Patents

Literature

95 results about "Exothermic welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exothermic welding, also known as exothermic bonding, thermite welding (TW), and thermit welding, is a welding process that employs molten metal to permanently join the conductors. The process employs an exothermic reaction of a thermite composition to heat the metal, and requires no external source of heat or current. The chemical reaction that produces the heat is an aluminothermic reaction between aluminium powder and a metal oxide.

Exothermic welding

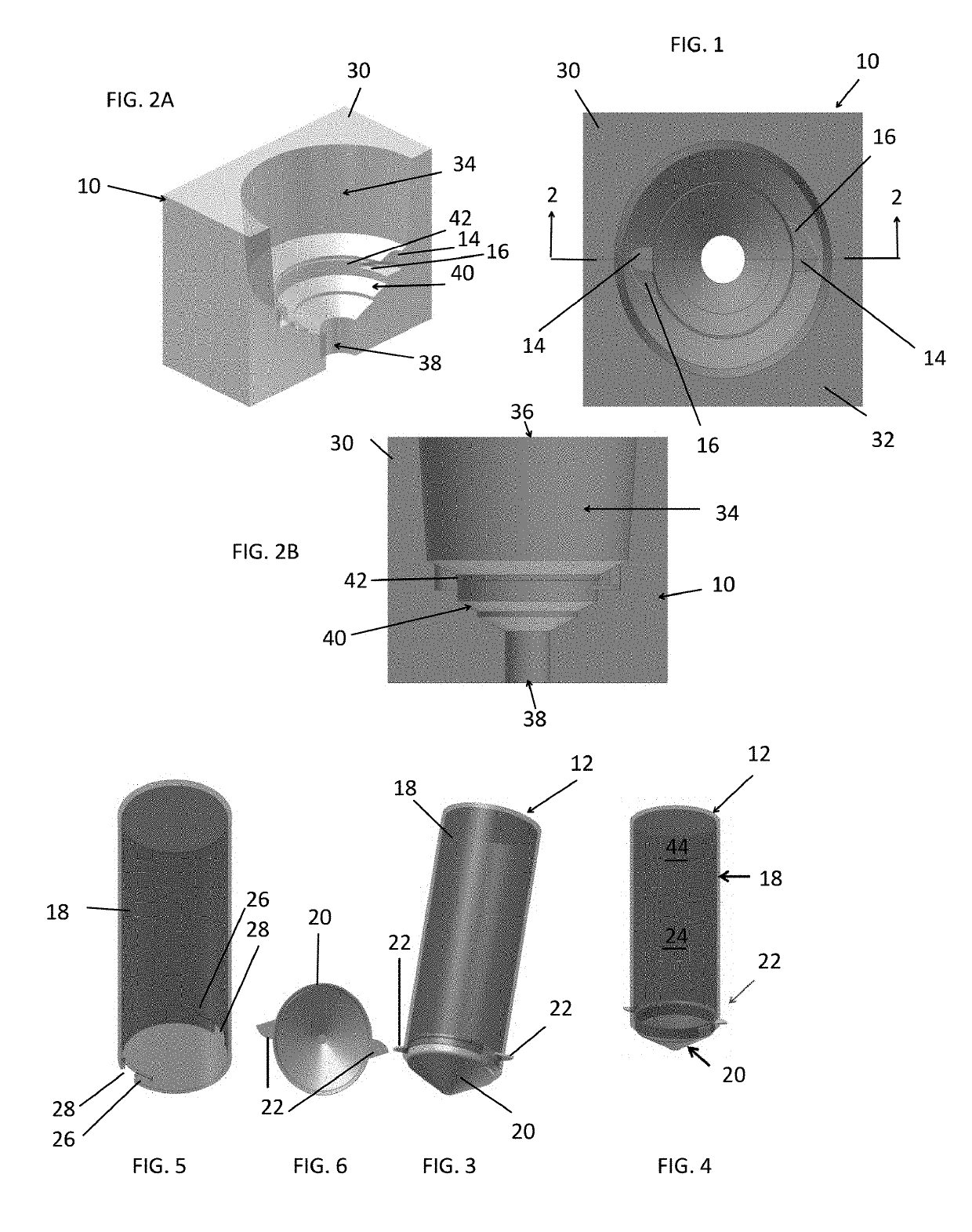

ActiveUS6994244B2Eliminate needImprove the immunityWelding/soldering/cutting articlesMetal working apparatusExothermic weldingEngineering

