Patents

Literature

264 results about "Resin casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin casting is a method of plastic casting where a mold is filled with a liquid synthetic resin, which then hardens. It is primarily used for small-scale production like industrial prototypes and dentistry. It can be done by amateur hobbyists with little initial investment, and is used in the production of collectible toys, models and figures, as well as small-scale jewellery production.

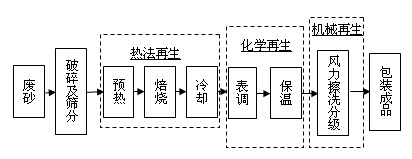

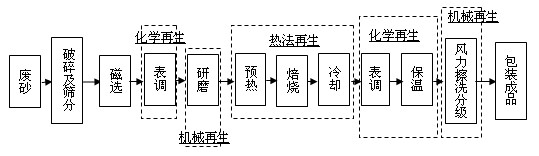

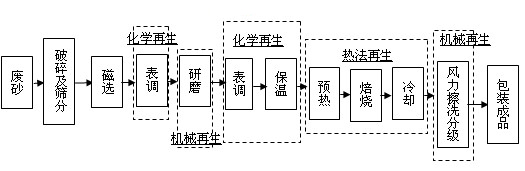

Chemical regeneration method in casting waste sand disposing process

InactiveCN102000764AGood regeneration performanceSolve sinteringMould handling/dressing devicesChemical treatmentDie casting

The invention provides a chemical regeneration method in the casting waste sand disposing process, relating to a process for performing surface chemical processing on various impurities which are attached on the surface of waste sand and are better not be reused in casting-form sand materials. During the chemical regeneration, chemical surface conditioning liquid I or / and chemical surface conditioning liquid II is or are used, and the disposing sand temperature is not more than 400 DEG C. The chemical regeneration method in the invention is carried out before or after the hot-method regeneration disposing or mechanical regeneration disposing of the casting waste sand disposing processing, and the chemical disposing technique is combined with the traditional hot-method regeneration and mechanical friction regeneration. The regeneration new sand formed in the method has better quality of the new sand, can better meet the application requirement on multi-form sand producing technique (hot core box, warm core box and cold core box) for recycling different casting waste sands (hot core box resin casting waste sand, warm core box resin casting waste sand, gas or / and organic fat hardening cold core box resin casting waste sand and profile damp die casting sand), and has better economical efficiency.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

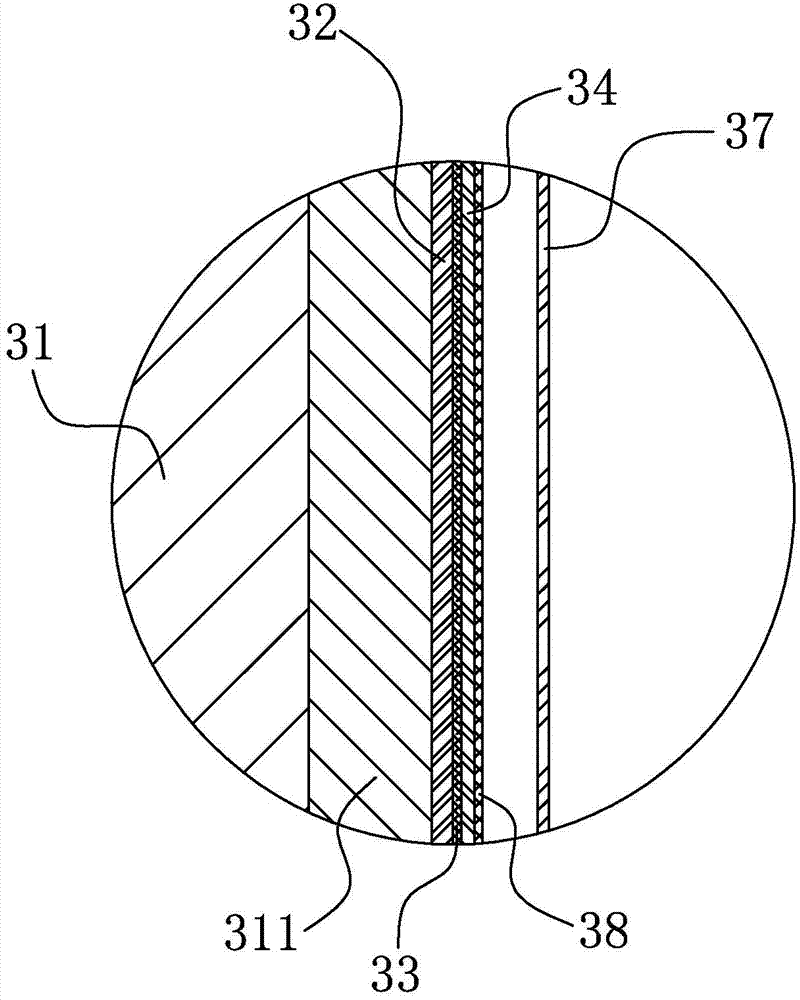

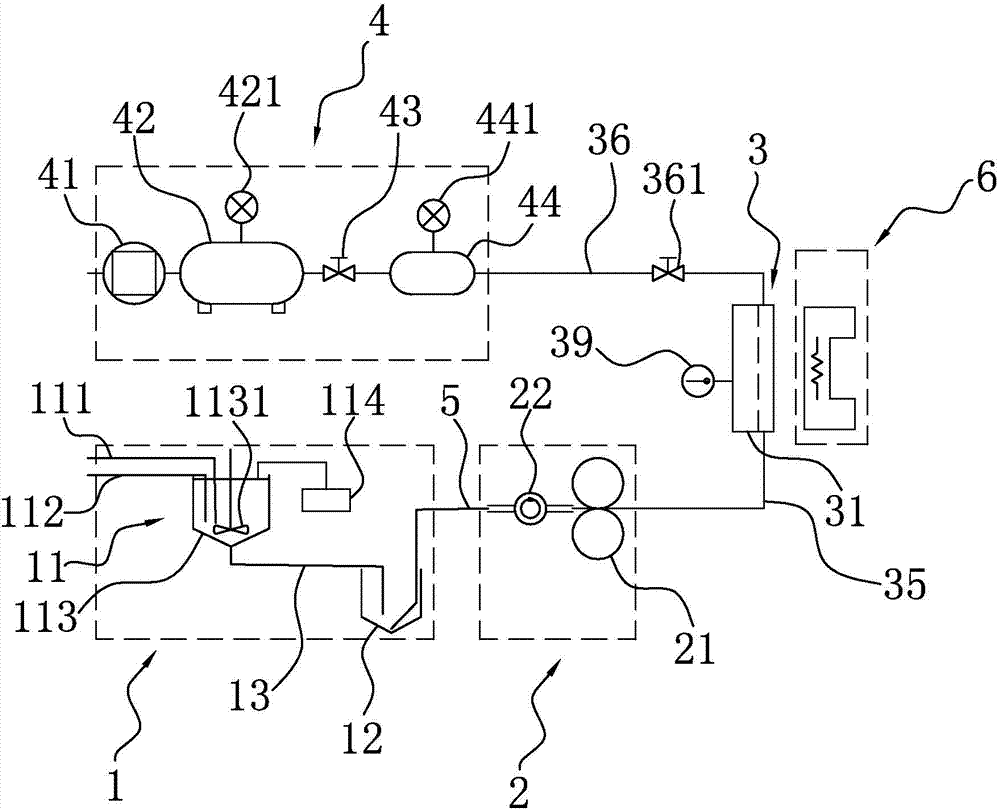

Vacuum assistant resin casted protection coating, system and method of permanent magnet motor rotor

InactiveCN104325657AEasy to achieve thickness controlImprove mechanical propertiesManufacturing dynamo-electric machinesDomestic articlesMagnetic polesResin coating

The invention provides a vacuum assistant resin casted protection coating, system and method of a permanent magnet motor rotor. The provided protection coating comprises an enhancing phase, demoulding cloth, and a flow guide net, wherein the enhancing phase, the demoulding cloth and the flow guide net are paved on the surfaces of the magnetic poles of a rotor in sequence. The end part of a resin injection pipeline and the end part of an air suction pipe are fixed on the exterior of the flow guide net. The rotor is hermetically connected to a vacuum isolation membrane, and the vacuum isolation membrane covers the enhancing phase, the demoulding cloth, the flow guide net, the end part of the resin injection pipeline, and the end part of the air suction pipe. Vacuum assistant resin casting and moulding equipment is applied to the magnetic pole protection of permanent magnet motor rotor so as to form a resin coating on the magnetic pole surfaces of a permanent magnet motor rotor; moreover the thickness of the resin coating is easily controlled, and mould sleeve tools are not required. The provided system and method can achieve a good casting effect, and thus the mechanical performance and anticorrosion grade of rotor magnetic poles can be enhanced.

Owner:XINJIANG GOLDWIND SCI & TECH

Resin casting molding sand and preparation method thereof

ActiveCN102380575AEasy to prepareReasonable formulaFoundry mouldsFoundry coresDry mixingPotassium dichromate

The invention discloses resin casting molding sand and a preparation method thereof. The method mainly comprises: performing dry mixing of component raw materials including quartz sand, straw ash, tung oil, asbestos, a furan resin, a phenolic resin, kaoline and potassium dichromate by certain weight parts; and adding water, mixing, placing sand after mixing, molding, casting, cooling and separating to obtain a finished product. The preparation method is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of the aluminum sand is made smooth by strictly controlling the particle size of the quartz sand, and the breathability is high.

Owner:托普工业(江苏)有限公司

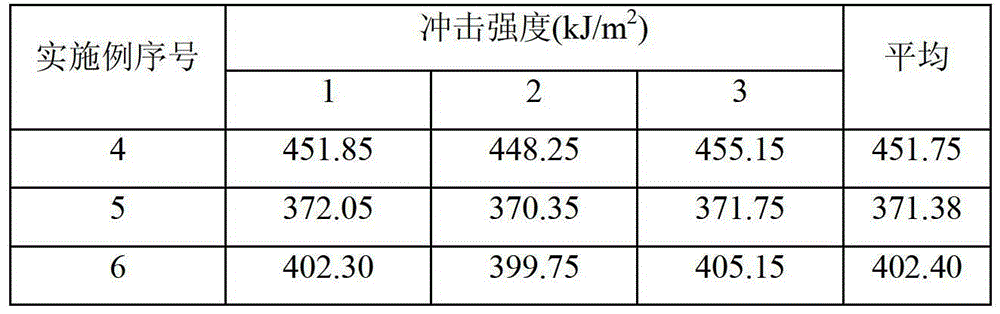

Toughened epoxy resin/glass fiber prepreg and preparation method

InactiveCN103146147AImprove mechanical propertiesImprove impact performanceLayered product treatmentPhysical treatmentEpoxyFiber

The invention relates to the field of high polymer materials, in particular to a toughened epoxy resin / glass fiber prepreg and a preparation method thereof. In a vacuum apparatus, a glass fiber cloth treated by plasmas is impregnated by toughened epoxy resin so as to form the prepreg with reinforced fiber fully impregnated by the matrix resin, wherein the resin content is greater than or equal to 15% and is less than or equal to 30%. A vacuum infusion process employed in the invention solves the problems of complex preparation process, high cost, difficult control of resin content and the like in current glass fiber prepregs. In addition, the toughened epoxy resin used in the prepreg adopts a mixed amine curing agent and a nano-toughening agent, the toughening effect is obvious, a resin cast body can have excellent properties. Under a vacuum condition, the resin cast body and the glass fiber woven cloth can be impregnated to prepare a prepreg, and after curing, the composite material obtained has excellent impact resistance.

Owner:CHANGZHOU LOONG TOP NEW MATERIALS TECH

Resin casting mould rapid manufacturing method

InactiveCN101992264ASimple designEasy to modifyFoundry moulding apparatusComputer Aided DesignRoom temperature

The invention belongs to the technical field of material processing engineering, and in particular relates to a resin casting mould rapid manufacturing method. The resin casting mould rapid manufacturing method is characterized by comprising the following steps of: (1) drawing a three-dimensional CAD (Computer-Aided Design) model of a mould according to a casting process drawing of a casting, and preparing a resin prototype for manufacturing a resin casting mould by a rapid prototyping device; (2) rapidly obtaining a die cavity for manufacturing the resin casting mould through a rolling over of a room temperature vulcanized silicone rubber mould by utilizing the prepared resin prototype; (3) manufacturing the resin mould through a manual paste mode by utilizing the die cavity for manufacturing the resin casting mould; and (4) assembling the resin mould prepared by manual paste on a mouldboard to complete the manufacturing process of the mould. Compared with the prior art, the invention has the advantages of facilitating design and modification to the appearance of the casting, being capable of rapidly obtaining the die cavity for manufacturing the resin casting mould, manufacturing the mould with a few tenths of millimeter of dimensional accuracy and shortening the manufacturing cycle of the mould.

