Patents

Literature

35results about How to "Solve sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

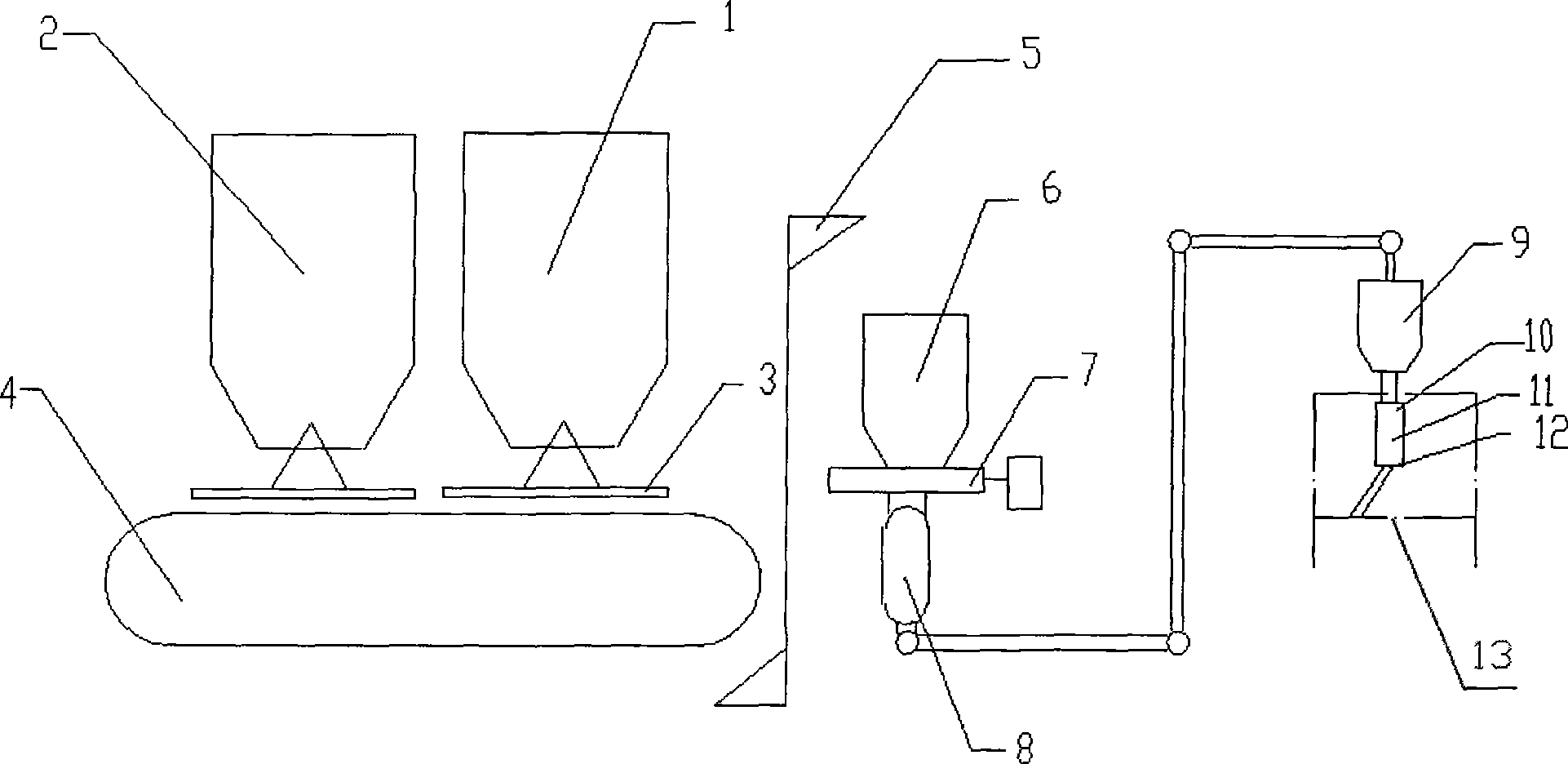

Equipment for preparing mixed crude sand of sand core and method for preparing mixed crude sand

InactiveCN101497106ASolve sinteringSolve quality problemsMould handling/dressing devicesPolyresinMaterials science

The invention relates to a device for preparing mixed roughing sand of a sand core and a method for preparing the mixed roughing sand. The device comprises a regenerated sand storage hopper and a new sand storage hopper which are arranged in parallel, a disk feeder, a belt conveyer, a hoisting machine, a sand hopper, a sand conveyer, a sand mixer and the like. The method comprises the following steps: putting regenerated sand into the regenerated sand storage hopper and putting new sand into the new sand storage hopper simultaneously with the weight ratio of the regenerated sand to the new sand being 1:1; unloading the regenerated sand and the new sand to the belt conveyer at the same time; conveying the regenerated sand and the new sand to the sand hopper and then mixing the regenerated sand and the new sand in the sand hopper; and conveying the mixed sand to the sand mixer through the sand conveyer, and controlling quantitative mixed sand to enter the mixer to be mixed with resin therein so as to form the mixed roughing sand of a sand core. The device and the method have the advantages of effectively controlling the product quality, and preventing a regenerated sand core from being sintered and generating veins.

Owner:GUANGXI YUCHAI MASCH CO LTD

Method for oxygen-enriched calcification calcination of high-grade vanadium slag

InactiveCN102828019ALow firing temperatureImprove industrialization technologyProcess efficiency improvementSlagCalcification

The invention discloses a method for oxygen-enriched calcification calcination of high-grade vanadium slag. The method comprises the following steps of mixing high-grade vanadium slag and a calcification agent to obtain a mixture and carrying out calcination of the mixture in an atmosphere having oxygen volume content of 12 to 21%. The method for oxygen-enriched calcification calcination of high-grade vanadium slag greatly reduces a calcification calcination temperature of high-grade vanadium slag, solves the problem that in calcification calcination of high-grade vanadium slag, abnormal running problems such as material agglomeration and calcination equipment ring-forming are caused by a high calcination temperature, and improves an industrialization technology of calcification calcination of high-grade vanadium slag.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

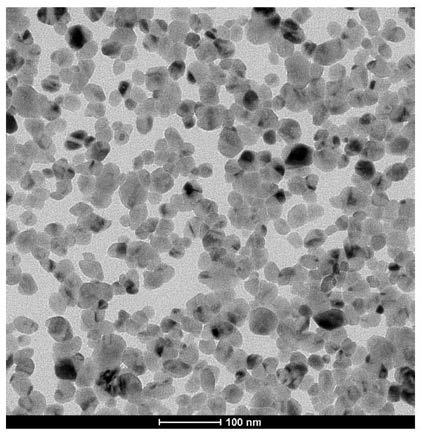

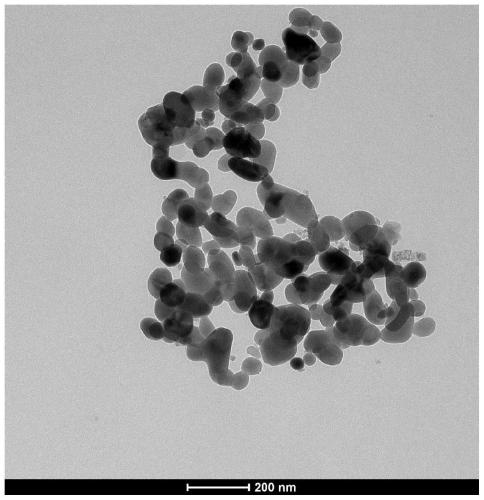

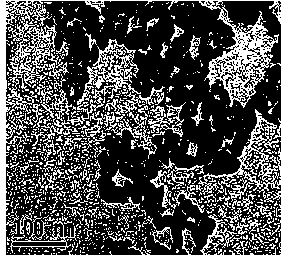

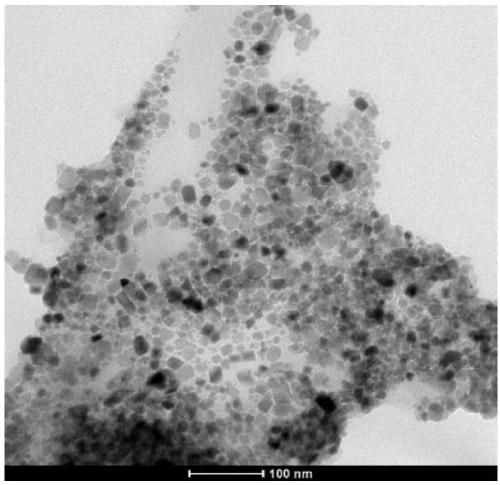

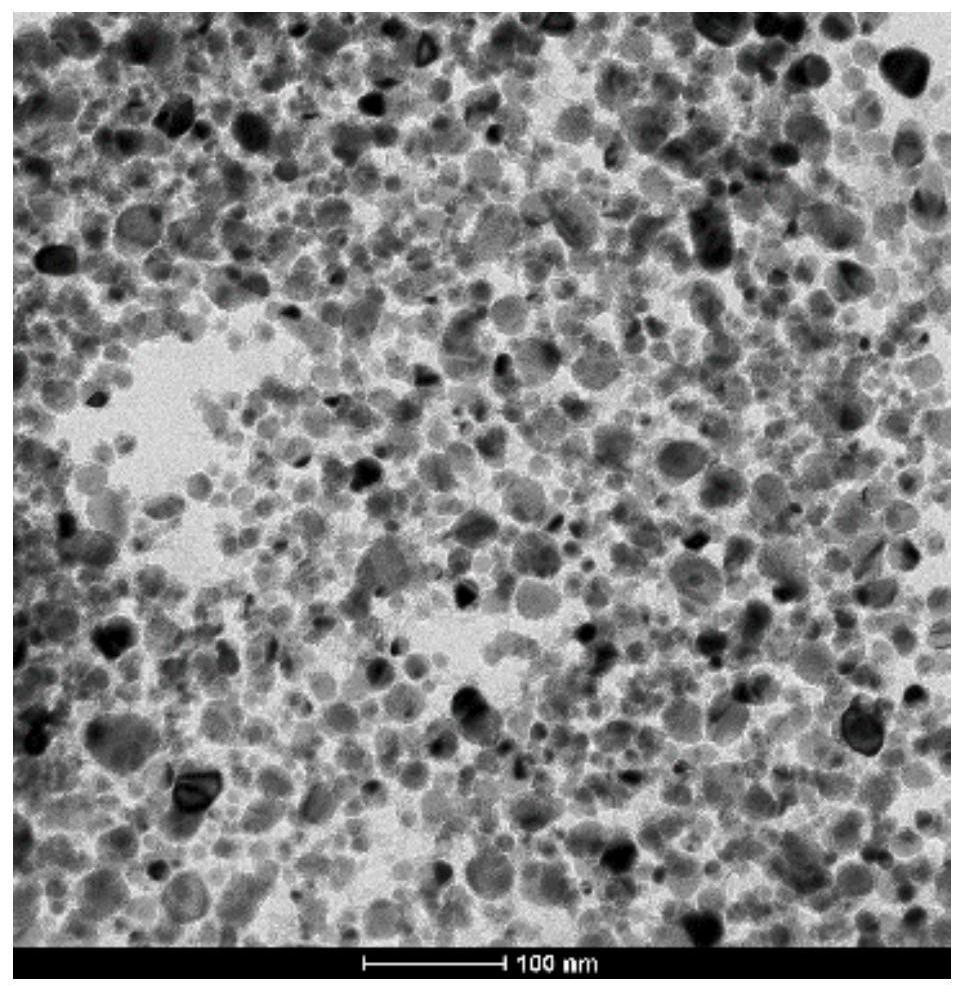

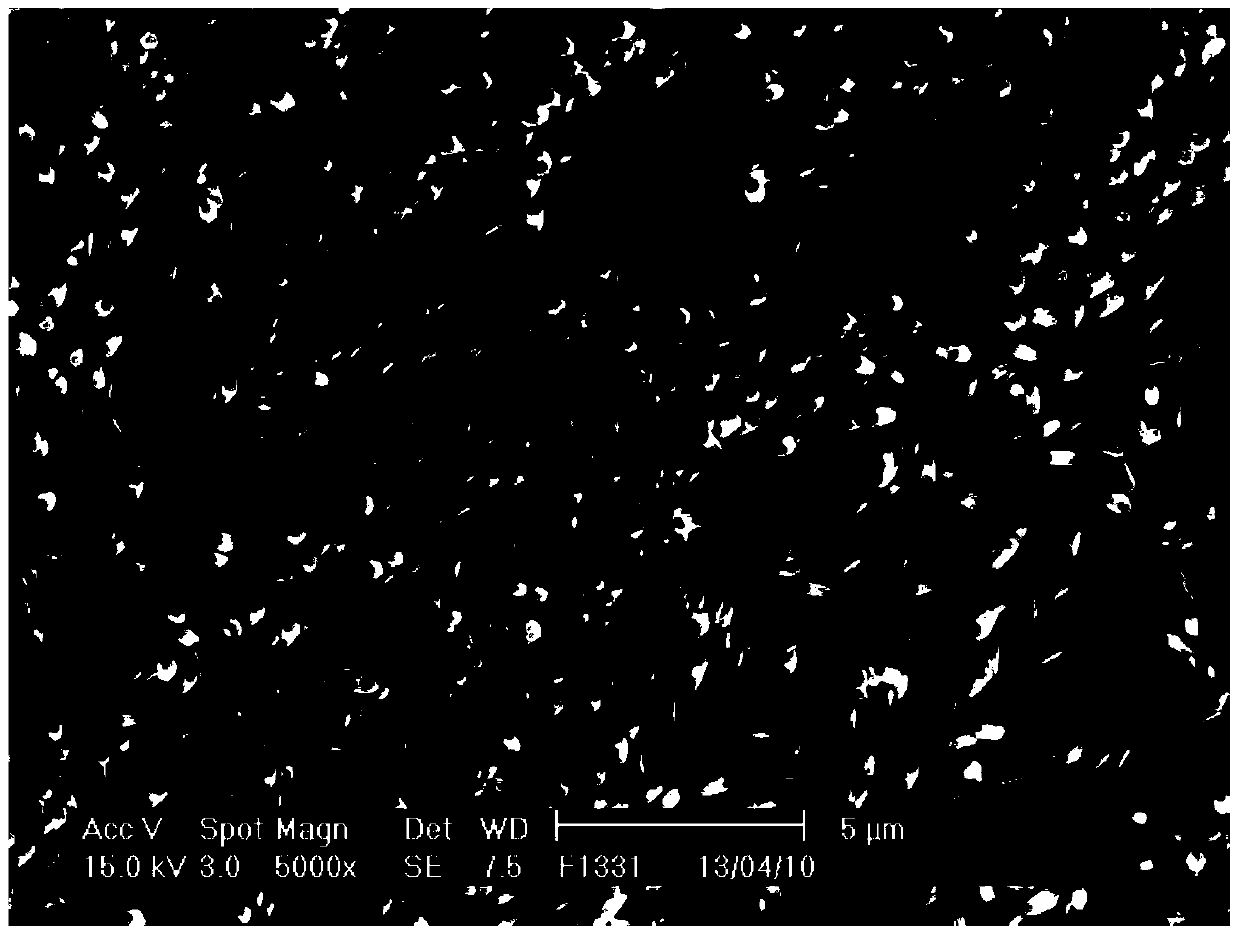

Metal oxide nanoparticles and preparation method of metal oxide nanoparticles

PendingCN111320193AGood dispersionHigh crystallinityMaterial nanotechnologyAluminium oxide/hydroxide preparationMetal oxide nanoparticlesPhysical chemistry

The invention discloses a metal oxide nanoparticle and a preparation method of the metal oxide nanoparticle, which comprises the following steps: preparing an organosol containing the metal element, mixing the organosol with a water-soluble salt, performing standing or centrifuging to precipitate the water-soluble salt, removing the superfluous organosol at the upper part, and keeping the temperature to convert the organosol into gel; along with evaporation of the solvent, shrinking the gel, and coating the surfaces of the water-soluble salt particles with a layer of xerogel film; and calcining the sample at a high temperature between 400 DEG C and a salt melting point, converting the dry gel film into metal oxide nanoparticles, dispersing and attaching the nanoparticles to the surfaces ofwater-soluble salt particles, cooling, and washing with water to remove the salt, thereby obtaining the high-dispersion metal oxide nanoparticles; if the calcined product is reduced in a reducing atmosphere, converting the metal oxide nanoparticles attached to the surfaces of the water-soluble salt particles into corresponding metal nanoparticles, cooling, and washing with water to obtain the high-dispersion metal nanoparticles. According to the method, the high-crystallinity and high-dispersion metal oxide and metal nanoparticles can be rapidly prepared in batches.

