High-volume low carbon cement doped with large amount of industrial waste residue and preparation method thereof

A technology of industrial waste and large dosage, applied in the direction of cement production, etc., can solve the problems that the mixed materials cannot be fully stimulated, it is difficult to meet the strength requirements of cement, it is difficult to reduce energy consumption and low carbon emissions, and it can promote the development of later strength and excellent Mechanical properties and anti-corrosion properties, the effect of reducing energy consumption and carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

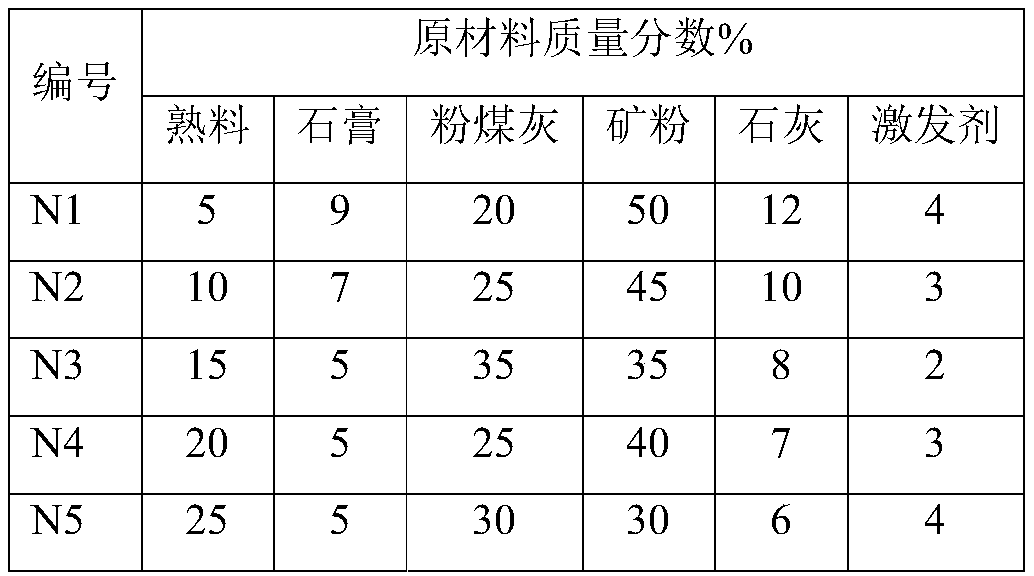

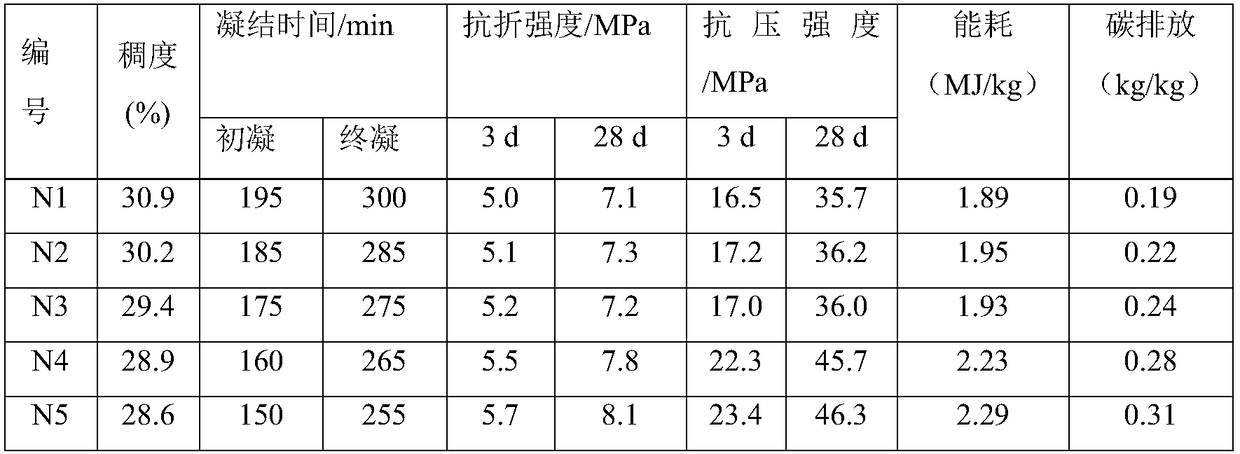

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the present invention, the present invention will be fully described below using examples. However, the present invention can be implemented in many different forms and is not limited to the embodiments described herein. The purpose of providing these implementation cases is to make others understand more thoroughly and comprehensively the disclosure content of the present invention.

[0023] The cement clinker used in this example comes from Nanjing Onoda Cement Company, which meets the requirements of GB / T21372-2008, and its particle size needs to be ground to 350-500m by a ball mill 2 / kg, and the 3d compressive strength of Portland cement clinker should be greater than or equal to 30MPa, and the 28d compressive strength of Portland cement clinker should be greater than or equal to 52.5MPa.

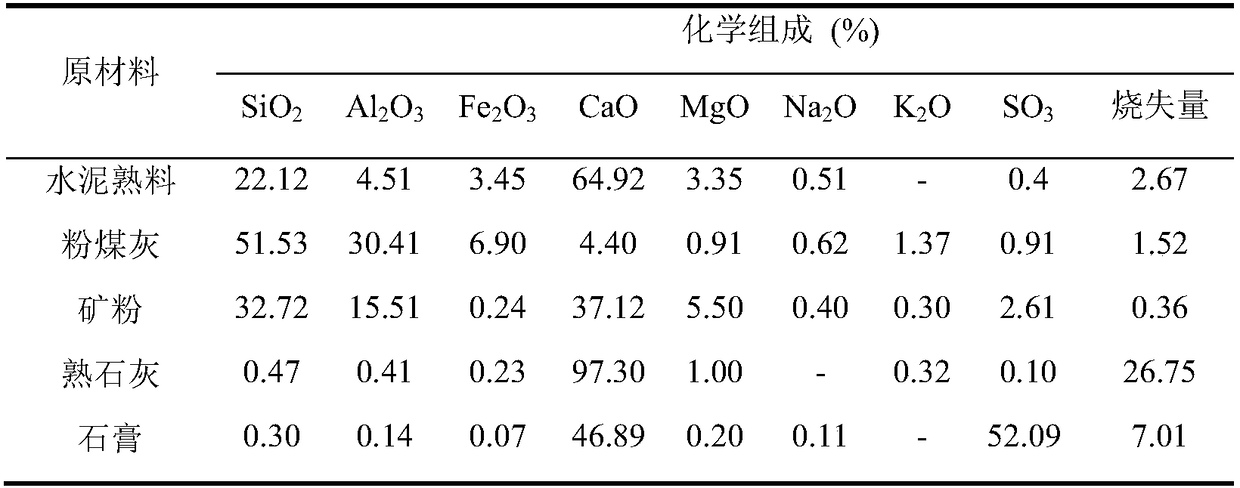

[0024] The fly ash used in this example comes from a thermal power plant in Nanjing, which meets the requirements of grade II and ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com