Owner:SHANDONG UNIV OF TECH

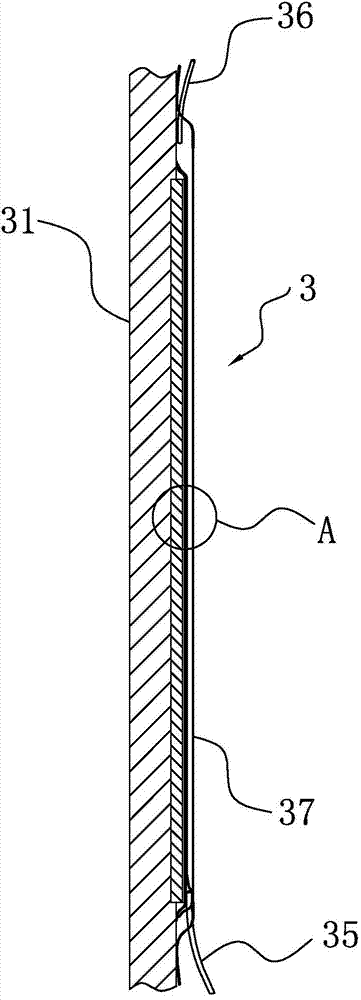

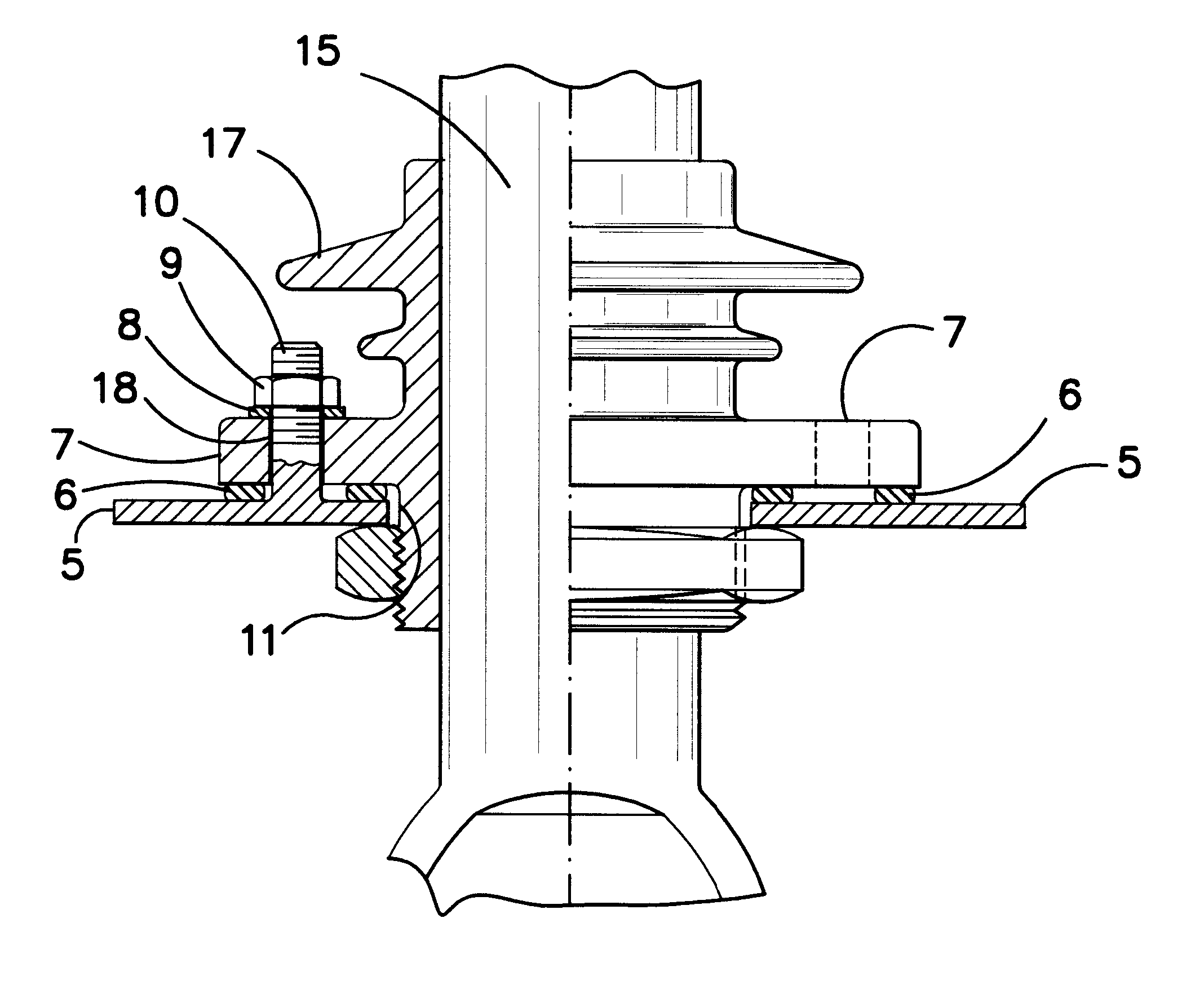

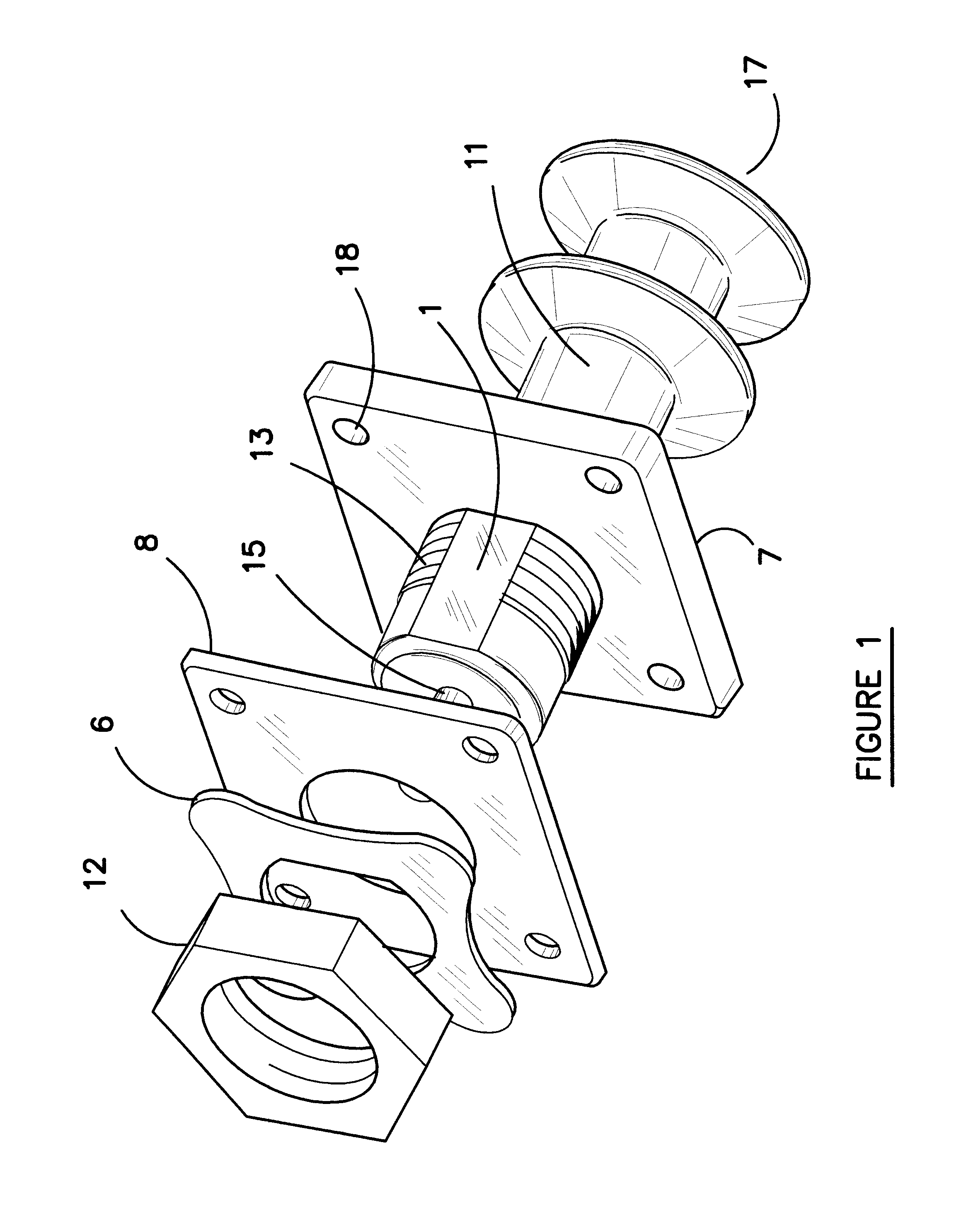

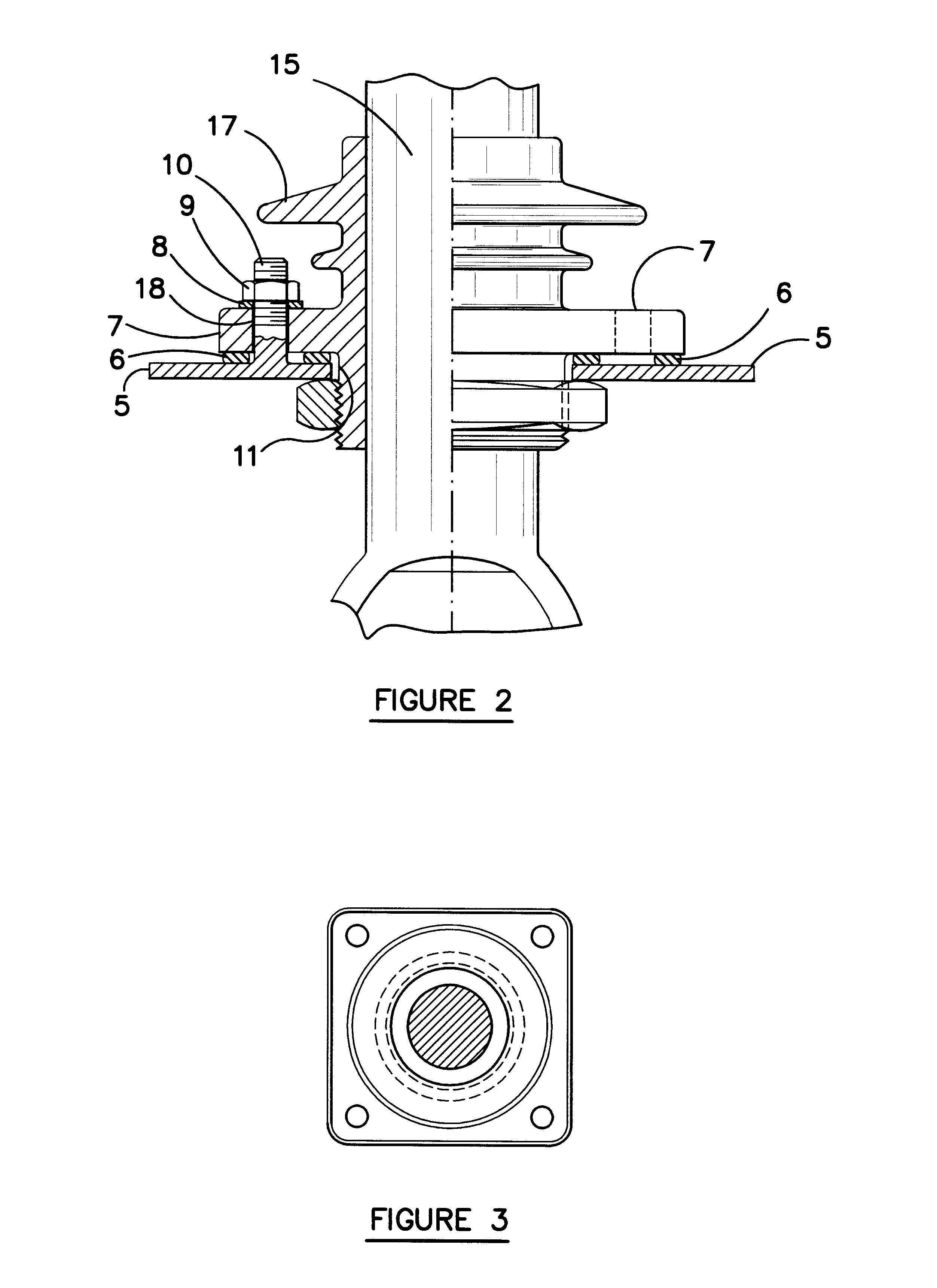

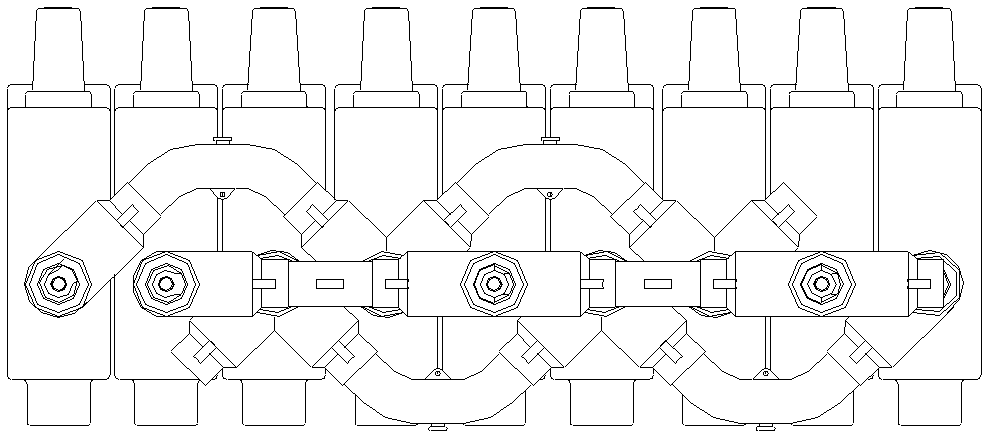

Electrical bushings with resin casting

InactiveUS6610933B2Easy to useImproves and facilitates fixing and sealingElectrically conductive connectionsTransformers/inductances casingsElectrical conductorTransformer

The invention in a first aspect relates to an improved cast resin bushing assembly for use in a transformer wherein the busing assembly includes a bushing which includes locating means for aligning the bushing assembly within a transformer casing; wherein the bushing further includes a locking means for releasably securing the bushing assembly to a transformer casing; a bushing conductor; and a bushing flange in circumferential arrangement with the bushing. In a second aspect the invention relates to a method of securing an improved cast resin bushing assembly to a transformer casing which bushing assembly includes a bushing which includes a locating means for aligning the bushing assembly within a transformer casing; the bushing further includes a locking means for releasably securing the bushing assembly to a transformer casing; a bushing conductor, and a bushing flange in circumferential arrangement to the bushing; wherein the transformer casing has an opening adapted to receive the bushing assembly or part thereof; and the bushing flange is mounted on the outside of the transformer casing and secured thereto by engaging the locking means on the inside of the transformer casing.

Owner:WAMCO PACIFIC

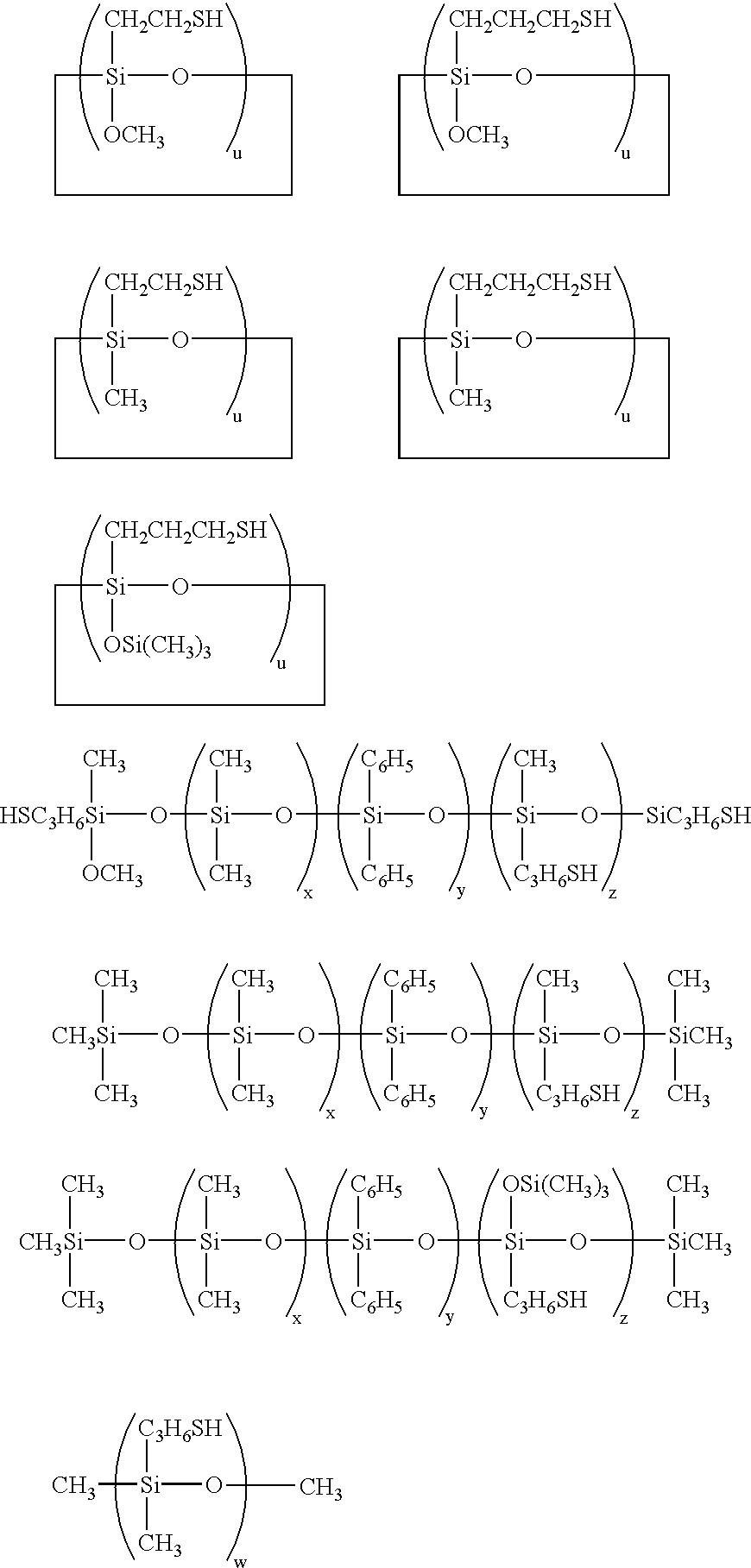

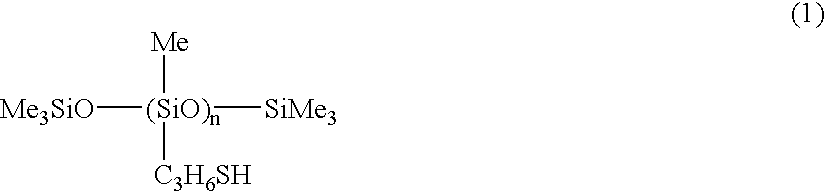

Replica molding

InactiveUS20020113334A1Easy to operateAuxillary shaping apparatusCopying process control systemsReplica moldingLiquid resin

Replicas are molded by curing a photo-curable liquid silicone rubber composition to form a transparent mother mold having a cavity corresponding to the outer contour of a master model, casting a photo-curable liquid resin into the mold cavity, and irradiating light to the liquid resin through the mold wall. Replicas can be fabricated by simple steps and within a short time.