Owner:SOUTHEAST UNIV

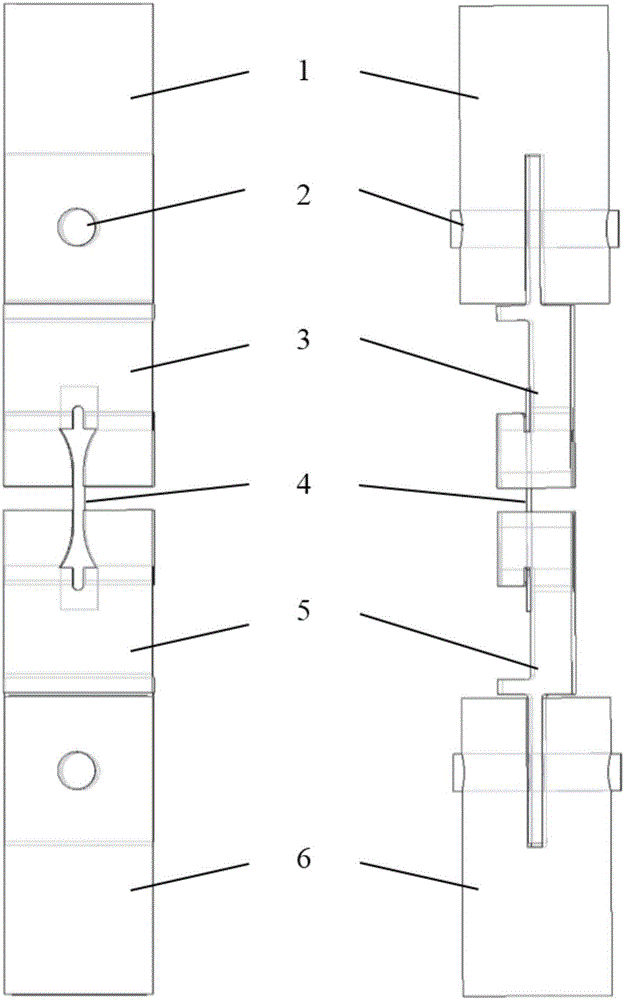

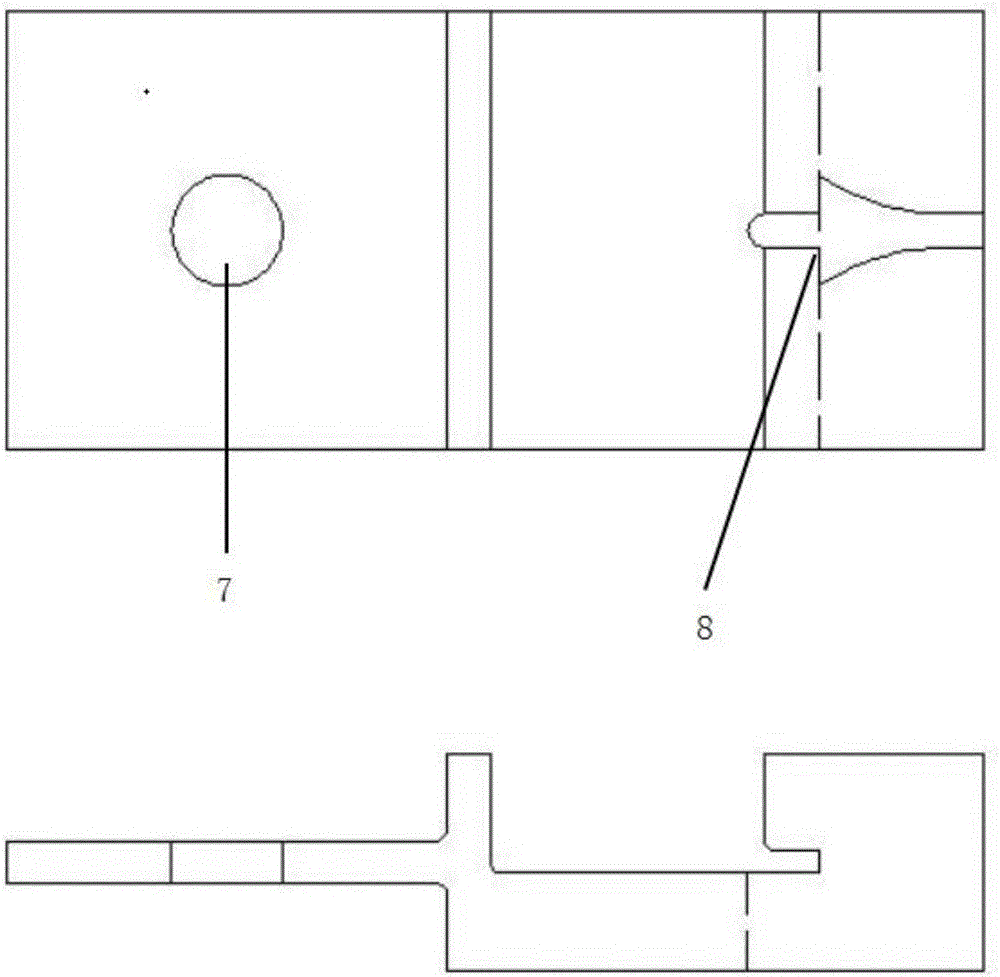

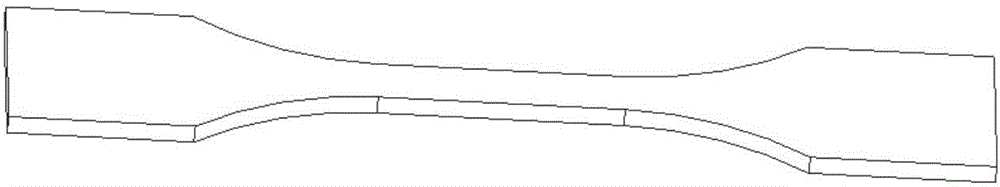

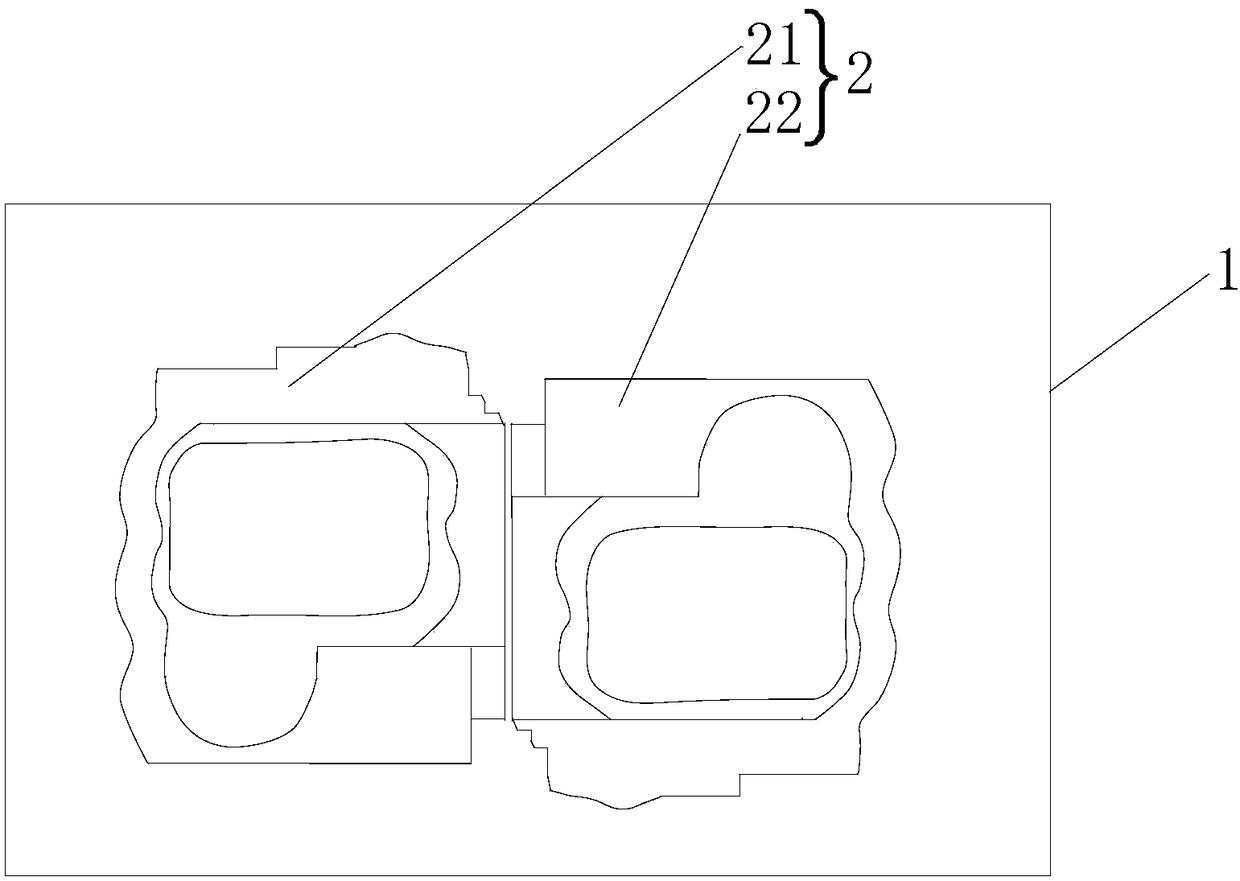

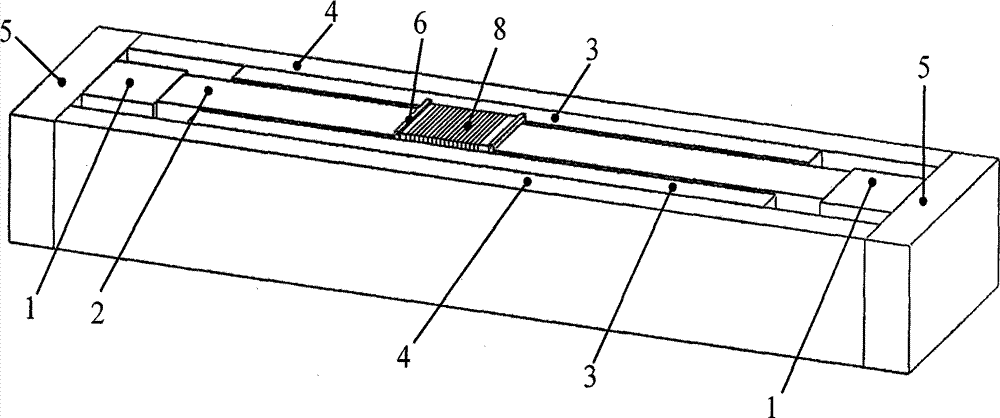

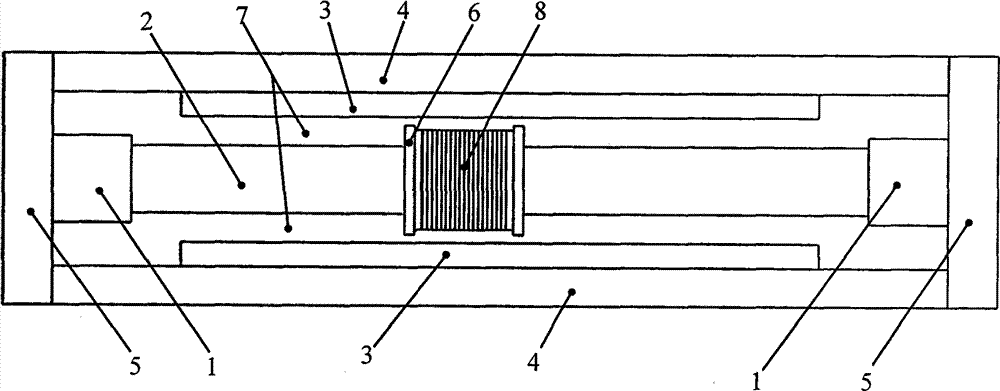

Tensile fixture for platy sample and application method thereof

PendingCN106483019AOvercome the problem of high machining accuracyGuaranteed coincidenceMaterial strength using tensile/compressive forcesHardnessHigh intensity

The invention discloses a tensile fixture for a platy sample, characterized by comprising fixture bodies (3 and 5) each of which provided with a pinhole (7) in one end and which are connected to tensile tester connection rods (1 and 6) through pins (2) so that axes of test tensile force, the fixture and a test piece are superposed; the other ends of the fixture bodies (3 and 5) are each provided with a vertical slot running through the fixture, the bottom of each groove slot is provided with a sample groove (8), the width of the sample grooves (8) is slightly greater than the thickness of the test piece (4) so that it is ensured that the test piece (4) may be placed in the fixture bodies (3 and 5) for a tensile test. The invention also discloses a tensile test method employing the fixture. According to the scheme of the invention, the end of each fixture body is provided with the vertical slot running through the fixture, and it is possible to carry out a tensile test for various samples of high strength, high hardness and high processing difficulty.

Owner:HUAZHONG UNIV OF SCI & TECH

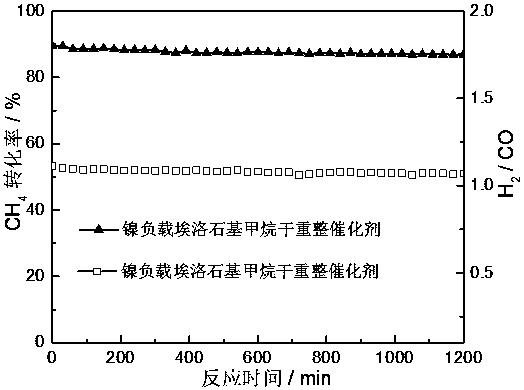

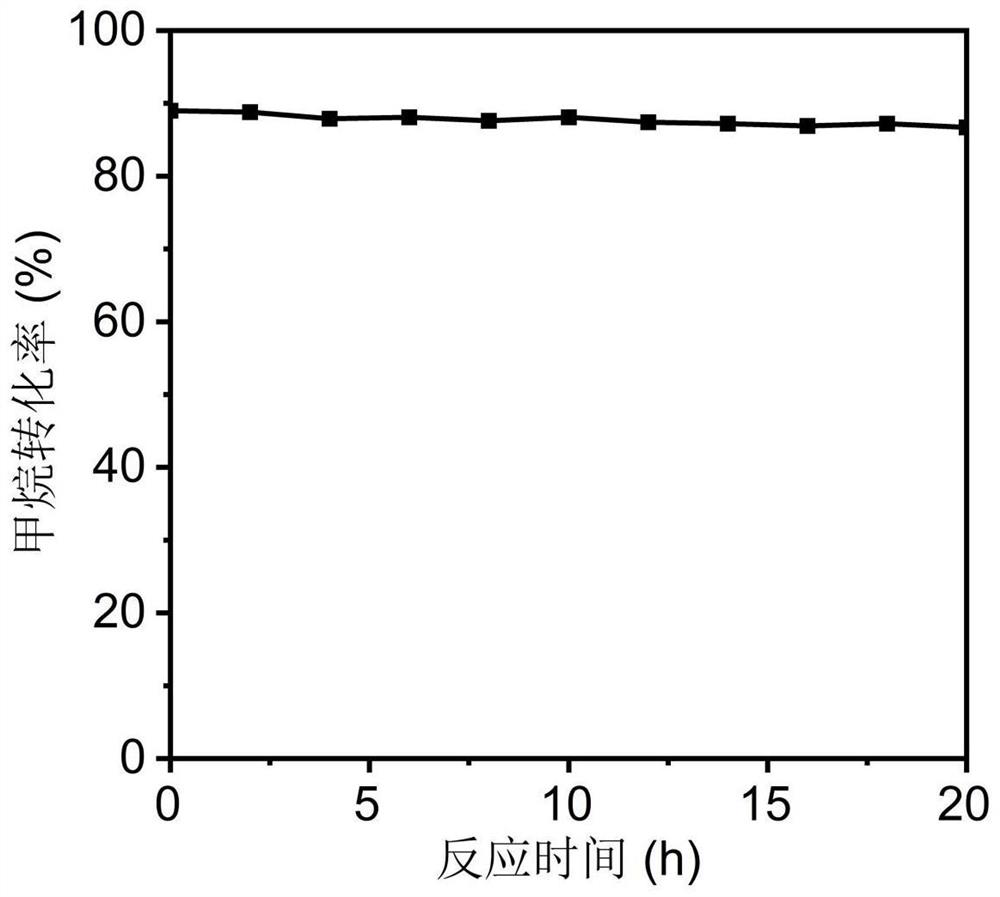

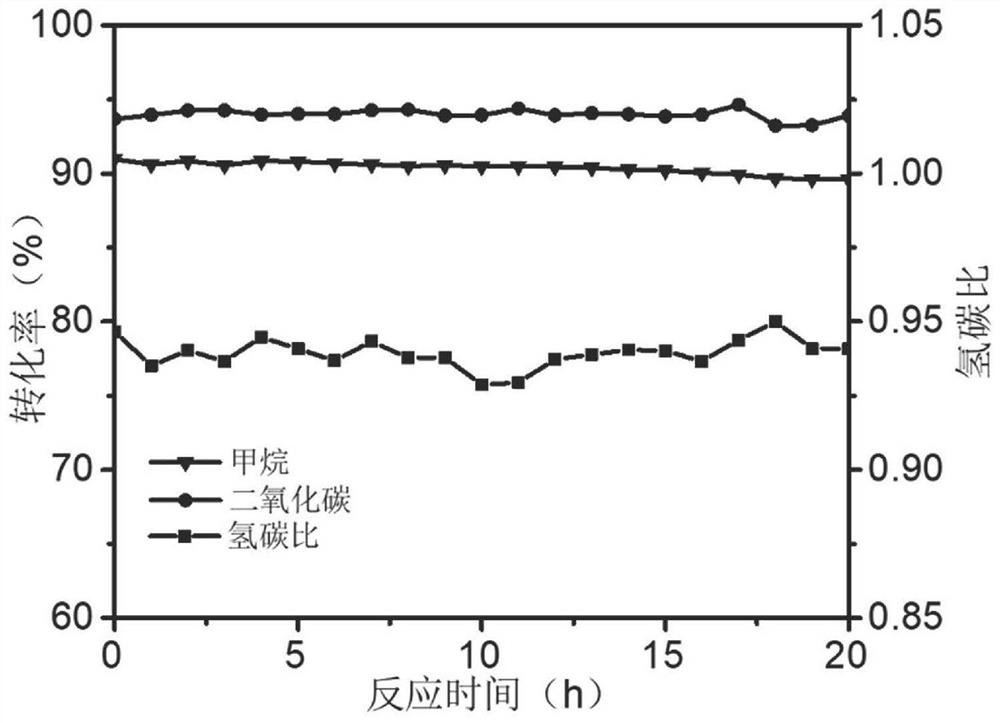

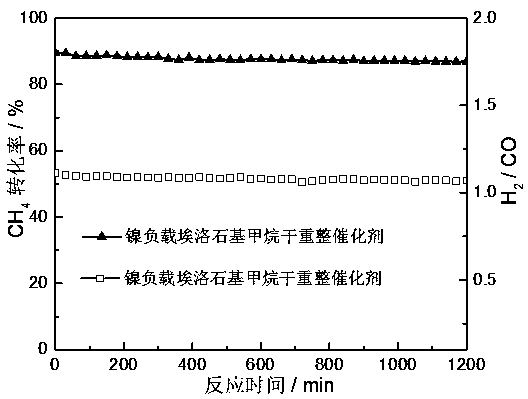

Method for preparing nickel-loaded halloysite-based methane dry reforming catalyst

ActiveCN108355662AWill not cause secondary pollutionSolve sinteringHydrogenCatalyst activation/preparationHigh resistanceHalloysite

The invention relates to a method for preparing a nickel-loaded halloysite-based methane dry reforming catalyst. The preparation method comprises the following steps: performing in situ modification on the surface of halloysite used as a carrier by a molten salt ball-milling technology to disperse and anchor an active nickel species, loading a nickel precursor on the modified surface of halloysiteby a rotary evaporative impregnation technology in order to realize uniform dispersion and strong interaction of all metals, and performing drying, high-temperature calcination and temperature programming reduction to finally obtain the catalyst with high resistance to sintering and carbon deposition. The catalyst has the advantages of simple preparation process, low cost, no pollution to the environment, high catalytic efficiency and the like.

