Patents

Literature

231results about How to "Small heat release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antiflaming plywood or veneer lamination and manufacturing method thereof

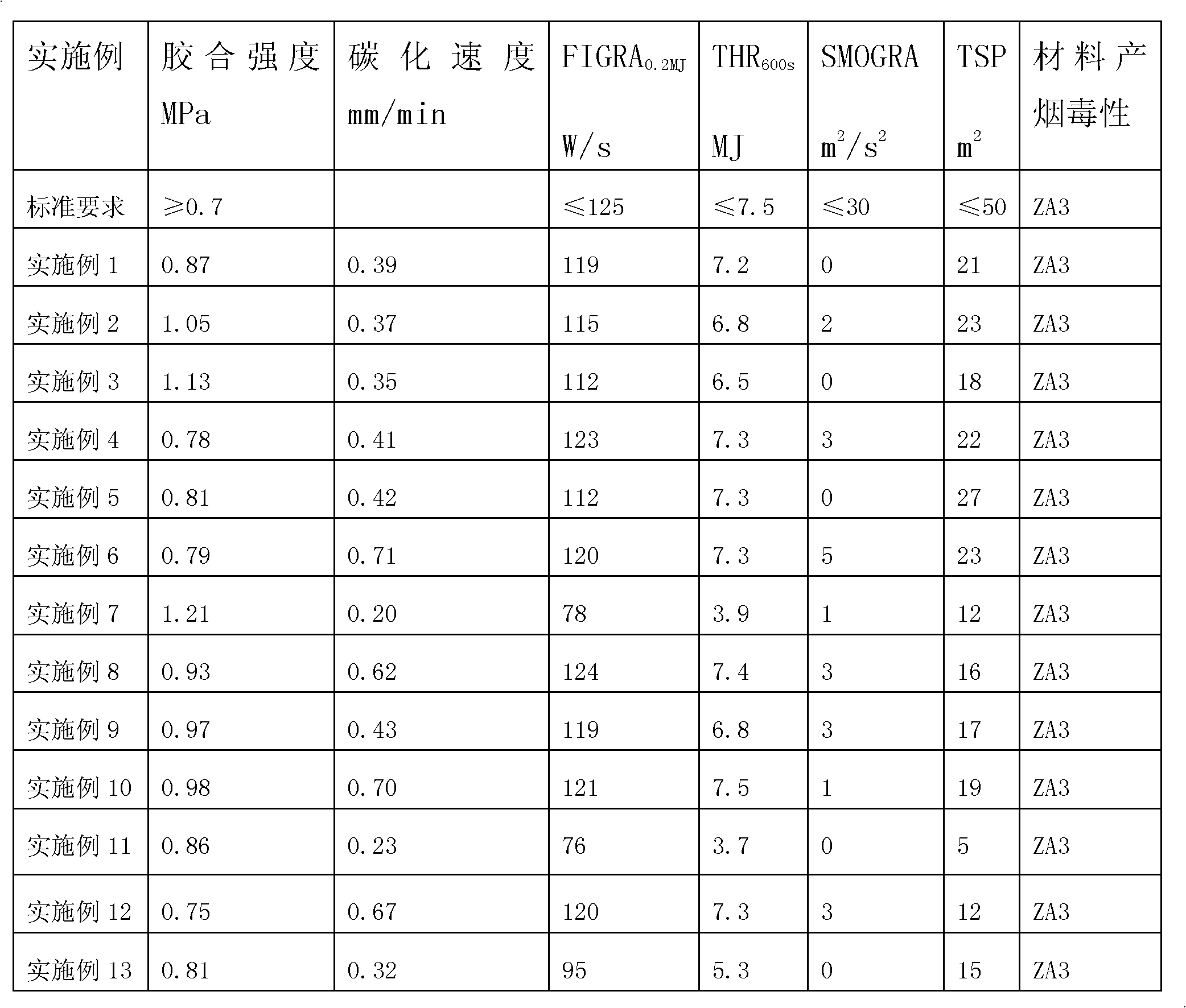

ActiveCN102114650ASlow down the rate of carbonizationReduce burnWood veneer joiningWood impregnation detailsAdhesiveCarbonization

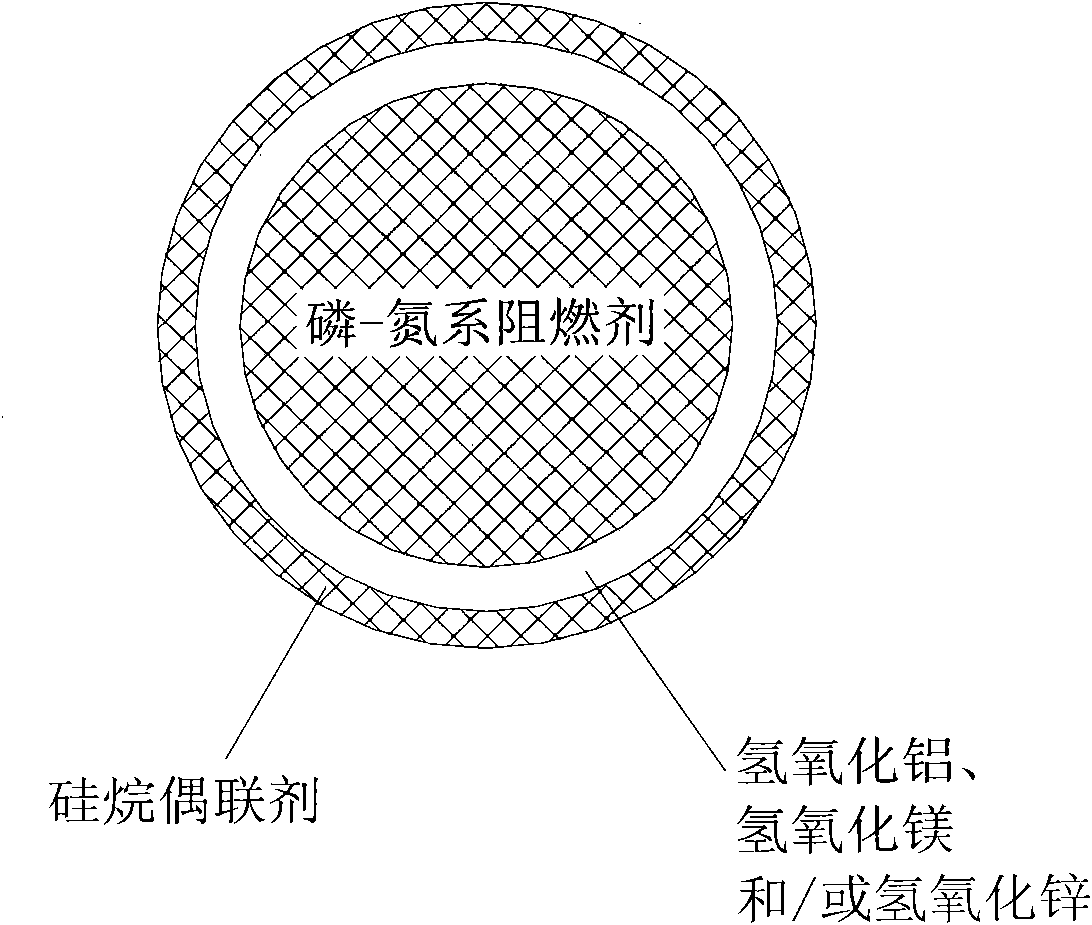

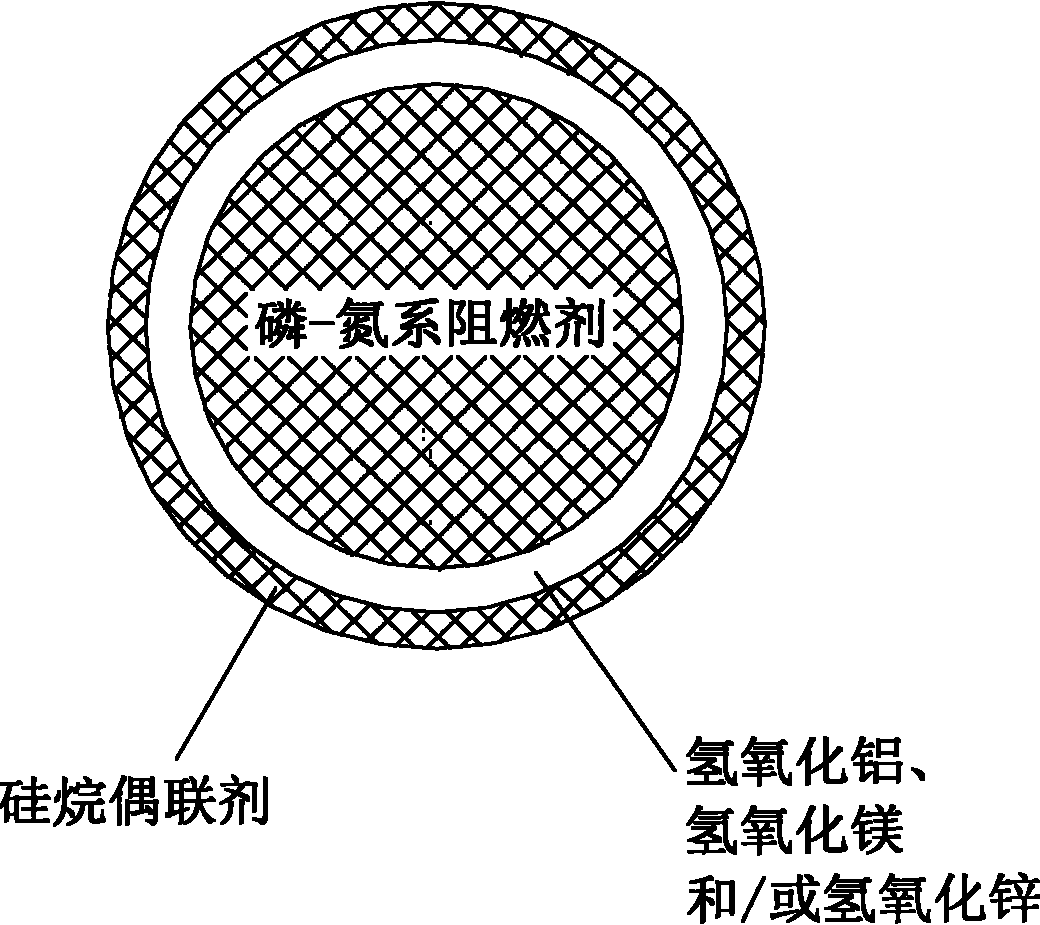

The invention discloses an antiflaming plywood or a veneer lamination, which comprises a wood veneer, a phosphorus-nitrogen fire retardant, a boron fire retardant, oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium, and an adhesive, which have over dry weight percentage ratio being 100:2-50:0.2-30:4-40. The antiflaming plywood or the veneer lamination has the characteristics of low carbonization speed, accordance with related standards on physical mechanics property, flame retardant property and smoke toxicity, low formaldehyde emission values, and the like; the invention further discloses a manufacturing method for the antiflaming plywood or the veneer lamination, which comprises the following steps: impregnating the phosphorus-nitrogen fire retardant, the boron fire retardant, the oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium on the wood veneer, coating the adhesive, and conducting processing of assembling, prepressing, hot pressing, sand polishing and the like.

Owner:固安盛辉阻燃材料有限公司

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

Sulfurized hydrogenation catalyst, prepn. method

ActiveCN1861260AGood pre-vulcanization effectEasy to useCatalyst activation/preparationRefining to eliminate hetero atomsHydrodesulfurizationSulfur

A process for preparing the sulfurizing hydrocatalyst used for the hydrodesulfurizing and hydrodenitrifying reactions of light fractional oil and the hydrosaturating of arylhydrocarbon includes such steps as carrying a certain part of the precursor compound of the metal in VI and VIII families, introducing sulfur to it, heat treating, introducing the rest of said precursor compound, and drying.

Owner:CHINA PETROLEUM & CHEM CORP +1

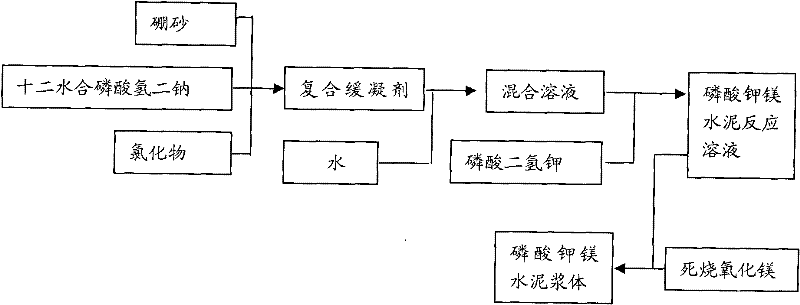

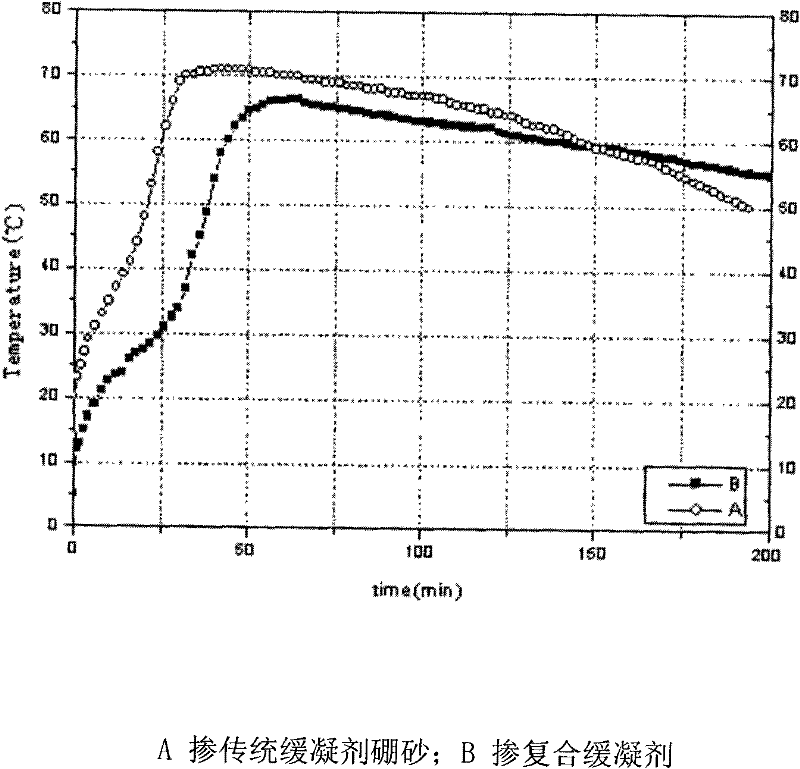

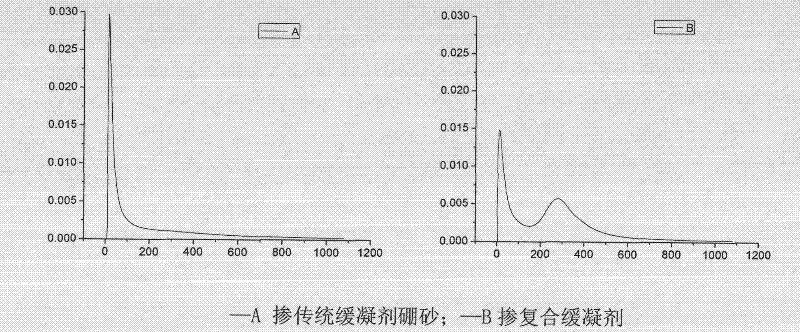

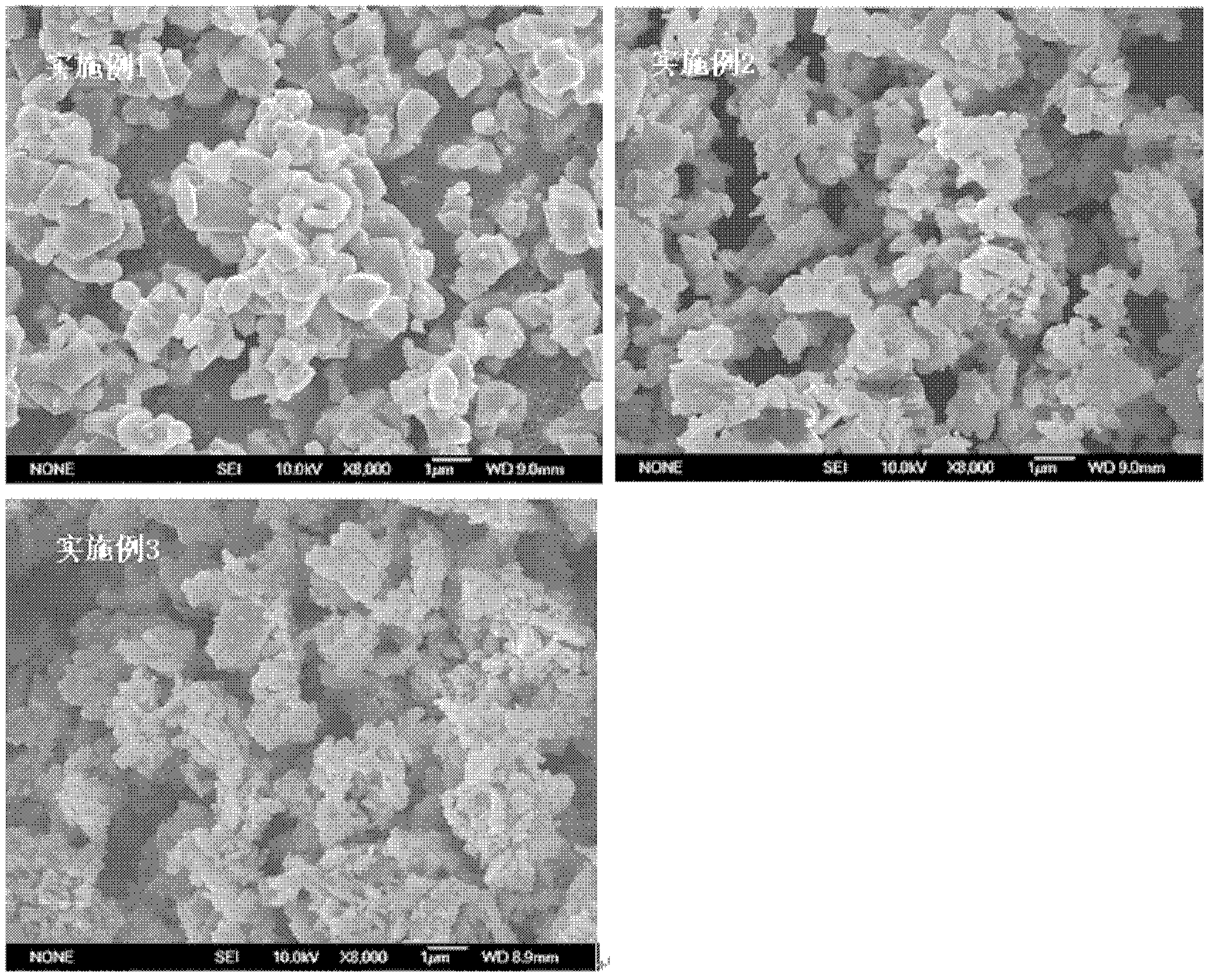

Method for controlling setting time and early hydration speed of magnesium potassium phosphate cement

InactiveCN102234200AEffective adjustment of clotting timeEffective control of clotting timeControl setOperability

The invention relates to a method for controlling the setting time and early hydration speed of magnesium potassium phosphate cement, and belongs to an early strength quick hardening cement cementing material. A composite retarder can effectively adjust the setting time of magnesium potassium phosphate cement slurry, and the setting time of the magnesium potassium phosphate cement slurry can be effectively controlled in the range of 10 minutes to 6 hours by adjusting the content of chloride and disodium hydrogen phosphate dodecahydrate in the composite retarder, so that the problems of a limited retarding effect, low operability and the like are solved; the composite retarder can change the hydration heat release characteristic of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement slurry doped with the conventional retarder borax has a hydration heat release peak at the initial reaction stage and has a high heat release speed and large heat release amount, and the magnesium potassium phosphate cement doped with the composite retarder has two hydration heat release peaks and has small hydration heat release amount at the initial hydration stage; and the doped composite retarder improves the microstructure and later strength of a hardened magnesium potassium phosphate cement body, so that enough construction operable time can be ensured while the magnesium potassium phosphate cement slurry has early strength and is quickly hardened.

