Patents

Literature

112 results about "Core product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A core product is a company product or service that is most directly related to its core competencies. The core product enable the use, benefit or problem-solving service for which the consumer is purchasing the product. Core products may be integrated into end products, either by the company producing the core product or by other companies to which the core product is sold.

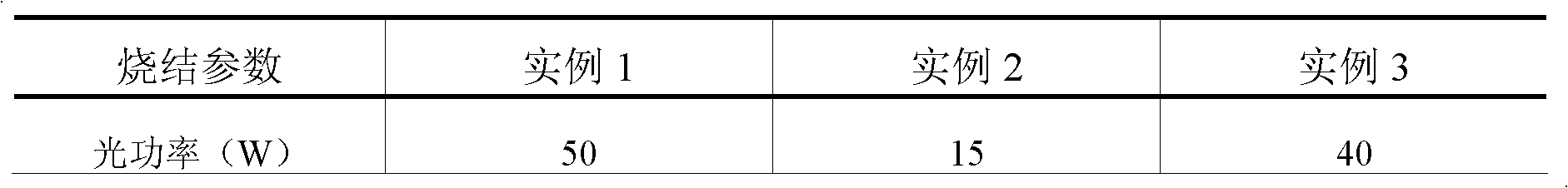

Method for quickly forming and manufacturing ceramic core

ActiveCN101890480ASimple processEasy to modify the designFoundry mouldsFoundry coresCore productMetallurgy

The invention relates to a method for quickly forming and manufacturing a ceramic core, which comprises the following steps of: uniformly mixing a low temperature reinforcer and ceramic powder and then performing SLS quick forming on the mixture; performing pretreatment on the obtained ceramic core blank; removing the low temperature reinforcer from the ceramic core blank, and soaking the blank into a high temperature adhesive for presintering and degreasing; and sintering at a high temperature to obtain a final integral ceramic core product. The method has the advantages that: (1) the ceramic core of a hollow radiating blade with complex section can be integrally manufactured; (2) a mold is avoided, flexibility is high, and various ceramic workpieces can be quickly formed; and (3) process flow is simple and production efficiency is high. The ceramic core of the hollow radiating blade which is manufactured by the method has the advantages of high heat conductivity, light mass, accurate size and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

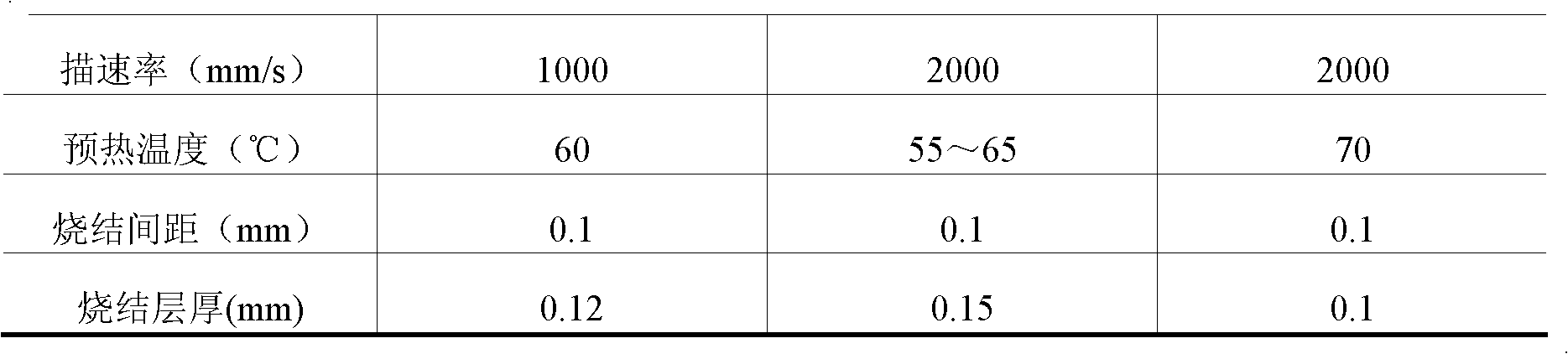

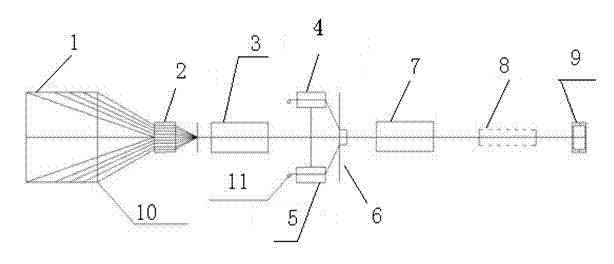

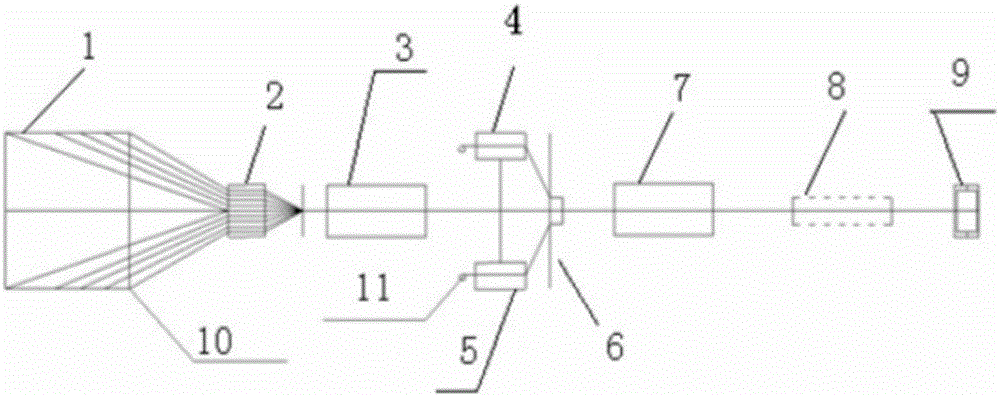

Heat treatment method and device of amorphous alloy cores

InactiveCN101993986AGuaranteed uniformityGuaranteed synchronicityHeat treatment process controlFurnace temperatureCore product

The invention discloses a heat treatment method of amorphous alloy cores, which comprises the following steps: measuring the temperature of a heat treatment furnace with a temperature sensor; monitoring the real-time temperature of a plurality of the amorphous alloy cores to be treated by a plurality of additional temperature sensors; and adjusting the heating power of the heat treatment furnace in real time according to the measured furnace temperature and the real-time temperature of the plurality of amorphous alloy cores. In the invention, the real-time temperature of the plurality of amorphous alloy cores is monitored with the plurality of temperature sensors and the heating power of the heat treatment furnace is adjusted correspondingly, thus ensuring heating uniformity and synchronization of the amorphous alloy cores during the heat treatment process, effectively improving the performance of the amorphous alloy core product, greatly enhancing the product qualification rate and obviously increasing the economic benefit.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

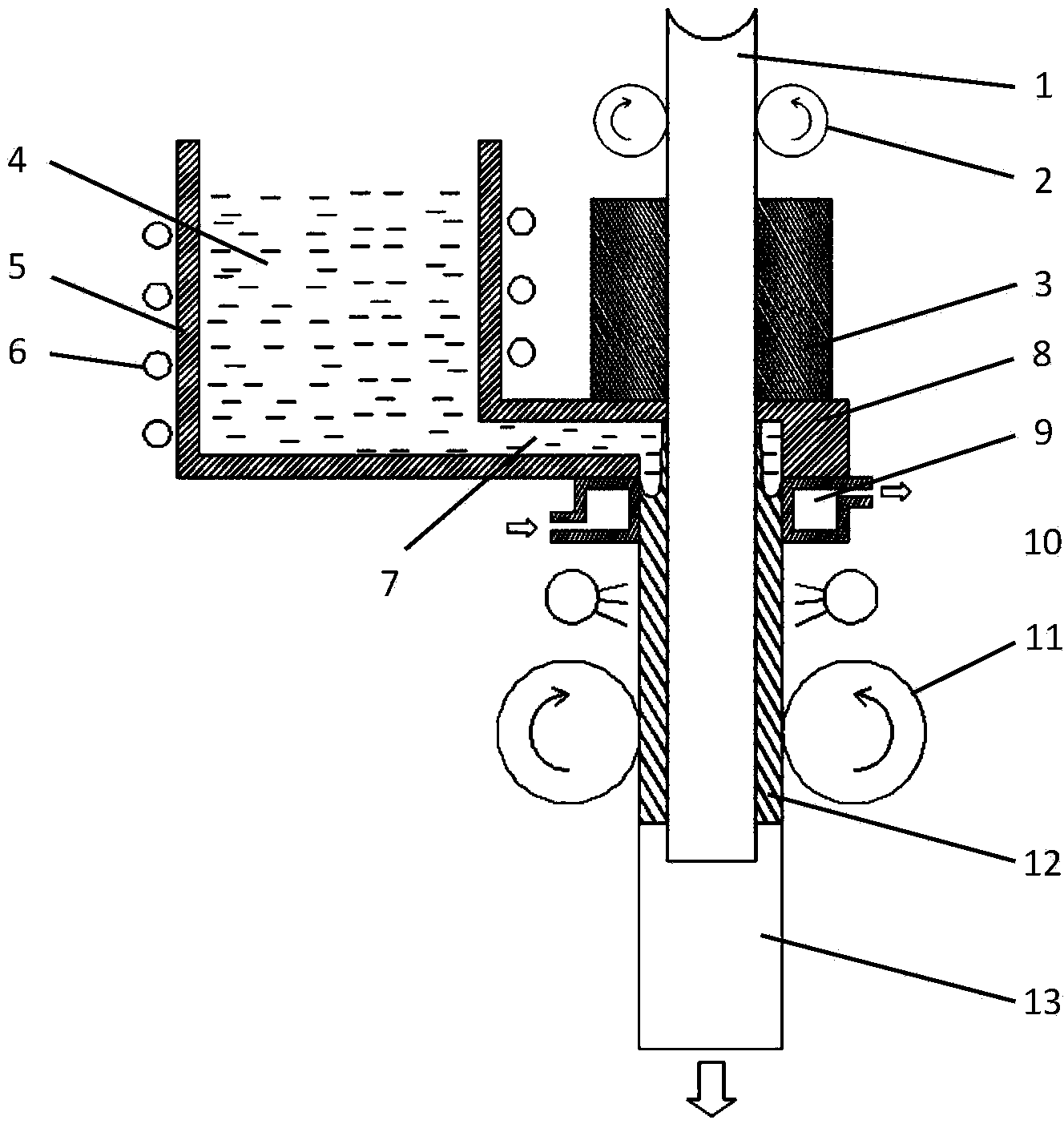

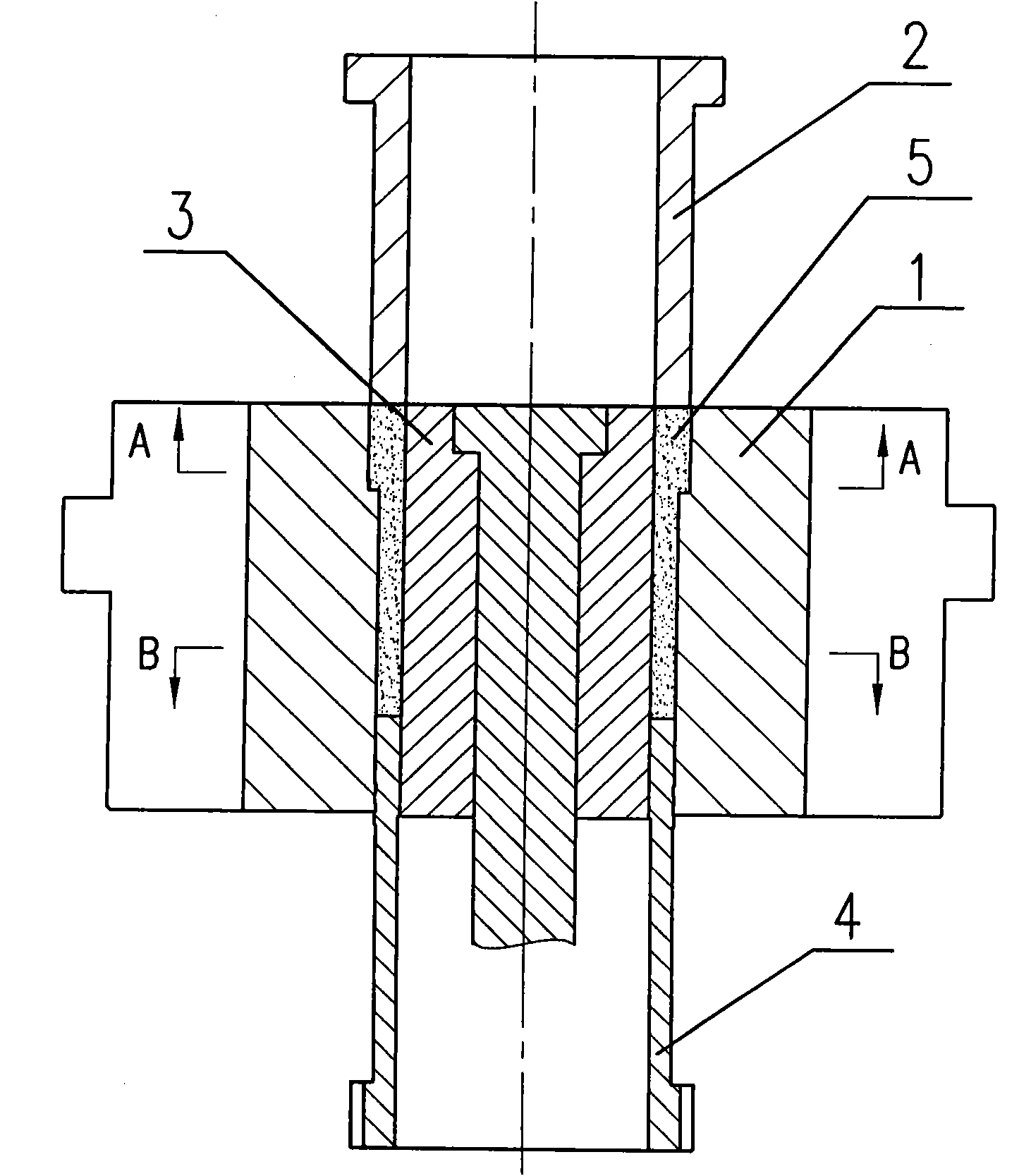

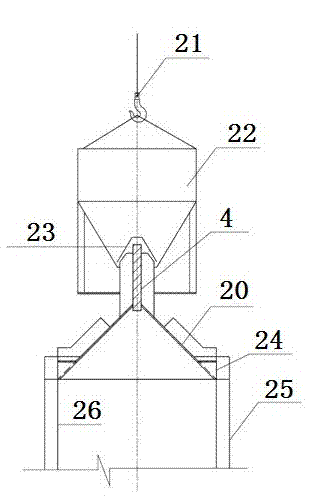

Clad material solid/liquid composite continuous-casting forming device and method

The invention discloses a clad material solid / liquid composite continuous-casting forming device and method and belongs to the technical field of clad material continuous casting. A core product protecting device, a guide pipe, a reverse coagulator and the like are installed on the side of a crucible, a core material is not heated in advance, the designed small-capacity reverse coagulator is used for preventing the core material from penetrating a cladding layer metal melt for a long period of time, the melt flows out of the side of the bottom of the crucible by relying on self weight, the sizes of the reverse coagulator and a water-cooling crystallizer are effectively regulated and controlled, and other measures are adopted, so that a high-quality clad material with required shape and size is formed through continuous casting. The clad material solid / liquid composite continuous-casting forming device is simple in structure, convenient to operate and maintain, reasonable and compact in layout, high in production efficiency, low in investment, short in forming process, energy-saving, environment-friendly, efficient and low in cost, parts are easy to replace, automatic control is easy to achieve, large-scale industrial production is facilitated, combination freedom degree of cladding layer metal and core material metal is high, and the prepared clad material is good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