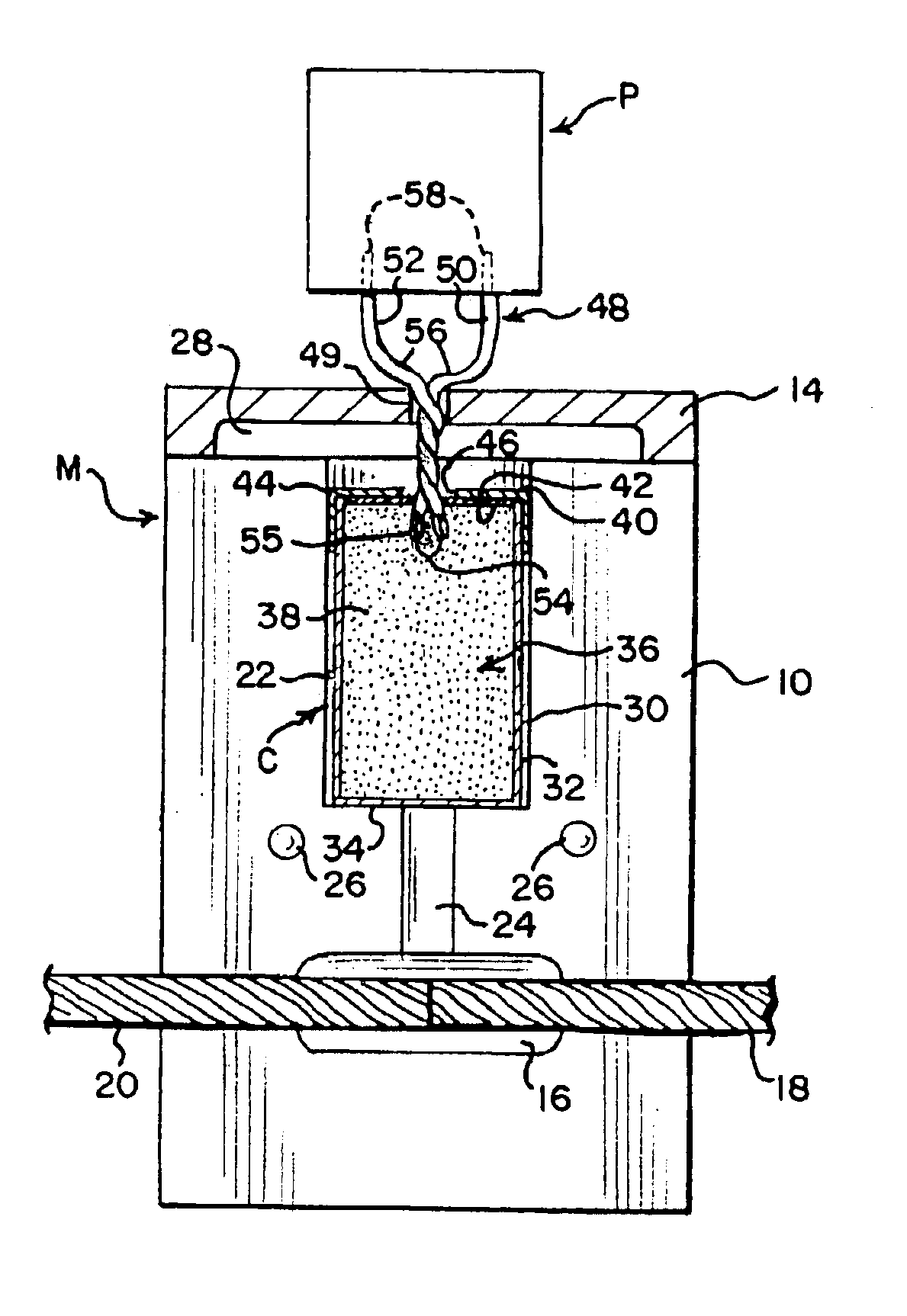

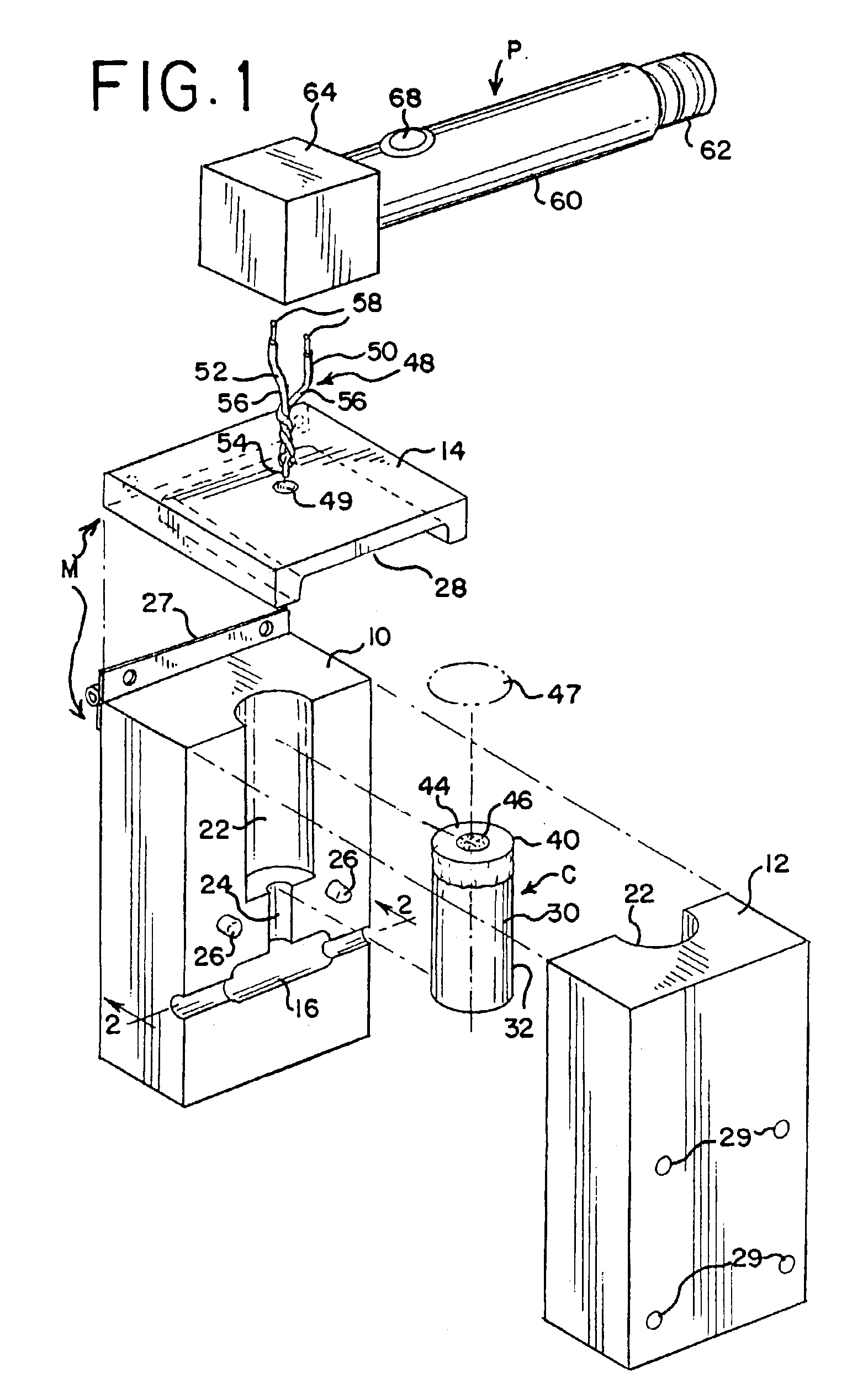

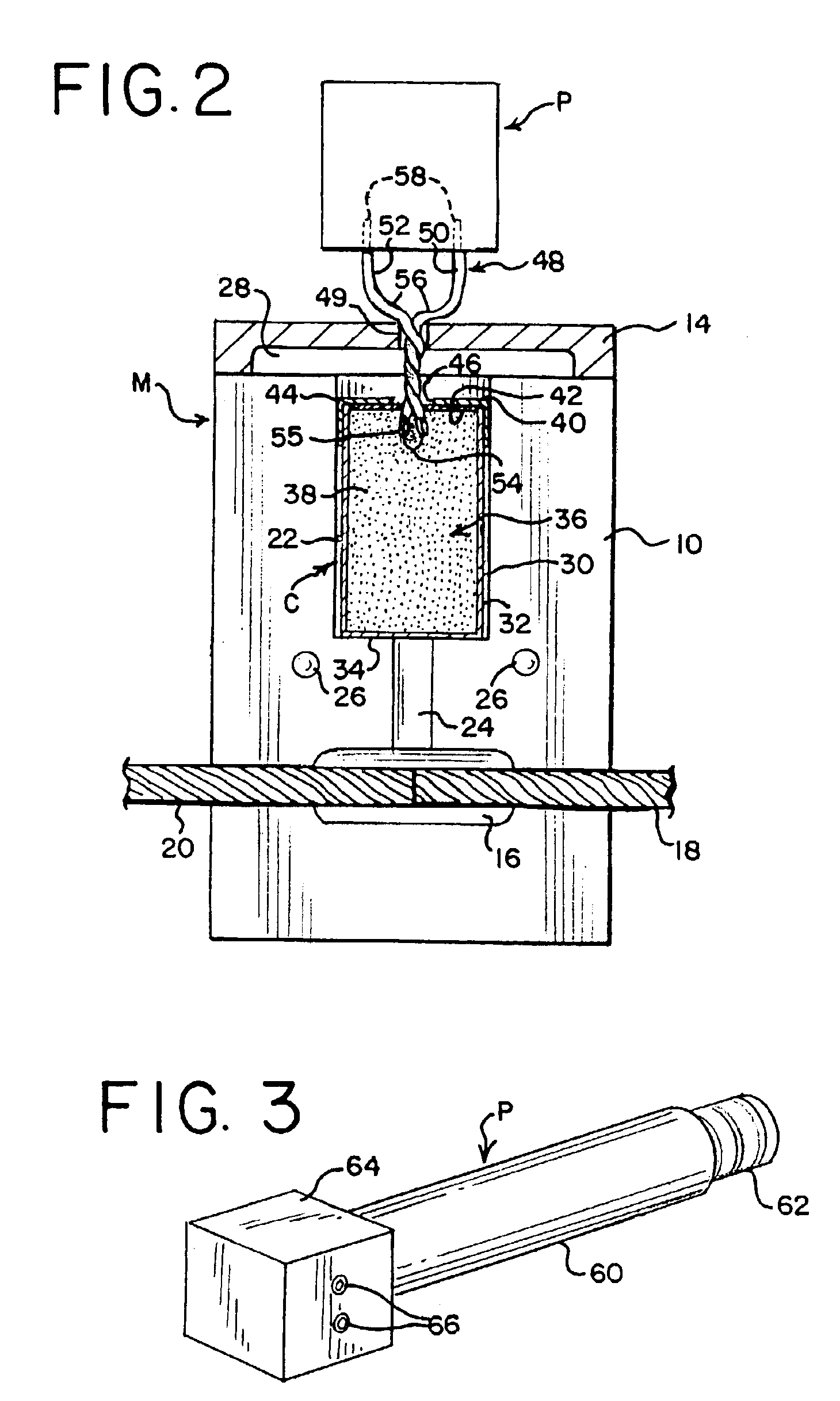

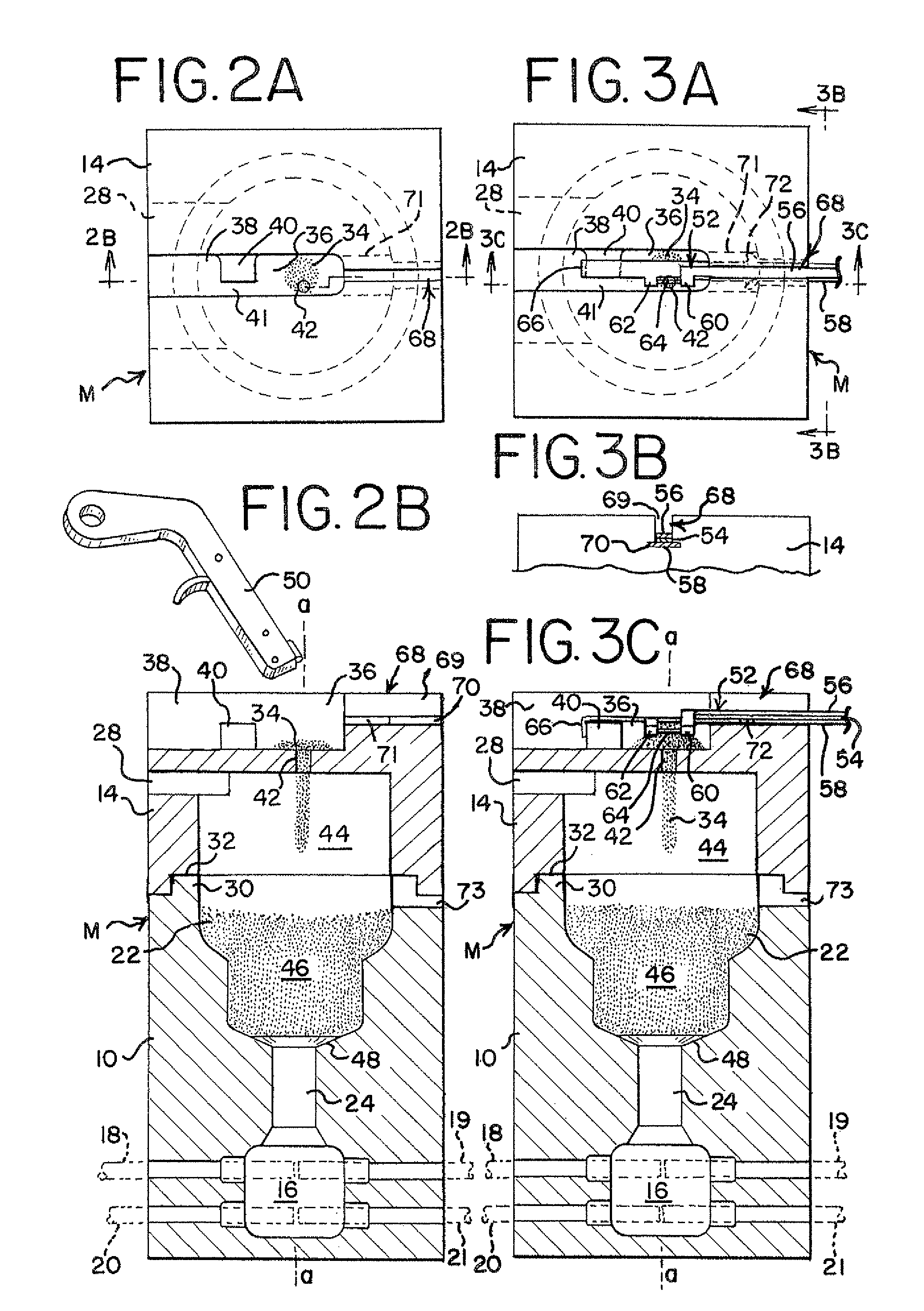

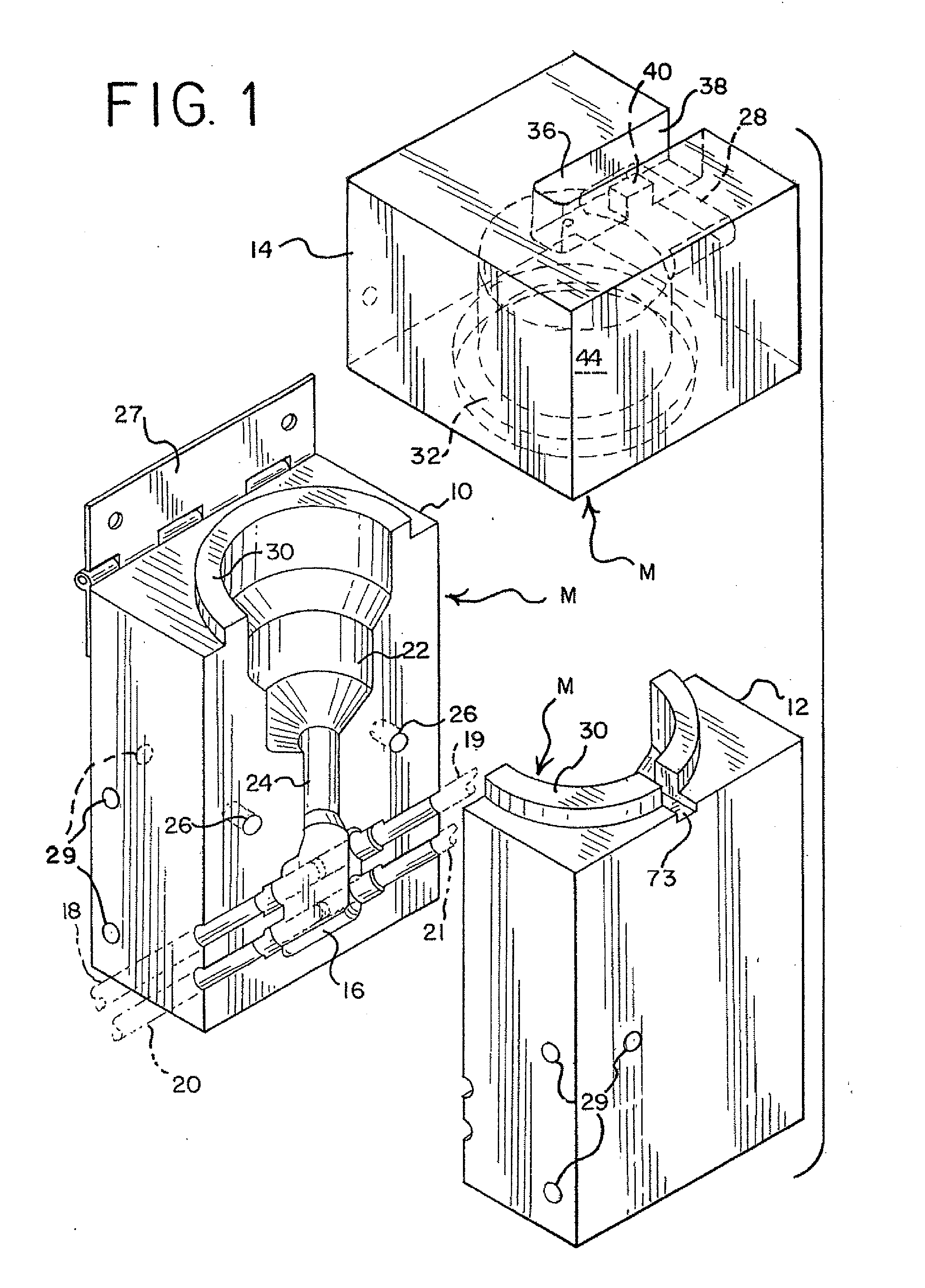

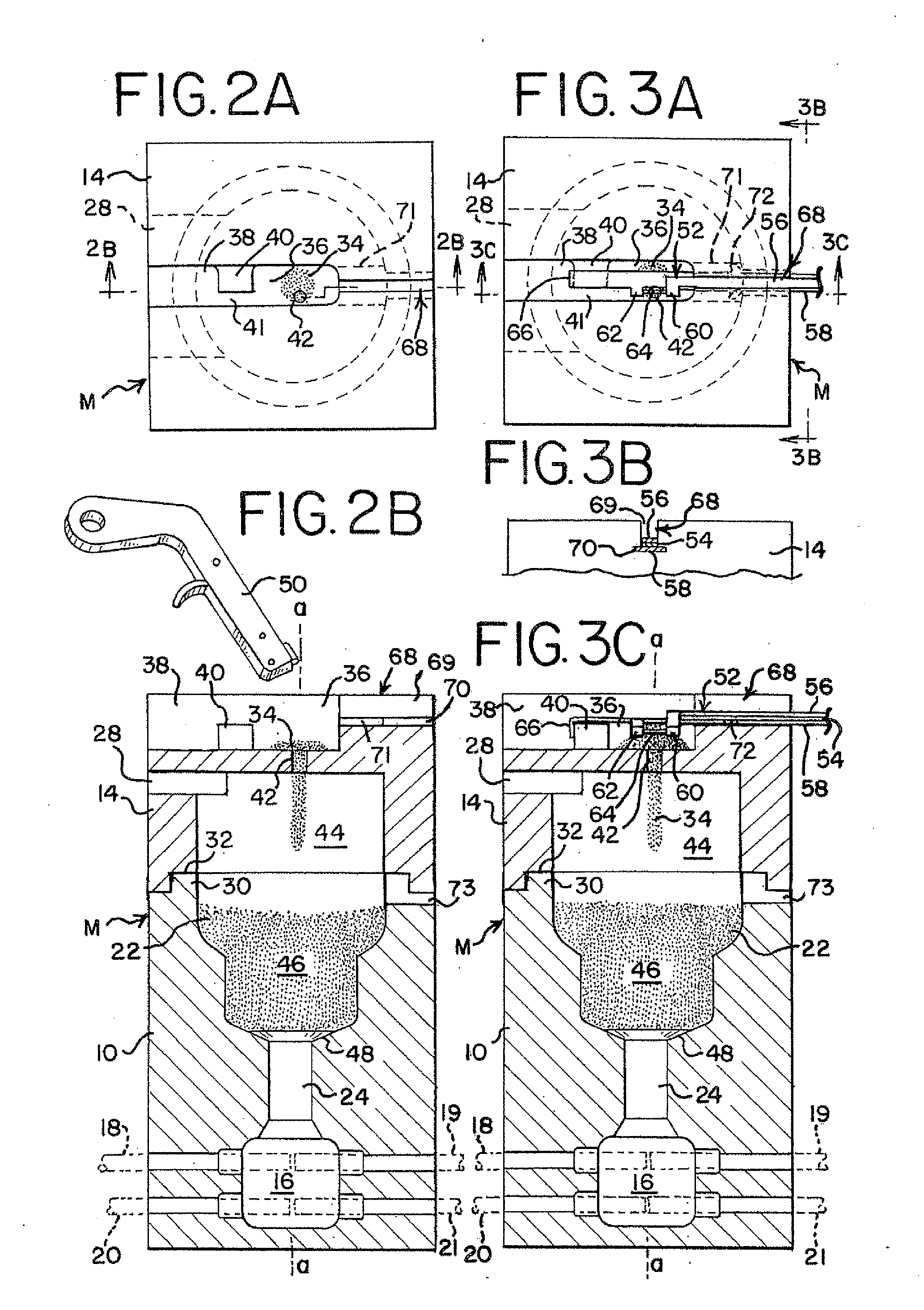

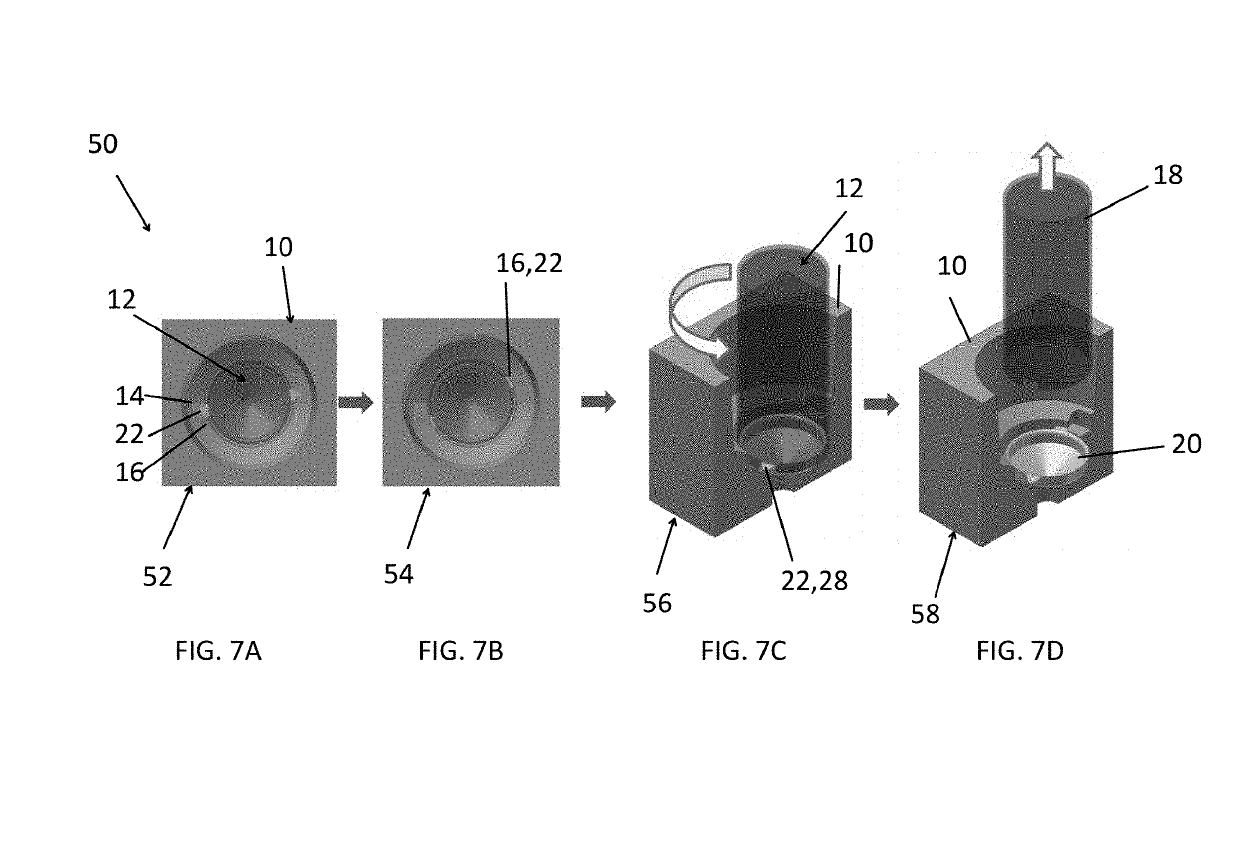

An assembly and method are disclosed for exothermic welding including a mold which is formed of a material which withstands exothermic welding temperatures, and includes a weld cavity therein for positioning at least two members which are to be exothermically welded together adjacent to each other, and an ignition cavity communicating with the first cavity. The members which are to be exothermically welded together are positioned adjacent to each other using the weld cavity, and a weld metal cartridge is positioned in the ignition cavity. The cartridge comprises a container having copper walls which define a chamber therein, and a particulate weld metal in the chamber. The tip of an electrical igniter is positioned into the chamber of the container and particulate weld material therein, the igniter is electrically fired while the container is in the ignition cavity of the mold to melt the particulate weld material, and the contents of the ignition cavity are passed after melting the particulate weld metal to the weld cavity to weld the members together.

Owner:HARGER

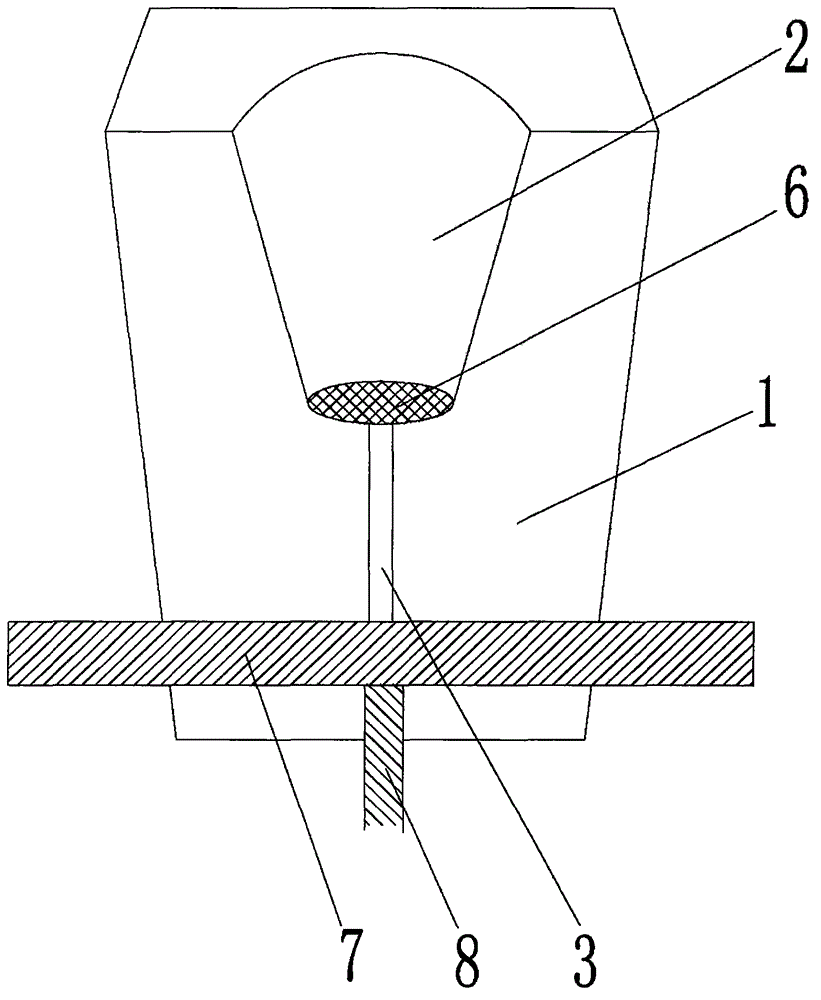

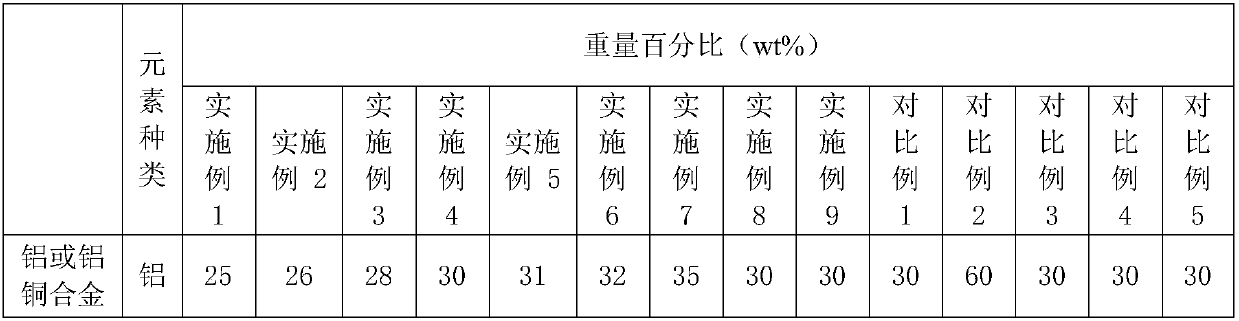

A kind of solder and its igniter for exothermic welding of grounding body in grounding system

InactiveCN102267024AWelding/cutting media/materialsAlumino-thermic welding apparatusHigh resistanceExothermic welding

The invention discloses a solder for exothermic welding of a grounding body in a grounding system and an ignition agent of the solder, relates to the solder for the exothermic welding and the ignition agent of the solder and solves the technical problem of poor welding performance caused by impurities contained in a welding joint which is obtained by the conventional exothermic welding hot-melting soldering agent. The solder for the exothermic welding of the grounding body in the grounding system consists of copper oxide powder, copper powder, industrial pure aluminum powder, zinc powder, zirconium powder, silicon iron powder, fluorite powder, marble powder and lanthanum cerium alloy powder. The ignition agent of the solder for the exothermic welding of the grounding body in the groundingsystem consists of magnesium powder, the copper oxide powder, the industrial pure aluminum powder, potassium permanganate powder and red phosphorus powder. When the solder and the ignition agent are used, the mass ratio of the solder for the exothermic welding of the grounding body in the grounding system to the ignition agent is (78-82):1. All elements in the solder and rare-earth elements can purify the welding joint. The invention is applicable to welding of copper, copper alloy, steel, galvanized steel, copper-clad steel, stainless steel and high-resistance heating source materials.

Owner:HEILONGJIANG PATENT TECH DEV

High melting point exothermic welding flux for copper-clad steel/copper grounding grid

InactiveCN101637852ABalanced reliabilityUniform tissue formationWelding/cutting media/materialsSoldering mediaExothermic weldingCopper oxide

A high melting point exothermic welding flux for a copper-clad steel / copper grounding grid belongs to the metal welding field. The existing exothermic welding flux for welding copper-clad steel has the defects of lower melting point of the metal on a joint than the temperature of a base material, poor structural uniformity and the like. The exothermic welding flux comprises the following components by weight percent: 50-60% of copper oxide, 9-10% of aluminium metal powder, 20-35% of copper metal powder, 3-4% of fluorite powder, 2-3% of tin metal powder, 0-5% of nickel metal powder and the balance alloy powder. The exothermic welding flux has the melting temperature close to that of the base metal, and can assure that a grounding body formed by the joint and the base material has even reliability.