Owner:SHANGHAI UNIV

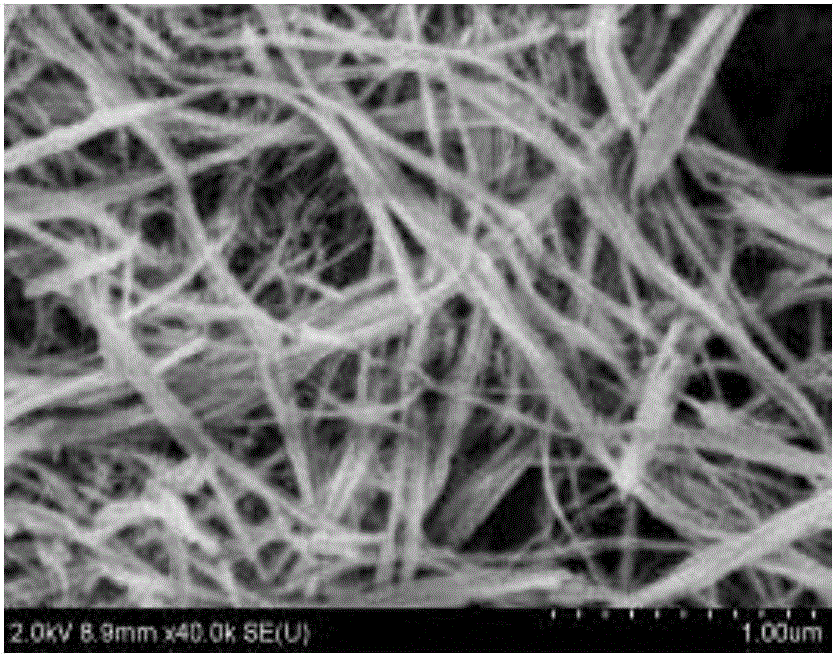

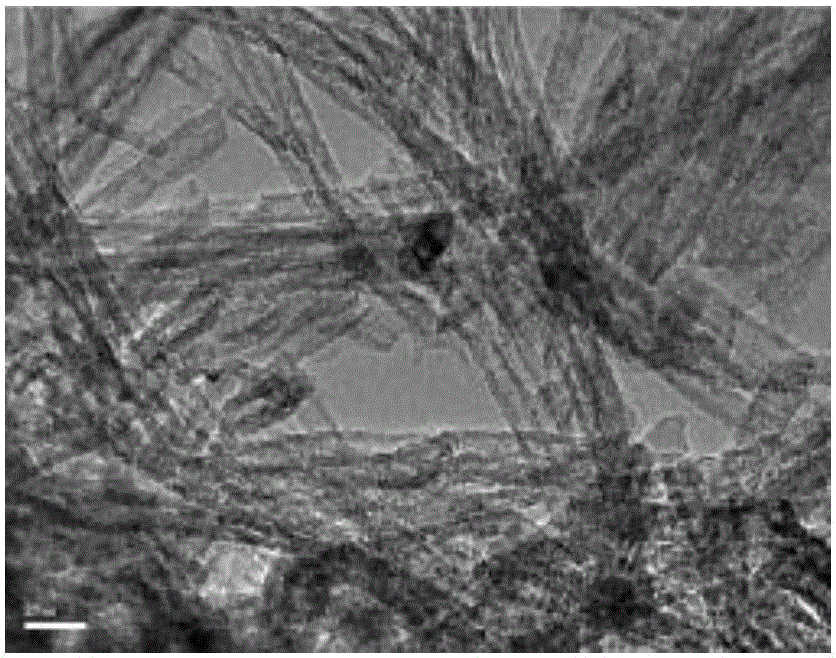

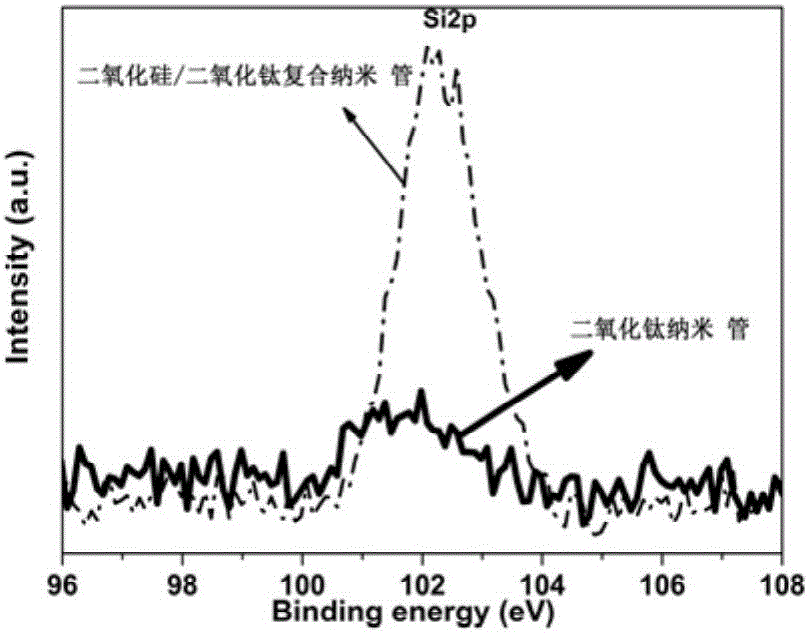

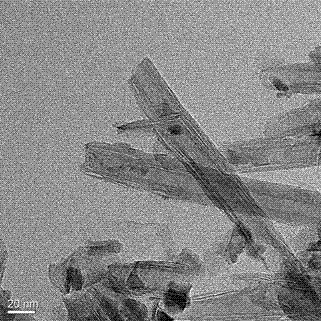

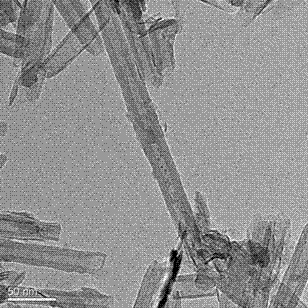

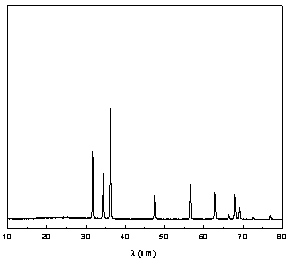

Preparation method of high temperature stable titanium dioxide nanotube powder

ActiveCN106745218AThe preparation method is simple and easyEasy to operatePhysical/chemical process catalystsTitanium dioxideCatalytic effectSolar cell

The invention discloses a preparation method of a high temperature stable titanium dioxide nanotube powder. According to the preparation method, firstly, a titanic acid nanotube powder is prepared via hydro-thermal synthesis, a silicon dioxide / titanium dioxide composite nanotube powder is obtained via surface modification and high temperature calcinations, and at last, silicon dioxide is removed via etching in a low-concentration sodium hydroxide solution so as to obtain the high temperature stable titanium dioxide nanotube powder. The high temperature stable titanium dioxide nanotube powder is capable of maintaining favorable tubular morphology at a high temperature higher than 400 DEG C, possesses excellent anatase crystal form and excellent catalytic effect, can be widely used in fields such as photocatalysis, lithium battery, solar cell, confinement catalysis, medical science, and catalytic combustion, and is capable of solving problems of the prior art that sintering, breaking, or even collapse of titanium dioxide nanotube are caused by surface or interlayer dehydration via calcination of titanic acid nanotube at a temperature higher than 400 DEG C.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

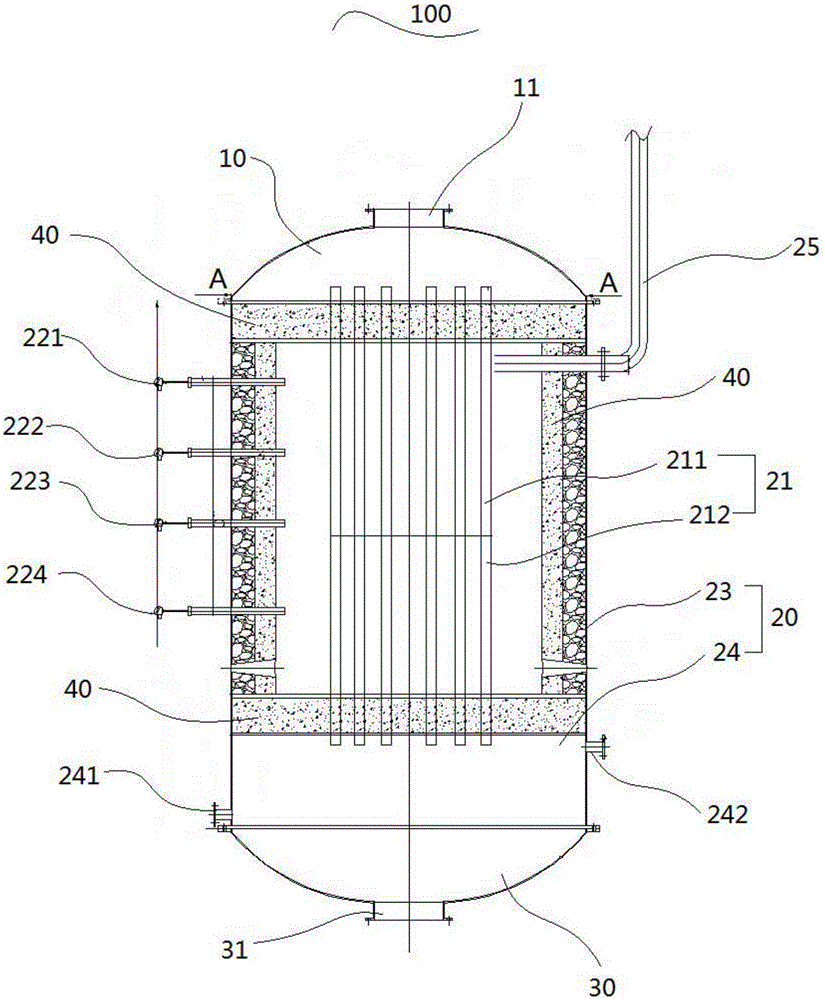

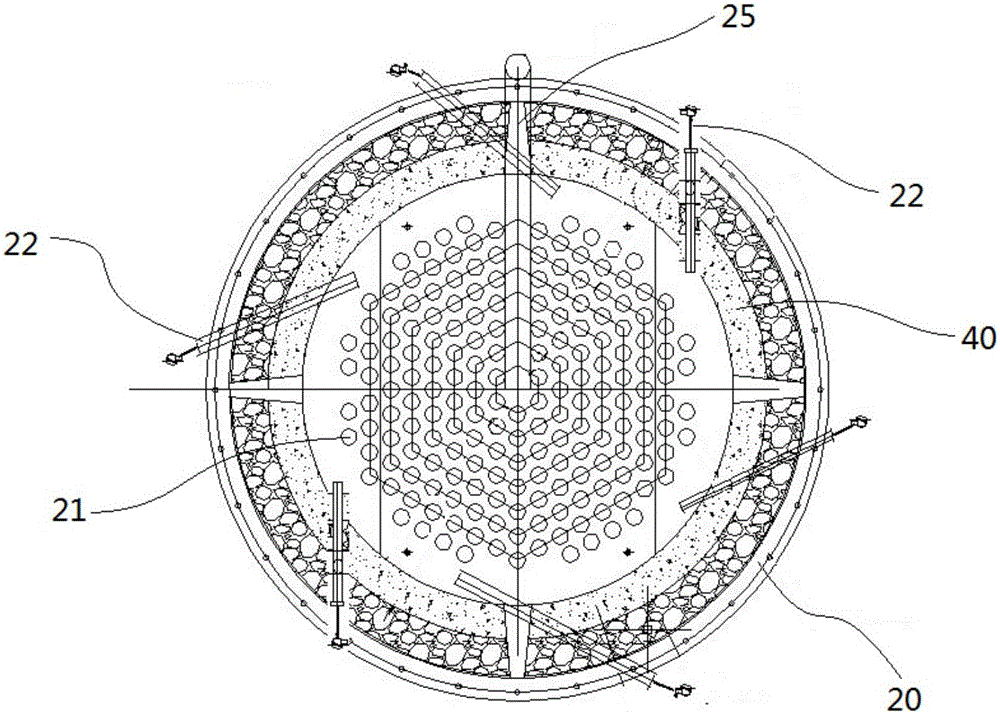

Reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide

ActiveCN105861055ASolve sinteringSolve problems such as easy carbon depositionHydrogenCarburetting gasesTemperature controlCatalytic reforming

The invention discloses a reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide, and belongs to the technical field of energy utilization. The reaction device comprises a gas distributor, a shell-pass shell and a gas collector which are connected in sequence, multiple gas reaction tubes are contained in an inner cavity of the shell-pass shell and are arrayed in a regular hexagon shape, one ends of the gas reaction tubes are arranged in the gas distributor, the other ends of the gas reaction tubes are arranged in the shell-pass shell, at least two layers of flame nozzles are connected to the outer surface of the shell-pass shell, and at least one layer of flame nozzles are matched with the corresponding gas reaction tubes and are arranged annularly. According to the reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide, the flame nozzles of the shell-pass shell are uniformly distributed along the side boundary of the hexagon array of the gas reaction tubes in the same direction, and the effects of stable and uniform heat transfer and easy temperature control are achieved.

Owner:TAIYUAN UNIV OF TECH

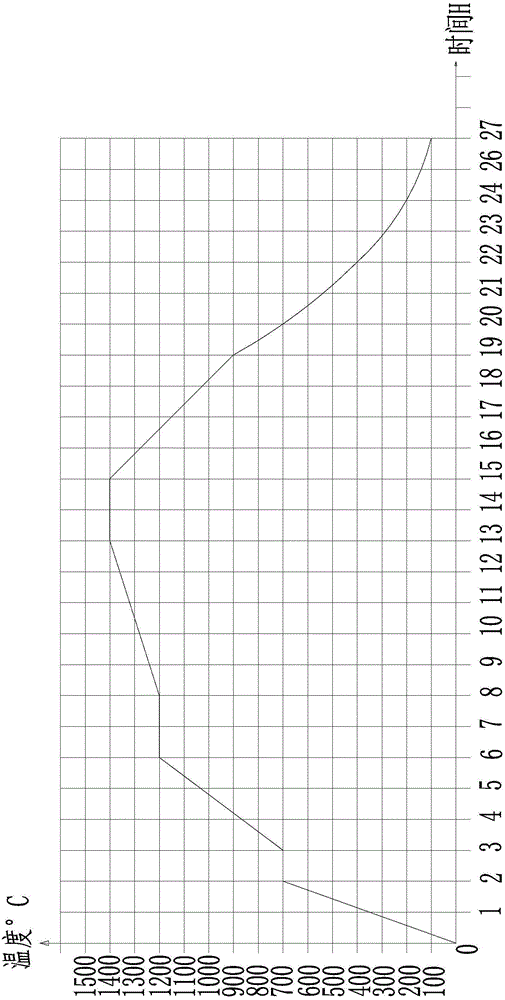

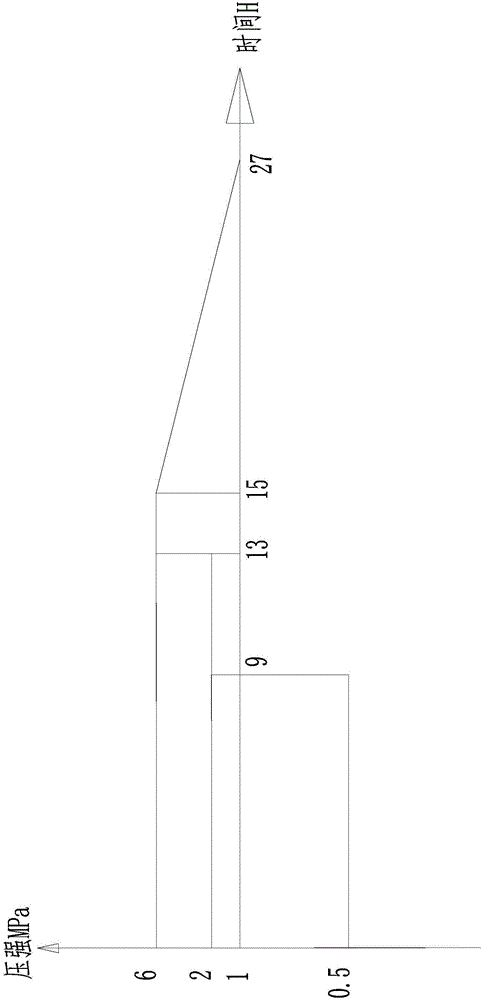

Large scale hard alloy butting joint process

The invention discloses a large scale hard alloy butting joint process which sequentially comprises the following steps that a material is divided into two sections or three sections and to be manufactured into hard alloy blanks in a burning mode according to the size of a component needing to be machined, and the diameter difference of every two adjacent blanks is 0.5-1mm; the butt joint faces of every two adjacent blanks are machined to meet the specific requirements; the connection portion of every two two adjacent blanks is coated with metal glue, and then the blanks are placed in a furnace for sintering; the temperature evenly raises to 680-720 DEG C in two hours during vacuum sintering, and the pressure is 0.5MPa; the temperature is kept for one hour; then the temperature evenly raises to 1180-1220 DEG C after three hours; the temperature is kept for two hours; then the temperature evenly raises to 1380-1420 DEG C after five hours, and the pressure raises to 2MPa after the temperature raises for one hour; then the pressure raises to 6MPa after the temperature is kept for two hours; finally, the temperature and the pressure are reduced to normal temperature and normal pressure in eleven hours, sintering is finished, and the blanks are machined to the required size. The process has the advantage that hard alloy products machined through the method can reach performance parameters of one-time sintered products.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

Preparation method of stop-off agent for stainless steel vacuum brazing

ActiveCN108044259ASolve sinteringSolve agglomerationWelding/cutting auxillary devicesAuxillary welding devicesTitanium oxideBall mill