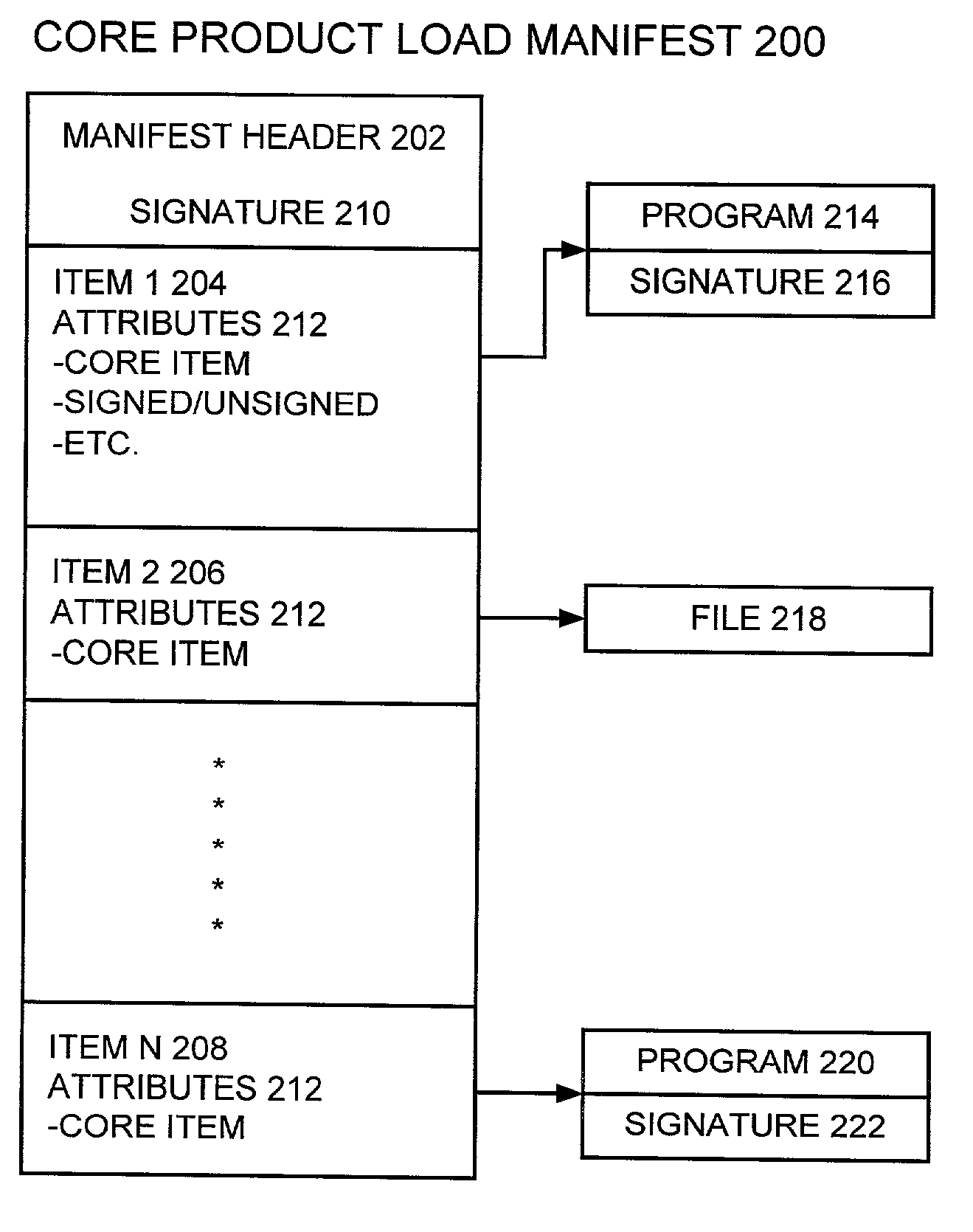

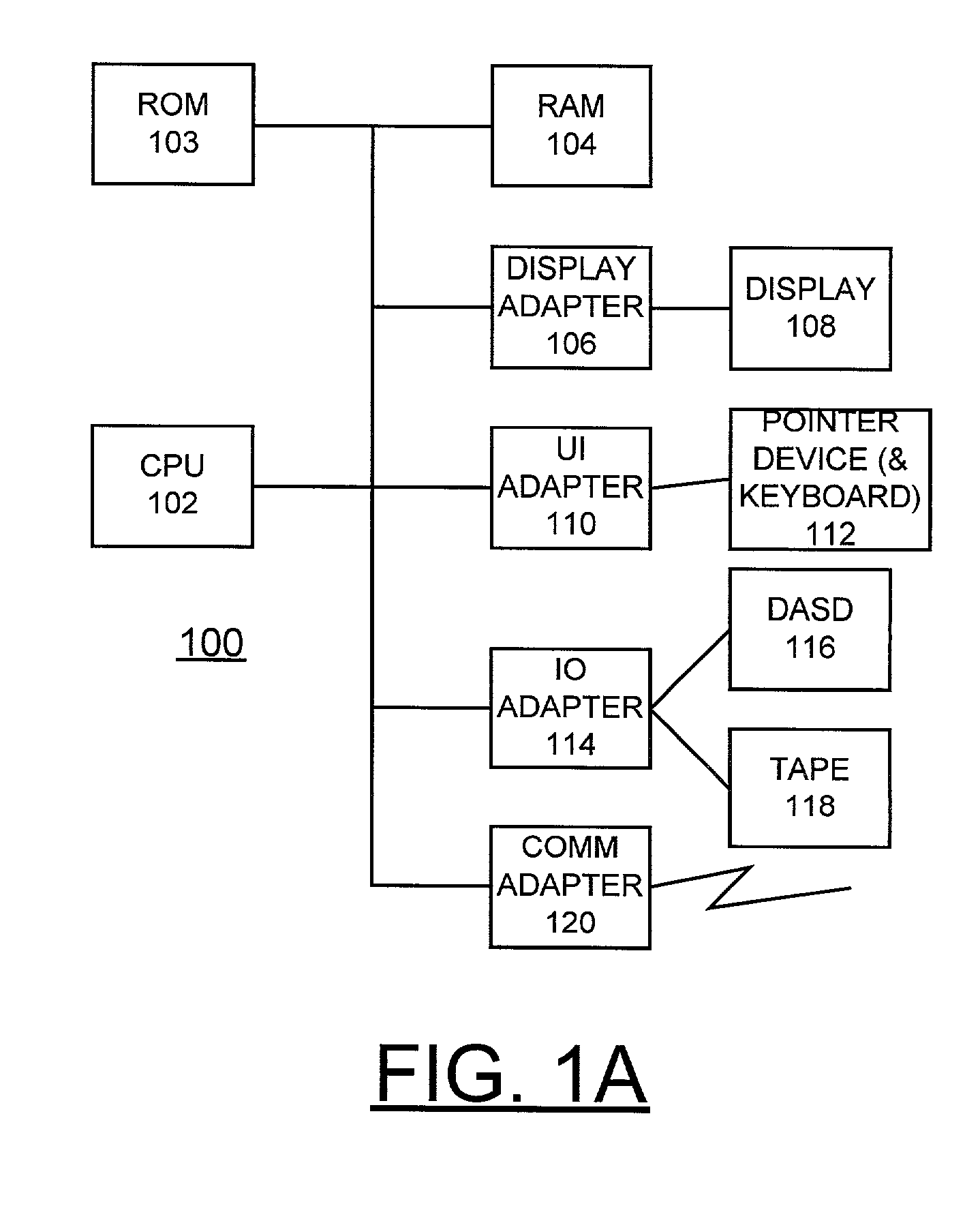

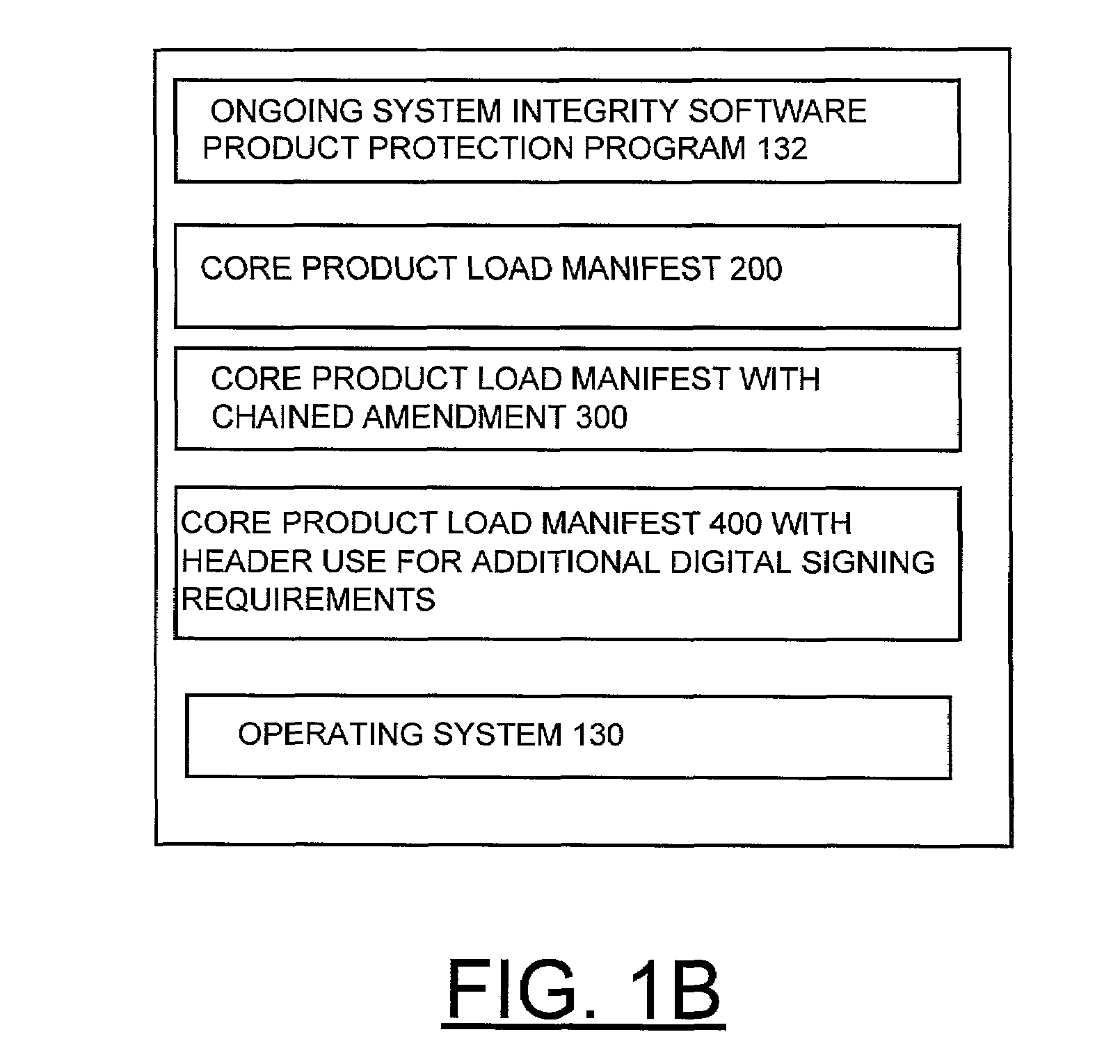

Method and apparatus for protecting ongoing system integrity of a software product using digital signatures

InactiveUS7093132B2Digital data processing detailsUser identity/authority verificationCore productDigital signature

A method, apparatus and computer program product are provided for protecting ongoing system integrity of a software product using digital signatures. A core product load manifest for protecting ongoing system integrity of a software product having a plurality of pieces includes a manifest header including header attributes of the software product. A list of a plurality of manifest items is stored with the manifest header. Each manifest item identifies a corresponding piece of the software product. Each manifest item includes at least one attribute. A manifest digital signature is stored with the manifest header. The manifest header, the header attributes, each of the plurality of items, and each item attribute are included in the manifest digital signature. A digital signature is computed for each signable piece of the software product and is stored with the piece of the software product. The digital signature of each signed software product piece is excluded from the core product load manifest. An amended manifest is created for identifying added and deleted pieces of the software product and is chained to the core product load manifest. Each signable, added item in the amended manifest has a digital signature that is excluded from the amended manifest.

Owner:IBM CORP

Product search method and system

ActiveUS20130318101A1Reduction of informationReduce weightMetadata text retrievalDatabase updatingCore productTheoretical computer science

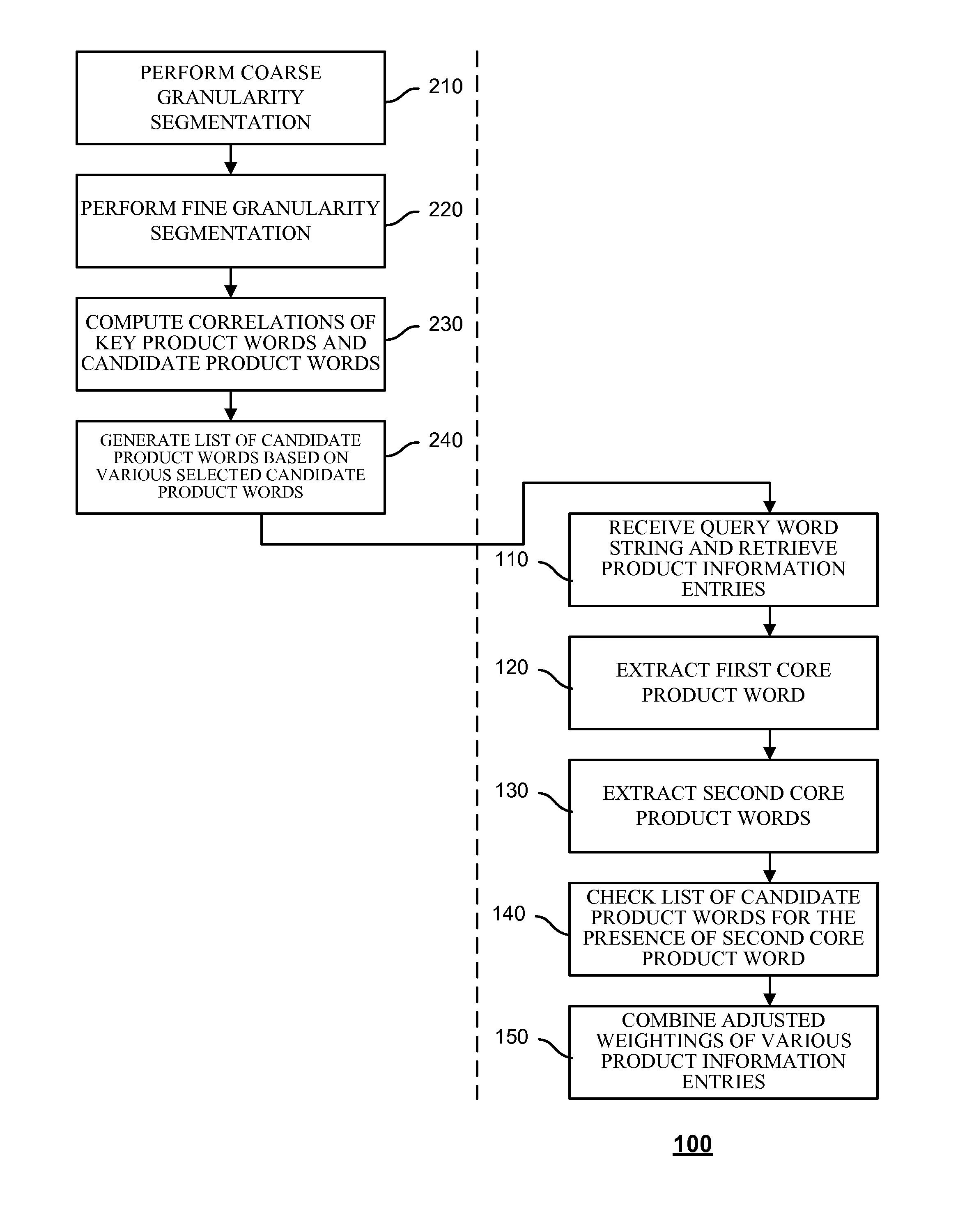

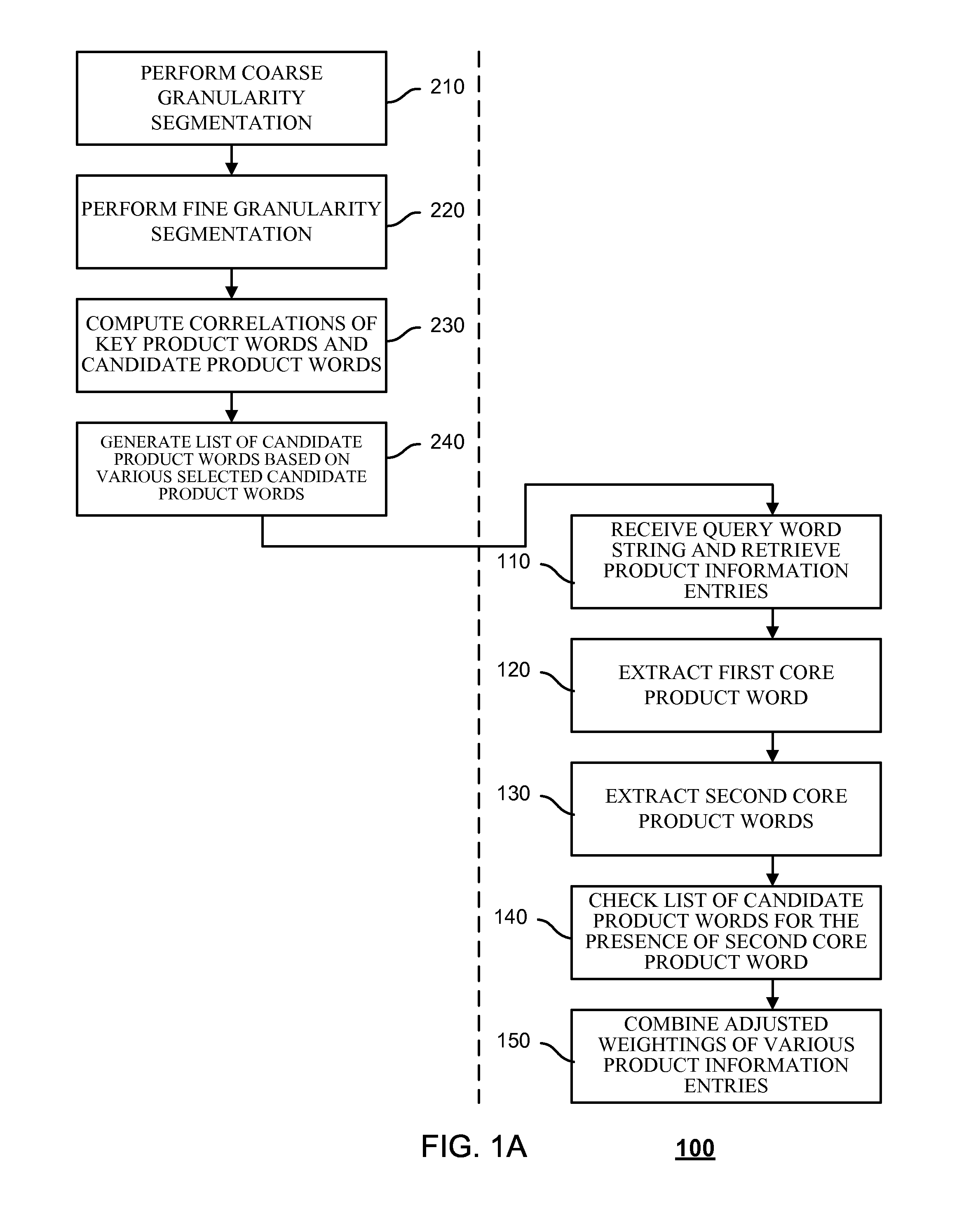

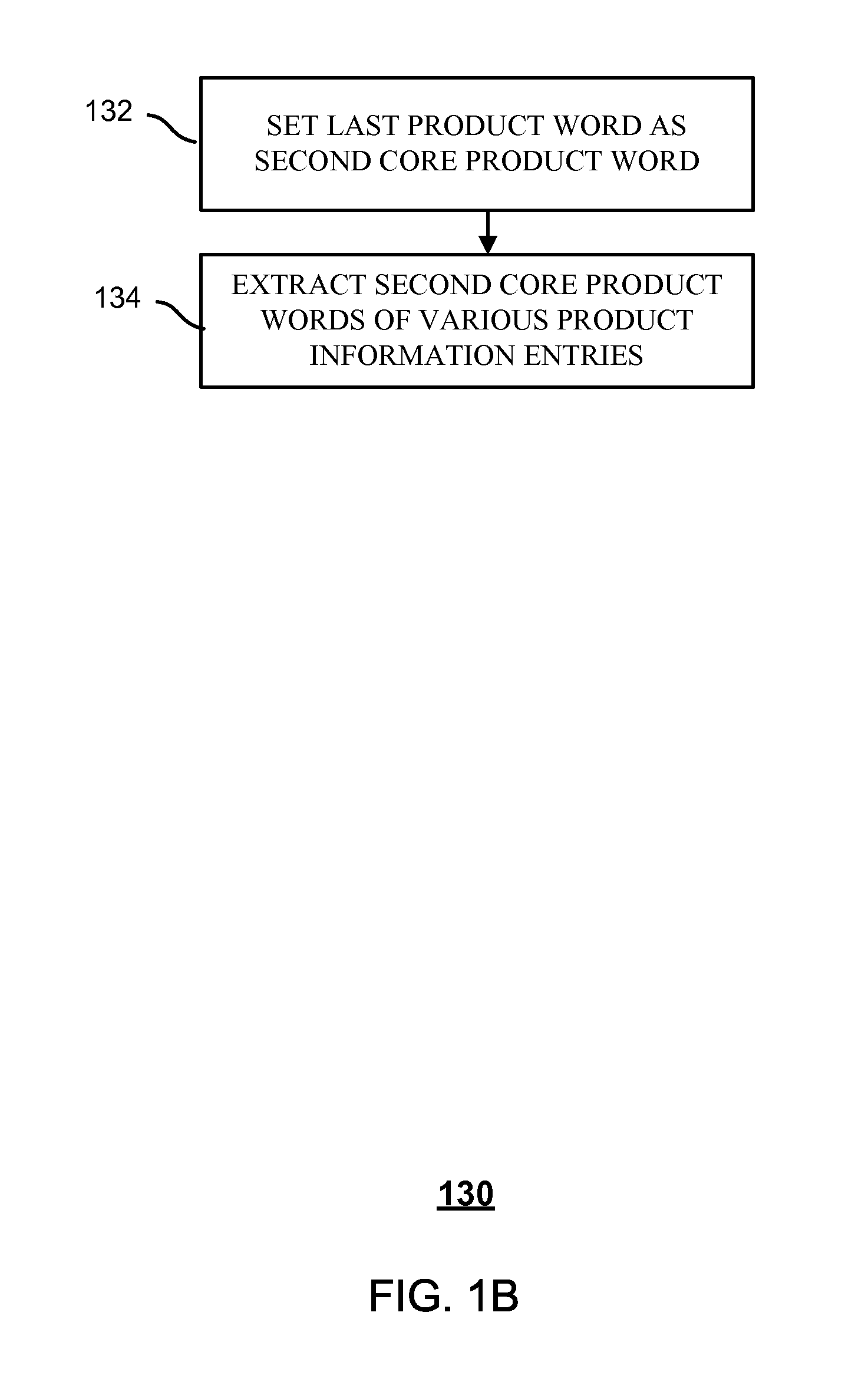

Embodiments of the present application relate to a search method, a system for searching, and a computer program product for searching. A search method is provided. The method includes receiving a query word string, retrieving a plurality of various product information entries related to the query word string, extracting, from a memory, a first core product word from the query word string, extracting, from the memory, second core product words from the various product information entries, for each second core product word, checking a list of candidate product words relating to a key product word for a presence of the each second core product word, in the event that the each second core product word is present, reducing a weighting of the product information entry corresponding to the each second core product word, and sorting the product information entries according to the adjusted weightings of the product information entries.

