Waterproof protection material for surface layer of prefabricated outer wall and manufacturing method of waterproof protection material

A technology for protecting materials and manufacturing methods, which is applied in the field of building materials, can solve the problems of reducing the reliability of protective layers, shortening the service life of concrete, and unreliable painting processes, etc., to achieve waterproof and stain-resistant performance, reduce carbonization speed, and improve surface quality. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

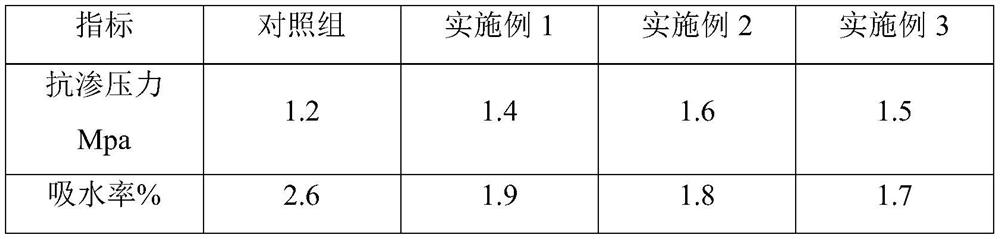

Embodiment 1

[0038] An assembled prefabricated exterior wall surface layer waterproof protection material, comprising the following components in parts by weight: 200 parts of cement, 15 parts of silica fume, 80 parts of mineral powder, 800 parts of machine-made sand, and 15 parts of additives.

[0039] The cement is white, and the model is 52.5; the silica fume and mineral powder are both Class I products.

[0040] The machine-made sand is continuously graded and dry sand, and the density of the machine-made sand is 1-6g / cm 3 .

[0041] The machine-made sand includes two specifications of components, and the density of one machine-made sand is 1g / cm 3 , another machine-made sand with a density of 6g / cm 3 .

[0042] The manufacturing method of the above-mentioned assembled prefabricated outer wall surface layer waterproof protection material comprises the following steps:

[0043] 101. Automatically measure ingredients for each component to ensure the accuracy of the weight of each com...

Embodiment 2

[0056] An assembled prefabricated exterior wall surface layer waterproof protection material, comprising the following components in parts by weight: 250 parts of cement, 20 parts of silica fume, 65 parts of mineral powder, 650 parts of machine-made sand, and 25 parts of additives.

[0057] The cement is white, and the model is 52.5; the silica fume and mineral powder are both Class I products.

[0058] The machine-made sand is continuously graded and dry sand, and the density of the machine-made sand is 1-6g / cm 3 .

[0059] The machine-made sand includes two specifications of components, and the density of one machine-made sand is 2g / cm 3 , another machine-made sand with a density of 4g / cm 3 .

[0060] The manufacturing method of the above-mentioned assembled prefabricated outer wall surface layer waterproof protection material comprises the following steps:

[0061] 101. Automatically measure ingredients for each component to ensure the accuracy of the weight of each com...

Embodiment 3

[0074] An assembled prefabricated exterior wall surface layer waterproof protection material, comprising the following components in parts by weight: 300 parts of cement, 30 parts of silica fume, 50 parts of mineral powder, 500 parts of machine-made sand, and 35 parts of additives.

[0075] The cement is white, and the model is 52.5; the silica fume and mineral powder are both Class I products.

[0076] The machine-made sand is continuously graded and dry sand, and the density of the machine-made sand is 1-6g / cm 3 .

[0077] The machine-made sand includes two specifications of components, and the density of one machine-made sand is 3g / cm 3 , another machine-made sand with a density of 4g / cm 3 .

[0078] The manufacturing method of the above-mentioned assembled prefabricated outer wall surface layer waterproof protection material comprises the following steps:

[0079] 101. Automatically measure ingredients for each component to ensure the accuracy of the weight of each com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com