The invention relates to the technical field of welding, and aims to provide a preparation method of a stop-off agent for stainless steel vacuum brazing. The method includes the steps that zirconium oxide powder and titanium oxide powder are ball-milled and then a first mixture is obtained; the first mixture, aluminum oxide powder and neodymium oxide powder are ball-milled and then a second mixture is obtained; after propylene glycol and deionized water are evenly mixed, VAE emulsion is added to be evenly stirred, and accordingly a third mixture is obtained; methylcellulose and Carbomer 940 are added into the third mixture to be stirred and then a fourth mixture is obtained; the second mixture is added into the fourth mixture to be stirred and then a fifth mixture is obtained; and ammoniumhydroxide is added into the fifth mixture to adjust the pH to 8-10 while stirring is conducted, and then the stop-off agent for stainless steel vacuum brazing can be obtained after grinding. By the adoption of the method, the problem that oxide components in the stop-off agent are sintered in the course of stainless steel vacuum brazing processing to form hard agglomerate or cakes is solved, thehard agglomerate or cakes can be removed in non-destructive modes like water scrubbing and air blowing after brazing, and the surfaces of workpieces cannot be damaged.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

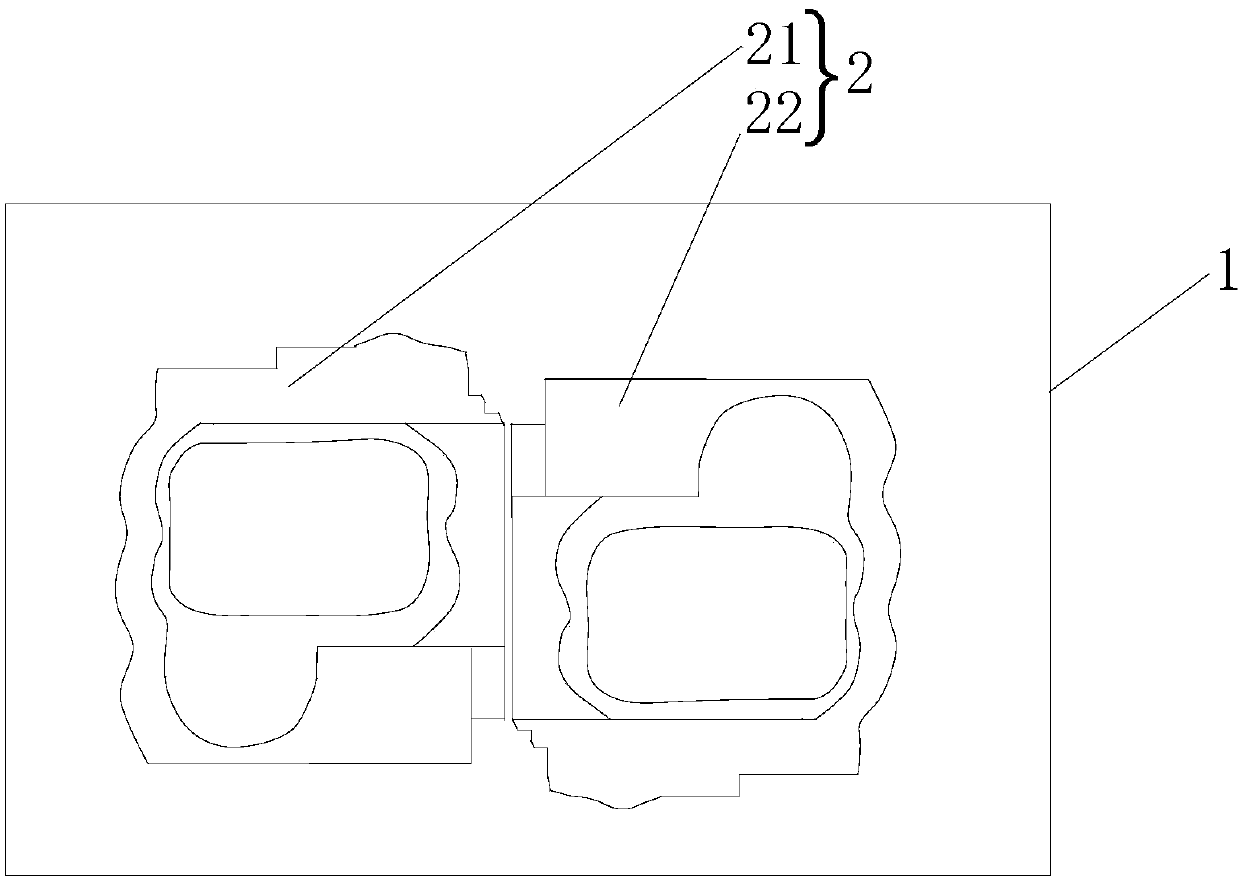

Casting mold for multiple directional control valve

InactiveCN108500206ASolve the difficulty of assemblySolve cleanupFoundry mouldsFoundry coresCasting moldMaterials science

The invention discloses a casting mold for a multiple directional control valve. The casting mold for the multiple directional control valve comprises a sand box, outer shells and a mud core. The mudcore is horizontally arranged in the outer shells, and the outer shells are embedded in the sand box. A cavity for the multiple directional control valve is formed between the outer shells and the mudcore. The number of the outer shells is two, the outer shells refer to the outer shell I and the outer shell II, the outer shell I and the outer shell II are arranged in the sand box side by side, and the two corresponding outer side surfaces of the outer shell I and the outer shell II are attached to each other. The mud core comprises a main core and a plurality of small cores, the main core andthe multiple small cores are assembled into the whole mud core through auxiliary holes, a core rod for forming the multiple directional control valve is arranged in the whole mud core, an air outlethole is formed in the top of the whole mud core, and the air outlet hole is guided out through a steel wire. By means of the casting mold for the multiple directional control valve, assembling difficulty of the mud core can be solved, and the number of defects of castings can be reduced.