Owner:CHINA ELECTRIC POWER RES INST

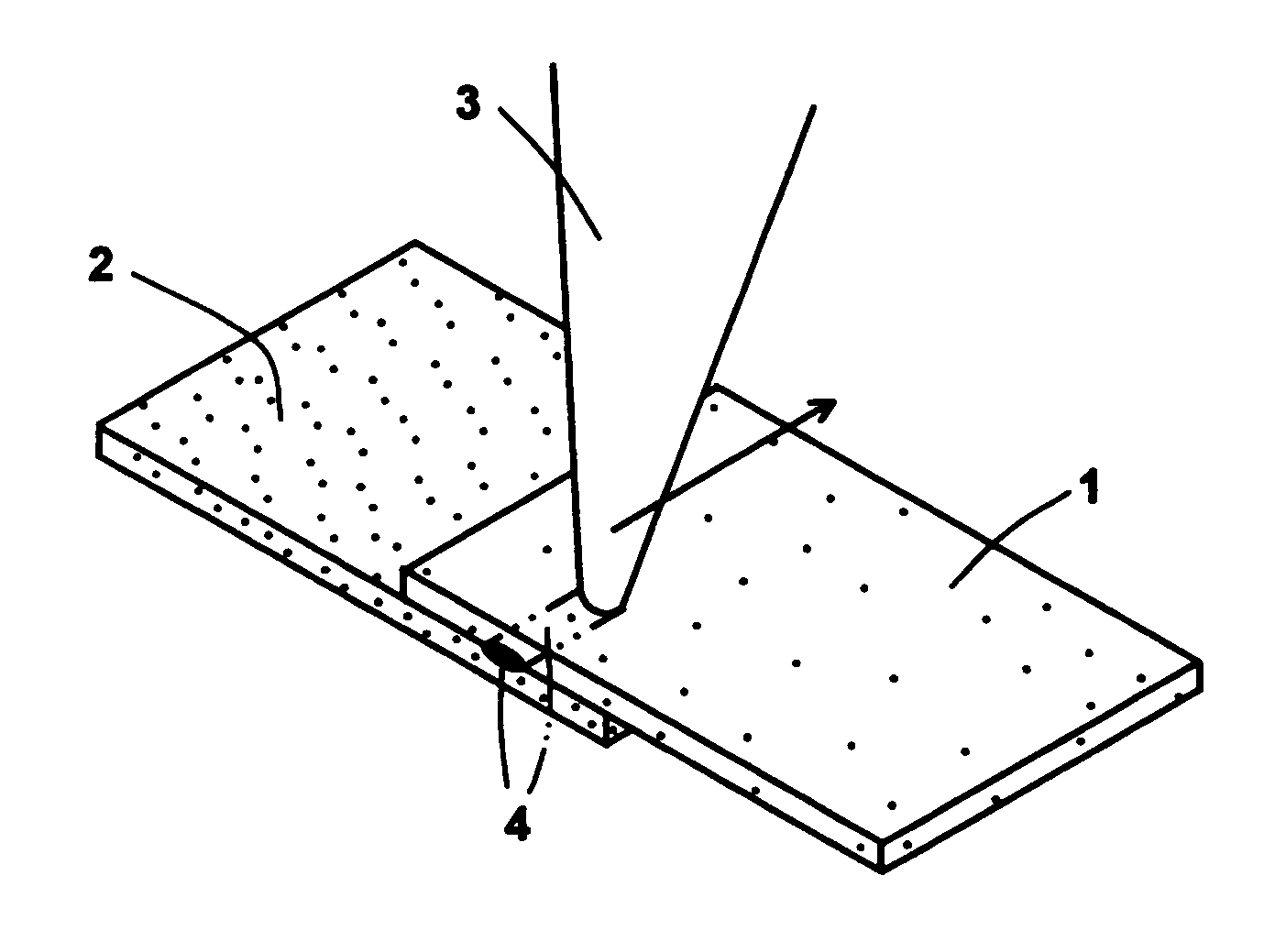

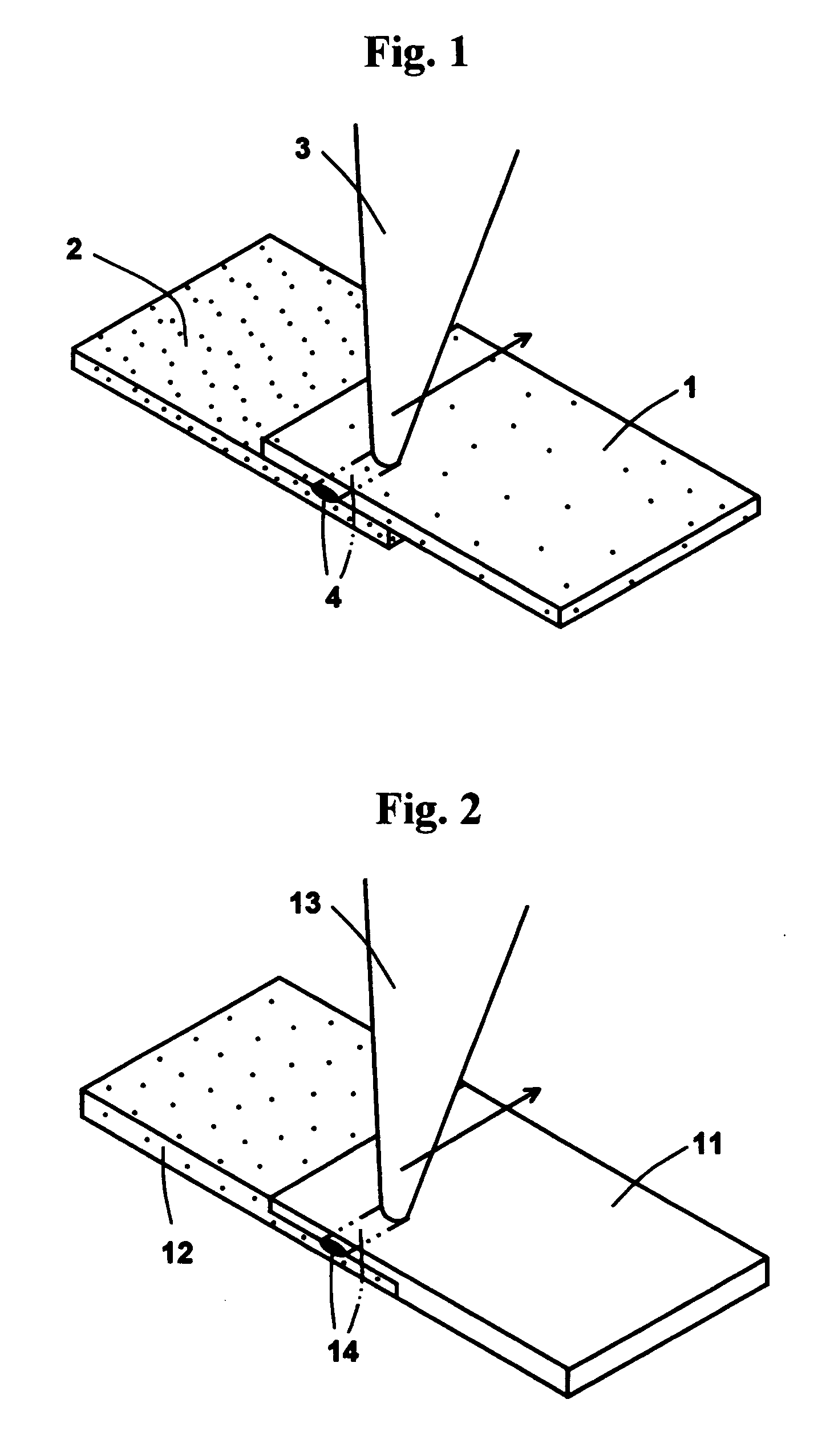

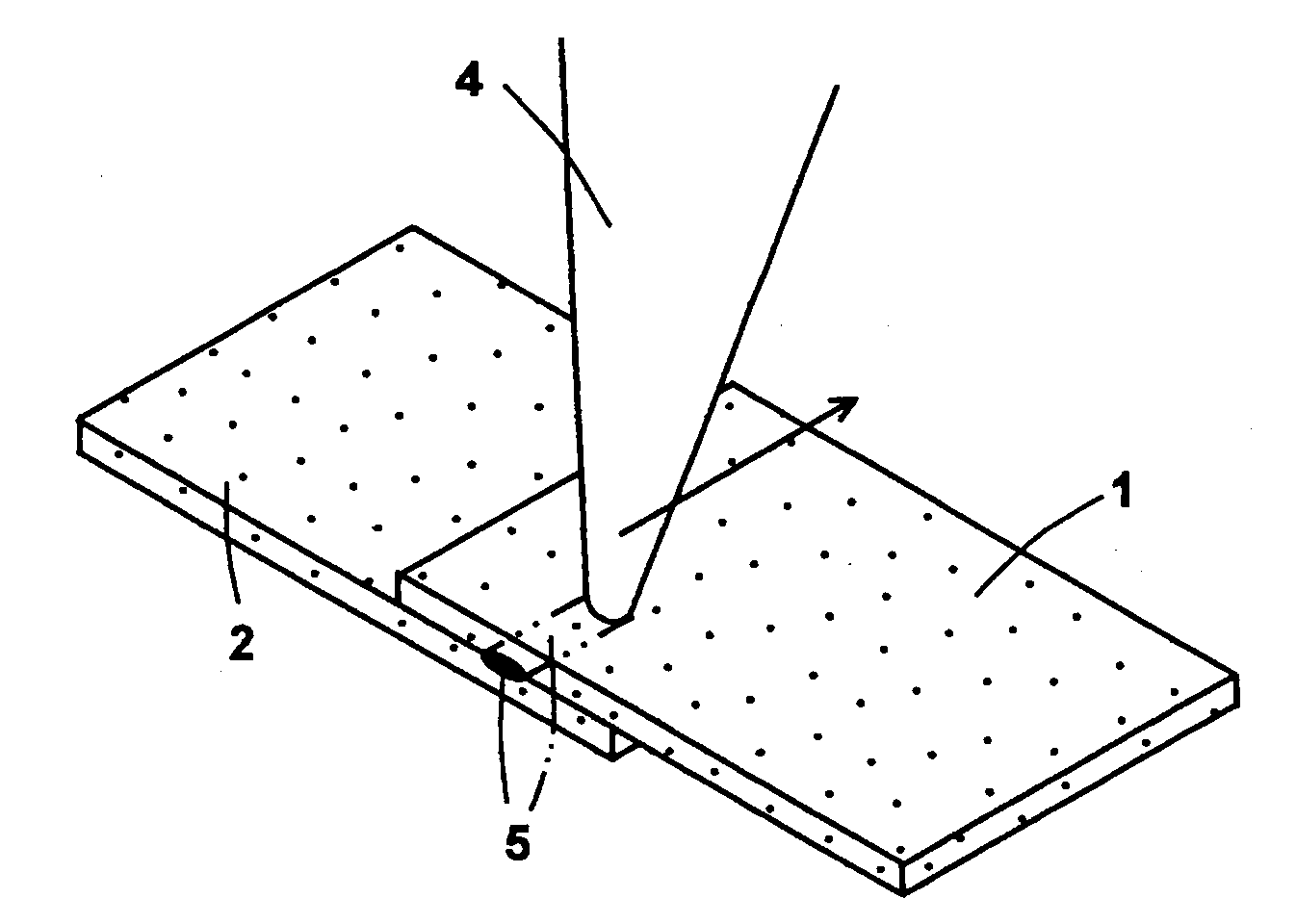

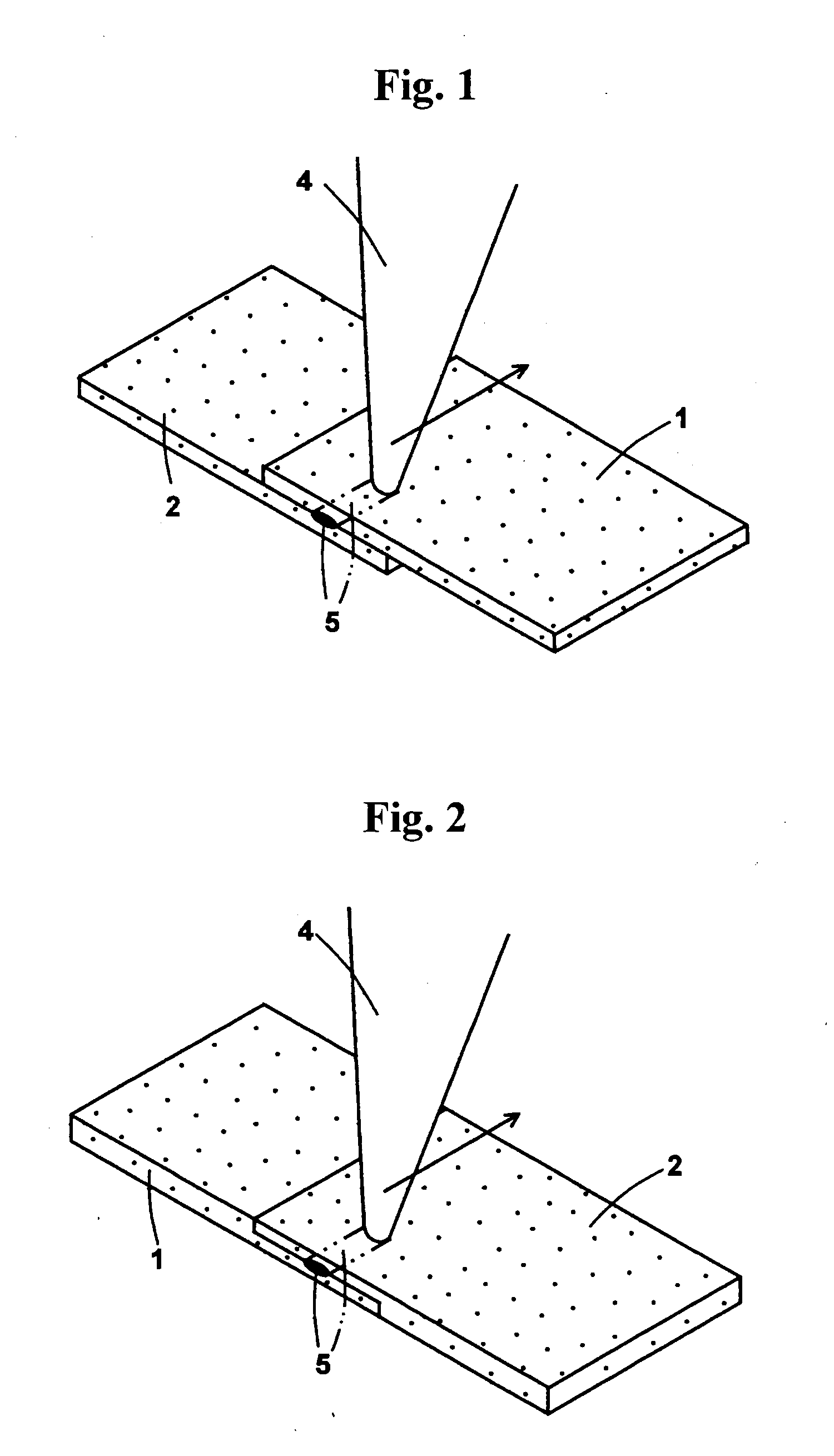

Laser-welded article

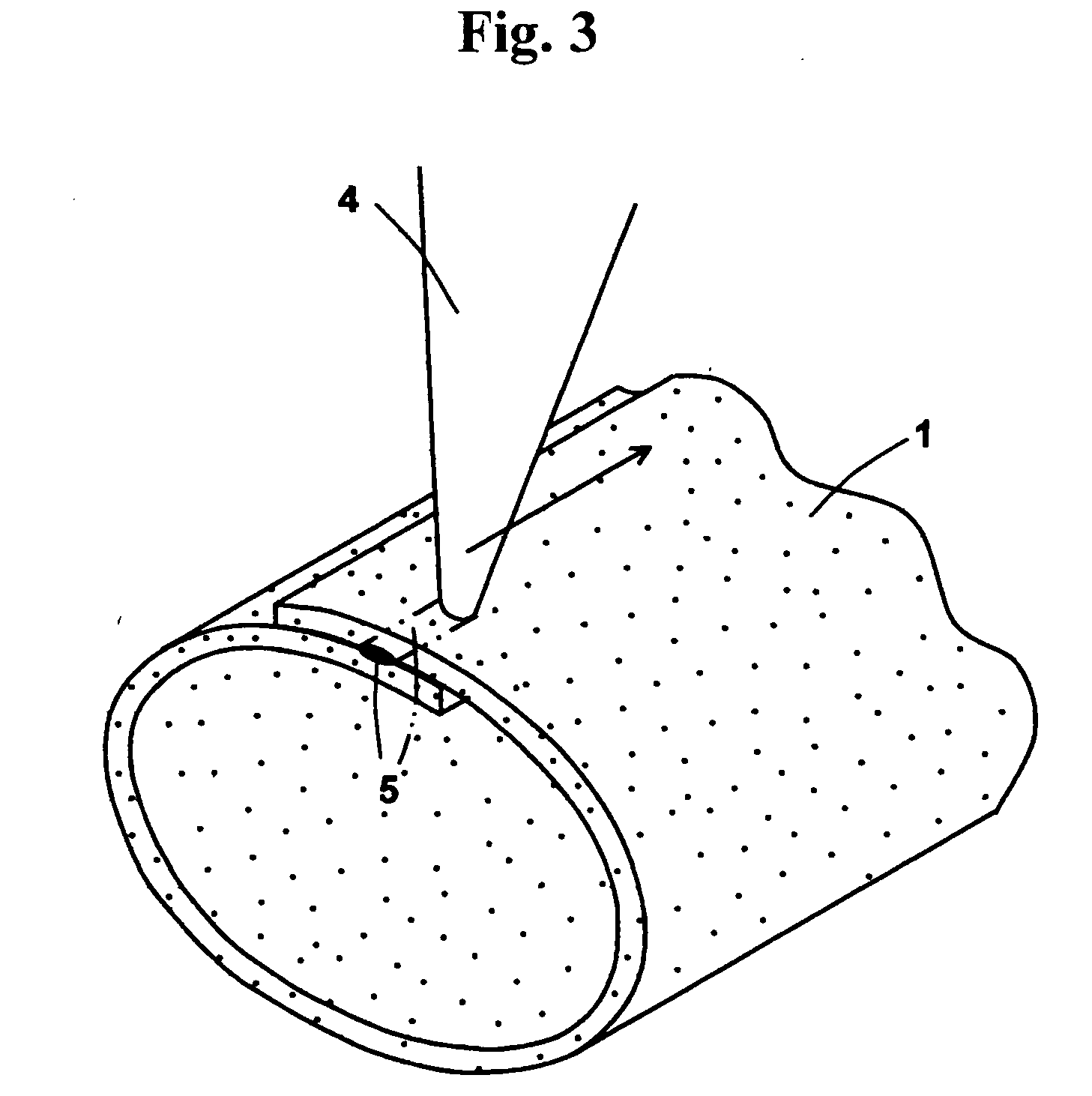

InactiveUS20070065659A1Improve welding strengthGood lookingLayered productsThin material handlingExothermic weldingIrradiation laser

A laser-welded article comprises: an integral construction of piled workpieces, that are welded by exothermic through irradiating laser and include thermoplastic resin, comprises of a laser-transmissible-absorptive molded workpiece including a thermoplastic resin and 0.001 to 0.3 weight % of colorant consisting of nigrosine which has an absorption coefficient: ε for a ray of 940 nm ranging form 4000 to 7000, that transmits laser partially and absorbs laser partially, and a laser-absorptive molded workpiece including a thermoplastic resin and 0.1 to 5 weight % of diverse colorant comprising of nigrosine and / or carbon black, that absorbs the laser.

Owner:ORIENT CHEM INDS

Laser-Welded Article

ActiveUS20090136717A1Sufficient welding strengthNot to damageLamination ancillary operationsSynthetic resin layered productsExothermic weldingShell molding

It is an object of the present invention to provide a laser-welded article that workpieces prepared simply can be easily unified by laser in one laser welding process without using complicated processes. Moreover, the laser-welded article has an excellent appearance and sufficient welding strength of the molded workpieces, and does not damage the resin property.The laser-welded article comprises:an integral construction of a single workpiece that at least a part of curled workpiece is overlapped or plural workpieces that at least a part of each workpiece is piled, which is welded by exothermic through irradiating laser, wherein the single laser-transmissible-absorptive molded workpiece or the plural laser-transmissible-absorptive molded workpieces include a thermoplastic resin and a laser-transmissible absorbent to have an absorbance: a ranging from 0.07 to 2.0, and have abilities of absorbing at least partial beam of the laser and transmitting another partial beam of the laser.

