High-strength high-mobility epoxy resin grouting material and preparation method thereof

A technology of epoxy resin grouting and high fluidity, applied in the field of epoxy resin materials, can solve the problems of slowing down curing speed, slowing down heat release, inability to meet, etc., to reduce curing heat release, realize self-leveling, and easy construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

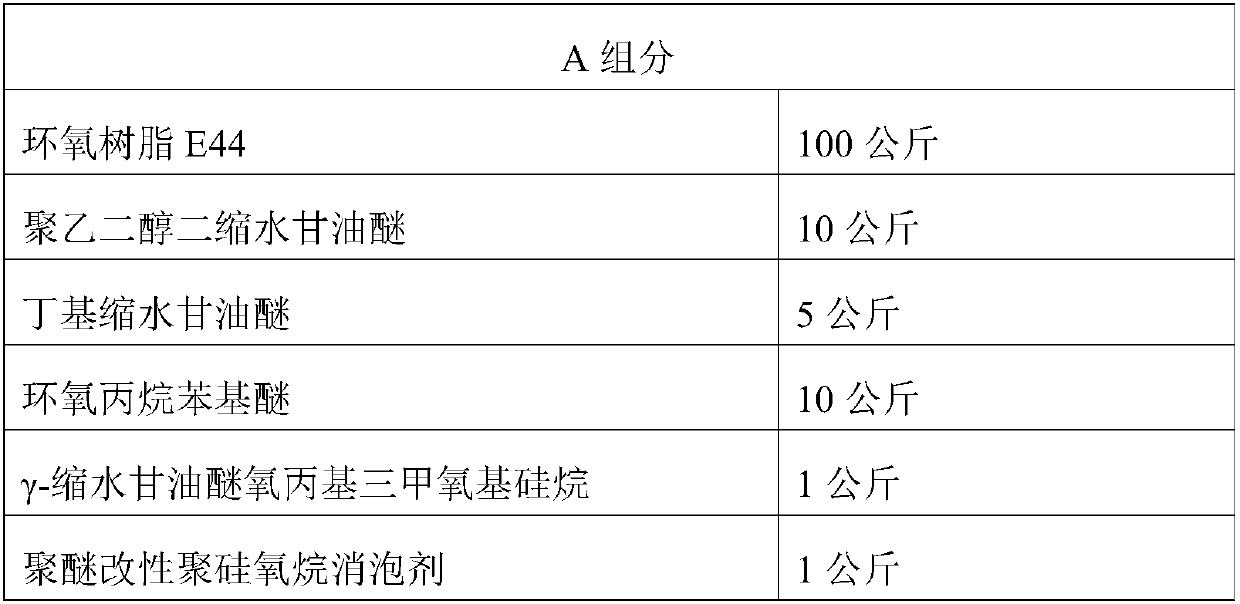

[0041] The high-strength and high-fluidity epoxy resin grouting material of the present embodiment is composed as follows:

[0042] Table 1

[0043]

[0044]

[0045] The mass ratio of component A, component B and component C is 127:38:801.2, that is, 1:0.3:6.3.

[0046] The preparation method is as follows:

[0047] Take each component A and mix to obtain component A;

[0048] Take the B components and mix them to obtain the B components;

[0049] Take the C components and mix them to obtain the C components.

[0050] During on-site construction, first mix components A and B evenly, and then add component C to complete the grouting construction. After construction, no maintenance is required. 20°C, 3-day compressive strength is 70MPa, see Table 4 below for specific properties (refer to the "Cement Mortar Strength Test" GB / T17671-1999 standard for testing).

