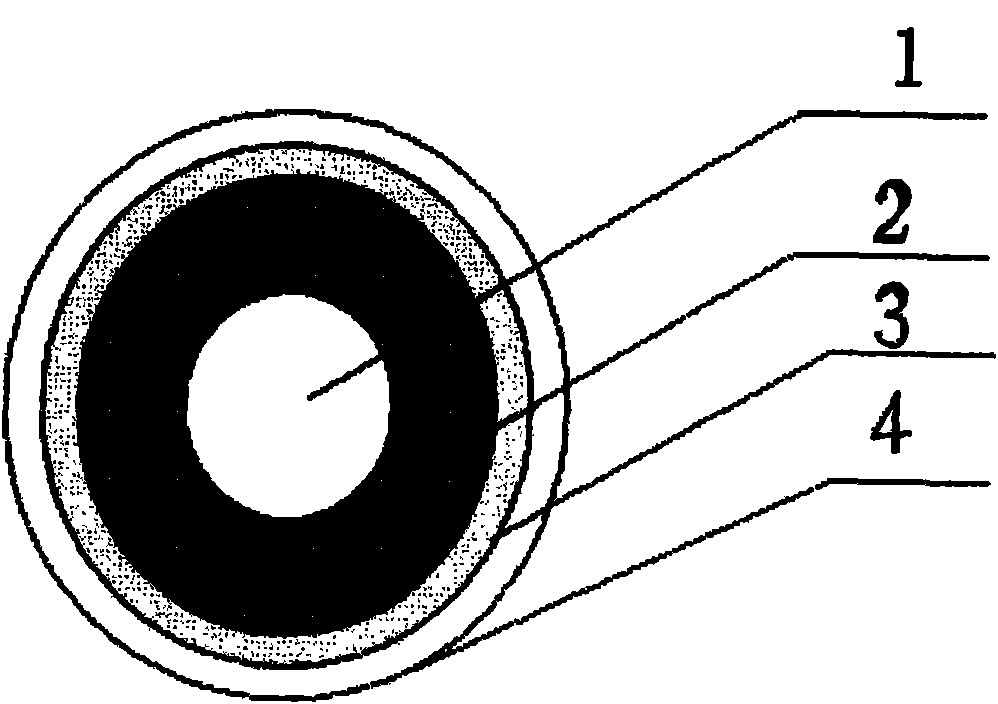

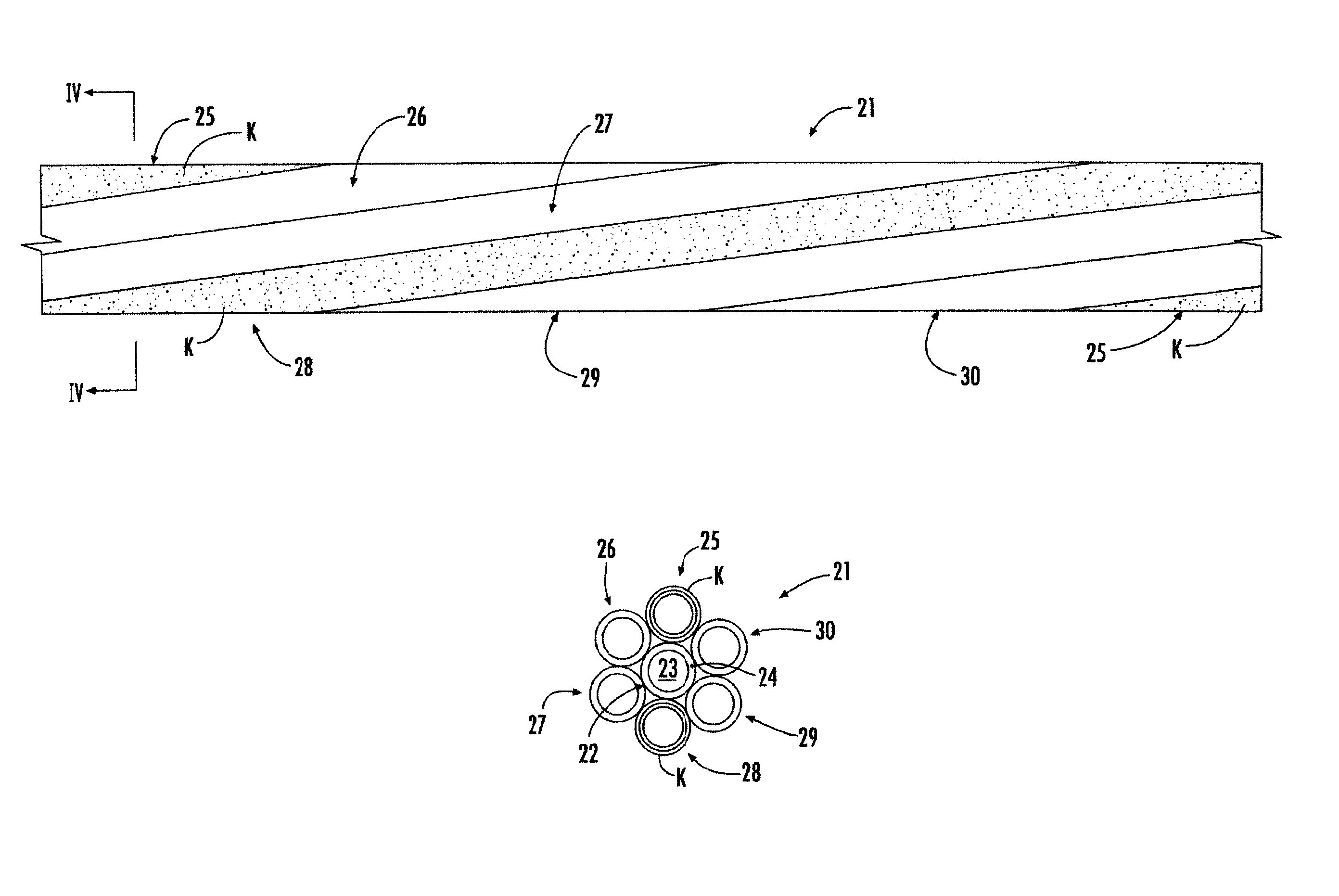