Owner:苏州诚开新材料有限公司

Inorganic modified polyurethane grouting material and preparation method thereof

The invention discloses an inorganic modified polyurethane grouting material. The inorganic modified polyurethane grouting material comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 85-98 parts of sodium silicate solution, 0.5-3 parts of catalyst, 1-5 parts of chain extender and 0-8 parts of water; and the component B comprises the following components in parts by weight: 10-80 parts of modified polymeric MDI-PU2101, 10-75 parts of modified polymeric MDI-PU2102, 5-20 parts of viscosity reducing agent and 5-15 parts of plasticizer. A preparation method of the material disclosed by the invention is simple, and the material is injected into a coal-rock mass through a dual-liquid grouting pump and can achieve the function of reinforcing the coal-rock mass after fast curing; compared with the conventional polyurethane grouting material, the material has the advantages of lower highest reaction temperature, excellent flame resistance, lower cost, capability of keeping the mechanical properties at a higher level, capability of still keeping the higher strength in a water environment and the like; and the material does not contain toxic, volatile and corrosive substances and can meet underground safety and environmental protection requirements of the material.

Owner:SHANDONG ANLENG NEW MATERIAL TECH CO LTD

Epoxy resin adhesive and preparation method thereof

ActiveCN103450835AImprove toughnessPlay a toughening effectNon-macromolecular adhesive additivesEpoxy resin adhesivesRoom temperatureResin adhesive

The invention provides an epoxy resin adhesive comprising a component A and a component B. The component A comprises 70-85 parts by weight of bisphenol A epoxy resin, 15-30 parts by weight of toughness modified bisphenol A epoxy resin and 20-40 parts by weight of a first filler; and the component B comprises 40-70 parts by weight of a polymercaptan curing agent, 30-60 parts by weight of a modified amine curing agent and 15-30 parts by weight of a second filler. According to the two-component epoxy resin adhesive provided by the invention, introduction of the toughness modified bisphenol A epoxy resin into the component A and compound of the modified amine curing agent and polymercaptan curing agent in the component B improve toughness of the epoxy resin adhesive, and the epoxy resin adhesive can be quickly cured at room temperature.

Owner:浙江东大树脂科技股份有限公司

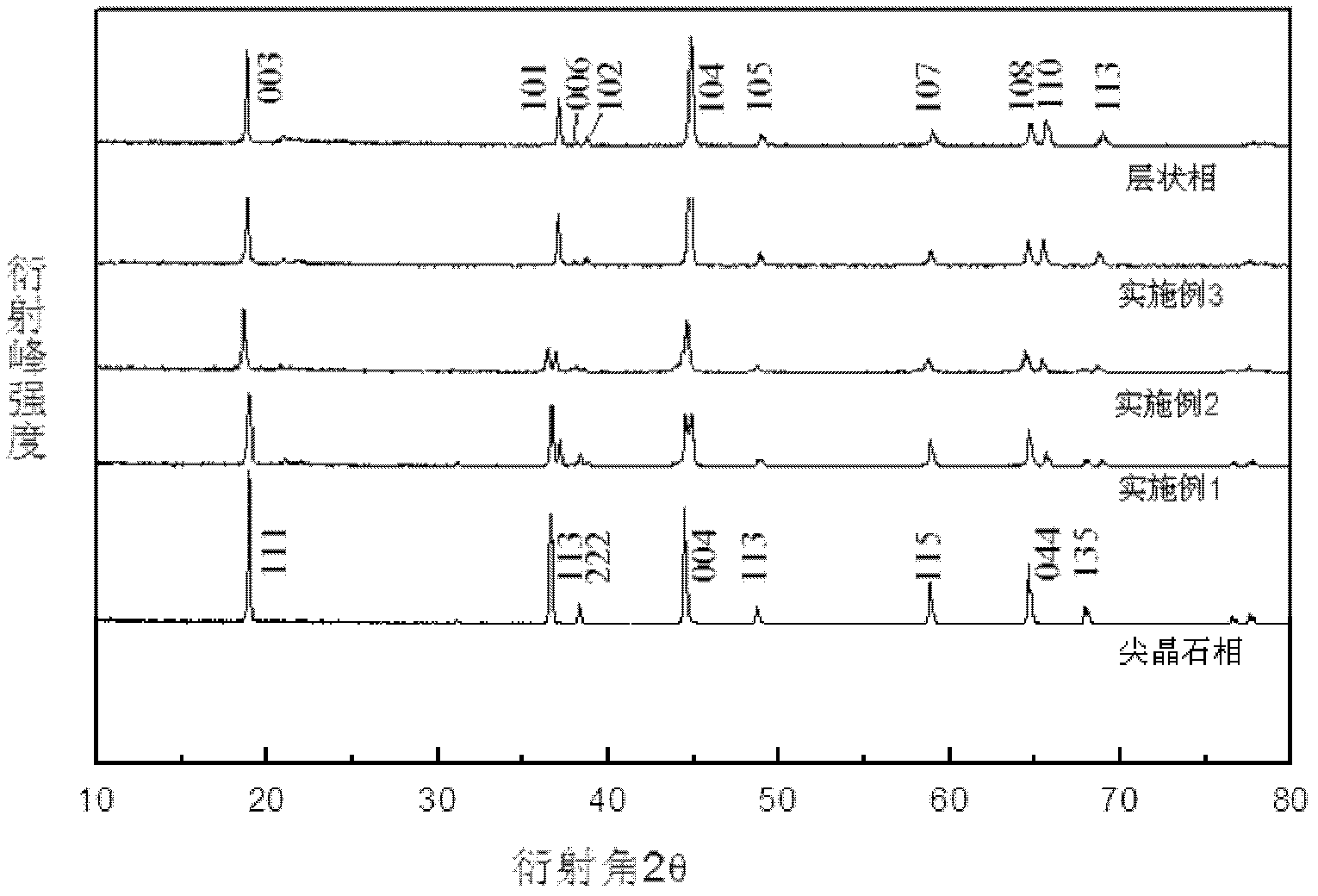

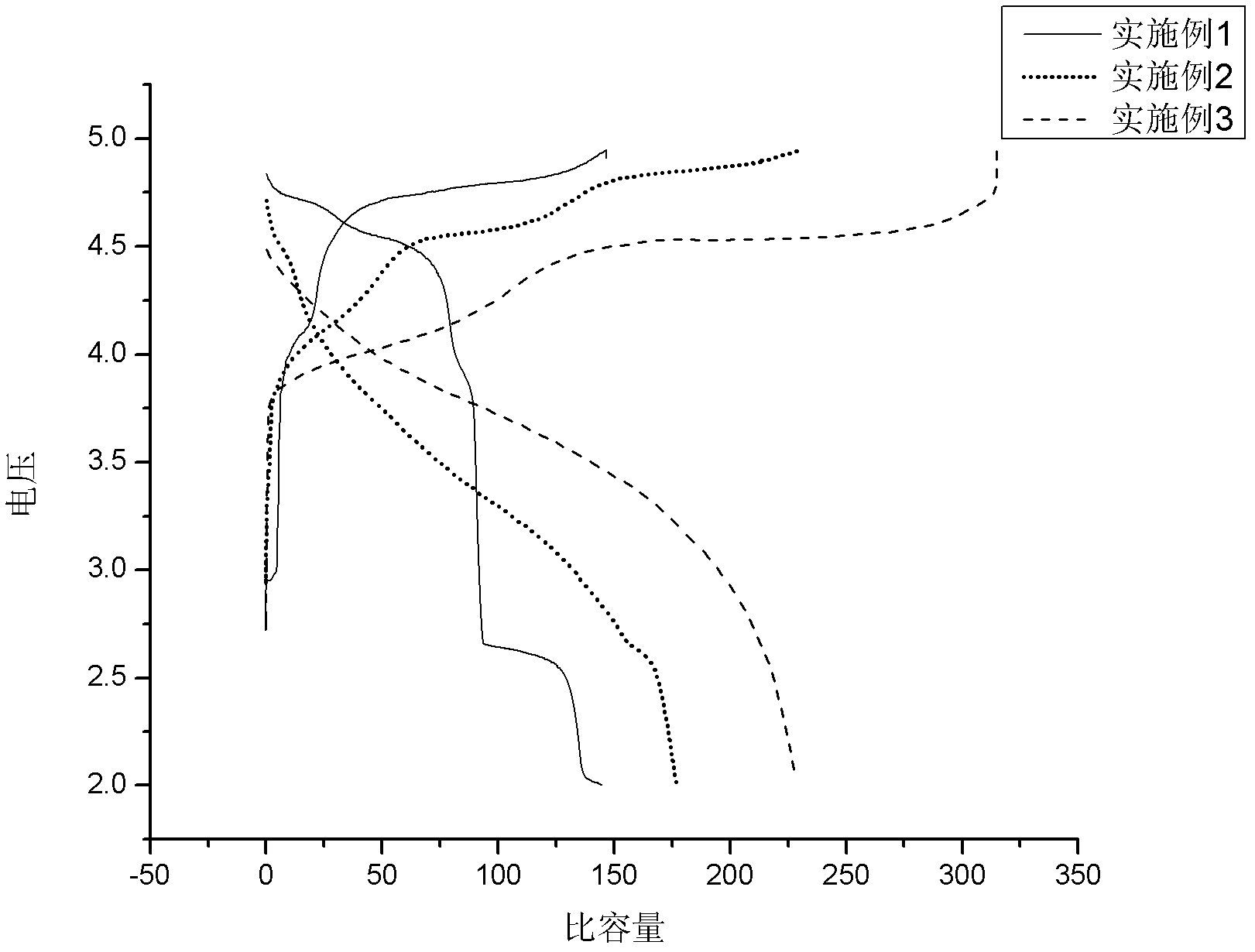

High-voltage lithium ion battery cathode material and preparation method thereof

ActiveCN102569781AExpand the voltage application rangeImprove cycle stabilityCell electrodesManganeseLithium-ion battery

The invention discloses a high-voltage lithium ion battery cathode material and a preparation method thereof. The high-voltage lithium ion battery cathode material is a solid solution material with a stratiform and spinel composite structure, and the molecular formula of the cathode material is LixNi0.25-zMn0.75-zM2zOy, wherein M is one or two of doped metals of Co, Al, Cr, Mn and Ga, x is more than 0 and less than 2, y is more than or equal to 2 and less than or equal to 3, and z is more than 0 and less than or equal to 0.25. The invention has the advantages that: the cathode material has the stratiform and spinel composite structure, the high specific capacity advantage of a manganese-based solid solution material is kept, and the cycle stability and the thermal stability of the material are improved; the impedance of the cathode material is reduced by doping, so that the thermal stability of the material is further improved, and the heat release is reduced to improve the comprehensive electrochemical performance of the material; and the preparation process of the material has high controllability, the manufacturing cost is low, and the manufacturing process has high repeatability and high batch stability, production management is facilitated, and the application demands on high-voltage and high-specific-capacity materials on the market are met.

Owner:徐源庆

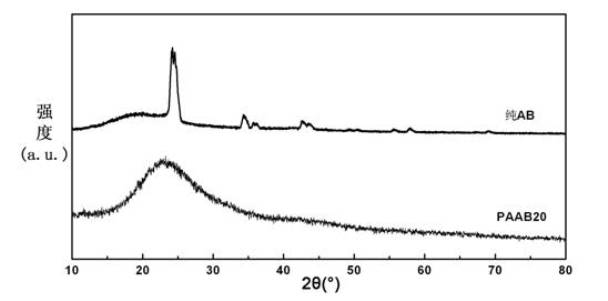

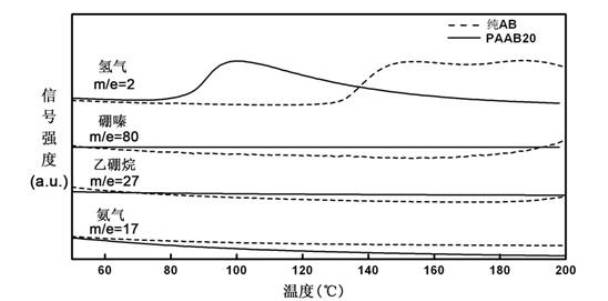

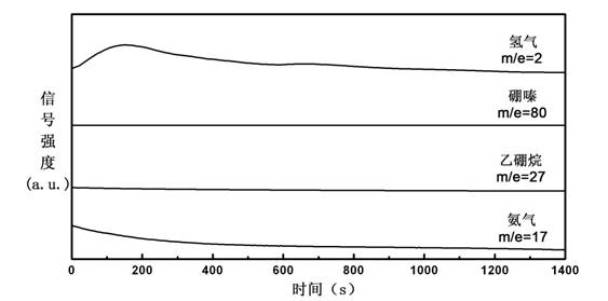

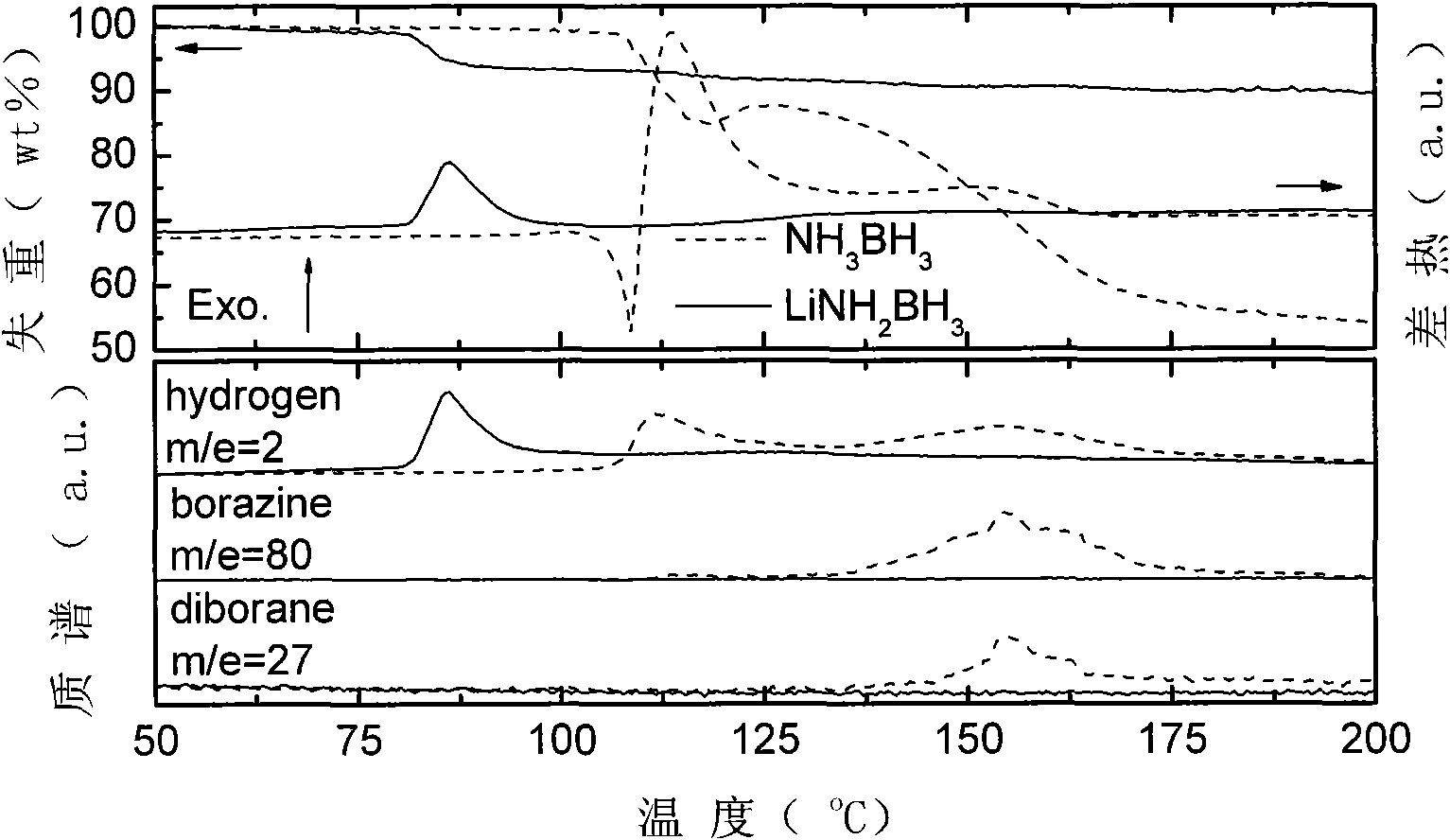

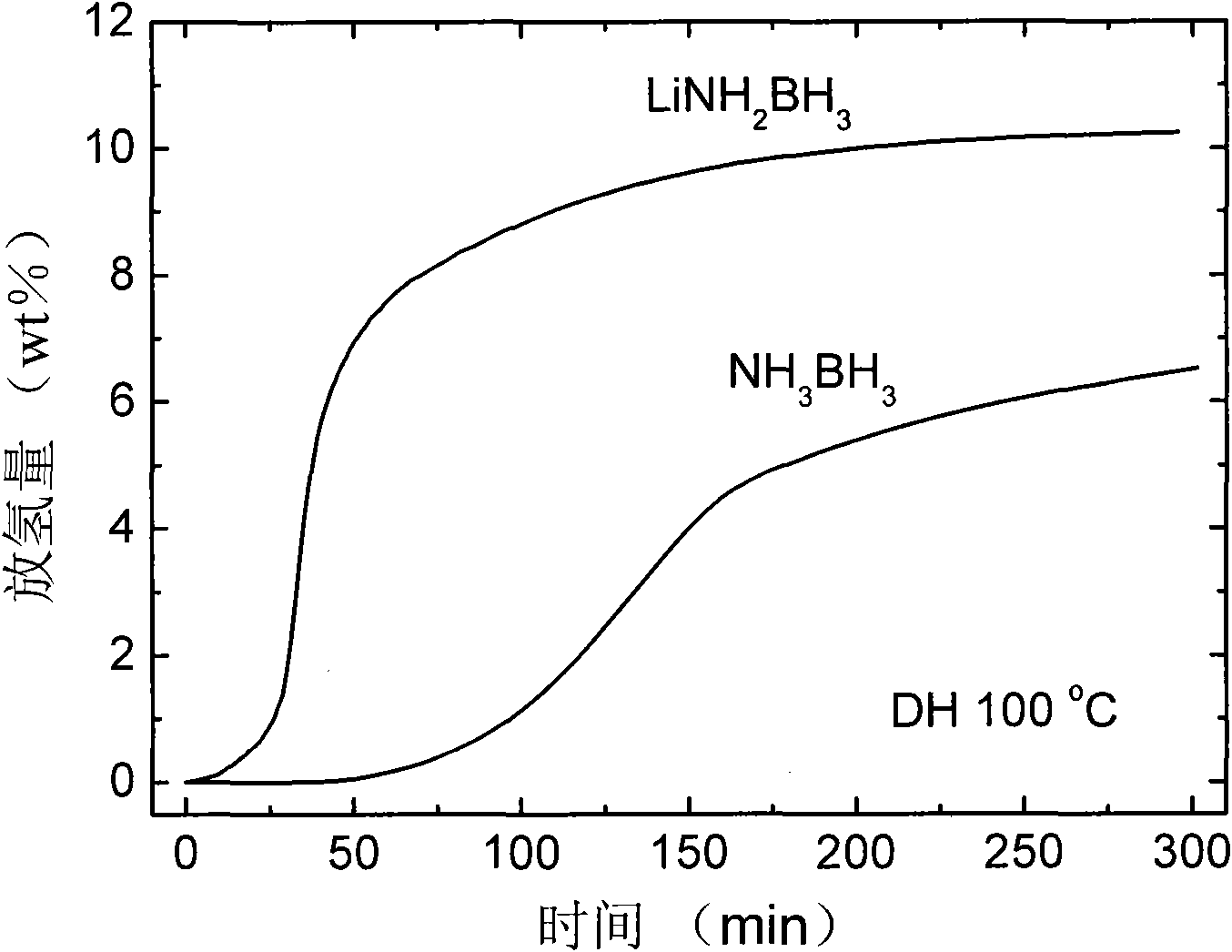

Organic matter and ammonia borane compounded hydrogen storage material and preparation method thereof