Owner:南通曼淇威电气有限公司

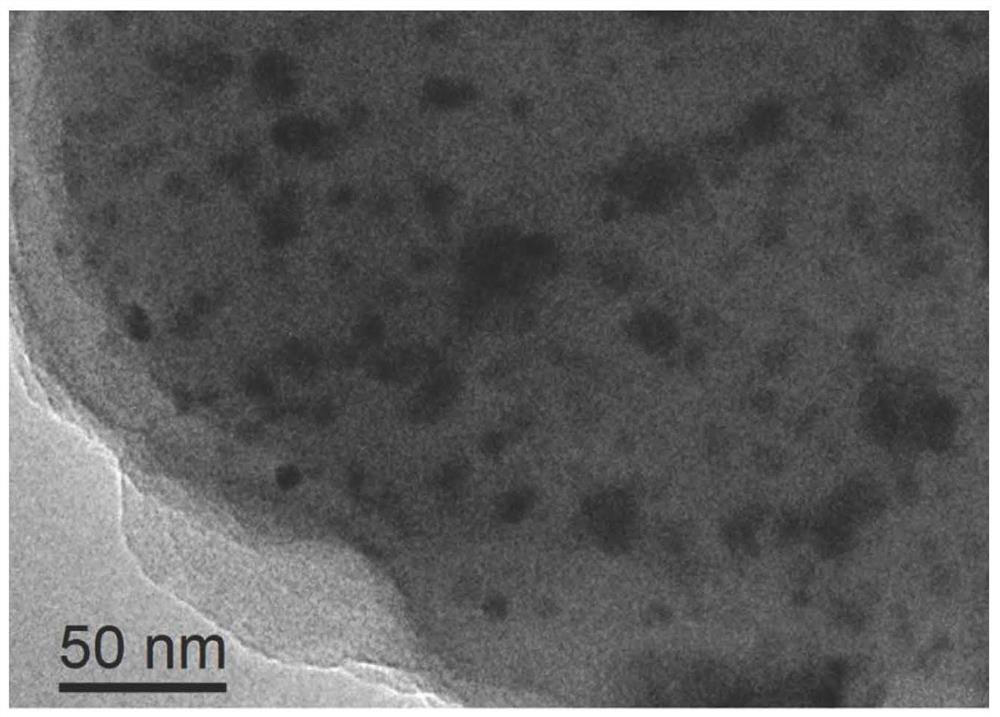

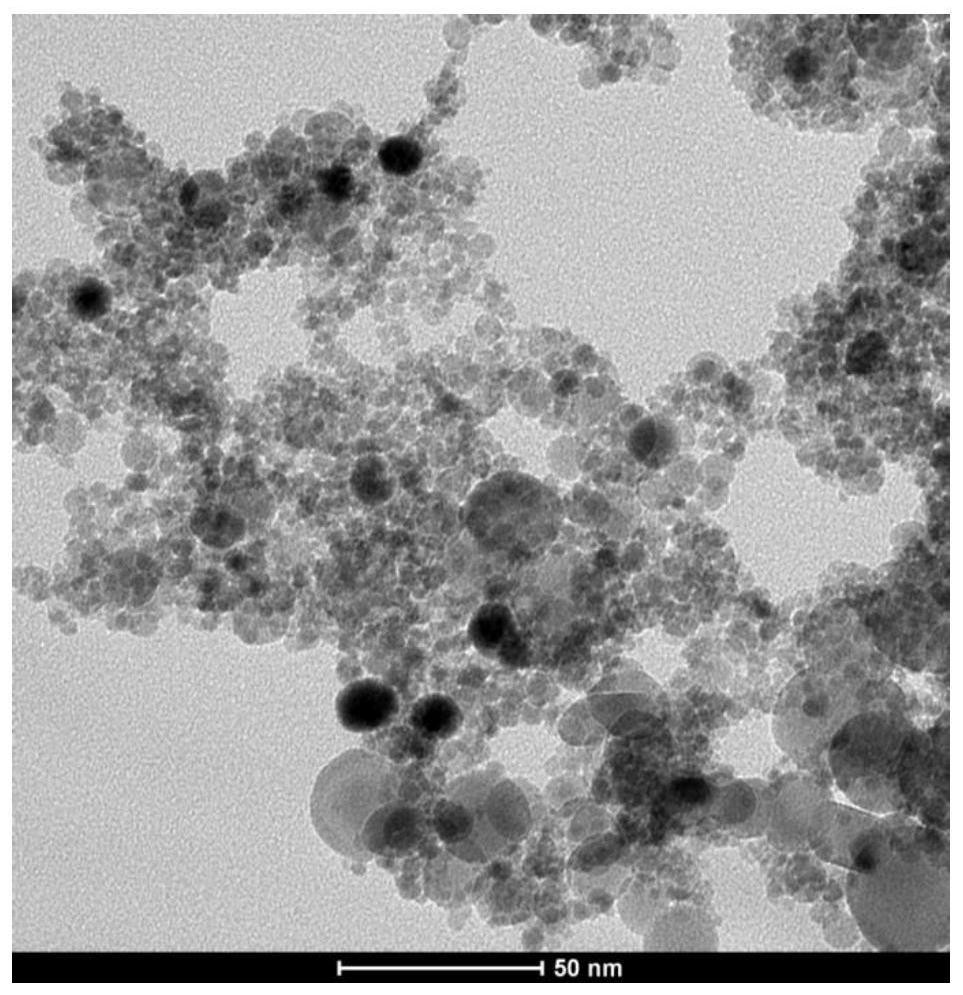

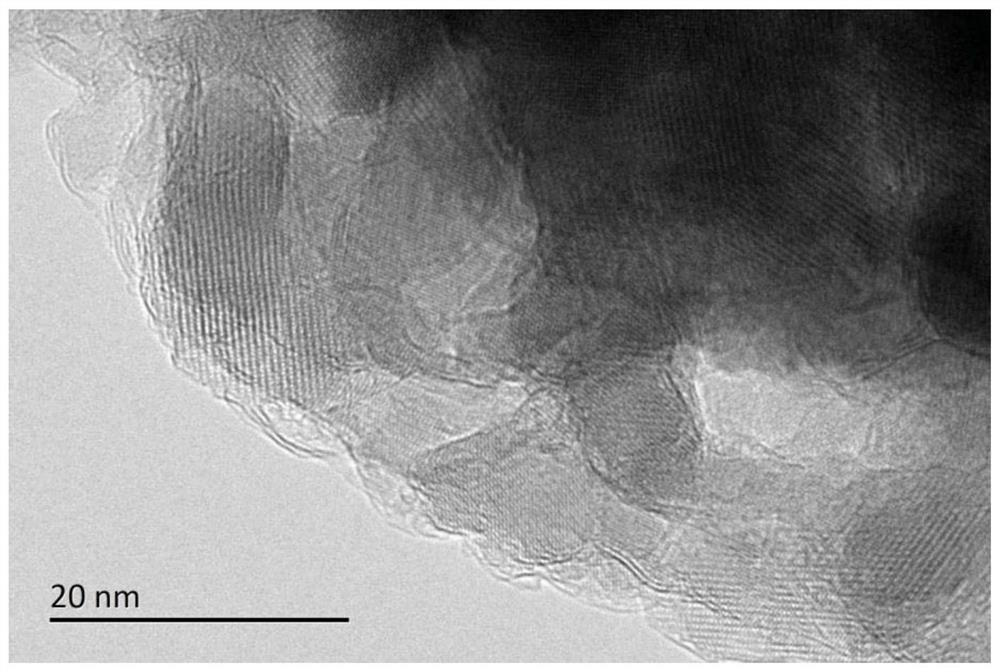

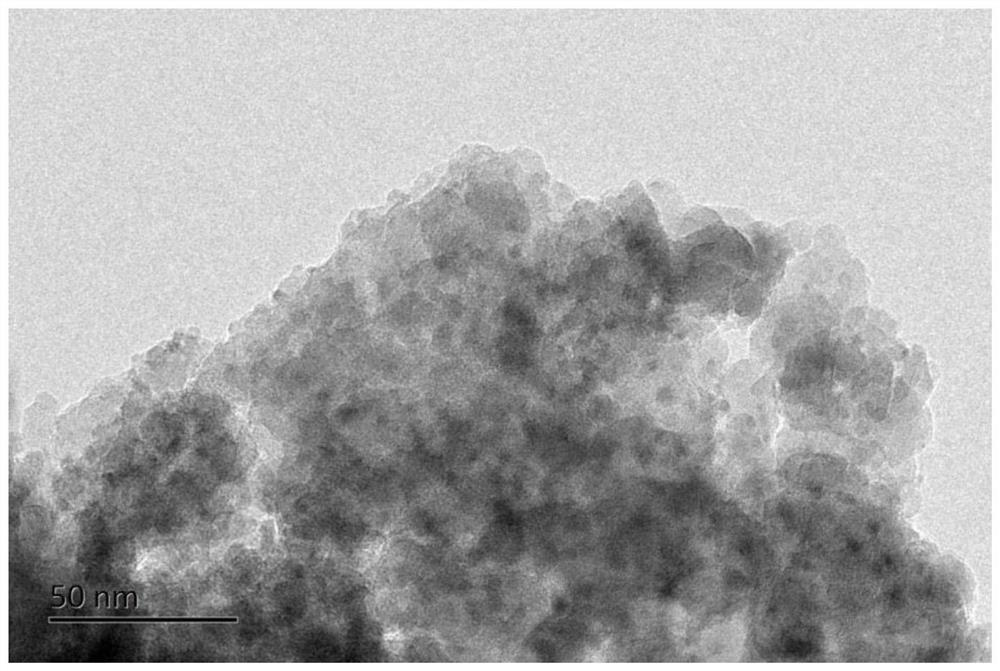

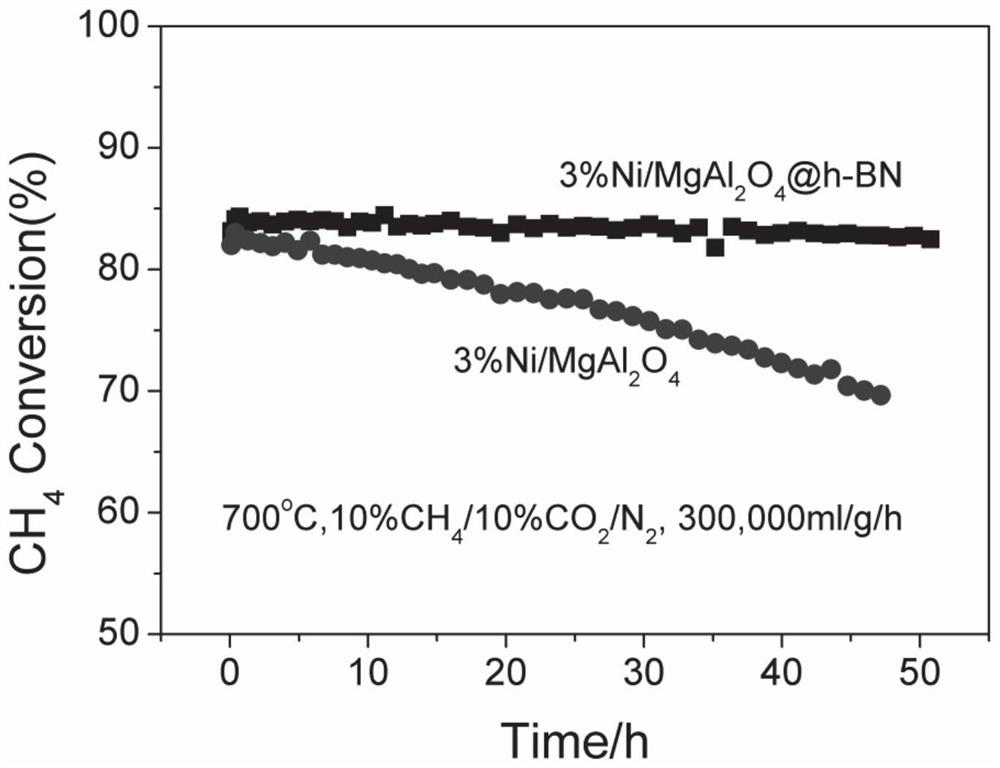

Catalyst for methane dry gas reforming reaction and preparation method thereof

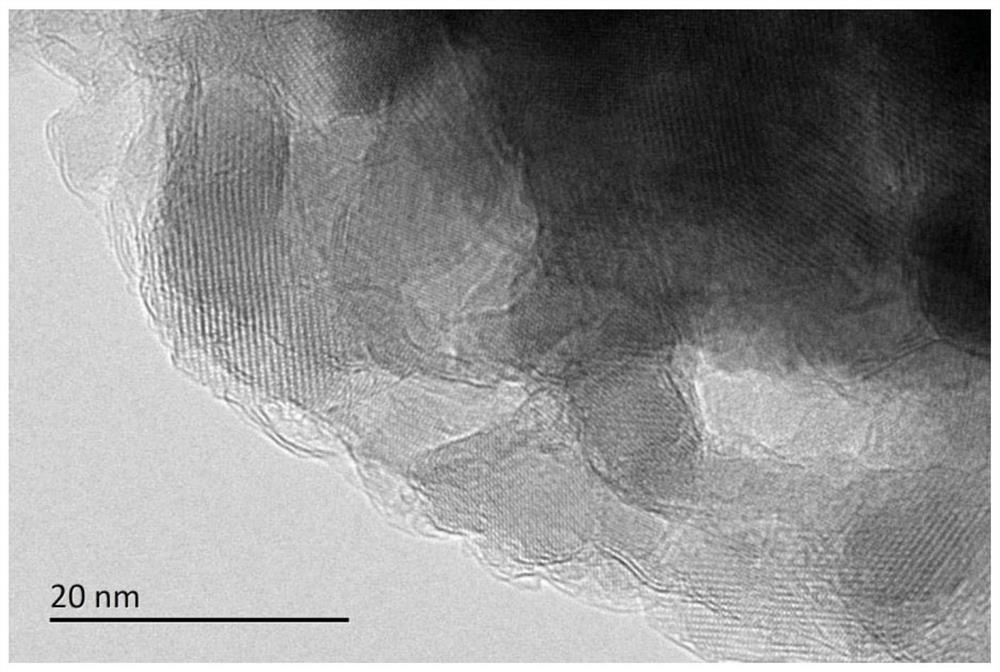

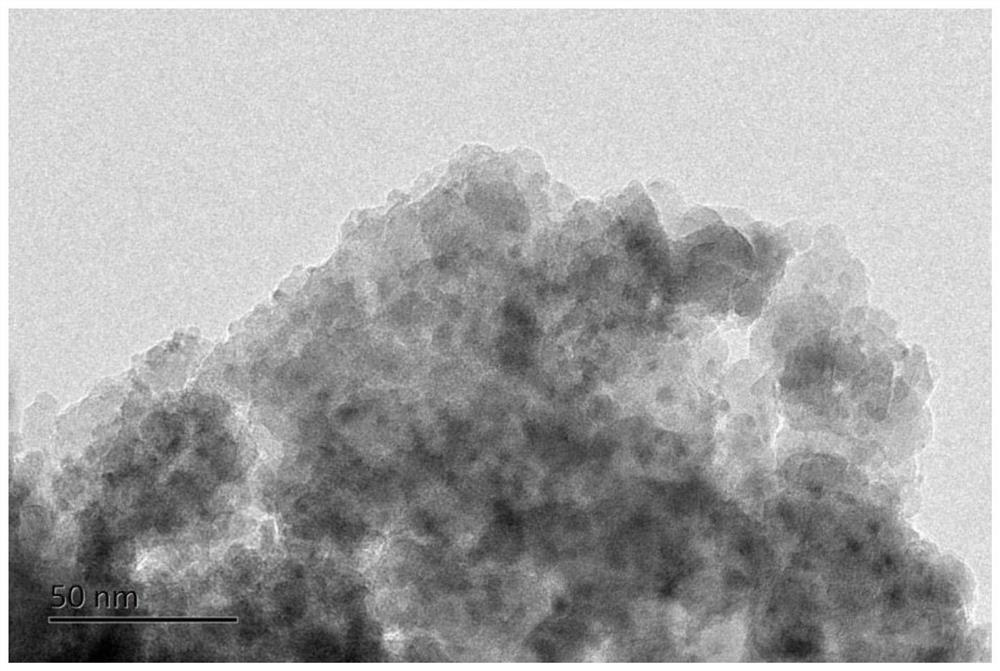

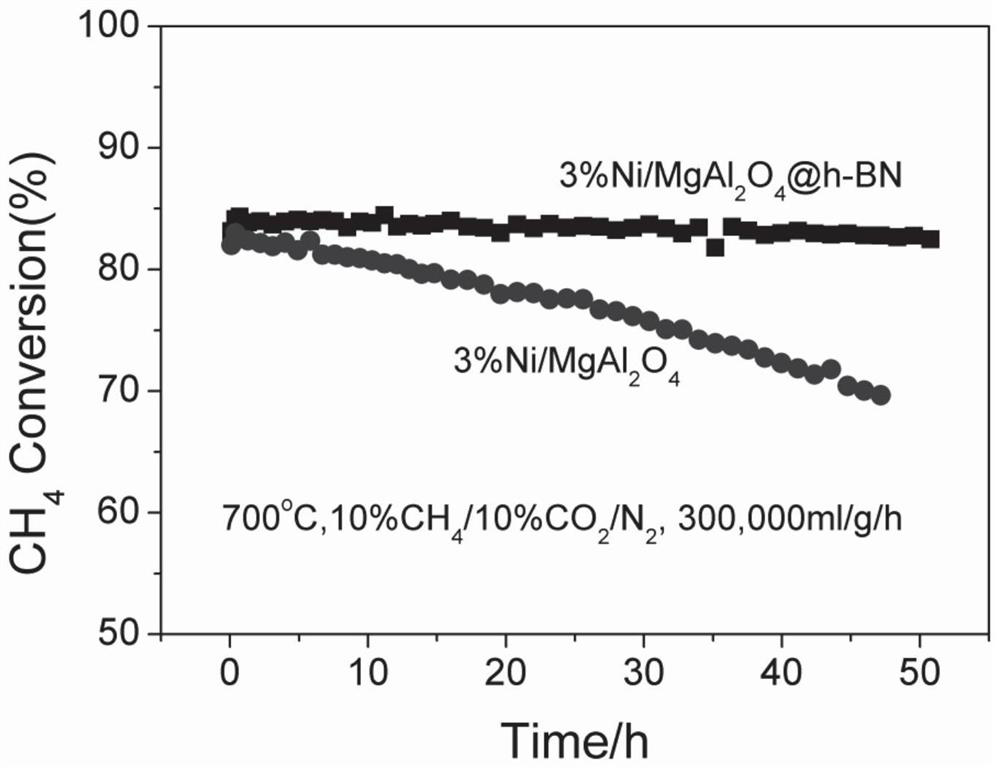

ActiveCN113209999AImprove thermal conductivityImprove transmission efficiencyHydrogenCatalyst activation/preparationPtru catalystBoron nitride

The invention discloses a catalyst for methane dry gas reforming reaction and a preparation method thereof. According to the catalyst, an oxide with the surface wrapped by ultra-thin boron nitride (h-BN, 1-2 layers) is adopted as a carrier, the size of an active component Ni nano particle supported on the oxide ranges from 2 nm to 5 nm, and the oxide is any one of SiO2, Al2O3, MgAl2O4, MgO and ZrO2. The prepared catalyst can be used for a reaction of reforming methane and carbon dioxide to prepare synthesis gas, the h-BN ultra-thin wrapping layer can greatly enhance the heat-conducting property of the oxide carrier, and the transfer efficiency of heat around Ni particles is improved; and in the reaction atmosphere, CO2 and CH4 can interact with the h-BN layer rich in defects, Ni particles can be partially wrapped and prevented from being sintered, the Ni particles can be modified by the element B in real time, and the carbon deposition resistance of the Ni particles is greatly improved. The catalyst simultaneously solves the problems of carbon deposition and sintering of metal nano particles in the reaction, the preparation method is simple, and the catalyst has a wide application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