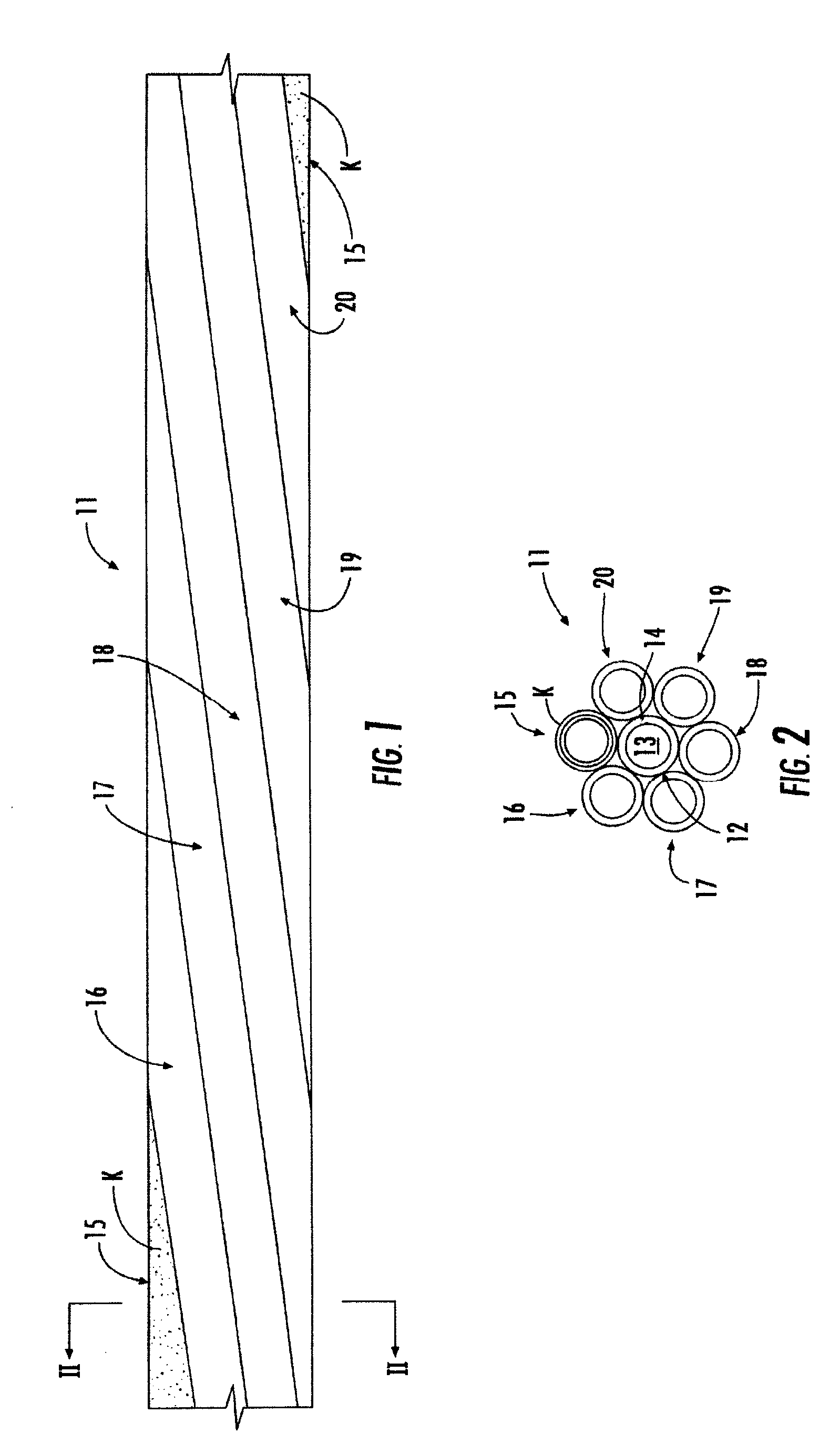

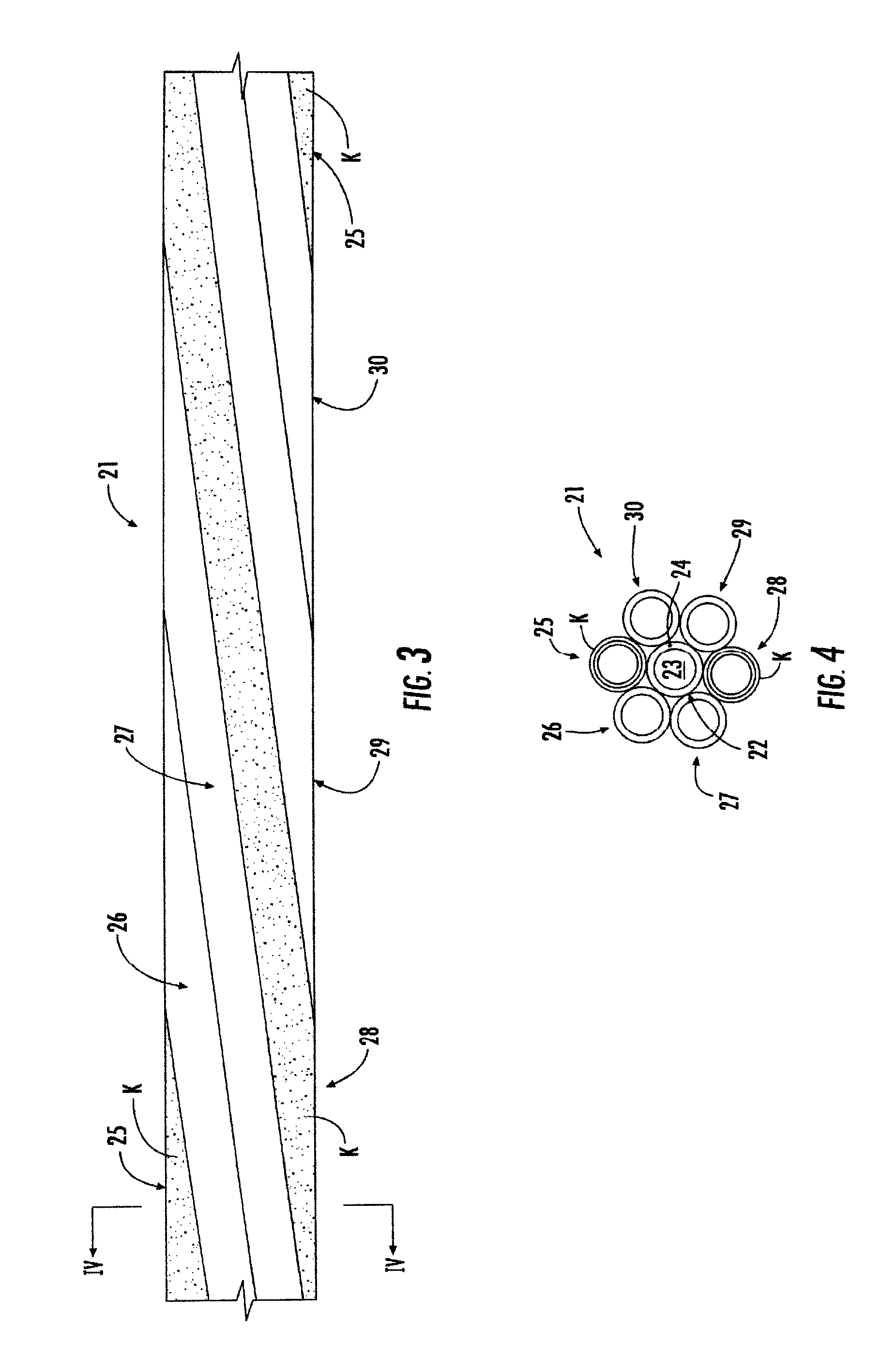

Nickel/silver-coated copper-clad steel conductor core for special cable and manufacturing method thereof