ActiveCN102030313ALowering the temperature of thermally liberated hydrogenInhibitionMonoborane/diborane hydridesPolyethylene oxideSolvent

The invention relates to an organic matter and ammonia borane compounded hydrogen storage material. The hydrogen storage material is prepared by compounding the organic matter and the ammonia borane, wherein the organic matter is phthalic anhydride, polyethylene oxide, dextrose, mannitol or mannitol hexaacetic ester. The preparation method comprises the following steps: 1) adding the organic matter to the purified acetonitrile solvent, and stirring for dissolving; 2) dissolving the ammonia borane into the mixing solvent comprising acetonitrile and methanol, and stirring at the temperature of 20 to 70 DEG C to obtain a uniform solution; and 3) carrying out vacuum drying, and removing the solvent, thus obtaining the hydrogen storage material. The invention has the advantages that the ammonia borane and the organic matter are taken as raw materials to prepare the hydrogen storage material at the lower hydrogen discharge temperature; the thermal decomposition and hydrogen discharge temperature of the ammonia borane can be effectively reduced; the generation of harmful gas impurities of borazole, diborane, ammonia and the like is effectively inhibited; the hydrogen storage material has quicker hydrogen discharge kinetics; in addition, the heat discharge amount is less in the hydrogen discharge course; and the enthalpy change of a decomposition reaction approaches to thermal neutrality; and the hydrogen storage material is beneficial to realizing the regeneration of reaction products through a solid-gas reaction or a chemical process under the relatively mild condition.

Owner:NANKAI UNIV

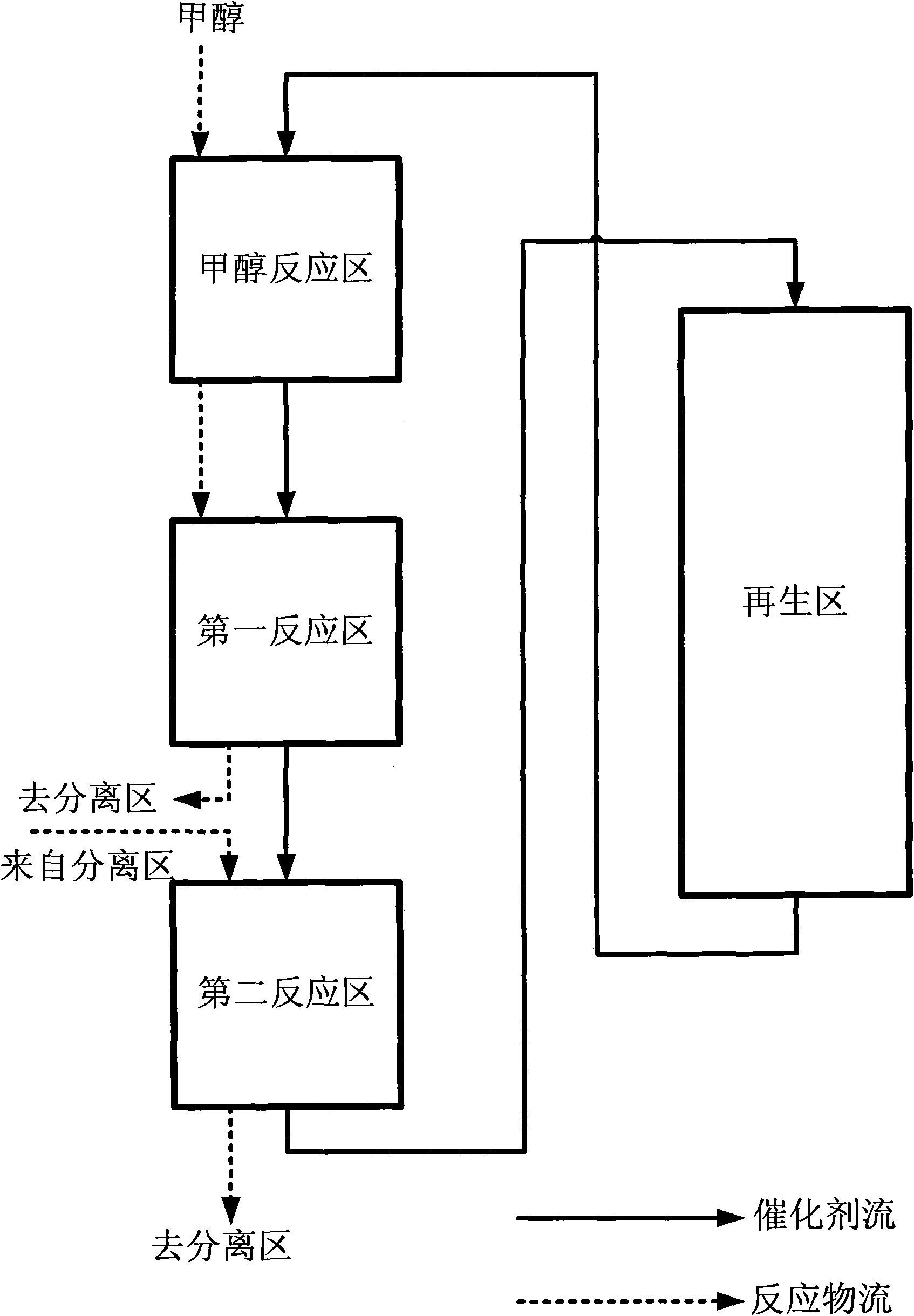

Method for converting methanol into propylene

InactiveCN101830769AImprove cooling capacityIncrease raw material throughputHydrocarbon from oxygen organic compoundsBulk chemical productionDimethyl etherCarbon atom

The invention discloses a method for converting methanol into propylene, which comprises the following steps of: introducing methanol into a methanol reaction zone to perform reaction so as to obtain a mixture of the methanol, dimethyl ether and water; dividing the mixture into a plurality of reactant streams; feeding the first reactant stream to a first reaction zone to perform reaction to obtain a product stream, mixing the product stream and any one of the other reactant streams, feeding the mixture to the first reaction zone to perform reaction until the product stream is mixed with the last reactant stream and feeding the mixture to the first reaction zone to perform reaction so as to obtain a primary reaction product stream; separating the primary reaction product stream to obtain the propylene, propane, C1 to C2 hydrocarbon, C4 hydrocarbon, C5 to C6 hydrocarbon and hydrocarbons with more than seven carbon atoms; circulating the C1 to C2 hydrocarbon and the C4 hydrocarbon to the first reaction zone to perform reaction continuously; feeding the C5 to C6 hydrocarbon and part of the hydrocarbons with more than seven carbon atoms to the second reaction zone to perform reaction so as to obtain a secondary reaction product stream; and separating the secondary reaction product stream to obtain the propylene. The method is suitable for the reactions with high heat discharge and temperature sensitivity such as the reaction for preparing the propylene from the methanol and has the advantages of high target selectivity, continuous and stable reaction and high efficiency.

Owner:ZHEJIANG UNIV

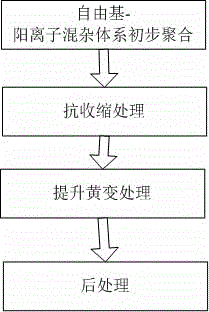

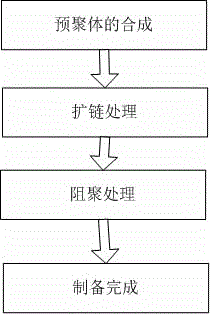

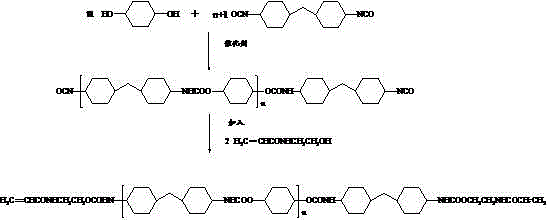

3D printing-based photo-curing material and preparation method thereof

The invention discloses a 3D printing-based photo-curing material and a preparation method thereof. The 3D printing-based photo-curing material comprises the following components in parts by weight: 50-55 parts of aqueous polyurethane acrylic resin, 20-30 parts of hydrogenated bisphenol A epoxy resin, 10-15 parts of alkoxylated pentaerythritol hexaacrylate, 10-15 parts of three-ring decane dimethyl carbinol dimethacrylate, 8-10 parts of hydroxyl ethyl methacrylate, 8-10 parts of vinyl ether, 3-5 parts of 1-hydroxy cyclohexyl phenyl ketone, 3-5 parts of 4,4'-bis(p-toly) iodonium hexafluorophosphate and 0.5-1 part of an 1080 antioxidant. The method comprises the following preparation steps: primary polymerization of a free radical-cation hybrid system, anti-shrinkage treatment, anti-yellowing treatment and post-treatment. The obtained material has the characteristics of excellent performance, low cost, good consistency and the like; and the used preparation method has the characteristics of being environment-friendly, short in production cycle and good in batch stability.

Owner:河源然生新材料有限公司

Photo-thermal dual-curing anisotropic conductive adhesive film and preparation method thereof

ActiveCN104673113AImprove crosslink strengthHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyCross-link

The invention relates to a photo-thermal dual-curing anisotropic conductive adhesive film and a preparation method thereof. The anisotropic conductive adhesive film is prepared from raw materials in percentage by mass as follows: 35%-45% of epoxy resin, 10%-25% of acrylic resin, 5%-10% of a cross-linking agent, 2%-7% of a diluent, 0.6%-1% of a photoinitiator, 2.5%- 4% of a thermal curing agent, 5%-10% of an accelerant, 0.5%-2% of a silane coupling agent and 20%-35% of conductive balls. The preparation method comprises steps as follows: the raw materials are blended, subjected to rotary coating and then subjected to ultraviolet exposure processing, and the anisotropic conductive adhesive film is prepared. The anisotropic conductive adhesive film has good conductive performance, excellent weather fastness, low curing temperature, long storage time, high curing degree and high bonding strength; the preparation process is simple, the cost is low, and the application prospect is broad.

Owner:DONGHUA UNIV

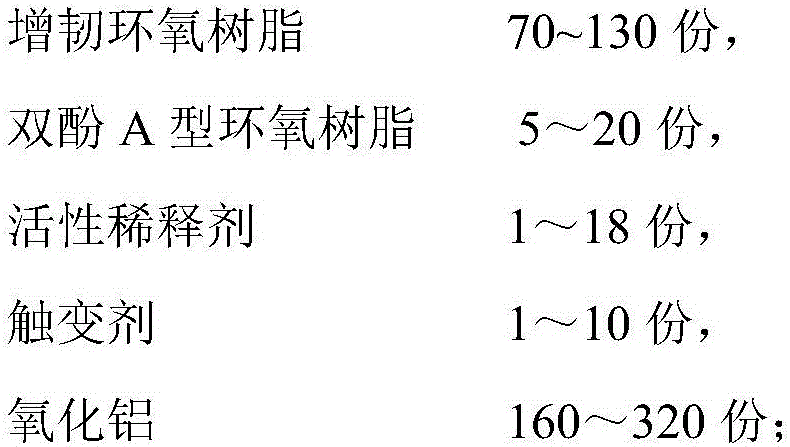

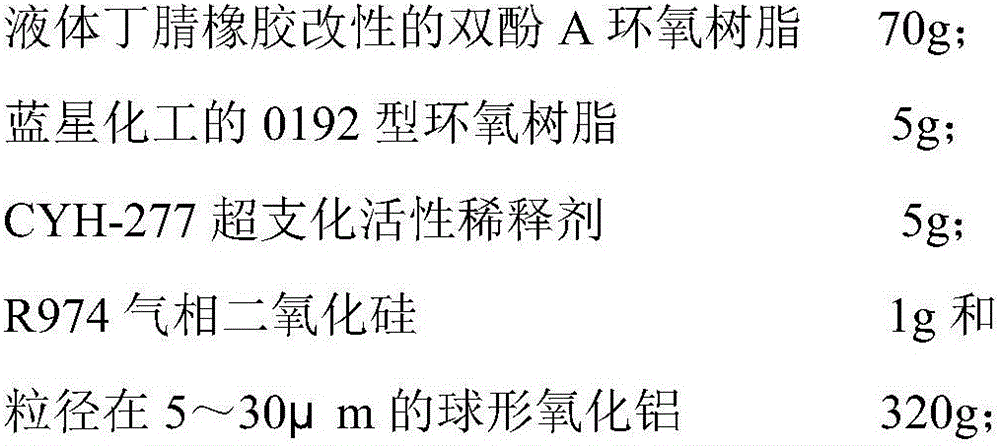

High-toughness, anti-impact and high-flexibility epoxy pouring sealant and preparation method thereof

ActiveCN106281174AGuaranteed crosslink densityGuaranteed heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesTO-18Diluent

The invention discloses a high-toughness, anti-impact and high-flexibility epoxy pouring sealant. The high-toughness, anti-impact and high-flexibility epoxy pouring sealant is composed of a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 0 to 130 parts of toughening epoxy resin, 5 to 20 parts of bisphenol A type epoxy resin, 1 to 18 parts of an active diluent, 1 to 10 parts of a thixotropic agent and 160 to 320 parts of aluminum oxide; the component B is prepared from the following raw materials in parts by weight: 20 to 50 parts of a flexible curing agent, 25 to 50 parts of a hyperbranched curing agent and 1 to 5 parts of an accelerant; the mass ratio of the component A to the component B ranges from (10 to 1) to (20 to 1). According to a preparation method provided by the invention, the materials are prepared and mixed according to formulas of the component A and the component B respectively. The epoxy resin provided by the invention not only has rubber flexibility, but also has excellent heat-resisting performance and rigidity.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Safety belt pre-tightening instrument gas production medicine and preparation method thereof

The gas forming agent for safety belt pre-fastener consists of nitrocellulose 60-90 wt%, combustion improver 1-10 wt%, oxidant 1-20 wt% and adhesive 1-10 wt%. The combustion improver is one or several selected from boron powder and inflammable metal powder; the oxidant is one or several selected from nitrate, chlorate and perchlorate; and the adhesive is one or several selected from phenolic resin, shellac varnish, bone glue, cellulose-base polymer and its salt. The gas forming agent for safety belt pre-fastener has no combustion residue, high gas producing rate and excellent safety belt fastening performance.

Owner:BYD CO LTD

Preparation method of high-purity lithium tetrafluoroborate

The invention provides a preparation method of high-purity lithium tetrafluoroborate; and the method comprises the following steps that high-purity lithium fluoride and a boron trifluoride coordination compound react in chain carbonate organic solvent, and lithium tetrafluoroborate is obtained after filtration, concentration, extractive crystallization, washing and drying. In the preparation method of high-purity lithium tetrafluoroborate, the boron trifluoride coordination compound has wide sources of raw materials and is low in price, the linear carbonate organic solvent has low toxin and is environment-friendly, the synthetic reaction conditions are mild, the operation is simple, the equipment investment is low, the lithium tetrafluoroborate productivity is high, the yield is high, the energy consumption is low, the post-treatment is simple, and the method is applicable to large-scale production.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Epoxy resin base damping packaging material

InactiveCN101186803AImprove liquidityCuring reaction is gentleOther chemical processesWorking temperaturePolyamide

The invention relates to a damping package material of epoxy resin group, which consists of component A and component B, wherein the component A is composed of 0-90 parts of bisphenol A epoxy resin, 0-60 parts of polyurethane epoxy resin, 20-90 parts of flexible epoxy resin according to part by weight, the component B is composed of 25-55 parts of aliphatic amine, 10-45 parts of aliphatic cyclic amine, 0-80 parts of versamid and 0-8 parts of silane coupling agent according to part by weight, the parts are mixed uniformly according to part by weight of A:B=100:15-100. The invention has the advantages that the mixture has good mobility, the solidification reaction is mild, the condensate has good mechanical property and good tensile shear strength with metals, the invention can resist high and low temperature impact, thermal aging and humidity heat aging, the condensate does not erode rigid aluminium alloy, steel, aldary and PVC plastics in sealed humidity heat condition, the solidification shrinkage ratio is low, with the damping coefficient (tan delta max>=0.5). Particularly, the invention has instantaneous high impact property and the operational temperature is from -54 DEG C to 70 DEG C.