Owner:ALIBABA GRP HLDG LTD

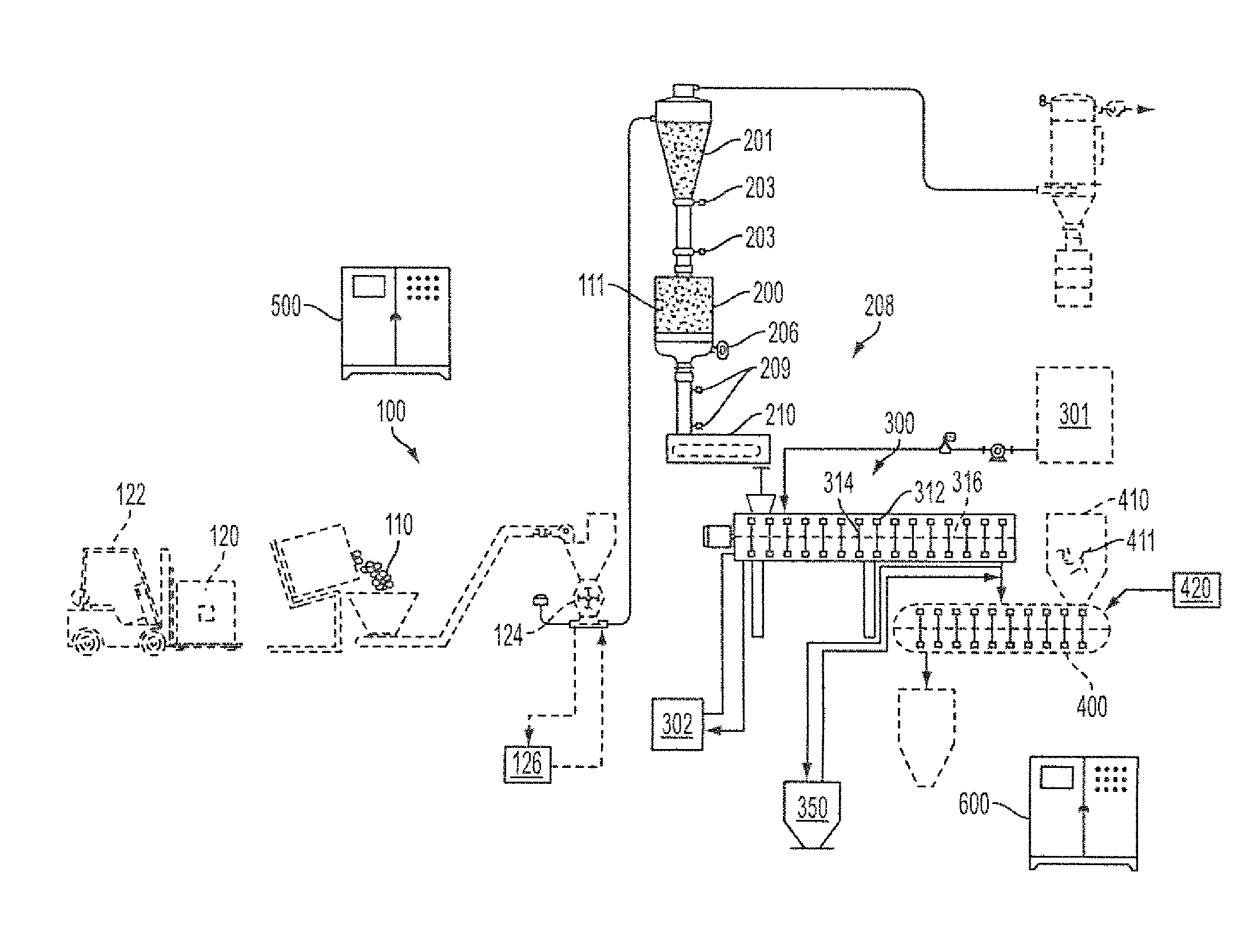

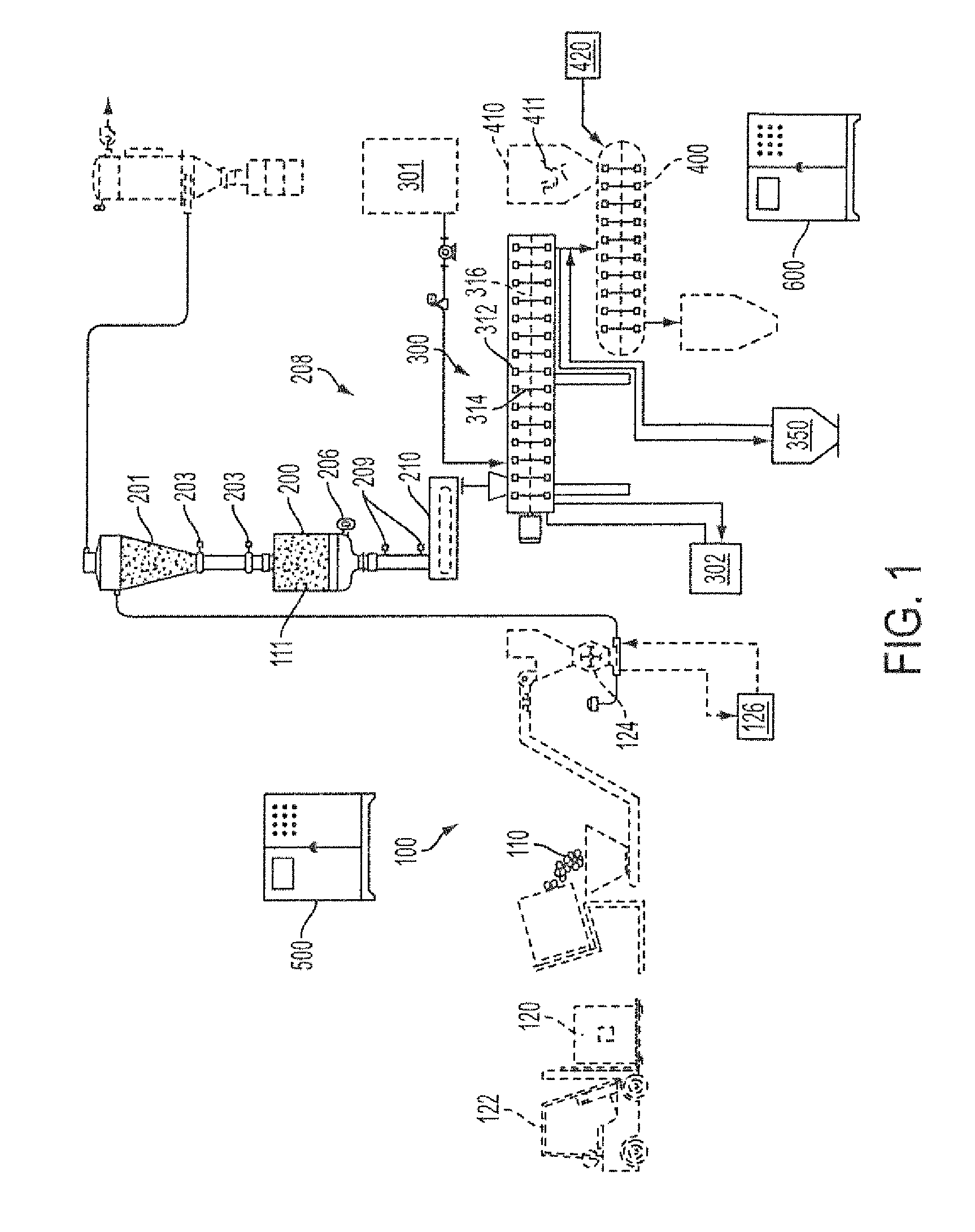

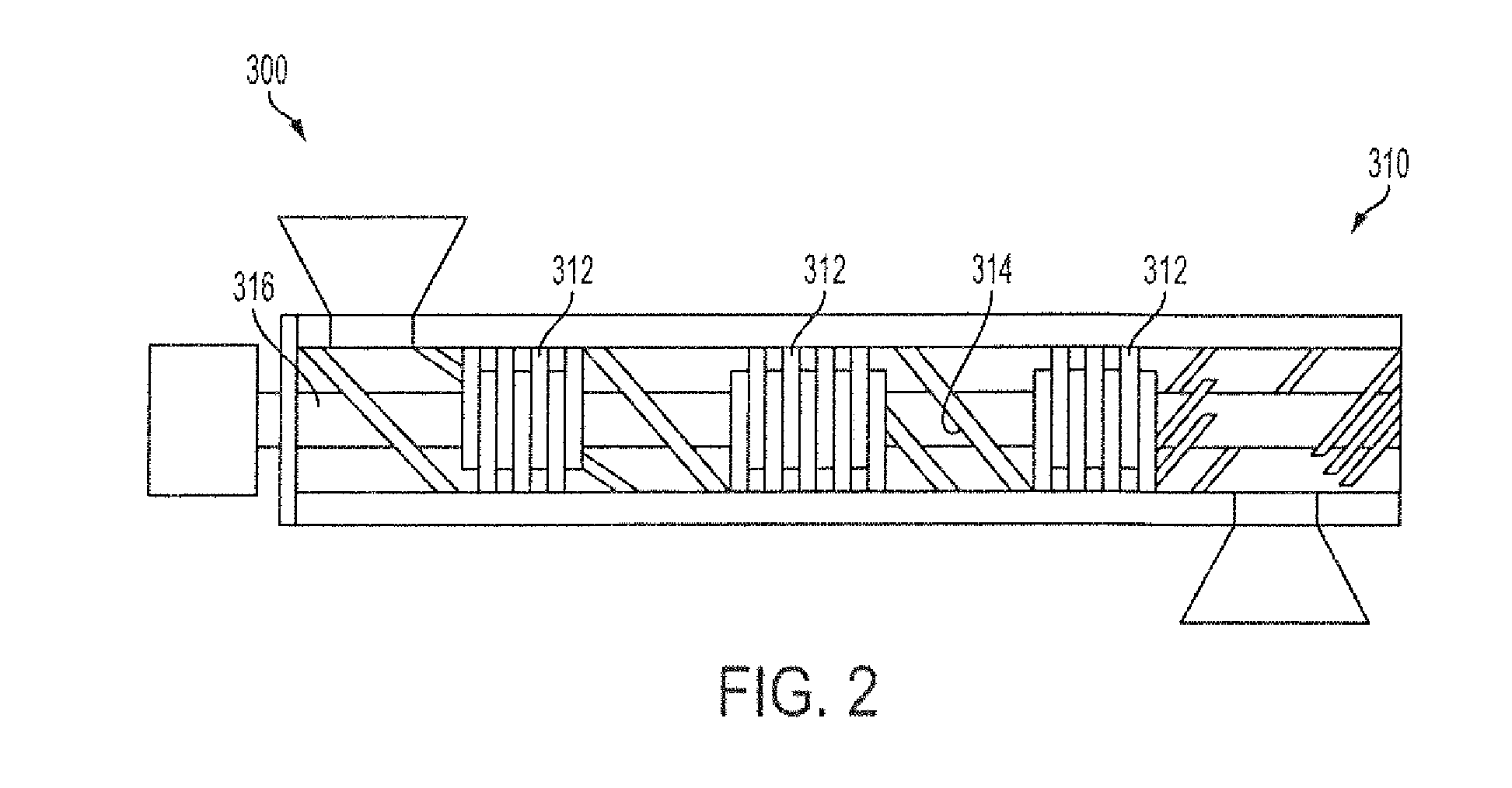

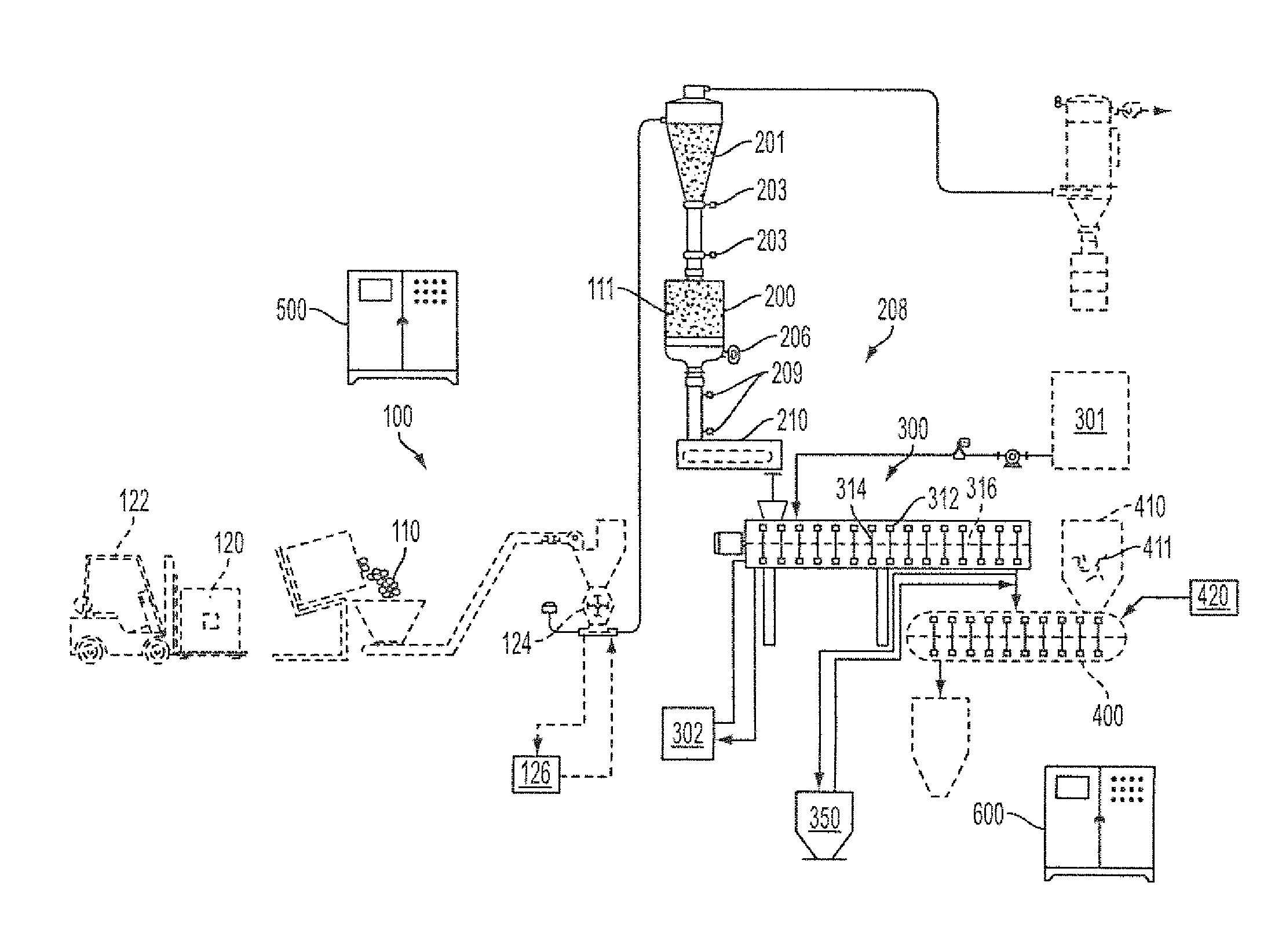

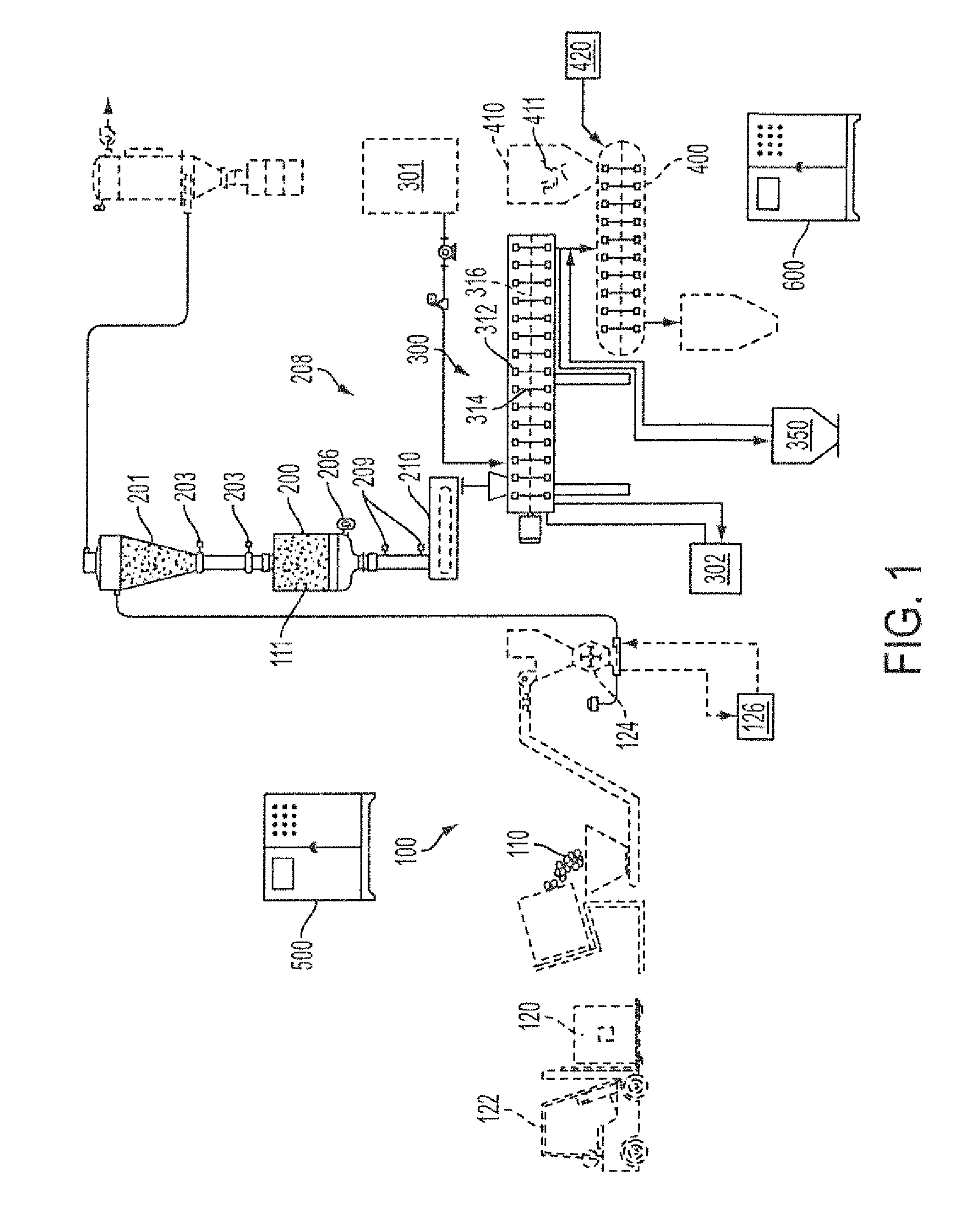

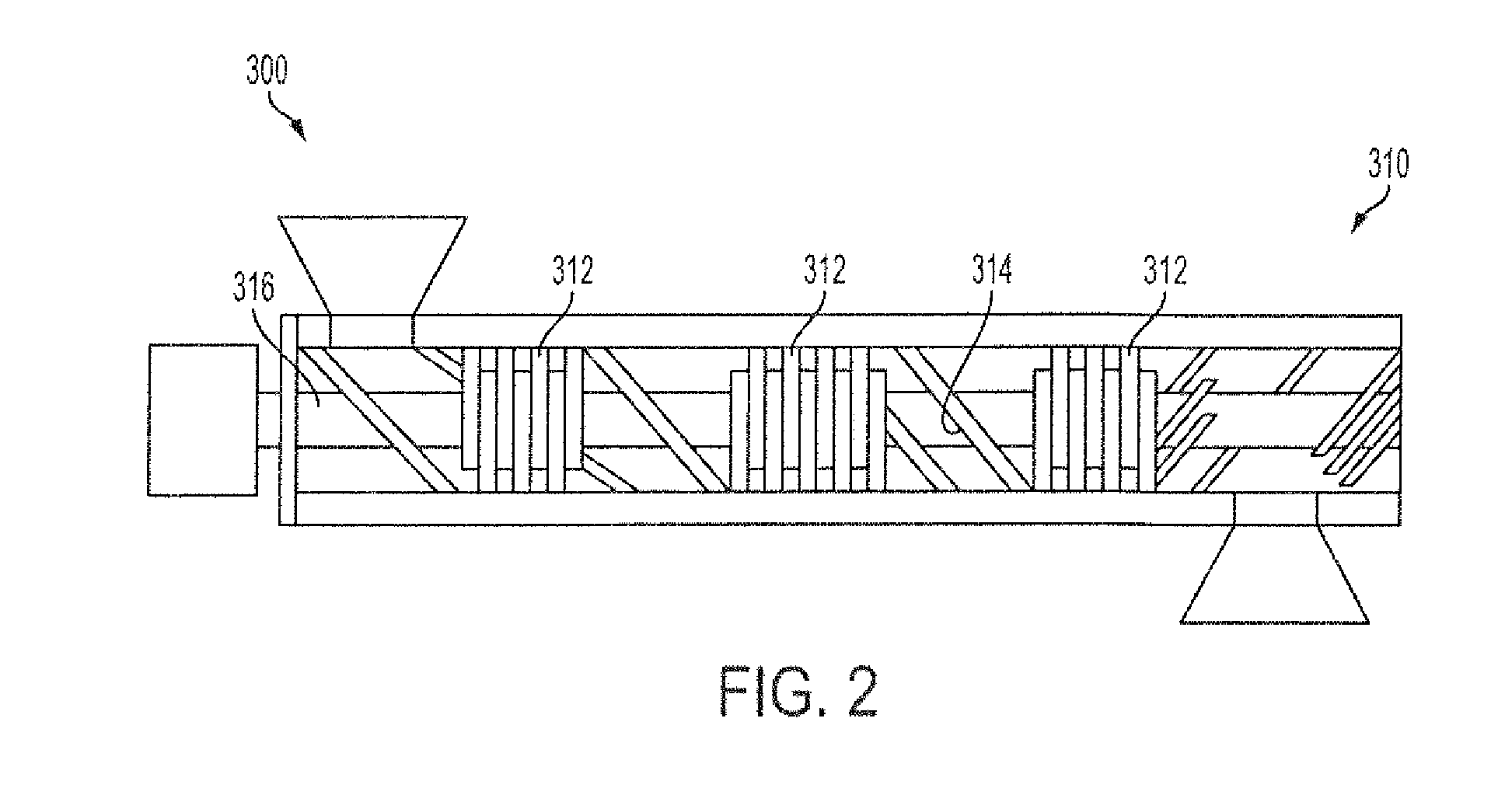

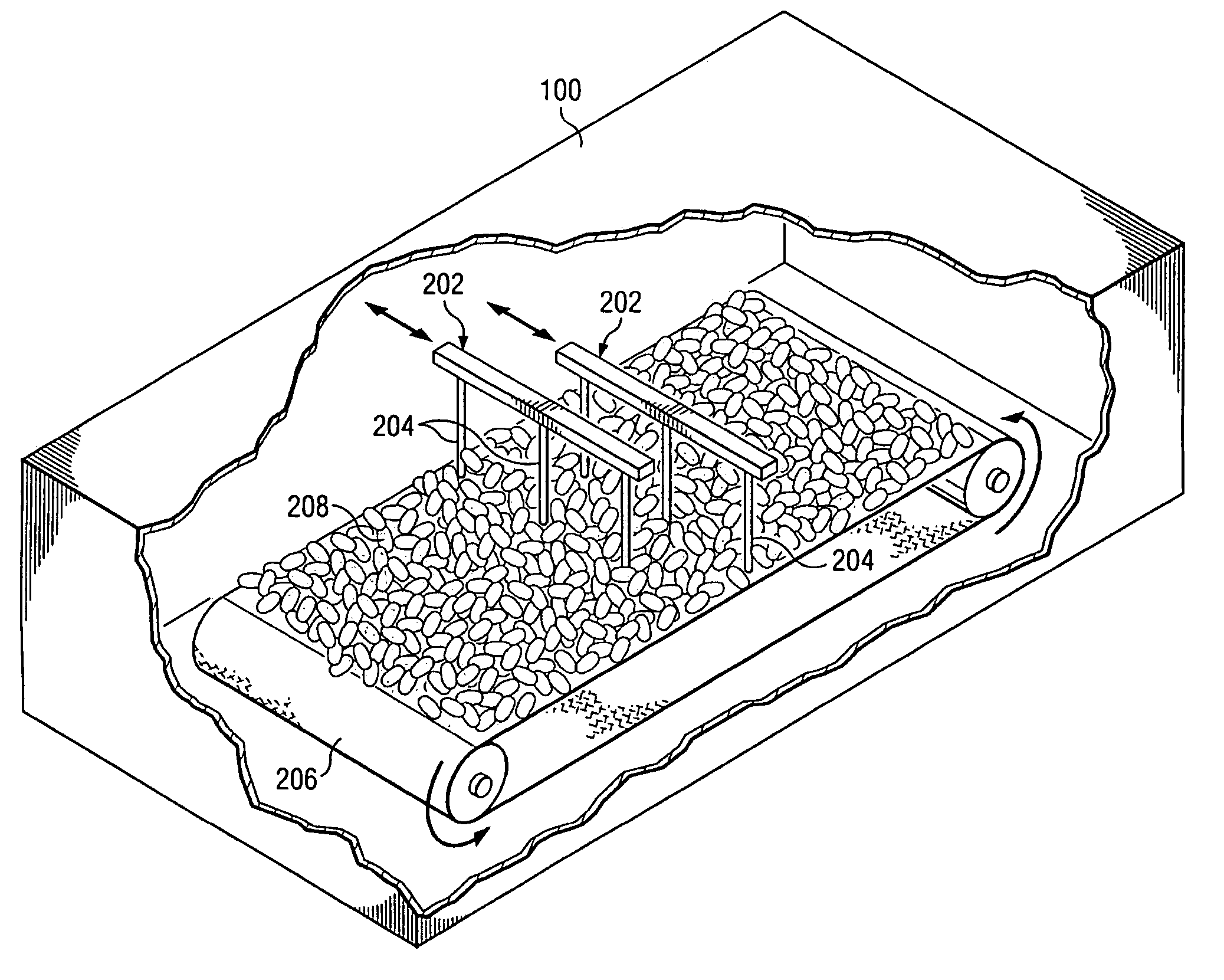

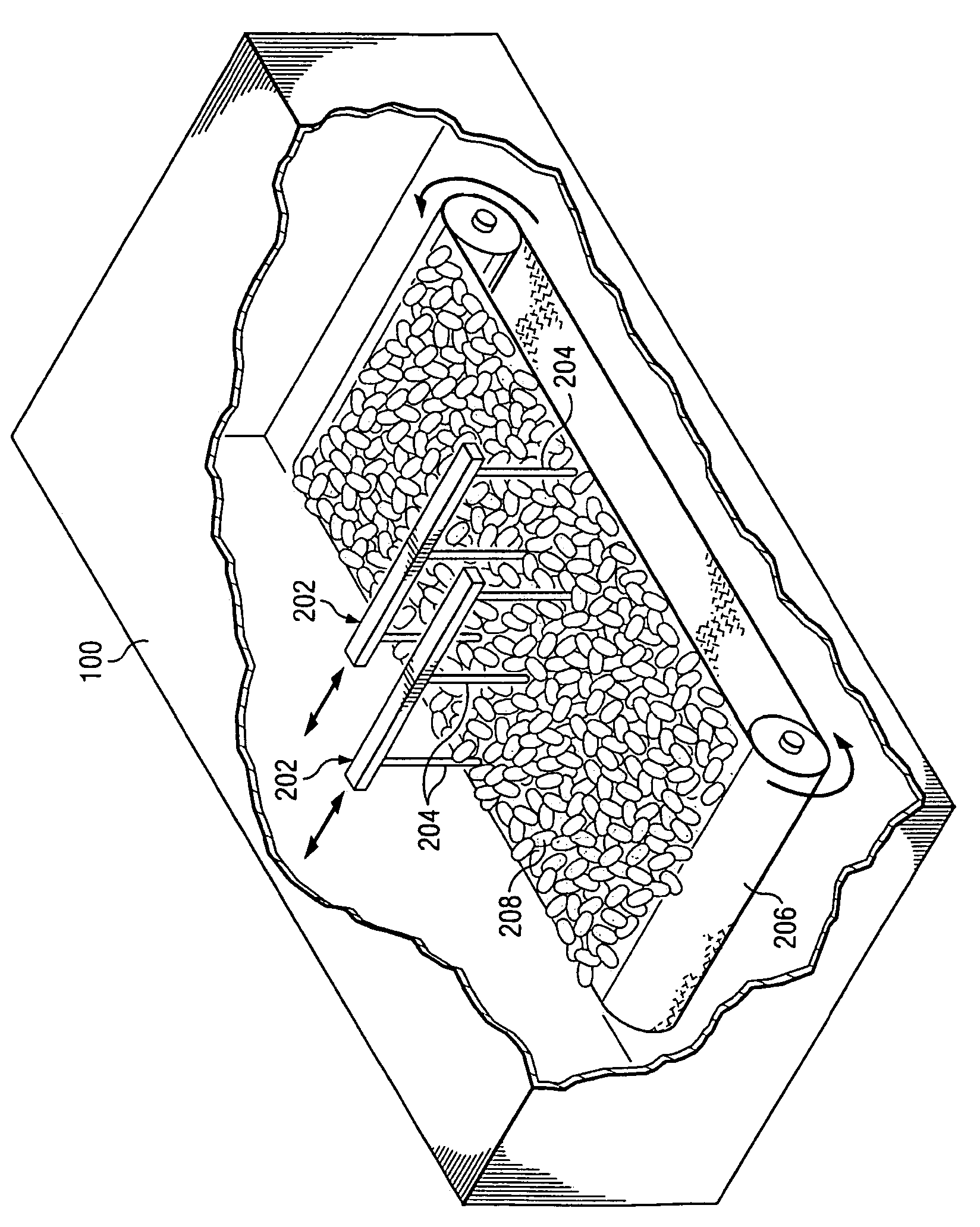

System and method for continuous processing of recyclable material

A continuous system for making shingles from recyclable material is provided comprising a milling device to receive recyclable material and process the recyclable material into particulate and a transfer device to receive and transfer the particulate from the milling device. An apparatus receives the particulate from the transfer device and weighs the particulate. A continuous processor receives the particulate and reacts and / or mixes the particulate with at least one admixture to form a homogenous mixture. A filler mixer receives the homogenous mixture and incorporates the homogenous mixture with shingle material to form core product and a control panel controls input of the homogenous mixture into the filler mixer.