InactiveCN101950604AImprove corrosion resistanceImprove heat resistanceSingle bars/rods/wires/strips conductorsMetal/alloy conductorsElectrolysisElectrical conductor

The invention discloses a nickel / silver-coated copper-clad steel conductor core for special cable. A wire conductor thereof is composed of a plurality of single wires with each sequentially comprising four metal layers, wherein the inner layer is a base material (1), the second layer is a copper layer (2), the outmost layer is a silver layer (4), and a nickel layer (3) is arranged between the copper layer (2) and the silver layer (4). The invention further discloses a manufacturing method of the nickel / silver-coated copper-clad steel conductor core for special cable, which comprises the steps of: using carbon-structured steel as the base material (1) for performing copper coating by means of electrolysis; implementing drawing for formation on the copper layer (2)-forming material many times and then implementing first heat treatment; bringing the material which is subjected to the first heat treatment to nickel coating by means of electrolysis in order to form the silver layer (4); implementing drawing for formation on the silver-coated material via a mold and then implementing second heat treatment, and finally, drawing and polishing the material via the mold to form single wires.

Owner:施义明

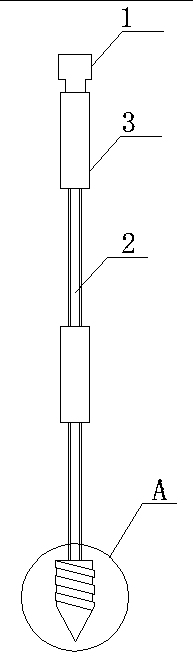

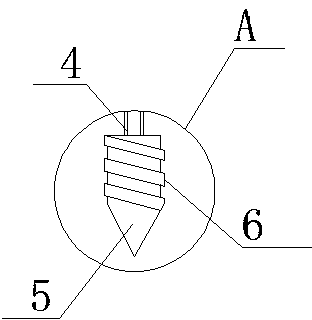

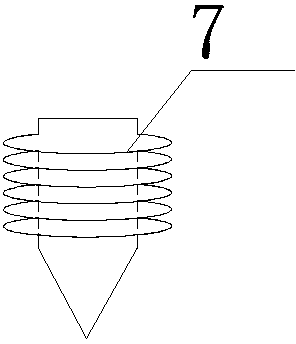

Anti-corrosion and anti-theft grounding electrode

InactiveCN103996909AConvenient and fast entryIncrease the difficulty of extractionConnection contact member materialTowerCopper-clad steel

The invention discloses an anti-corrosion and anti-theft grounding electrode. The anti-corrosion and anti-theft grounding electrode comprises a driving head, grounding rods and connecting rods respectively connected with the driving head and the grounding rods. External threads are arranged at one end of the driving head and the two ends of each grounding rod respectively, and internal threads are arranged at the two ends of each connecting rod. Each grounding rod is a steel core with the surface covered with a copper layer. The end of the lowermost grounding rod is connected with a drill bit. The ratio of the outer diameter of the large end of the drill bit to the outer diameter of each grounding rod is larger than 3, and the surface of the drill bit is spiral or in the shape of a parachute tower. The thickness of each copper layer ranges from 0.3 mm to 0.8 mm, the number of the grounding rods ranges from 1 to 4, and all the grounding rods are connected through the connecting rods. After the grounding electrode is driven into the ground, the gap between the grounding rod bodies and the peripheral soil wall is filled with powdery or mushy resistance reducing agents. Due to the fact that an optimized copper-clad steel technology scheme is adopted for the anti-corrosion and anti-theft grounding electrode and an anti-theft structure convenient to install and detach is adopted for assistance, not only can the anti-corrosion performance and the anti-theft performance be achieved, but also the grounding pass-through performance can be enhanced, and the anti-corrosion and anti-theft grounding electrode has the advantages of being long in service life and high in cost performance ratio.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