Owner:张向宇

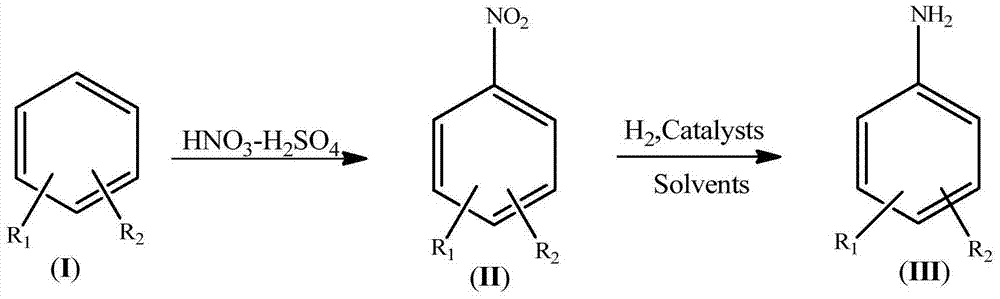

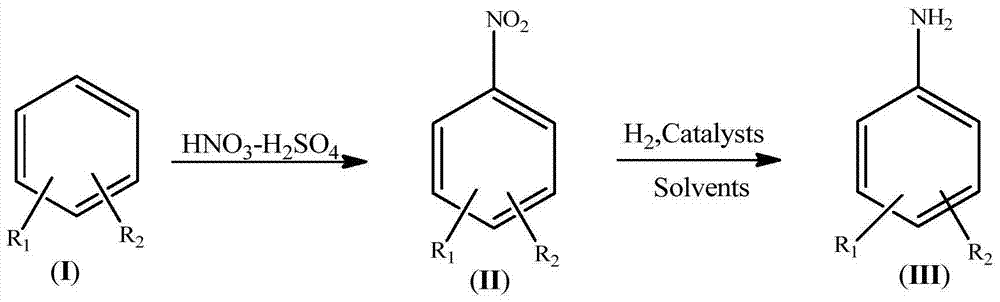

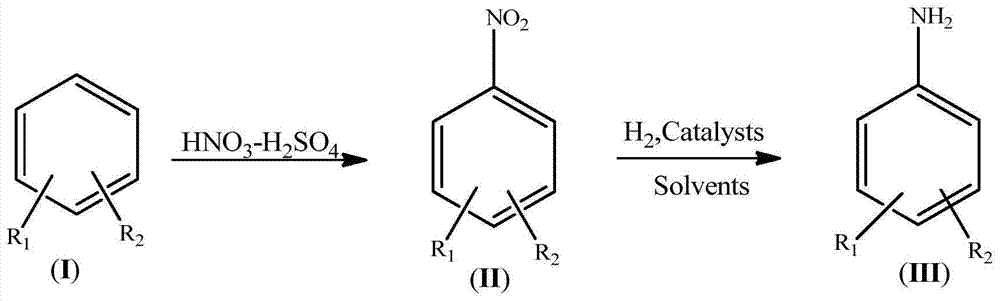

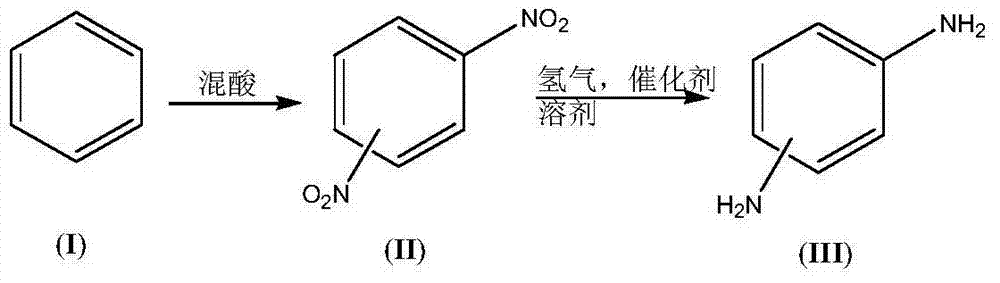

Synthetic process for amino aromatic hydrocarbon compound

InactiveCN104844461AImprove securityImprove concentrationOrganic compound preparationCarboxylic acid amides preparationEnvironmental resistanceHydrogen

The invention discloses a synthetic process for an amino aromatic hydrocarbon compound. The process comprises the following steps: pre-preparing reaction solutions -1 and -2 by using an aromatic hydrocarbon compound (I), concentrated sulphuric acid and concentrated nitric acid, respectively pumping the solutions in a micro reactor, heating to react, cooling the reaction liquid, and pos-treating to obtain a nitryl aromatic hydrocarbon compound (II); mixing the nitryl aromatic hydrocarbon compound (II), a catalyst and a solvent as a reaction solution -3; respectively pumping the reaction solution -3 and hydrogen into the micro reactor, heating to react, cooling the reaction liquid and post-treating to obtain the amino aromatic hydrocarbon compound (III). The process disclosed by the invention is less in use level of nitric acid, convenient to concentrate and apply waste acid; in the nitrification reaction process, the heat release is little, and the nitration product nitryl aromatic hydrocarbon compound (II) is quickly transferred. The reaction phenomenon is stable without intense heat release and even material punching of a common kettle nitration reaction, so that the safety of nitration reaction is improved; the process is easy to realize industrialization, simple to operate and high in industrial safety degree and meets the environmental requirements.

Owner:ANHUI SHENGYUAN CHEM

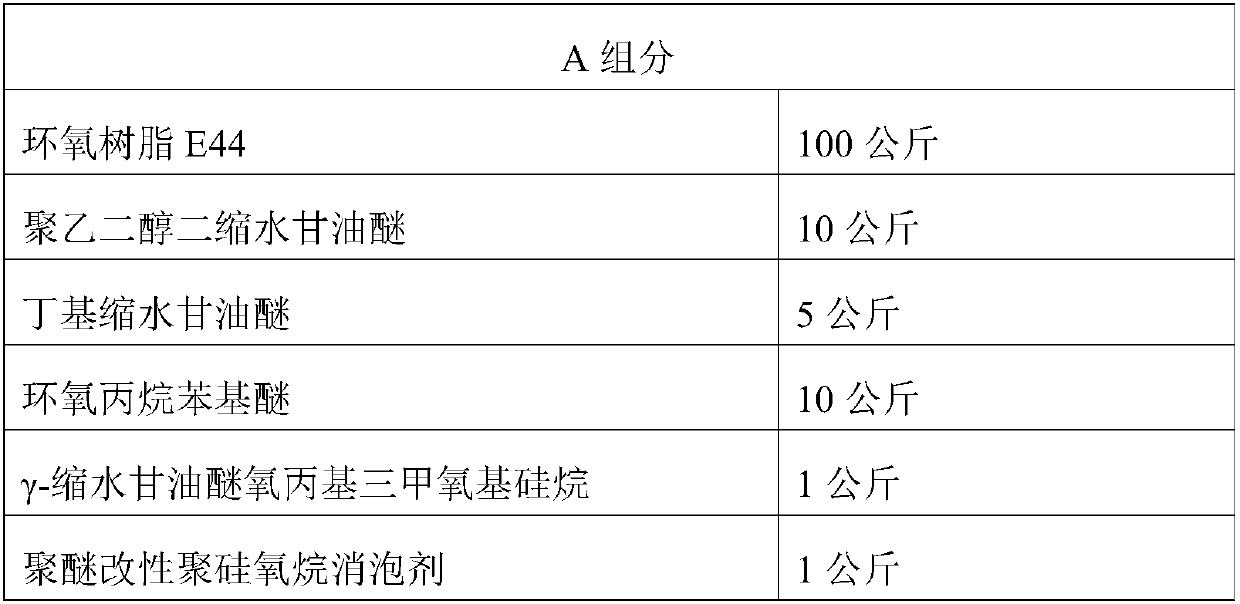

High-strength high-mobility epoxy resin grouting material and preparation method thereof

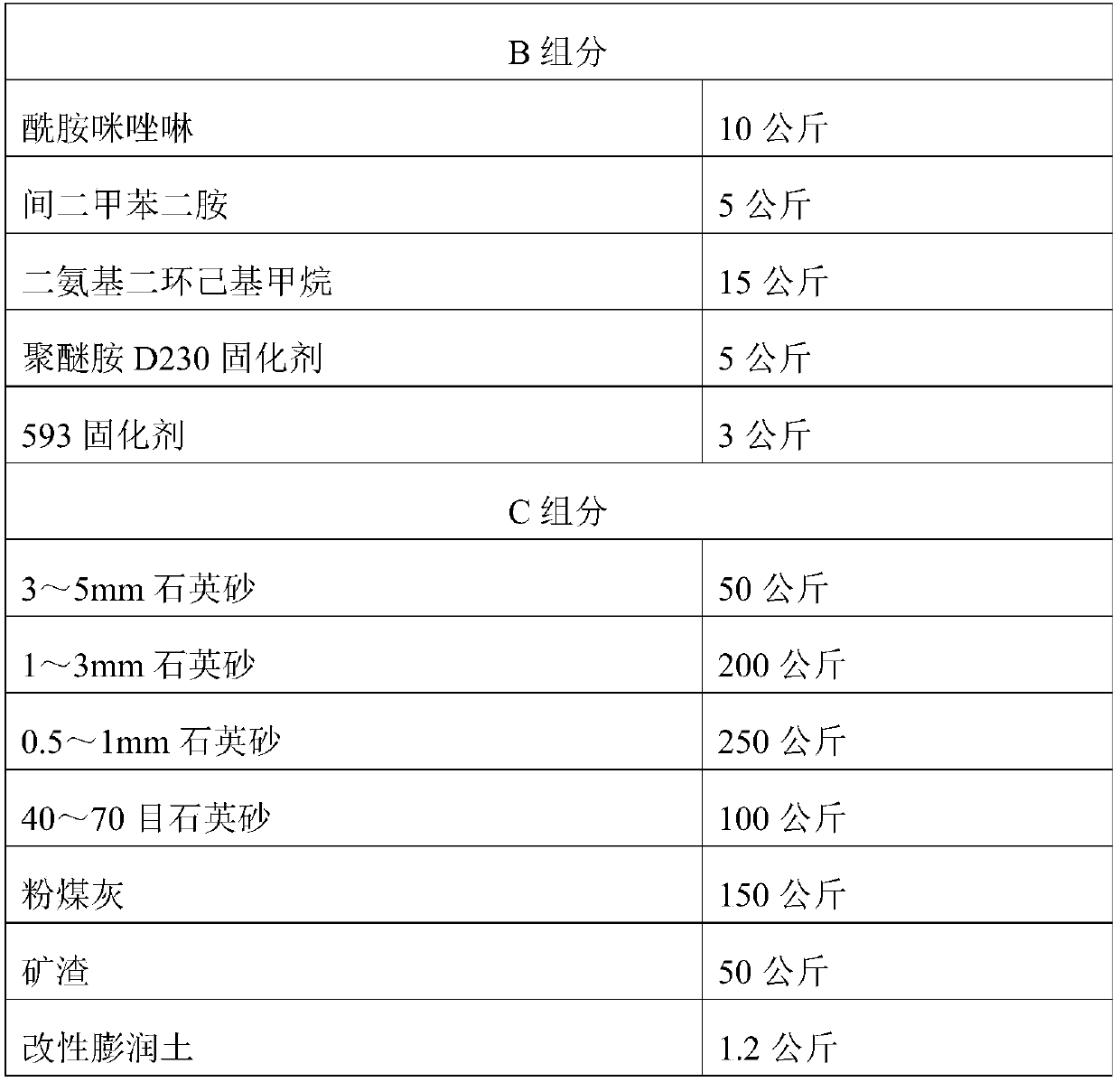

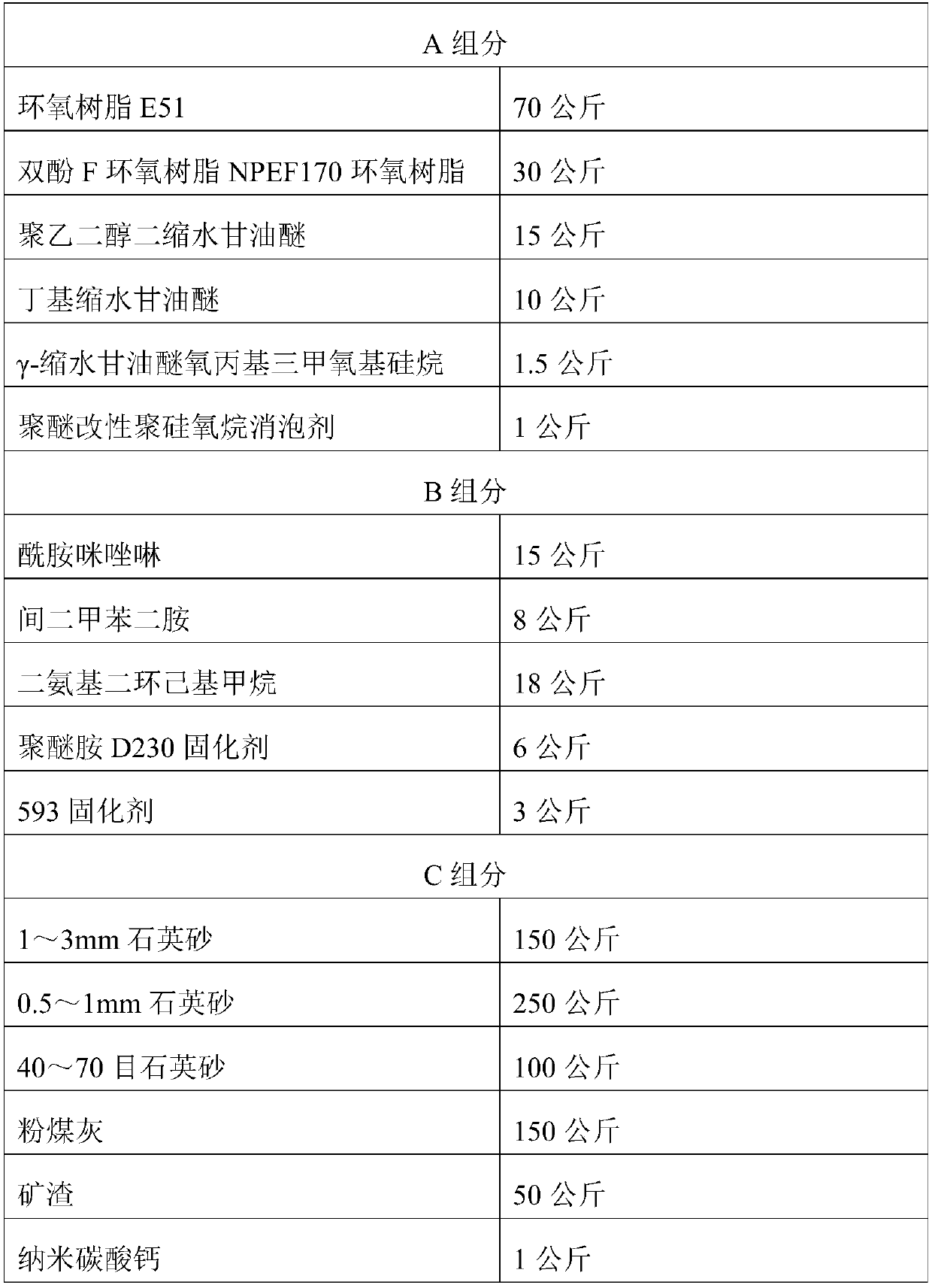

ActiveCN108047657AGood mechanical properties and medium corrosion resistanceSimple production processDiamineDefoaming Agents

The invention discloses a high-strength high-mobility epoxy resin grouting material and a preparation method thereof. The high-strength high-mobility epoxy resin grouting material comprises componentA, component B and component C; the component A comprises, by weight, 100 parts of epoxy resin, 5-30 parts of a diluent, 1-2 parts of a coupling agent and 0.5-2 parts of a defoaming agent; the component B comprises, by weight, 5-15 parts of aliphatic amide polyamine, 0-10 parts of aliphatic amine containing aromatic rings, 5-20 parts of alicyclic diamine, 0-10 parts of a polyether amine curing agent, and 0-10 parts of 593 curing agent; the component C comprises, by weight, 1-5 parts of a thixotropic agent, 0-100 parts of quartz sand 3-5 mm, 0-300 parts of quartz sand 1-3 mm, 0-400 parts of quartz sand 0.5-1 mm, 100-400 parts of quartz sand 40-70 mesh, 150-400 parts of flyash, and 0-100 parts of mineral waste. The high-strength high-mobility epoxy resin grouting material has high strength and mobility; by adjusting powder ratio and addition, the high-strength high-mobility epoxy resin grouting material can adapt to different grouting thicknesses; the performance of the high-strength high-mobility epoxy resin grouting material can be improved, and the requirement for better simplicity and environmental friendliness in production can also be met.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