Owner:BMIC LLC

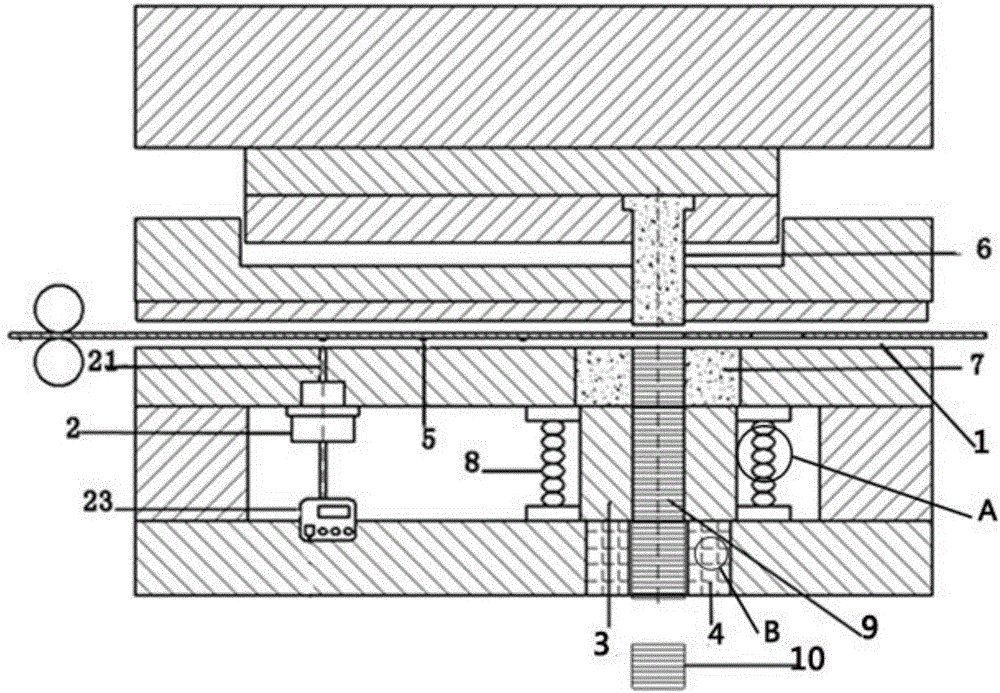

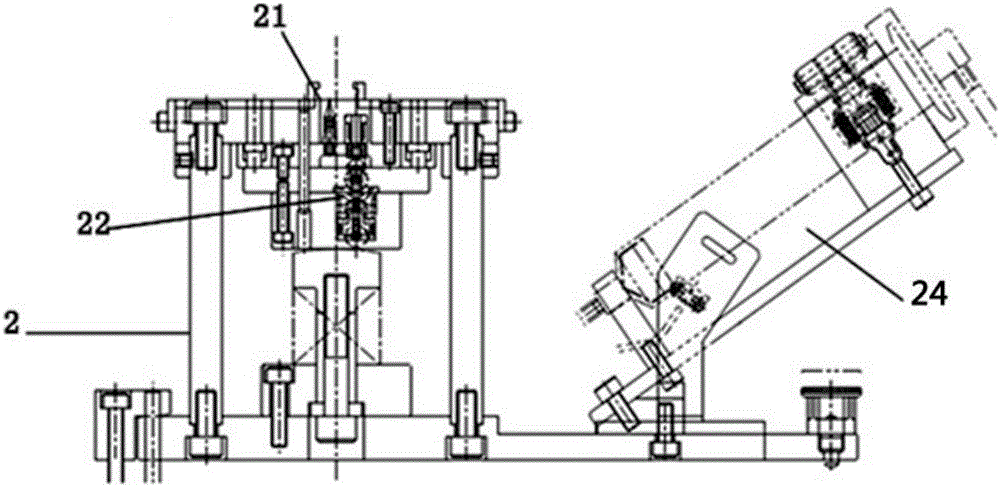

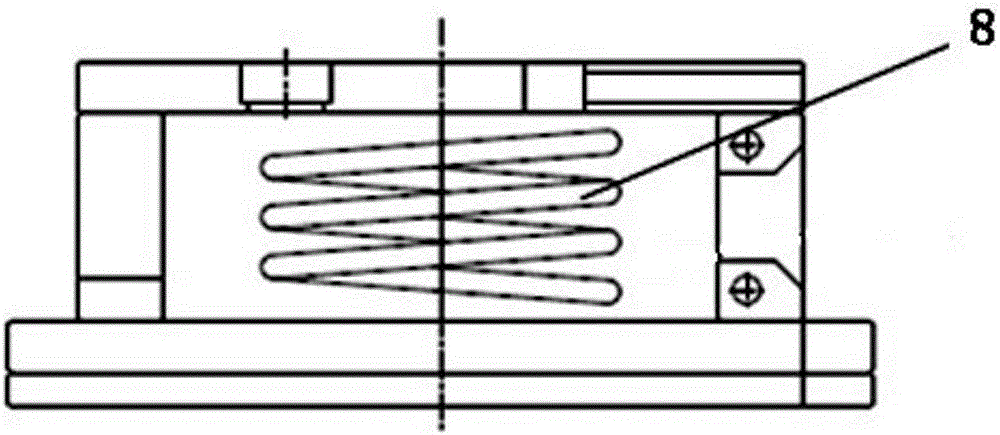

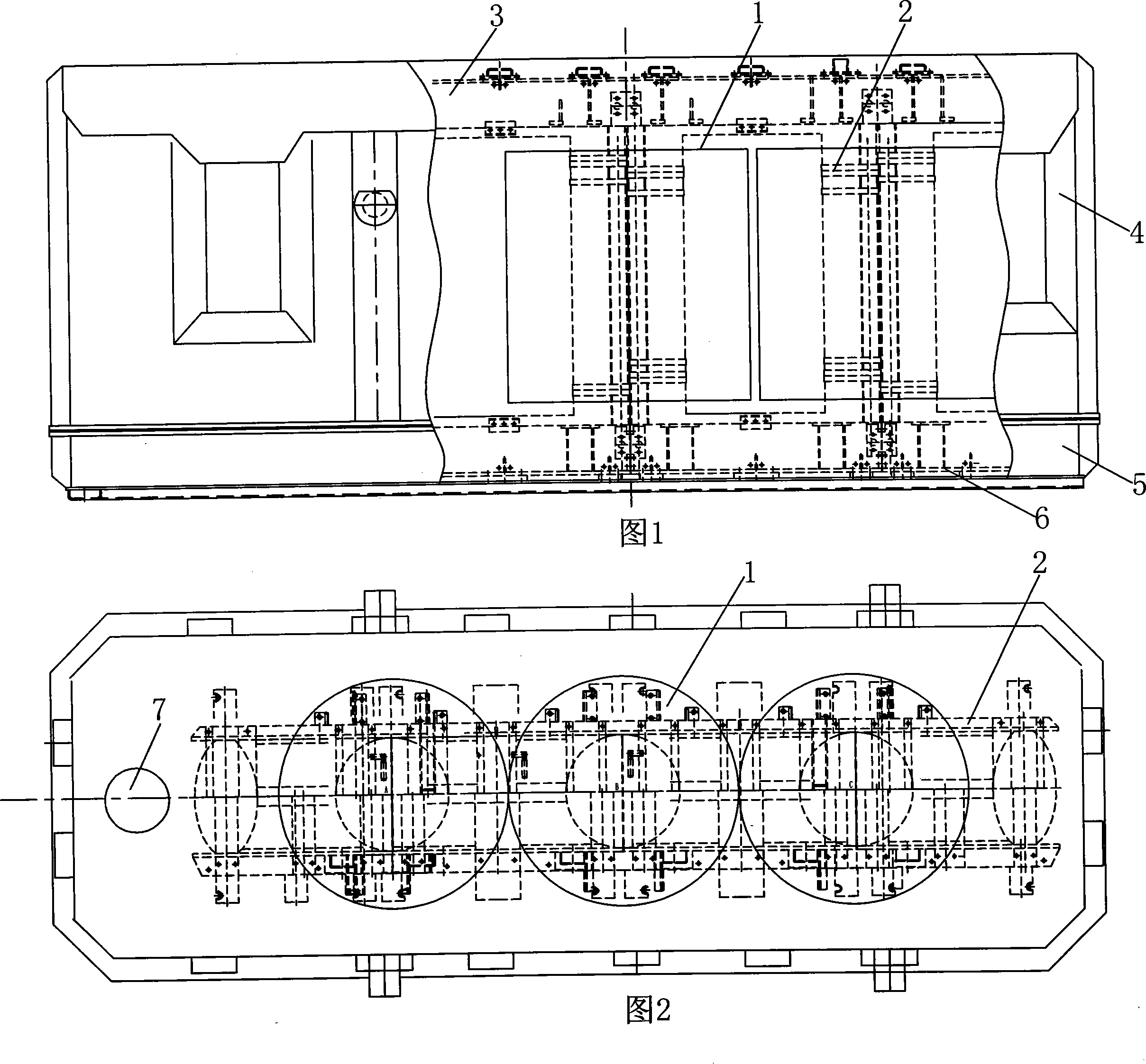

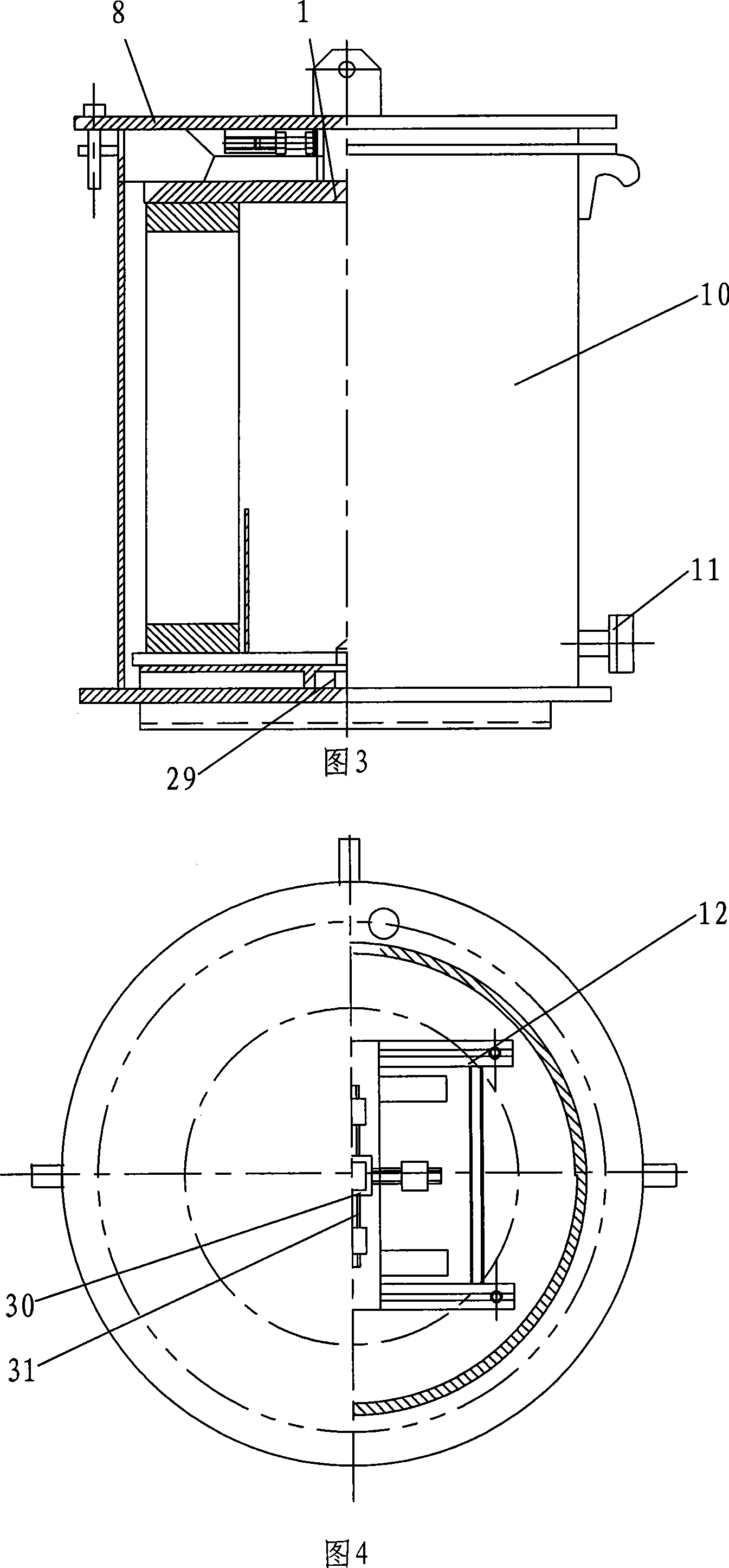

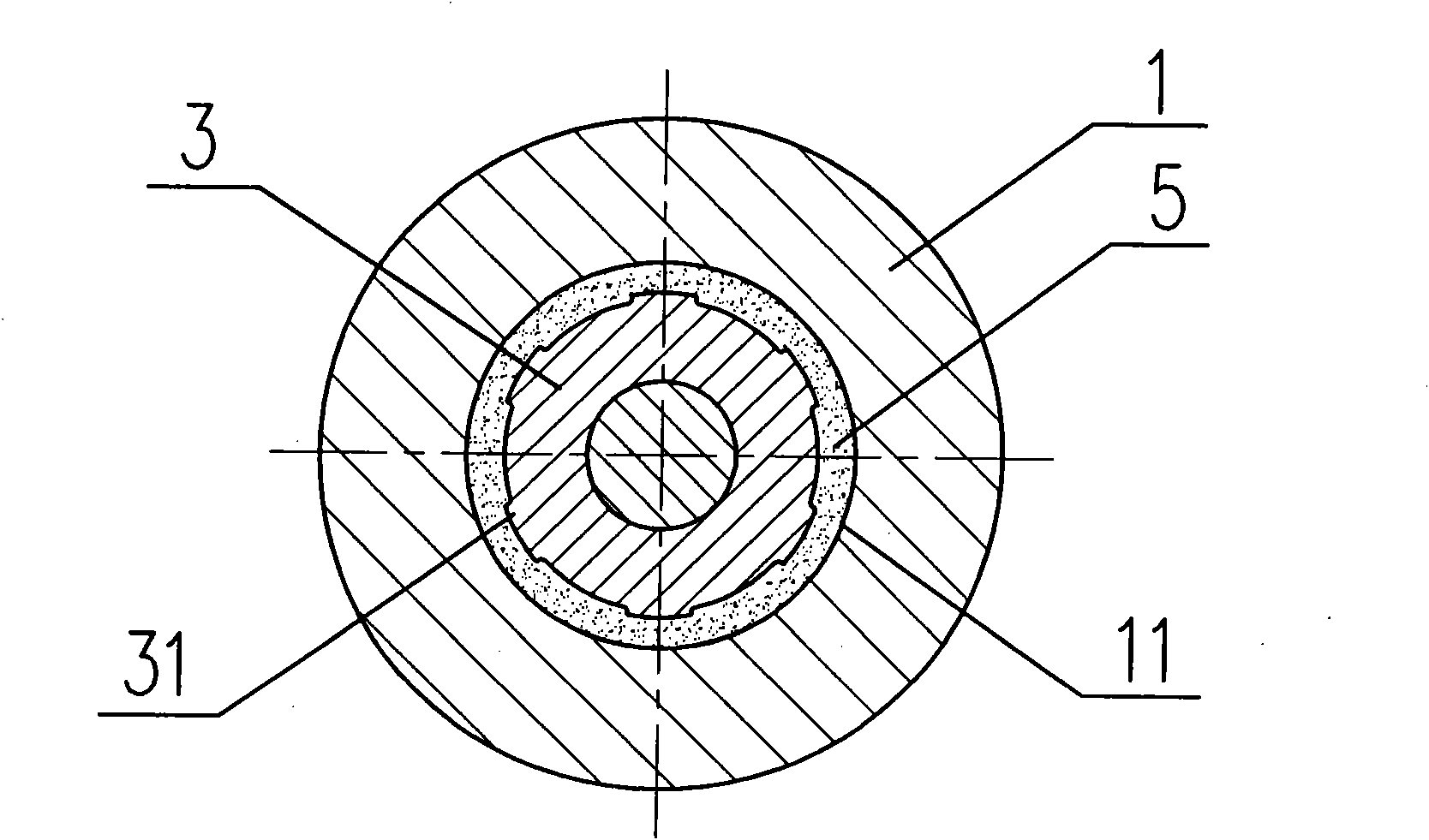

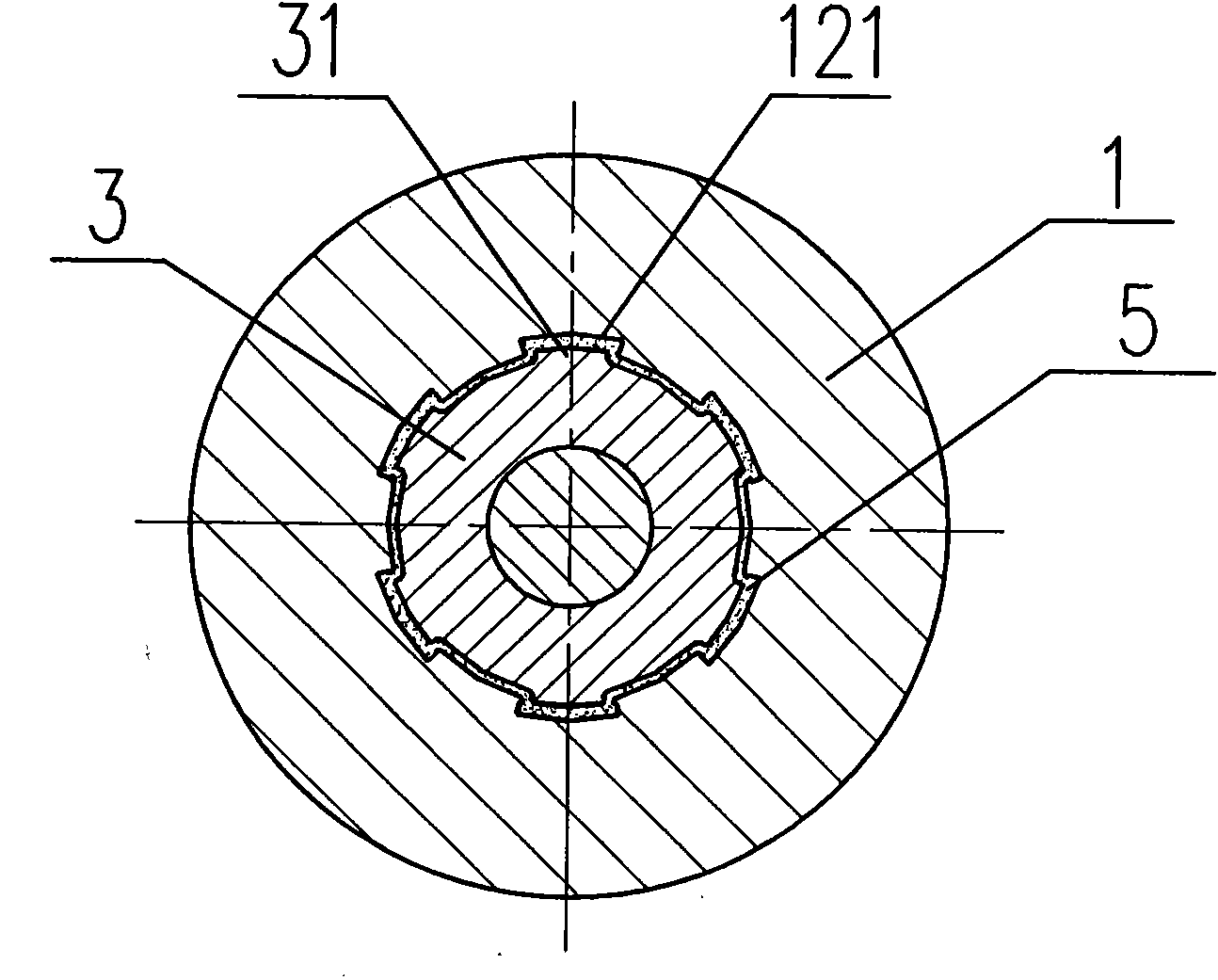

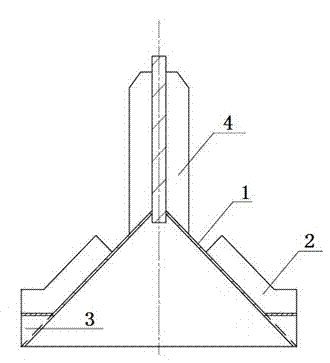

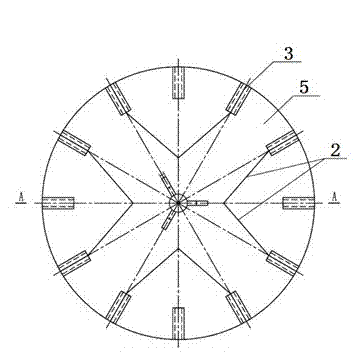

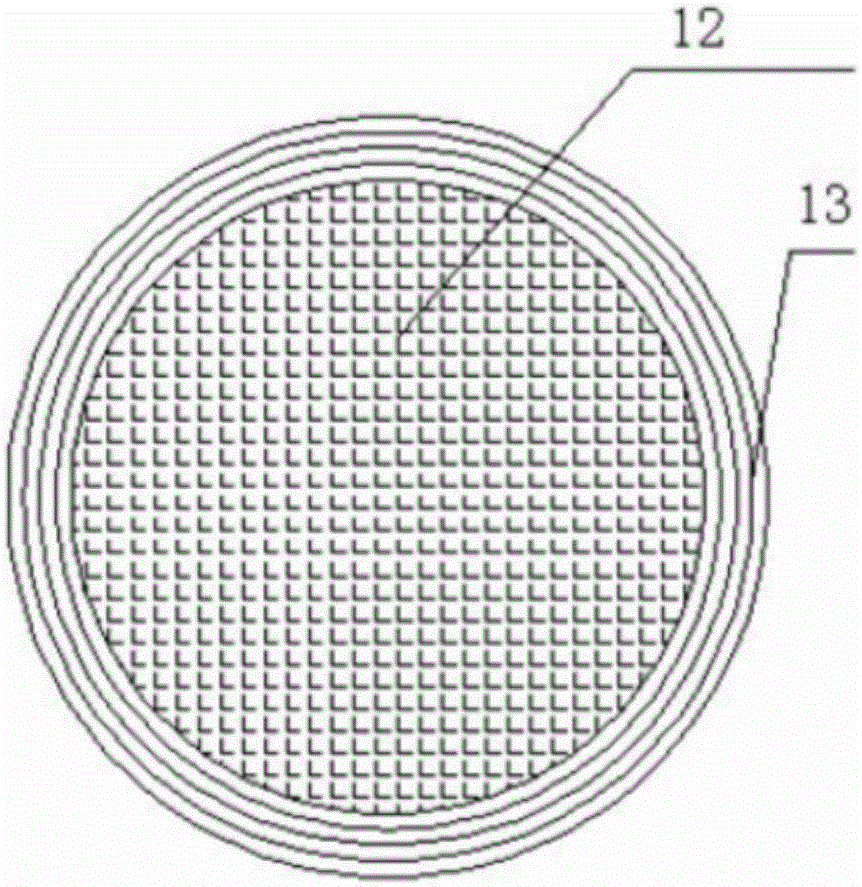

Automatic adhering and laminating device for in-mold motor core

ActiveCN106787487AGuaranteed verticalityGuaranteed flatnessManufacturing stator/rotor bodiesCore productPunching

The invention discloses an automatic adhering and laminating device for an in-mold motor core. The automatic adhering and laminating device comprises a material strip, a blanking male die and a blanking female die, wherein the blanking male die is arranged at the upper part of the material strip; the blanking female die matched with the blanking male die is arranged at the lower part of the material strip; a locking ring is arranged at the lower part of the blanking female die; a cooling pipe is arranged at the lower part of the locking ring; heating coils are arranged at two sides of the locking ring; and an adhering device is arranged at the left side of each heating coil. The automatic adhering and laminating device has the beneficial effects that synchronous stamping and bonding are achieved through the arranged adhering device, no point for laminated riveting exists on punching plates, a core product is smooth in surface and small in magnetic resistance effect and a layer of quick-drying anaerobic adhesive is arranged between two punching plates to play a certain insulating effect; by adopting the locking ring, the perpendicularity and the planeness of the core and the coincidence degree between the adjacent punching plates are ensured under the action of the gravity and the impact force of the product; and full-automatic digital control of high-temperature baking and fast cooling is achieved through a heating device and a cooling device.