Heat-releasing welding flux for iron-base copper-clad steel grounding grid

InactiveCN103639613AStable mechanical propertiesImprove toughnessWelding/cutting media/materialsSoldering mediaAlloyTin

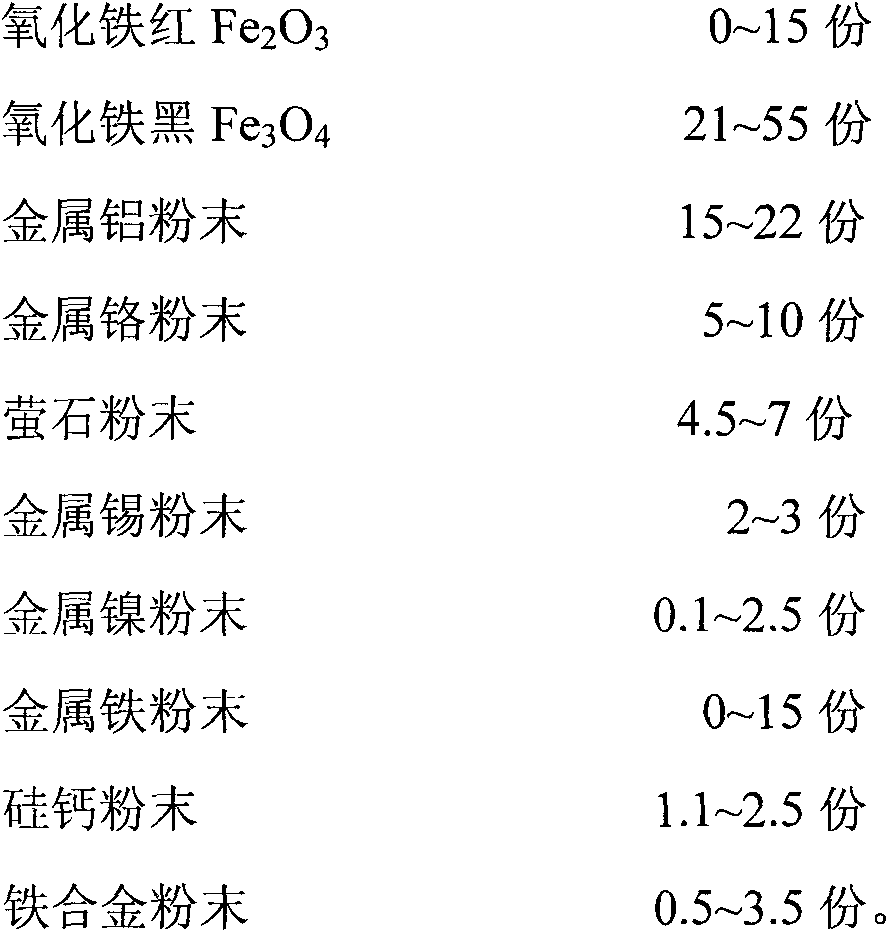

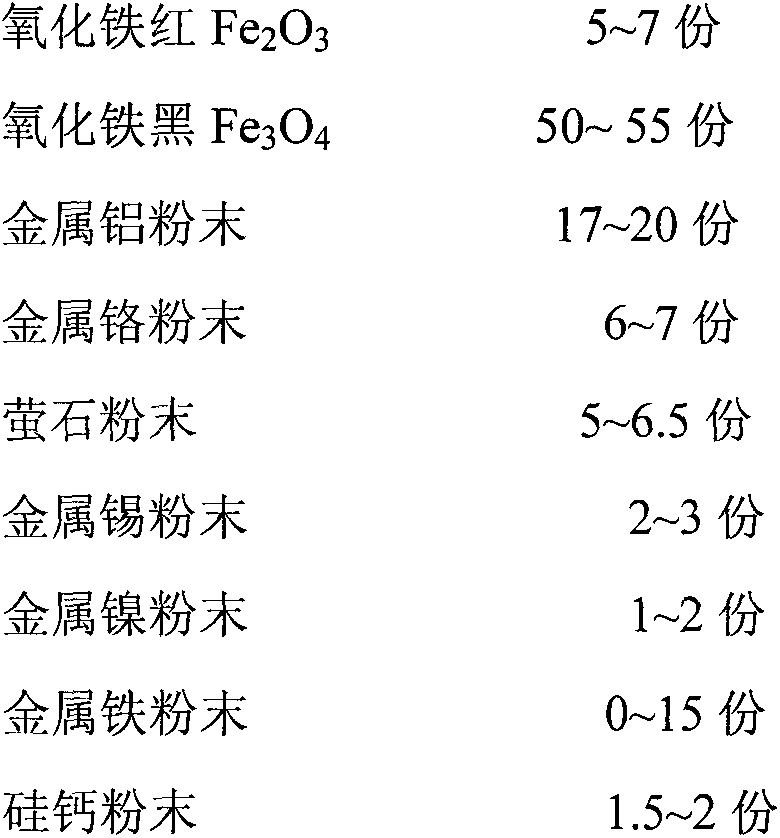

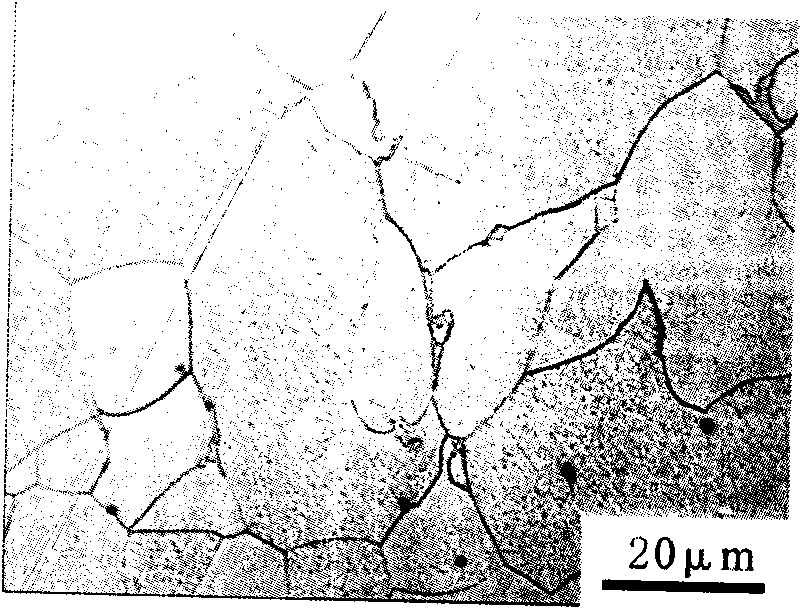

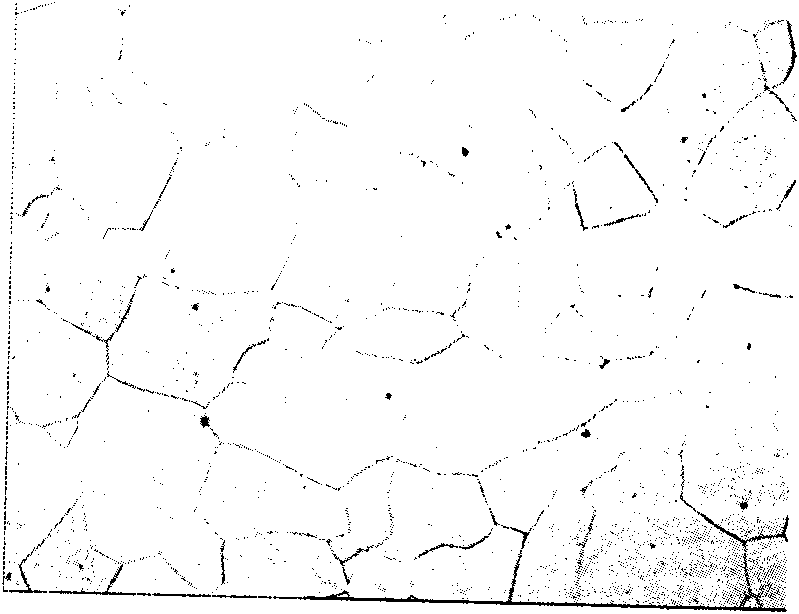

The invention provides heat-releasing welding flux for an iron-base copper-clad steel grounding grid. The heat-releasing welding flux comprises, by weight, 0-15 parts of Fe2O3, 21-55 parts of Fe3O4, 15-22 parts of metal aluminum powder, 5-10 parts of metal chromium powder, 4.5-7 parts of CaF2 powder, 2-3 parts of metal tin powder, 0.1-2.5 parts of metal nickel powder, 0-15 parts of metal iron powder, 1.1-2.5 parts of calcium silicon powder and 0.5-3.5 parts of iron alloy powder. According to the heat-releasing welding flux, the iron oxide and the aluminum powder serve as basic materials, and cost is greatly reduced; the fluidity of molten metal can be improved through the CaF2 powder, and gas is easily discharged. The metal chromium powder is added, a stable and compact oxide film can be generated by the chromium, and the corrosion resistance of metal can be remarkably improved by the fact that the chromium is added into the metal such as the iron.