Owner:SHIN ETSU CHEM IND CO LTD

Replica molding

Replicas are molded by curing a photo-curable liquid silicone rubber composition to form a transparent mother mold having a cavity corresponding to the outer contour of a master model, casting a photo-curable liquid resin into the mold cavity, and irradiating light to the liquid resin through the mold wall. Replicas can be fabricated by simple steps and within a short time.

Owner:SHIN ETSU CHEM IND CO LTD +1

Preparation process of vacuum epoxy resin casting type mutual inductor

InactiveCN104319088AImprove permeabilityImprove compactnessTransformersInductances/transformers/magnets manufactureInductorCasting types

The invention provides a preparation process of a vacuum epoxy resin casting type mutual inductor. The preparation process comprises the following steps of (1) winding a primary winding and a secondary winding on a mutual inductor iron core; (2) fully drying a mutual inductor iron core winding and a part die; (3) mounting the dried mutual inductor part in a die, and after moving the die into a vacuum can, vacuumizing the die; (4) preheating an injection molding material, and casting the injection molding material into the die; (5) stopping and vibrating the vacuum can; (6) changing the vacuum state into a normal-pressure state; (7) taking the die out, and after performing a post curing process, opening the die. The preparation process has the beneficial effects that due to the fact that the injection molding material is preheated in advance, bubbles are prevented from being generated during product injection molding, and local discharging amount of a product is increased; due to the fact that the injection molding material in the vacuum can is vibrated by an electromagnetic vibrator, the infiltration filling property and the compaction degree of the injection molding material are greatly improved, and the electric appliance insulating property and the mechanical strength of the mutual inductor are greatly improved.

Owner:TIANJIN BINHAI NEW TECH ELECTRIC

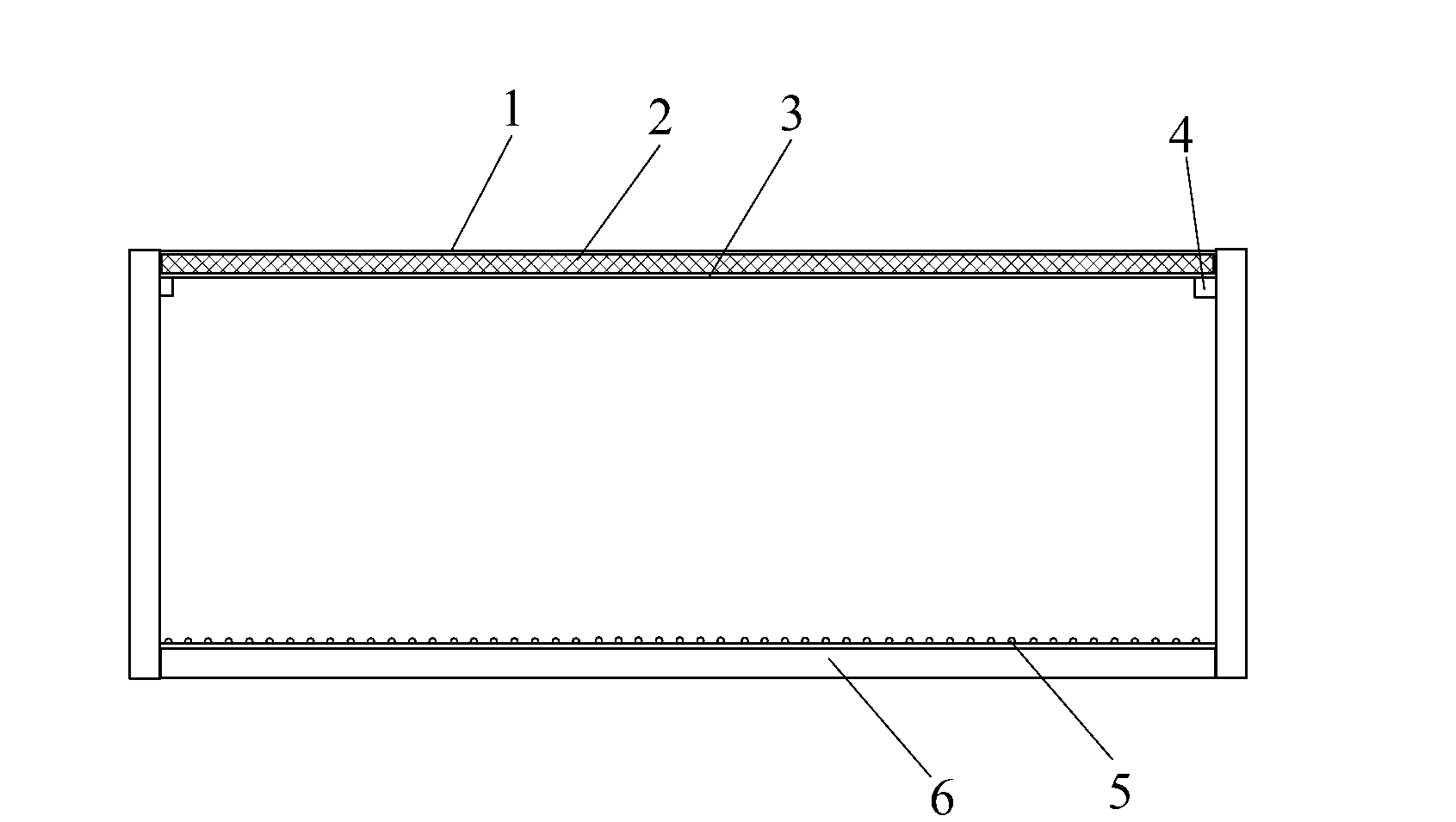

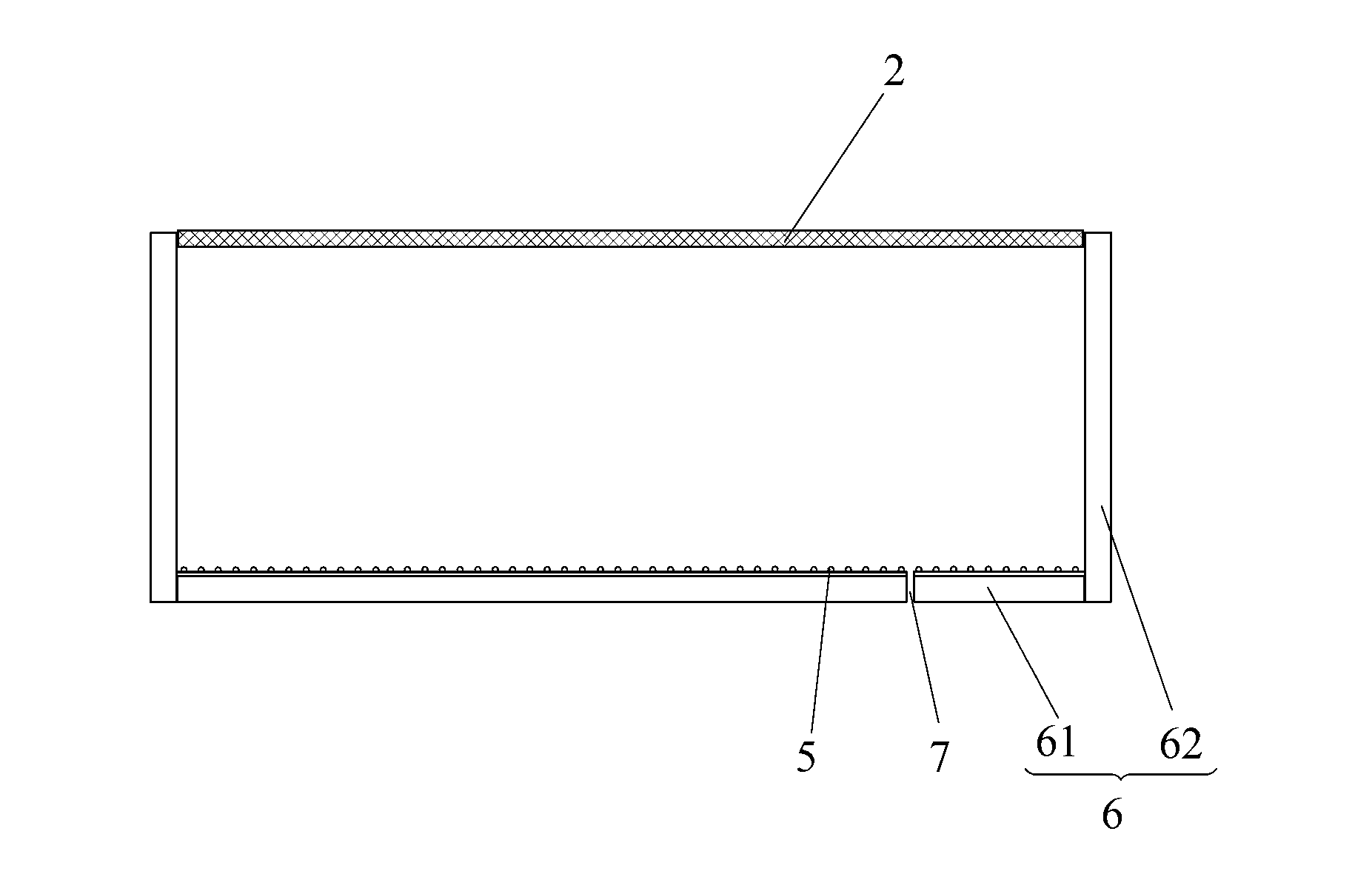

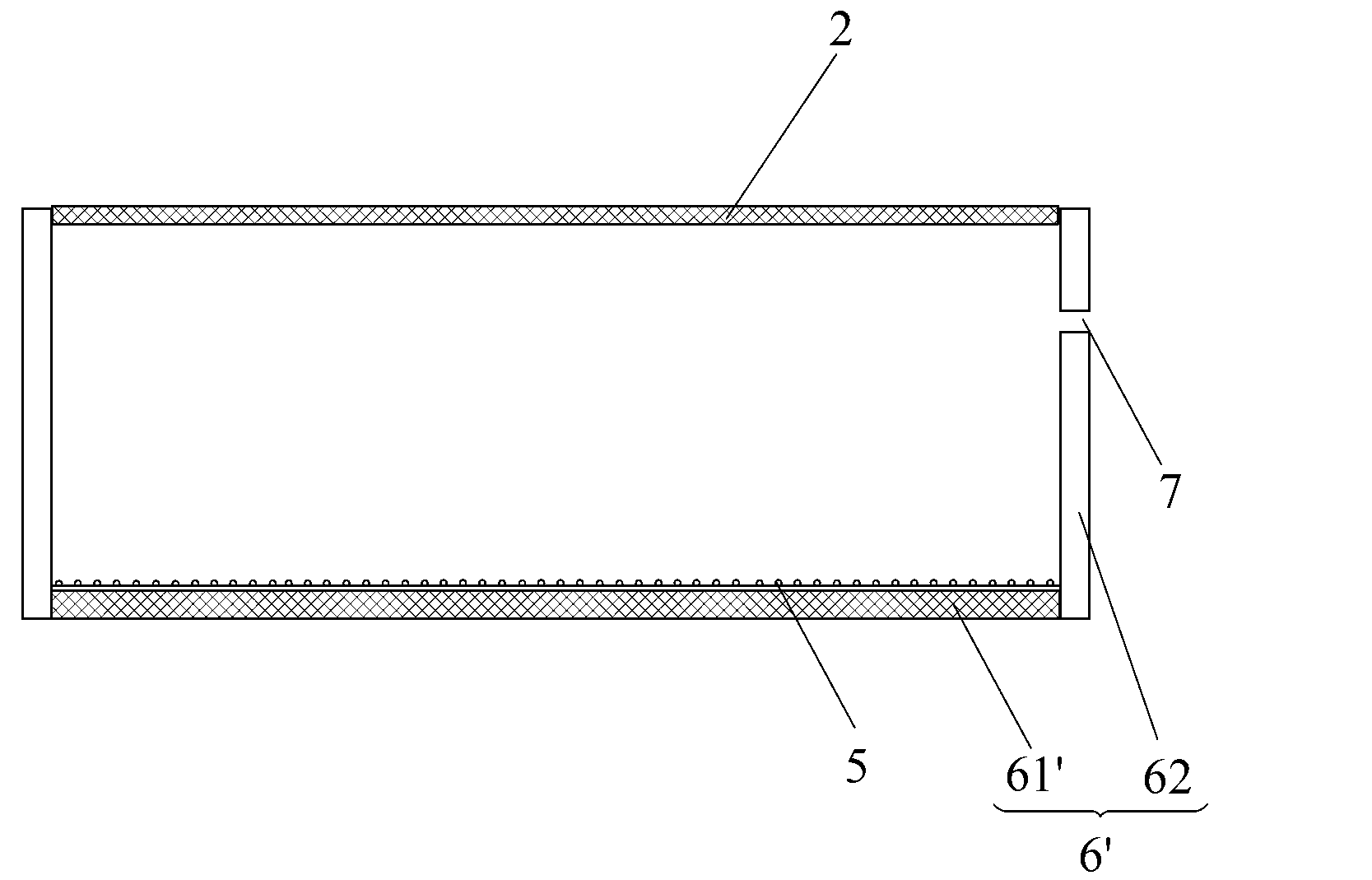

Three-dimensional hollow-resin-poured luminous character structure and manufacturing method thereof

InactiveCN103295491AAvoid technical issues that affect aestheticsSimple methodIlluminated signsEngineeringOpen structure

The invention provides a three-dimensional hollow-resin-poured luminous character structure and a manufacturing method thereof. The three-dimensional hollow-resin-poured luminous character structure comprises a shell, a luminous light source and a resin pouring layer, the shell is of an open structure formed by surrounding of an undersurface and side faces, the middle portion of the resin pouring layer is hollow, and the periphery of the resin pouring layer is fixedly connected with the periphery of an opening of the open structure in a sealed manner. A reverse-side pouring method is adopted, resin is directly poured on a horizontal glass tabletop, and after the resin is coagulated, the horizontal glass tabletop is fixedly connected with a luminous character shell, so that light can uniformly transmit, a luminous character is high in brightness and uniform in light emitting, the manufacturing method is simple, and the luminous character structure is simplified.