Owner:ORIENT CHEM INDS

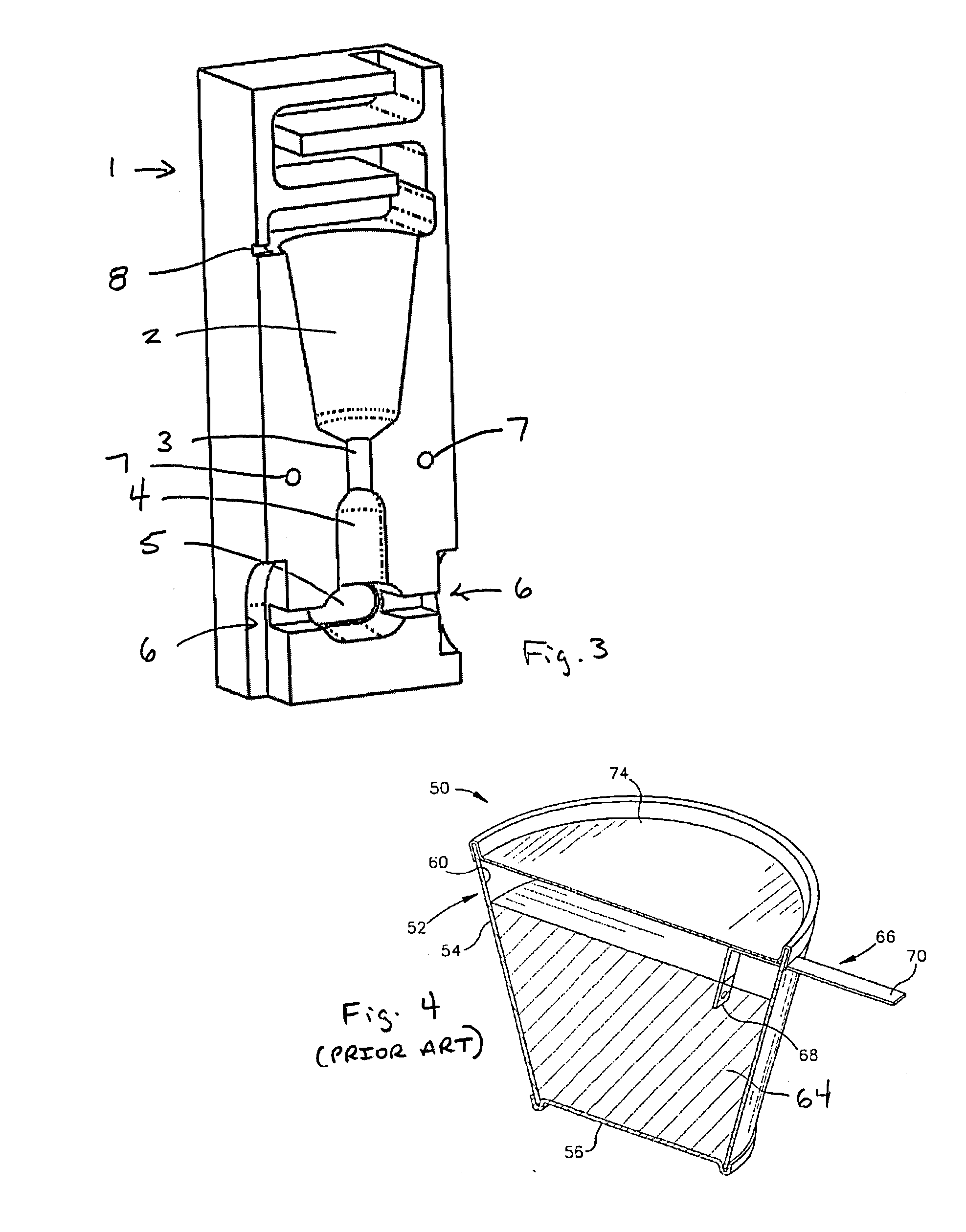

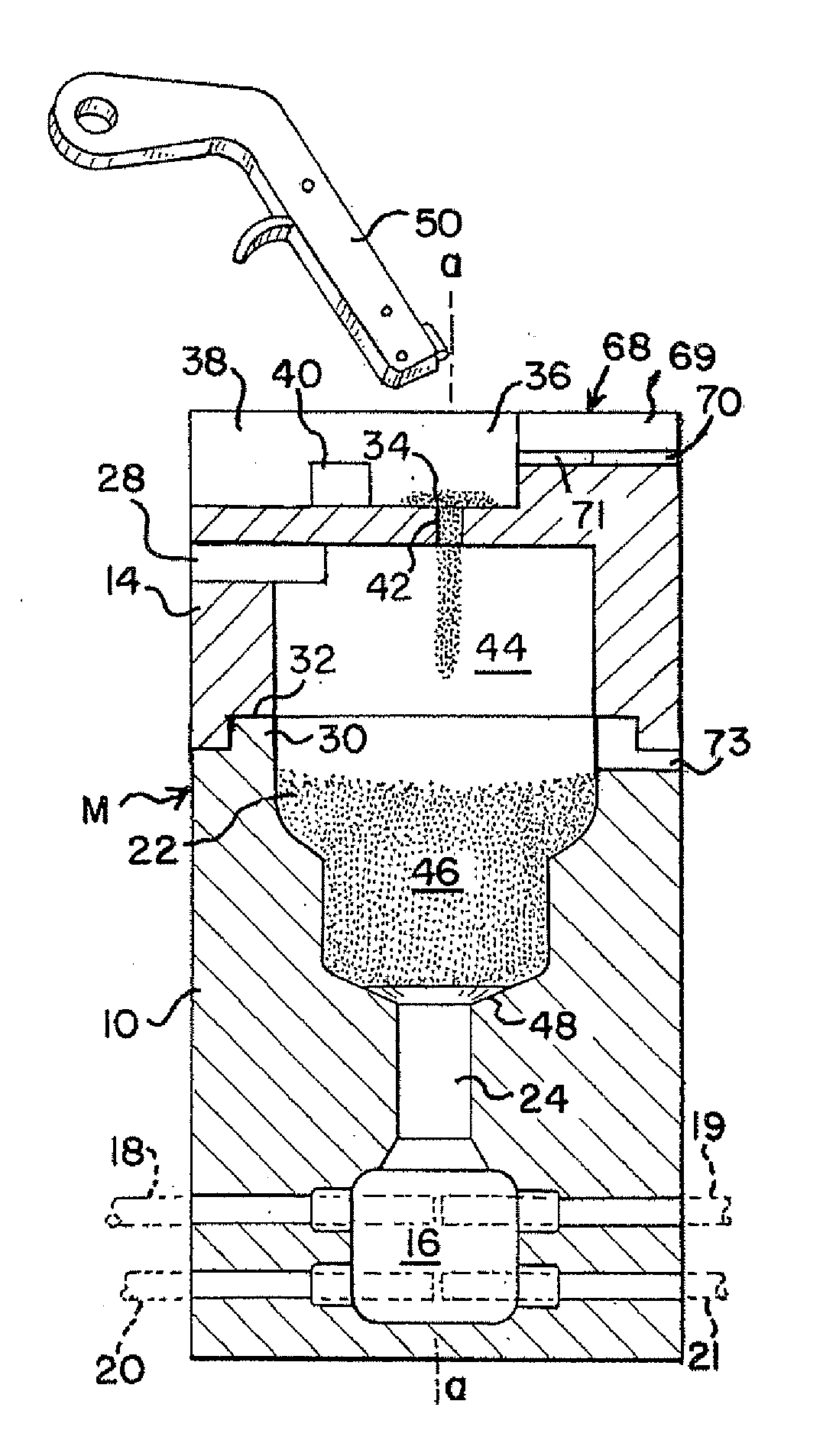

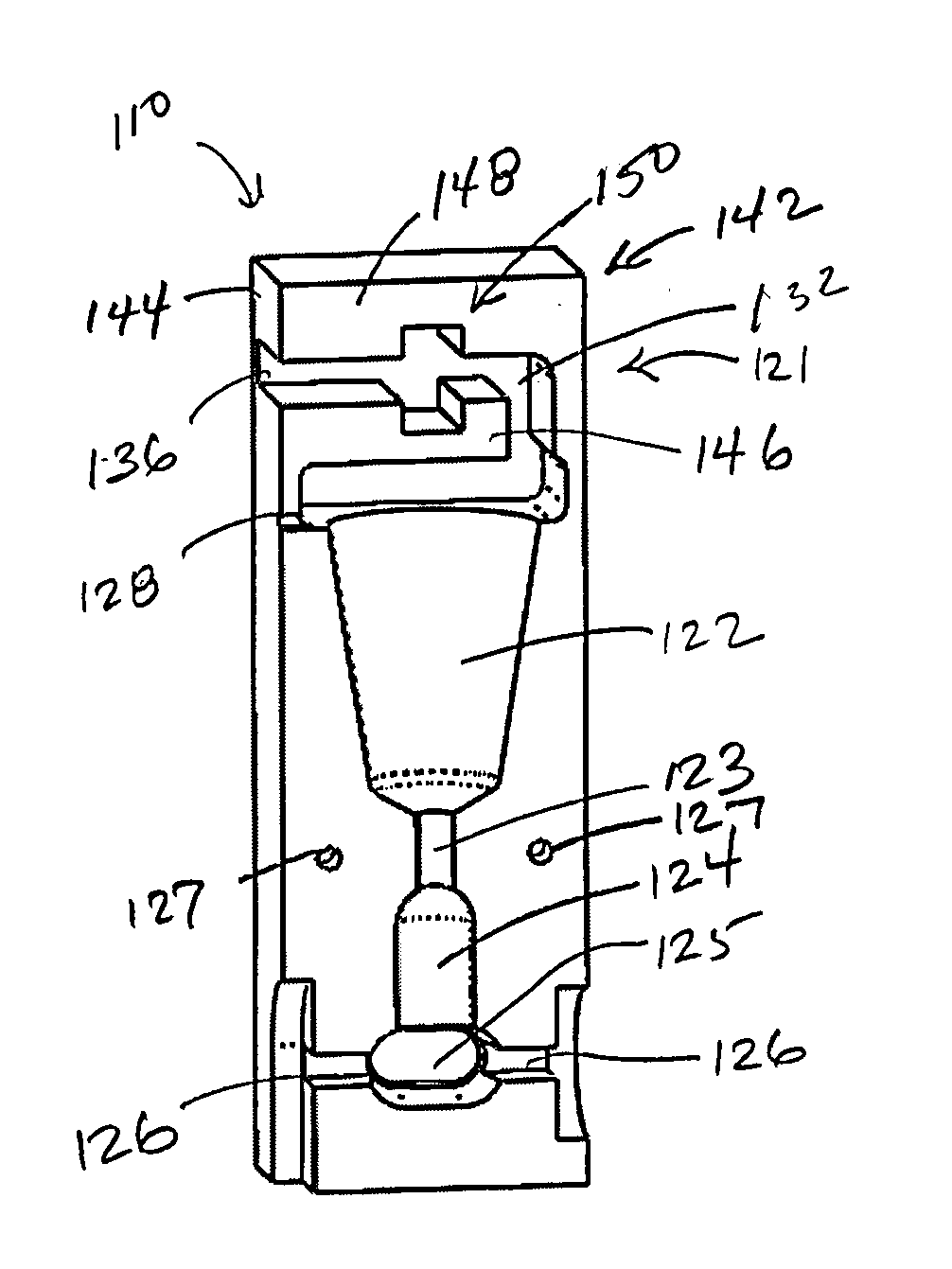

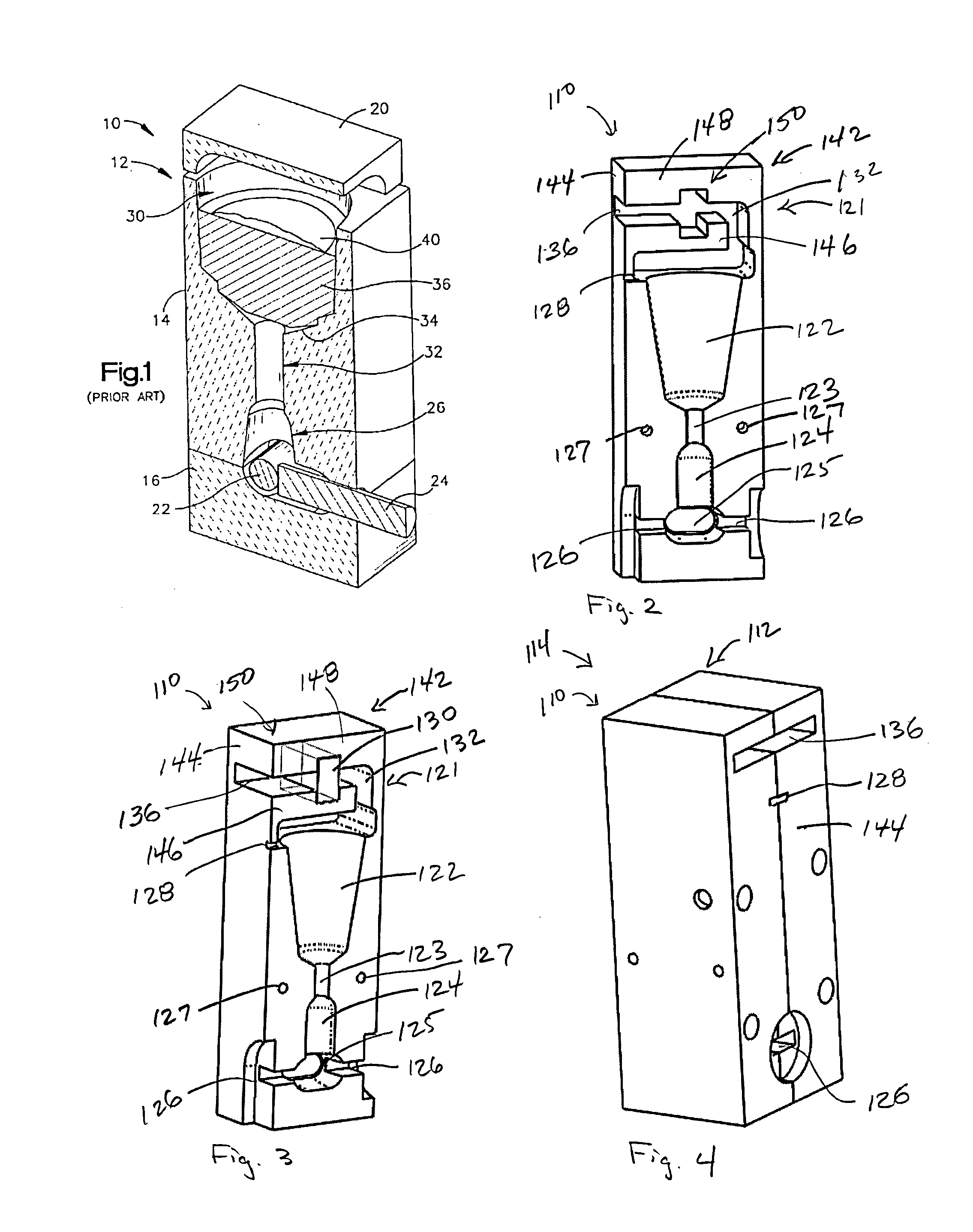

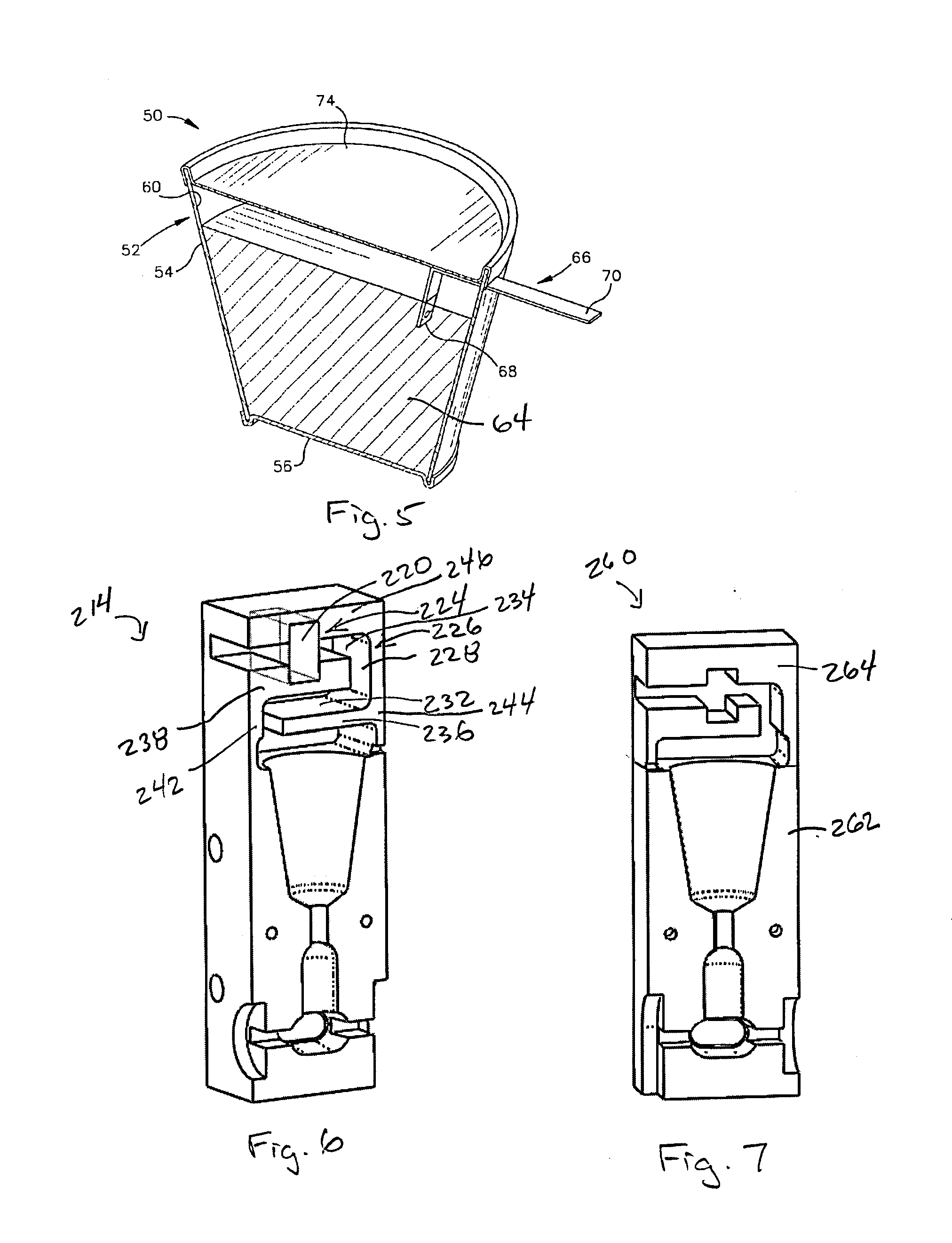

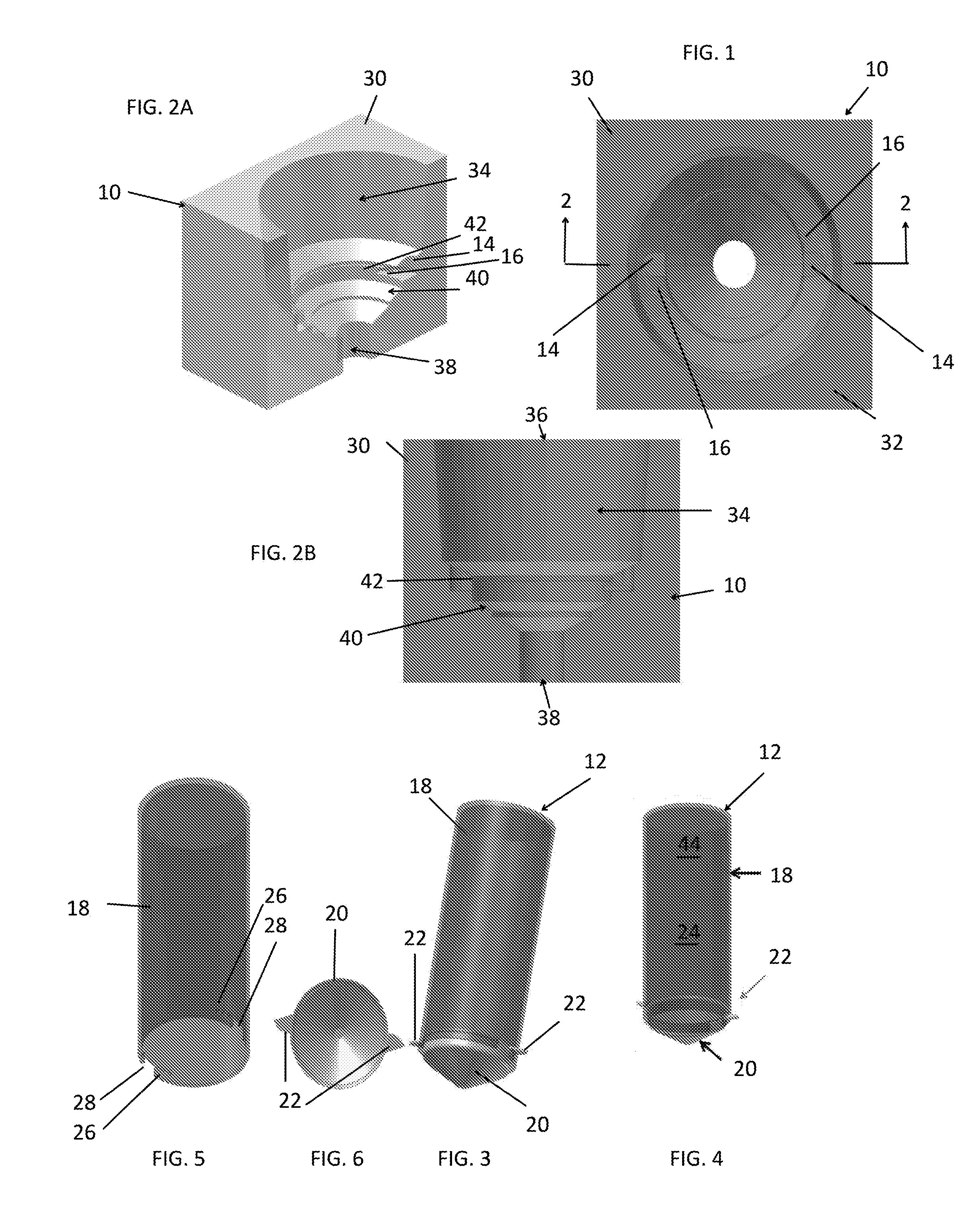

Exothermic welding mold with integral cover

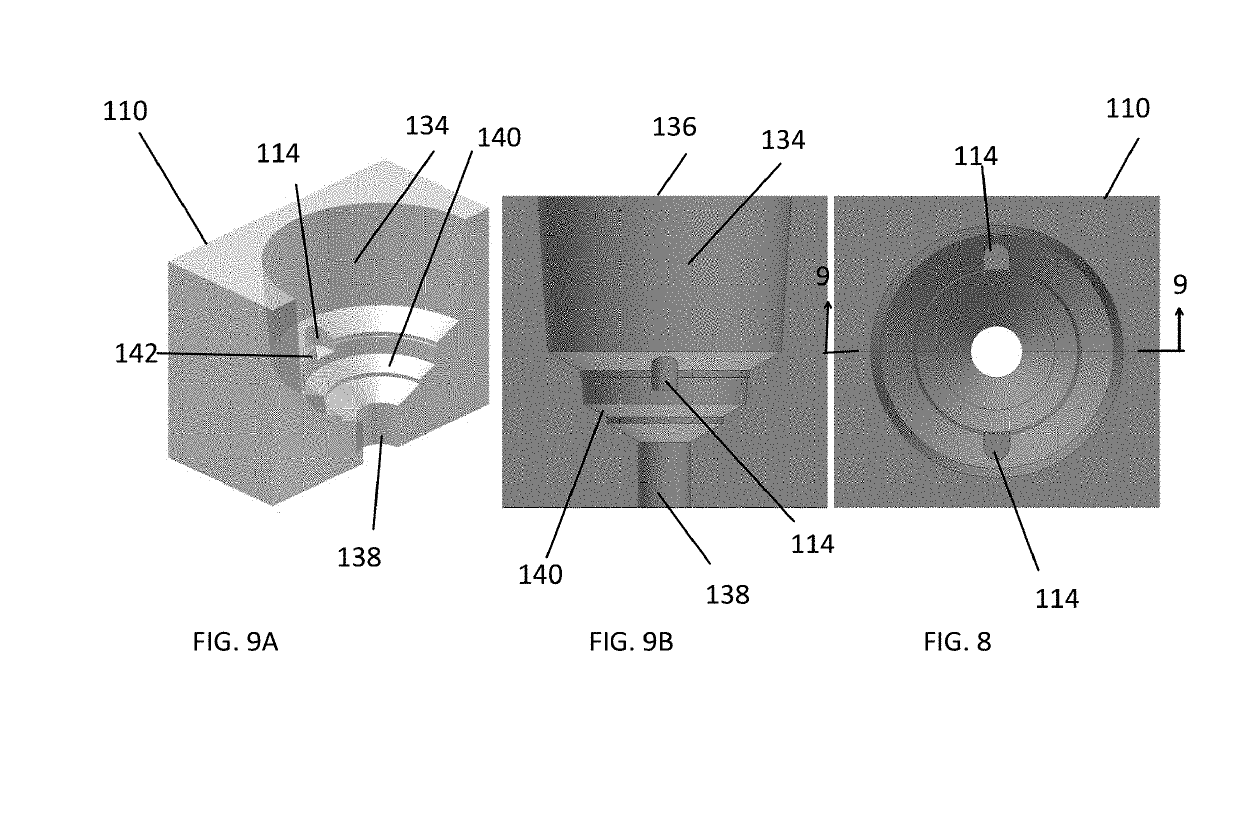

InactiveUS20110240244A1Increased exothermic welding reaction containmentIncreased gas-venting controlMelt-holding vesselsAlumino-thermic welding apparatusExothermic weldingCrucible

An exothermal weld mold includes a mold section with an integral cover portion, made as part of a single piece of material with the rest of the mold section. The mold section may be a mold half of a vertically split mold, or may constitute most of a half of the mold. The cover portion may be part of an integral cover that covers substantially all of a reaction chamber or crucible of the mold. The cover may have one or more vent holes, in the top and / or side of the mold. The cover may have a baffled passage for expansion of gases produced by reaction of the weld material, before the gases are expelled from the mold at an opening in the top or side of the mold. The passage may be a serpentine passage. A filter may be placed in the passage.

Owner:ERICO INT

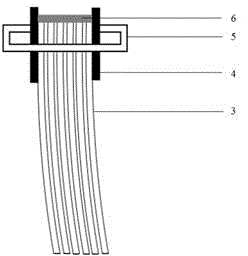

Method for welding cathode flexible bus of aluminum electrolysis cell without series power failure

ActiveCN102806425AProduction impactAchieve the purpose of repairWelding apparatusExothermic weldingAluminium electrolysis

The invention relates to the industry of electrolytic aluminum, and in particular to a method for performing repair work under the condition of no series power failure in the occurrence of damage to a cathode flexible bus of an aluminum electrolysis cell. The method provided by the invention comprises following steps: 1. steps of removing, grinding and flattening; 2. a step of welding a transition aluminum block; 3. a step of welding an explosion block; 4. a step of making preparation for welding; 5. a step of filling a heat release welding flux; 6. a step of heating a welding part; 7. a step of ignition; and 8. removing a mould after naturally cooling a cavity; performing insulation treatment on the welding part and slowing the cooling in places where the climate is cold; and after the completion of the welding, cleaning a site. With the adoption of the method provided by the invention, the cathode flexible hose of the aluminum electrolysis cell can be welded without the series power failure; due to good generality, the method is applicable for various slots; in such a way, the series power failure of the electrolytic cell is prevented, the ferrous welding under a strong magnetic field is prevented, and the condition that the heat release welding cannot be directly used for the flexible bus with a laminated structure is prevented; and therefore, the economic benefits of an aluminum electrolysis enterprise are improved, and the technical difficult in repairing the cathode flexible bus is solved for the aluminum electrolysis enterprise.

