Exothermic weld mold clamp

A technology of exothermic welding and fastening clips, which can be used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

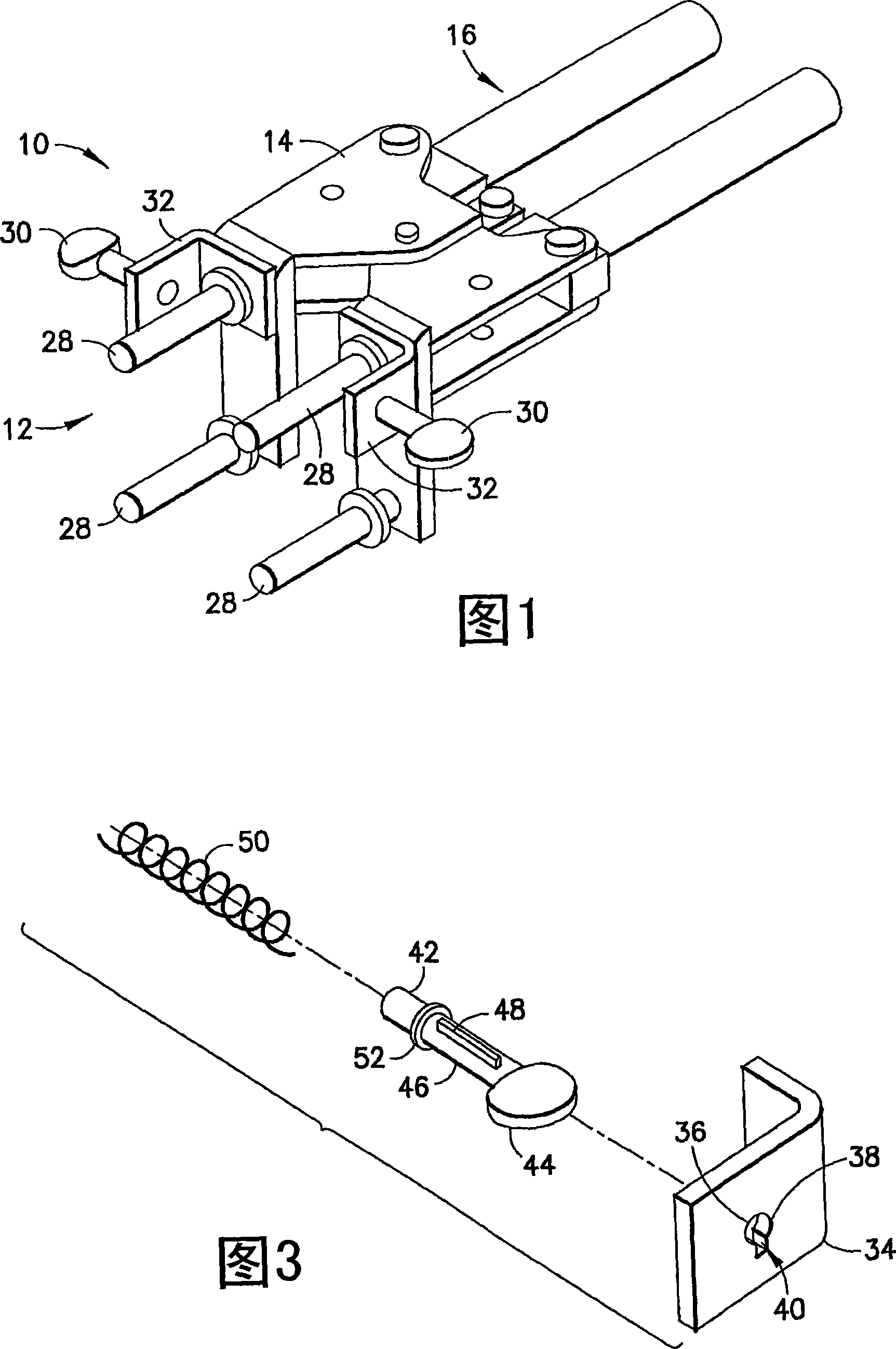

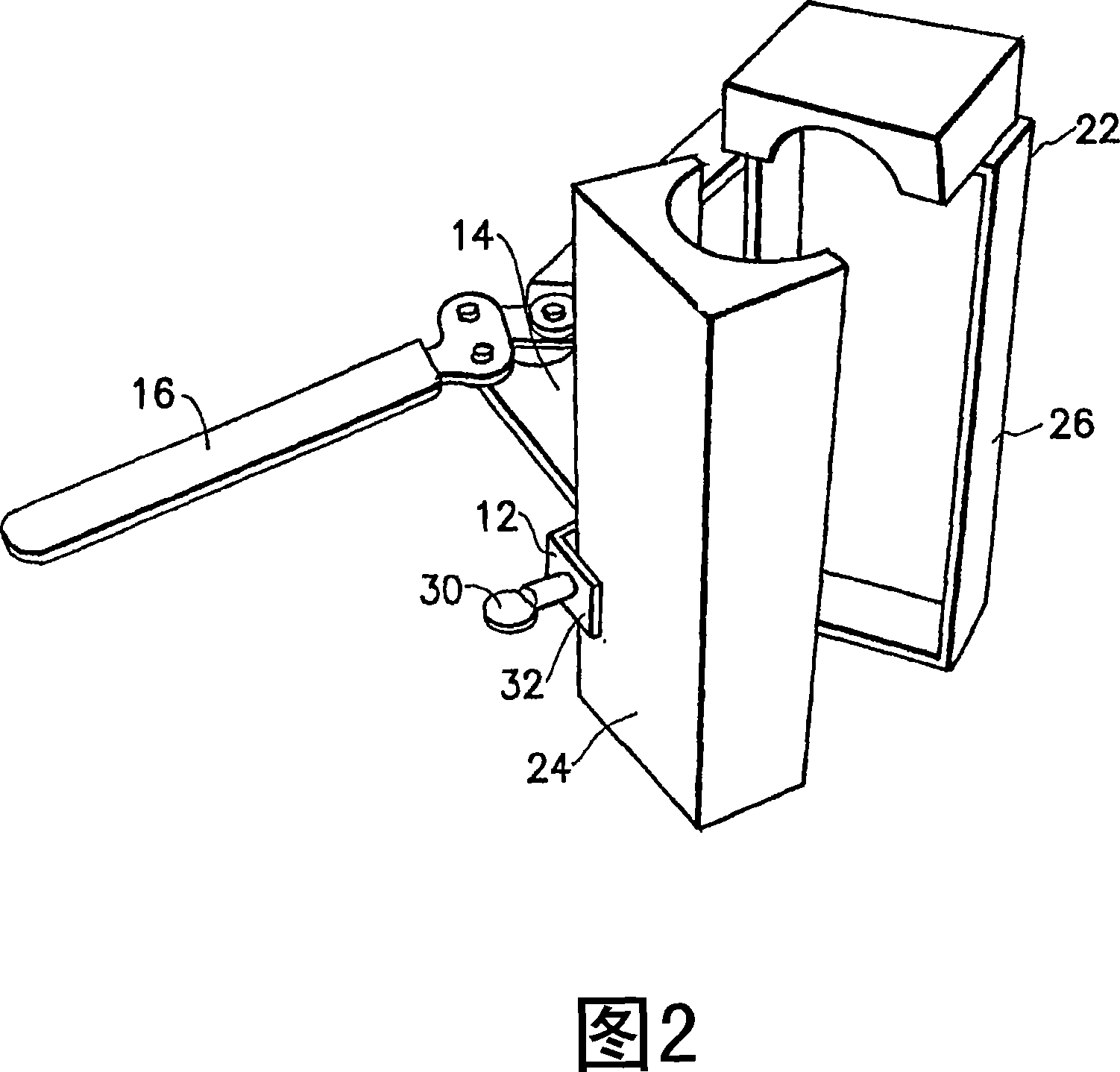

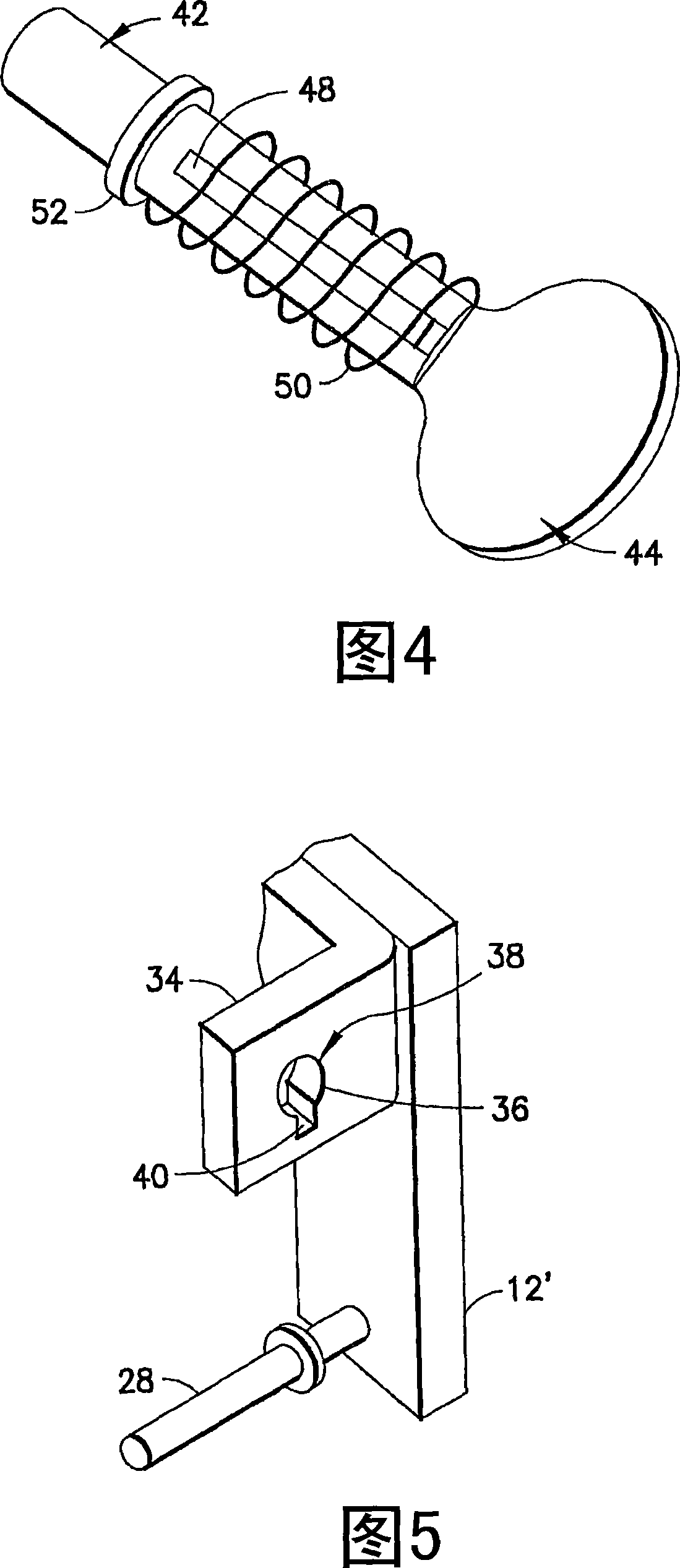

[0017] Referring to FIG. 1, a perspective view of a conventional exothermic welded die fastening clip 10 is shown. The fastening clip 10 includes an exothermic mold mounting portion 12 , a moving portion 14 , and a rear gripping portion 16 . The mold mounting part 12 includes a left part 18 and a right part 20 . Each section 18, 20 is adapted to individually mount a mold piece of an exothermic mold thereon. Referring also to FIG. 2 , the fastener 10 is shown coupled to the exothermic die 22 . The moving part 14 is adapted to move said left part 18 and right part 20 relative to each other to move the mold parts 24, 26 between an open position shown in Fig. 2 and a closed position relative to each other. Other types of fastening clips exist in the prior art. The present invention has been described with reference to the fastening clip shown in Figures 1 and 2 for illustrative purposes only and should not be construed as limiting the invention.

[0018] Typically, each side 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com