Owner:东莞市乙方环保新材料有限公司

Preparation method of transparent self-toughening dicyandiamide/epoxy resin-based composite material

The invention belongs to the technical field of application of high performance epoxy resin and particularly relates to a preparation method of a transparent self-toughening dicyandiamide / epoxy resin-based composite material, in particular to a preparation method of a transparent self-toughening epoxy resin composition with low heat release, a heavy-thickness prepreg unidirectional tape and a composite material. The composition comprises the following raw materials in parts by weight: 60-100 parts of liquid epoxy resin, 0-40 parts of solid epoxy resin, 1.0-12 parts of a dicyandiamide curing agent and 0.5-6 parts of an accelerant. The epoxy resin is prepared by adopting a solution reaction manner; compared with a general dicyandiamide / epoxy resin system, a system in the invention has the advantages that the peak heat flux is decreased by 48% or higher, the heat release is decreased by 38% or higher, and the reaction heat is low; moreover, a resin casting body has 3.5% or more of breaking elongation, 80MPa or higher of tensile strength and 24kJ / m<2> of higher impact strength and has good toughness without adding a toughening agent; 130-DEG C medium temperature curing can be realized, and a cured product is transparent.

Owner:AVIC BASIC TECH RES INST

Method for manufacturing resin casting die used for modeling sodium silicate self-hardening sand

The invention relates to a method for manufacturing a resin casting die used for modeling sodium silicate self-hardening sand. The method is characterized by comprising the following steps of: (1) preparing a resin prototype by rapid modeling equipment according to a three-dimensional CAD (Computer-Aided Design) model; (2) rapidly obtaining a die cavity for manufacturing a resin casting die by utilizing the made resin prototype through the rollover of a room-temperature silicified rubber die; (3) manufacturing the resin casting die by utilizing the die cavity through a manual pasting mode; and (4) making the inner cavity of the resin casting die into a hollow structure mode, leaving an air inlet at the bottom of the resin casting die and alternately drilling a plurality of air outlets along the surface of the resin casting die. The invention has the advantages of (1) being convenient to design and modify the casting appearance; (2) improving the size accuracy of the die and the surface smoothness of the die and shortening the processing cycle of the die; (3) rapidly hardening the sodium silicate self-hardening sand on the die surface to facilitate a subsequent die-drawing process; and (4) improving the surface quality of the casting and lightening the labor intensity of workers.

Owner:山东宏泰车辆部件有限公司

Piezoelectric ceramic fibrous composite material and preparation method thereof

ActiveCN102437282AImprove efficiencySimple processPiezoelectric/electrostrictive device manufacture/assemblyEpoxyCeramic composite

The invention relates to a 1-1 type piezoelectric ceramic fibrous composite material. The composite material is formed by cutting an alternative lamination of a piezoelectric ceramic sheet and a high molecular material polymer. The invention also provides a method for preparing the 1-1 type piezoelectric ceramic fibrous composite material, comprising the following steps: sintering by using a ceramic powder tape-casting method to obtain piezoelectric ceramic sheets; vertically arranging a certain amount of the piezoelectric ceramic sheets in parallel, and inserting PE (Polyethylene) thin film between every two piezoelectric ceramic sheets to form a piezoelectric ceramic stack; injecting epoxy resin casting liquid to a gap of the piezoelectric ceramic stack, finally, pressurizing, raising the temperature and demoulding to obtain 2-2 type piezoelectric ceramic composite lamination, and cropping and preparing the 1-1 type piezoelectric ceramic fibrous composite material with required size. The 1-1 type piezoelectric ceramic fibrous composite material obtained by using the method can be used as a driver applied to the fields such as structure control, vibration abatement, structure health monitoring and the like after being polarized by an interdigital electrode and has a wide application prospect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

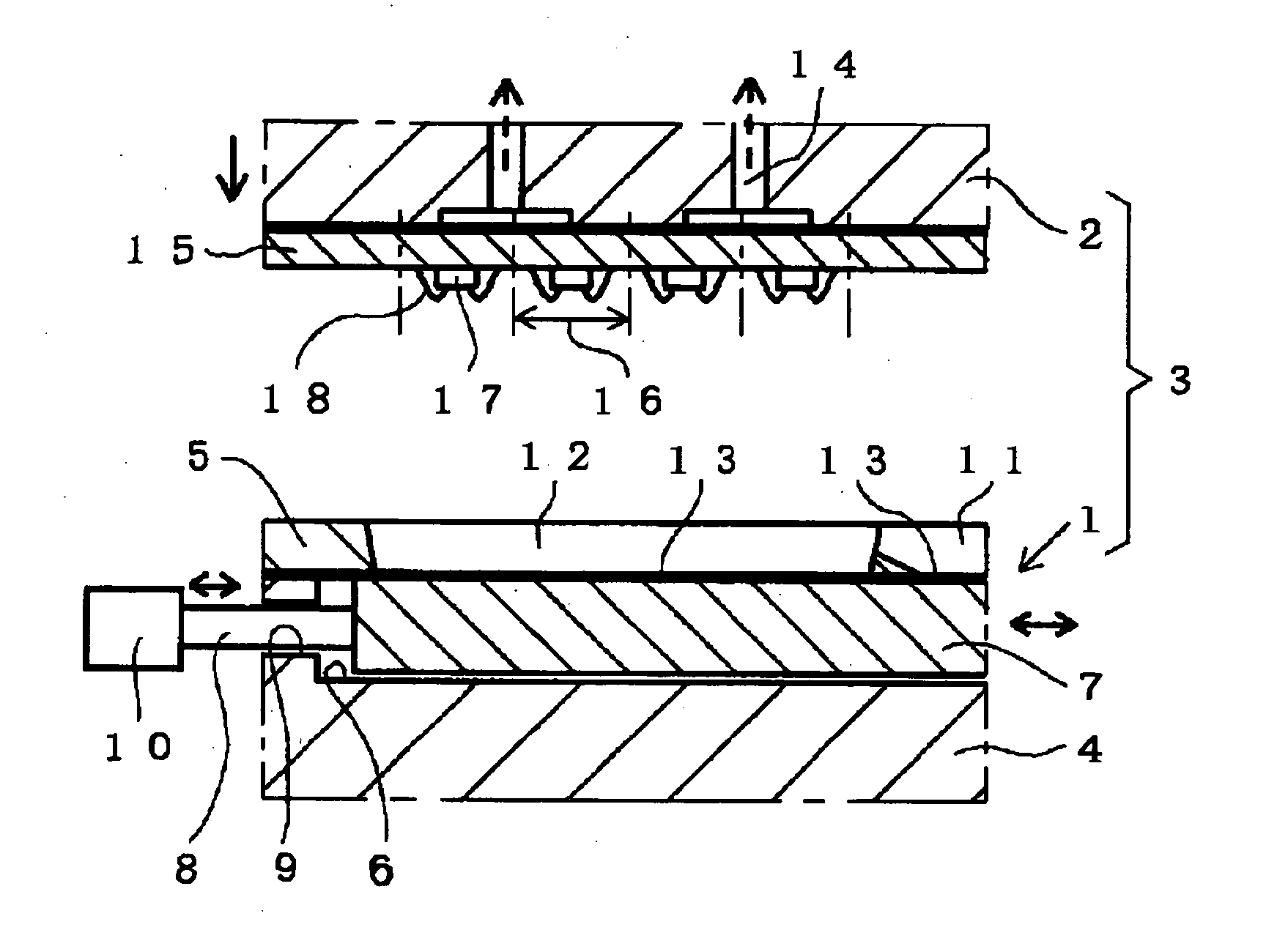

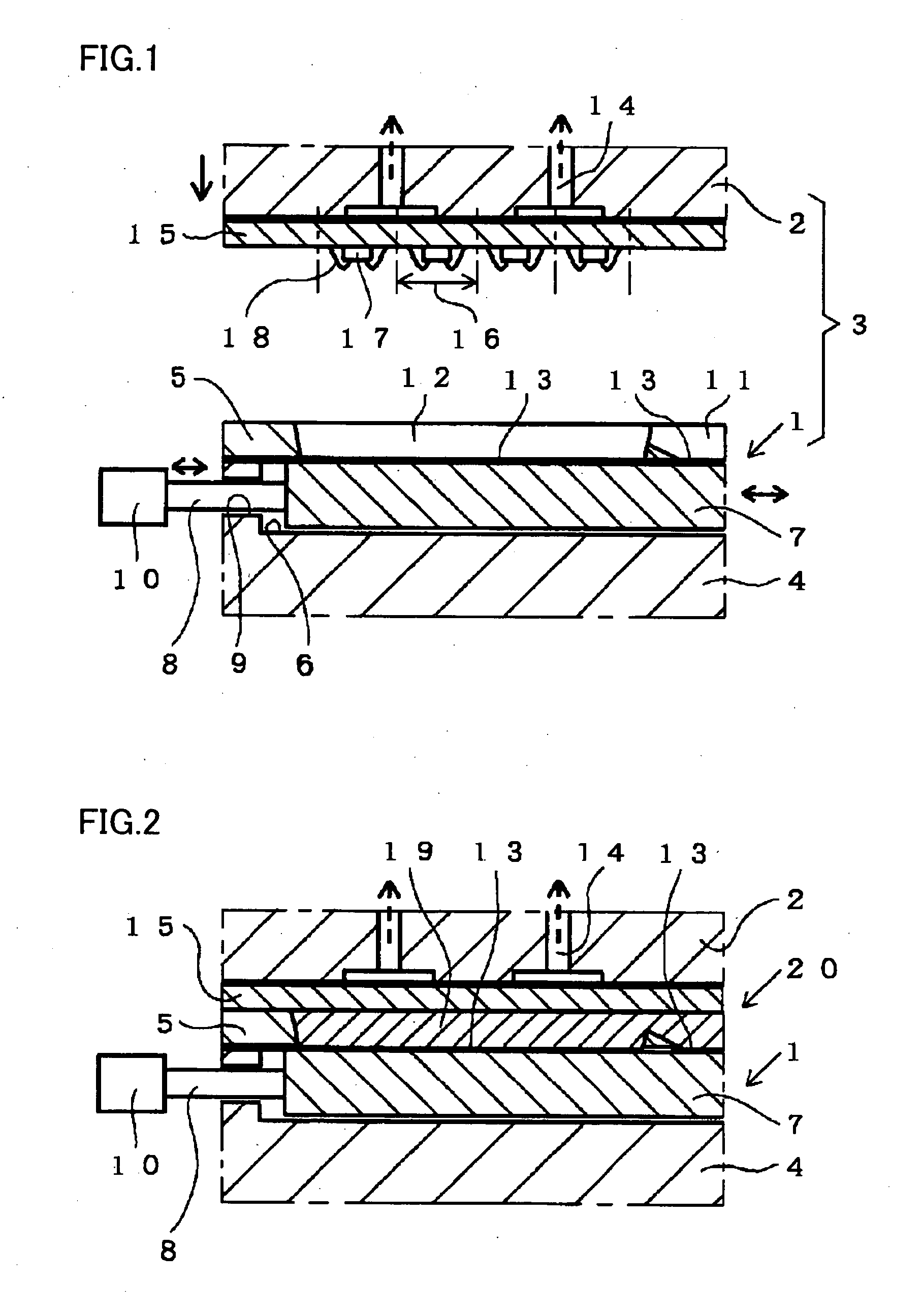

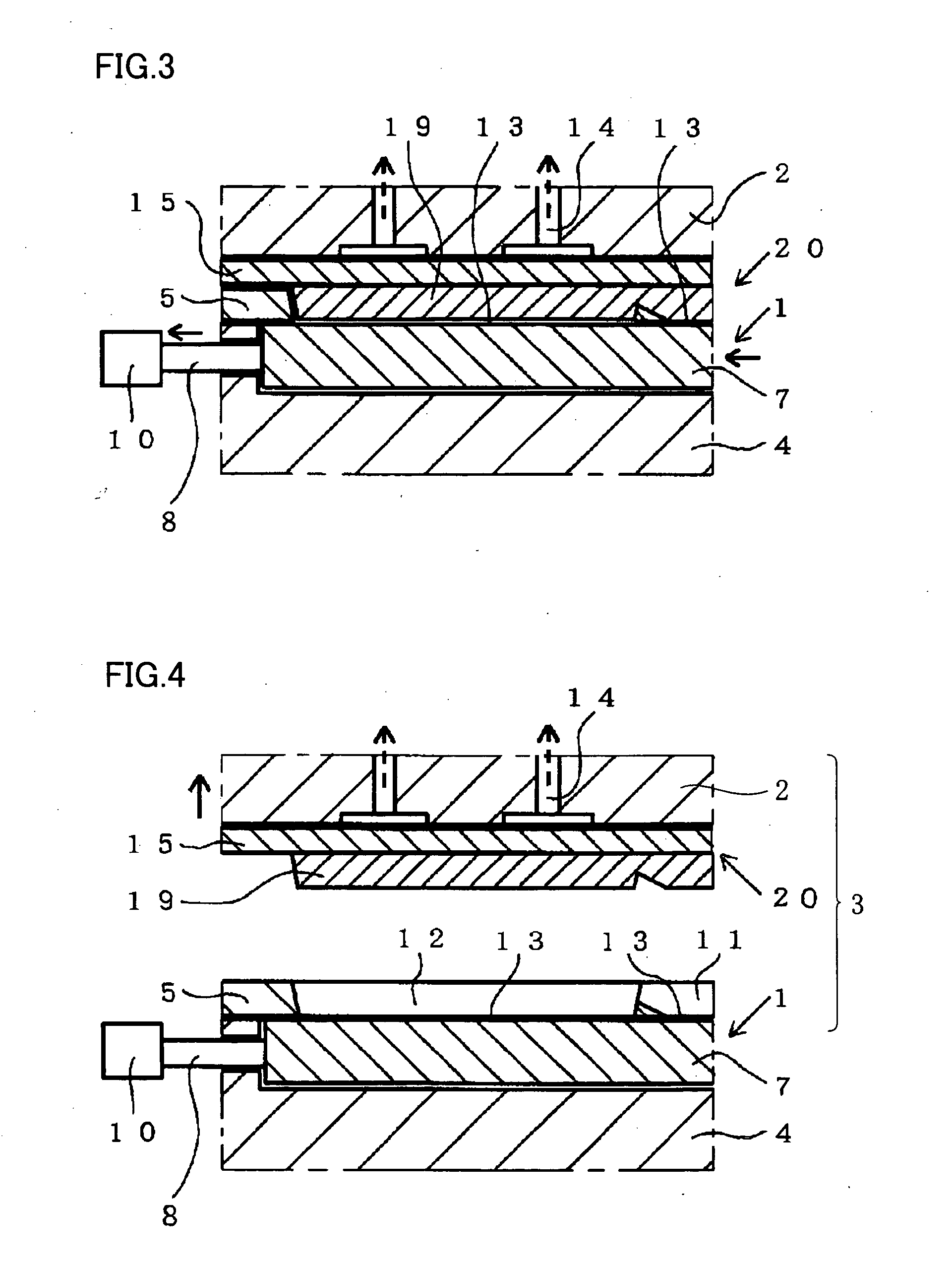

Resin casting mold and method of casting resin

InactiveUS20060131780A1Improve driving efficiencySmall sizeMouldsConfectioneryCasting moldLarge size

A resin casting mold used for manufacturing a casting product including a cured resin produced by curing a fluid resin filling a cavity includes: a block providing the bottom surface of the cavity; and a driver mechanism for applying a force to the block to move the block in a direction that lies along the bottom surface. The driver mechanism moves the block when the cured resin has been formed to separate the cured resin from the bottom surface. This arrangement allows a thinner casting product with a larger major surface to be properly separated from the cavity surface without damaging the casting product and with high driving efficiencies and without equipment including a resin casting mold with a complicated structure or a large size.