Owner:HUANGHE XINYE

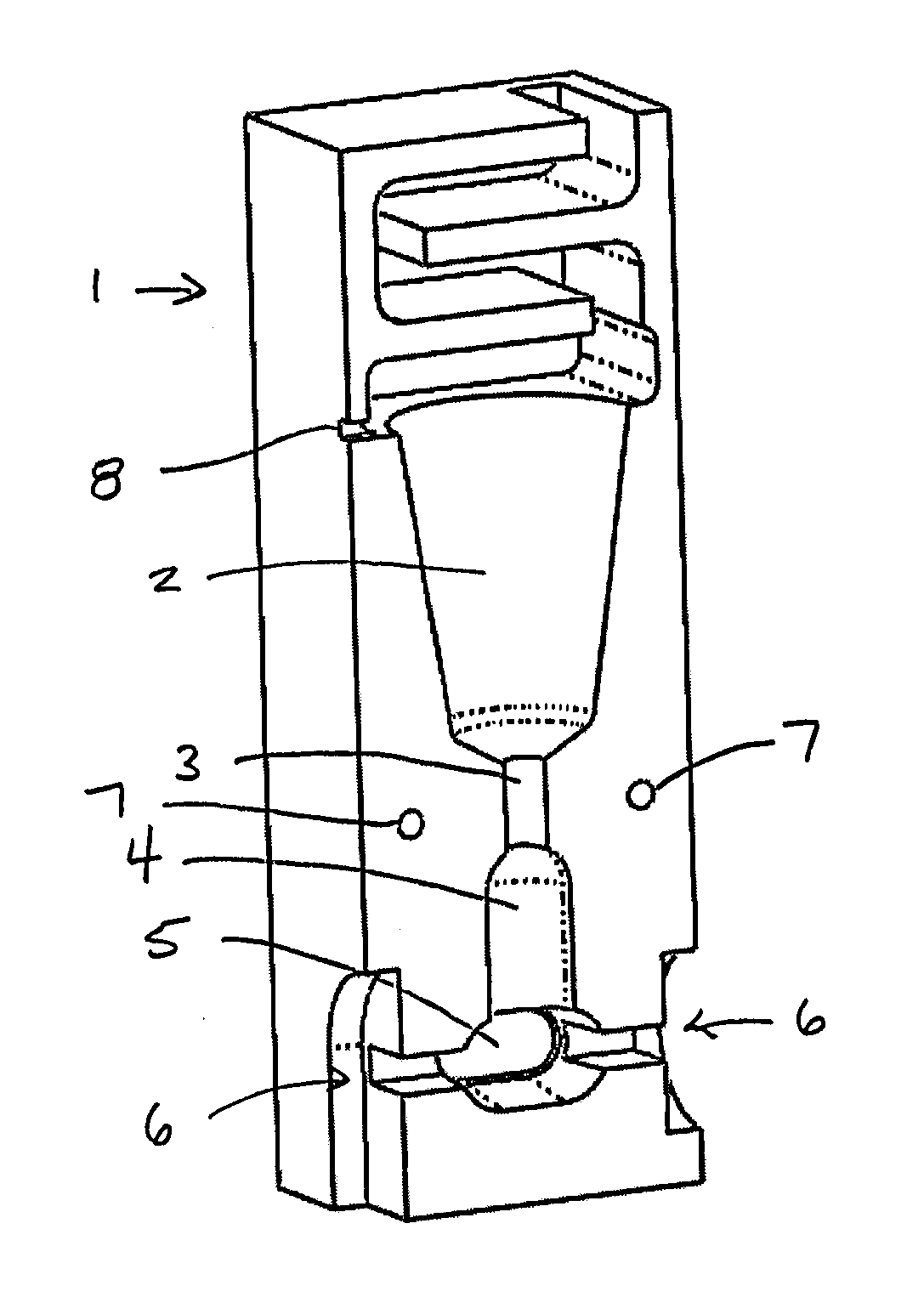

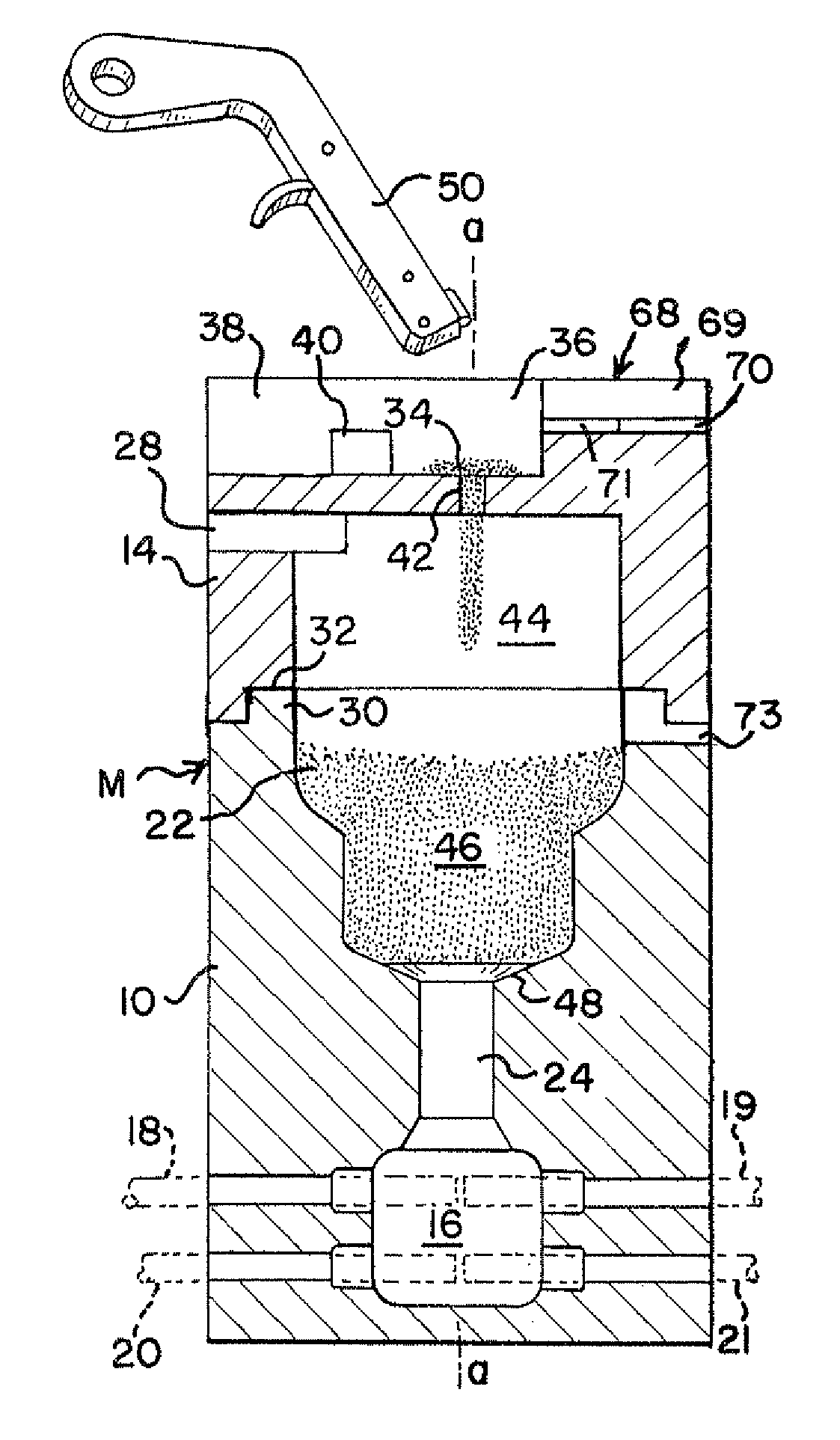

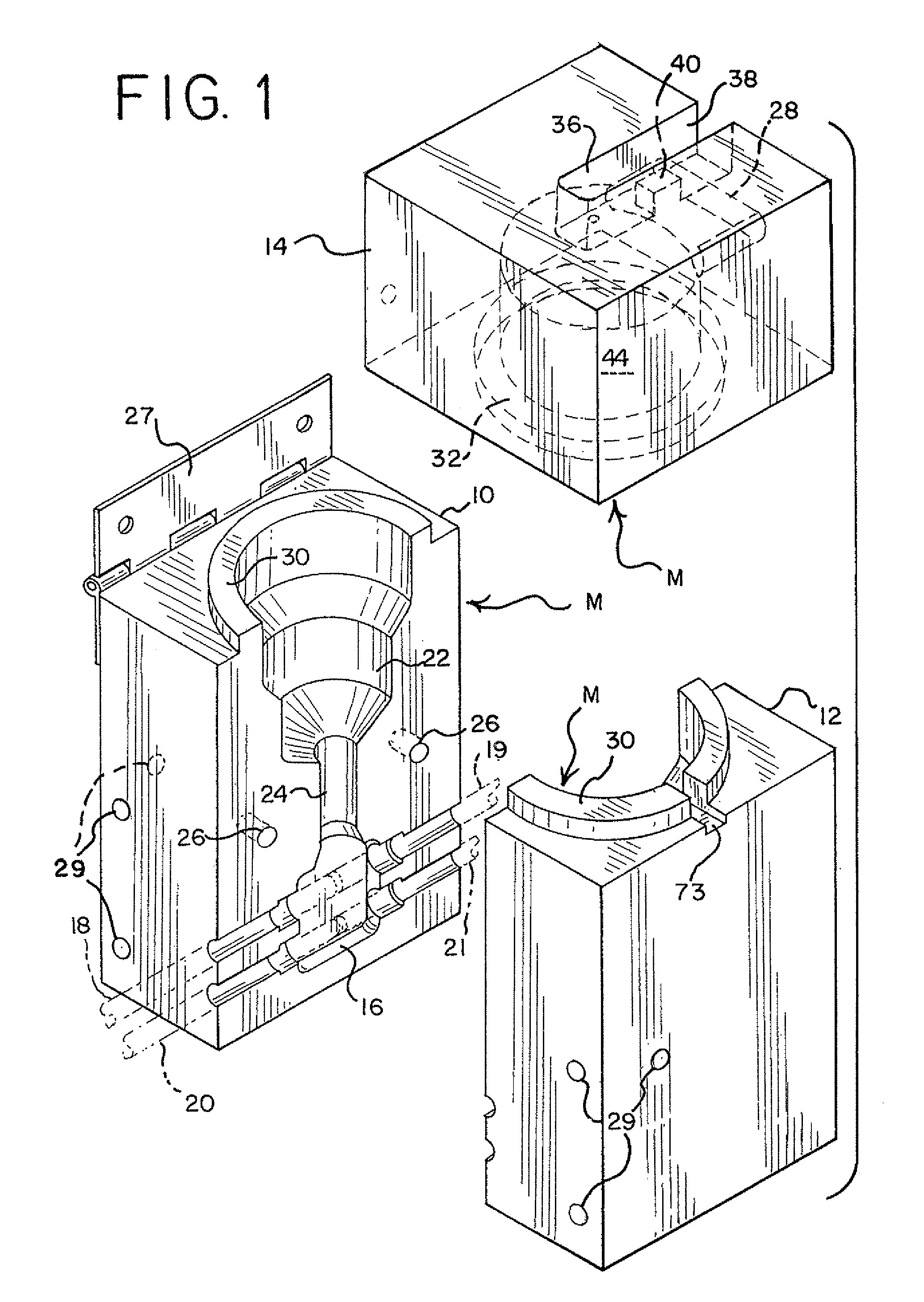

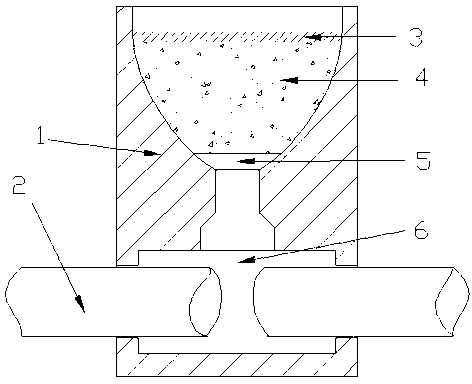

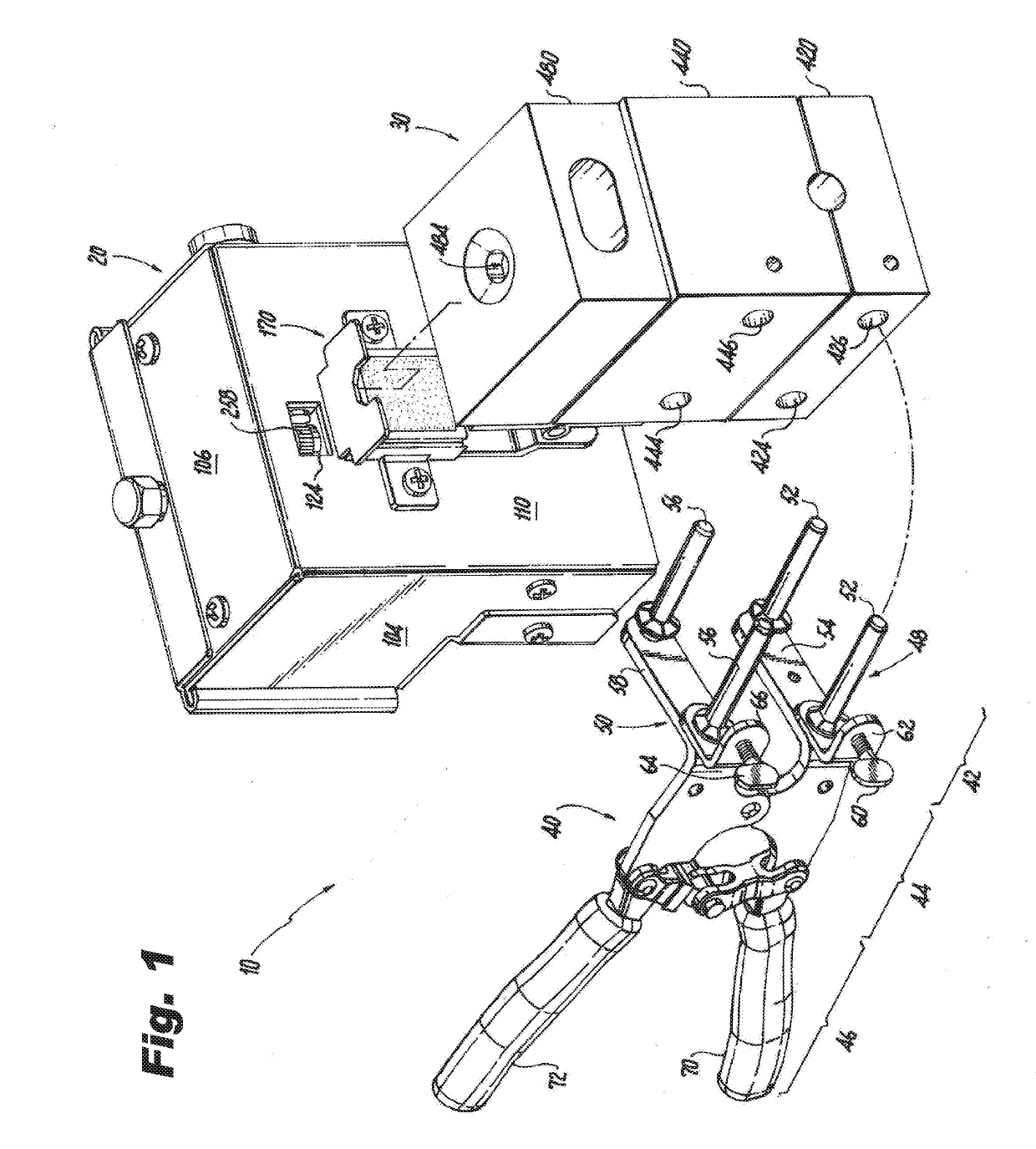

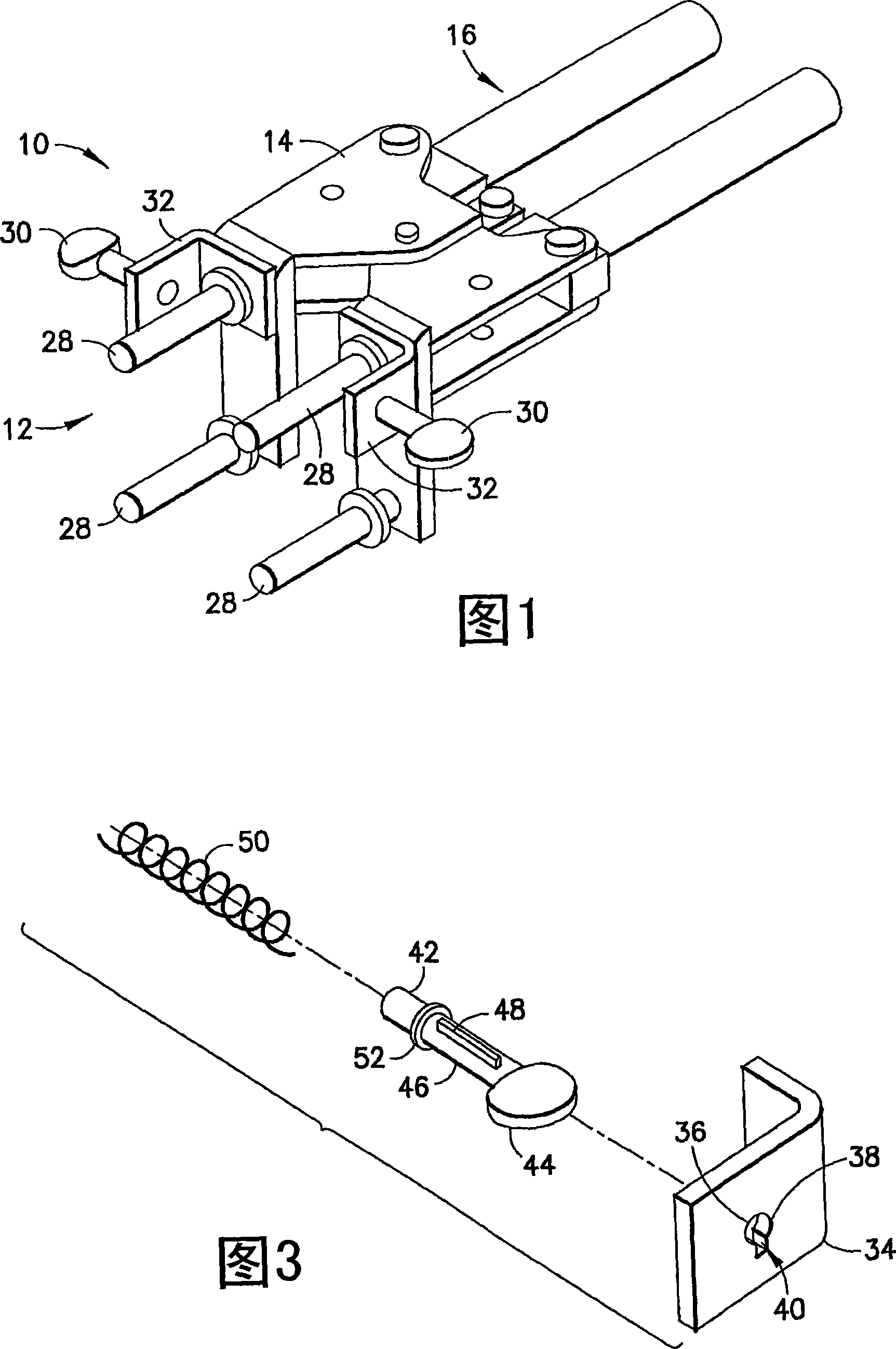

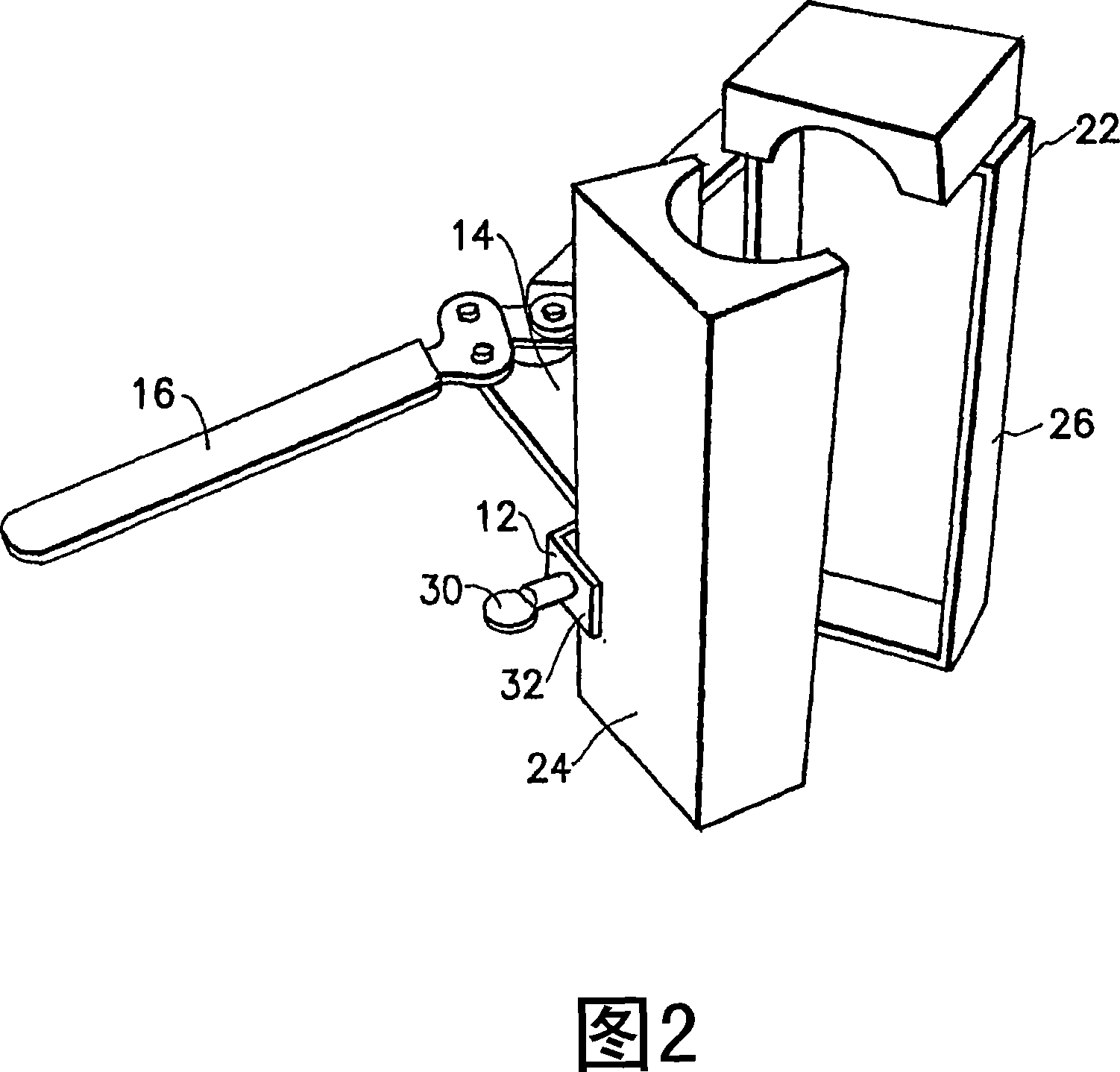

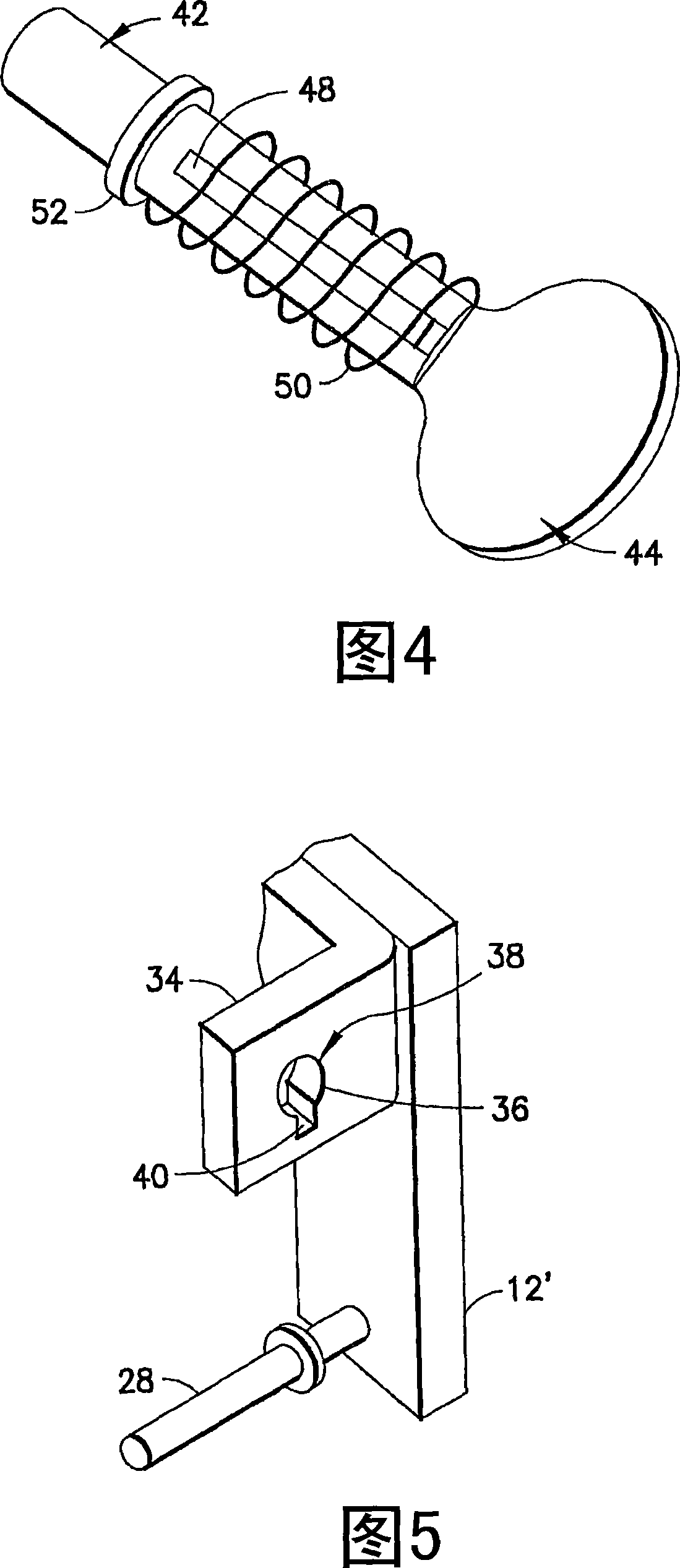

Exothermic welding assembly

ActiveUS7950568B2Improve the immunityEliminate needMould separation apparatusBlasting cartridgesExothermic weldingElectrical conductor

An assembly is disclosed for exothermic welding comprising a mold which is formed of a material which withstands exothermic welding temperatures and includes a weld cavity therein for positioning at least two members which are to be exothermically welded together, and an ignition cavity communicating with the weld cavity. The mold is capable of accommodating any one of several exothermic welding procedures which may involve either a flint igniter or the use of an electrical igniter which is readily accommodated by the mold in the performance of several of the procedures. The electrical igniter is formed of a pair of flat, longitudinally extending conductor strips with a sheet of insulation laminated therebetween, a filament adjacent one end of the strips, and one or more positioning tabs adjacent one end of the strips. A cartridge is also provided which contains the weld metal and the electrical igniter and which may be positioned in the ignition cavity of the mold. The cartridge is formed of a material which is consumed during the welding procedure and may contain a plate of a different material adjacent its bottom which melts at a higher temperature than the materials of the cartridge.

Owner:HARGER

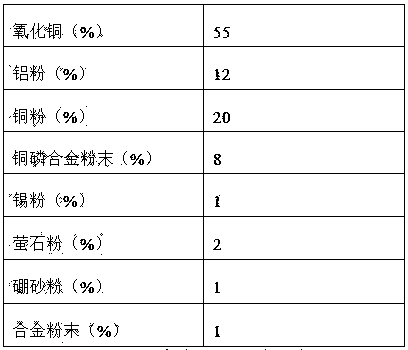

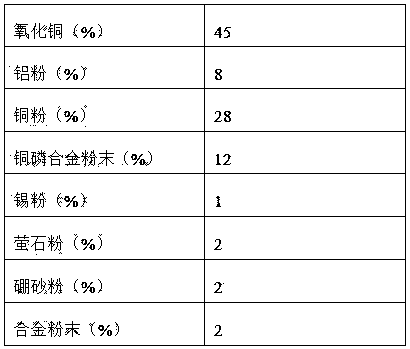

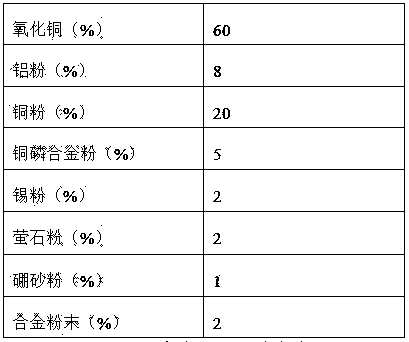

Exothermic welding powder for welding novel grounding grid materials

ActiveCN104043913AQuality improvementLower connection costsWelding/cutting media/materialsAlumino-thermic welding apparatusExothermic weldingAl powder

The invention discloses exothermic welding powder for welding novel grounding grid materials. The exothermic welding powder comprises, by weight, 45%-60% of copper oxide, 8%-13% of aluminum powder, 20%-30% of copper powder, 5%-15% of copper-phosphorus alloy powder, 1%-5% of tin powder, 2%-6% of fluorite powder, 1%-4% of borax powder and the balance alloy powder. The alloy powder comprises, by weight, 8%-12% of Ca, 40%-47% of Si, 28%-32% of Ba and the balance impurities. According to the exothermic welding powder, raw materials are low in price and easy to get, the problems that pores, slag inclusion, hot tear and the like can be easily generated in the welding process by using the exothermic welding powder are solved, the quality of welded joints is reliable, the connecting cost of the novel grounding grid materials is lowered, and the development of a grounding system in electric power engineering in China is facilitated.

Owner:STATE GRID CORP OF CHINA +3

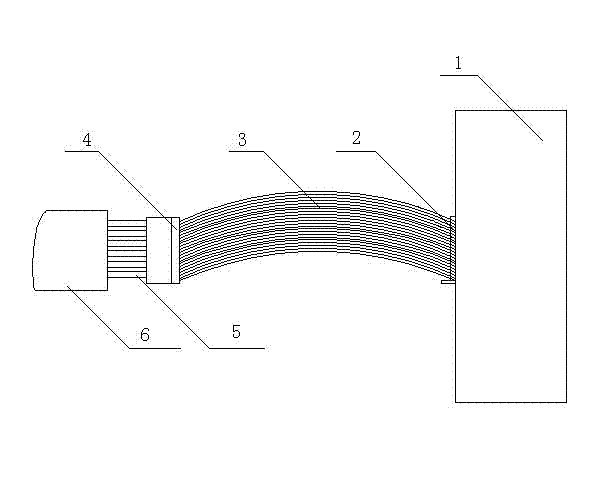

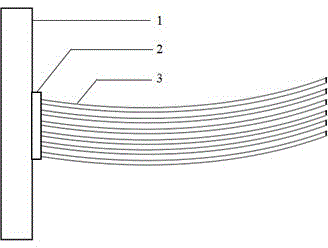

In-situ power-cut-free welding method for soft mother belts and aluminum bus of cathode of aluminum electrolysis cell

ActiveCN104972220ASolve technical problemsAvoid the defect that exothermic welding cannot be used directlyWelding/cutting media/materialsSoldering mediaExothermic weldingEconomic benefits

The invention relates to the electrolytic aluminum industry, in particular to an in-situ power-cut-free welding method for soft mother belts and an aluminum bus of the cathode of an aluminum electrolysis cell. The method comprises the following steps of 1 in-situ grinding, 2 in-situ fixing, 3 in-situ fusion, 4 pre-welding treatment, 5 preheating, 6 exothermic welding and 7 post-welding treatment. By means of the method, in-situ connection between the soft mother belts and the aluminum bus is directly completed through exothermic welding, the defect that the soft mother belts of a sheet type structure cannot be directly welded in a magnetic field is overcome, the economic benefits of an aluminum electrolysis enterprise are increased, and repairing of the soft mother belts for the aluminum electrolysis enterprise is realized. The operation can be completed under the condition that serial aluminum electrolysis cells are powered all the time, and the repairing purpose can be achieved on the promise of not affecting production of the serial aluminum electrolysis cells. The method is suitable for welding of the soft mother belts and the aluminum bus in various cell types, and is good in universality, easy to operate and high in welding repair efficiency.

Owner:WUHAN UNIV

Exothermic welding assembly

ActiveUS20110198391A1Improve the immunityEliminate needIncandescent ignitionFuel lightersExothermic weldingElectrical conductor

An assembly is disclosed for exothermic welding comprising a mold which is formed of a material which withstands exothermic welding temperatures and includes a weld cavity therein for positioning at least two members which are to be exothermically welded together, and an ignition cavity communicating with the weld cavity. The mold is capable of accommodating any one of several exothermic welding procedures which may involve either a flint igniter or the use of an electrical igniter which is readily accommodated by the mold in the performance of several of the procedures. The electrical igniter is formed of a pair of flat, longitudinally extending conductor strips with a sheet of insulation laminated therebetween, a filament adjacent one end of the strips, and one or more positioning tabs adjacent one end of the strips. A cartridge is also provided which contains the weld metal and the electrical igniter and which may be positioned in the ignition cavity of the mold. The cartridge is formed of a material which is consumed during the welding procedure and may contain a plate of a different material adjacent its bottom which melts at a higher temperature than the materials of the cartridge.

Owner:HARGER

Exothermic welding mold with filter

InactiveUS20120255699A1Reduce smokeReduce exhaustFoundry mouldsFoundry coresExothermic weldingEngineering

Owner:ERICO INT

Self-propagating welding powder

InactiveCN103071949ARaise the ratioIncrease heatWelding/cutting media/materialsSoldering mediaExothermic weldingSlag

The invention relates to self-propagating welding powder, which is prepared from the following raw materials according to mass percent: 15 to 30% of aluminium powder, 30 to 40% of copper powder, 40 to 60% of barite powder and 4 to 7% of calcium fluoride. The copper powder is melt to form molten metal of high temperature using a lot of heat generated by the oxidation-reduction reaction of the aluminium powder and the barite powder; and the molten copper of high temperature is adopted to weld the fillers of a weld groove. The aluminum oxide generated by reaction is combined with silicon dioxide and calcium fluoride in barite to promote the molten metal and slag to be separated. The reaction process is stable and a good welding effect can be achieved during exothermic welding.

Owner:WUHAN UNIV

Ignition powder for copper-clad steel/copper grounding grid exothermic welding

InactiveCN101637851AEasy to storeEasy to transportWelding/cutting media/materialsSoldering mediaExothermic weldingGrounding grid

An ignition powder for copper-clad steel / copper grounding grid exothermic welding belongs to the metal welding field. The existing ignition powder for exothermic welding has the problems of poor safety, no environmental protection, complex components, high reaction brightness and the like. The ignition powder for exothermic welding comprises the following components by weight percent: 20-70% of copper oxide powder with granularity of 40-80 meshes and 85% of oxidation degree; 0-50% of copper oxide powder with granularity of 200-300 meshes and 99.9% of oxidation degree; 10-15% of aluminium metalpowder with granularity of 200-300 meshes and 99.9% of purity; and 15-35% of magnesium metal powder with granularity of 40-100 meshes and 99.9% of purity. The ignition powder has the advantages of simple components, environmental protection, good safety, even reaction speed, moderate brightness and the like.

Owner:CHINA ELECTRIC POWER RES INST

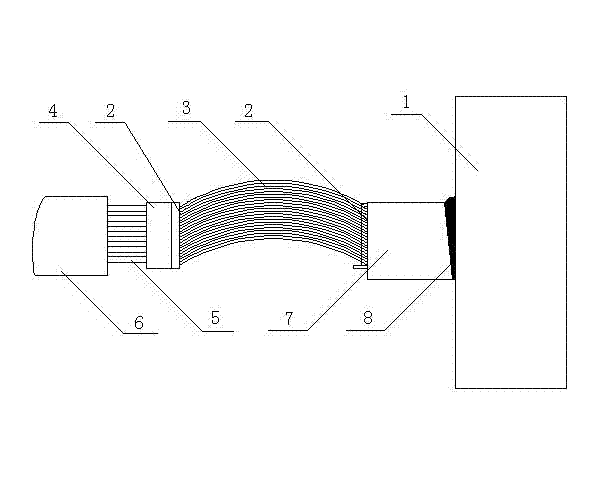

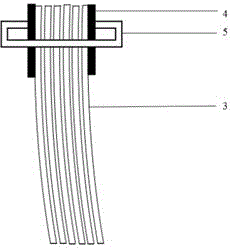

Electrolytic tank aluminum bus and soft tape electric heat-release welding method

InactiveCN102990222ALow costReduce repair costsAlumino-thermic welding apparatusExothermic weldingAluminium electrolysis

The invention relates to the technical field of aluminum electrolysis, and particularly relates to an electrolytic tank electric aluminum bus and aluminum soft tape damage re-welding repairing method. The electric heat-release welding method comprises the following steps of: 1) selection of crucible materials; 2) preparation of a crucible die; 3) preparation of a welding die; 4) preparation of a pouring piece and a blocking piece; and 5) welding. The method provided by the invention designs a 200kA electrolytic tank aluminum bus and soft band electric welding die by use of the heat-release welding principle and successfully performs electric welding. Through the method provided by the invention, the electrolytic tank aluminum bus and soft band electric welding can be performed for an electrolytic tank by a heat-release welding mode without cutting power, and the power cut of the electrolytic tank is not required, thus the cost can be saved, and the repairing cost is reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

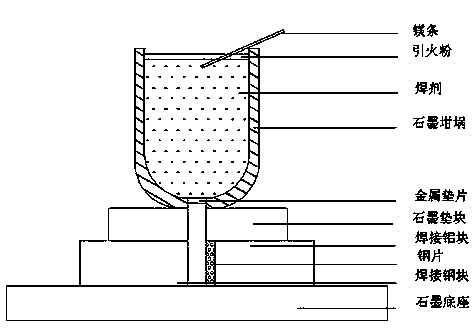

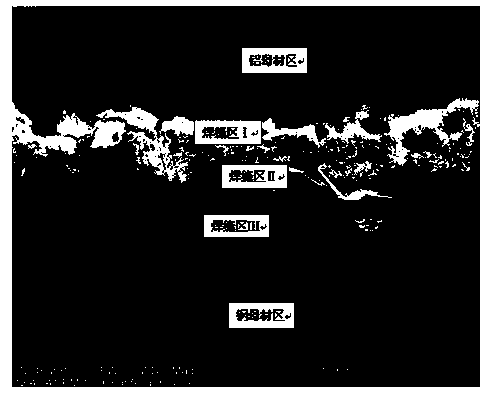

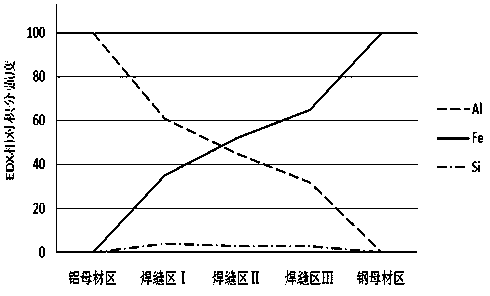

Aluminum-steel heat release welding method

InactiveCN103639589AReduce embrittlementIt conforms to the thermodynamic law that the temperature of the flow down gradually decreasesWelding/cutting media/materialsWelding/soldering/cutting articlesExothermic weldingAl powder

The invention discloses an aluminum-steel heat release welding method. The method comprises the steps that to-be-welded sections of an aluminum block and a steel block are polished cleanly; a pre-polished steel sheet is placed to cling to the aluminum block between a gap of the to-be-welded sections of the aluminum block and the steel block; a bottom through hole of a graphite crucible is aligned to the center of the gap; a self-propagating welding flux is put into the graphite crucible; pyrophoric powder on the surface of the self-propagating welding flux is ignited; molten liquid generated by self-propagating welding flux reaction flows into the gap between the aluminum block and the steel block from the bottom small hole of the graphite crucible; the steel sheet is heated, molten, and cooled to a room temperature; and then aluminum-steel welding is accomplished. The adopted self-propagating welding flux comprises the following raw materials by mass percent: 22-28% of Al powder, 62-68% of Fe2O3 powder, 4-7% of Si powder and 3-6% of slag forming constituent. The method is simple to operate, simple in equipment, stable, safe and reliable in reaction, extensive in raw material, low in cost and less in joint slag inclusion, and has a great industrial popularization value; aluminum steel bonding adopts metallurgical bonding; and the quality is good.

