Organic matter and ammonia borane compounded hydrogen storage material and preparation method thereof

A technology for composite ammonia borane and hydrogen storage materials, which is applied in the field of organic composite ammonia borane hydrogen storage materials and its preparation, can solve the problems of lack of mature systems and achieve lower thermal release hydrogen temperature, fast hydrogen release kinetics, and release The effect of low heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of the composite ammonia borane hydrogen storage material whose organic matter is phthalic anhydride, taking the preparation of PAAB20 sample as an example:

[0023] Experimental procedure: Add phthalic anhydride (PA) to purified acetonitrile at room temperature, AB is dissolved in a mixed solvent of acetonitrile and methanol (volume ratio is 5:2), and the molar ratio of PA to AB is 1:2 Join AB. Stir slowly at room temperature to a homogeneous solution, then vacuum-dry at 50°C for 12 hours to obtain a new type of organic compound ammonia borane hydrogen storage material, and the sample is labeled PAAB20.

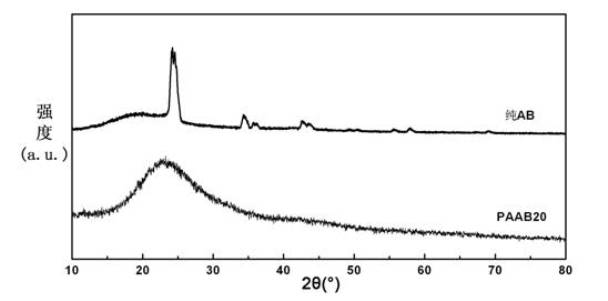

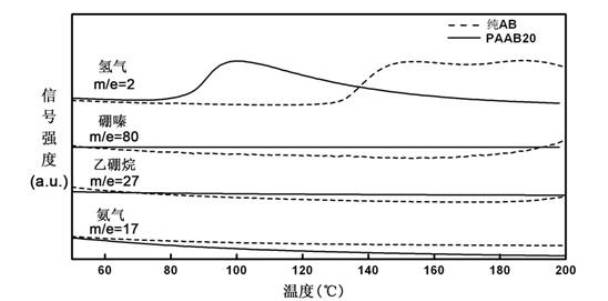

[0024] The XRD spectrum of PAAB20 prepared according to the above-mentioned method is as follows figure 1 shown and compared with pure AB. It can be seen from the spectrum that pure AB has obvious crystal diffraction peaks, while the new organic (phthalic anhydride) composite ammonia borane hydrogen storage material PAAB20 sample formed after adding ...

Embodiment 2

[0028] The organic matter is the preparation of composite ammonia borane hydrogen storage material of polyethylene oxide, taking the preparation of PAB15 as an example:

[0029] Experimental procedure: Add polyethylene oxide (PEO) to purified acetonitrile, AB is dissolved in a mixed solvent of acetonitrile and methanol (volume ratio is 5:3), and the molar ratio of PEO to AB is 1:1.5 Join AB. Stir slowly at room temperature to a homogeneous solution, and then vacuum-dry at 25°C for 20 hours to obtain a new type of organic compound ammonia borane hydrogen storage material, and the sample is labeled PAB15.

[0030] Figure 4 Infrared (FITR) curve of the new organic compound ammonia borane hydrogen storage material PAB15 prepared according to the above method, and compared with pure AB. The results show that: compared with pure AB, the N-H and B-H stretching vibrations of the prepared PAB15 have shifted to different degrees, which indicates that the two may have certain effects. ...

Embodiment 3

[0032] The preparation of the composite ammonia borane hydrogen storage material whose organic substance is glucose, taking the preparation of GAB10 as an example:

[0033] Experimental procedure: Add glucose (Glucose) to purified acetonitrile, dissolve AB in a mixed solvent of acetonitrile and methanol (volume ratio 5:1), and add AB at a ratio of 1:1 molar ratio of glucose to AB. Stir slowly at room temperature to a homogeneous solution, and then vacuum-dry at 60°C for 18 hours to obtain a new type of organic compound ammonia borane hydrogen storage material, and the sample is marked as GAB10.

[0034] Figure 6 It is the temperature-programmed desorption-mass spectrometry (TPD-MS) curve of the new organic compound ammonia borane hydrogen storage material GAB10 prepared according to the above method. The results show that: the initial dehydrogenation temperature of the GAB10 sample is 58°C, the dehydrogenation reaction proceeds in one step, and the peak temperature is 74°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com