A method for manufacturing a high-quality perovskite thin film

A technology of perovskite and a new method, applied in the field of preparing high-quality perovskite thin films, can solve problems such as increasing the cost of perovskite and limiting the large-scale preparation of perovskite thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

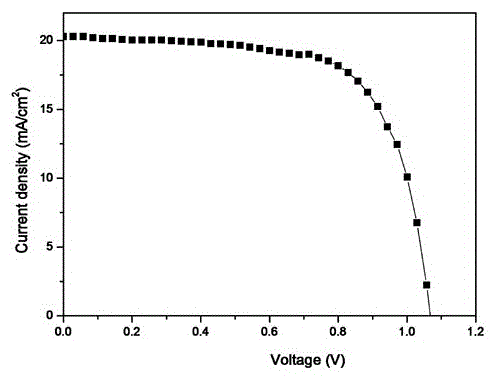

[0019] First, TiO was prepared by sol-gel method 2 Colloid, spin-coated on the cleaned FTO glass, then 500 o C heat treatment for 30 min to obtain dense TiO 2 film. Spin-coating TiO on dense thin films 2 Slurry, TiO 2 particle size ~20 nm, and then a further 500 o C heat treatment for 30 min to obtain TiO 2 mesoporous film. Preparation of MAPbI by Antisolvent Method 3 Perovskite crystals, and then place the crystals in an atmosphere of methylamine gas to obtain a perovskite liquid phase with excess methylamine, and then use a scraper rod to scrape this liquid phase onto the mesoporous TiO 2 film, heated to 100 o C, 10 min, to promote the volatilization of methylamine gas, and prepare a dense perovskite film with good crystallinity. Finally, the hole transport layer spiro was spin-coated on the perovskite layer, and the silver electrode was vapor-deposited to assemble a solar cell device.

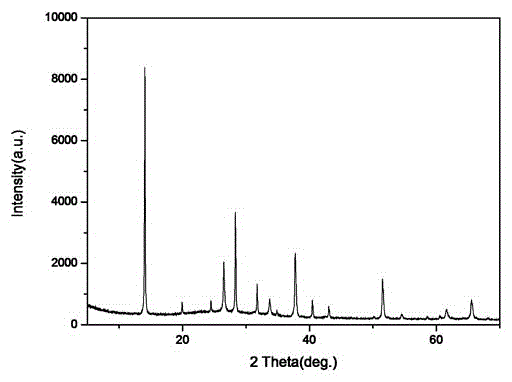

[0020] Characterize the perovskite film obtained in this embodiment and the so...

Embodiment 2

[0022] First, TiO was prepared by sol-gel method 2 Colloid, spin-coated on the cleaned FTO glass, then 500 o C heat treatment for 30 min to obtain dense TiO 2 film. Spin-coating TiO on dense thin films 2 Slurry, TiO 2 particle size ~20 nm, and then a further 500 o C heat treatment for 30 min to obtain TiO 2 mesoporous film. Will NH 4 I and PbI 2 According to the molar ratio of 1:1, it is configured into a DMF solution with a solute content of 50%, and then at 80 o The solvent was dried under vacuum at C to obtain NH 4 PB 3 powder, then NH 4 PB 3 The powder was placed in an atmosphere of methylamine gas to obtain a perovskite liquid phase with excess methylamine, which was then spin-coated onto mesoporous TiO 2 On the membrane, place it for 1h to completely volatilize the methylamine gas, and prepare dense MAPbI with good crystallinity 3 perovskite thin film. Finally, the hole transport layer spiro was spin-coated on the perovskite layer, and the silver electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com