Owner:WUHAN UNIV

Exothermic welding powder

ActiveCN107671452ASpeed up the replacement reaction rateWell mixedWelding/cutting media/materialsSoldering mediaExothermic weldingChemical reaction

The invention relates to the technical field of welding powder of welding materials, in particular to exothermic welding powder. The welding powder comprises alloy powder and composite powder particles, wherein the alloy powder comprises, by weight, 49-50% of copper, 47-48% of aluminum, 0.8-1.2% of calcium, 0.8-1.2% of tin, 0.4-0.6% of iron, 0.1-0.3% of carbon, 0.1-0.3% of rare earth and 0-0.2% ofsilver, and the composite powder particles comprises, by weight, 12-16 parts of aluminum powder, 18-24 parts of copper oxide powder and 3-5 parts of slag-making agents. According to the exothermic welding powder, the composite powder particles are added into the alloy powder, by triggering the chemical reaction in the composite powder particles, a lot of heat are released, the fluidity of moltenmetal is greatly increased, the replacement reaction rate of the exothermic welding powder is speeded up, meanwhile, mixing of raw materials is more even, after cooling, the connection strength is good, the surface is smooth, and the welding part quality is stable.

Owner:JIAXING JIAHE ELECTRIC POWER EQUIP

Laser- welded article

ActiveUS20090291244A1Sufficient welding strengthNot to damageLamination ancillary operationsSynthetic resin layered productsExothermic weldingLight beam

Owner:ORIENT CHEM INDS

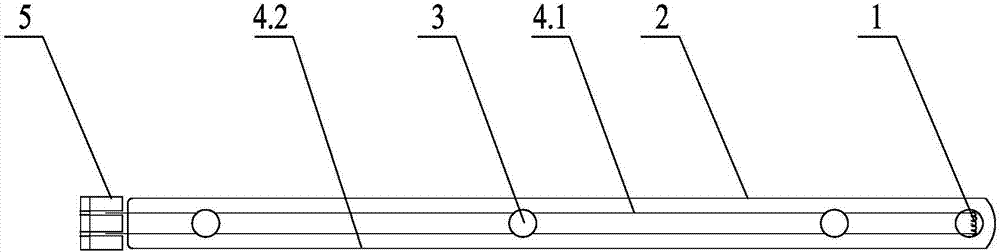

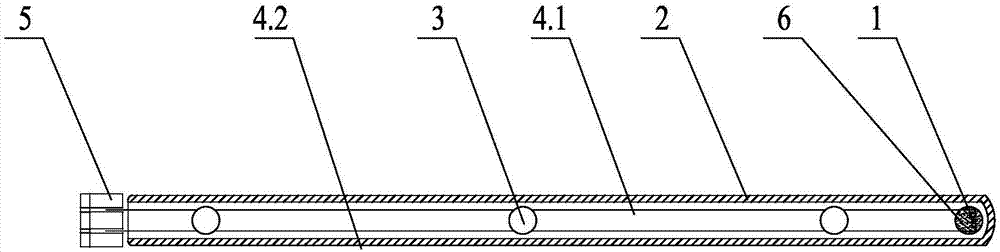

Safety remote-control ignition rod

InactiveCN107030372ASimple operation processSimple structureAlumino-thermic welding apparatusExothermic weldingElectrical resistance and conductance

The invention relates to a safety remote-control ignition rod, in particular to a safety appliance which is used for ensuring the body security of operation technicists during metal welding by use of an exothermic welding flux, and belongs to the technical field of welding. The safety remote-control ignition rod comprises a resistance wire, a guide-in pipe, insulating blocks, a first wire, a second wire and a plug connector, wherein the first wire and the second wire are mounted in the guide-in pipe in the length direction; the right end part of the first wire is connected with the right end part of the second wire through the resistance wire; the insulating blocks are arranged between the first wire and the second wire; the plug connector is arranged on the left side of the left end part of the guide-in pipe; and the left end part of the first wire and the left end part of the second wire are inserted into the plug connector. The safety remote-control ignition rod is simple, safe and reasonable in structure, takes the resistance wire as the main element, realizes 'direct' ignition, and ensures that the technicists are prevented from being injured by jetting during reaction of the exothermic welding flux; and hands of the technicists can be moved from 8 cm away from a die to a safe operation area 1-5 m away from the die.

Owner:GELIN ELECTRICAL EQUIP PLANT WUXI CITY

Heat release welding process for grounding electrode facility of power grid direct current engineering

InactiveCN102049625ALow resistivityEasy connection processWelding apparatusExothermic weldingPower grid

The invention relates to a heat release welding process for a grounding electrode facility of power grid direct current engineering, which is used for welding a grounding rod. The heat release welding process comprises the following steps of: carrying out cleaning, drying and deoxygenization treatment on the surface of the wending end part of a steel rod; then carrying out heating treatment on the welding end part and the adjacent part of the steel rod by a blow lamp; drying a die and removing steam by adopting a heating tool; installing the welding end part of the steel rod to the corresponding position of the die and ensuring the tightness of the contact surface of the die; and igniting for carrying out heat release welding. A welding head obtained by the heat release welding process for a grounding electrode facility of power grid direct current engineering has low resistivity and corrosion resistance. The heat release welding process improves the connecting process among grounding bodies of the traditional grounding system and integral engineering quality and overcomes the difficulty and defects of a grounding electrode feed rod in the welding construction to a great extent.

Owner:国家电网有限公司特高压建设分公司

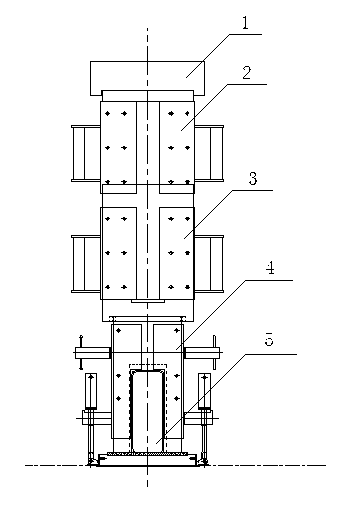

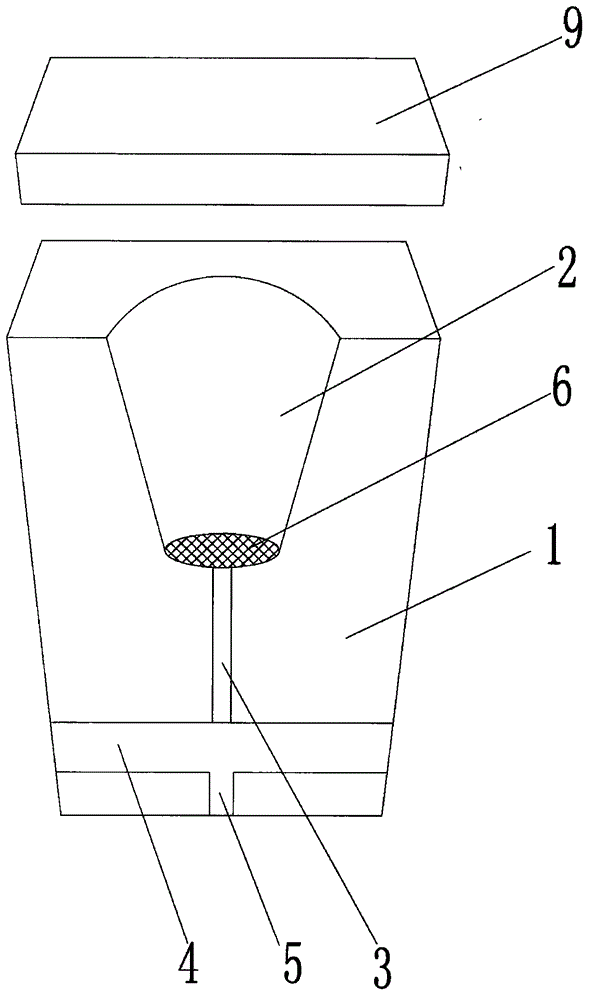

Die for exothermic welding of grounding grid and welding method

InactiveCN104625513ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesExothermic weldingGrounding grid

The invention relates to a die for exothermic welding of a grounding grid and a welding method. The welding method includes the process steps: cleaning a copper bar, a grounding rod and a die body and placing the copper bar and the grounding rod to be welded into a copper bar placing cavity and a grounding rod placing cavity respectively; clamping a left piece and a right piece of the die body, laying down a supporting piece, sealing the top of a die cavity and stopping exothermic welding flux before reaction from flowing into the die cavity; pouring the exothermic welding flux into a welding powder filling area, spreading initial pyrophoric powder and covering a die cover; igniting the pyrophoric powder by a firing gun and performing exothermic reaction of the exothermic welding flux in the die; opening the die after hot melting reaction of the exothermic welding flux for 10-20 seconds; taking out the copper bar and the grounding rod which are welded, and removing molten slag. The shortcomings of welding slag, easiness in oxidation, low connecting strength, easiness in corrosion, small contact area, large contact resistance and the like in traditional welding such as electric welding and braze welding, additional energy and power are omitted, and the welding method is a simple, high-efficiency and high-quality metal connecting process.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD

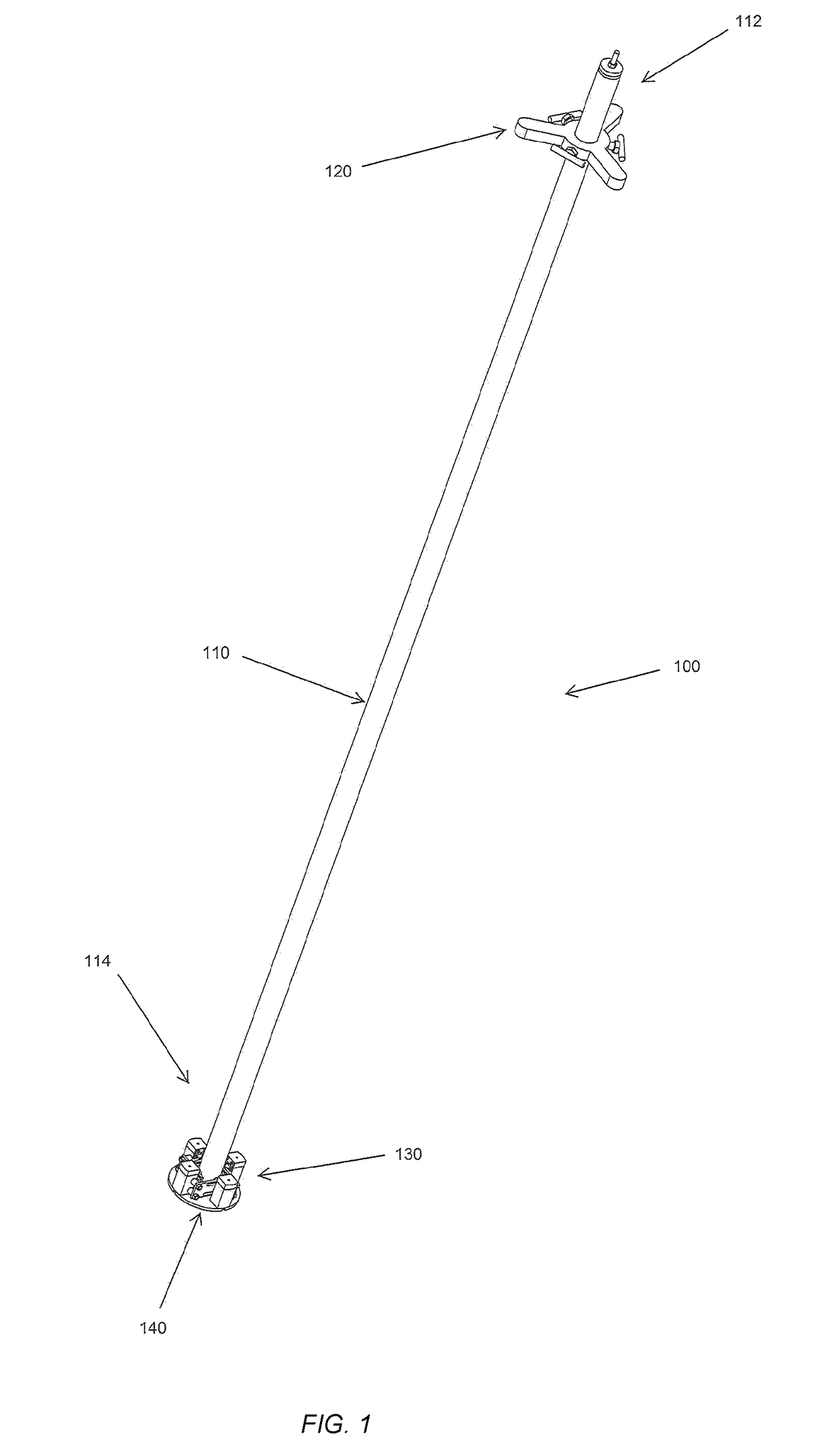

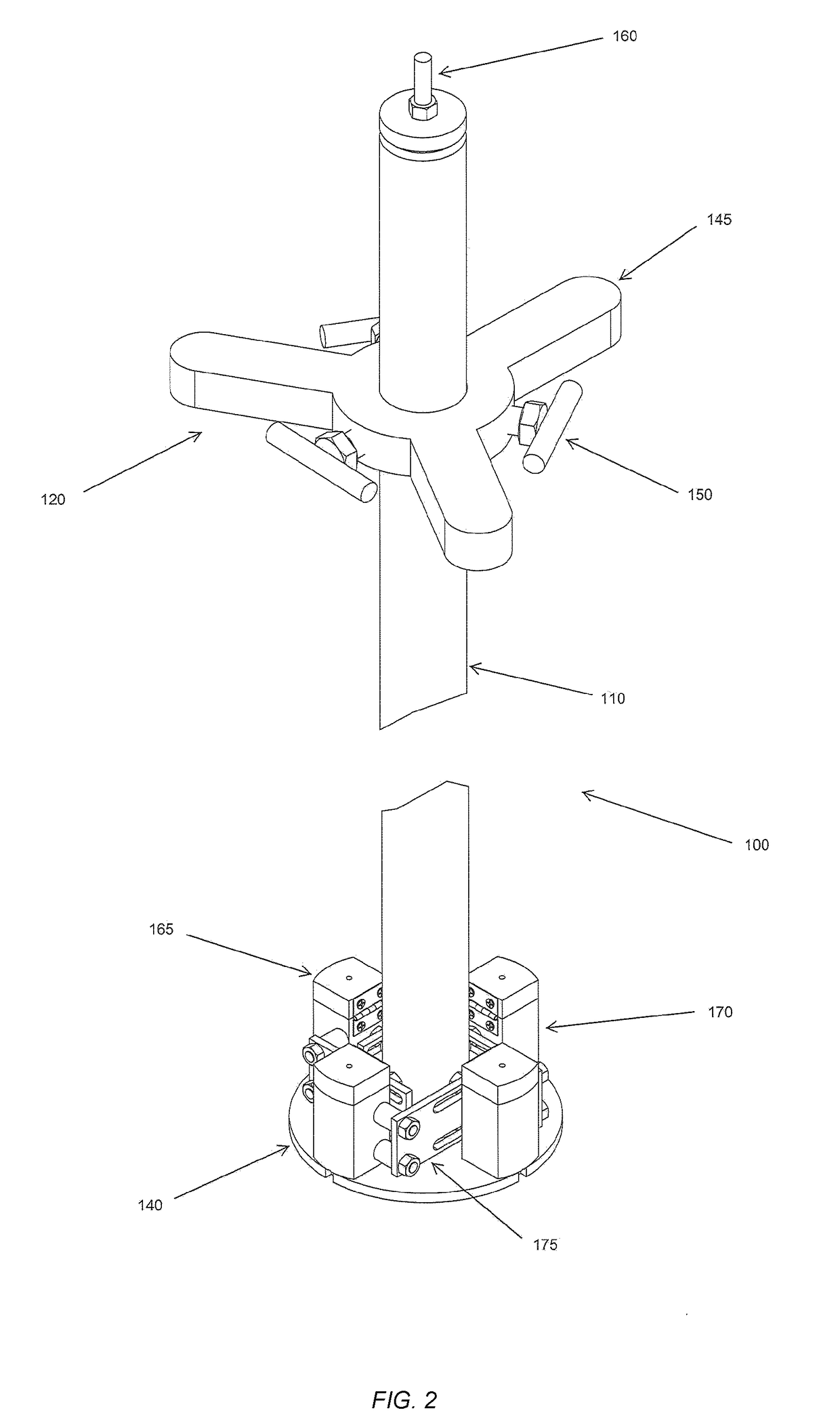

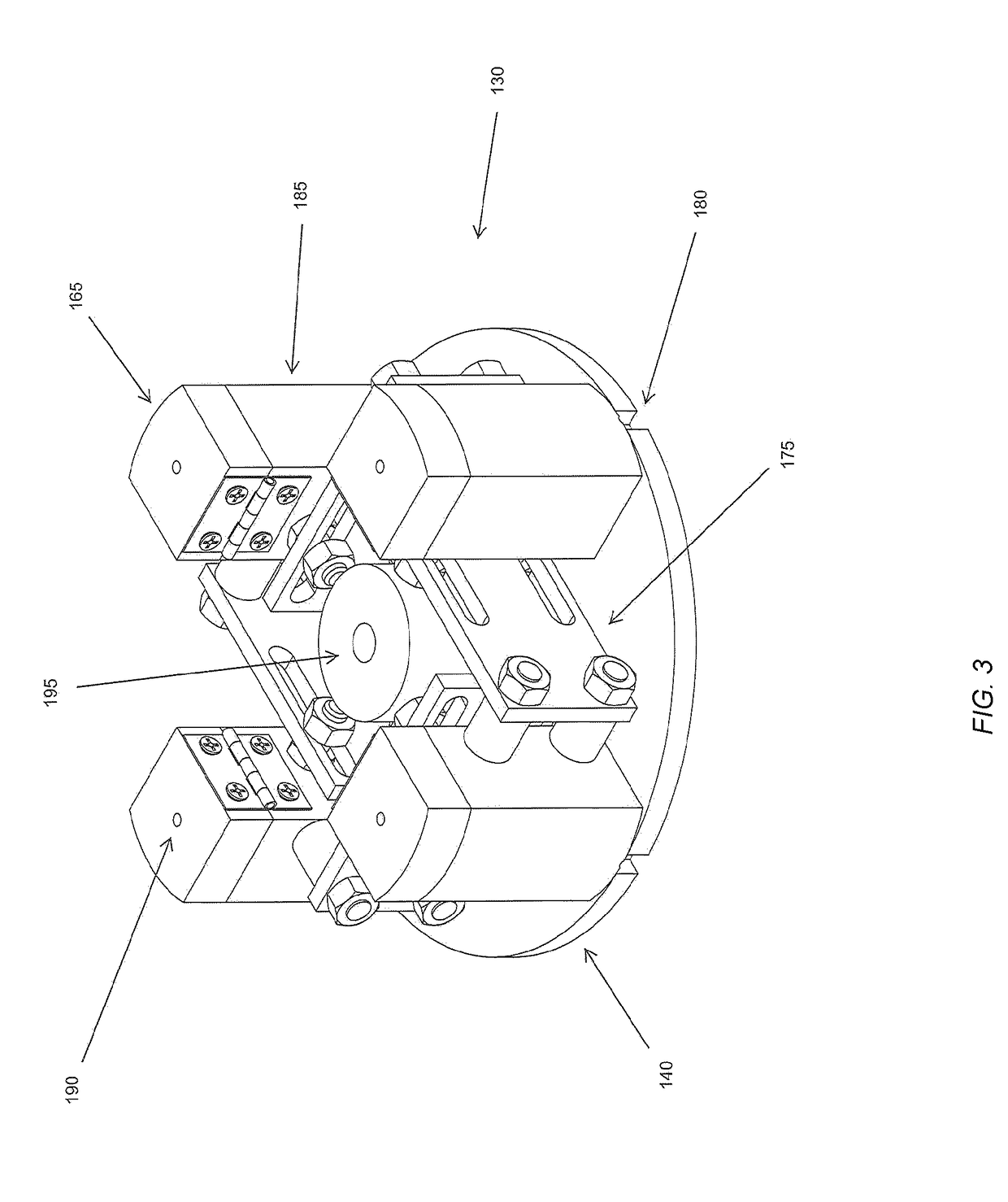

Downhole welding process and tool therefore

ActiveUS20180363424A1Welding/cutting auxillary devicesAuxillary welding devicesExothermic weldingEngineering

A welding tool for welding a blanking plate within a wellbore casing downhole thereby sealing the wellbore is described. The tool comprises a tubular body of a diameter sufficiently narrow to fit in a wellbore casing, the tubular body having a downhole end and a surface end; and a welding head assembly connected to the downhole end of the tubular body. The welding head assembly comprises a connector device for retaining a blanking plate to be welded within the wellbore casing, and a welding powder container which comprises a chamber for holding the exothermic welding powder, the chamber having at least a portion extending adjacent the blanking plate to be retained and proximate the wellbore casing to which the blanking plate is to be welded when the tool is positioned downhole in the wellbore casing; and an igniter wire opening for accommodating an igniter wire extending into the chamber.