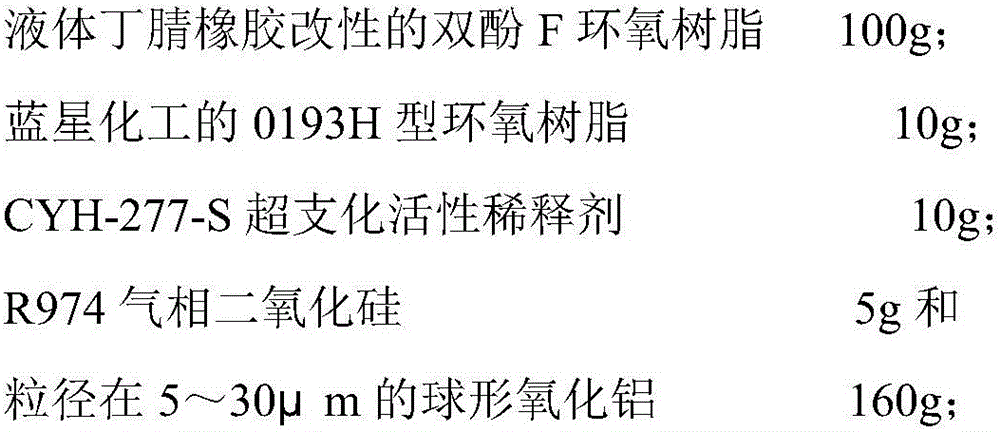

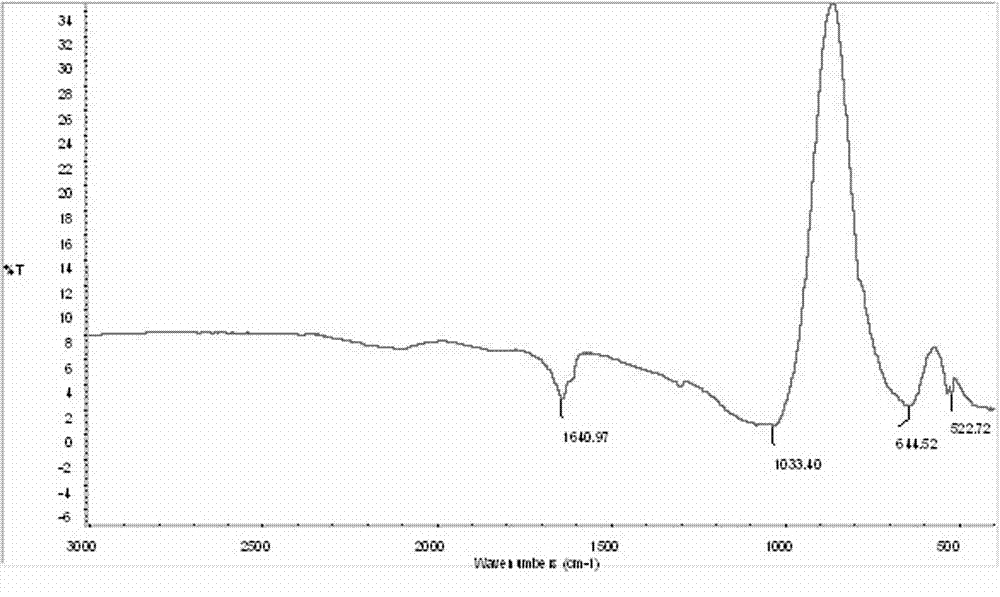

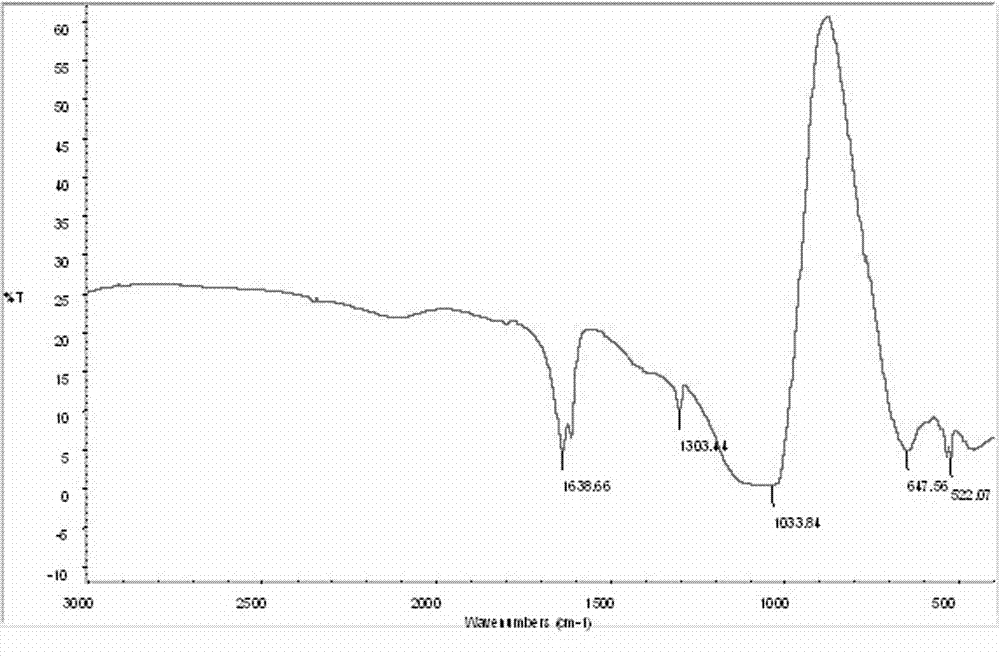

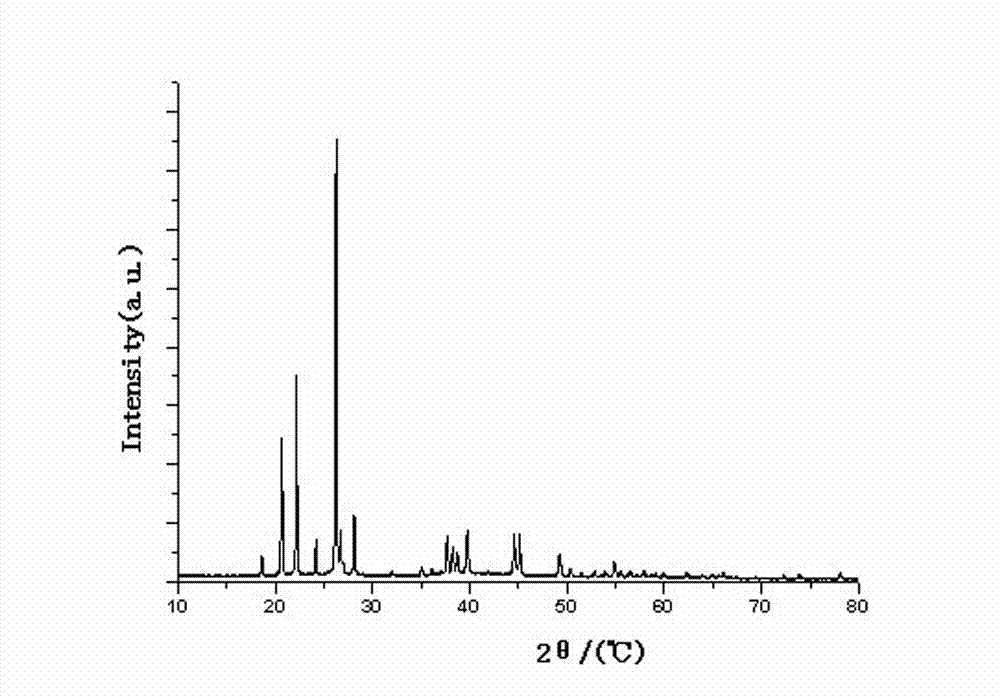

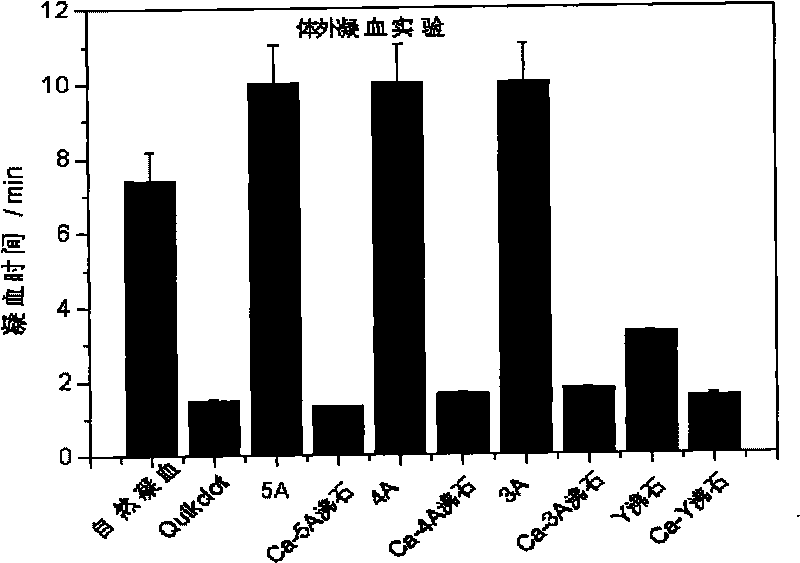

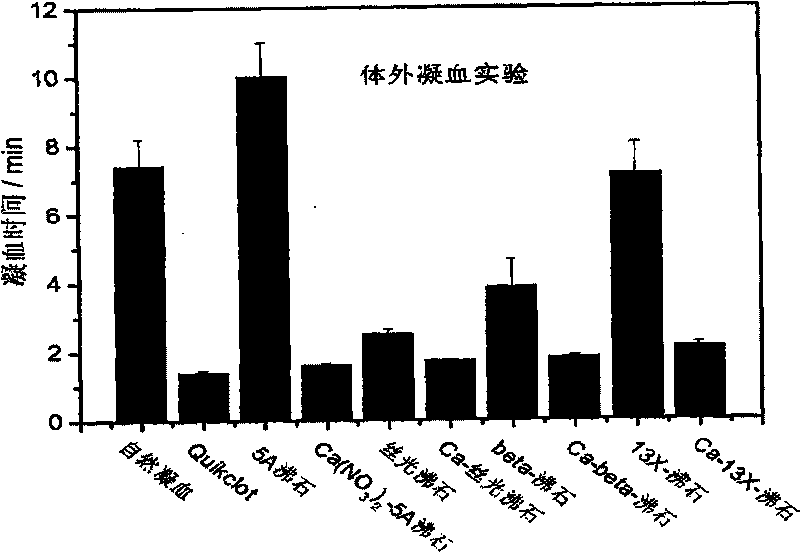

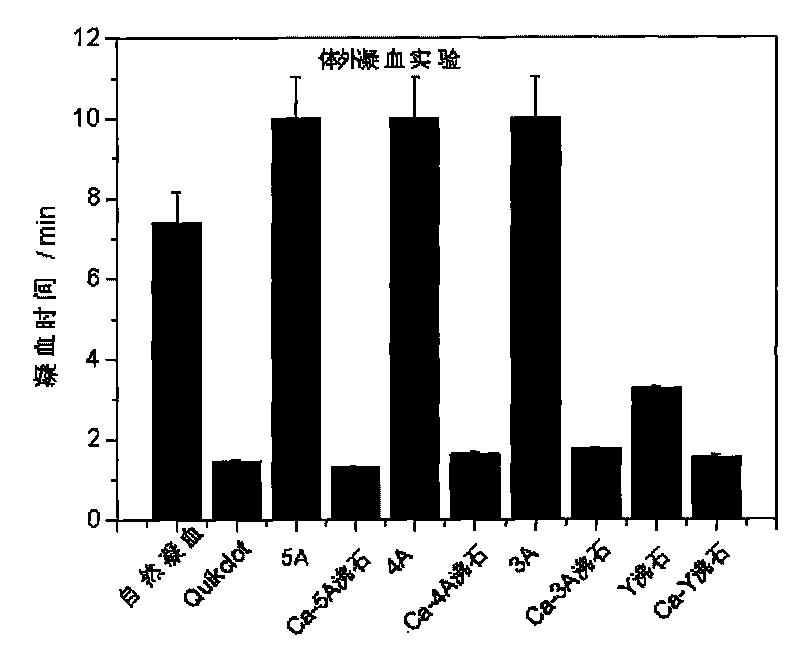

Method for improving hemostatic effect of external-use zeolite hemostat by calcium ion modification

InactiveCN101703519AGood hemostatic effectSmall heat releaseAbsorbent padsAluminium/calcium/magnesium active ingredientsLiquid ratioAtherion elymus

The invention relates to a method for improving the hemostatic effect of external-use zeolite hemostat by calcium ion modification, comprising the steps of using 5A zeolite, 4A zeolite, 3A zeolite, combined Y zeolite, synthesized mercerizing zeolite, synthesized 13x zeolite and synthesized beta-zeolite as the materials, grinding the materials into particles with the grain diameter of 1 micro to 1 mm with a traditional Chinese medicine grinder, mixing the grinded zeolite and the calcium ion solution in which the concentration of the calcium ion is 0.1-10 mol / L in the solid-to-liquid ratio of 1 g:10 ml, reacting for 3-6 h at a temperature of 60-120 DEG C, washing till no calcium ion is available in the eluate, and then drying at a temperature of 60-200 DEG C to obtain the external-use zeolite hemostat with better hemostatic effect.

Owner:ZHEJIANG UNIV

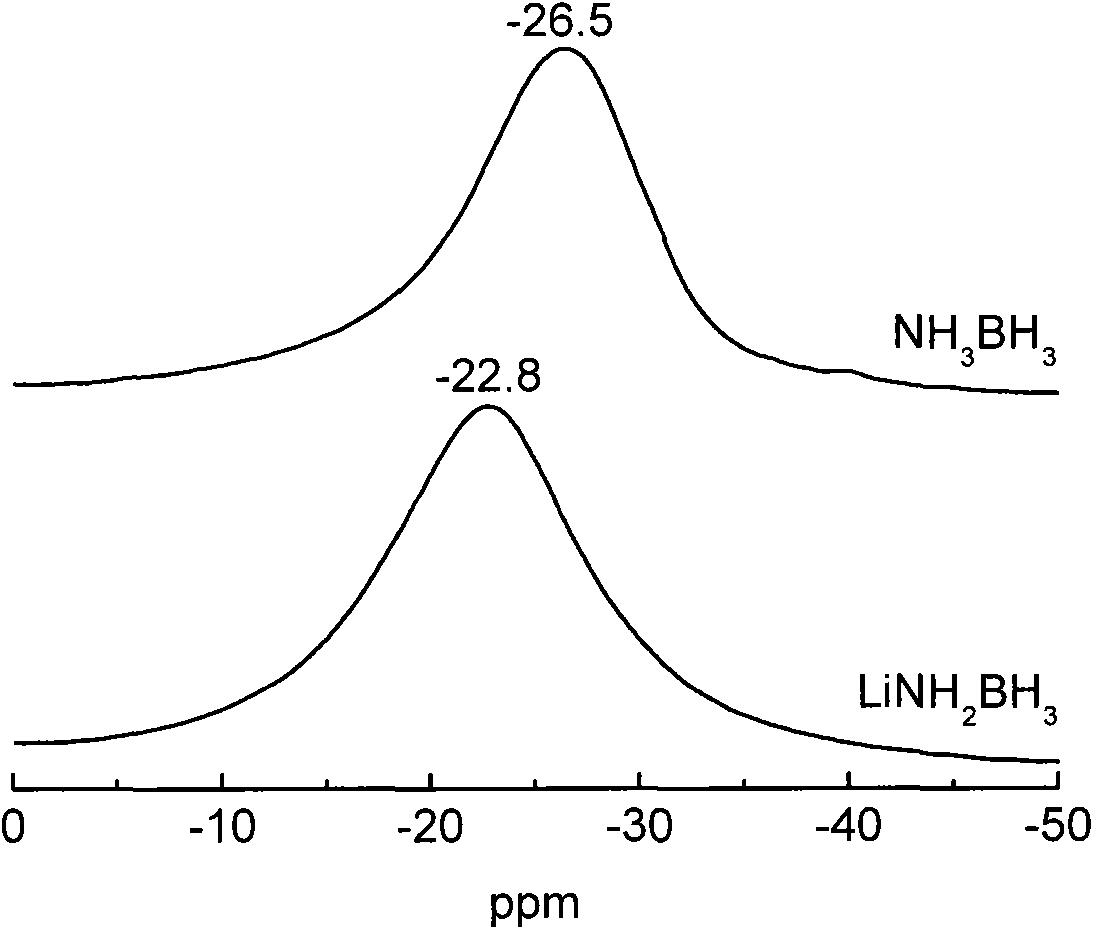

Metal ammonia borane compound hydrogen storage material and preparation method thereof

InactiveCN101613083AImproved hydrogen release performanceStrong donating abilityHydrogen productionMetal hydridesHydrogen atmosphereImpurity

The invention relates to a material and technology for storing hydrogen, in particular to a novel metal ammonia borane compound hydrogen storage material and a preparation method thereof. The novel metal ammonia borane compound hydrogen storage material is prepared by taking the mixture of ammonia borane NH3BH3 and metal M or metal hydride NHy as an initial raw material and performing ball milling on the raw material in an inert protective atmosphere or a reactive hydrogen atmosphere. The molecular formula of the novel metal ammonia borane compound hydrogen storage material is MxNH(3-nx)BH3, wherein x is more than 0 and less than or equal to 1, and n is more than or equal to 1 and less than or equal to 3. The mole ratio of NH3BH3 to M or NHy in the phase composition of the raw material is 1-50:1. The preparation method provided by the invention has high efficiency and simple and easy operation. The novel metal ammonia borane compound hydrogen storage material provided by the invention has the advantages of high hydrogen storage capacity, low hydrogen production temperature, fast hydrogen production dynamics, no impurities, no gaseous pollutants and the like and has the application prospective of automobile-mounted hydrogen storage.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of transparent self-toughening dicyandiamide/epoxy resin-based composite material

The invention belongs to the technical field of application of high performance epoxy resin and particularly relates to a preparation method of a transparent self-toughening dicyandiamide / epoxy resin-based composite material, in particular to a preparation method of a transparent self-toughening epoxy resin composition with low heat release, a heavy-thickness prepreg unidirectional tape and a composite material. The composition comprises the following raw materials in parts by weight: 60-100 parts of liquid epoxy resin, 0-40 parts of solid epoxy resin, 1.0-12 parts of a dicyandiamide curing agent and 0.5-6 parts of an accelerant. The epoxy resin is prepared by adopting a solution reaction manner; compared with a general dicyandiamide / epoxy resin system, a system in the invention has the advantages that the peak heat flux is decreased by 48% or higher, the heat release is decreased by 38% or higher, and the reaction heat is low; moreover, a resin casting body has 3.5% or more of breaking elongation, 80MPa or higher of tensile strength and 24kJ / m<2> of higher impact strength and has good toughness without adding a toughening agent; 130-DEG C medium temperature curing can be realized, and a cured product is transparent.

Owner:AVIC BASIC TECH RES INST

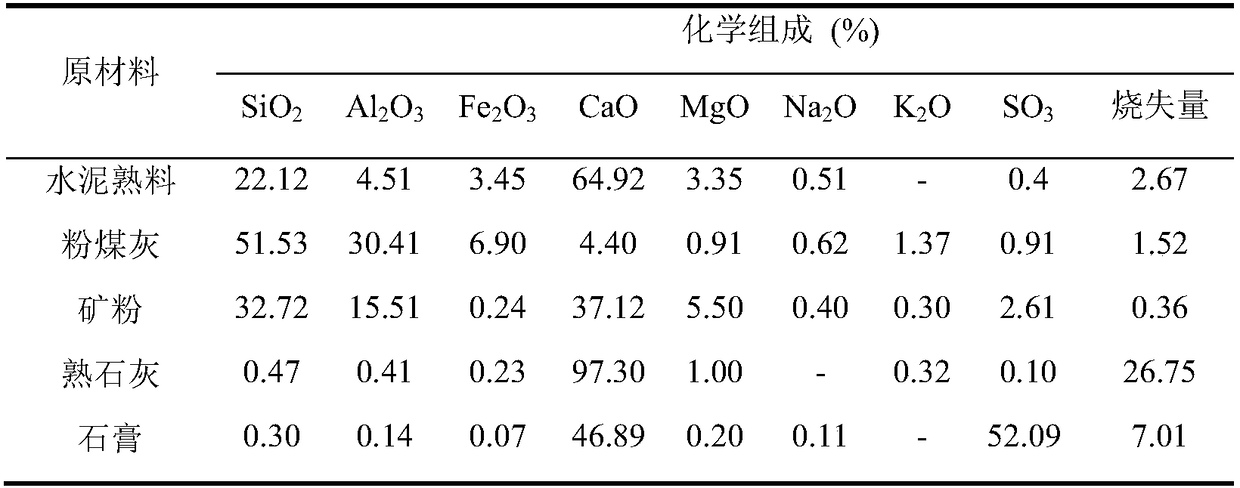

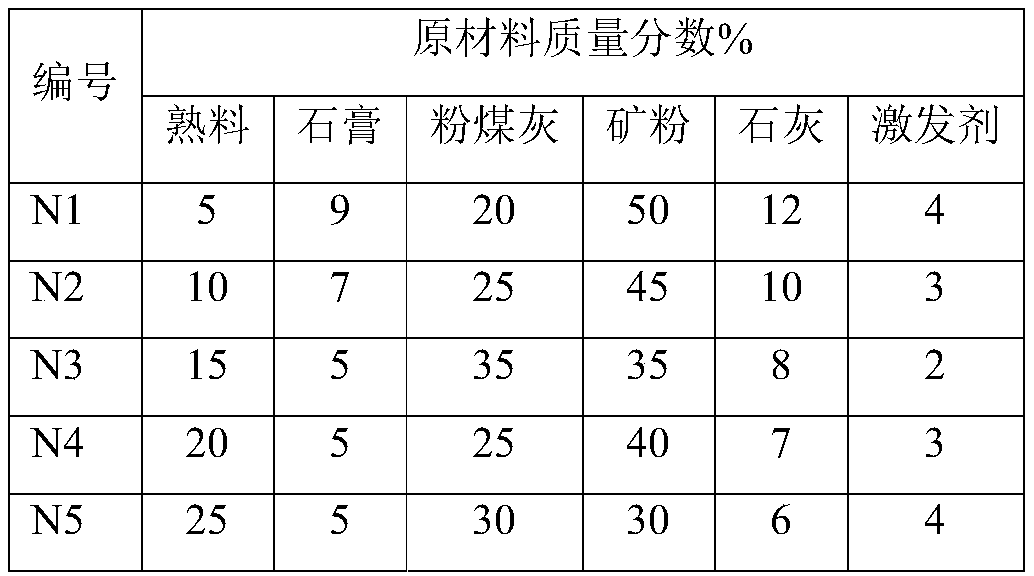

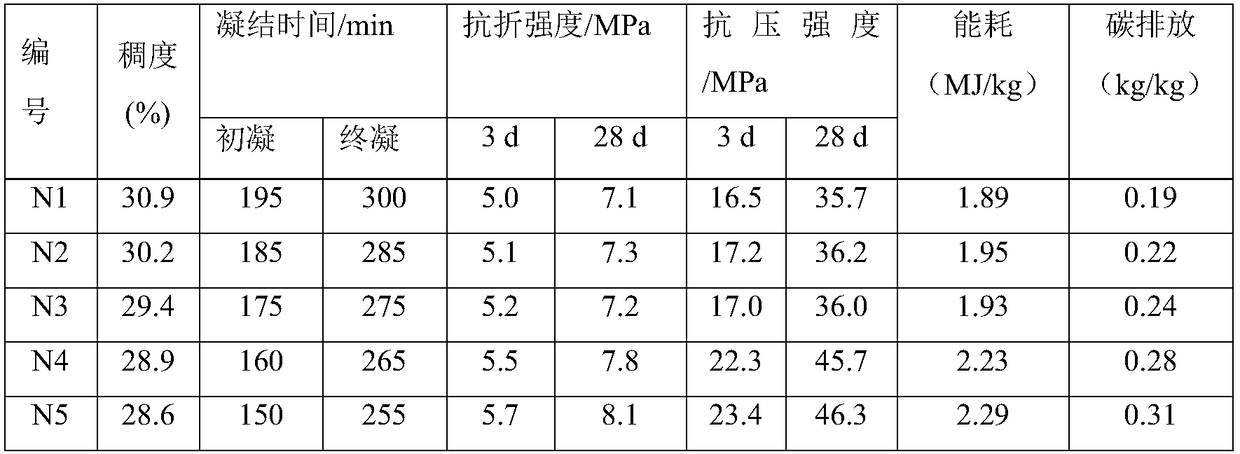

High-volume low carbon cement doped with large amount of industrial waste residue and preparation method thereof

InactiveCN108623196ALow gel calcium contentHigh compressive strengthCement productionUltimate tensile strengthFly ash

The invention discloses high-volume low carbon cement doped with a large amount of industrial waste high-volume and a preparation method thereof. The low carbon cement is characterized by comprising the following components in parts by weight: 10 to 40 parts of cement clinker, 1 to 35 parts of fly ash, 20 to 45 parts of ore powder. 3 to 10 parts of lime, 3 to 7 parts of gypsum, and 1 to 4 parts ofactivator. The cement clinker and gypsum are mixed and co-powdered in proportion, and after the fineness requirement is met, the mixture is mixed and homogenized with fly ash, high-volume, lime and the activator. The composite portland cement prepared by the method has the advantages of less cement clinker consumption, low carbon emission and energy consumption in the production process, high early strength and large strength enhancement rate in the later stage.