Owner:TOWA

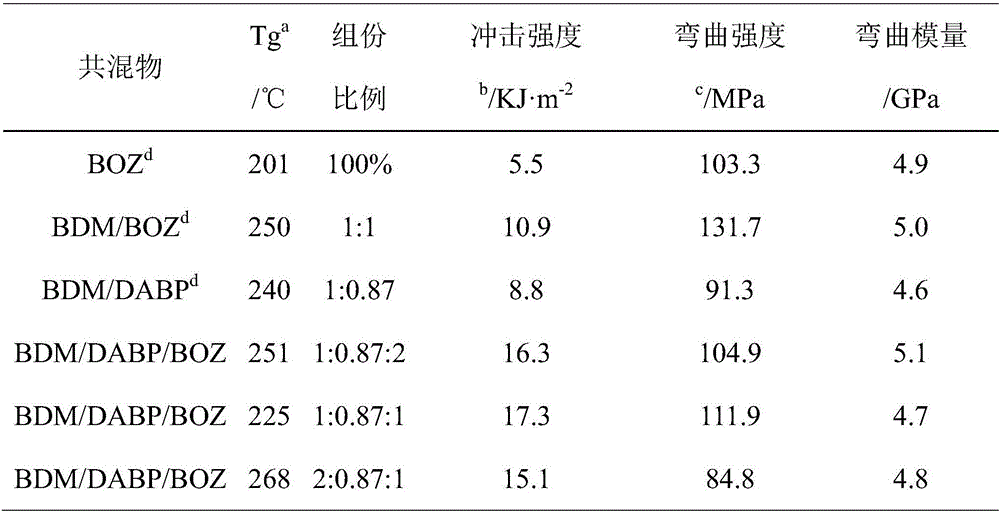

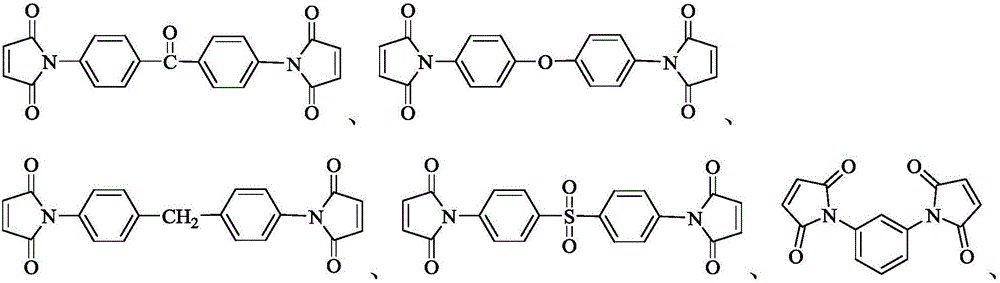

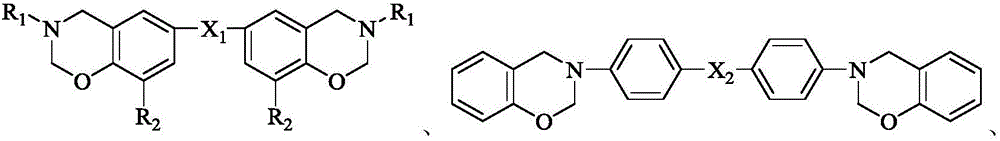

High-toughness and low-viscosity benzoxazine/diallyl diphenol/bismaleimide blended resin and preparation method thereof

The invention belongs to the field of high polymer materials, and relates to a high-toughness and low-viscosity benzoxazine / diallyl diphenol / bismaleimide blended resin and a preparation method thereof. The method includes the steps that 100 parts of bismaleimide, 60-95 parts of diallyl diphenol and 10-500 parts of benzoxazine are dissolved with a polar organic solvent, solution blending or melt blending is carried out at 105-125 DEG C to prepare a blended resin casting body through a vacuum defoaming method, heating curing is carried out at 120-200 DEG C for 1-20 h, and cured benzoxazine and diallyl diphenol toughening-modified bismaleimide blended resin is obtained. The bismaleimide blended resin has excellent heat resistance and toughness and good processability and can serve as matrix resin for preparing high-temperature-resistant and high-performance resin-based fiber reinforced composite materials.

Owner:DALIAN UNIV OF TECH

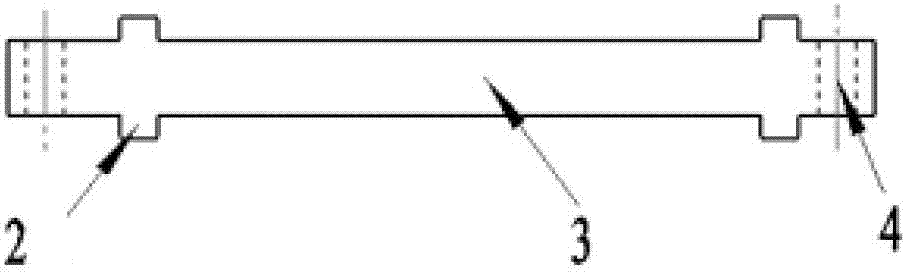

Resin casting body processing die

The invention provides a resin casting body processing die, which is composed of two double-cross components, the double-cross components comprise a short beam and a through beam, the length of the short beam is more than two times of thickness of the prepared casting body and the width of the through beam, the spacing between the short beams is the length of the casting body and the width of the short beam, and the thickness of the through beam and the width of the prepared casting body. The resin casting body processing die is composed of two double-cross components, which enables flexible combination, convenient assembling and dismounting, and the die can be used for one-time moulding of resin casting body bending spline, a DMA test spline and other splines required to be tested.

Owner:HARBIN ENG UNIV

Non post cure epoxy resin casting system

The invention provides a non post cure epoxy resin casting system including a formula toughening epoxy resin and a formula toughening anhydride curing agent; the formula toughening epoxy resin is milk white to pale yellow solvent-free pre-acceleration liquid epoxy resin; the formula toughening anhydride curing agent is an improved pre-acceleration anhydride liquid curing agent; components are mixed at the lower temperature in the desired quantity, are defoamed under vacuum condition for 0.5 to 2 hours after even mixing, and then are poured into a mold for curing reaction. The non post cure epoxy resin casting system has the following main characteristics: after demoulding, curing is not needed, the comprehensive energy consumption of electrical equipment manufacturing plants can be reduced, the production cycle time can be shortened by more than 20%, the product delivery time can be shortened, the product cost and labor intensity of workers can be reduced.

Owner:广州仑利奇合成树脂有限公司

High-toughness low-shrinkage epoxy resin composition, insulating part and preparation method

The invention discloses a high-toughness low-shrinkage epoxy resin composition which comprises the following components in parts by weight: 100 parts of an epoxy resin, 50-100 parts of a curing agent, 1-5 parts of a curing accelerator and 200-450 parts of an inorganic filler, wherein the epoxy resin comprises a modified epoxy resin; and the modified epoxy resin refers to an epoxy resin modified by rubber or a thermoplastic resin. The invention also provides an insulating part prepared by adopting the high-toughness low-shrinkage epoxy resin composition, and a preparation method of the composition. According to the epoxy resin cured material modified by the rubber or thermoplastic resin, the high temperature resistance and mechanical property of the epoxy resin can be maintained, the epoxy resin has the obvious advantages of high impact strength, basically no shrinkage after curing and the like, the problems that the epoxy resin casting product is high in brittleness and easy to crack and the like can be effectively solved, the insulating property is enhanced, and the insulation sealing properties of the insulating part are improved, and the service life of the insulating part is prolonged.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

Epoxy resin casting insulating material and preparation method thereof

The invention relates to an epoxy resin casting insulating material. The epoxy resin casting insulating material comprises the following raw materials in parts by mass: 7-13 parts of epoxy resin, 5-11parts of a curing agent, 20-30 parts of modified silicon dioxide powder and 2-8 parts of mica powder. The epoxy resin casting insulating material has an excellent formation processing property, is suitable for an APG technology and a vacuum casting technology, and suitable for manual casting moulding. An insulating component prepared by the material has a good insulating property and excellent arc resistance, and is capable of solving a technical problem that the arc resistance of an epoxy casting material is poor, wherein the arc resistance of the material can reach more than 210 s. The material has a lower curing shrinkage rate which is 0.1%-0.05% only. An overlarge stress is prevented from being generated between a metal insert and an insulator through the smaller curing shrinkage rate, and a problem that a product is cracked in a place of the metal insert is prevented from happening. The insulating component formed and prepared by using the insulating material has higher strengthand toughness, and is good in secondary machining property.

Owner:株洲电力机车广缘科技有限责任公司

Phenolic resin casting plate preparation method

The invention discloses a phenolic resin casting plate preparation method, and belongs to the technical field of material molding. The method comprises the following three steps: a vacuum pumping step, a phenolic resin solidification step, and a demoulding step. The preparation method can prepare a smooth, bubble-free, easily-molded phenolic resin casting.

Owner:HONGYANG MACHINERY FACTORY

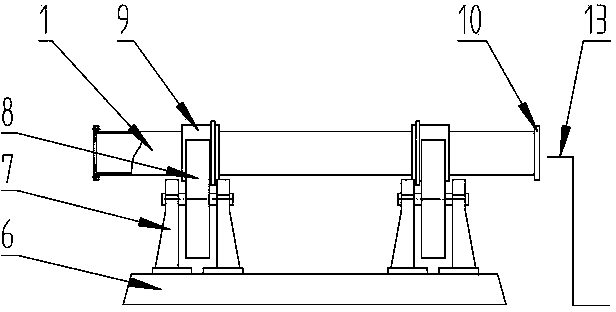

Method for producing silicon rubber mutual inductor

The present invention is production process of silicon rubber mutual inductor with the advantages of both epoxy resin and silicon rubber. The production process includes two steps, one vacuum epoxy resin casting step to form epoxy resin layer on the windings of mutual inductor and one silicon rubber casting step to form silicon rubber layer in all the non-winding parts of the mutual inductor. The silicon rubber casting includes pre-treatment of the mutual inductor and casting inside a vacuum casting apparatus.

Owner:刘辉南

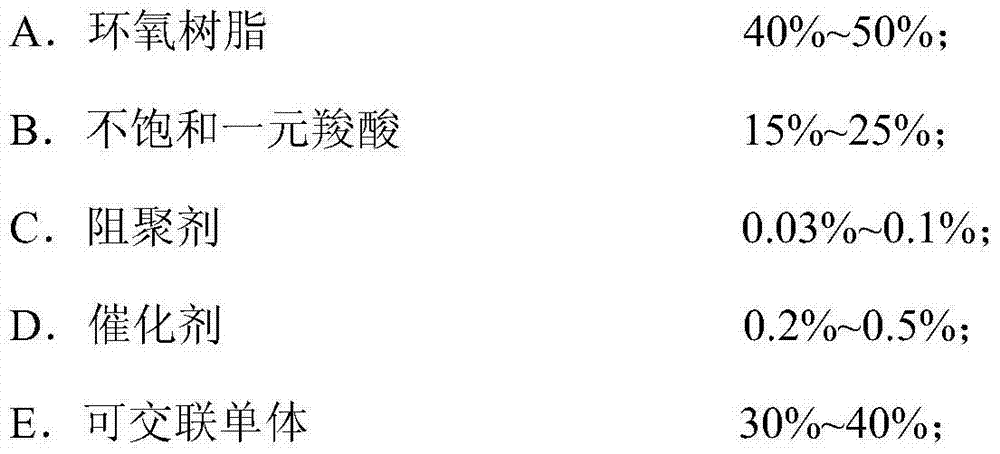

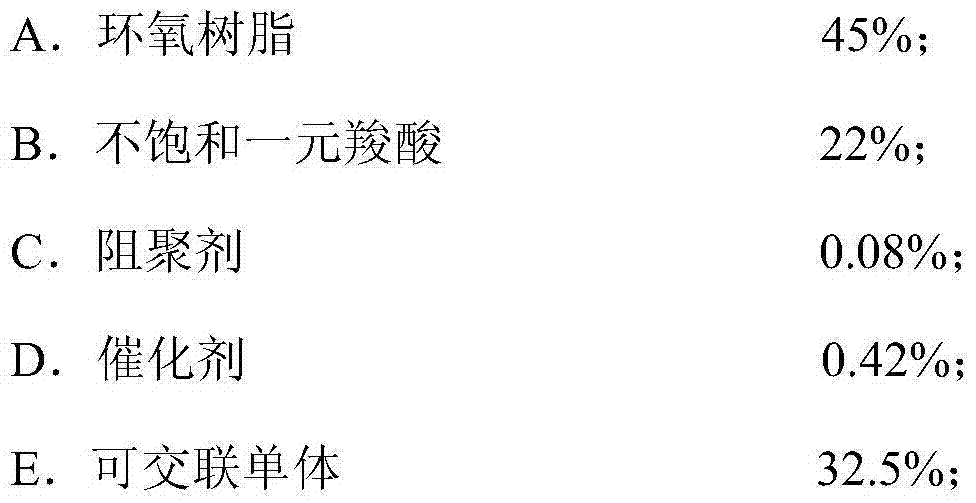

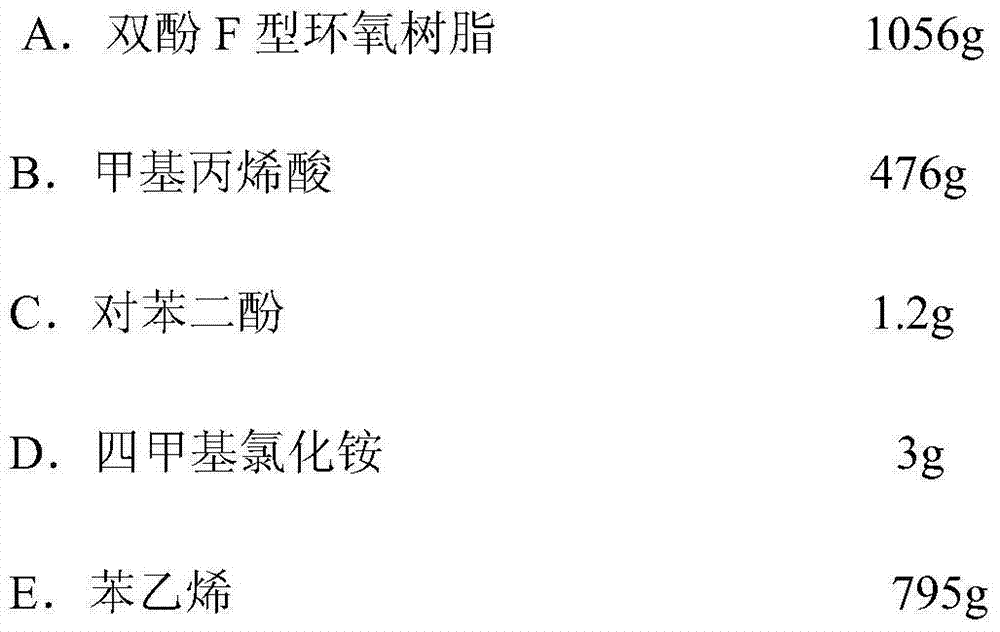

Impact-resistant epoxy vinyl ester resin and its preparation method and use

InactiveCN104725575AAffects impact resistanceAffect other mechanical strength propertiesCarboxylic acidVinyl ester

The invention relates to an impact-resistant epoxy vinyl ester resin and its preparation method and use. The impact-resistant epoxy vinyl ester resin comprises, by mass, A, 40-50% of epoxy resin, B, 5-25% of unsaturated monocarboxylic acid, C, 0.03-0.1% of a polymerization inhibitor, D, 0.2-0.5% of a catalyst and E, 30-40% of a crosslinking monomer. The epoxy resin is one of bisphenol F epoxy resin, hydrogenated bisphenol A epoxy resin, and dimer acid-modified epoxy resin. The preparation method utilizes a ring-opening esterification reaction of the flexible epoxy resin and organic unsaturated monocarboxylic acid, utilizes an appropriate raw material ratio, greatly improves resin toughness, realizes resin casting impact strength of 20-30KJ / m<2>, utilizes less types of the raw materials, has simple synthesis processes, is environmentally friendly, and does not produce three wastes. The impact-resistant epoxy vinyl ester resin has good stability.