Owner:NUWAVE IND

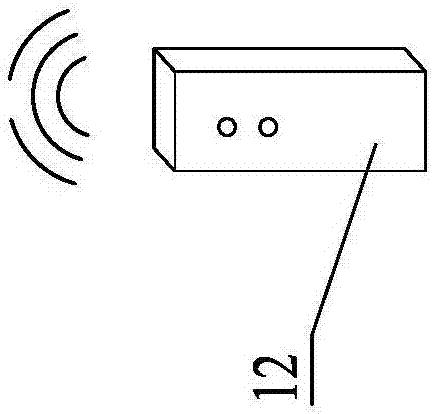

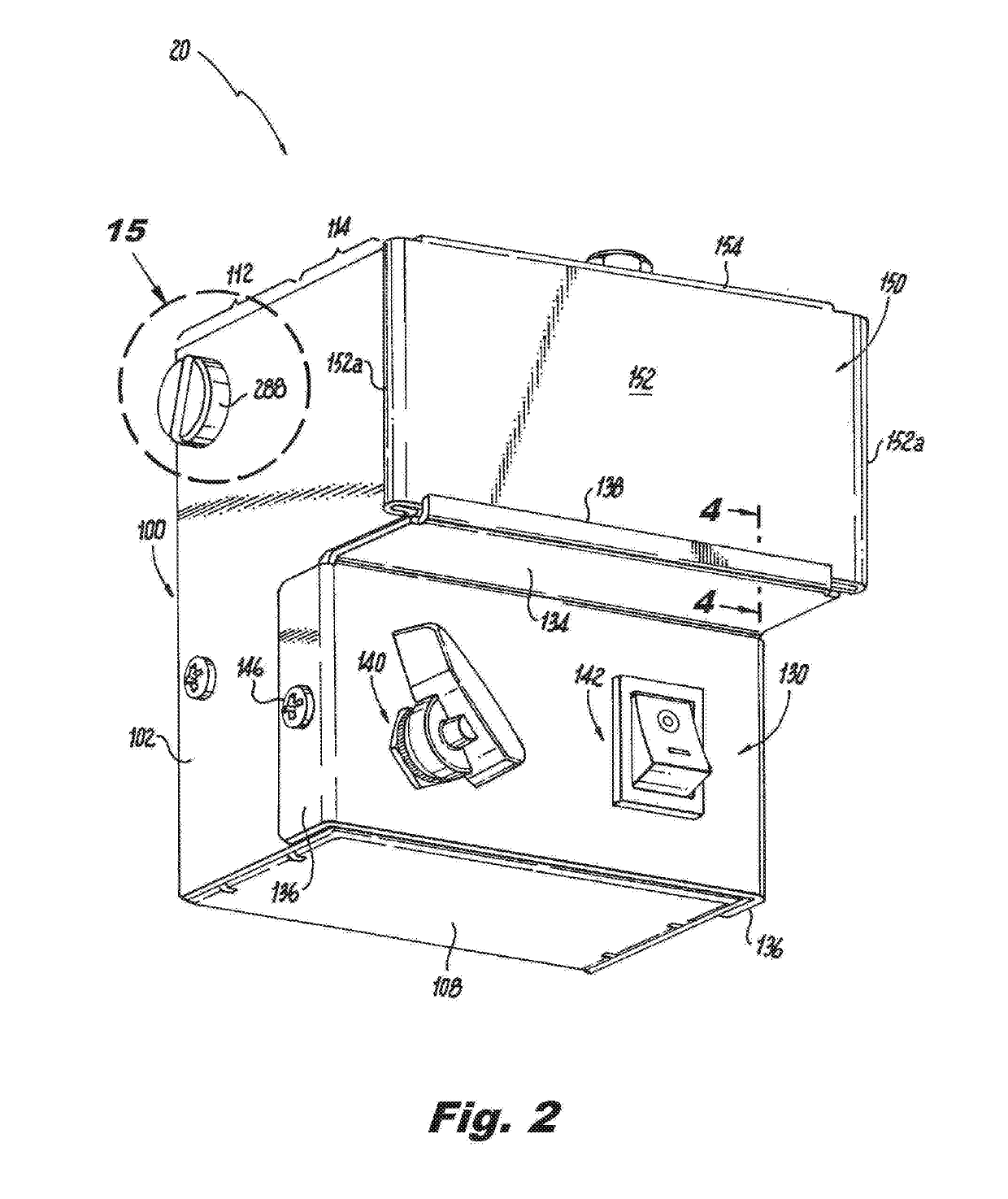

Trigger devices for exothermic welds

ActiveUS20190101288A1Soldering apparatusAlumino-thermic welding apparatusExothermic weldingExothermic reaction

Trigger devices for igniting an exothermic reaction is provided. The trigger devices may be flint type trigger devices and electronic type trigger devices. The flint type trigger device has a housing with a spark opening on a rear wall of the housing. A mold mounting assembly is secured to an exterior of the rear wall of the housing. A motor assembly is secured to the inside of the rear wall of the housing. The motor assembly has a flint wheel attached to a shaft of a motor, where the flint wheel is located adjacent the spark opening. A flint assembly is positioned within the housing such that a flint of the flint assembly is in contact with the flint wheel. A controller positioned within the housing is configured to selectively activate the motor to cause the flint wheel to rotate against the flint to create one or more sparks that are ejected from the spark opening.

Owner:HUBBELL INC

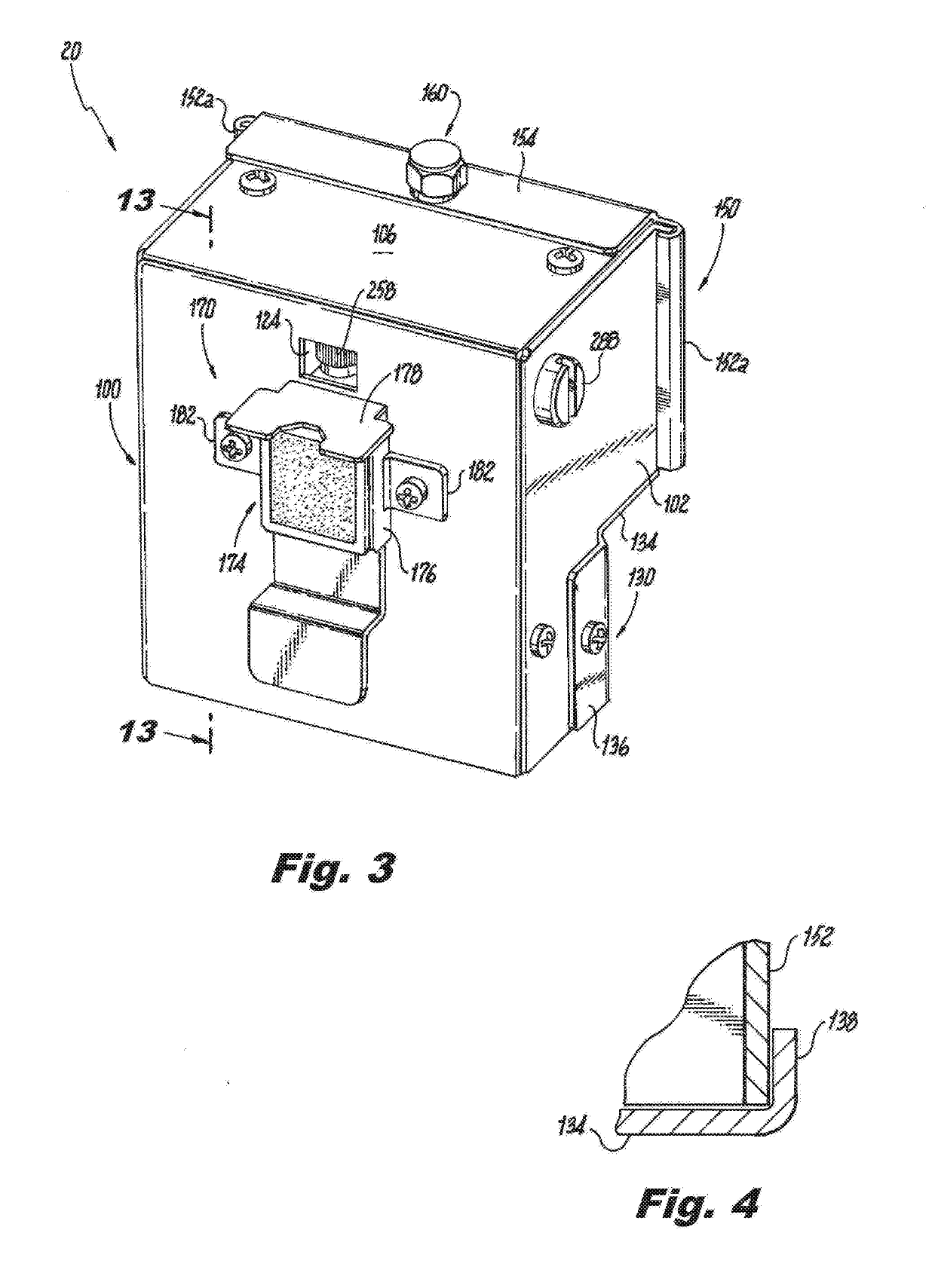

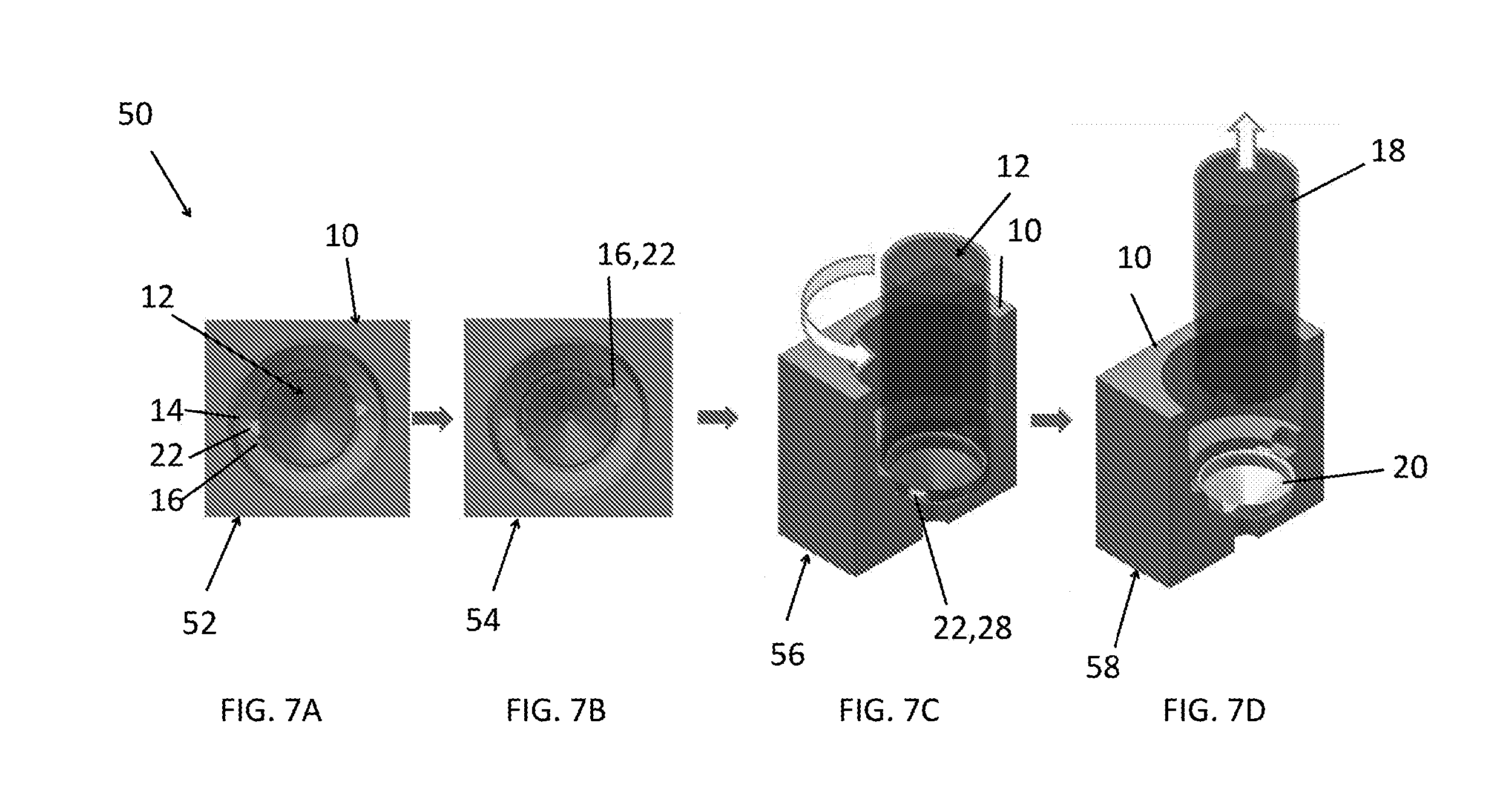

Exothermic reaction welding molds, weld-metal containing cartridges for such molds, and methods of use

ActiveUS10239162B2Prevent exitWelding/cutting auxillary devicesShearing machinesExothermic weldingInternal pressure

Owner:HUBBELL INC

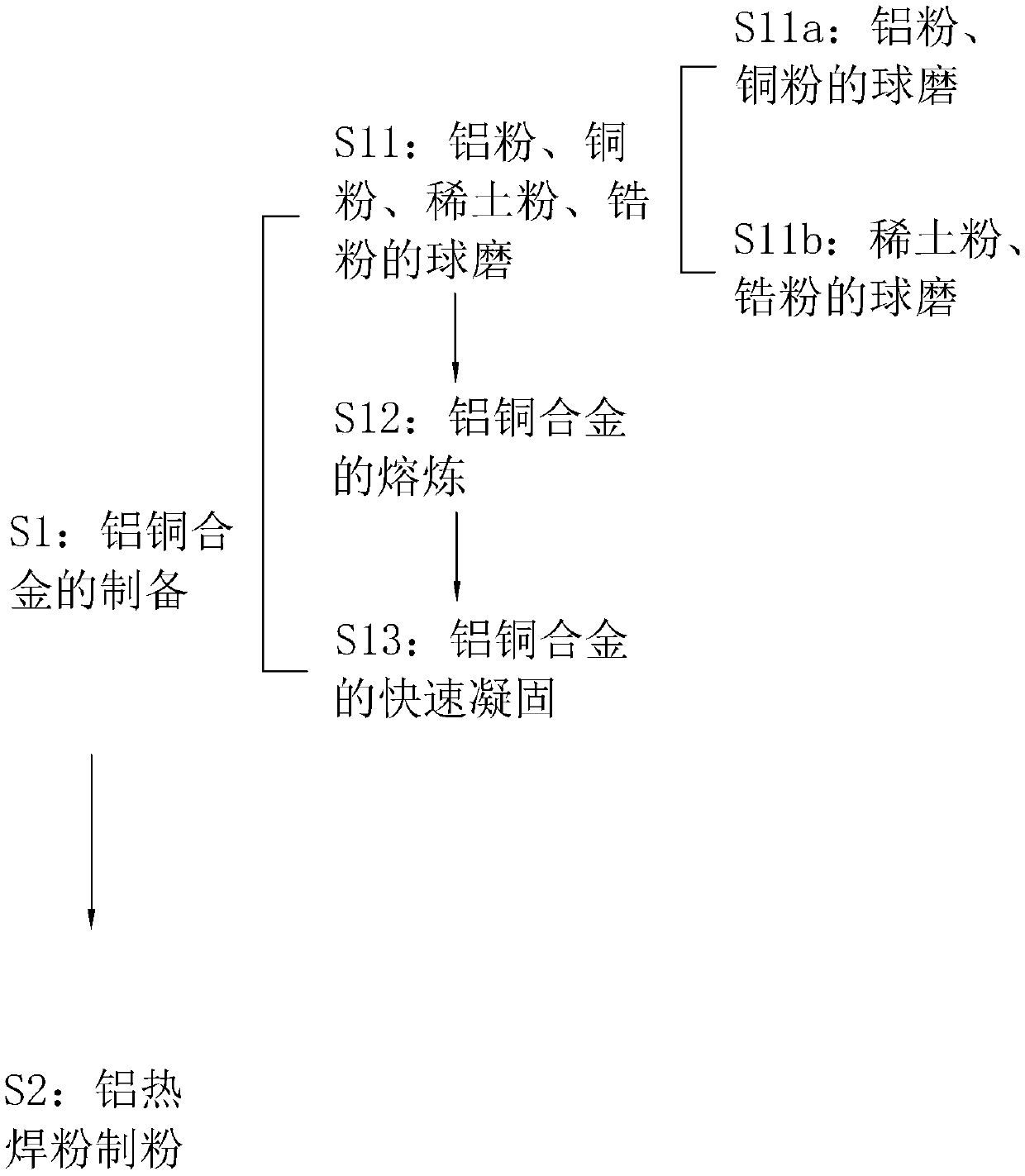

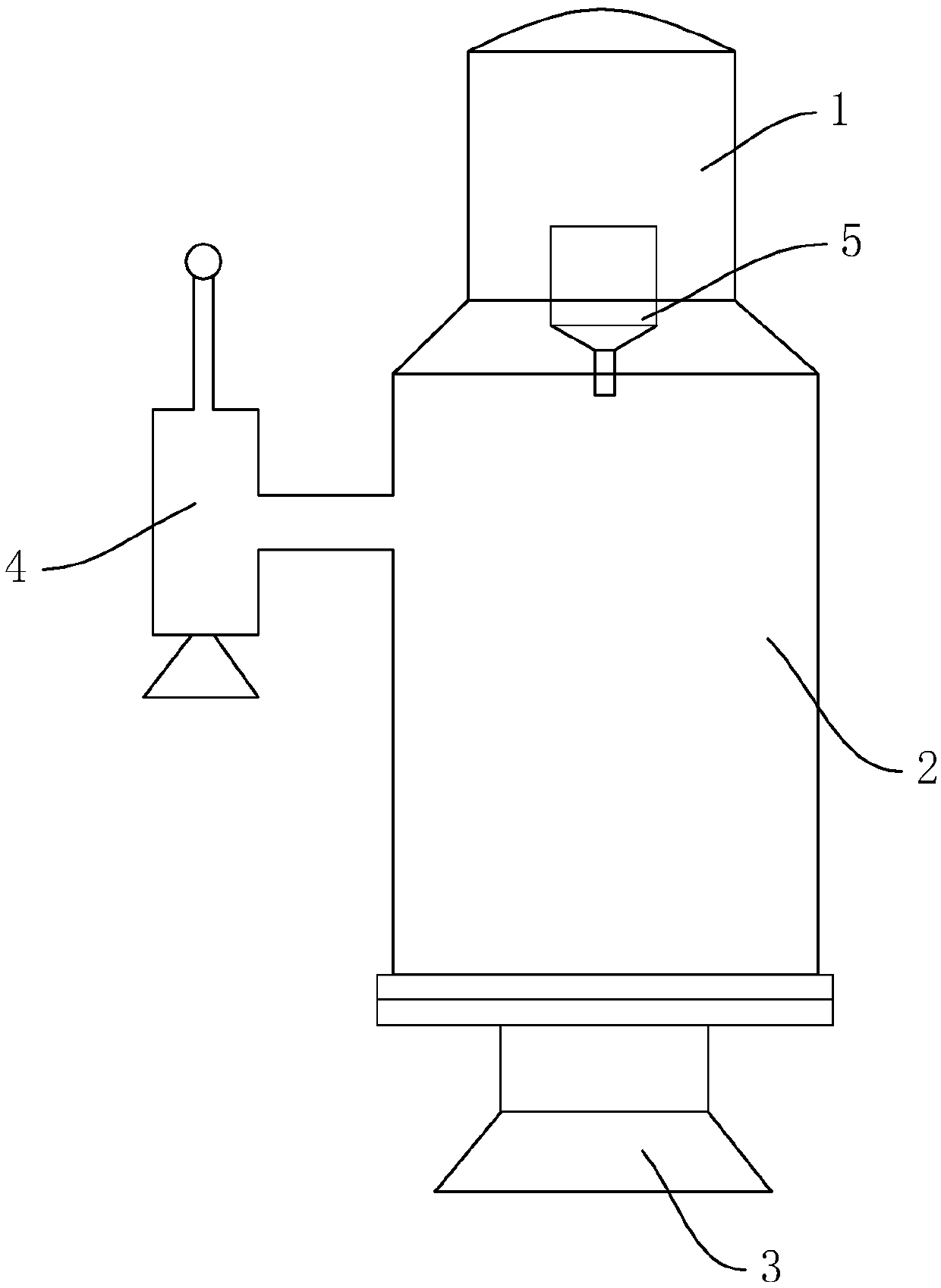

Exothermic welding powder and preparation process and application method thereof

ActiveCN108672978AHigh ignition pointPrevent volatilizationWelding/cutting media/materialsSoldering mediaSpontaneous combustionExothermic welding

The invention relates to the technical field of exothermic welding, in particular to exothermic welding powder and a preparation process and an application method thereof, and solves the problem of easy spontaneous combustion or explosion of the exothermic welding powder. The exothermic welding powder comprises 50-65 mass parts of aluminum copper alloy, 120-150 mass parts of copper oxide, 3-5 massparts of nickel, 3-5 mass parts of calcium fluoride, 3-4 mass parts of calcium oxide, 2-3 mass parts of chromium, 2-3 mass parts of silicon, 1-2 mass parts of boron, 1-2 mass parts of barium, 0.5-1 mass part of platinum. Traditional welding powder is easy to generate spontaneous combustion or explosion; the root cause is that aluminum powder in the traditional welding powder is easy to generate spontaneous combustion or explosion; aluminum copper alloy powder is higher in combustion point compared with common aluminum powder; the combustion point of the common aluminum powder is about 550 DEGC; and the combustion point of the aluminum copper alloy powder is increased above 730 DEG C, so that the combustion point is increased by above 32%, and the safety of the welding powder in the transportation process is improved.

Owner:江苏银锐通电工设备有限公司

Solder for exothermal soldering of railway track joint, igniting agent and soldering method

InactiveCN102528312AGuarantee personal safetyGuaranteed decomposition temperatureWelding/cutting media/materialsAlumino-thermic welding apparatusExothermic weldingCerium

The invention discloses a solder for exothermal soldering of a railway track joint, an igniting agent and a soldering method, and relates to a solder, an igniting agent and a soldering method. The invention solves the problems about high hot brittleness of the joint, production of pores and oxidative ablation in the conventional exothermal soldering of the steel. The solder for the exothermal soldering of the railway track joint is formed by mixing ferric oxide powder, iron powder, industrial aluminum powder, molybdenum powder, titanium powder, ferrosilicon powder, fluorite powder, marble powder and lanthanum-cerium alloy powder; the igniting agent for the solder is formed by mixing magnesium powder, ferric oxide powder, industrial aluminum powder, potassium permanganate powder and red phosphorus powder; and the welding method comprises the following steps of: weighing the solder for the exothermal soldering of the railway track joint and the igniting agent for the solder in a mass ratio of (78-82): 1, soldering by adopting an exothermal soldering method, and thus finishing soldering of the railway track joint. The invention mainly relates to the solder for the exothermal soldering of the railway track joint, the igniting agent for the solder and the soldering method.