Owner:NINGBO ZHENYU TECH

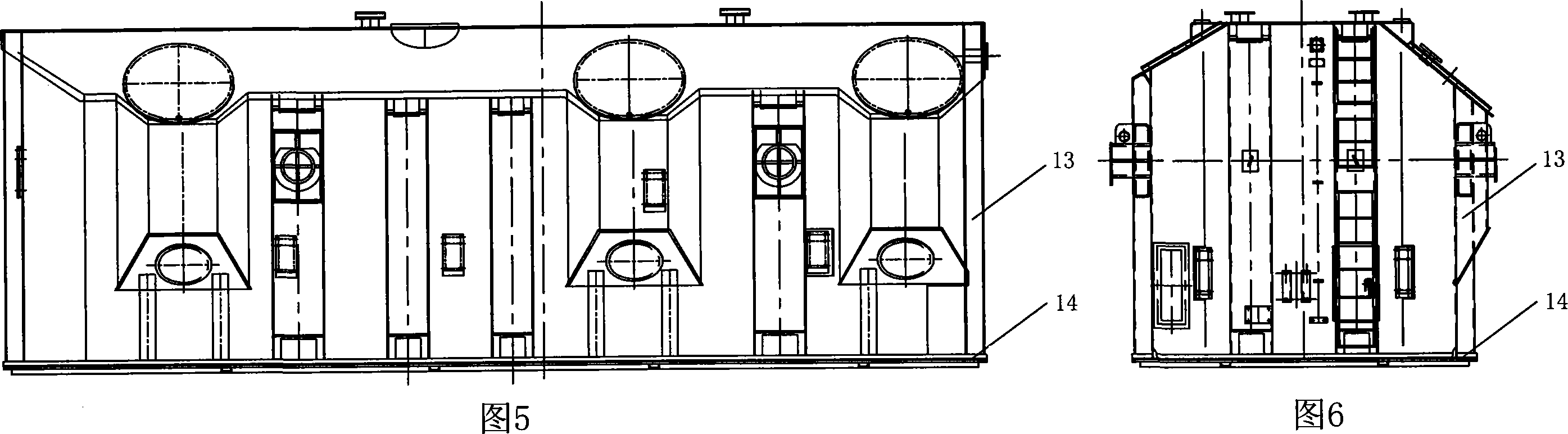

Convenience-for-transportation disorganized transportation transformer and transport case thereof

ActiveCN101183605ARealize disintegration transportationReduce shipping weightInductances/transformers/magnets manufacturePackagingCore productTransformer

The invention relates to a transportation-friendly disintegrating transportation transformer and a transport case, belonging to the transformer technical field, which comprises single frame double column iron cores, an upper oil tank, a lower oil tank, a coil, an upper integral iron core product clamp and a lower integral iron core product clamp; wherein, two layers of insulation paperboards are arranged between two adjacent single frame double column iron cores and are fixed by adhesive tapes; the coil is arranged on the adjacent single frame double column iron core; a steel washer is arranged between the lower integral product clamps of two adjacent single frame double column iron cores; the upper integral iron core product clamp is arranged above the assembled single frame double column iron core and is fixed with the assembled integral iron core; the upper oil tank and the lower oil tank are combined and then arranged on one end of the iron core. The invention has the advantages that the transportation weight of a single part of the transformer is reduced to 30 tons or below due to disintegrating transportation of the transformer, so the overall transportation weight of the transformer is also reduced; meanwhile, the transformer can bear transportation acceleration during transportation, thereby avoiding deformation and ensuring good performance after reaching the site; the transformer, the transportation clamps of the iron cores and the integral product clamps are all convenient to assembly to meet the on-site assembly requirements.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

Iron core for engine cooling fan and manufacturing process thereof

ActiveCN102034585AIncrease profitImprove product qualityInorganic material magnetismInductances/transformers/magnets manufactureIron powderHigh volume manufacturing

The invention discloses an iron core for an engine cooling fan and a manufacturing process thereof. The iron core is a powder metallurgical material prepared from the following raw materials by weight percent: 0.01-1.0% of phosphorus, 0.1-1.5% of free cutting agents, 0.2-2% of lubricating agents, 0.01-1.5% of binding agents and the balance iron powder. The manufacturing process of the iron core comprises the steps of material mixing, forming, sintering, sealing, reshaping, auxiliary machining and surface treatment. The invention has the following beneficial effects: a powder metallurgy process is simple and reliable, ensures that the production efficiency and material utilization are greatly improved, and is especially suitable for mass production; and the iron core product formed by a mould has the advantages of stable quality, high machining precision, low manufacturing cost, good sealing property, capability of reducing the weight of the engine when the iron core is used for the engine cooling fan, low energy consumption, obvious oil saving effect, improvement of the overall property of the engine cooling fan and the like, and is convenient and safe in assembly.

Owner:LAIZHOU SANWANG POWDER METALLURGY

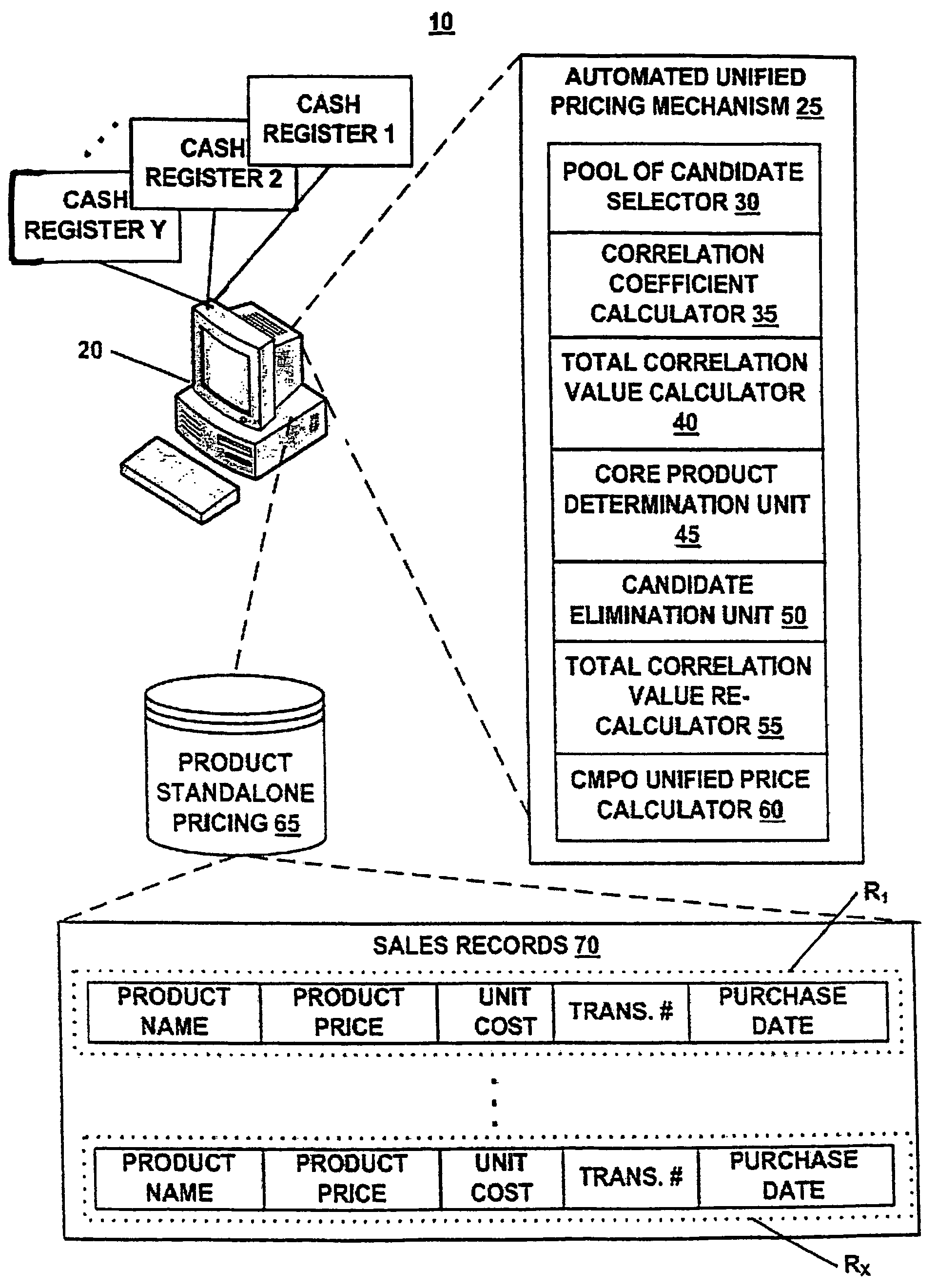

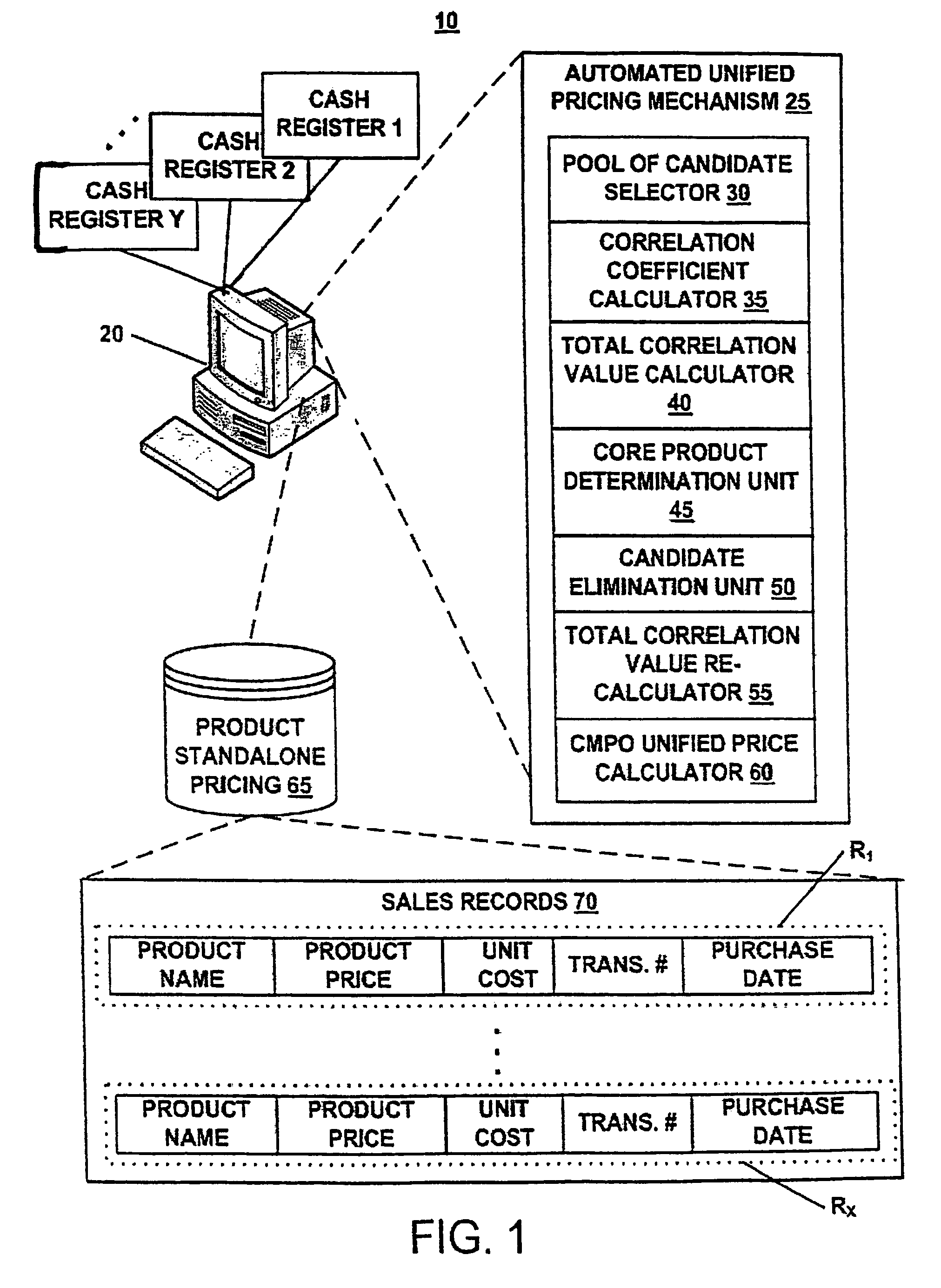

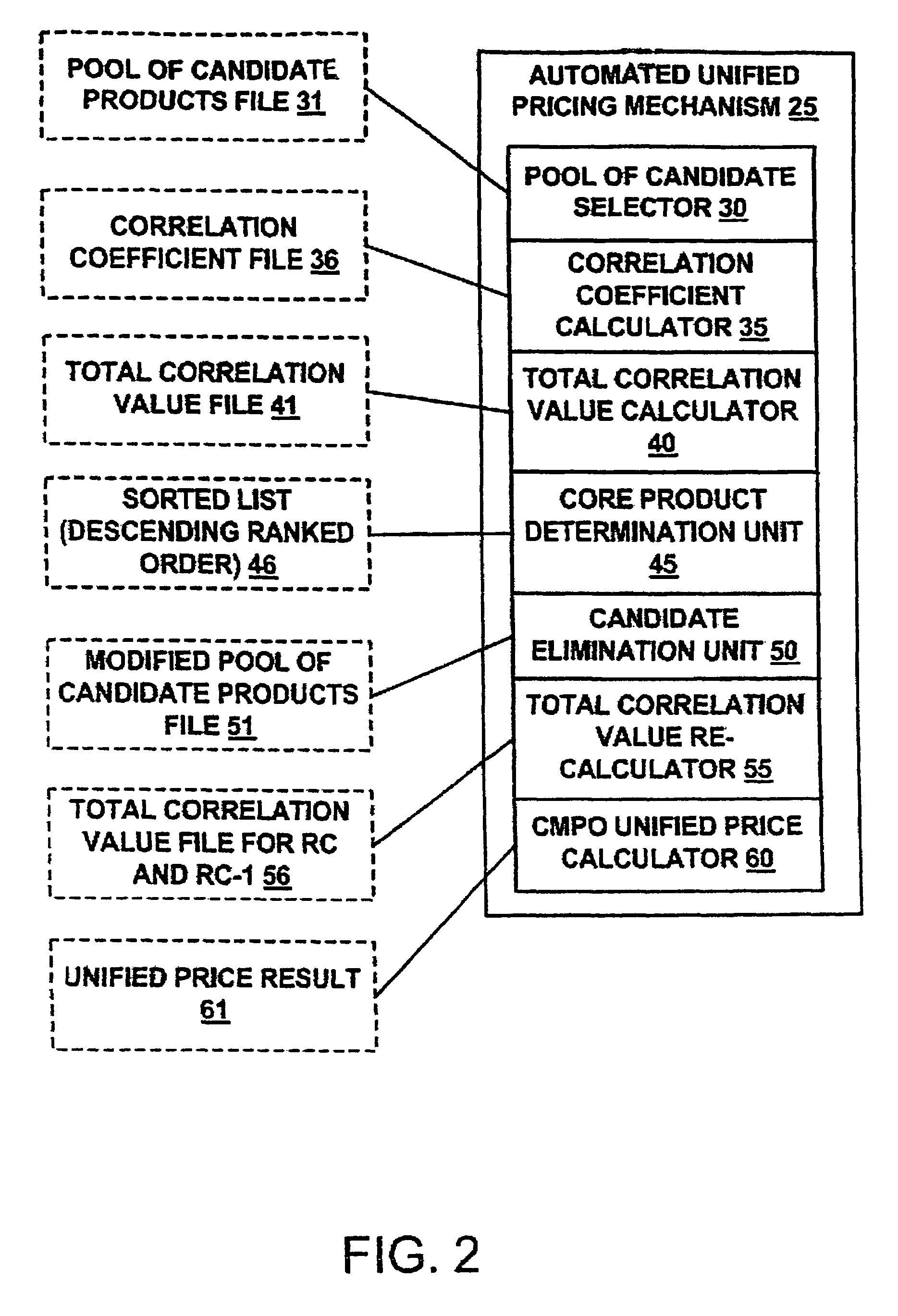

Automated unified pricing method and system for improved pricing of a bundle of goods or services

InactiveUS7739204B1Low priceReduce contributionBuying/selling/leasing transactionsElectric/magnetic computingService compositionCorrelation coefficient

An automated unified pricing method and system that allow companies to precisely calculate the price of a combination of products and / or services when those products or services are offered together in a bundle for a unified price are described. This methodology applies to the situation where there is some observable or predicted market value to the bundle elements sold individually, or to bundles which are a subset of a larger bundle being contemplated. The method and system determine linked usage correlation values to determine a core product of a pool of candidate products. The selection of the core product is maximized or optimized by eliminating substitutes from the pool and recalculating the linked usage correlation values. The unified price is calculated by multiplying the price (retail price) of each individual candidate product by the correlation coefficient related to the joint relationship of the core product and the respective candidate product to create adjusted prices for the candidate products. The adjusted prices are added together to determine the bundle value or unified price for the combined multiple product offer.