Owner:CHANGZHOU HUAKE POLYMERS

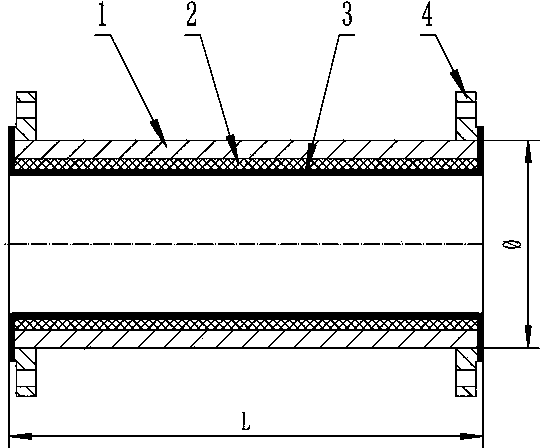

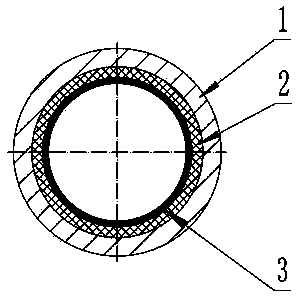

Manufacturing method of large-caliber wear-resistant and corrosion-resistant ternary composite pipe

InactiveCN103453236AReduce distortionTight and smoothMetallic material coating processesRigid pipesThermal dilatationShock resistance

The invention relates to a manufacturing method of a large-caliber wear-resistant and corrosion-resistant ternary composite pipe. The ternary composite pipe has the nominal diameter (DN) to be 600-1200mm. The method concretely comprises the steps: 1, using a matched wedge ring type fixture or a sleeve wedge ring type fixture on a centrifugal machine, and enabling a large-caliber steel pipe to make centrifugal rotation; 2, carrying out an SHS (self-propagating high-temperature synthesis) to enable the reaction product TiB2 / ZrB2-Al2O3 to be effectively distributed on the inner surface of the steel pipe; 3, adopting a centrifugal vacuum impregnation process and carrying out inner surface mixed resin casting molding. According to the manufacturing method, the wear-resistant and corrosion-resistant ternary composite pipe is manufactured on the inner surface of the steel pipe by the matched mould equipment, so that the problems caused by the SHS technology applied to the manufacture of the large-caliber pipe can be solved. The large-caliber wear-resistant and corrosion-resistant ternary composite pipe manufactured by the method is strong in bonding force between an inner liner composite layer and an outer layer steel pipe interface and high in mechanical shock resistance, effectively solves the problems of cracking and falling off of different composite layers due to different thermal expansions of different mediums, is good in wear resistance and corrosion resistance and long in service life, and has important construction value.

Owner:FUDAN UNIV

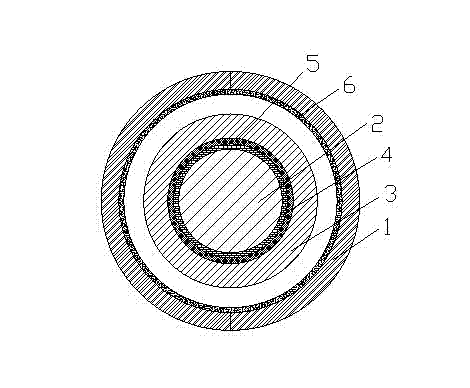

Noise-reducing demagnetizing electric reactor

InactiveCN102856047AReduce noiseReduce vibrationTransformers/inductances casingsTransformers/inductances noise dampingNuclear engineeringThermal expansion

The invention discloses a noise-reducing demagnetizing electric reactor which comprises an iron core post body and a coil, wherein the iron core post body is arranged in an insulating tube, the coil is wound around the iron core post body, the iron core post body is wrapped by a noise-reducing layer, the noise-reducing layer is wrapped by a tensile layer, and a shielding layer made of permeability magnetic materials is attached to the inner wall of the insulating tube. According to the noise-reducing demagnetizing electric reactor disclosed by the invention, through arranging a resin casting layer on the outside of the iron core post body, the noise and vibration generated by the electric reactor are greatly reduced; because the resin casting layer is wrapped by a tensile layer, a situation that the resin casting layer is cracked due to thermal expansion can be prevented; and because the shielding layer made of permeability magnetic materials is attached to the inner wall of the insulating tube, the electric reactor has a good shielding effect, good iron core saturation resistance and a low magnetic conductivity, thereby ensuring the quality of the electric reactor.

Owner:臧建虎

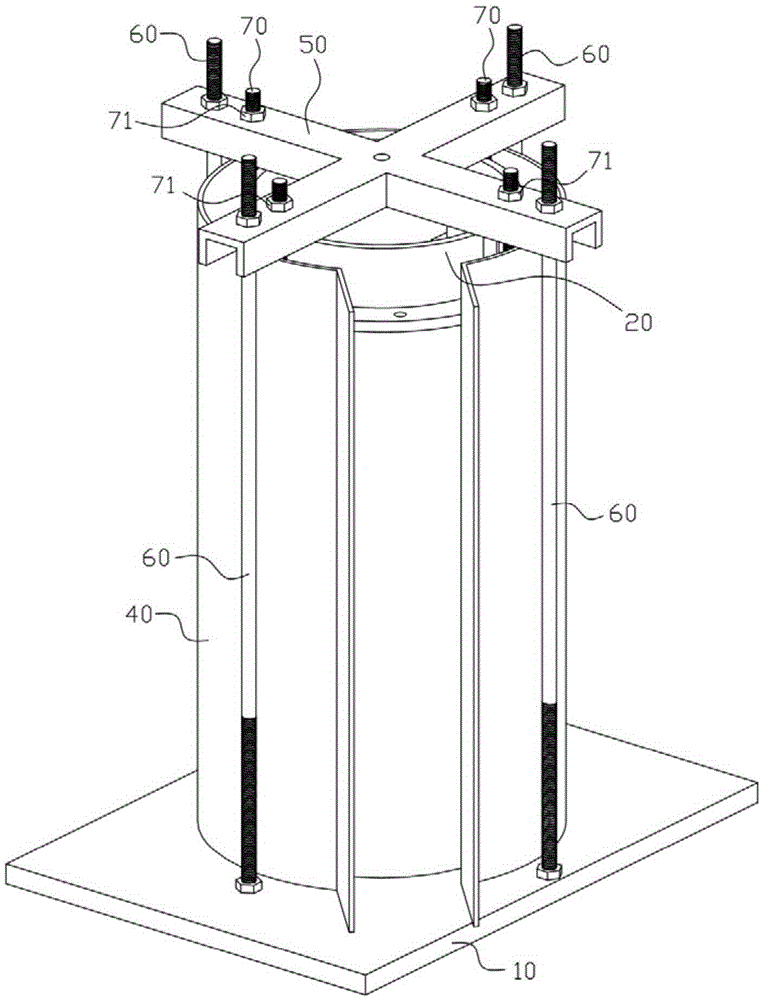

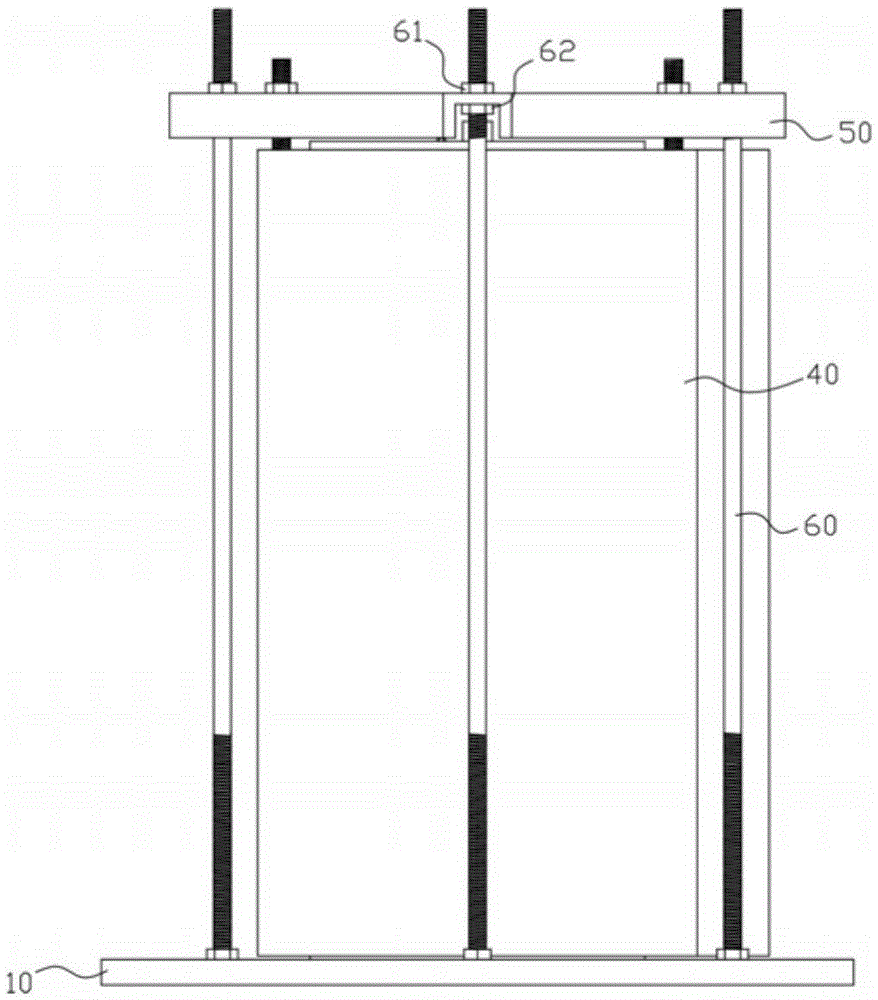

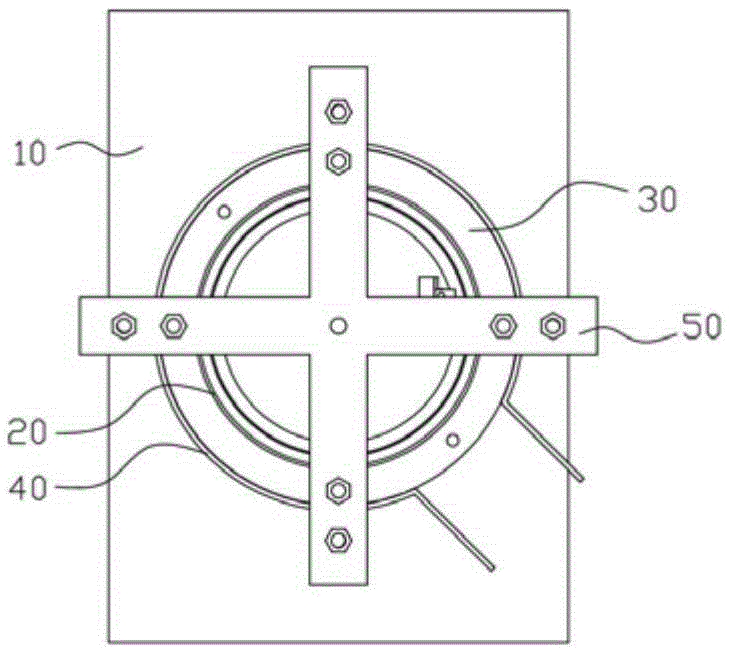

Epoxy casting mold with adjustable casting height and easy-to-disengage inner mold body

The invention discloses an epoxy casting mold with the adjustable casting height and an easy-to-disengage inner mold body. The epoxy casting mold comprises a bottom plate, the inner mold body, an outer mold body, an upper end cover and a pressing part. The inner mold body and the outer mold body are installed on the bottom plate, the upper end cover is located between the inner mold body and the outer mold body, and the pressing part is located above the outer mold body. The tops of long threaded rods installed on the bottom plate are inserted into first through holes of the pressing part, and upper nuts and lower nuts for clamping the pressing part are screwed to the long threaded rods. The tops of short threaded rods screwed to the upper end cover are inserted into second through holes of the pressing part, and upper nuts and lower nuts for clamping the pressing part are screwed to the short threaded rods. Lifting of the long threaded rods for the pressing part and the short threaded rods are matched to adjust the height of the upper end cover, the position of the upper end cover is adjusted at will within a certain range accordingly, and then the epoxy resin casting height of various transformers is met. The inner mold body is formed by coiling a board in a barrel shape, and a certain gap is formed between the two ends of the board. After casting is completed, a worker can conveniently dismount the short threaded rods so as to remove attachments on the short threaded rods, and the inner mold body and a finished product can be conveniently disengaged.

Owner:AQ ELECTRIC SUZHOU

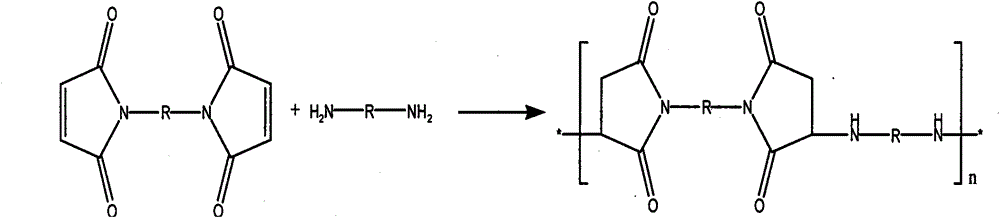

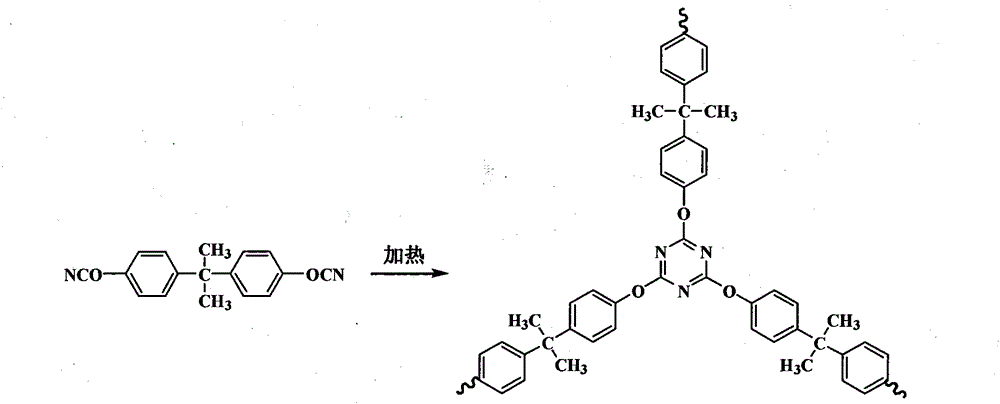

Thermosetting shape-memory resin capable of memorizing multiple shapes, and preparation method thereof

ActiveCN104130426AAchieving the shape memory effectImprove mechanical propertiesCross-linkTemperature resistance

The invention relates to a thermosetting shape-memory resin capable of memorizing multiple shapes, and a preparation method thereof. The method comprises the following steps: bismaleimide and polyether amine are mixed and dissolved in tetrahydrofuran; a reaction is allowed for 24h under a temperature of 65 DEG C; when the solution has an amber color, bisphenol A type cyanate is added; the mixture is fully and uniformly mixed; and resin casting body or shape-memory composite material preparation is carried out according to required process parameters. Polyether amine can be subjected to a reaction with bismaleimide resin monomer, such that a linear molecular framework can be formed, and can be adopted as a resin deformation and recovery reversible phase. Resin shape memory effect can be realized, and resin mechanical performance can be improved. With the existences of various cross-linked structures, the resin has a relatively wide glass transition temperature range, such that the function of resin system of memorizing different shapes under different temperatures can be realized. Also, high mechanical performance and temperature resistance level can be maintained.