Owner:STATE GRID CORP OF CHINA +1

Ultra-low carbon steel fine wire drawing method

InactiveCN106311781AAvoid secondary rapid work hardeningPrevent wire breakageFurnace typesHeat treatment furnacesWire rodRapid processing

The invention discloses an ultra-low carbon steel fine wire drawing method, which comprises a first stage of drawing process, a recrystallization annealing process, and a second stage of drawing process. According to the first stage of drawing process, the total deformation is calculated to be 75 percent to 85 percent according to a wire rod axial circle area. The method is applicable to the processing field of products such as copper-clad steel wires and electronic leading wires. The cold plastic deformation is hardly carried out during a second-time rapid processing and hardening process, so that the occurrence of the phenomenon that the tensile strength of middle wires is too high can be effectively avoided, the wire breaking rate can be remarkably reduced, the middle wires are prevented from being processed and hardened excessively, and the die loss is reduced; the finished products i.e. fine wires obtained according to the method provided by the invention can meet the requirement of low tensile strength. The ultra-low carbon steel fine wire drawing method provided by the invention has no special requirement on drawing equipment, is applicable to a common connecting tank drawing machine, and has no need to increase equipment and reformation investment; the diameter of each winding drum can be equal or unequal; and the ultra-low carbon steel fine wire drawing method provided by the invention is applicable to ultra-low carbon steel with the carbon content being not more than 0.05 weight percent, and the raw material steel types are wider.