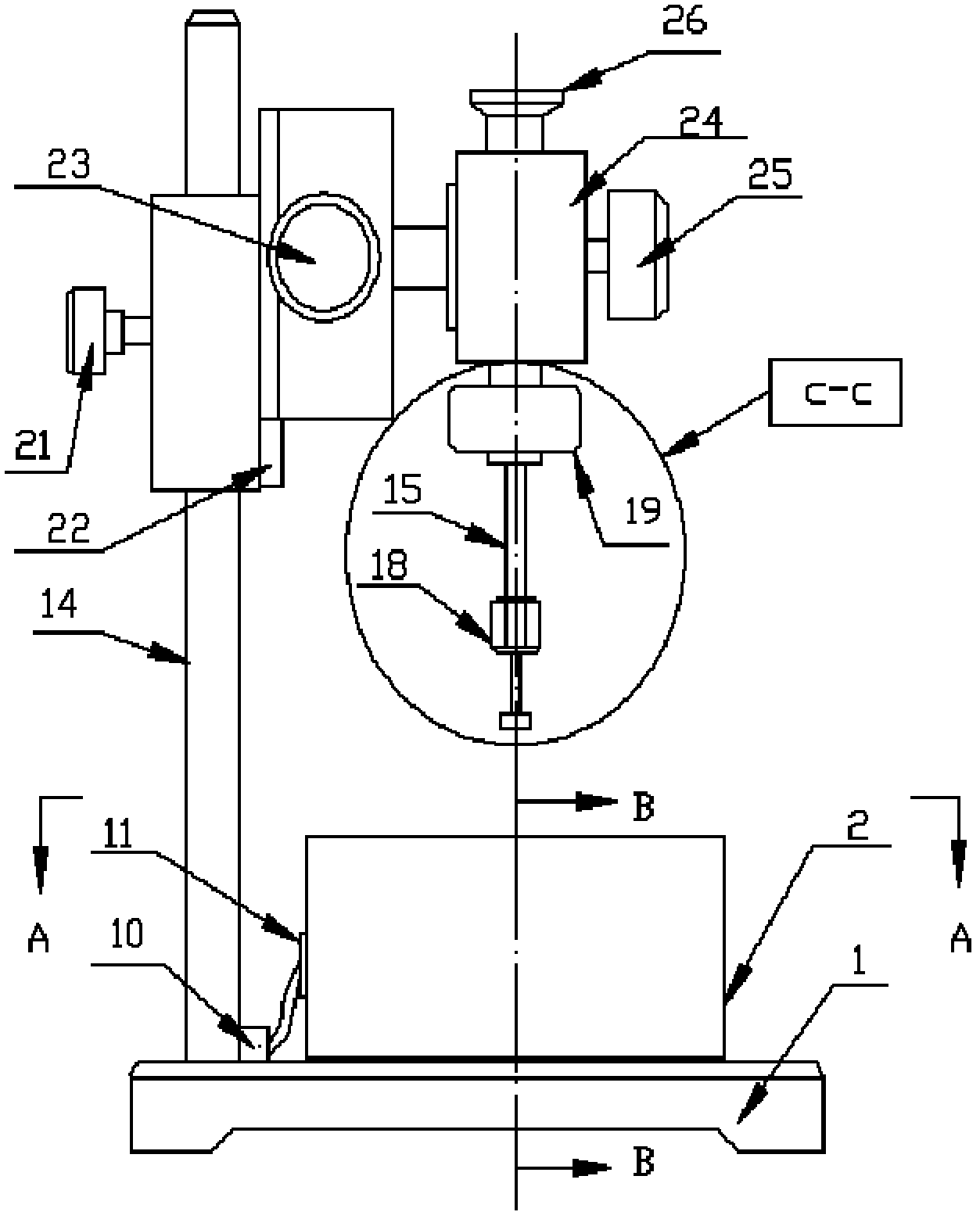

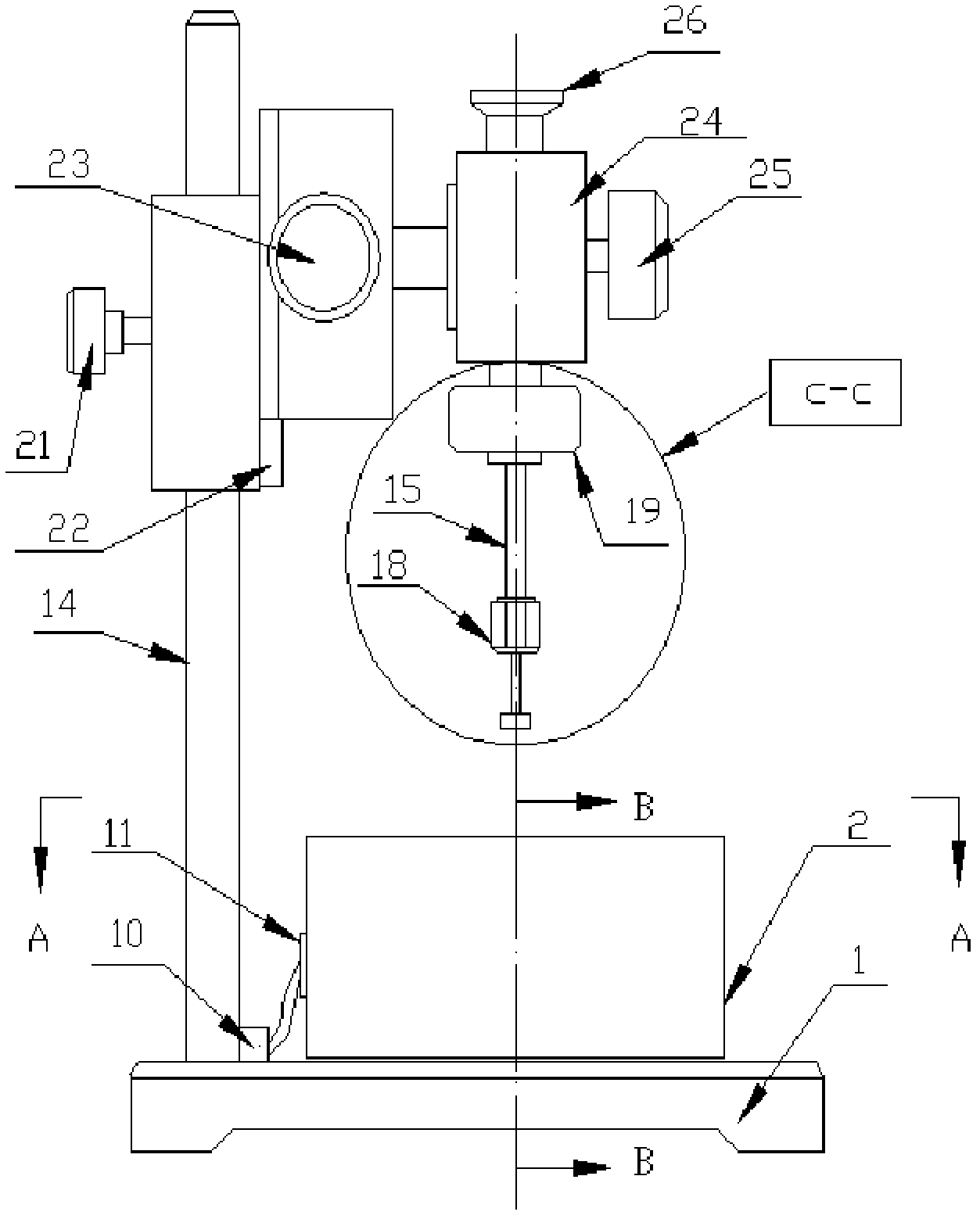

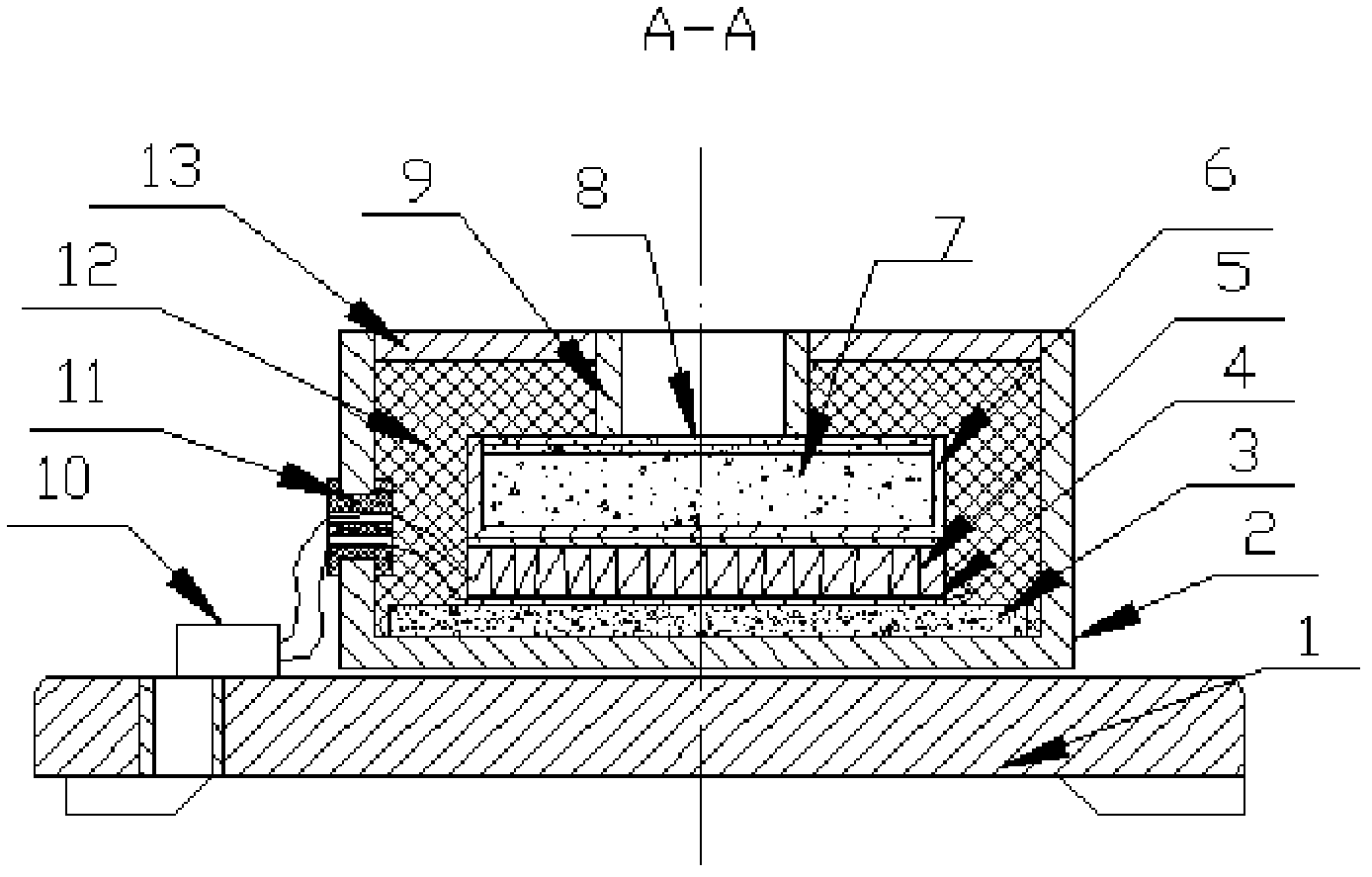

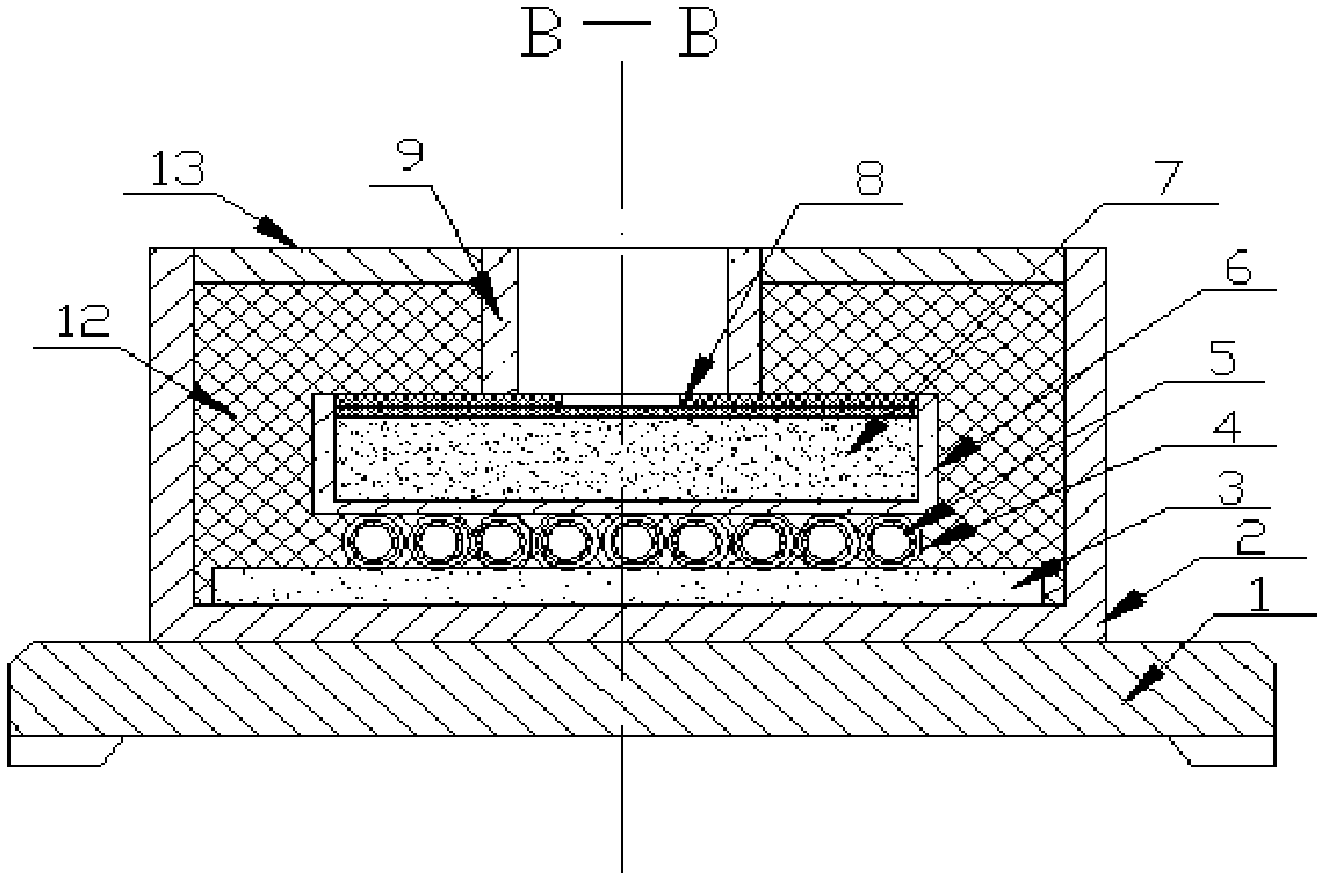

Airtight sintering device of glass tube and MEMS chip

ActiveCN102358616ASolve problems that cannot be ruled outImprove pass rateDecorative surface effectsChemical vapor deposition coatingIntegrated circuit manufacturingSlurry

The invention discloses an airtight sintering device of glass tubes and MEMS chips, which comprises a main frame, a heating furnace body, a lifting adjusting member, and a lifting pressure adjusting handle, a stop valve, an air exhaust connecting member, and the like. In the device of the invention, two MEMS chips are sintered together with a glass tube; the glass tube is connected to a vacuum-pumping device for vacuum pumping; the glass tube is sintered together with two MEMS chips through glass powder so as to form a vacuum microcavity; the invention solves the problem in traditional devices that organic gas which is generated during glass slurry sintering and is released into the vacuum microcavity can not be removed; the vacuum degree is up to 5*10-5 Pa, and the qualified rate of high-precision resonance-type pressure sensors is increased. The invention is applicable to fields of packaging technology of resonance-type pressure sensors in micro-electro-mechanical system manufacturing, and integrated circuit manufacturing.

Owner:NO 24 RES INST OF CETC

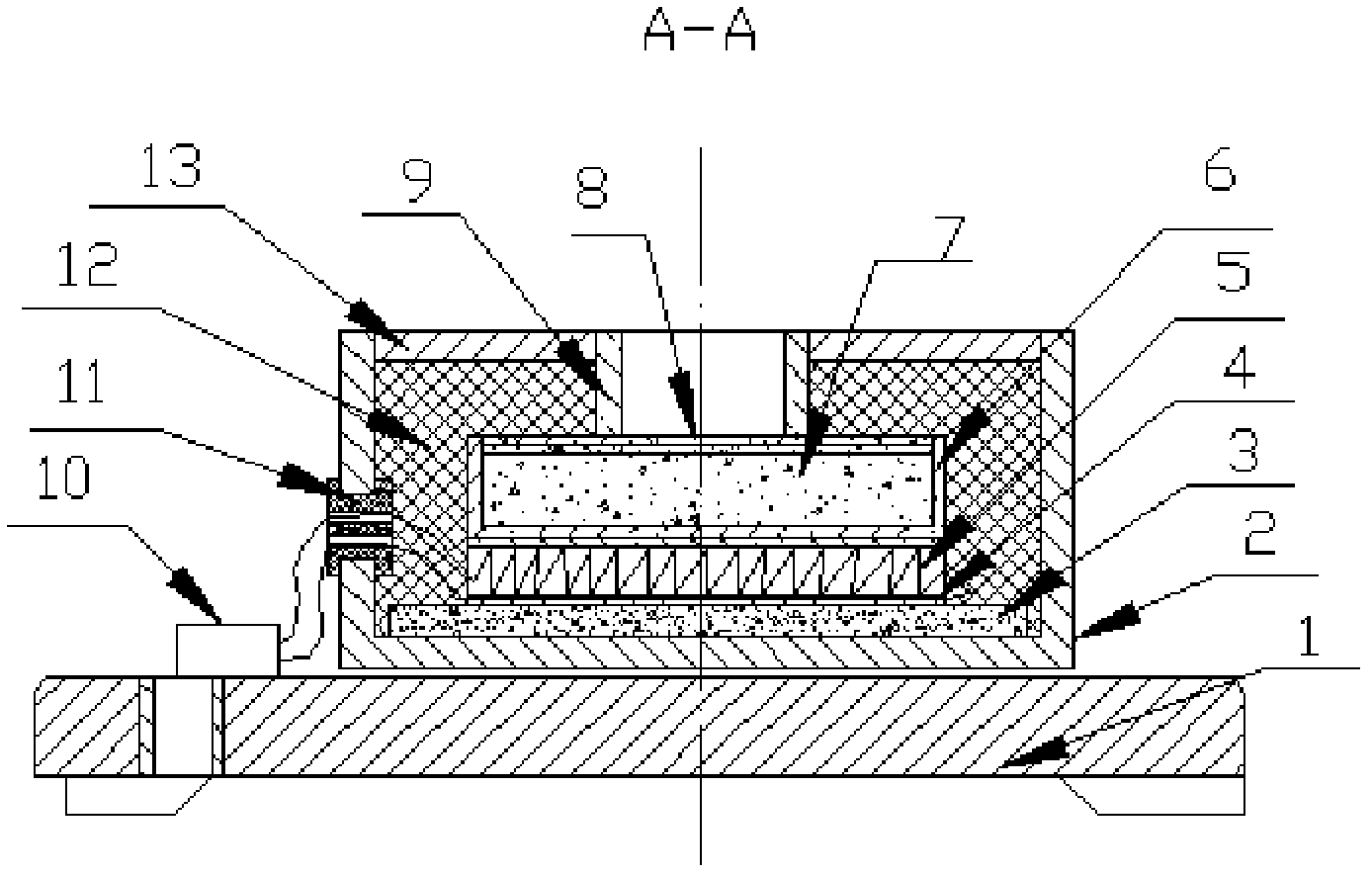

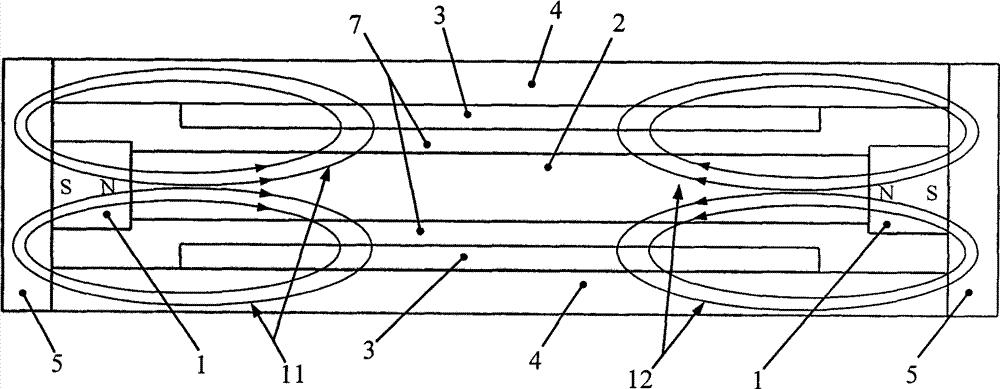

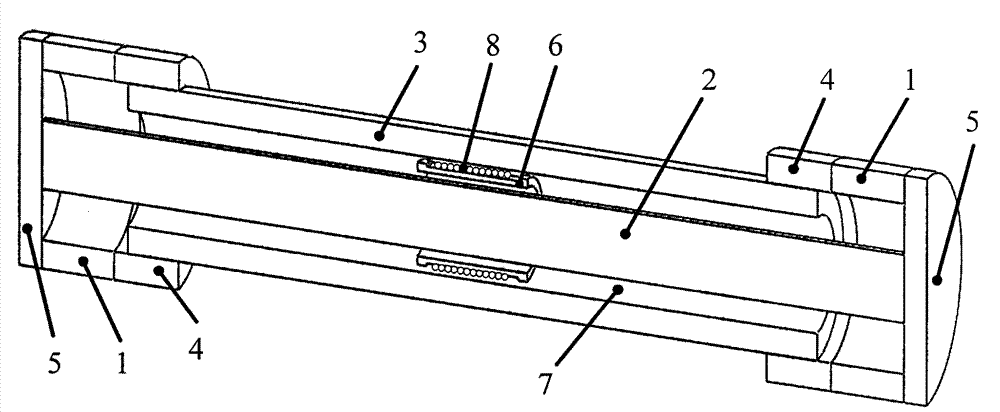

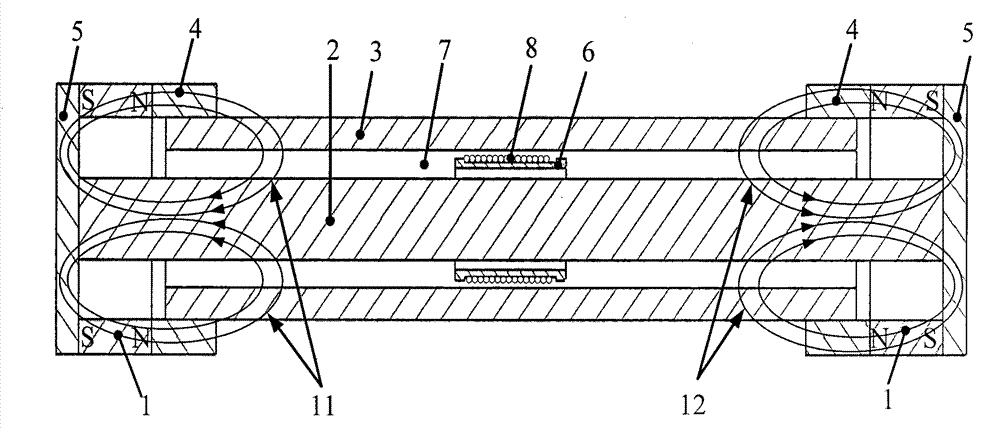

Rectangular open magnetic field type electromagnetic vibration table magnetic circuit structure with double-magnetic-circuit two-end symmetric excitation

ActiveCN104849005AGood effectThe overall structure is simple and reliableMechanical vibrations separationVibration testingMicro structureMagnetic poles

The invention provides a rectangular open magnetic field type electromagnetic vibration table magnetic circuit structure with double-magnetic-circuit two-end symmetric excitation, belonging to the field of vibration measurement technology. A rectangular open type magnetic field structure design is provided. Two permanent magnets are symmetrically installed at two ends of a center magnet yoke and face magnetic poles. Two symmetric closed magnetic circuits are formed by magnet yokes. The magnetic induction intensity distribution with high uniformity is generated in air gaps. After a working coil is energized, the working coil is affected by Lorentz force in a magnetic field, and precisely controllable electromagnetic drive force is generated. The surfaces of the magnet yokes adjacent to the air gaps are provided with an array type micro structure in the form of deep trenches, and the eddy current loss can be effectively inhibited. According to the rectangular open magnetic field type electromagnetic vibration table magnetic circuit structure, large stroke, high magnetic field uniformity, high thrust and a linear electromagnetic driving force characteristic can be considered, the disadvantages in the existing technical scheme can be effectively solved, and a high precision and large stroke electromagnetic vibration table magnetic circuit structure technical scheme is provided for low-frequency / ultra-low frequency vibration calibration.

Owner:HARBIN INST OF TECH

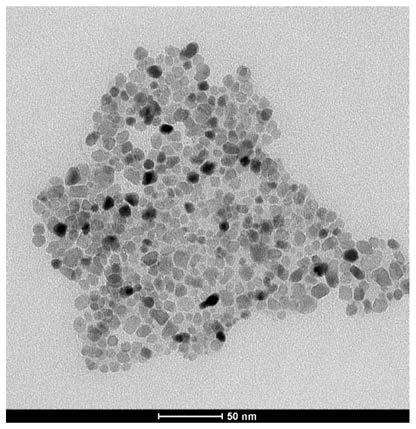

Method for preparing yttrium aluminum garnet nanoparticles

ActiveCN111233022AEasy to prepareEase of mass productionMaterial nanotechnologyRare earth metal compoundsNanoparticlePhysical chemistry

The invention provides a method for preparing yttrium aluminum garnet nanoparticles, which comprises the following steps: preparing organic sol containing aluminum and yttrium, mixing the organic solwith water-soluble salt, performing standing or centrifuging to precipitate the water-soluble salt, removing superfluous organic sol at the upper part, and keeping the temperature to convert the organic sol into gel; along with evaporation of the solvent, contracting the gel, and coating the surfaces of the water-soluble salt particles with a layer of xerogel film, and calcining a sample at a hightemperature between 600 DEG C and a salt melting point, converting a dried gel film into yttrium aluminum garnet nanoparticles, dispersing and attaching the yttrium aluminum garnet nanoparticles to the surfaces of water-soluble salt particles, cooling, and washing with water to remove the salt, thereby obtaining the yttrium aluminum garnet nanoparticles with favorable dispersity and crystallinity. According to the method, the high-dispersion and high-crystallinity yttrium aluminum garnet nanoparticles can be rapidly prepared in batches, and the method is suitable for preparing LED fluorescentpowder, YAG transparent ceramic and other materials.

Owner:SOUTHEAST UNIV

Modified boron nitride loaded nickel-based methane dry reforming catalyst as well as preparation method and application thereof

PendingCN114192180AHigh activityImprove stabilityHydrogenPhysical/chemical process catalystsNickel catalystPtru catalyst

The invention relates to a modified boron nitride loaded nickel-based methane dry reforming catalyst as well as a preparation method and application thereof. According to the method, different stripping methods are used for modifying the boron nitride, then the modified boron nitride is used as a carrier for supporting the active metal Ni, and the excellent sintering resistance and carbon deposition resistance are achieved in the methane dry reforming reaction. According to the invention, the content of Ni is adjusted by using a simple impregnation method, and the modified boron nitride loaded nickel catalyst with high activity and high stability is obtained. The catalyst can be used for solving the problems of sintering and serious carbon deposition of active components in a methane dry reforming reaction. The catalyst has the advantages of simple preparation process, low cost and high catalytic efficiency.

