Antiflaming plywood or veneer lamination and manufacturing method thereof

A technology of laminated veneer lumber and a manufacturing method, which is applied in the directions of manufacturing tools, joining of wooden veneers, impregnating wood, etc., and can solve the problems of high carbonization speed, increased concentration, and increased smoke hazard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

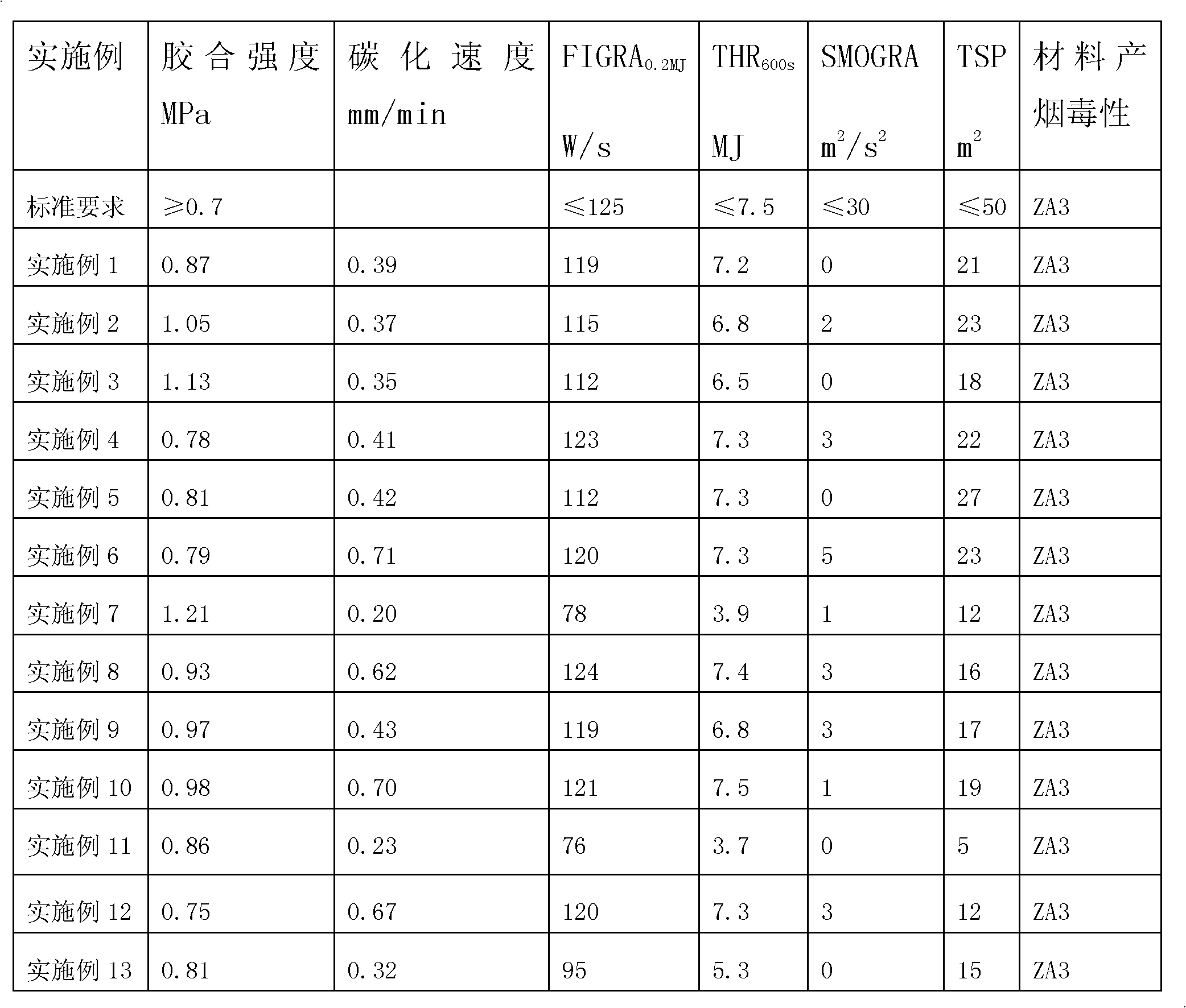

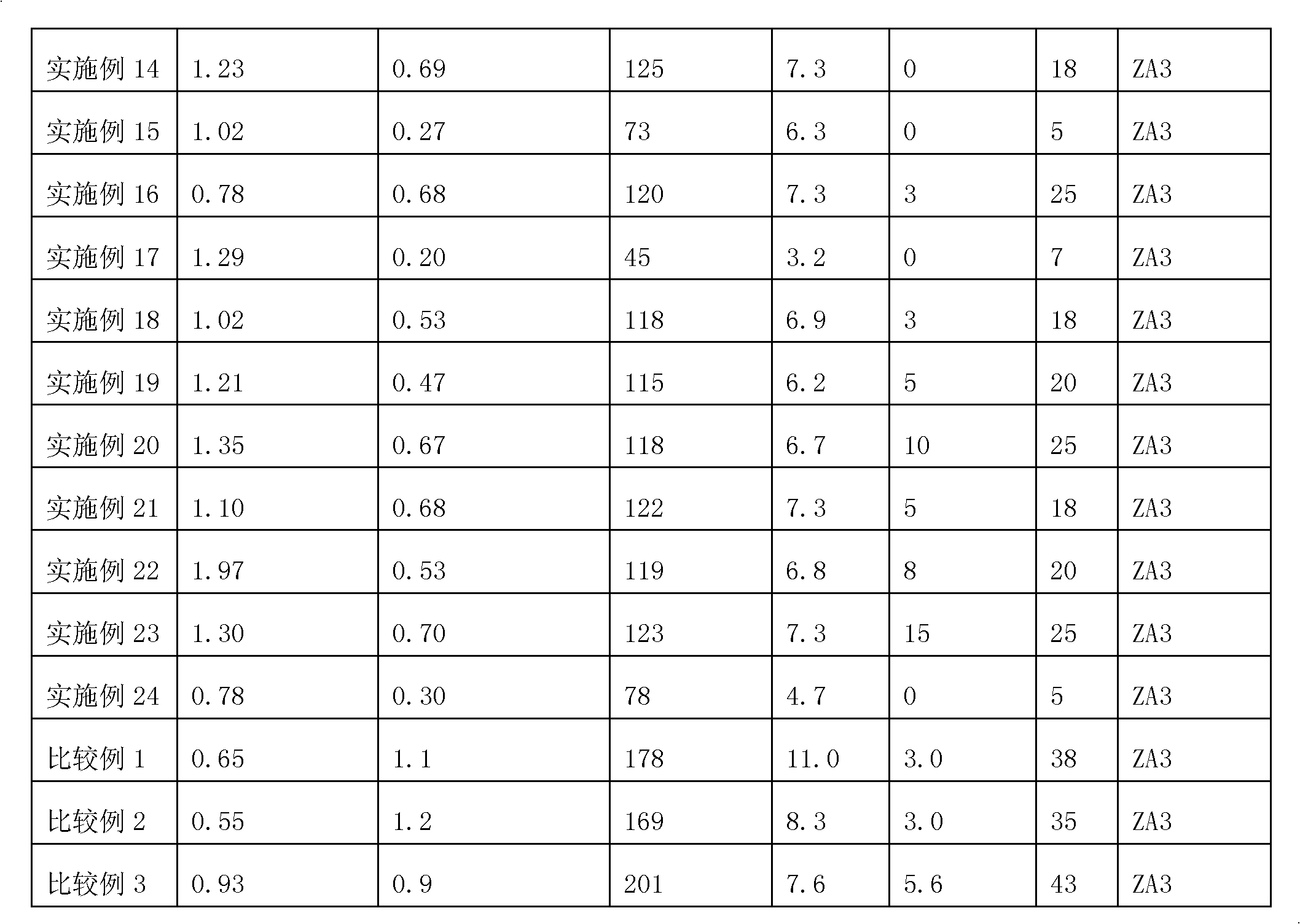

Examples

Embodiment 1

[0067] A method for manufacturing flame-retardant plywood or laminated veneer lumber, comprising the steps of:

[0068] 1) Add 15 parts of ammonium polyphosphate, 5 parts of ammonium dihydrogen phosphate, and 5 parts of boric acid into 75 parts of water, heat the mixed solution to 45°C-95°C, stir to dissolve, and obtain a flame retardant mixture; The poplar veneer of mm is immersed in the above solution for 20 minutes, taken out, and naturally air-dried to a moisture content of 20wt% to 35wt%;

[0069] 2) Add 10 parts of aluminum sulfate and 4 parts of zinc sulfate to 86 parts of water, stir to dissolve, soak the veneer obtained in step 1 in the solution for 15 minutes, take it out, and let it dry naturally until the water content is 20wt%-50wt%; Then add 10 parts of ammonia water and 0.5 parts of γ-diethylenetriaminopropyltriethoxysilane to 89.5 parts of water, stir and mix well, soak the air-dried veneer in the solution for 35 minutes, take it out, and let it dry naturally u...

Embodiment 2

[0074] A method for manufacturing flame-retardant plywood or laminated veneer lumber, comprising the steps of:

[0075] 1) Add 15 parts of melamine pyrophosphate, 5 parts of ammonium dihydrogen phosphate, and 5 parts of boric acid into 75 parts of water, heat the mixed solution to 45°C-95°C, stir to dissolve, and obtain a transparent liquid, which is the flame retardant mixture solution; soak a poplar veneer with a thickness of 1.7mm in the above solution for 20 minutes, take it out, and let it dry naturally until the water content is 20wt% to 35wt%;

[0076] 2) Add 10 parts of aluminum sulfate and 4 parts of zinc sulfate to 86 parts of water, stir to dissolve, soak the veneer obtained in step 1 in the solution for 15 minutes, take it out, and let it dry naturally until the water content is 20wt%-50wt%; Then add 13 parts of sodium hydroxide and 2 parts of sodium methyl silicate with a content of 40% to 85 parts of water, stir and mix well, soak the air-dried veneer in the solu...

Embodiment 3

[0081] A method for manufacturing flame-retardant plywood or laminated veneer lumber, comprising the steps of:

[0082] 1) Add 18 parts of sodium silicate to 80 parts of water, stir to dissolve, add 2 parts of sodium methyl silicate with a content of 40%, stir to mix, put 3.5mm thick eucalyptus veneer in the solution Soak for 35 minutes, take it out, and let it dry naturally until the moisture content is 20wt%-50wt%; then add 12 parts of zinc sulfate and 3 parts of magnesium chloride to 85 parts of water, stir to dissolve, soak the veneer after drying in it for 45 minutes, take it out , and naturally dry until the moisture content is 20wt% to 50wt%;

[0083] 2) Add 15 parts of ammonium polyphosphate, 5 parts of guanidine phosphate, and 5 parts of borax to 74.5 parts of water, heat to 45°C-95°C, stir to dissolve to obtain a flame retardant mixture, and then add 0.5 parts of vinyl tri Ethoxysilane, stirring and mixing; soak the veneer treated in step 1 in the above solution for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com