Owner:CRANNER BRUCE A +2

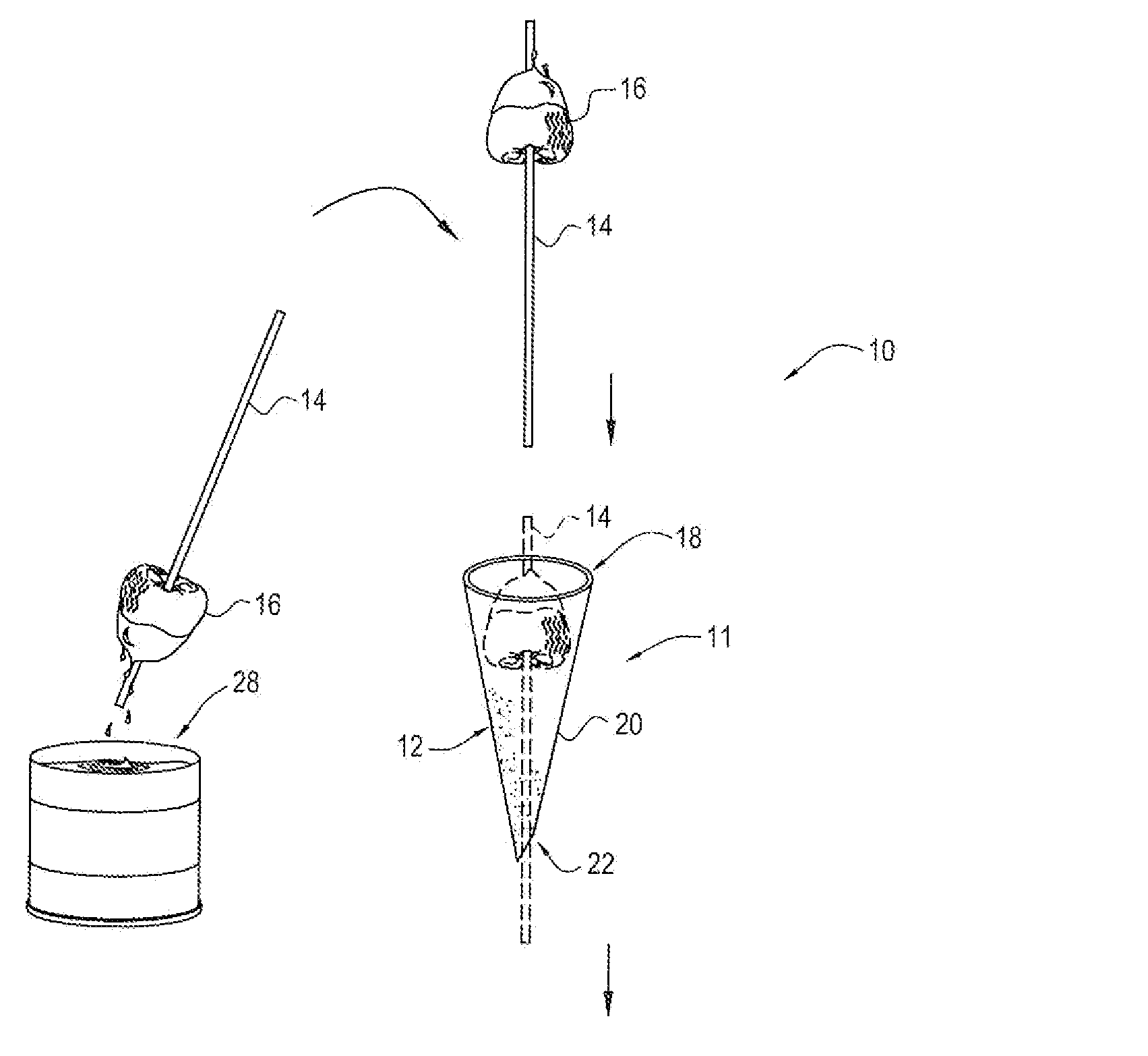

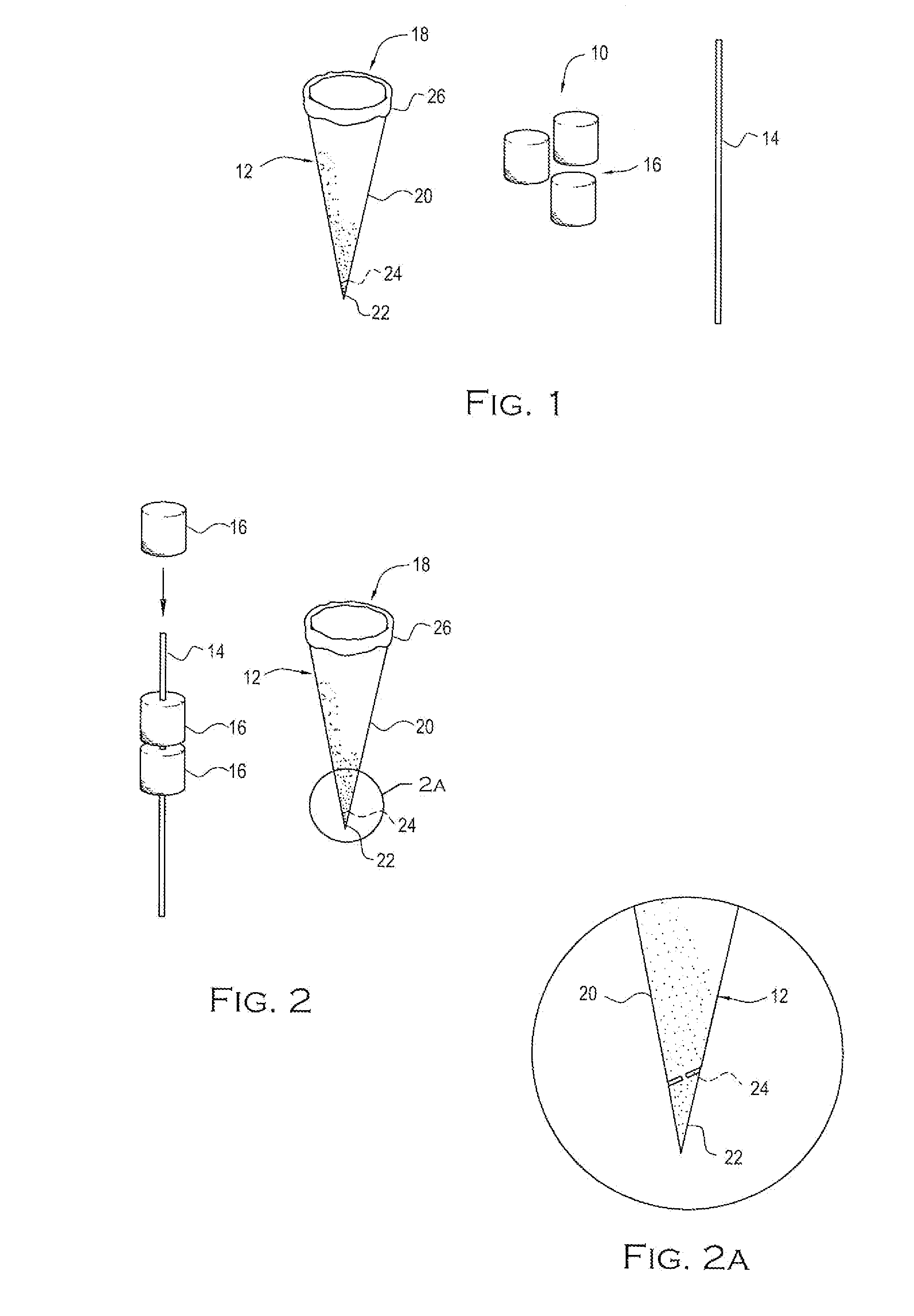

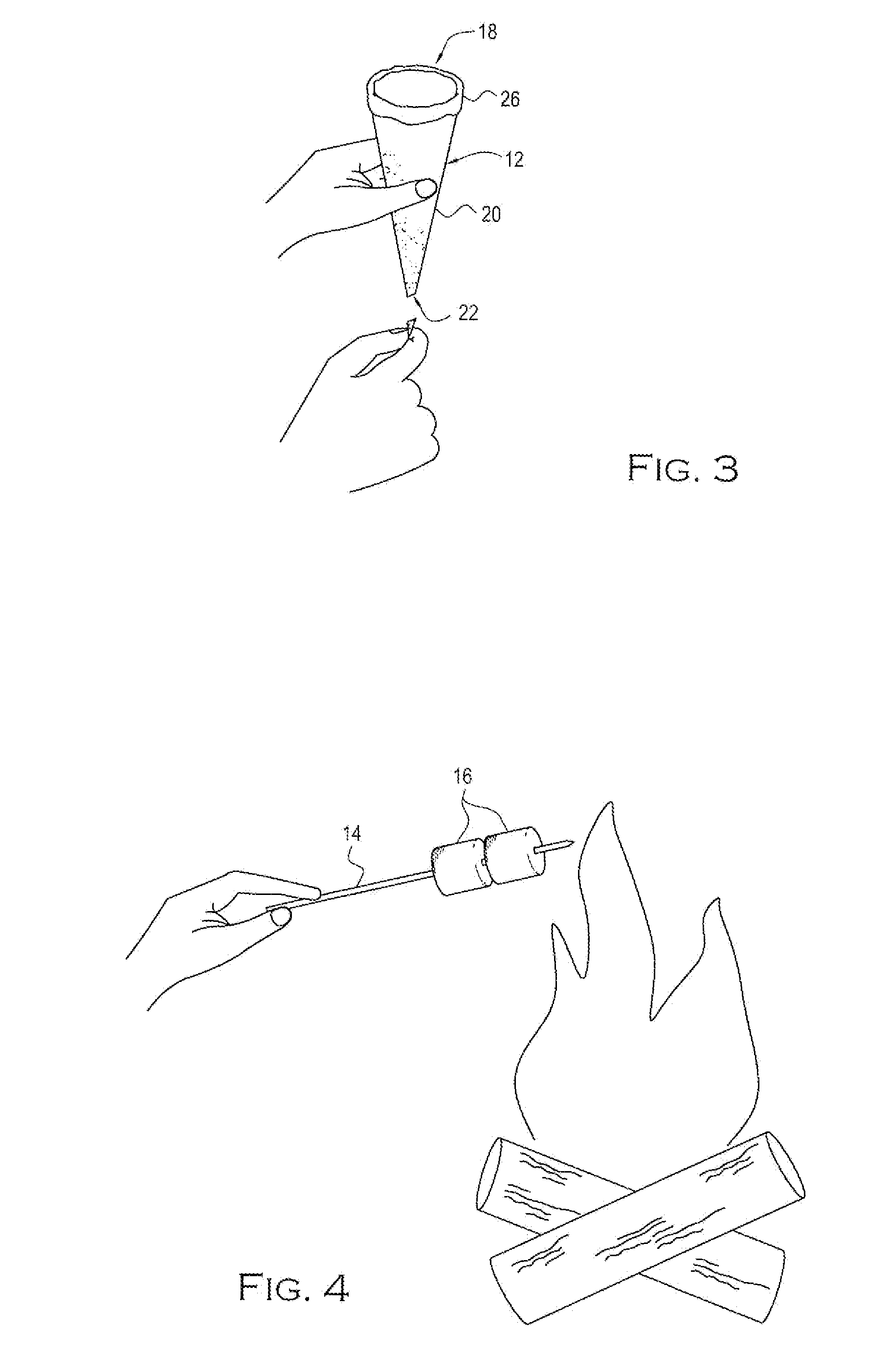

Food Product System and Associated Methods

InactiveUS20090148567A1Easy to useEnjoyable for user to assembleBaking mixturesSausage casingsCore productMechanical engineering

A food product system preferably includes an edible handheld container and an edible core product adapted to be detachably connected to a skewer and selectively carried by the container. The core product may be detached from the skewer and selectively carried by the container as the skewer is moved from an engaged position with the container to a disengaged position with the container.

Owner:PHILLIPS ROBERT

System and method for continuous processing of recyclable material

A continuous system for making shingles from recyclable material is provided comprising a milling device to receive recyclable material and process the recyclable material into particulate and a transfer device to receive and transfer the particulate from the milling device. An apparatus receives the particulate from the transfer device and weighs the particulate. A continuous processor receives the particulate and reacts and / or mixes the particulate with at least one admixture to form a homogenous mixture. A filler mixer receives the homogenous mixture and incorporates the homogenous mixture with shingle material to form core product and a control panel controls input of the homogenous mixture into the filler mixer.

Owner:BMIC LLC

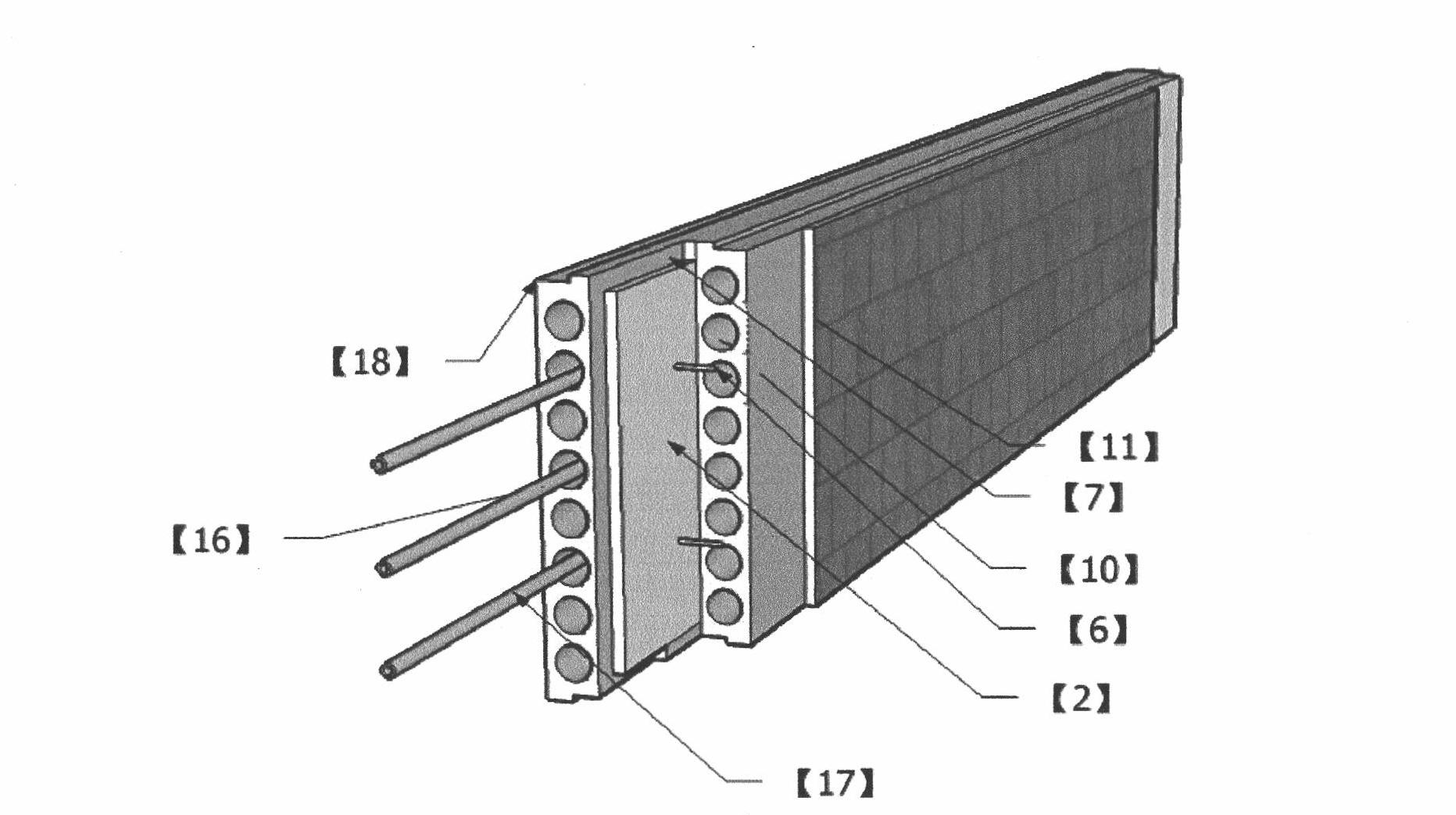

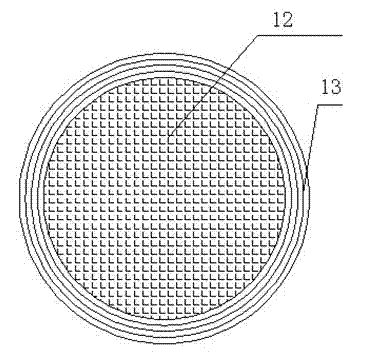

Ultrathin composite core product and production system thereof

ActiveCN107280864AGood diversion and diffusion performancePromote absorptionAbsorbent padsBaby linensCore productReverse osmosis

The invention discloses an ultrathin composite core product, and a composite core comprises a hot-blast nonwoven, a fluffy hot-blast nonwoven, a polymer absorbent material and a cladding nonwoven which are successively laid from top to bottom. A production system for producing the ultrathin composite core product comprises a plurality of clamping driving rolls, a polymer feeding device, a composite drum device and a cladding device; the clamping driving rolls are disposed at the upstream side or downstream side of the composite drum device; the hot-blast nonwoven and the fluffy hot-blast nonwoven are gradually conveyed to the composite drum device after being clamped by a first pressing roll; a discharge port of the polymer feeding device is disposed at a product composite position on the composite drum device; the cladding nonwoven is gradually conveyed to the composite drum device; and a composite core is formed after a product composited by the composite drum device is claded by the cladding device. Compared with the prior art, the ultrathin composite core product has the advantages of good diversion diffusion performance, excellent absorption property, fast permeability speed and small reverse osmosis amount.