Owner:SHANGHAI UNIV

Stop-off agents for stainless steel vacuum brazing

ActiveCN108098093AGood pinningPrevent sinteringWelding/cutting media/materialsSoldering mediaTitanium oxideCaking

The invention relates to the technical field of welding, and aims to provide a stop-off agent for stainless steel vacuum brazing. The stop-off agent comprises, by weight percentage, 5-10% of zirconiapowder, 5-10% of titanium oxide powder, 35-55% of aluminum oxide powder, 0.5-5% of neodymium oxide powder, 0.15-0.5% of carbomer 940, 4.0-9.0% of VAE emulsion, 1.5-5% of methylcellulose, 2-4% of propylene glycol and 18-30.35% of deionized water. By means of the stop-off agent for stainless steel vacuum brazing, the problem that in the processing procedure of stainless steel vacuum brazing, oxide components in stop-off agents are sintered and cause hard aggregation or caking is solved. The stop-off agent can be removed through non-destructive modes like water washing and blowing after brazing,and the surface of a workpiece is not damaged.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Molybdenum-modified molecular sieve-loaded nickel-based methane dry reforming catalyst as well as preparation method and application thereof

PendingCN113019439AImprove anti-carbon performanceHigh activityHydrogenMolecular sieve catalystsNickel catalystMolecular sieve

The invention relates to a preparation method of a molybdenum modified molecular sieve loaded nickel-based methane dry reforming catalyst. The catalyst takes a molecular sieve as a carrier, nickel and molybdenum are respectively loaded on the molecular sieve by a sequential impregnation method, and dispersion of active species and strong interaction with the carrier are realized. The molybdenum-modified molecular sieve supported nickel catalyst is obtained through drying, high-temperature calcination and programmed heating reduction, the catalytic activity can be effectively improved, and carbon deposition in the reaction is effectively eliminated through dynamic conversion of molybdenum oxide and molybdenum carbide on the molecular sieve constructed in the reaction. Finally, the catalytic material with high sintering resistance and carbon deposition resistance is obtained. The catalyst has the advantages of simple preparation process, low cost and high catalytic efficiency.

Owner:SHANGHAI UNIV

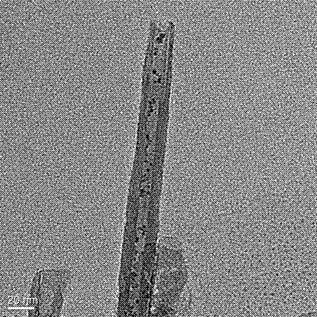

Preparation method of Rh@CuSiO3 core-sheath structured catalyst

InactiveCN107961798ASolve the problem of prone to grain migrationSolve sinteringCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDispersityNano structuring

The invention discloses an Rh@CuSiO3 nano-structure hydrogenation catalyst and a preparation method of same. The preparation method includes the steps of: 1) synthesizing silicate nanotubes in an ethanol-water system through a hydrothermal method, and controllably synthesizing cupric silicate nanotubes by adjusting experimental conditions; 2) supporting metal rhodium in the cupric silicate nanotubes through an impregnation method. In the Rh@CuSiO3 hydrogenation catalyst, the structural confinement effect of the core-sheath material and synergistic effect among the components are coupled, so that dispersity of active components is increased and interaction between the active components and the supporter is improved, thereby improving the catalytic performance in the hydrogenation. The catalyst has extensive application prospect.

Owner:SICHUAN UNIV

Casting mould for multi-way reversing valve

InactiveCN107812885ADifficult to clean upHigh strengthFoundry mouldsFoundry coresCasting defectEngineering

The invention discloses a casting mold for a multi-way reversing valve, which comprises a sand box, a shell and a mud core. The mud core is horizontally arranged in the shell, and the shell is embedded in the sand box; There are two shells, shell I and shell II, and shell I and shell II are arranged side by side in the sand box, and the two outer surfaces corresponding to shell I and shell II are attached to each other; the clay core includes the main core And several small cores, the main core and several small cores are assembled into a whole mud core through the process hole, the inside of the mud core is provided with a core bone for forming the flow channel of the multi-way reversing valve, and the top of the mud core is provided with an air outlet , the air outlet is derived from the steel wire. The invention can solve the difficulty of assembling the core and can reduce the defects of the casting.

Owner:JIANGSU TIANZIGE NEW MATERIAL TECH CO LTD

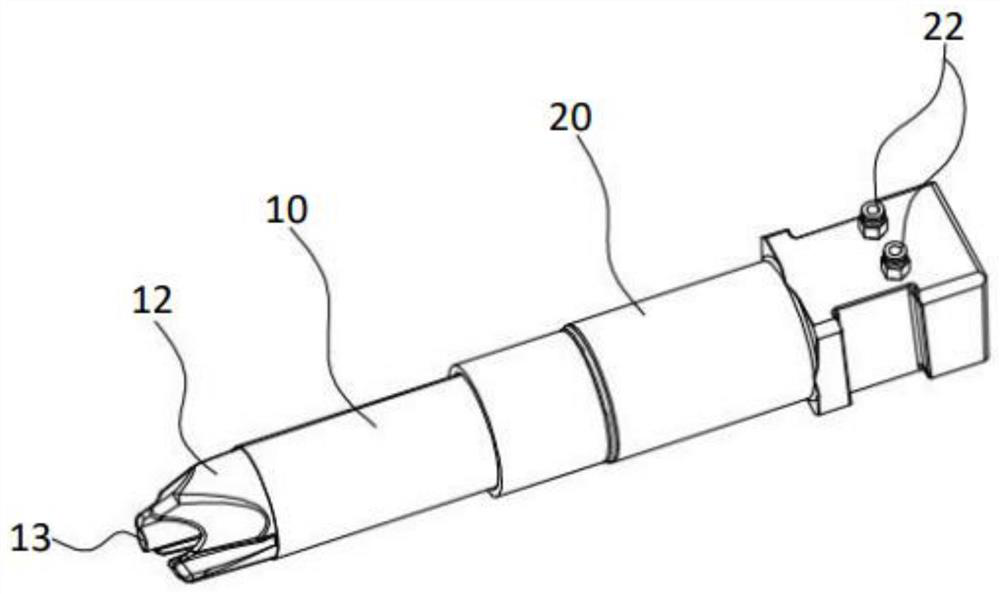

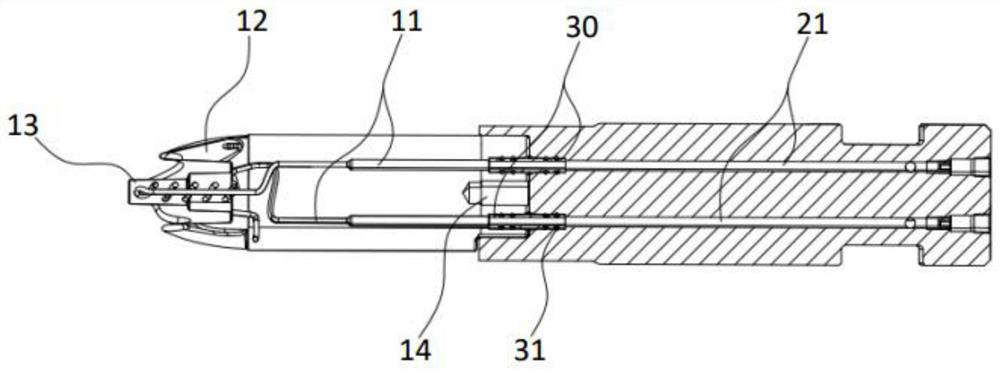

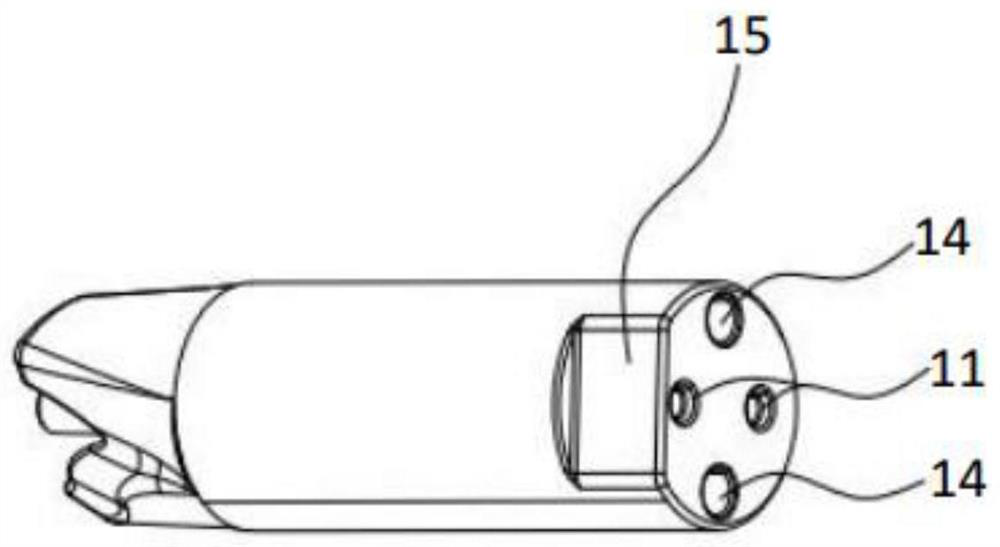

Cooling core puller

The invention discloses a cooling core puller. The cooling core puller comprises a core-pulling fixing base and a core pulling body which is detachably connected to the core-pulling fixing base, wherein one end, away from the core-pulling fixing base, of the core pulling body is a shaping end; the shaping end comprises an outer shaping part and an inner shaping part; the outer shaping part surrounds the inner shaping part, and a gap is formed between the outer shaping part and the inner shaping part; a first cooling water channel is arranged in the core pulling body; from the mounting end, away from the shaping end, of the core pulling body, the first cooling water channel sequentially passes through the inner shaping part and the outer shaping part, and finally returns to the mounting endof the core pulling body, so that a cooling water channel with inner and outer layers is formed in the core pulling body, and thus, cooling water uniformly cools the core pulling body by circulatinginside the core pulling body. The shaping end of the core pulling body is a structure with inner and outer layers, and the cooling water channel with inner and outer layers is arranged in the core pulling body, so that the cooling effect of a workpiece is improved, and the surface sintering and workpiece expanding and blocking problem is solved.

Owner:SUZHOU GUANGXING MOLD

Method for synthesizing nano-zinc oxide by micro-emulsion carbon black adsorption precipitation method

InactiveCN102838159BAvoid reunionPrevent sinteringMaterial nanotechnologyZinc oxides/hydroxidesPhoto catalyticEmulsion

The invention discloses a method for synthesizing nano-zinc oxide by a micro-emulsion carbon black adsorption precipitation method. The method for synthesizing nano-zinc oxide comprises the following steps: using zinc oxide, carbon black and ammonia water as raw materials, dripping a cyclohexane micro-emulsion system prepared by ammonia solution to a cyclohexane micro-emulsion system consisting of zinc chloride and carbon black, performing precipitation reaction after mixing and stirring at normal temperature and performing vacuum distillation, multiple washing, drying, grinding and calcination on the precipitate adsorbed by carbon black, and obtaining high thermal-stability nano-zinc oxide. The method is mild in reaction conditions, high in yield, and capable of preventing ultrafine zinc oxide from agglomerating and sintering to some extent; and the obtained products have the characteristics of high crystallinity, large specific surface area, small particle size, and good photo-catalytic performance.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

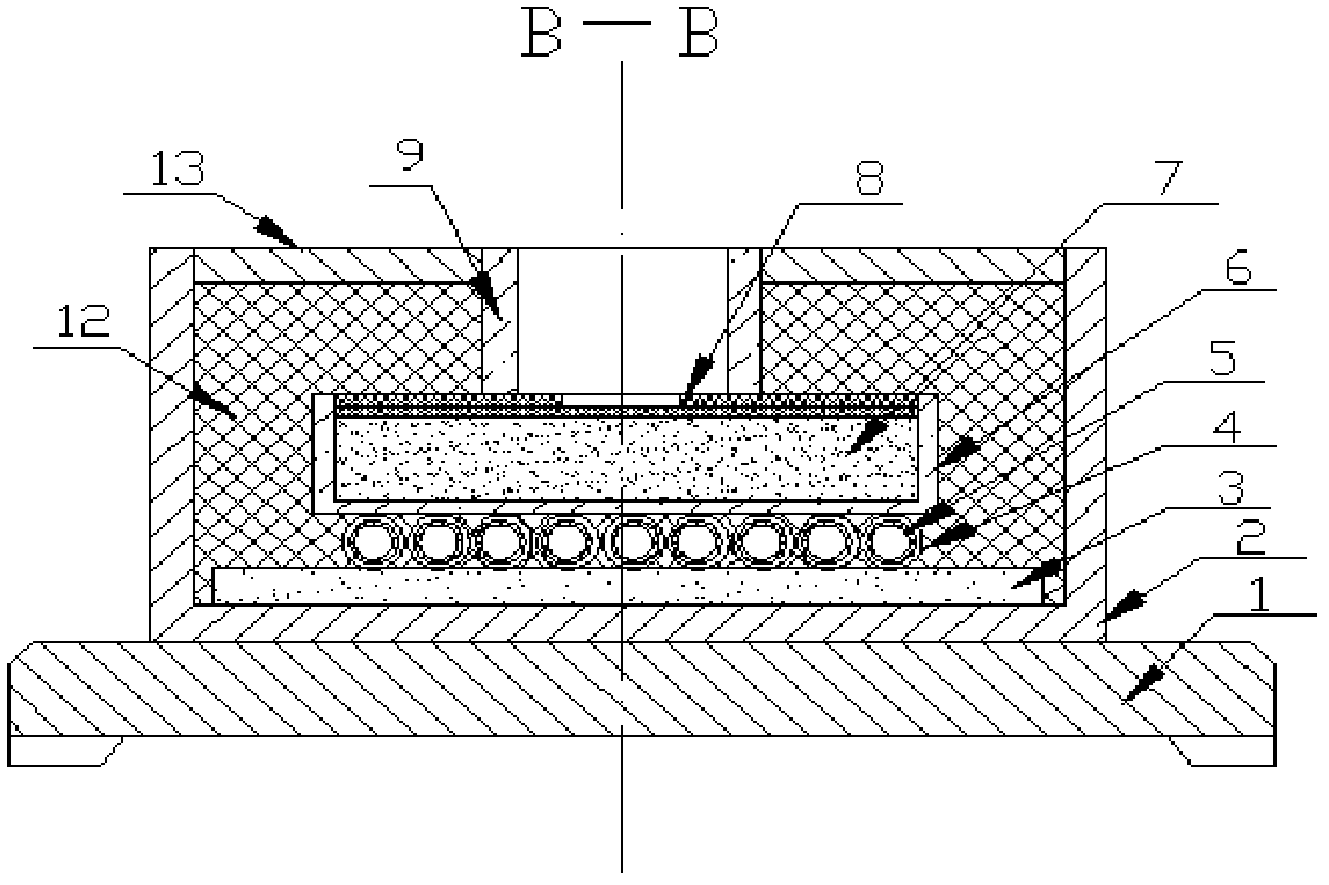

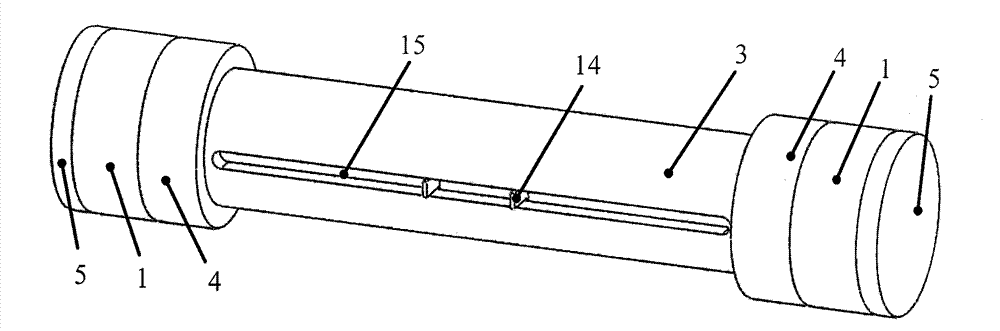

Double-permanent-magnetic-tube two-end symmetric excitation cylindrical closed magnetic field type electromagnetic vibration table magnetic circuit structure with eddy current compensation

ActiveCN104849006AGood effectSimple structureMechanical vibrations separationVibration testingMicro structureMagnetic poles

The invention provides a double-permanent-magnetic-tube two-end symmetric excitation cylindrical closed magnetic field type electromagnetic vibration table magnetic circuit structure with eddy current compensation, belonging to the field of vibration measurement technology. A cylindrical closed type magnetic field structure design is provided. Two cylindrical permanent magnetic tubes are symmetrically installed at two ends of a magnetic circuit structure and face magnetic poles. Two symmetric closed magnetic circuits are formed by magnet yokes. The magnetic induction intensity distribution with high uniformity is generated in air gaps. After a working coil is energized, the working coil is affected by Lorentz force in a magnetic field, and precisely controllable electromagnetic drive force is generated. The surfaces of the magnet yokes adjacent to the air gaps are provided with an array type micro structure in the form of deep trenches, and the eddy current loss can be effectively inhibited. According to the double-permanent-magnetic-tube two-end symmetric excitation cylindrical closed magnetic field type electromagnetic vibration table magnetic circuit structure, large stroke, high magnetic field uniformity, high thrust and a linear electromagnetic driving force characteristic can be considered, and a high precision and large stroke electromagnetic vibration table magnetic circuit structure technical scheme is provided for low-frequency / ultra-low frequency vibration calibration.

Owner:HARBIN INST OF TECH

Preparation method of nickel-supported halloysite-based methane dry reforming catalyst

ActiveCN108355662BWill not cause secondary pollutionSolve sinteringHydrogenCatalyst activation/preparationHigh resistanceHalloysite

The invention relates to a method for preparing a nickel-loaded halloysite-based methane dry reforming catalyst. The preparation method comprises the following steps: performing in situ modification on the surface of halloysite used as a carrier by a molten salt ball-milling technology to disperse and anchor an active nickel species, loading a nickel precursor on the modified surface of halloysiteby a rotary evaporative impregnation technology in order to realize uniform dispersion and strong interaction of all metals, and performing drying, high-temperature calcination and temperature programming reduction to finally obtain the catalyst with high resistance to sintering and carbon deposition. The catalyst has the advantages of simple preparation process, low cost, no pollution to the environment, high catalytic efficiency and the like.

