Metal manganese oxide-loaded ammonia borane hydrogen storage material, and preparation method thereof

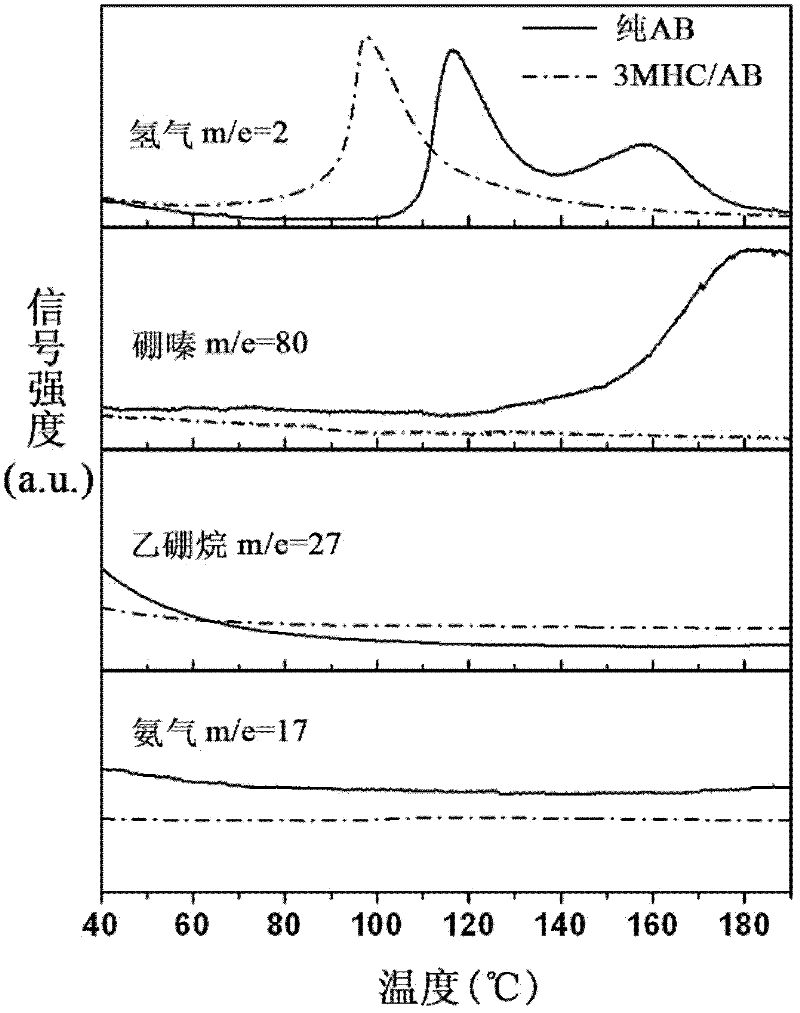

A technology of hydrogen storage materials and oxides, applied in the direction of hydrogen production, etc., can solve the problems of lack of mature systems, and achieve the effects of lowering the temperature of thermally released hydrogen, fast hydrogen release kinetics, and small heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of the metal manganese oxide-loaded ammonia borane hydrogen storage material, comprising the following steps:

[0029] 1) ultrasonically disperse 60 mg of manganese dioxide hollow cube (MHC) in 1.5 mL of purified tetrahydrofuran solvent to obtain a metal manganese oxide tetrahydrofuran solution;

[0030] 2) 20 mg of ammonia borane was dissolved in 1 mL of tetrahydrofuran solvent after purification to prepare ammonia borane tetrahydrofuran solution;

[0031] 3) The above two solutions are mixed, the mass ratio of metal manganese oxide and ammonia borane in the mixed solution is 3:1, and the mixed solution is slowly stirred to a uniform mixed solution at a temperature of 20° C.;