Owner:SOUTHEAST UNIV

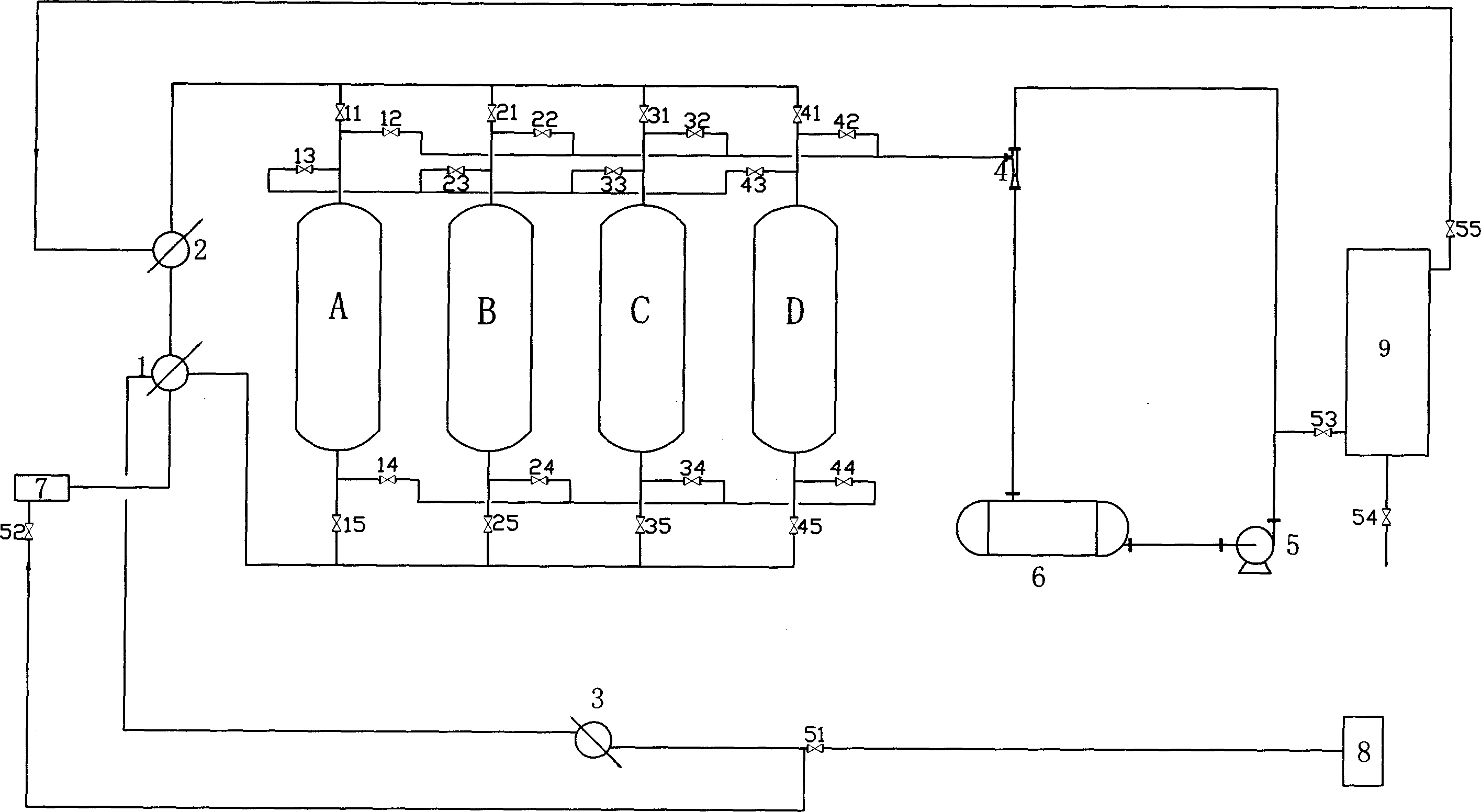

Multiple adsorption tower alternate internal recycle method for producing anhydrous alcohol

InactiveCN1733666AExtend your lifeSolve the problem of entrained sorbentAlcoholic beverage preparationDistillationAlcoholSorbent

Disclosed is a multiple adsorption tower alternate internal recycle method for producing anhydrous alcohol, which comprises the steps of heating, adsorbing, internal recycling, vacuum evacuating, flushing and resolving, the process has the advantages of extended adsorbent lifetime, reduced heat exchanger area, lowered cooling-water consumption, deep de-watering depth, and no pollution.

Owner:SICHUAN TECHAIRS

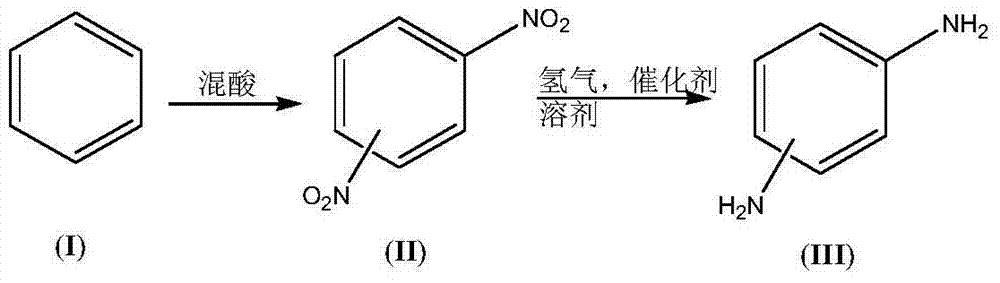

Synthesis process of dimido dipheny compound

InactiveCN104844462AIncrease dosageReduce dosageOrganic compound preparationAmino compound preparationBenzeneP-Phenylenediamine

The invention discloses a synthesis process of a dimido dipheny compound. The synthesis process disclosed by the invention comprises the following steps: by taking benzene(I) as a raw material, carrying out continuous nitration on a micro reactor platform to obtain a mixed nitrobenzene compound (II); then obtaining a mixed diaminobenzene compound (III) by carrying out catalytic hydrogenation reduction under a mild condition with temperature of 50~70 DEG C and hydrogen gas pressure not higher than 1.0MPa; and purifying to obtain o-phenylenediamine, p-phenylenediamine and m-phenylenediamine. The synthesis process disclosed by the invention has the benefits that: the use level of nitric acid is low, so that the waste acid is easy to concentrate and apply mechanically; the heat release is less, the product dinitrobenzene compound (II) is quickly transferred, the reaction phenomenon is stable without intense heat release and even punch of a common autoclave nitration reaction, so that the safety of nitration reaction is improved; the rate in nitrification reaction is fast, and the energy consumption is reduced; the reaction phenomenon is stable, so that the safety of catalytic hydrogenation reduction reaction is improved; the synthesis process is a new technique which is high in safety, easy to industrialize and less in environment protection.

Owner:ANHUI SHENGYUAN CHEM

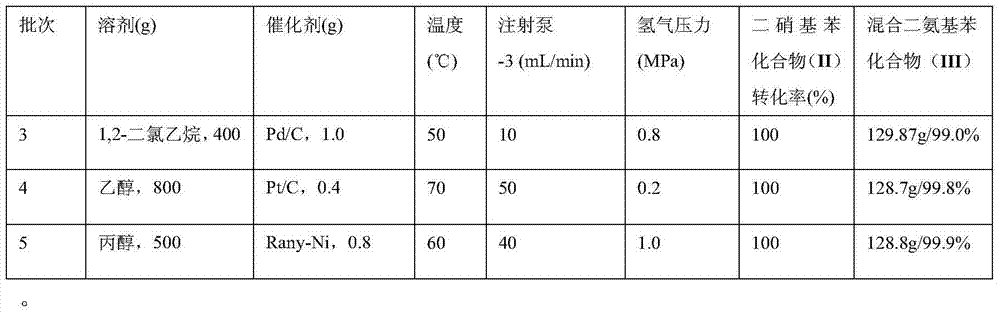

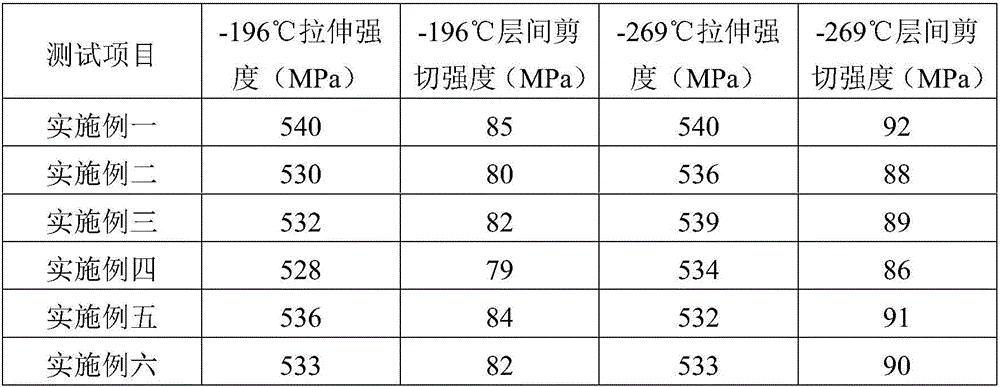

Novel low-temperature insulation and thermal insulation pre-impregnated fiber cloth and preparation method thereof

InactiveCN106042528AThickness is easy to controlQuality is easy to controlSynthetic resin layered productsPaper/cardboard layered productsGlass fiberFiber

The invention relates to a novel low-temperature insulation and thermal insulation pre-impregnated fiber cloth. The novel low-temperature insulation and thermal insulation pre-impregnated fiber cloth is obtained by impregnating 45 wt%-65 wt% of glass fiber cloth in 35 wt%-55 wt% of epoxy resin sizing agent; the epoxy resin sizing agent is prepared from 85 wt%-95 wt% of epoxy resin mixture, 5 wt%-15 wt% of modified latent curing agent mixture, 70 wt%-90 wt% of epoxy resin, 5 wt%-25 wt% of modified epoxy resin flexibilizer, 0 wt%-10 wt% of surfactant, 0 wt%-5 wt% of flame retardant, 4.5 wt%-12 wt% of latent curing agent and 0.5 wt%-3 wt% of accelerator. The invention further discloses a preparation method of the novel low-temperature insulation and thermal insulation pre-impregnated fiber cloth. The obtained material is not prone to cracking, and the requirement of low-temperature engineering can be met.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

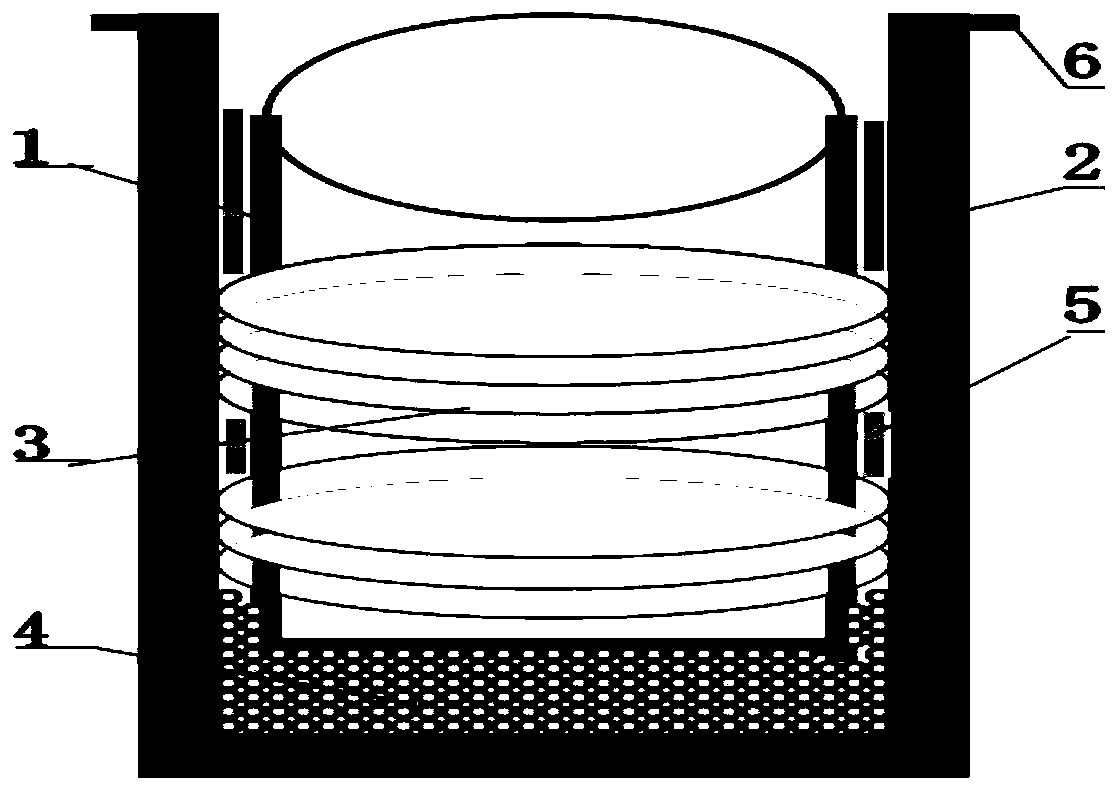

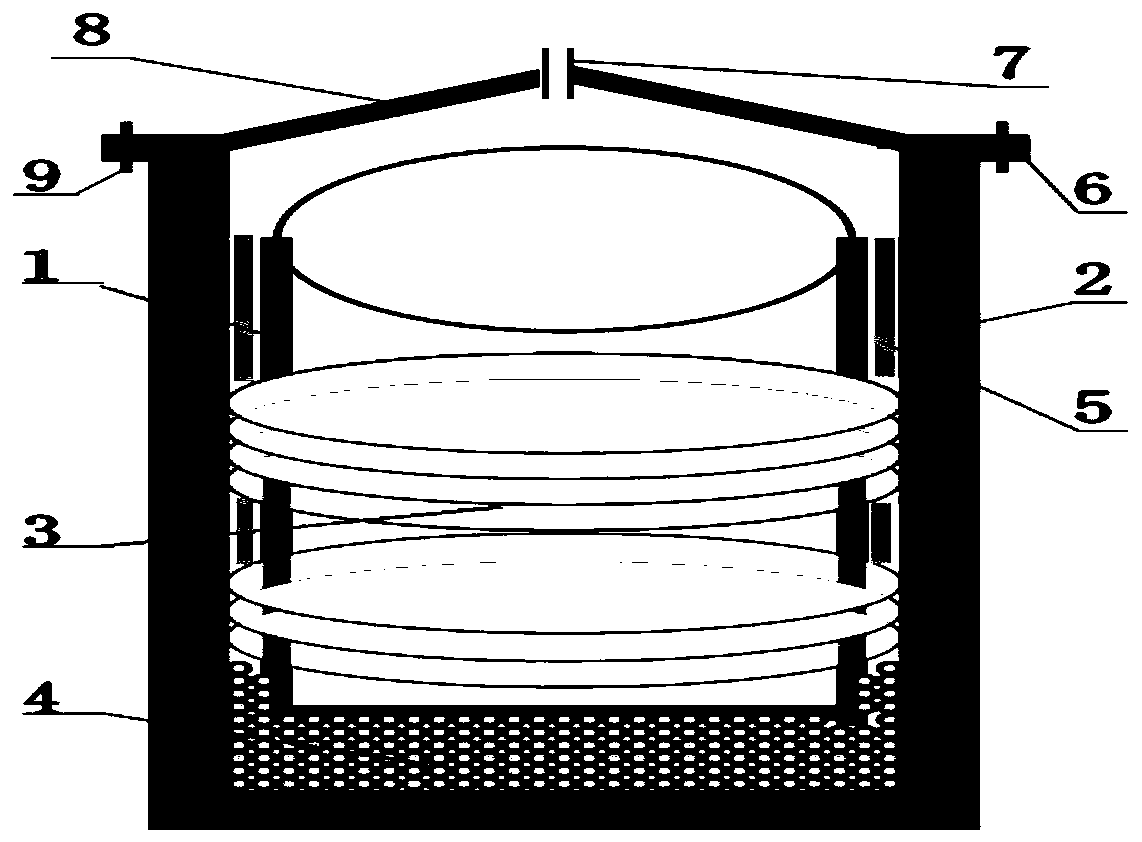

Preparation method for vanadium-aluminum alloy and reactor

The invention provides a preparation method for a vanadium-aluminum alloy and a reactor. The preparation method provided by the invention comprises the following steps: 1) mixing a vanadium source, analuminum source and a slag former to obtain a material mixture; 2) heating the material mixture to obtain a reaction product; and 3) under a vacuum-pumping condition or protective gas introducing condition, cooling the reaction product to obtain the vanadium-aluminum alloy. The reactor comprises a U-shaped container, a reaction container arranged in the U-shaped container, a heating device positioned on the outer wall of the reaction container, and a filler arranged between the U-shaped container and the reaction container. The preparation method provided by the invention solves the problemsthat a vanadium yield is low, the alloy separating effect is poor and an oxidization film appears in the prior art, overcomes splash due to fierce reaction, volatilization, due to a high temperature,of vanadium pentoxide, poor alloy separating effect, and vanadium loss due to the fact that the vanadium-aluminum alloy enters a slag phase.

