Exothermic welding powder and preparation process and application method thereof

A preparation process, aluminothermic welding technology, applied in manufacturing tools, welding equipment, welding media, etc., can solve problems such as spontaneous combustion or explosion, inconvenient use of aluminothermic welding powder, etc., to reduce electrical conductivity, improve ignition point, and increase resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

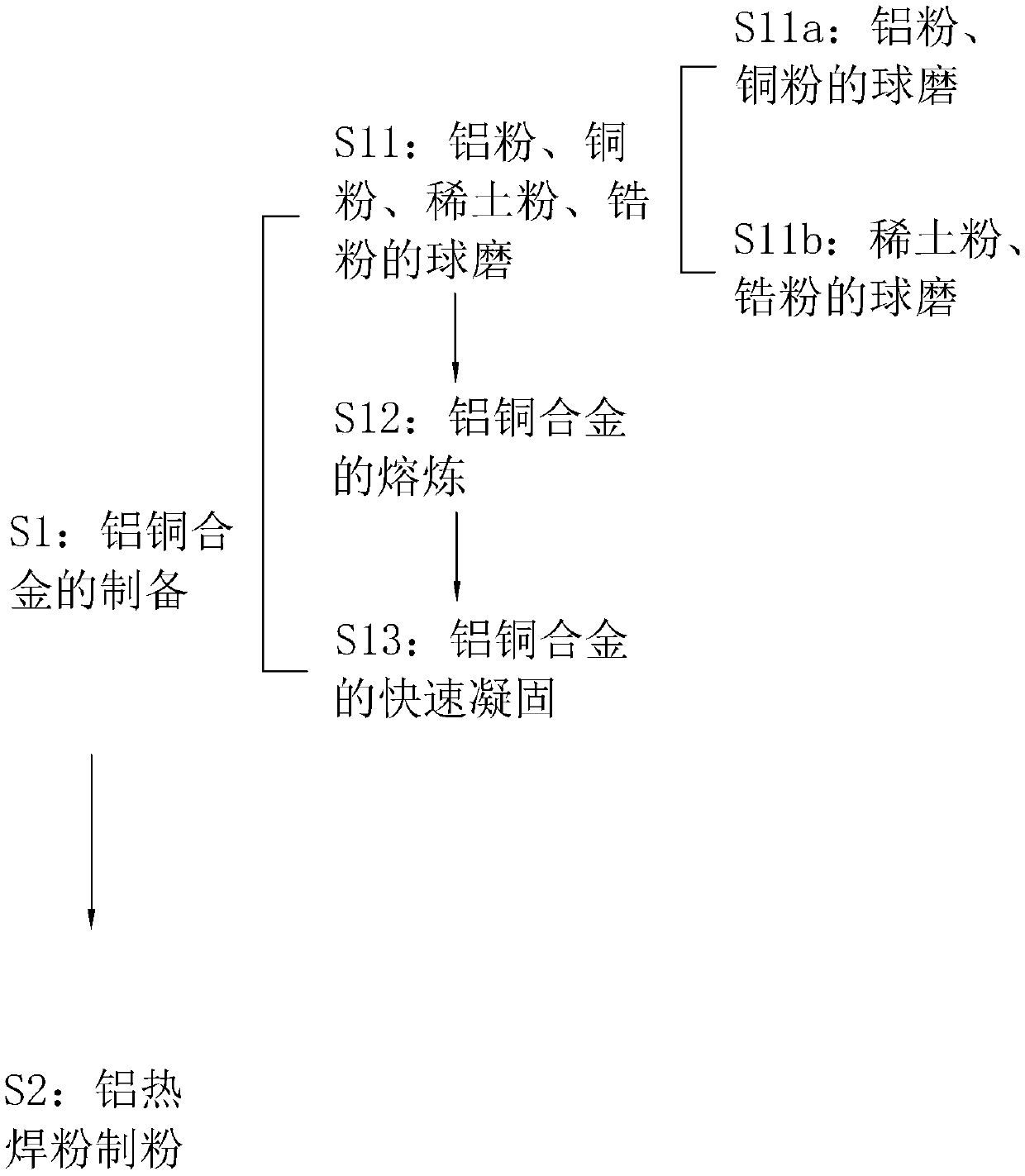

[0066] S1, the preparation of aluminum-copper alloy:

[0067] S11, aluminum powder, copper powder, calcium powder and zirconium powder are ball milled using a ball mill;

[0068] S11a: Grinding of aluminum powder and copper powder: Grinding the aluminum powder and copper powder with a ball mill, and grinding the mixed powder A for 3 hours with a stainless steel ball with a diameter of 8 mm as a ball milling medium at a speed of 226 r / min;

[0069] S11b: Grinding of rare earth powder and zirconium powder: Grinding the calcium powder and zirconium powder with a ball mill, and grinding the mixed powder B with stainless steel balls with a diameter of 5 mm in the ball milling medium for 6 hours at a speed of 226 r / min;

[0070] S12. Melting of aluminum-copper alloy: add the ground aluminum powder, copper powder, calcium powder, and zirconium powder into a vacuum melting furnace, and melt at a temperature of 1200°C for 3 hours;

[0071] S13. Rapid solidification of aluminum-copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ignite | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com