Owner:HARBIN INST OF TECH

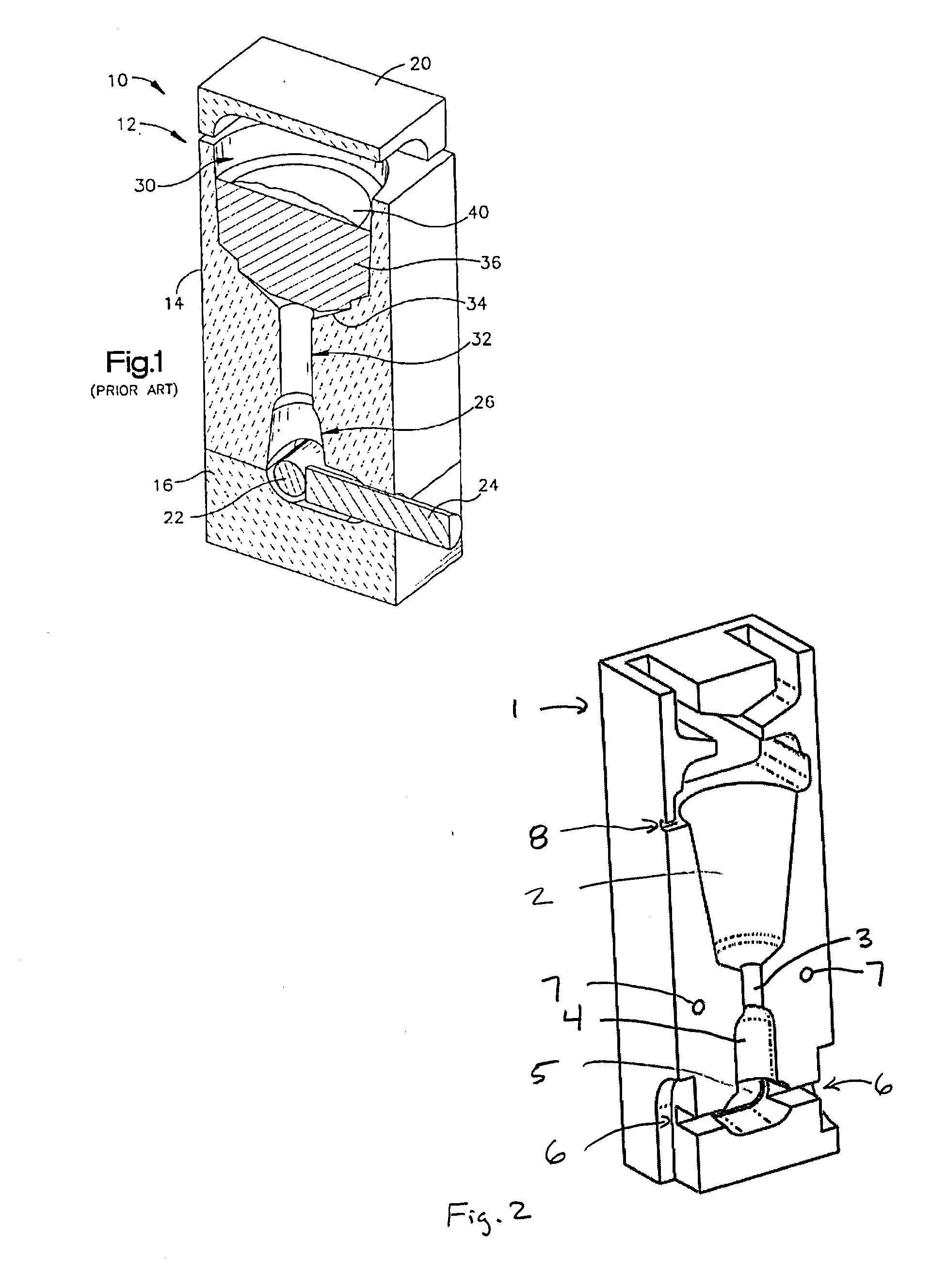

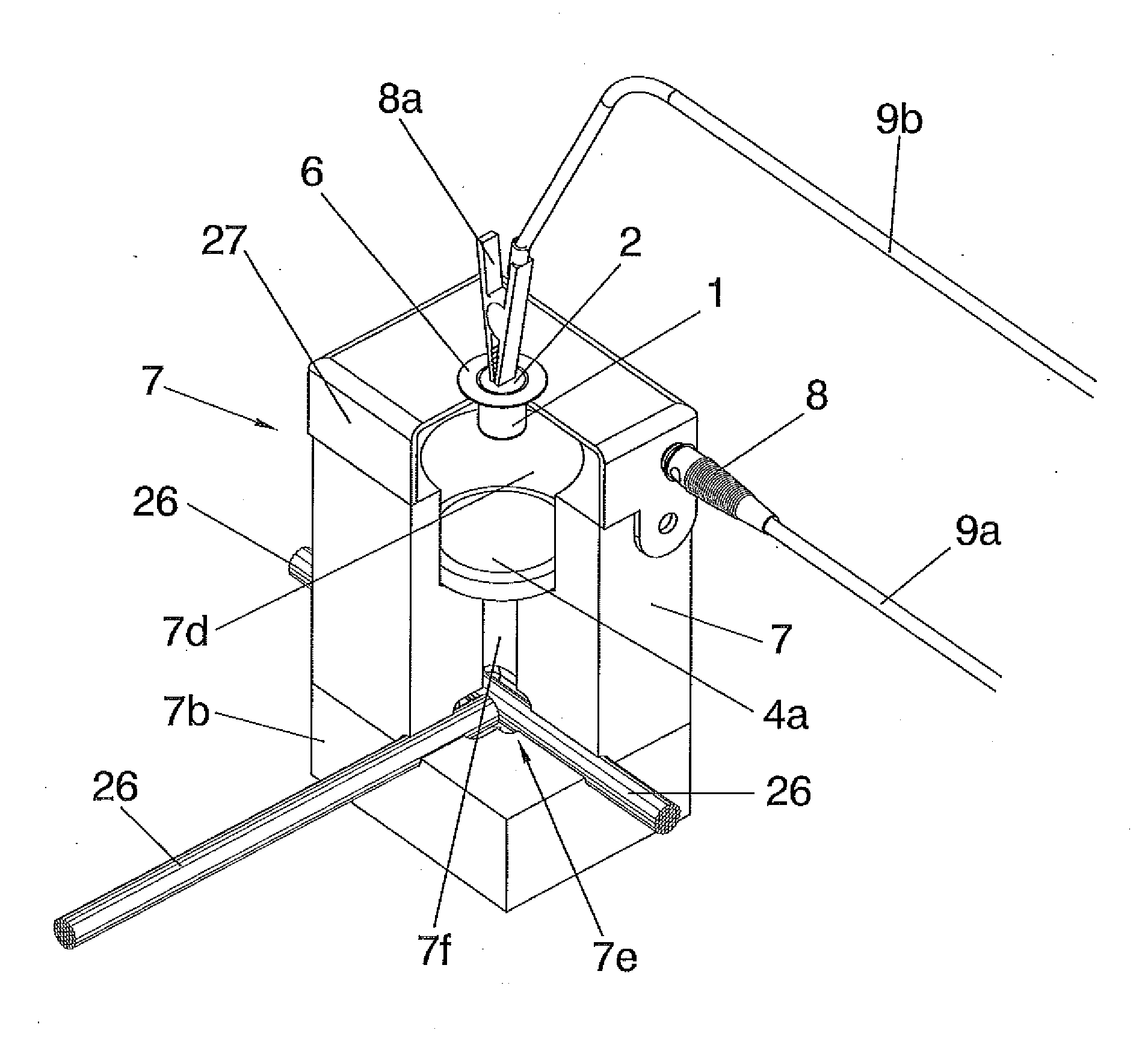

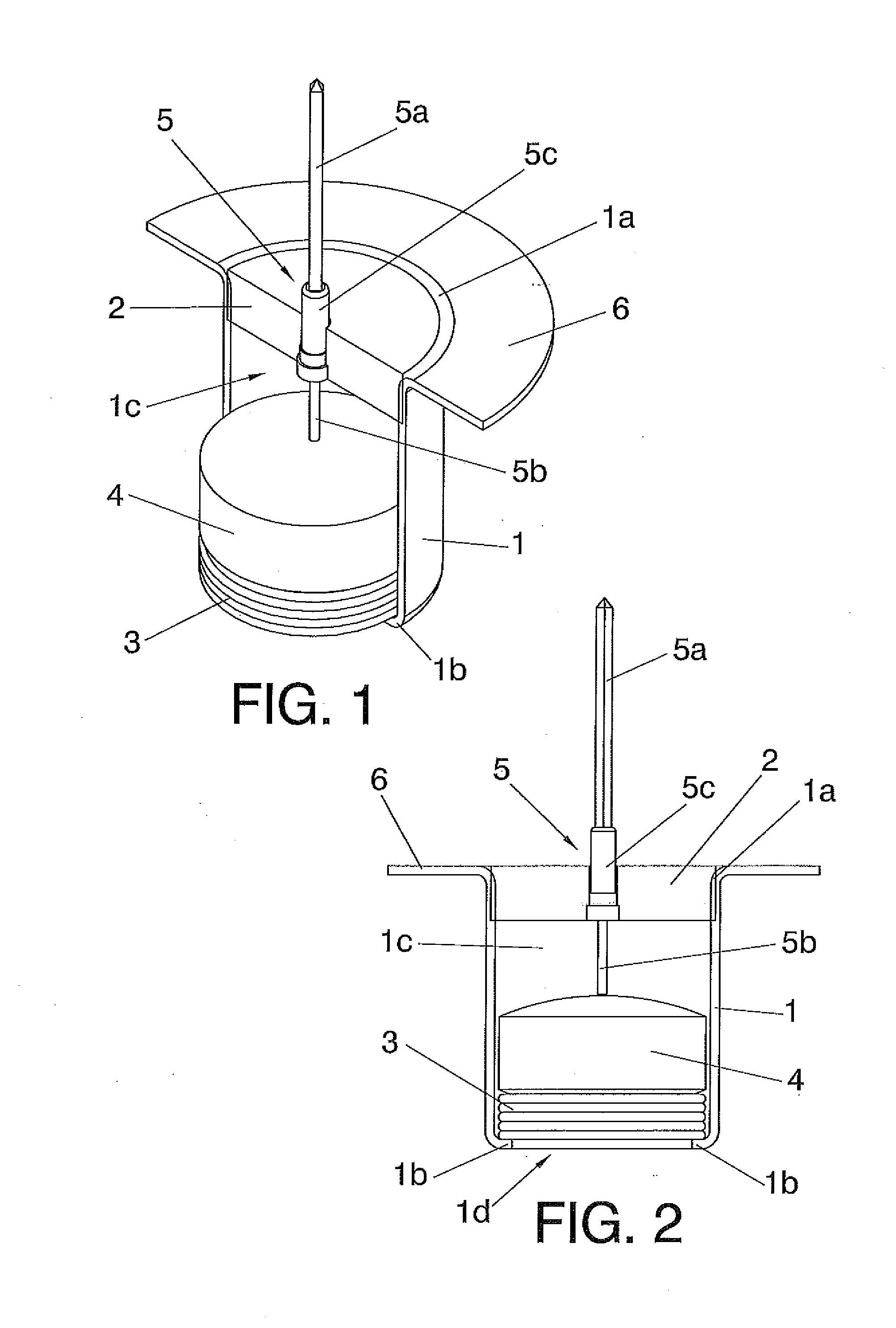

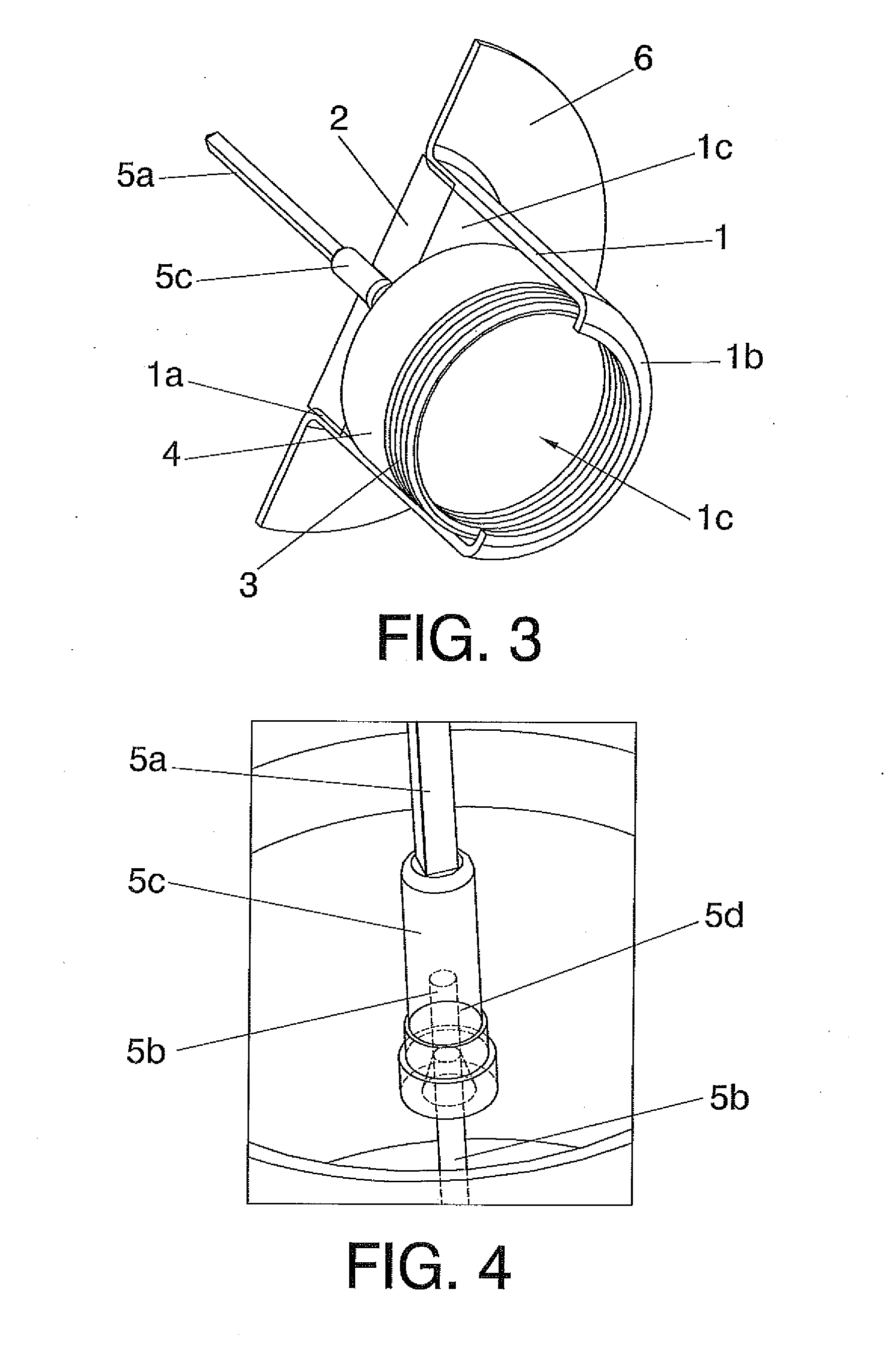

Ignition device for exothermic welding, mold for exothermic welding for the ignition device, and apparatus for exothermic welding comprising such a mold and such an ignition device

ActiveUS20150041520A1Reduce riskEffective and safe and simple mannerIncandescent ignitionBlasting cartridgesExothermic weldingVoltage generator

The present invention relates to an ignition device for exothermic welding comprising an electrically conductive metal bushing (1) that can house a pellet of a first welding material (4) in electrical contact with the inner wall of an inner chamber (1c) of the bushing (1), provided with an electrically insulating cap (2) and a bottom base (1b) with an opening (1d) through which the first welding material (4) falls in an incandescent state onto a second welding material (4a) arranged in a weld mold (7) when an exothermic reaction has been triggered in the first welding material (4); an electrode (5) that goes through the cap (2) of the metal bushing (1) and comprises a top contact (5a) connectable to a power output (24) of a voltage generator and a bottom contact in the form of a filament (5b) that can be in electrical contact with the pellet of the first welding material (4), the filament (5b) being made of a material having a melting temperature greater than the ignition temperature of the welding material (4); as well as a contact-assuring element (3) which is guided into the inner chamber (1c) between the bottom base (1b) and the pellet of the first welding material (4).

Owner:APLICACIONES TECHCAS

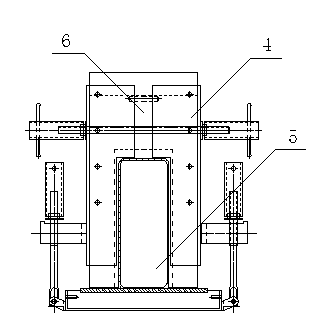

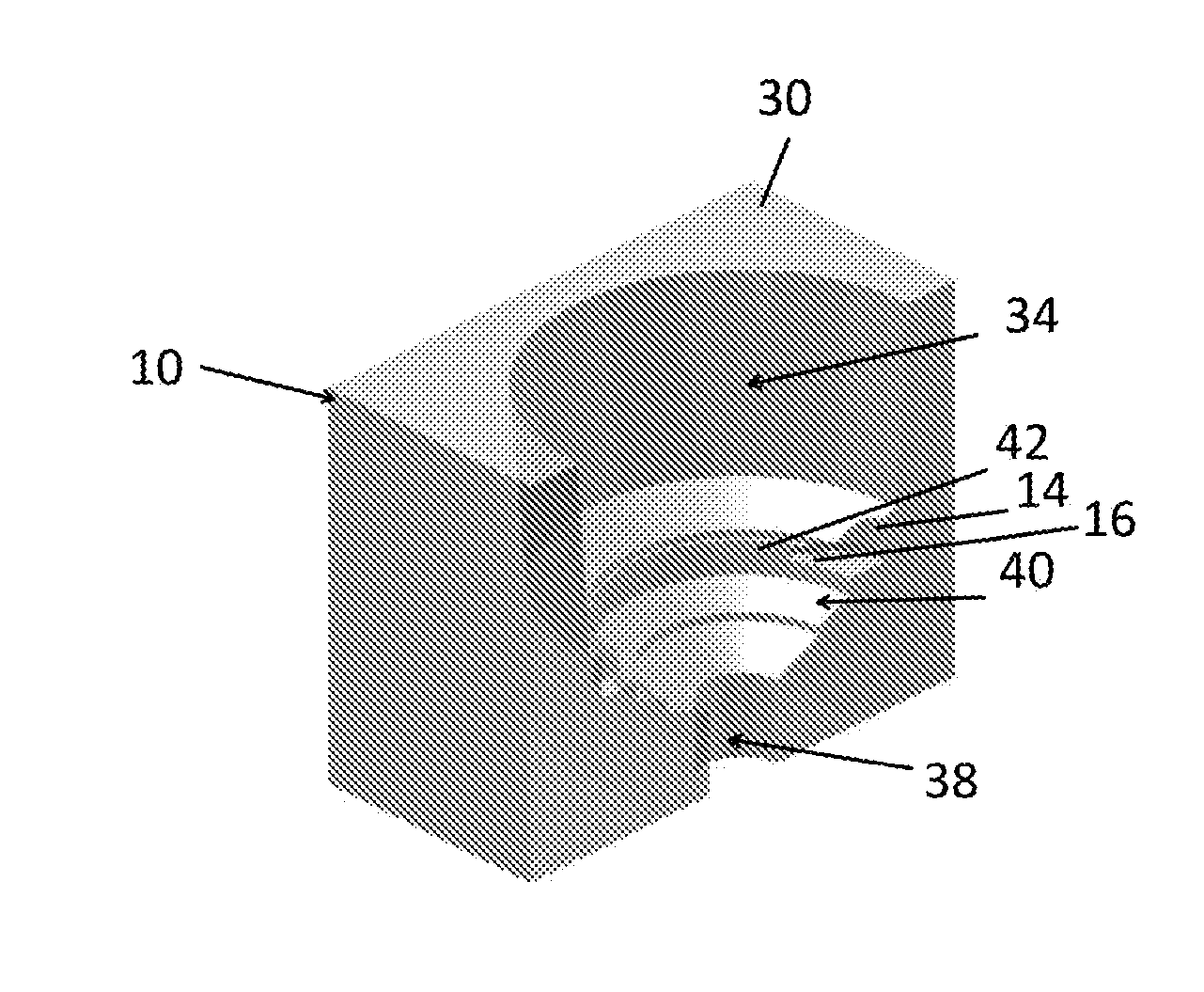

Exothermic weld mold clamp

InactiveCN101163566AWelding/cutting auxillary devicesAuxillary welding devicesExothermic weldingEngineering

An exothermic weld mold clamp including a mold locating system adapted to locate pieces of an exothermic mold relative to each other; and a mold locking system. The mold locking system includes at least one mold locking pin movably mounted on the mold locating system and a spring biasing the locking pin towards a locking position with at least one of the exothermic mold pieces.

Owner:FRAMATOME CONNECTORS INT SA

Exothermic reaction welding molds, weld-metal containing cartridges for such molds, and methods of use

ActiveUS20160311063A1Prevent exitWelding/cutting auxillary devicesShearing machinesExothermic weldingInternal pressure

Exothermic welding molds, weld-metal containing cartridges for such molds, and methods of use are provided. The mold, cartridges, and methods can provide interaction between the cartridge's disk member with the mold, which allows the housing member to be withdrawn from the mold while leaving the disk member and weld-metal in place. The interaction can be a rotational restraint alone, a vertical restraint alone, or combinations thereof. Alternately, the interaction can be an outward pressure on the housing member and / or disk member, a shear force on the housing member and / or disk member, or combinations thereof. The outward pressure on the housing member and / or disk member can alternately be provided without interaction between the disk member and the mold, but rather by the simple application of an internal pressure to the cartridge. The internal pressure can be applied by squeezing the walls of the cartridge and / or by depressing a pusher member.

Owner:HUBBELL INC

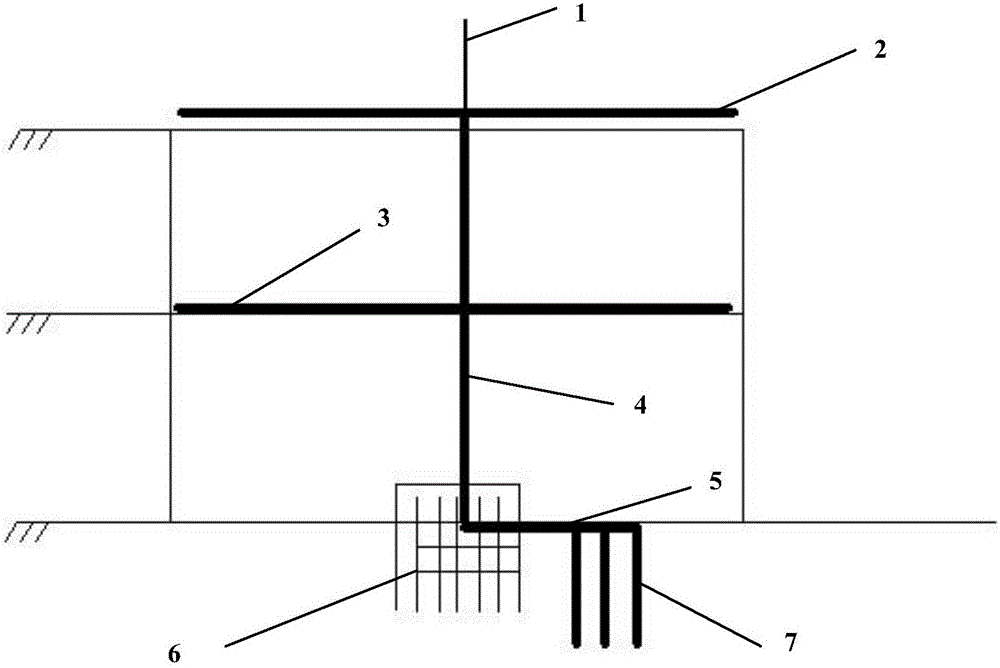

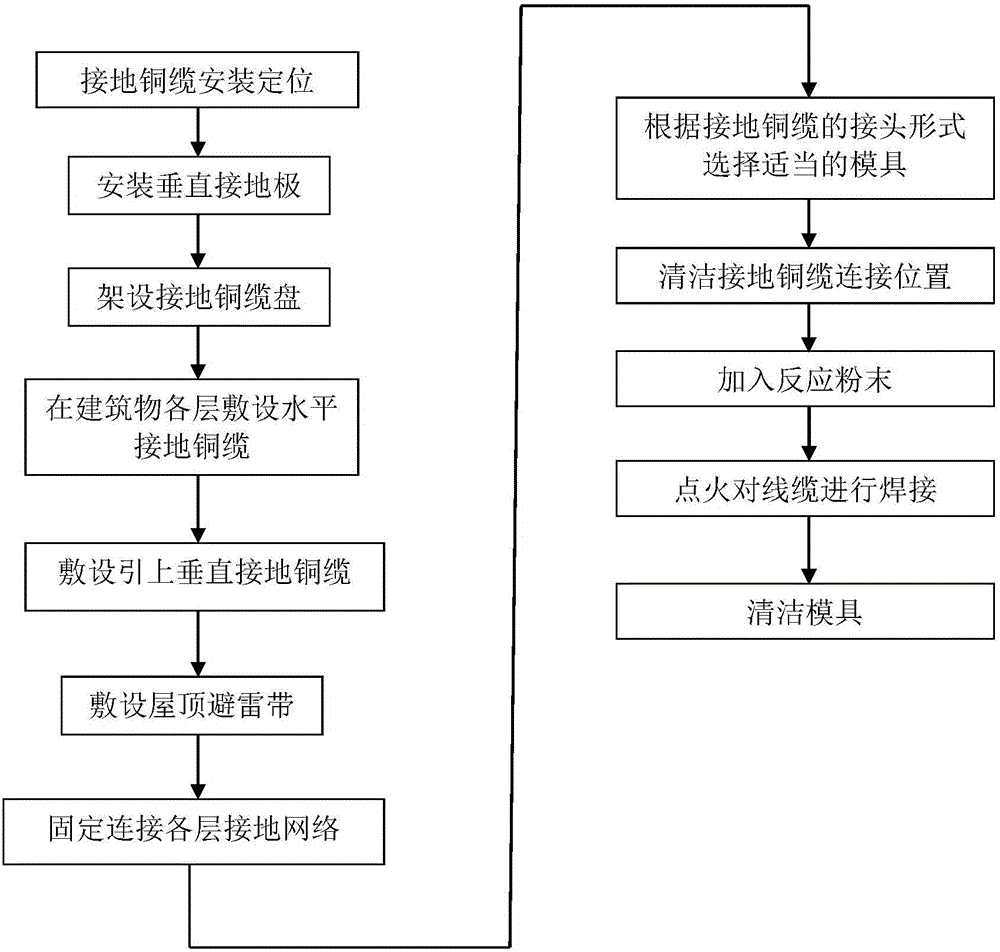

Installation and construction technology of grounding copper cables

ActiveCN105977661APerfect construction technologyAvoid destructionCorona dischargeMulticonductor cable end piecesExothermic weldingEngineering

The invention provides an installation and construction technology of grounding copper cables. The technology comprises the steps of: installing and positioning the grounding copper cables; installing a vertical grounding electrode; burying the grounding copper cables; laying the grounding copper cables on various layers of a building; laying a roof lightning protection belt; and carrying out indoor grounding network construction. The welding and connecting technology in the indoor grounding network construction step is an exothermic welding process and specifically comprises the following steps of: selecting a proper mold according to the joint form of the grounding copper cables; cleaning the connection positions of the grounding copper cables; adding reaction powder; and carrying out ignition for welding the cables and cleaning the mold. The same or different metals of copper and copper, copper and steel and the like can be completely fused by the exothermic welding process; and real molecules combination is achieved, so that a lightning-proof grounding device becomes a permanent maintenance-free device; the grounding protection technology provided by the invention is very perfect; the leakage damage of equipment is effectively prevented; the manpower resource is saved; and the time limit for a project is shortened.

Owner:中国能源建设集团江苏省电力建设第三工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com