Tensile fixture for platy sample and application method thereof

A plate-shaped sample and fixture technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problem of not being able to test small-sized samples, wasting time, manpower and material resources, and prone to oxidation. and sintering, to achieve the effect of reducing test cost, convenient loading and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiments of the present invention are a kind of tensile test method, which is completed by using the described tensile fixture for a plate-shaped sample. In this embodiment, the tensile test is carried out on nickel-based superalloys using the fixture of the present invention. The method includes Follow the steps below:

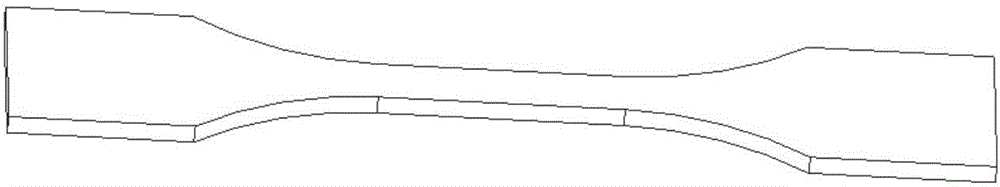

[0038] (1) Processed by wire cutting method image 3 The sheet sample 4 shown;

[0039] (2) The surface and sides of the sheet sample 4 are polished with sandpaper to improve the flatness of the sample surface;

[0040] (3) Clean the surface of sample 4 with acetone solution to remove surface oil and impurities;