Owner:XINGTAI IRON & STEEL

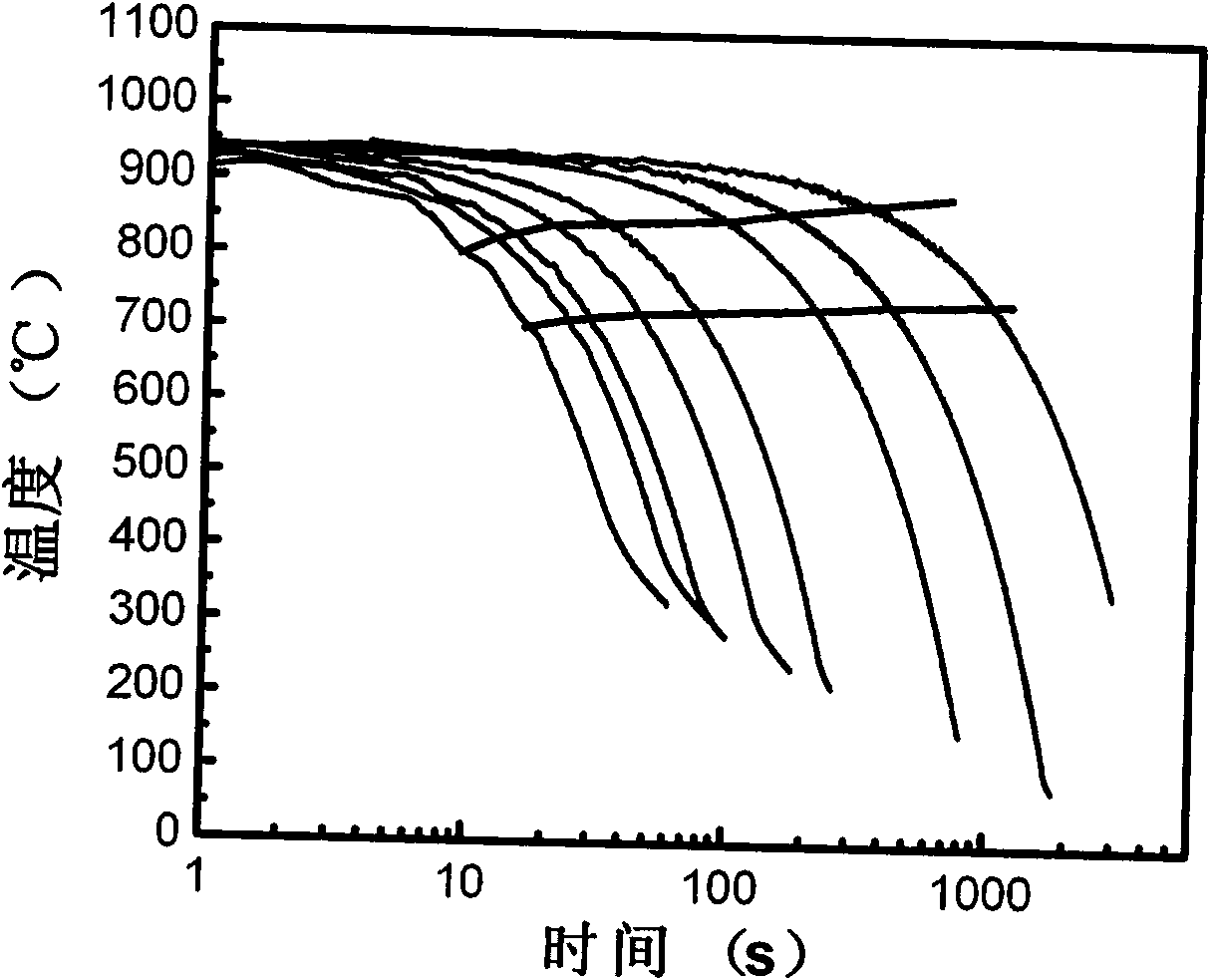

Structural transformation control method in continuous cooling process of ultra-low-carbon wire rod of square billet

The invention relates to a structural transformation control method in a continuous cooling process of an ultra-low-carbon wire rod of a square billet, belonging to the technical field of steel rolling. Aiming at the structural transformation in the continuous cooling process after thermal simulation transformation is carried out on a hot-rolling steel wire rod for a copper-clad steel wire, a continuous cooling structural transformation curve of the hot-rolling steel wire rod for the copper-clad steel wire is analyzed through structural transformation characteristics in the continuous coolingprocess under different cooling rates after the hot transformation. The invention solves the problems of cooling process and structural control after the hot-rolling steel wire rod for the copper-cladsteel wire rod is rolled, and provides data support on crystallite dimension control and tertiary cementite precipitation number for rolling and producing the ultra-low-carbon wire rod of the squarebillet.

Owner:SHOUGANG CORPORATION

Production technology of soft-state copper-clad steel wire

ActiveCN102254630AEliminate work hardeningGrain refinementCommunication cablesManufacturing extensible conductors/cablesElectricityMetallurgy

The invention relates to a production technology of a soft-state copper-clad steel wire. The production technology of the soft-state copper-clad steel wire successively comprises the following steps: drawing; high temperature tempering; electrodeposition pretreatment; acid electrolyzation; washing; pretreatment electrodeposition; washing; thick processing electrodeposition; washing; anti- oxidization; drying; drawing; washing; anti- oxidation treatment and ammonia-decomposition high temperature tempering. By using the production technology of the soft-state copper-clad steel wire of the invention, an elongation rate of the copper-clad steel wire is greater than or equal to 10%, which is more than one time of the elongation rate of the copper-clad steel wire produced by a traditional tempering technology.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Production process of active copper oxide

The invention discloses a production process of active copper oxide. The process comprises the steps that: (1) copper-clad steel scrap is added into a copper-melting tank; (2) needed ammonium bicarbonate is added into the copper-melting tank, and air is blown into the copper-melting tank from the bottom; (3) material liquid in the copper-melting tank is pumped into an iron-removing tank; hydrogen peroxide is added into the tank according to that a ratio of hydrogen peroxide to iron is 2-3:1; and a reaction is carried out for 2h under a temperature controlled at 30-40 DEG C; (4) obtained reaction liquid is added into a frame filter press; (5) a stirrer of a reaction vessel is started, a steam valve is opened, and a steam pressure is controlled at 0.1-0.3MPa; (6) a reaction vessel bottom valve is opened; a centrifuge provided with a filtering cloth is added under a stirring condition; and a filtrate formed in the centrifuge and washing solution are delivered into the copper-melting tank; (7) a filter cake formed in the centrifuge is delivered into a dryer, and a temperature in the dryer is controlled at 85-115 DEG C; and (8) obtained dry material is added into an externally heated rotary kiln. The production process provided by the invention does not cause sewage discharging.

Owner:辽宁拓合科技有限公司

Anti-theft marking for copper clad steel

A copper clad steel (CCS) wire is at least partially covered on its exterior to visibly distinguish the CCS wire from a pure / solid copper wire. A coating, such as tin, zinc or paint, covers at least portions of the CCS wire. The coating may be applied in strips, rings or a helix to identify the CCS wire as not be formed of solid copper. In the instance of a stranded CCS wire, one or more of the outer strands may be partially or entirely coated to give the overall stranded CCS wire a distinguishing outer structure.

Owner:BISON PATENT LICENSING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com