Owner:HEBEI IRON AND STEEL

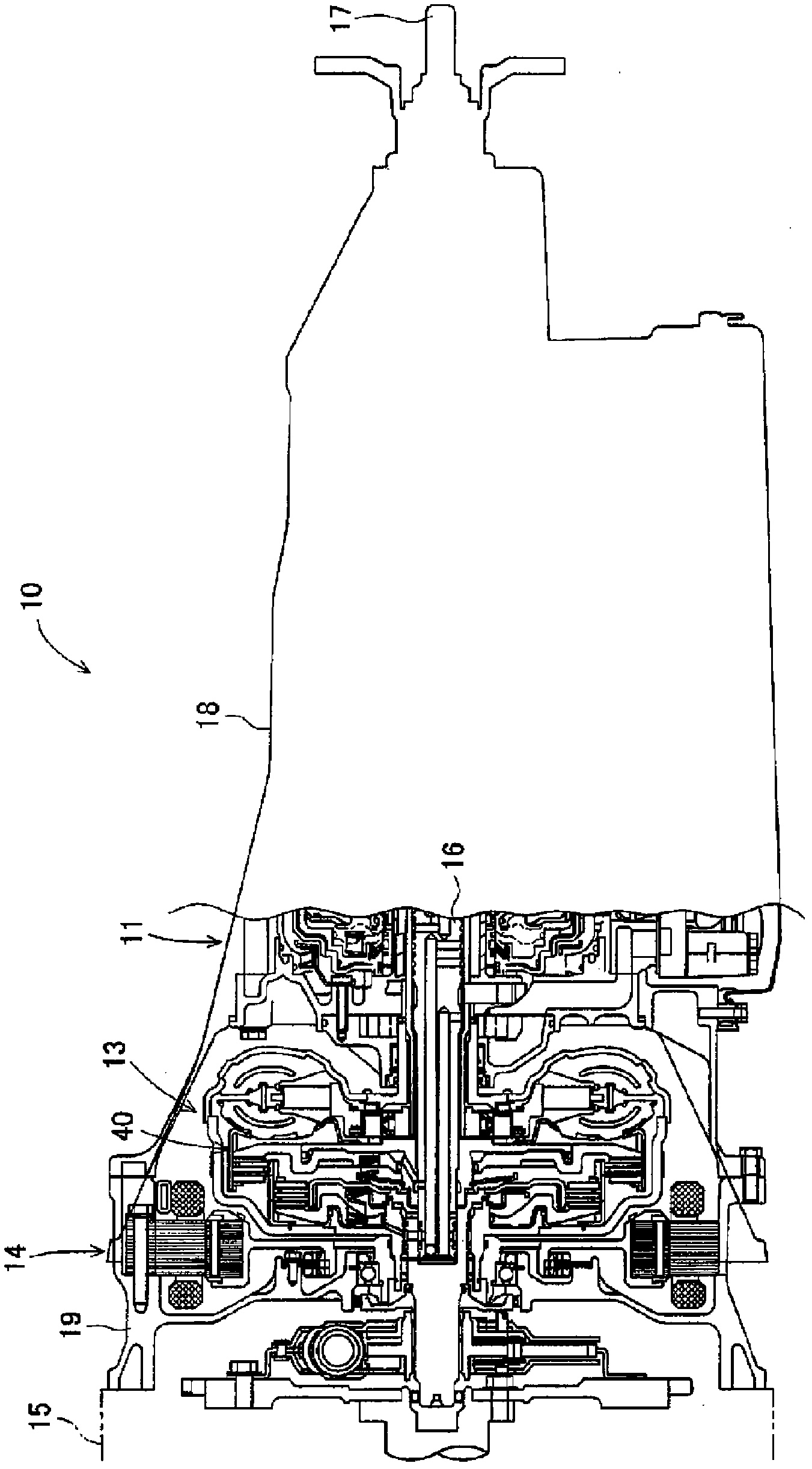

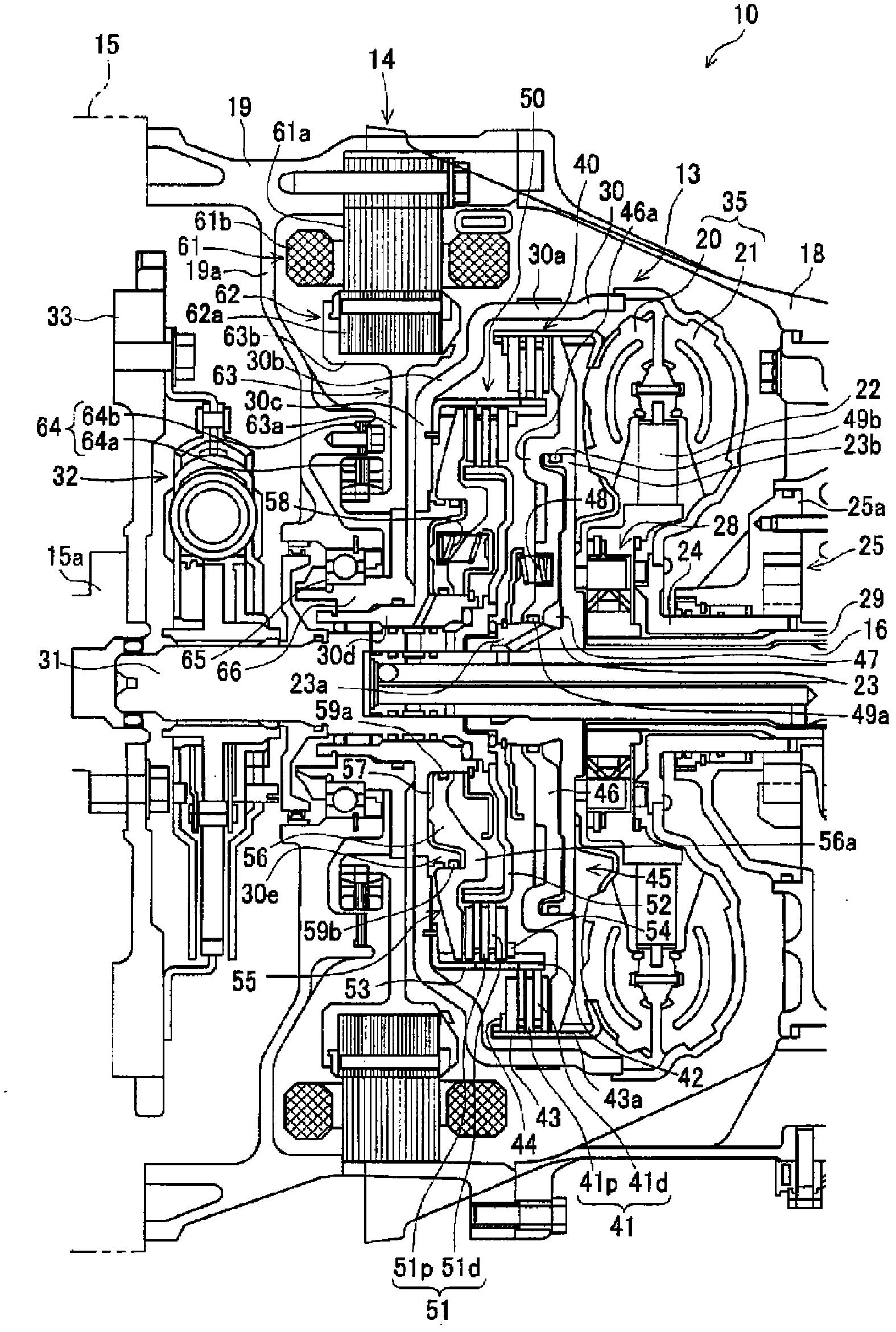

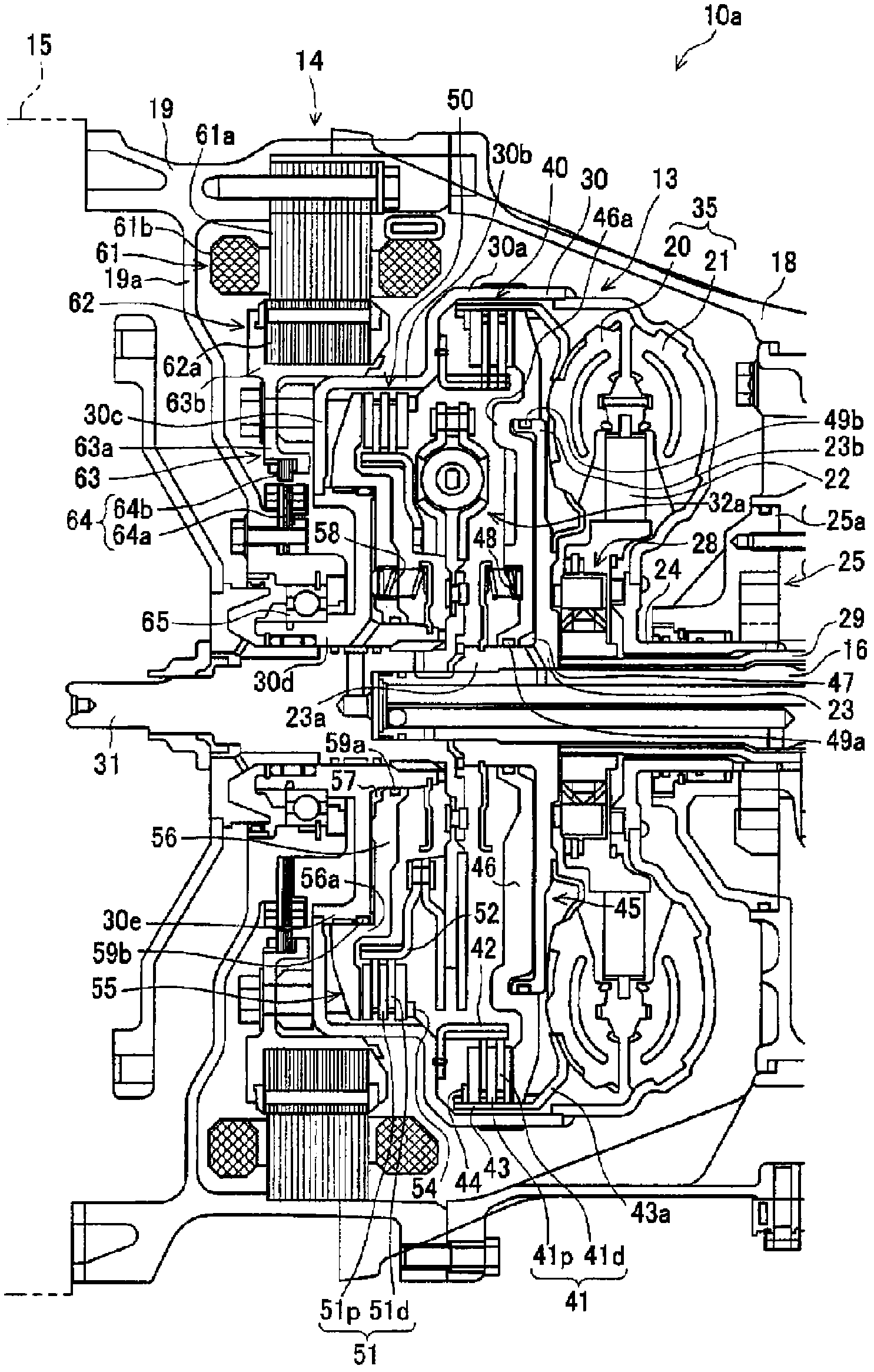

Vehicle drive device

InactiveCN102007012ASmall heat releaseImprove controllabilityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingTorque transmissionEngineering

A drive device for a vehicle, having an engine power disengaging clutch mounted in a lockup clutch-equipped fluid power transmitting device, wherein controllability and torque transmission capacities of both the clutches are increased, the amount of heat generation of friction materials when the clutches are engaged is reduced, the drive device allows a fluid drive device to be configured withoutan increase in the size thereof, and the drive device is configured without an increase in the size thereof. The lockup clutch and the engine power disengaging clutch are respectively formed as multi-plate clutches having actuators. Friction plates of the lockup clutch are provided on the outer diameter side of a torus. The engine power disengaging clutch is formed to have a smaller diameter thanthe lockup clutch. The engine power disengaging clutch is provided in a torque converter. On the outer diameter side of the engine power disengaging clutch, a motor generator is mounted overlapping axially the friction plates of the engine power disengaging clutch.

Owner:AISIN AW CO LTD

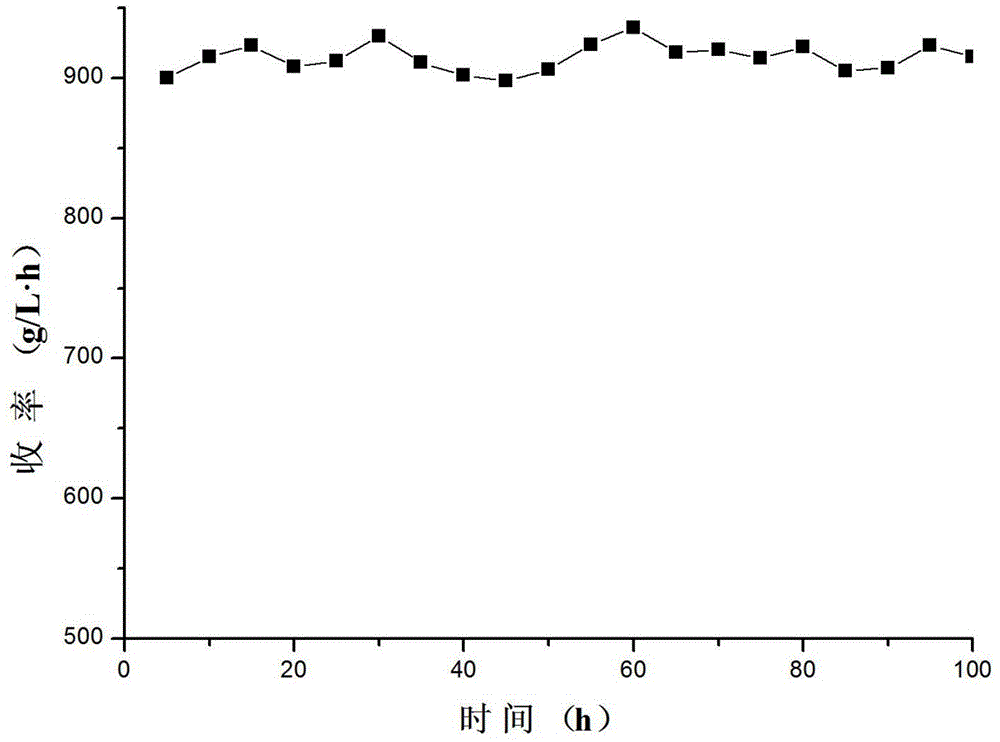

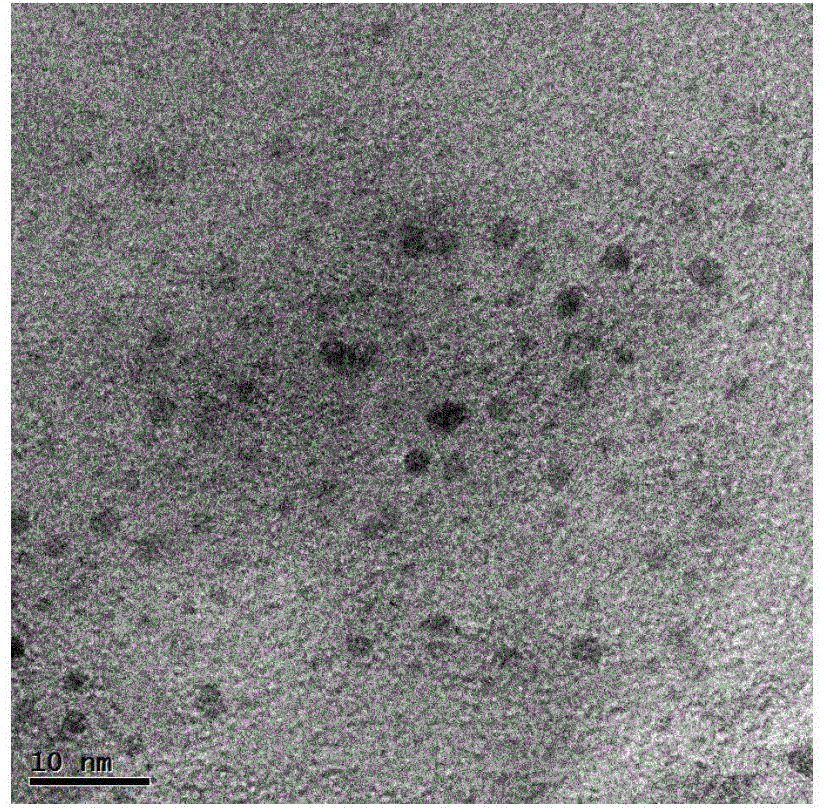

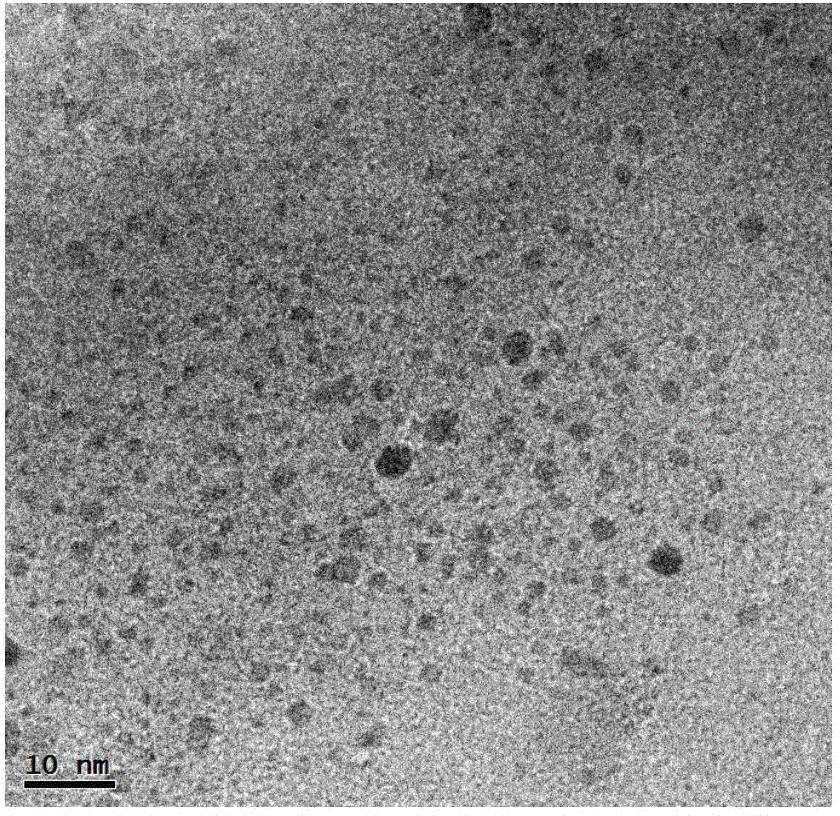

Catalyst for synthesizing dimethyl oxalate from CO and ultrasonic dispersion preparation method of catalyst

InactiveCN104148088AGuaranteed stabilityIncrease profitCatalyst activation/preparationPreparation by carbon monoxide or formate reactionActive componentUltrasonic dispersion