Owner:HARBIN INST OF TECH

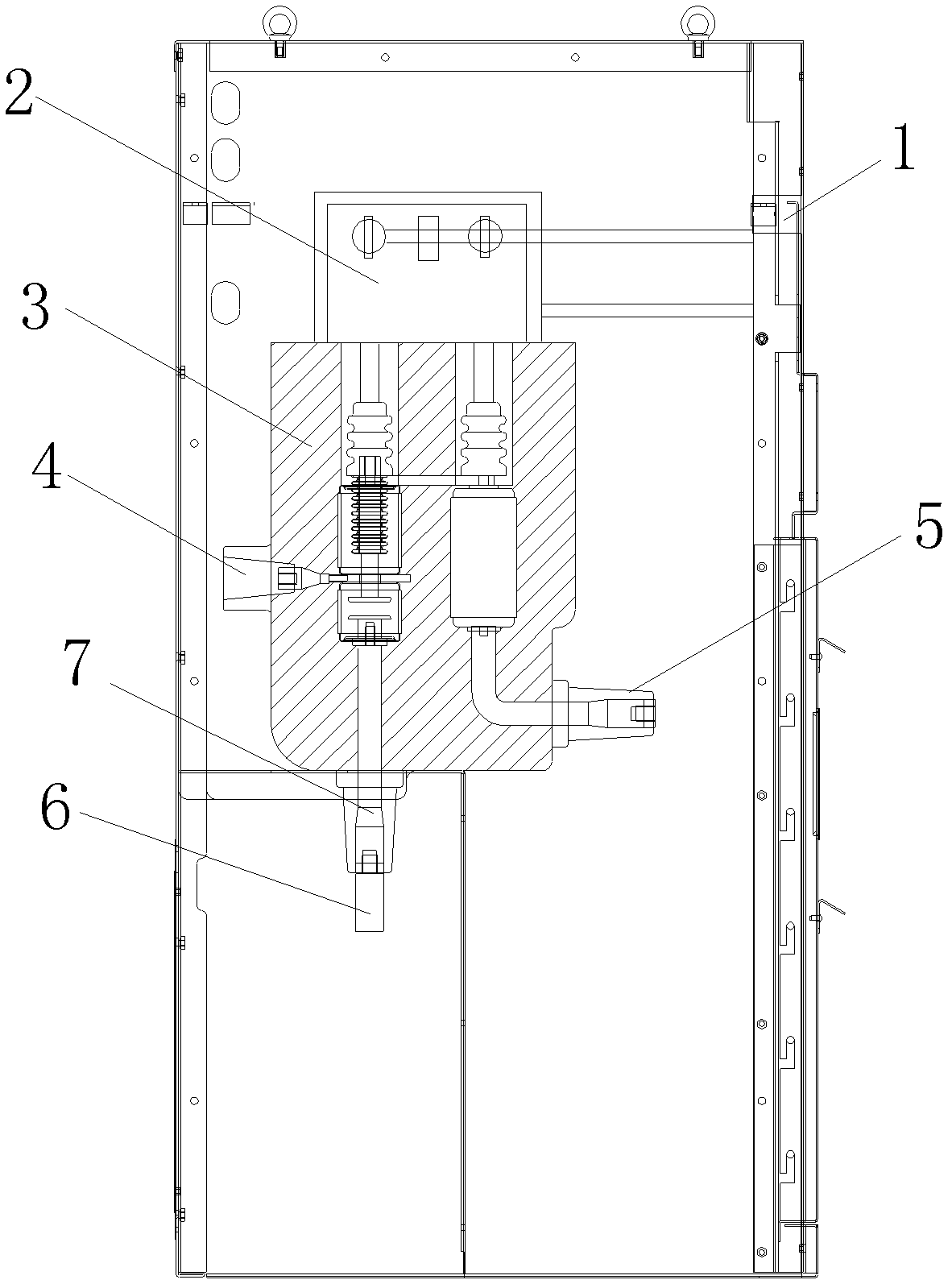

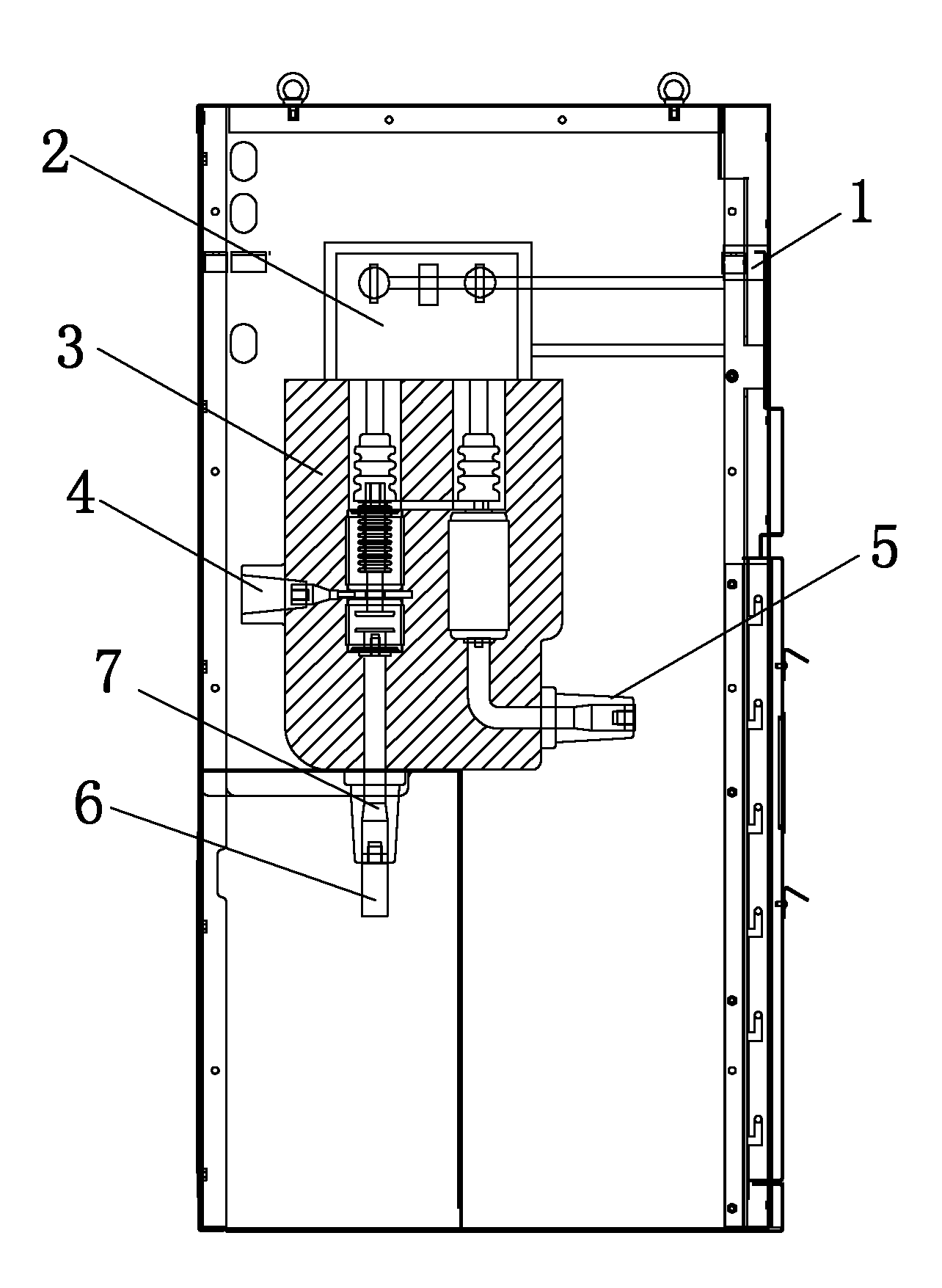

Full solid insulation ring network cabinet

ActiveCN102290733AAchieving a modular designEasy to replace in placeSwitchgear arrangementsEpoxyRing network

The invention discloses a total solid insulating ring network cabinet comprising a cabinet body, wherein a solid-sealed polar pole is arranged in the cabinet body; the solid-sealed polar pole comprises an epoxy resin casting block, a vacuum arc extinguish chamber and a vacuum isolation switch; the vacuum arc extinguish chamber and the vacuum isolation switch are arranged in the epoxy resin casting block; the static contact of the vacuum arc extinguish chamber is connected with a first line inlet and outlet casing pipe which is positioned at the side of the epoxy resin casting block; the dynamic contact of the vacuum arc extinguish chamber is linked with a first pull rod; the static end of the vacuum isolation switch is connected with a second line inlet and outlet casing pipe; the second line inlet and outlet casing pipe is positioned at the side of the epoxy resin casting block; the dynamic end of the vacuum isolation switch is linked with a second pull rod; the dynamic end of the vacuum isolation switch is connected with the dynamic contact of the vacuum arc extinguish chamber through soft connection; the upper ends of the first pull rod and the second pull rod extend out of the epoxy resin casting block; and the first pull rod and the second pull rod are connected with an operation mechanism. The total solid ring network cabinet can be used for enhancing the insulating capability and effectively eliminating potential safety hazard, and has a higher protection level.

