Heat-releasing welding flux for iron-base copper-clad steel grounding grid

A technology of exothermic flux and copper-clad steel, which is applied in the direction of aluminothermic welding equipment, welding medium, welding equipment, etc., can solve the problems of lowering the melting point temperature of welded joints, reducing the stability of joints, thermal cracks and pores, etc., to achieve improved resistance Corrosion ability, reduction of hot crack and porosity formation, effect of joint surface smoothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

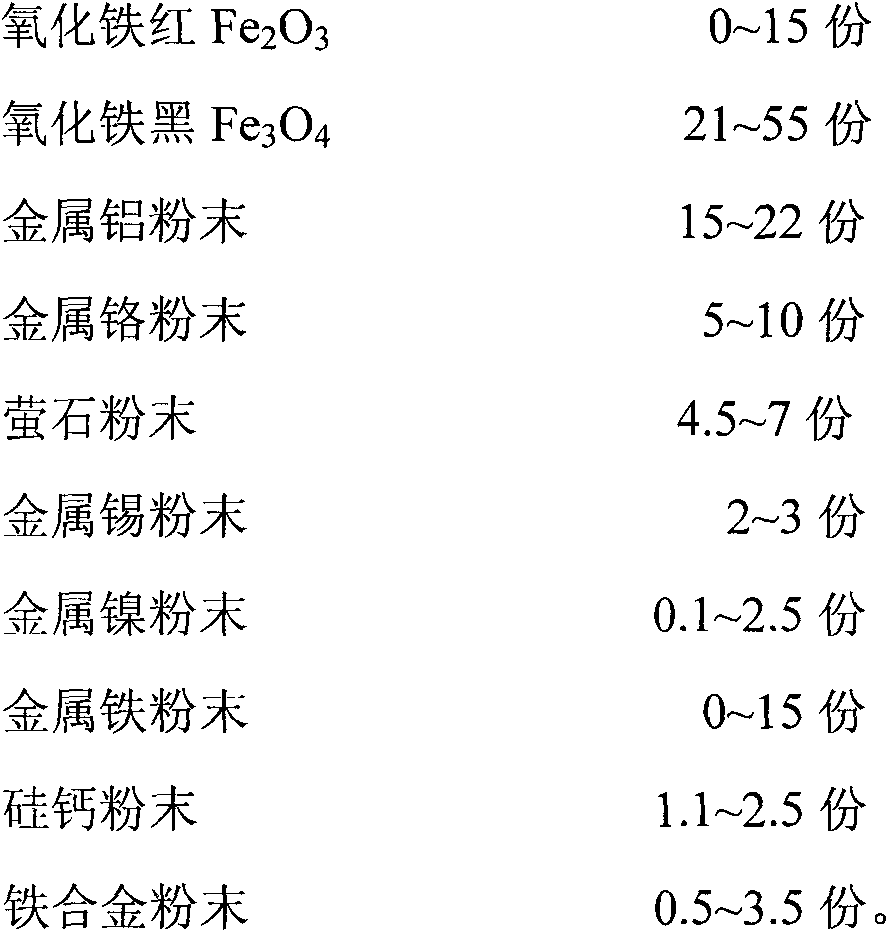

[0050] An exothermic flux for an iron-based copper-clad steel grounding grid, comprising the following components in parts by weight:

[0051]

[0052]

[0053] The mass percent content of molybdenum is 50%.

[0054] When using the ignition agent to ignite the exothermic flux of the present invention, the mass ratio of the ignition agent to the exothermic flux is 1:55.

Embodiment 2

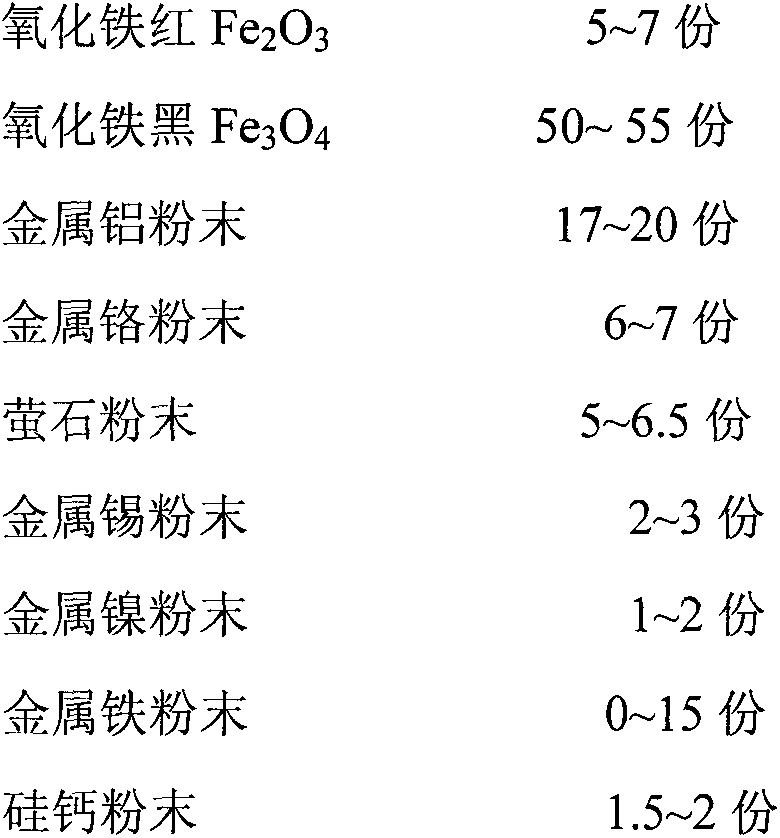

[0056] An exothermic flux for an iron-based copper-clad steel grounding grid, comprising the following components in parts by weight:

[0057]

[0058] The mass percent content of molybdenum is 55%. When using the ignition agent to ignite the exothermic flux of the present invention, the mass ratio of the ignition agent to the exothermic flux is 1:60.

Embodiment 3

[0060] An exothermic flux for an iron-based copper-clad steel grounding grid, comprising the following components in parts by weight:

[0061]

[0062]

[0063] The mass percent content of molybdenum is 60%.

[0064] When using the ignition agent to ignite the exothermic flux of the present invention, the mass ratio of the ignition agent to the exothermic flux is 1:60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com