The invention discloses a catalyst for synthesizing dimethyl oxalate from CO and an ultrasonic dispersion preparation method of the catalyst. A chemical general formula of the catalyst provided by the invention is Pd-M / Al2O3, wherein the mass percent of palladium serving as an active component is 0.1 to 1%, M is one of Fe, Cu or Zn, and the specific surface area of the catalyst is 1 to 10 m<2> / g; an adopted carrier is a-type spherical aluminum oxide with the particle diameter of 1 to 5 mm; the dispersion degree of the active component of the catalyst is 20 to 27%. The preparation method of the catalyst provided by the invention has the characteristic that the catalyst is prepared by soaking in an ultrasonic condition; according to the catalyst prepared by using the method, the dispersion degree of precious metal as the active component is obviously changed, and the precious metal in the catalyst is low in using amount; in the process of synthesizing dimethyl oxalate, at low bed temperature, the stability of the active component of the catalyst is guaranteed, in addition, the high catalytic activity and the space-time yield of dimethyl oxalate are guaranteed, and the utilization ratio of the precious metal is increased.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

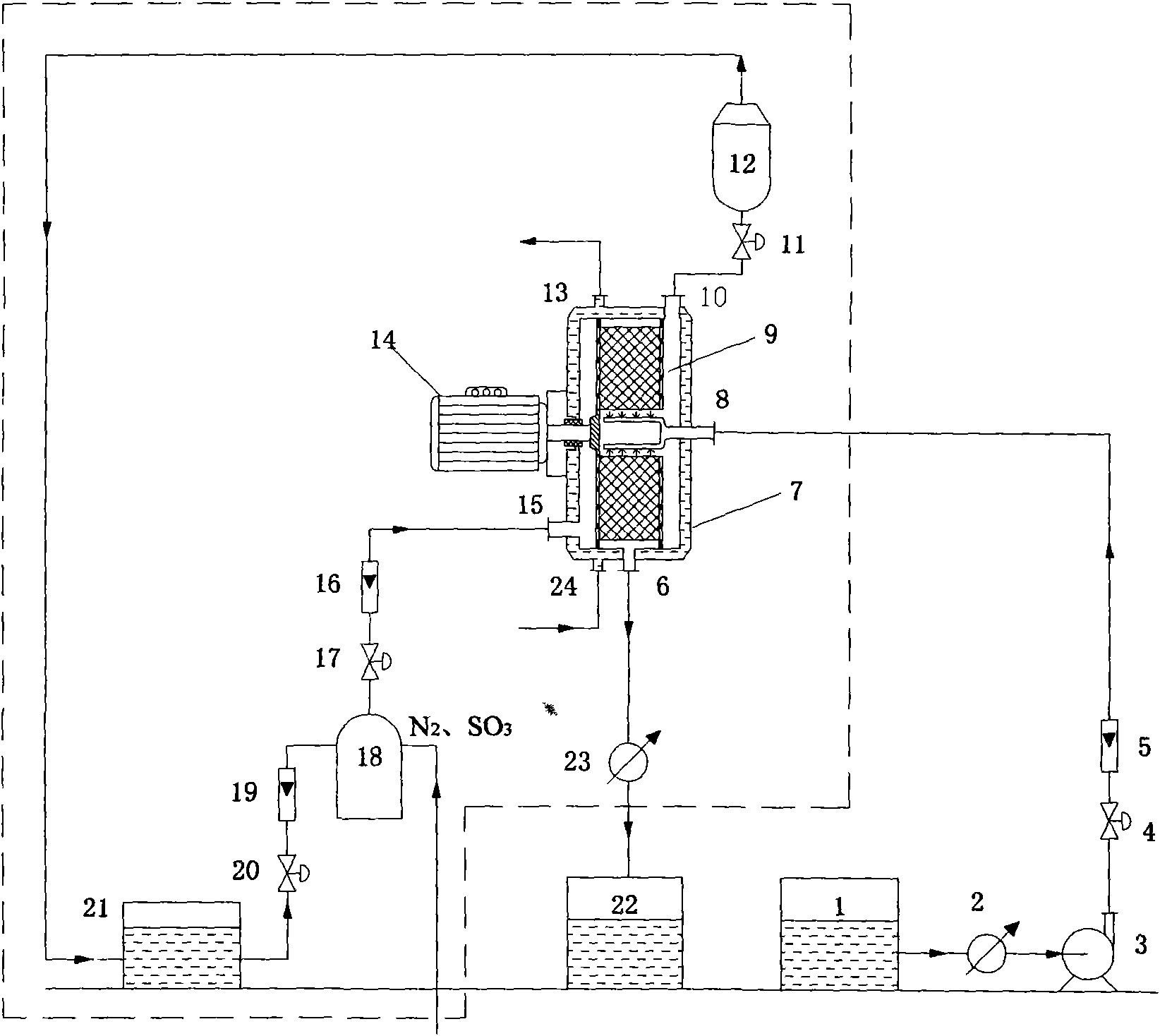

Method and equipment for preparing aromatic sulfonic acid by gas-phase sulphonation of aromatic organic compound

ActiveCN101570500AImprove mass transfer efficiencyQuick contact mixChemical industrySulfonic acid preparationLiquid productSimple Organic Compounds

The invention relates to a method and equipment for preparing aromatic sulfonic acid by the gas-phase sulfuric anhydride sulphonation of aromatic organic compounds with a rotating packed bed. The method solves the problems of the existing method in which the aromatic sulfonic acid is prepared by the sulphonation of aromatic organic compounds using sulfuric anhydride gas as sulphonating agent. The method is as follows: the aromatic organic compounds and the mixed sulfuric anhydride gas enter the started rotating packed bed and come into contact to produce partial sulphonation reaction; the liquid product after reaction enters a tubular heat exchanger and the reaction proceeds; and the aromatic sulfonic acid is obtained. The equipment comprises the rotating packed bed; the liquid inlet of the rotating packed bed is connected with a raw material storage tank; the gas inlet of the rotating packed bed is connected with the mixed sulfuric anhydride gas source; and the liquid outlet of the rotating packed bed is connected with a product storage tank through the tubular heat exchanger. The invention has the advantages of easy control of reaction temperature, reduction of the possibility of subsidiary reaction, enhancement of reactive selectivity, avoidance of environmental pollution, energy saving, small equipment volume, light weight, convenient installation and maintenance, and convenient starting and shutdown.

Owner:ZHONGBEI UNIV

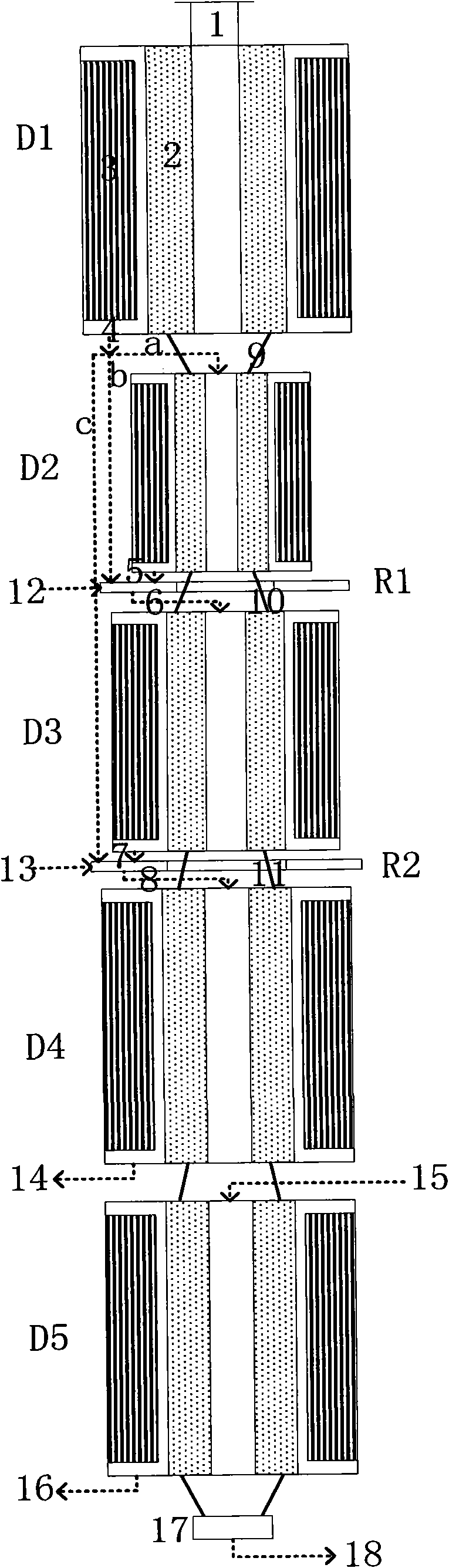

Method for synthesizing glycol by hydrogenation of dimethyl oxalate

ActiveCN102211978AInactivation rate avoidanceImprove heat resistanceOrganic compound preparationHydroxy compound preparationChemistryDimethyl oxalate

The invention relates to a method for synthesizing glycol by hydrogenation of dimethyl oxalate. The method comprises the following steps: I) based on dimethyl oxalate and hydrogen serving as raw materials, firstly, enabling a methanol solution of dimethyl oxalate serving as a first strand of liquid phase raw material and a first strand of hydrogen to enter into a first reactor so as to generate a first strand of reaction products in which methyl glycolate is used as a main product; and II) enabling the first strand of reaction products and a second strand of hydrogen to enter into a second reactor so as to generate a second strand of reaction products in which glycol is a main product. The stability of a catalyst can be improved by using the method.

Owner:PUJING CHEM IND SHA +1

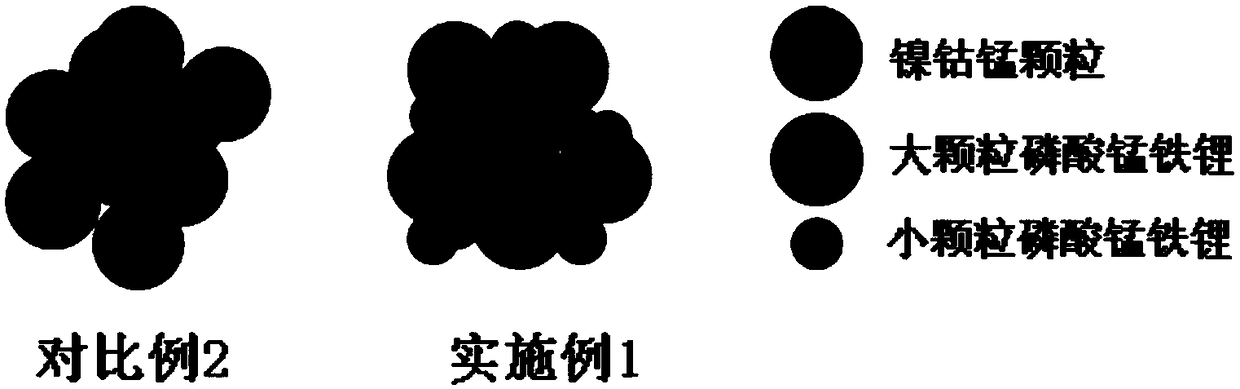

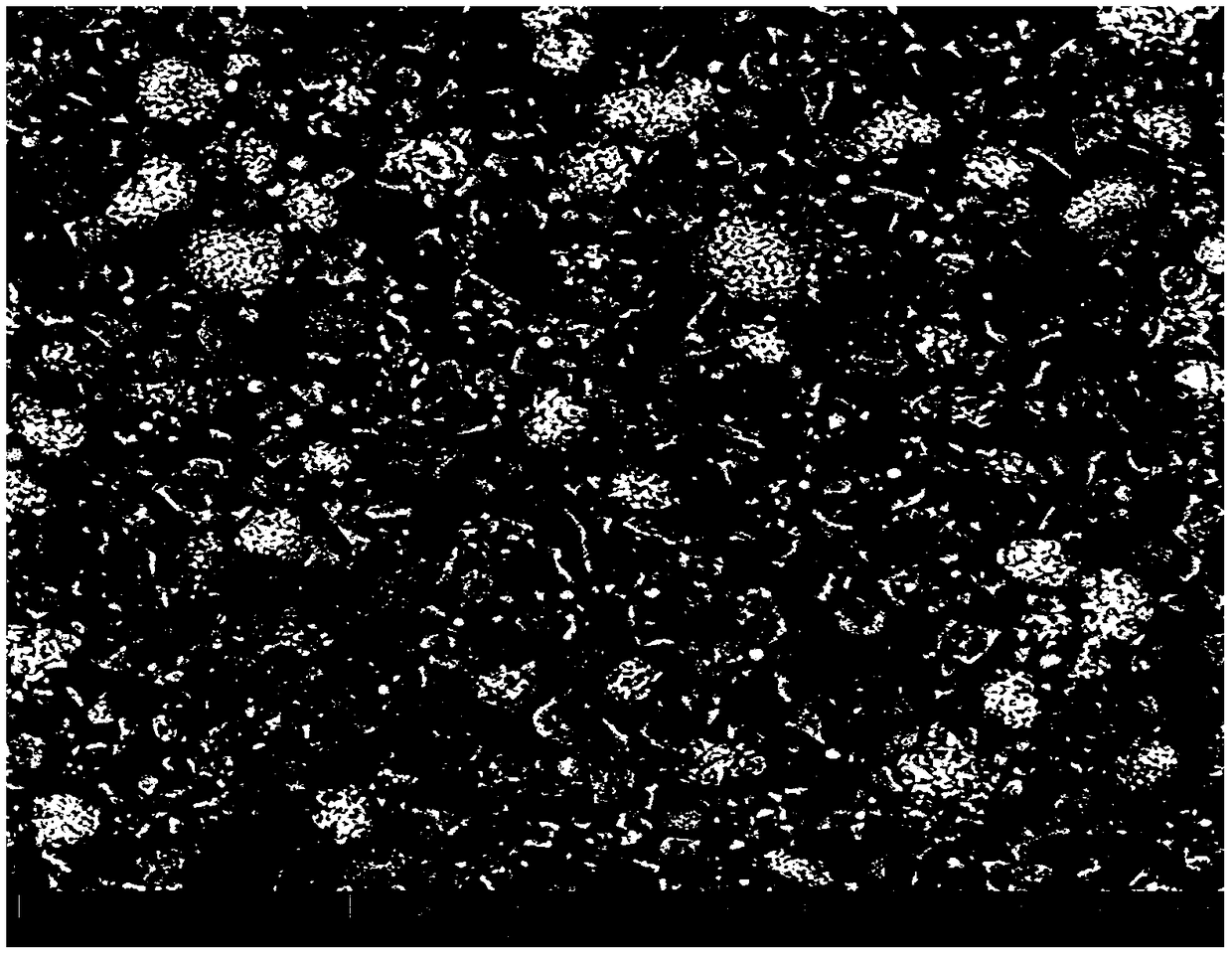

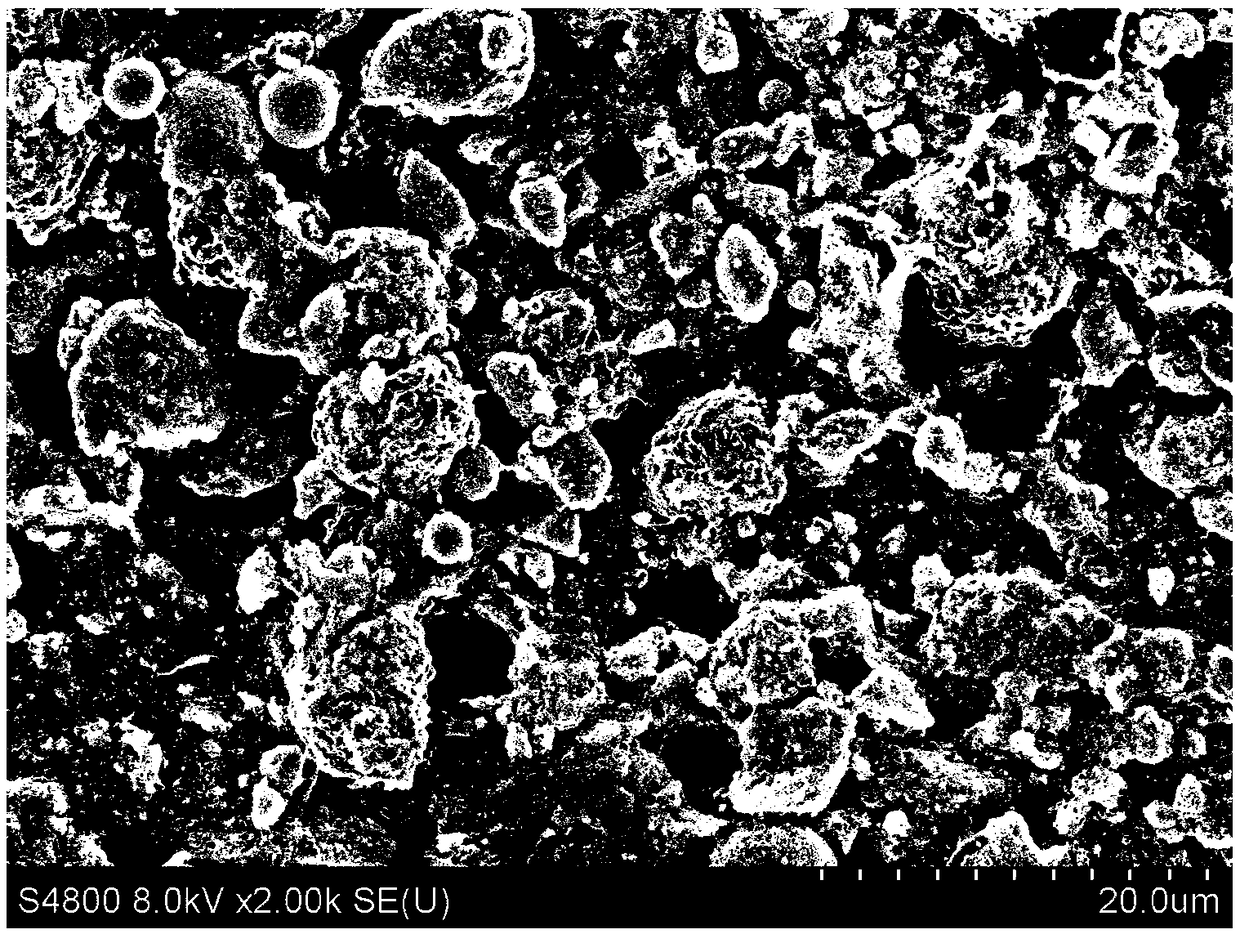

Positive material, positive plate and lithium ion battery

InactiveCN108777298ASmall heat releaseImprove securityCell electrodesSecondary cellsManganateIron phosphate

The invention provides a positive material, which is prepared from lithium manganese iron phosphate and a ternary material, wherein lithium manganese iron phosphate is LiMnzFe1-zPO4, and wherein z ismore than or equal to 0.6 and less than or equal to 0.9; the ternary material is lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate; the D50 of lithium manganese iron phosphate is3.6-6.5mu m; the D50 of lithium nickel cobalt manganate is 8.5-11.0mu m; the D50 of lithium nickel cobalt aluminate is 10.0-14.0mu m; the D50 of the ternary material is 1.5-2.5 times that of lithium manganese iron phosphate. The ternary material is surrounded by the lithium manganese iron phosphate material, so that the heat release amount of the positive material is reduced, the ignition point ofthe positive material is increased, and the safety performance of a battery can be improved; furthermore, the cycle performance of the battery is improved. The invention also provides a positive plate and a lithium ion battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com