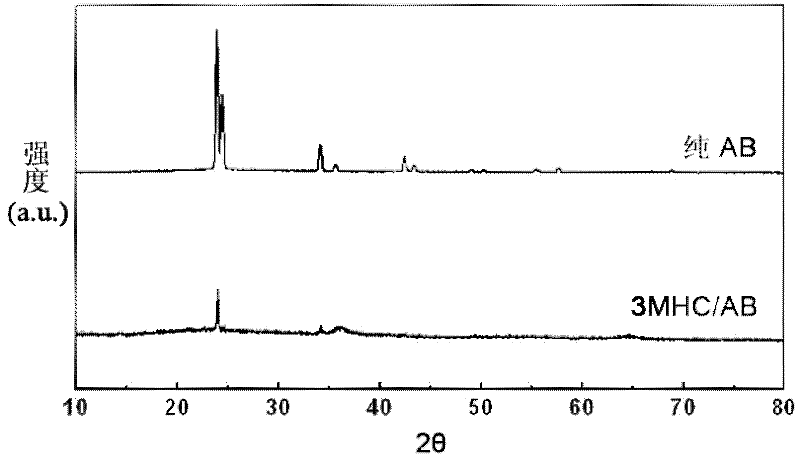

[0032] 4) After vacuum-drying the above-mentioned homogeneous mixed solution at a vacuum degree of 0.05 MPa and a temperature of 20°C to remove the solvent, the metal manganese oxide-loaded ammonia borane hydrogen storage material can be prepared, and the sample is marked as...

Embodiment 2

[0039] A preparation method of the metal manganese oxide-loaded ammonia borane hydrogen storage material, comprising the following steps:

[0040] 1) ultrasonically disperse 60 mg of manganese dioxide hollow spheres (MHS) in 1.5 mL of purified tetrahydrofuran solvent to obtain a metal manganese oxide tetrahydrofuran solution;

[0041] 2) Dissolving 20 mg of ammonia borane in 1 mL of purified tetrahydrofuran solvent to prepare ammonia borane tetrahydrofuran solution;

[0042] 3) The above two solutions are mixed, the mass ratio of metal manganese oxide and ammonia borane in the mixed solution is 3:1, and the mixed solution is slowly stirred to a uniform mixed solution at a temperature of 20° C.;

[0043] 4) After vacuum-drying the above homogeneous mixture at a vacuum degree of 0.07MPa and a temperature of 20°C to remove the solvent, the metal manganese oxide-loaded ammonia borane hydrogen storage material can be prepared, and the sample is marked as 3MHS / AB .

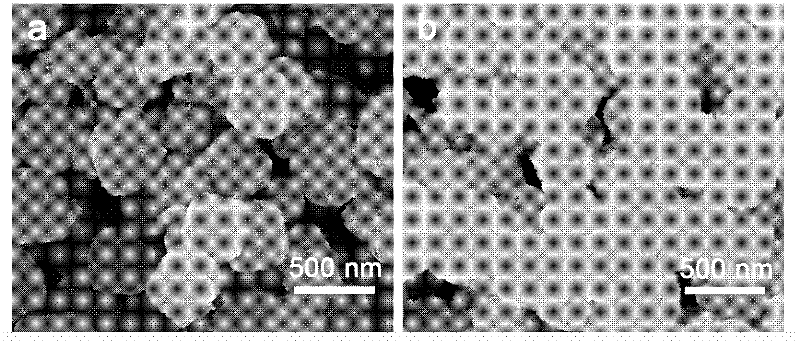

[0044] Imag...

Embodiment 3

[0046] A preparation method of the metal manganese oxide-loaded ammonia borane hydrogen storage material, comprising the following steps:

[0047] 1) ultrasonically disperse 60 mg of manganese dioxide nanoparticles (MNP) in 1.5 mL of purified tetrahydrofuran solvent to prepare metal manganese oxide tetrahydrofuran solution;

[0048] 2) Dissolving 20 mg of ammonia borane in 1 mL of purified tetrahydrofuran solvent to prepare ammonia borane tetrahydrofuran solution;

[0049] 3) The above two solutions are mixed, the mass ratio of metal manganese oxide and ammonia borane in the mixed solution is 3:1, and the mixed solution is slowly stirred to a uniform mixed solution at a temperature of 20° C.;

[0050] 4) After vacuum-drying the above homogeneous mixture at a vacuum degree of 0.1MPa and a temperature of 20°C to remove the solvent, the metal manganese oxide-loaded ammonia borane hydrogen storage material can be prepared, and the sample is marked as 3MNP / AB .

[0051] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com