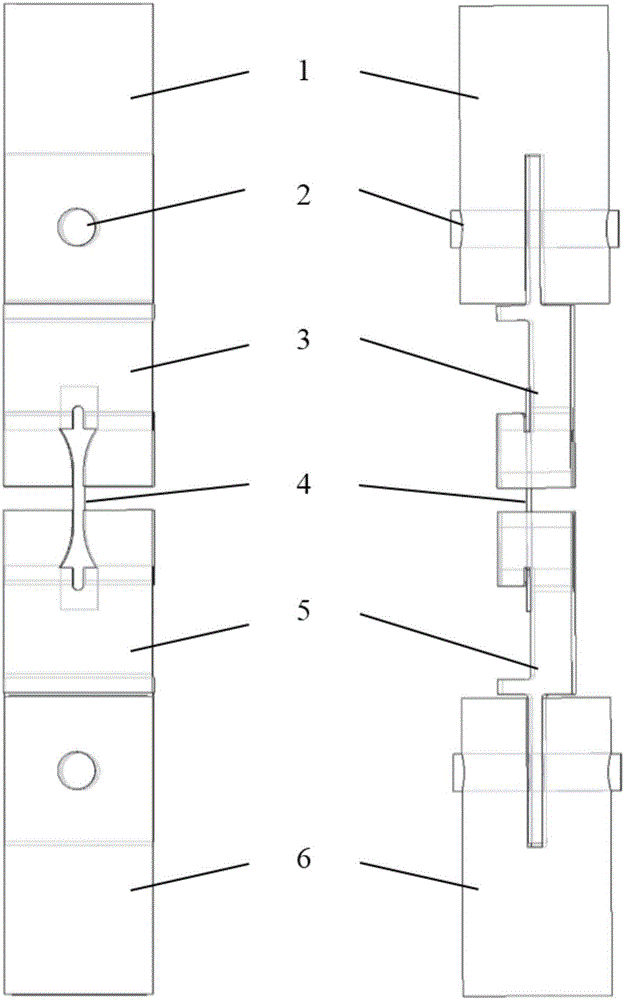

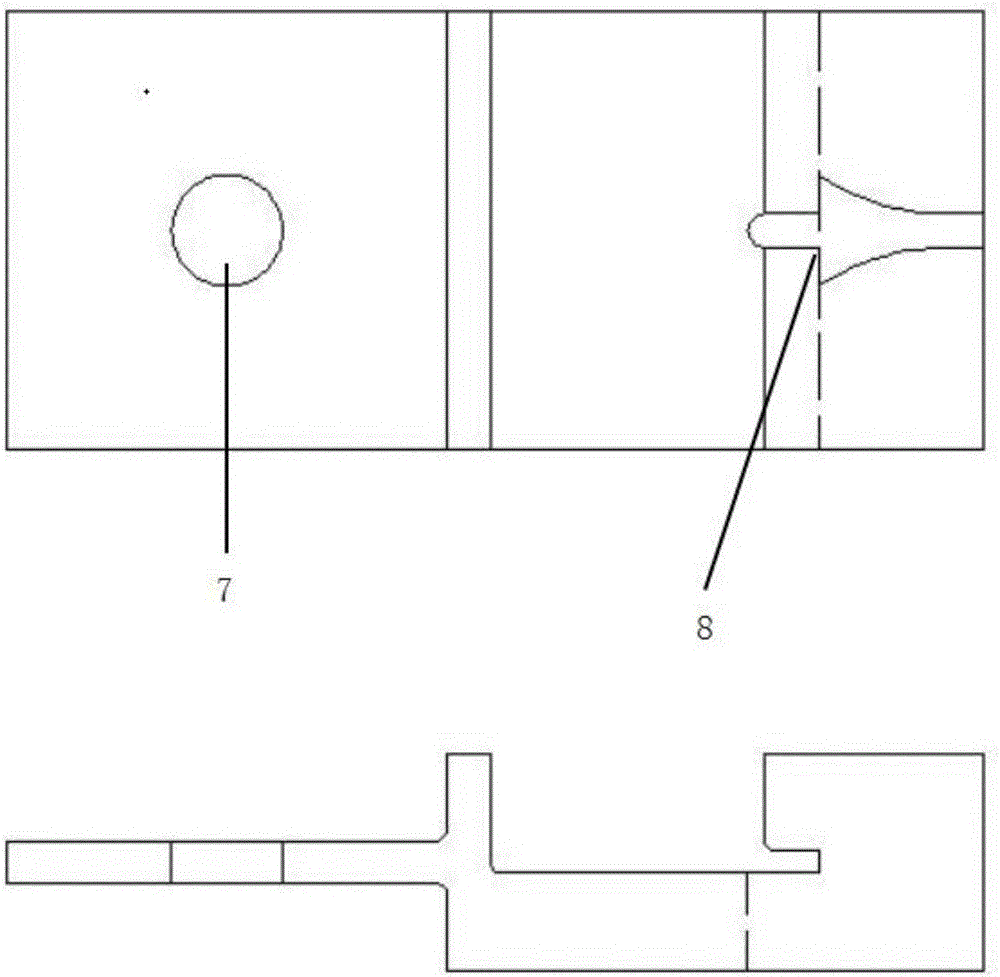

[0041] (4) Tensile clamps 3,5 are fixed on the connecting rods 1,6 at both ends of the tensile testing machine;

[0042] (5) Fix the sample 4 into the fixture, and pre-tighten the fixture and the sample after the temperature of the heating furnace rises to 650°C and stabilizes;

[0043] (6) Set the tensile parameters, and carry out the...

Embodiment 2

[0046] Embodiments of the present invention are a kind of tensile test method, which is completed by using the described tensile fixture for a plate-shaped sample. In this embodiment, the tensile test is carried out on nickel-based superalloys using the fixture of the present invention. The method includes Follow the steps below:

[0047] (1) Processed by wire cutting method image 3 The sheet sample 4 shown;

[0048](2) Use sandpaper to grind the side arc of the sheet sample 4 to reduce surface scratches caused by processing and avoid abnormal fracture of the sample due to stress concentration during stretching; surface parallelism;

[0049] (3) Clean the surface of sample 4 with acetone solution to remove surface oil and impurities;

[0050] (4) Raise the upper pull rod of the stretching machine for a certain distance, and fix the clamp to the upper pull rod of the stretching machine through pins. Adjust the height of the tie rod so that the two fixtures are close to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com