Embodiment 2

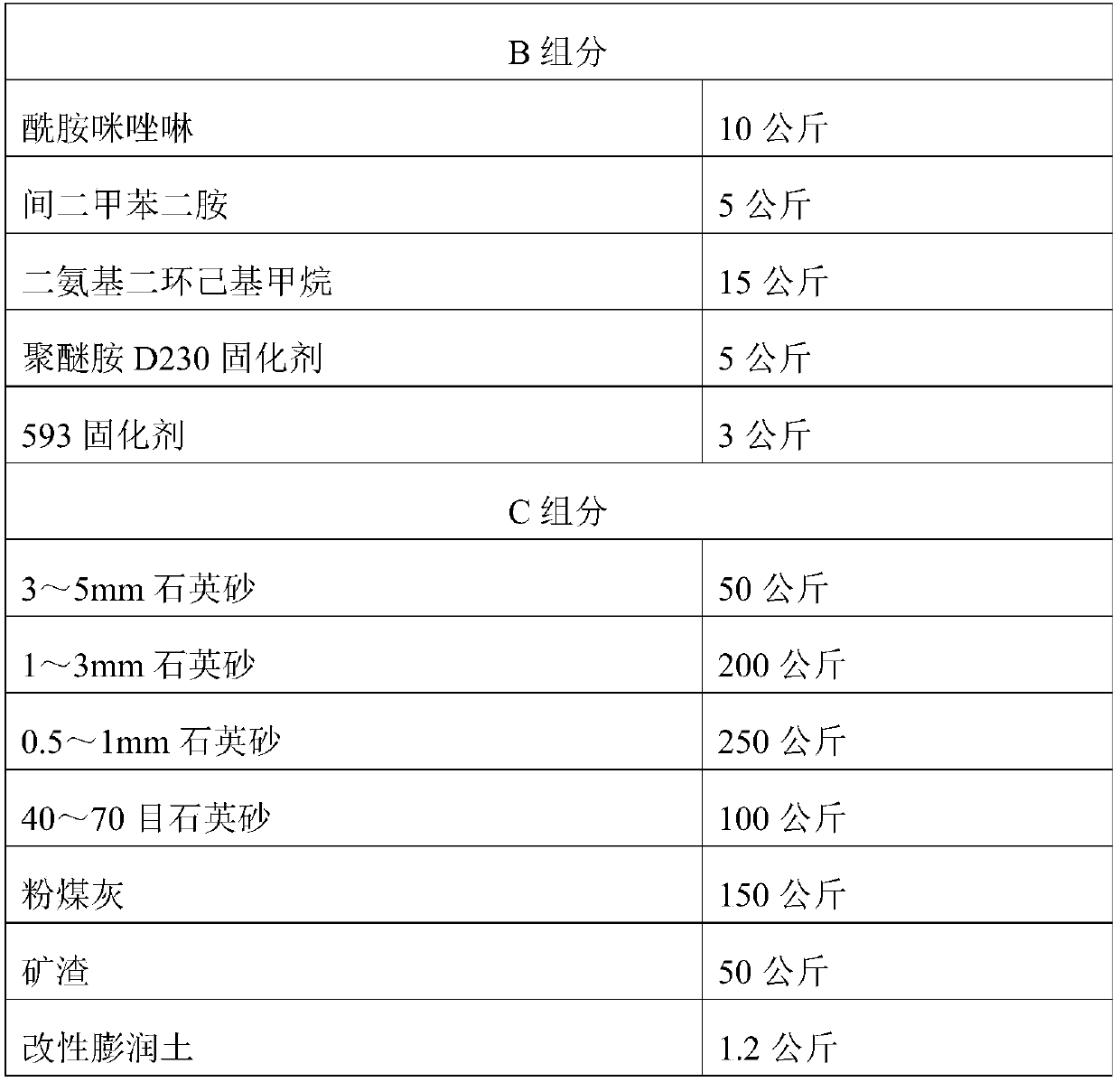

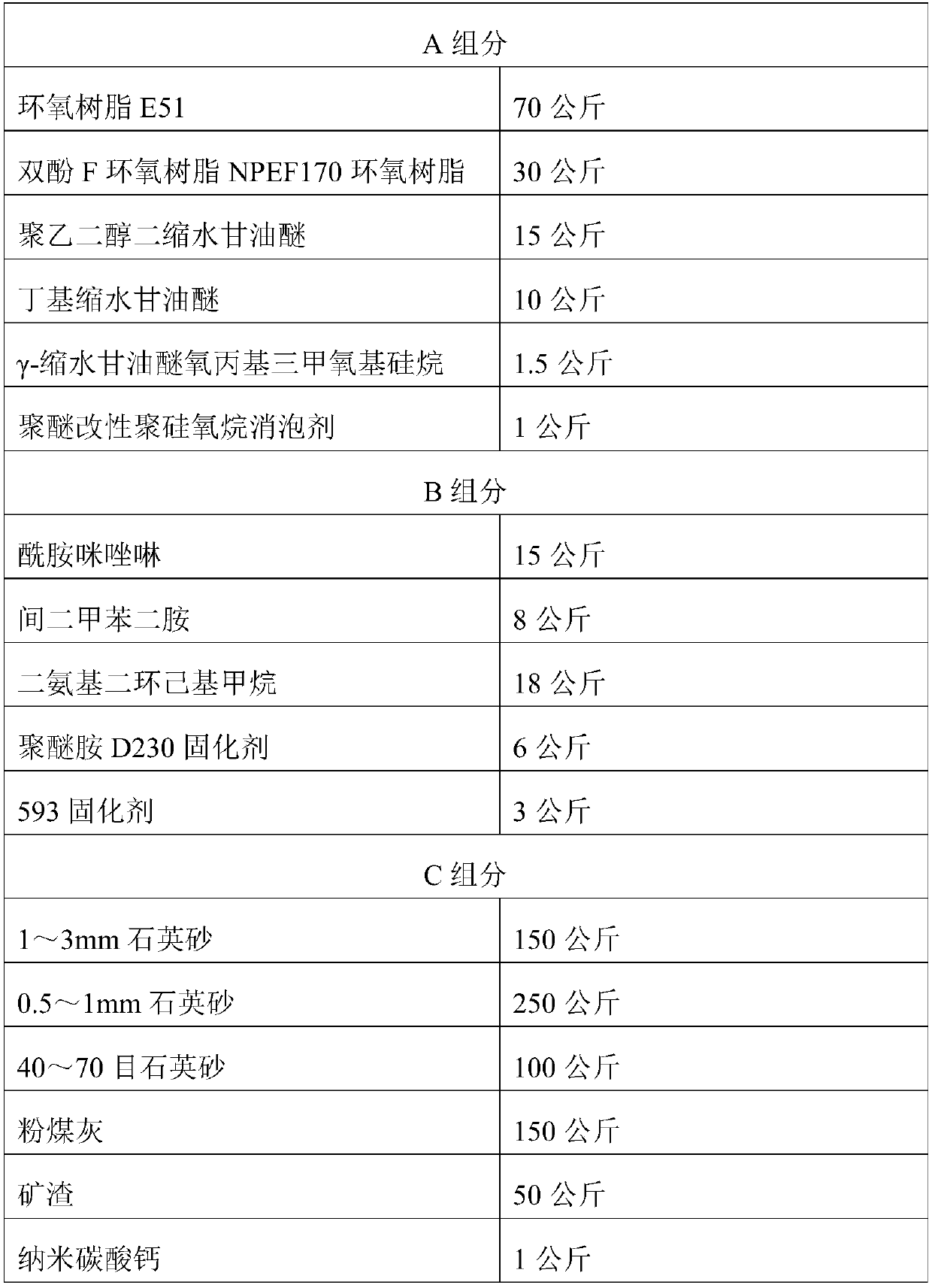

[0052] The high-strength and high-fluidity epoxy resin grouting material of the present embodiment is composed as follows:

[0053] Table 2

[0054]

[0055] The mass ratio of component A, component B and component C is 127.5:50:701, that is, 1:0.4:5.5. The preparation and construction methods are the same as in Example 1.

Embodiment 3

[0057] A and B components are the same as in Example 1.

[0058] The high-strength and high-fluidity epoxy resin grouting material of the present embodiment is composed as follows:

[0059] table 3

[0060]

[0061] The mass ratio of component A, component B and component C is 127:38:451, that is, 1:0.3:3.6. The preparation and construction methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com