Novel low-temperature insulation and thermal insulation pre-impregnated fiber cloth and preparation method thereof

A low-temperature insulation and pre-impregnation technology, which is applied in the field of pre-impregnated fiber cloth, can solve the problems of high material brittleness, difficulty in meeting the requirements of low-temperature engineering applications, and easy cracking, and achieve low porosity, controllable resin content, and heat release. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

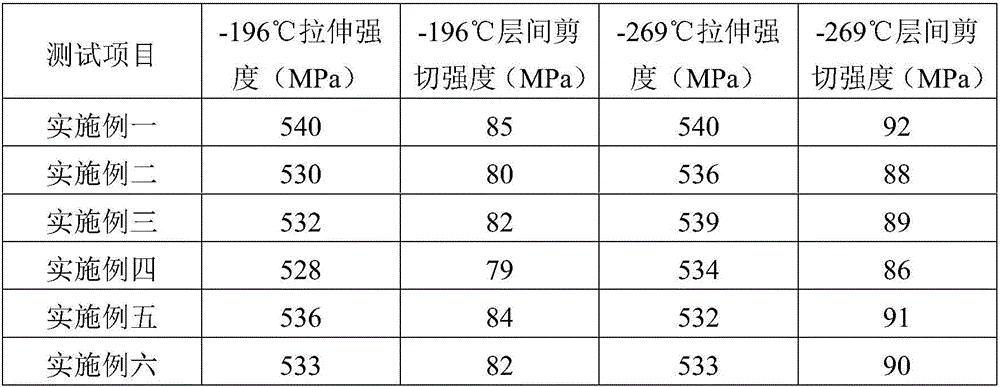

Examples

Embodiment 1

[0031] Pre-impregnated fiber cloth for low-temperature insulation and heat insulation is made of ultra-high-strength glass fiber cloth impregnated with epoxy resin slurry. The epoxy resin slurry is composed of epoxy resin and phenolic epoxy resin mixture, modified epoxy resin and double A mixture of cyanamide and accelerators. Taking the total amount of epoxy resin slurry as the base, the amount of epoxy resin and novolac epoxy resin mixture is 81.4wt%, the amount of modified epoxy resin is 9.0wt%, and dicyandiamide accounts for 7.2wt%. The used amount of agent is 2.3wt%.

[0032] The preparation method of the low-temperature insulation heat insulation pre-impregnated fiber cloth of the present embodiment comprises the following steps:

[0033] (1): Pour 90g of bisphenol A epoxy resin and novolac epoxy resin mixture (weight ratio 1:1) into an adjustable speed disperser, add 10g of modified epoxy resin, stir at 60°C for 30min, and then add The mixture of 8g dicyandiamide and ...

Embodiment 2

[0038] Pre-impregnated fiber cloth for low-temperature insulation and heat insulation is made of ultra-high-strength glass fiber cloth impregnated with epoxy resin slurry. The epoxy resin slurry is composed of epoxy resin and phenolic epoxy resin mixture, modified epoxy resin and double The mixture of cyanamide and accelerator is mixed, wherein the amount of epoxy resin and novolac epoxy resin mixture is 75wt%, the amount of modified epoxy resin is 12wt%, surfactant 2wt%, flame retardant 1wt%, Dicyandiamide accounts for 8.2wt%, and the amount of accelerator used is 1.8wt%.

[0039] The preparation method of the low-temperature insulation heat insulation pre-impregnated fiber cloth of the present embodiment comprises the following steps:

[0040] (1): Pour 100g of bisphenol A epoxy resin and bisphenol F type epoxy resin mixture (weight ratio 1:1) into an adjustable speed disperser, add 16g of modified epoxy resin, 2.6g of surfactant and 1.3g of flame retardant, stirred at 60°C...

Embodiment 3

[0045]Pre-impregnated fiber cloth for low-temperature insulation and heat insulation is made of ultra-high-strength glass fiber cloth impregnated with epoxy resin slurry. The epoxy resin slurry is a mixture of epoxy resin and novolac epoxy resin (weight ratio 1:1), A mixture of modified epoxy resin, dicyandiamide and accelerator is mixed, wherein the amount of epoxy resin and novolac epoxy resin mixture is 80wt%, the modified epoxy resin is 8wt%, and the surfactant is 5wt%. %, flame retardant 1wt%, the amount of dicyandiamide used is 5wt%, and the amount of accelerator used is 1wt%. The content of epoxy resin slurry in the pre-impregnated fiber cloth is 55%. The accelerator uses 1,1-dimethyl-3-phenylurea. The preparation method of the low-temperature insulating and heat-insulating pre-impregnated fiber cloth described in this example is the same as that of Example 1, and will not be described in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com