Owner:NINGBO YAOHUA ELECTRIC TECH

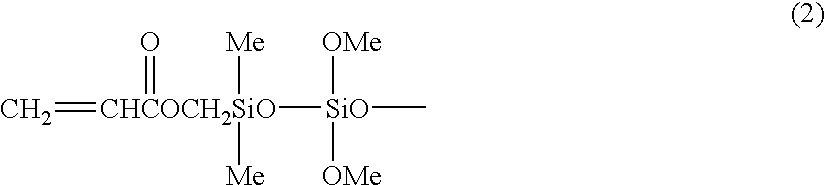

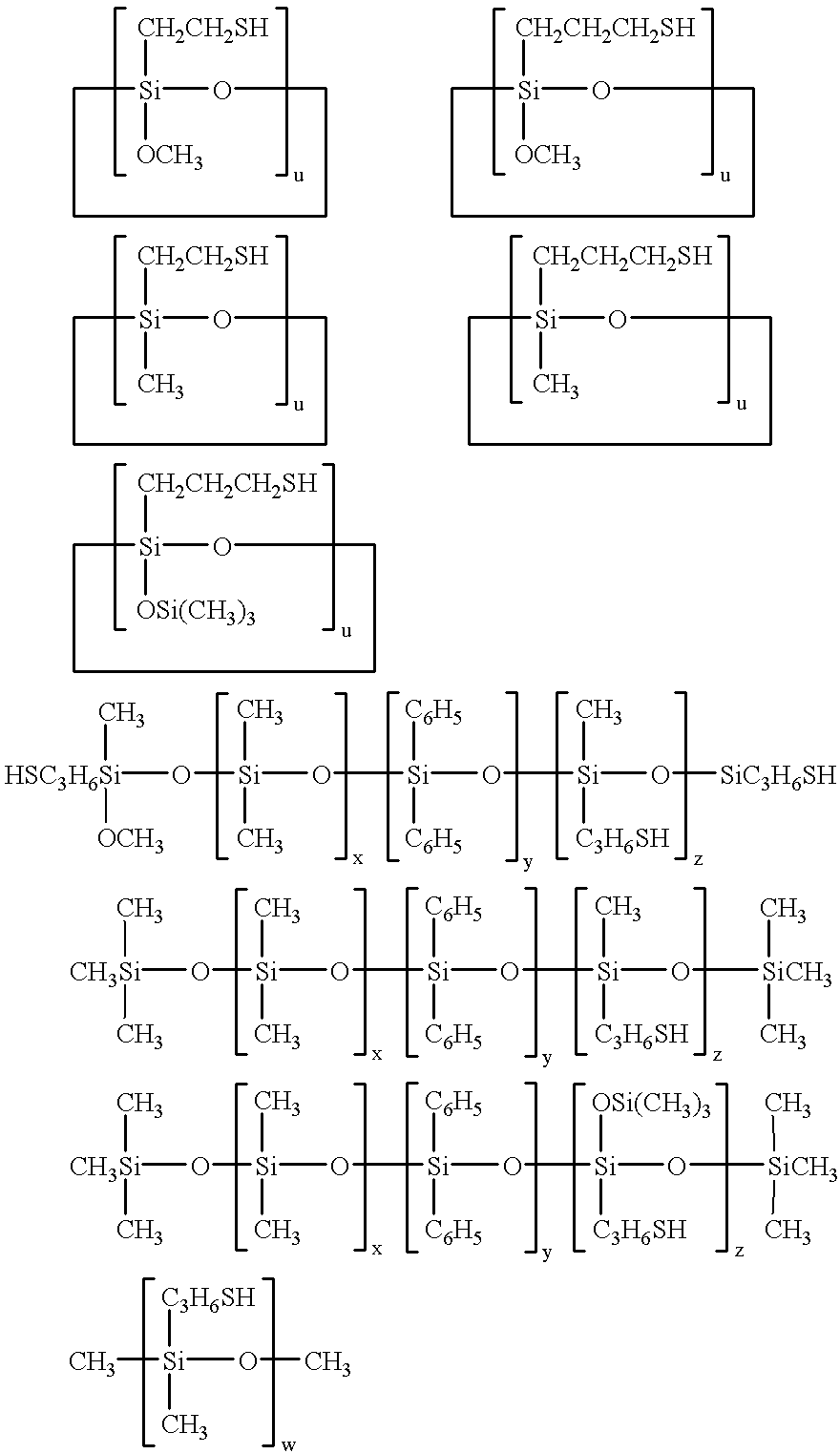

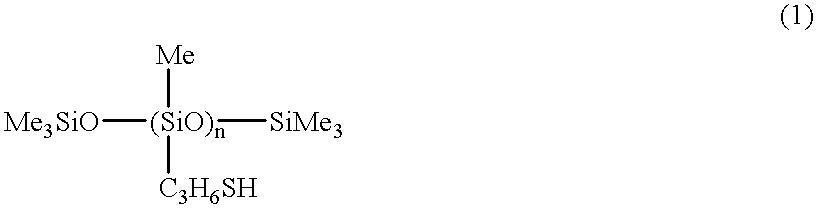

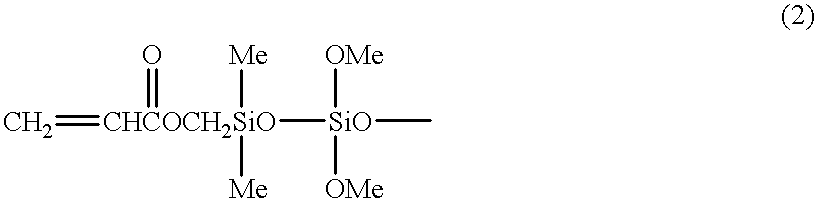

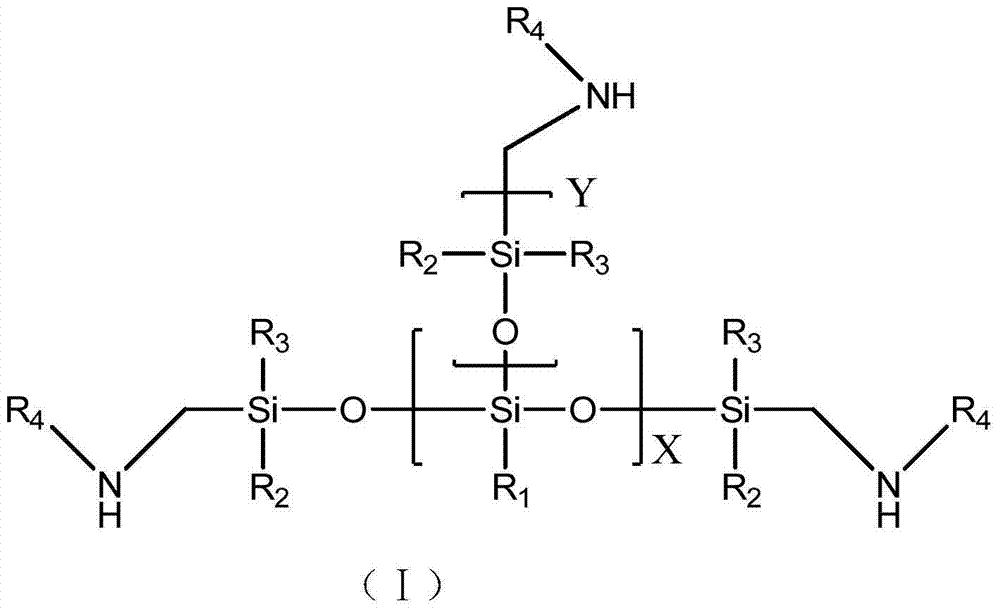

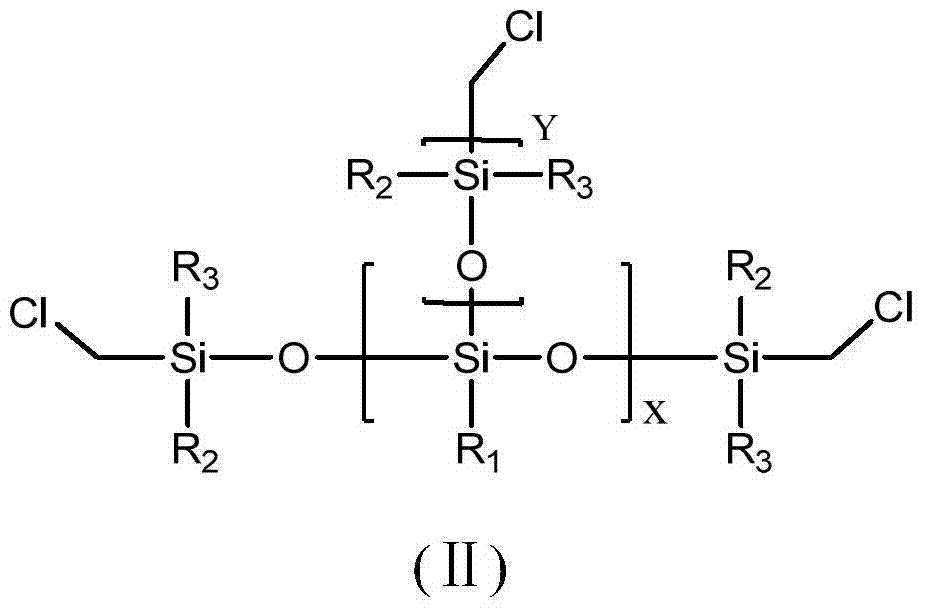

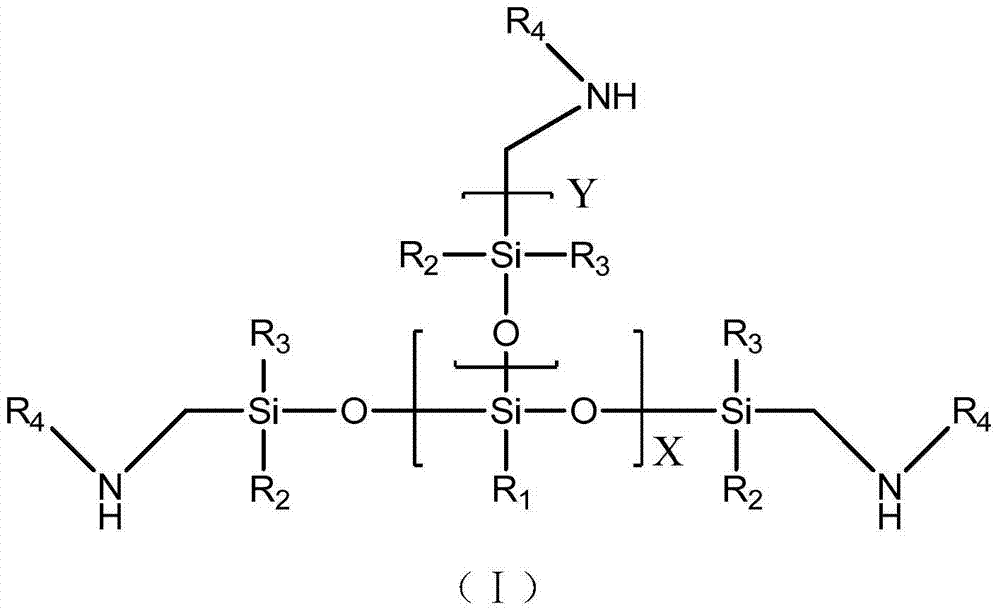

Branched organosilicon epoxy resin curing agent and epoxy curing system

ActiveCN103923320AWell mixedImprove impact resistanceGroup 4/14 element organic compoundsEpoxyLow temperature curing

The invention discloses a branched organosilicon epoxy resin curing agent and an epoxy curing system. The curing agent can improve the impact resistance, the adhesive property and the bending strength of an epoxy resin product and the toughness of epoxy resin. The epoxy curing system comprises the branched organosilicon epoxy resin curing agent and particularly comprises the following main components in parts by weight: 100 parts of epoxy resin, 5-80 parts of branched organosilicon epoxy resin curing agent and 0-20 parts of curing accelerator. The curing agent disclosed by the invention is a transparent liquid with low viscosity at normal temperature and is easy to be uniformly mixed with epoxy resin, and can be used for curing most types of epoxy resin. An epoxy resin casting body prepared by the curing agent is transparent and free from bubbles. The curing agent can cure most epoxy resins at low temperatures in range of 20-100 DEG C, and the epoxy resin solid lower than 100 DEG C is a colorless transparent solid. The property of the curing agent can be adjusted by changing the type and quantity of active groups on the curing agent or adjusting the length of the chain segment of siloxane. The curing agent is wide in application.

Owner:ZHEJIANG UNIV

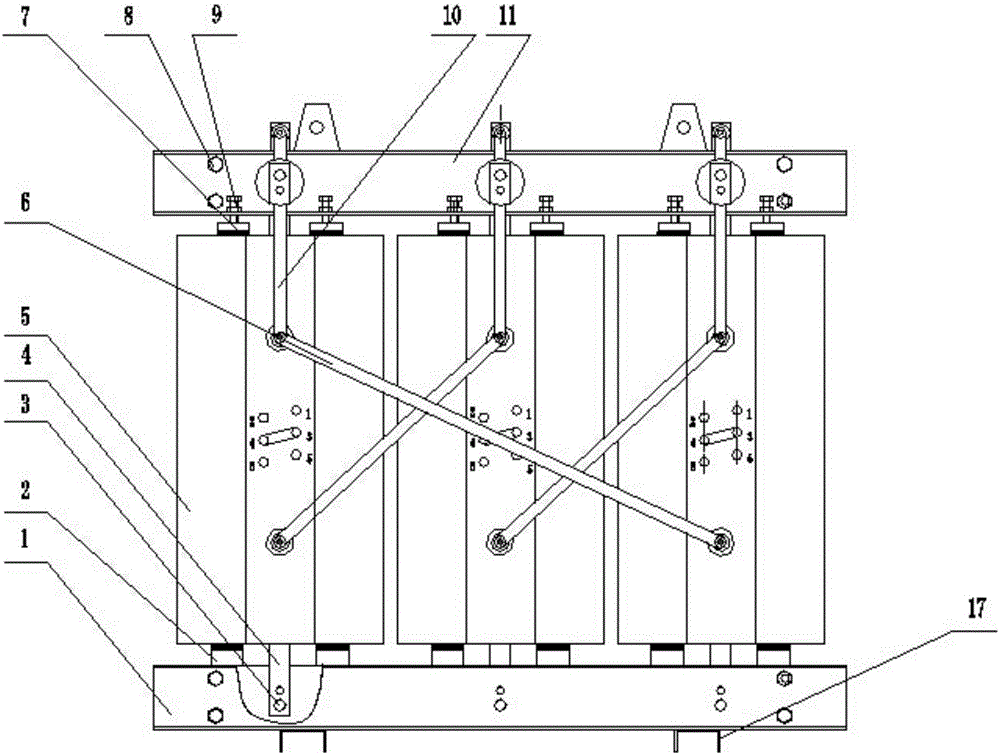

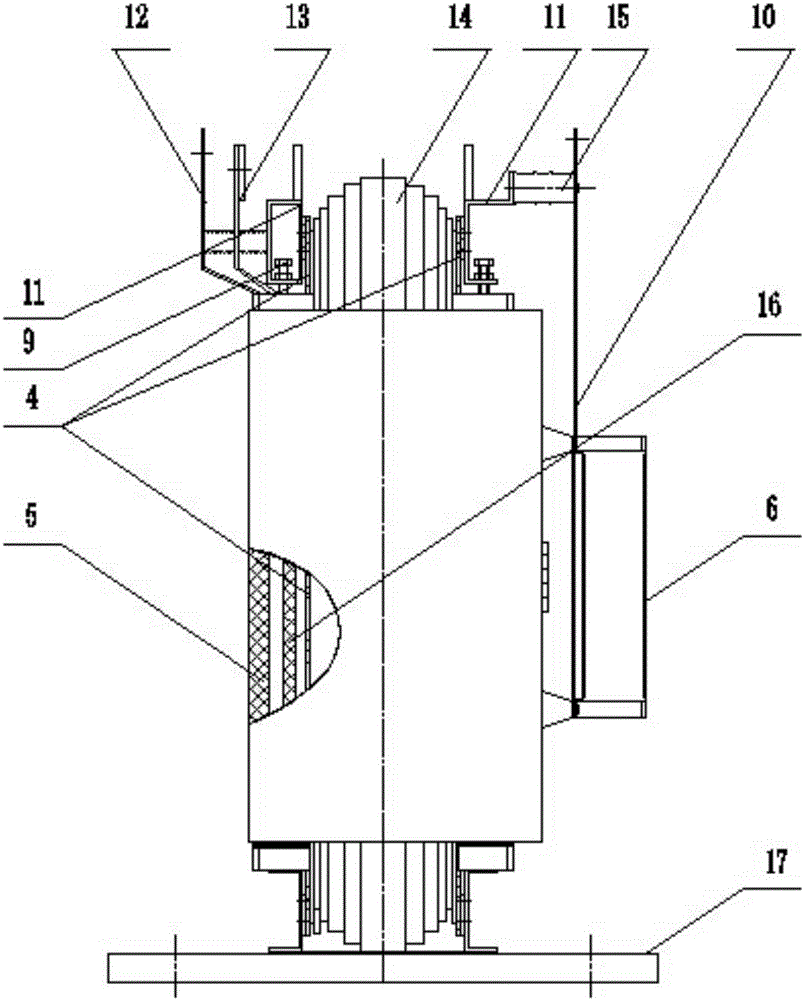

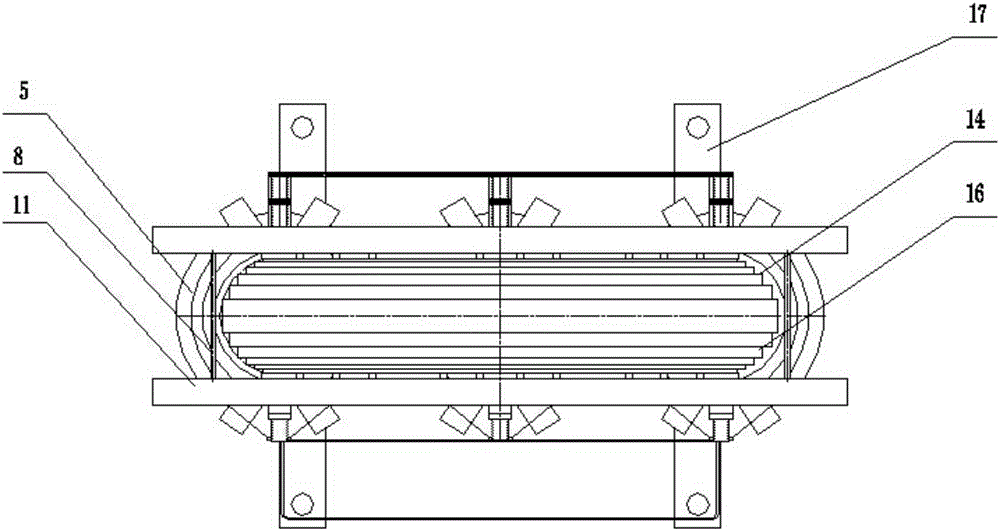

Resin casting coil dry-type transformer structure and assembling method thereof

ActiveCN106158284AIngenious structural designImprove performanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerLow voltage

The invention relates to a resin casting coil dry-type transformer structure and an assembling method thereof. The resin casting coil dry-type transformer structure comprises a transformer body arranged on a base, wherein the transformer body comprises an iron core, an upper clamping part, a lower clamping part and high-voltage and low-voltage resin coils; the low-voltage resin coil and the high-voltage resin coil sleeve the external circumference of a core column of the iron core respectively; the bottoms of the high-voltage and low-voltage resin coils are mounted on a cushion block and an embedding part of the lower clamping part by piers; a pressing block, an embedding part and a pressing plate are arranged at the top of the high-voltage and low-voltage resin coils and the pressing plate is tightly pressed by rotating a pressing stud through an upper clamping part screw hole, so that the high-voltage and low-voltage resin coils are tightly pressed and fixed; pull plates are arranged on the two sides of the core column of the iron core; and the upper and lower ends of the pull plates are fixedly connected with the upper clamping part and the lower clamping part through pins respectively. With the adoption of the dry-type transformer structure provided by the invention, the stability of the iron core and the coils is enhanced and a displacement phenomenon of the high-voltage and low-voltage resin coils in a transportation process of a transformer can be avoided. The creeping distance is increased through a pressing block reinforcing rib and a partial discharging condition is reduced; and the properties of the transformer are effectively improved.

Owner:鑫大变压器有限公司

Preparation method for high-viscosity resin casting body

The invention belongs to a macromolecular material evaluation technology. A resin matrix and / or a curing agent are / is dissolved or diluted through the dilution of a low-boiling-point solvent to resin and the characteristic that the low-boiling-point solvent is easy to discharge; the viscosity of a resin system at normal temperature is reduced; then heating is executed to remove the solvent and air bubbles in vacuum, including determination of initial curing temperature, dissolving and mixing, viscosity adjustment, bubble removal and curing processes. According to the method, the air bubbles formed in a high-viscosity resin casting forming process can be effectively eliminated; the non uniformity of the performance of the resin casting body, which is caused by deposition in the curing process, is prevented; the preparation method is suitable for resin systems which are liquid, semisolid and solid at the room temperature and also suitable for resin systems in which the curing agent, an accelerant and the like cannot be dissolved in main resin; the preparation method is particularly suitable for resin systems which are solid or semisolid under the room temperature and are still extremely high in viscosity after being heated to the initial curing temperature.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com