Owner:SHANGHAI UNIV

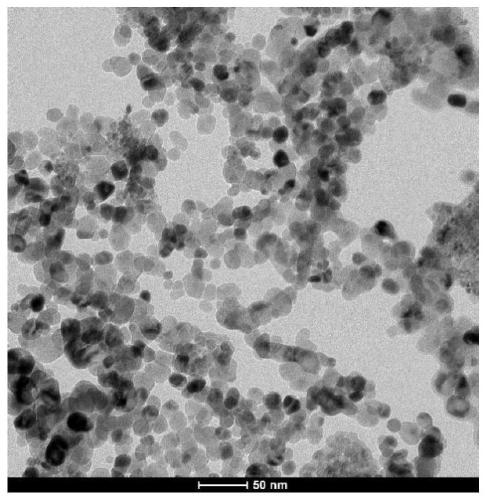

Preparation method of ferroferric oxide nanoparticles

ActiveCN109626442ALow costSimple processMaterial nanotechnologyFerroso-ferric oxidesInorganic saltsOrganic solvent

The invention discloses a preparation method of ferroferric oxide nanoparticles. The method comprises the following steps of dissolving ferric nitrate or ferric acetylacetonate in an organic solvent to obtain a steeping fluid, steeping water-soluble inorganic salts, drying and then reducing the mixture at the high temperature, and conducting washing with water to obtain the well-crystallized dispersed ferroferric oxide nanoparticles. According to the method, the high-dispersibility ferroferric oxide nanoparticles can be rapidly prepared in batches and is high in crystallinity and excellent inmagnetic property.

Owner:SOUTHEAST UNIV

A kind of preparation method of metal oxide nanoparticle and metal nanoparticle

ActiveCN109678118BImprove isolationEasy to wash and removeOxide/hydroxide preparationFerroso-ferric oxidesInorganic saltsMetal oxide nanoparticles

Owner:SOUTHEAST UNIV

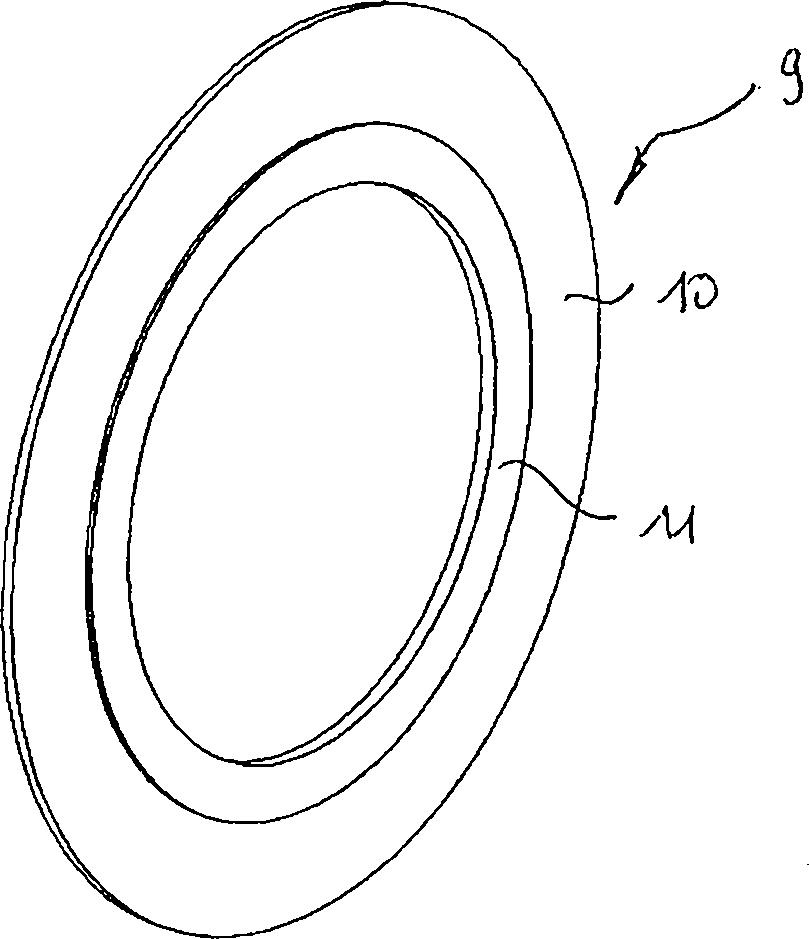

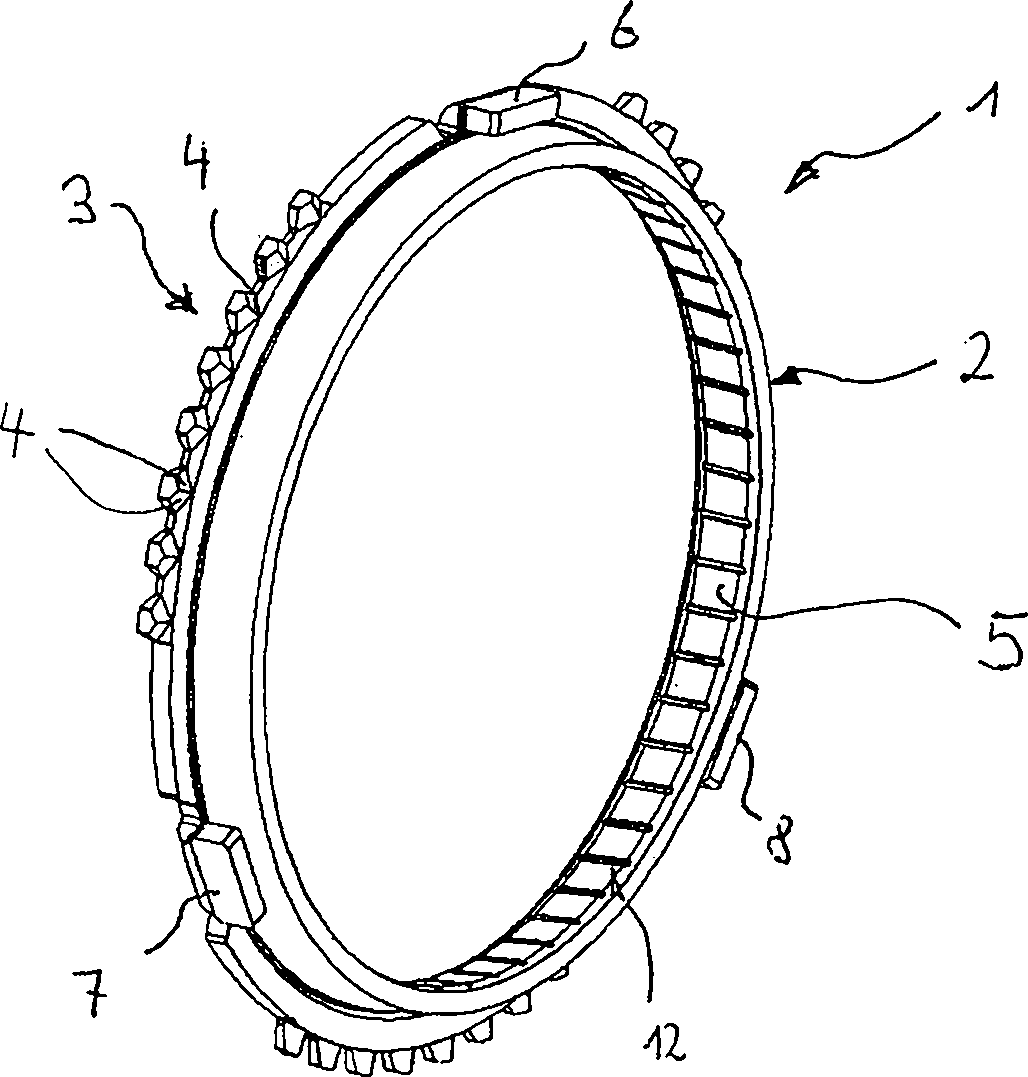

Method for producing an external synchronizer ring

ActiveCN102245346BImprove technical qualityPrevent sinteringMechanical actuated clutchesMetal-working apparatusEngineeringMechanical engineering

#CMT# # / CMT# The method involves pre-stamping a flat blank (9), covering an outer annular surface area (10) of a ring body, and sintering an inner annular surface area (11) of the ring body to form a sintered coating. Another sintered inner surface area is formed into a conical shape, where an external gearing is pre-stamped and index tabs are bent. #CMT#USE : # / CMT# Method for producing an external synchronizer ring. #CMT#ADVANTAGE : # / CMT# The method involves pre-stamping a flat blank, covering an outer annular surface area of a ring body, and sintering an inner annular surface area of the ring body to form a sintered coating, and hence increases technical quality of external synchronizer ring. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The drawing shows a perspective view of a flat blank. 9 : Flat blank 10 : Outer annular surface area 11 : Inner annular surface area.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

Catalyst for methane dry gas reforming reaction and preparation method thereof

ActiveCN113209999BImprove thermal conductivityImprove transmission efficiencyHydrogenCatalyst activation/preparationPtru catalystBoron nitride

The invention discloses a novel methane dry gas reforming reaction catalyst as well as its preparation and application. The catalyst of the present invention uses an oxide whose surface is covered by ultrathin boron nitride (h-BN, 1-2 layers) as a carrier, and the size of the active component Ni nanoparticles carried thereon is between 2nm and 5nm, wherein : The oxide is SiO 2 、Al 2 o 3 , MgAl 2 o 4 , MgO, ZrO 2 any of the. The catalyst prepared by the present invention can be used for the reaction of methane and carbon dioxide reforming to produce synthesis gas. The h-BN ultra-thin coating can greatly enhance the thermal conductivity of the oxide carrier and improve the heat transfer efficiency around the Ni particles; the CO in the reaction atmosphere 2 and CH 4 It can interact with the defect-rich h-BN layer, which can partially wrap Ni particles and prevent them from sintering, and the B element can also modify Ni particles in real time, greatly improving its anti-carbon deposition performance. The catalyst simultaneously solves the problems of carbon deposition and sintering of metal nanoparticles during the reaction, has a simple preparation method and has wide application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A composite metal hydrogen separation membrane and its preparation method and application

ActiveCN105478019BExtended service lifeImproved thermal cycling stabilitySemi-permeable membranesHydrogen separationHydrogenDehydrogenation

The invention discloses a composite metal hydrogen separation membrane, its preparation method and the application of the composite metal hydrogen separation membrane in dehydrogenation reaction. The separation membrane comprises a porous stainless steel layer and zinc oxide and palladium metal on the porous stainless steel layer composite film. The composite metal hydrogen separation membrane provided by the present invention can effectively separate hydrogen and improve the yield of the reaction product of the dehydrogenation reaction. At the same time, the combination between zinc oxide and palladium metal composite membrane and porous stainless steel is strong, effectively solving the problem of high temperature Sintering phenomenon of metallic palladium films. In addition, the preparation method of the composite metal hydrogen separation membrane provided by the present invention is simple and easy to operate, and is favorable for popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Airtight sintering device of glass tube and MEMS chip

ActiveCN102358616BSolve problems that cannot be ruled outImprove pass rateDecorative surface effectsChemical vapor deposition coatingVacuum pumpingIntegrated circuit manufacturing

The invention discloses an airtight sintering device of glass tubes and MEMS chips, which comprises a main frame, a heating furnace body, a lifting adjusting member, and a lifting pressure adjusting handle, a stop valve, an air exhaust connecting member, and the like. In the device of the invention, two MEMS chips are sintered together with a glass tube; the glass tube is connected to a vacuum-pumping device for vacuum pumping; the glass tube is sintered together with two MEMS chips through glass powder so as to form a vacuum microcavity; the invention solves the problem in traditional devices that organic gas which is generated during glass slurry sintering and is released into the vacuum microcavity can not be removed; the vacuum degree is up to 5*10-5 Pa, and the qualified rate of high-precision resonance-type pressure sensors is increased. The invention is applicable to fields of packaging technology of resonance-type pressure sensors in micro-electro-mechanical system manufacturing, and integrated circuit manufacturing.

Owner:NO 24 RES INST OF CETC

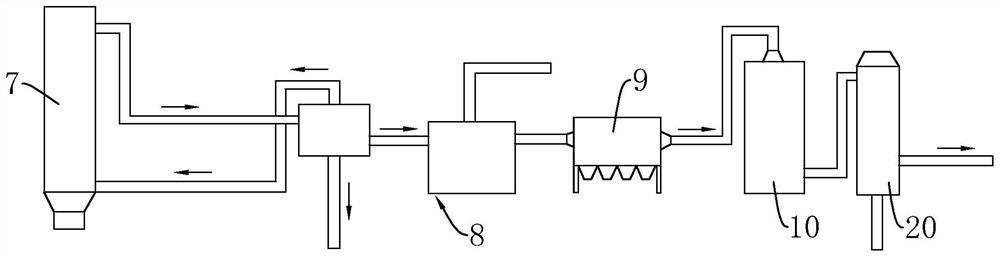

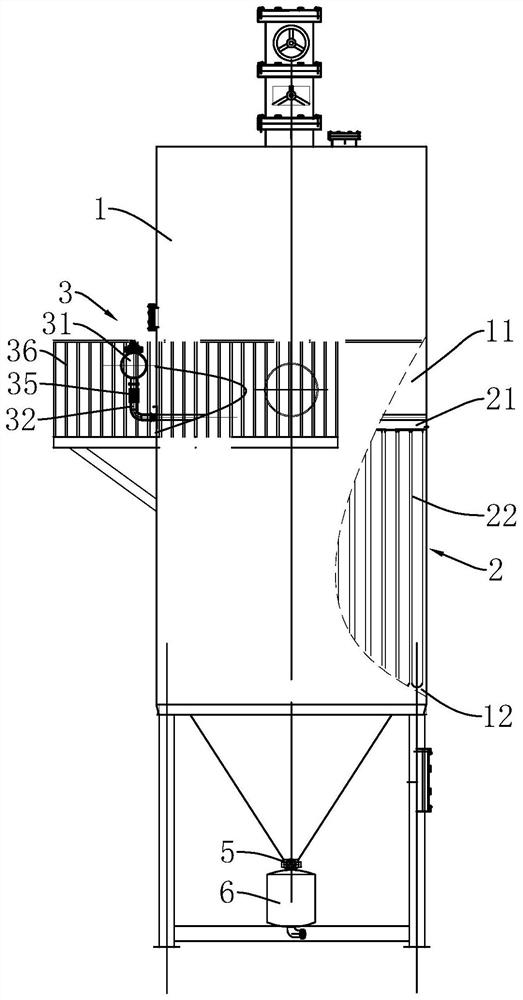

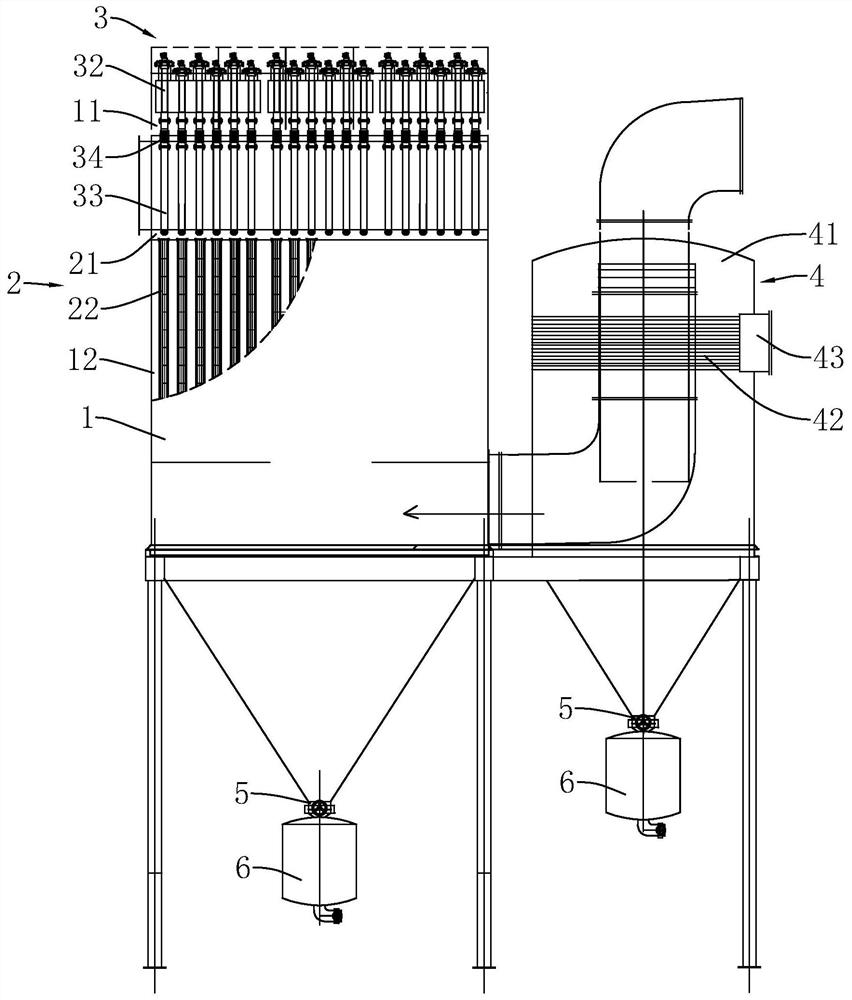

Pyrolysis raw gas high-temperature efficient dust removal method

PendingCN112480977AEfficient removalStrong acid and alkali resistanceGas purification by non-gaseous materials condensationGas purification by liquid washingProcess engineeringCoal gasifier

The invention discloses a pyrolysis raw gas high-temperature efficient dust removal method which comprises the following steps of externally connecting an enclosure with induced draft equipment to form negative pressure in a gas purification chamber, and pumping high-temperature dust-containing raw gas into a pre-dust remover from an outlet of a coal gasifier to perform primary dust removal, enabling the pre-dedusted raw gas to enter a dust collection chamber, performing fine dedusting by utilizing a ceramic fiber filter tube, and enabling the pre-dedusted raw gas to enter a gas purification chamber to obtain high-temperature purified gas, transferring the high-temperature clean gas into a washing tower and a drop catcher for deep purification and cooling to finish dust removal, and afterlong-time work, using a high-pressure blowback system to perform blowback ash removal on the ceramic fiber filter tube. According to the dust removal method, high-temperature dust-containing raw gas can be directly filtered, the situation that the raw gas needs to be cooled before being filtered by a cloth bag dust removal device in an existing coal-to-gas process is improved, and the problem thatdust below 2 mum is removed and separated again is effectively solved.

Owner:国科永基(北京)工程安装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com