Hot rolling steel plate for automobile girder, and manufacturing method thereof

A technology of hot-rolled steel plates and automobile beams, which is applied in the field of hot-rolled strip production, can solve the problems of difficult production process and high production cost, and achieve good strength and toughness matching, small performance difference between the same coils, and small anisotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

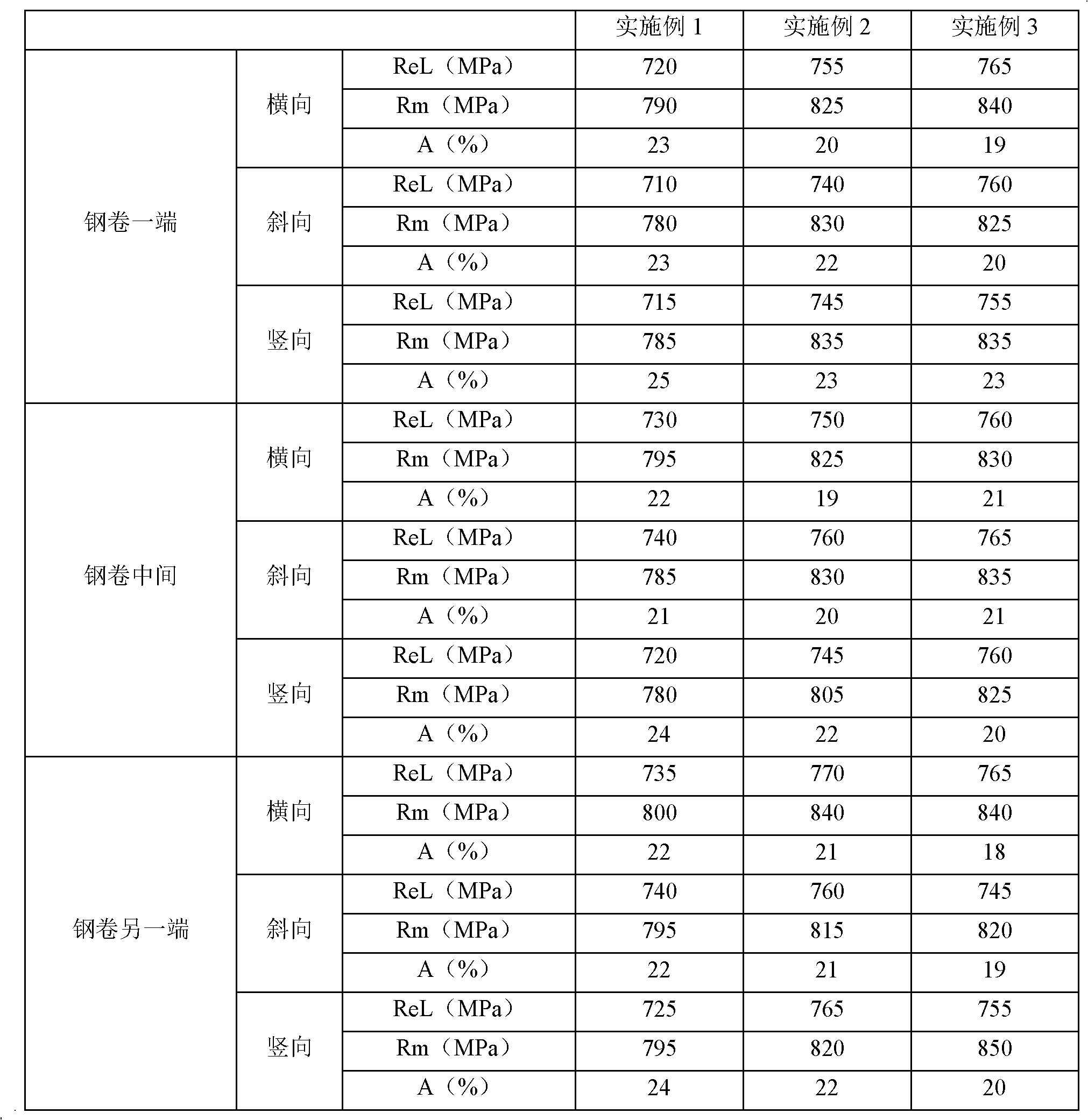

Embodiment 1

[0032] This embodiment is used to illustrate the manufacturing method of the hot-rolled steel plate for the automobile frame provided by the present invention.

[0033] The composition of molten steel after the steelmaking step is: 0.05% by weight of C, 0.21% by weight of Si, 1.5% by weight of Mn, 0.05% by weight of Nb, 0.05% by weight of Ti, 0.01% by weight of P, and 0.008% by weight of S , the balance is Fe and unavoidable impurities, and then the overall argon gas sealing is used for casting. The molten steel is injected into the tundish through the sliding nozzle at the bottom of the ladle. / min, the thickness of the continuous casting slab is 200mm, and then it is soaked in a heating furnace at 1220°C. After the heated slab is dephosphorized by high-pressure water to remove the oxide scale formed on the surface, it enters the reversible roughing unit, and the roughing exit The temperature is 1025°C, the thickness of the intermediate billet after rough rolling is 38mm, and...

Embodiment 2

[0035] This embodiment is used to illustrate the manufacturing method of the hot-rolled steel plate for the automobile frame provided by the present invention.

[0036] The composition of molten steel after the steelmaking step is: 0.08% by weight of C, 0.15% by weight of Si, 1.3% by weight of Mn, 0.03% by weight of Nb, 0.1% by weight of Ti, 0.025% by weight of P, and 0.005% by weight of S , the balance is Fe and unavoidable impurities, and then the overall argon gas sealing is used for casting, and the molten steel is injected into the tundish through the sliding nozzle at the bottom of the ladle. / min, the thickness of the continuous casting slab is 250mm, and then it is soaked in a heating furnace at 1230°C. After the heated slab is dephosphorized by high-pressure water to remove the oxide scale formed on the surface, it enters the reversible roughing unit, and the roughing exit The temperature is 1040°C, the thickness of the intermediate billet after rough rolling is 45mm,...

Embodiment 3

[0038] This embodiment is used to illustrate the production method of the hot-rolled steel plate for automobile frame provided by the present invention.

[0039] The composition of the molten steel after the steelmaking step is: 0.1% by weight of C, 0.35% by weight of Si, 1.7% by weight of Mn, 0.07% by weight of Nb, 0.08% by weight of Ti, 0.02% by weight of P, and 0.01% by weight of S , the balance is Fe and unavoidable impurities, and then the overall argon gas sealing is used for casting. The molten steel is injected into the tundish through the sliding nozzle at the bottom of the ladle. / min, the thickness of the continuous casting slab is 200mm, and then it is soaked in a heating furnace at 1250°C. After the heated slab is dephosphorized by high-pressure water to remove the oxide scale formed on the surface, it enters the reversible roughing unit, and the roughing exit The temperature is 1025°C, the thickness of the intermediate slab after rough rolling is 55mm, and then i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com