Owner:ZUIKO (SHANGHAI) CORP

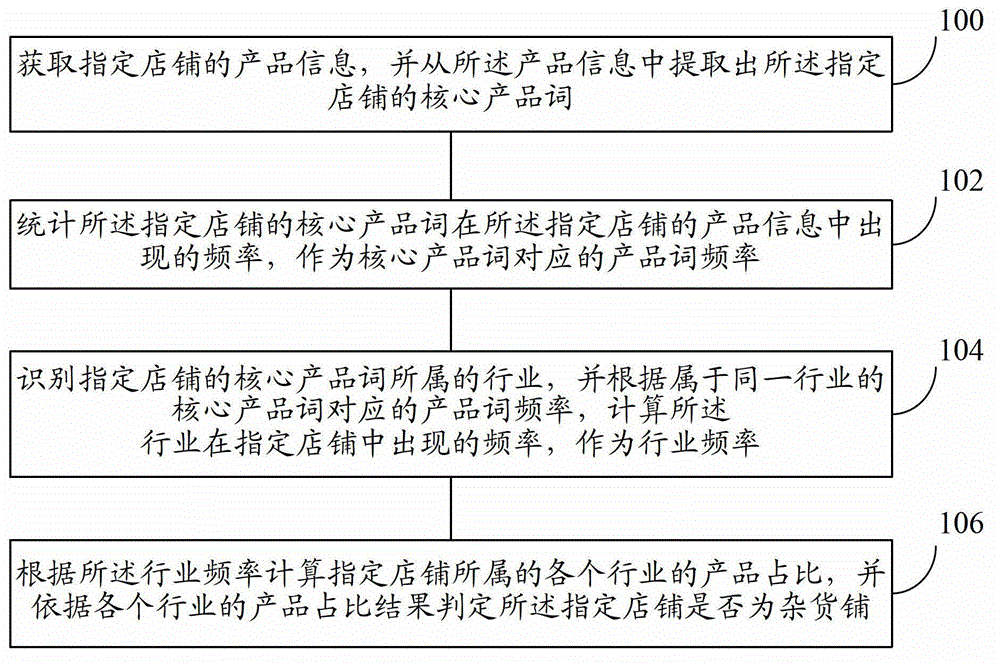

Method and device for recognizing variety shop and method and system for searching for shop

ActiveCN103942693AImprove accuracySolve the inaccurate identificationCommerceCore productComputer science

The invention provides a method and device for recognizing a variety shop. The purpose is to accurately recognize the variety shop and avoid the problem of inaccurate recognition caused by inaccurate industry information filling or category cheating. The method for recognizing the variety shop includes the steps that product information of an appointed shop is obtained, and core product words of the appointed shop are extracted from the product information; the occurrence frequencies of the core product words of the appointed shop in the product information of the appointed shop are counted as product word frequencies corresponding to the core product words; the industry to which the core product words of the appointed shop belong is recognized, and the occurrence frequency of the industry in the appointed shop is calculated as an industry frequency according to the product word frequencies corresponding to the core product words belonging to the same industry; according to the industry frequency, the product occupation ratios of all industries to which the appointed shop belongs are calculated, and whether the appointed shop is the variety shop or not is judged according to the product occupation ratios of all the industries.

Owner:ALIBABA GRP HLDG LTD

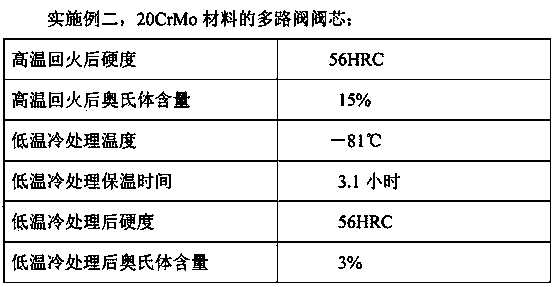

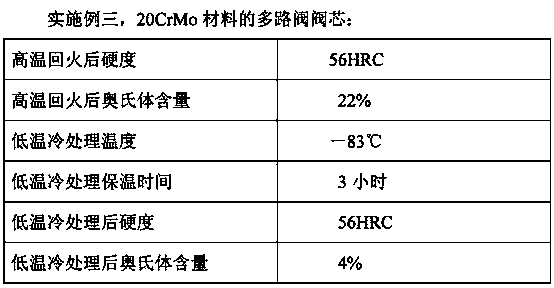

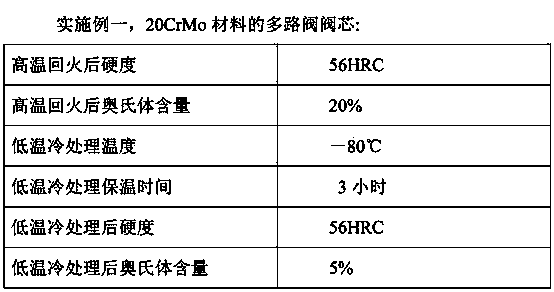

Processing method of valve core of multiway valve

InactiveCN103464968AEliminate residual internal stressImprove stabilityFurnace typesMetal working apparatusCold treatmentCore product

The invention discloses a processing method of a valve core of a multiway valve. The method mainly comprises the following steps including baiting, tempering treatment, coarse turning, carburization treatment, high-temperature tempering, low-temperature cold treatment, semi-finish machining, tempering and finish machining. The processing method has the advantages that semi-finished valve core products subjected to carburization, quenching and high-temperature tempering are placed into cold treatment media to be subjected to low-temperature cold treatment, residue austenite in internal tissues of the semi-finished valve core products can be eliminated through the low-temperature cold treatment, the tempering is carried out again after the semi-finish machining, the residue stress can be eliminated, and the stability is improved. The processing method is suitable for the processing of the valve core of the multiway valve.

Owner:GUANGZHOU YUNTAI PRECISION MACHINERY

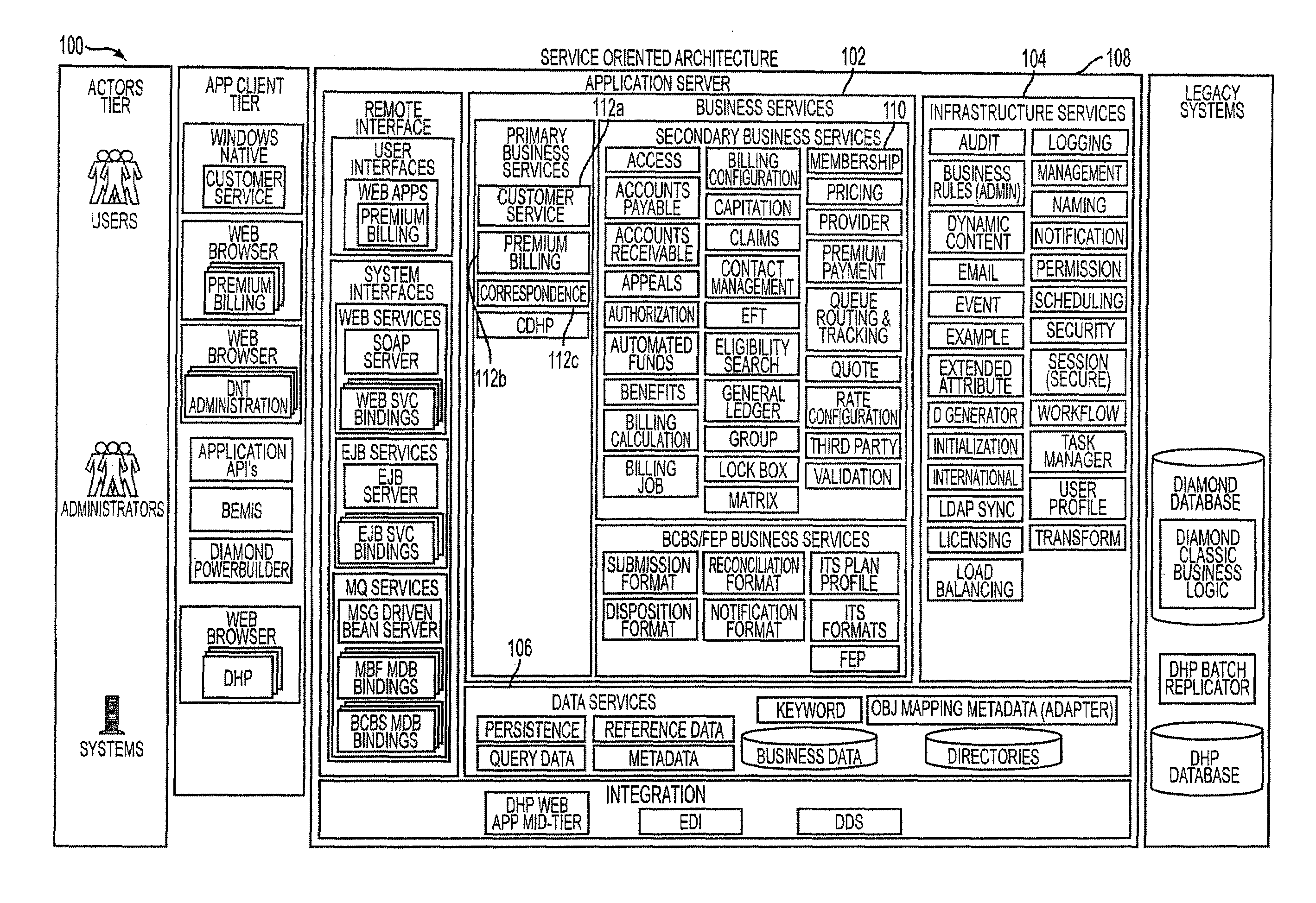

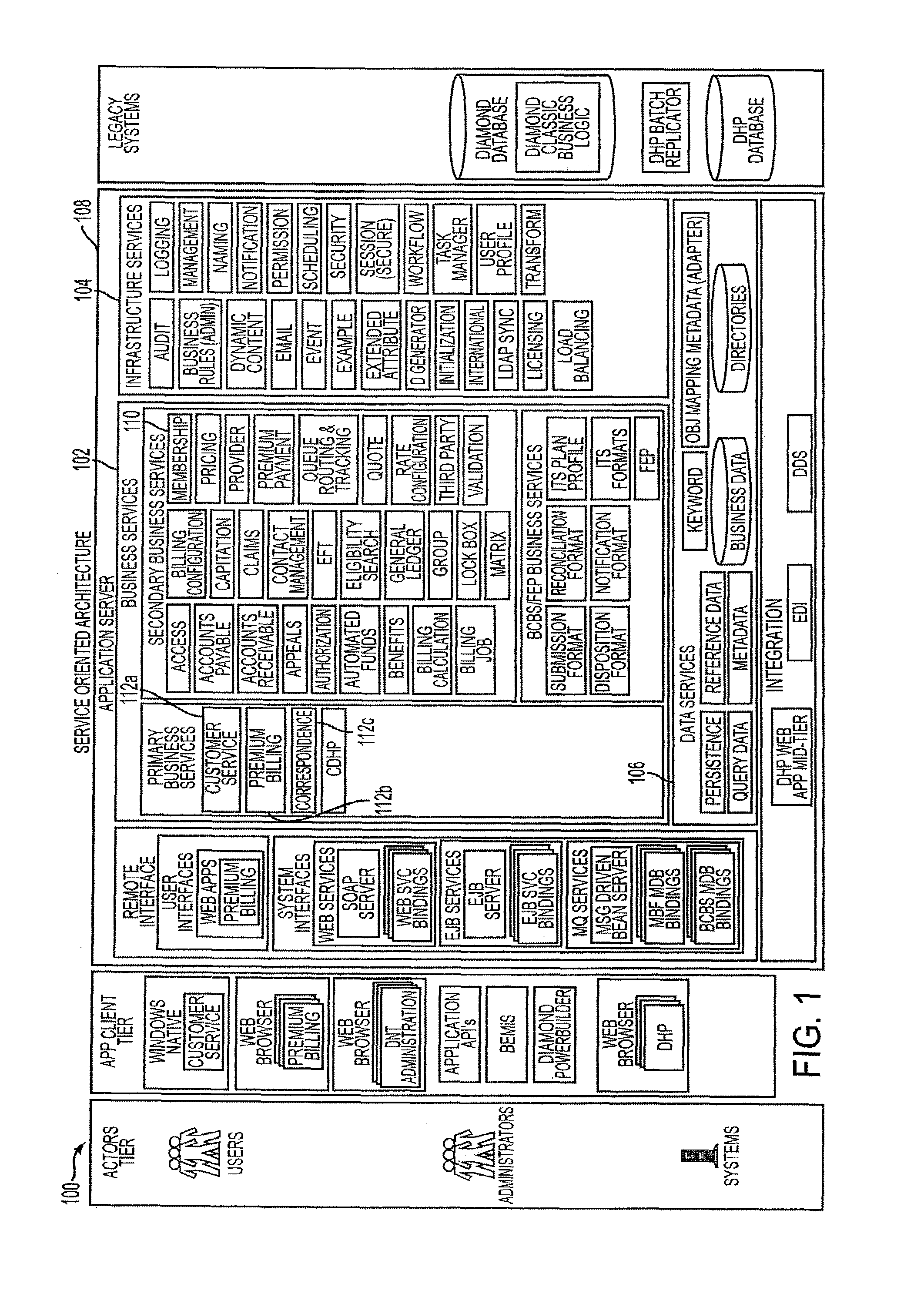

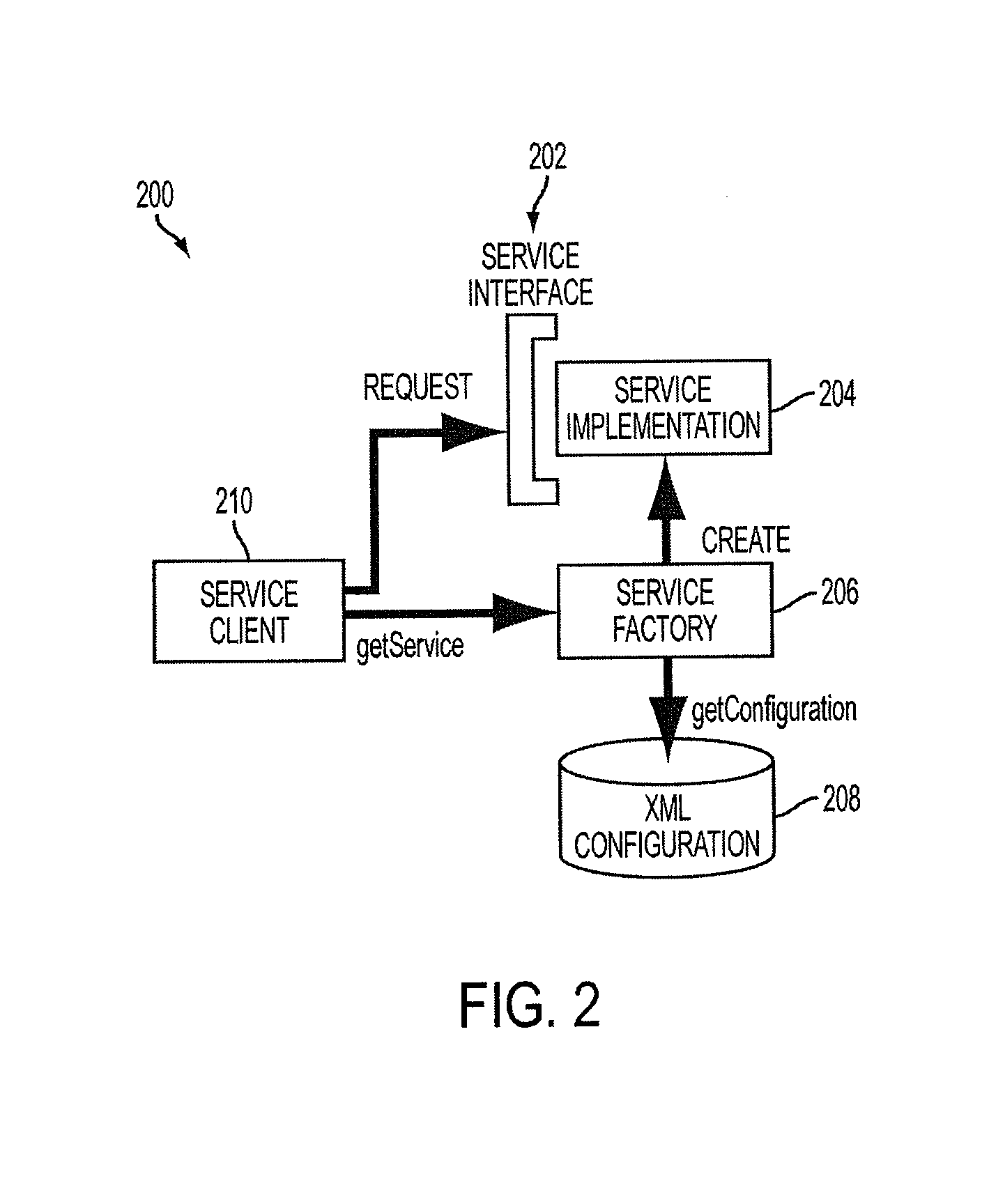

System and method for customizing a core product

An enterprise framework for a Service Oriented Architecture (SOA) is disclosed. The enterprise framework is utilized for creating, replacing, or modifying services on the SOA without modifying core code. With the framework, a service client may access services provided by the SOA via any middleware available now or in the future by utilizing auto-generation of middleware bindings via templates.

Owner:PEROT SYSTEMS

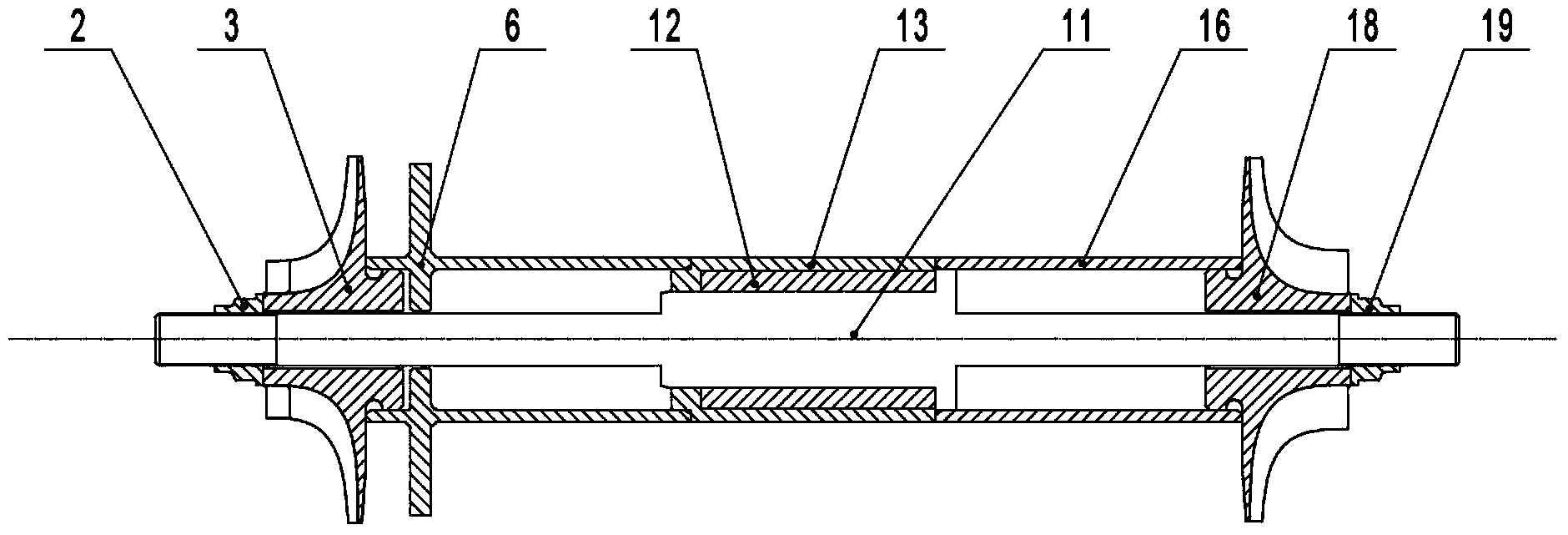

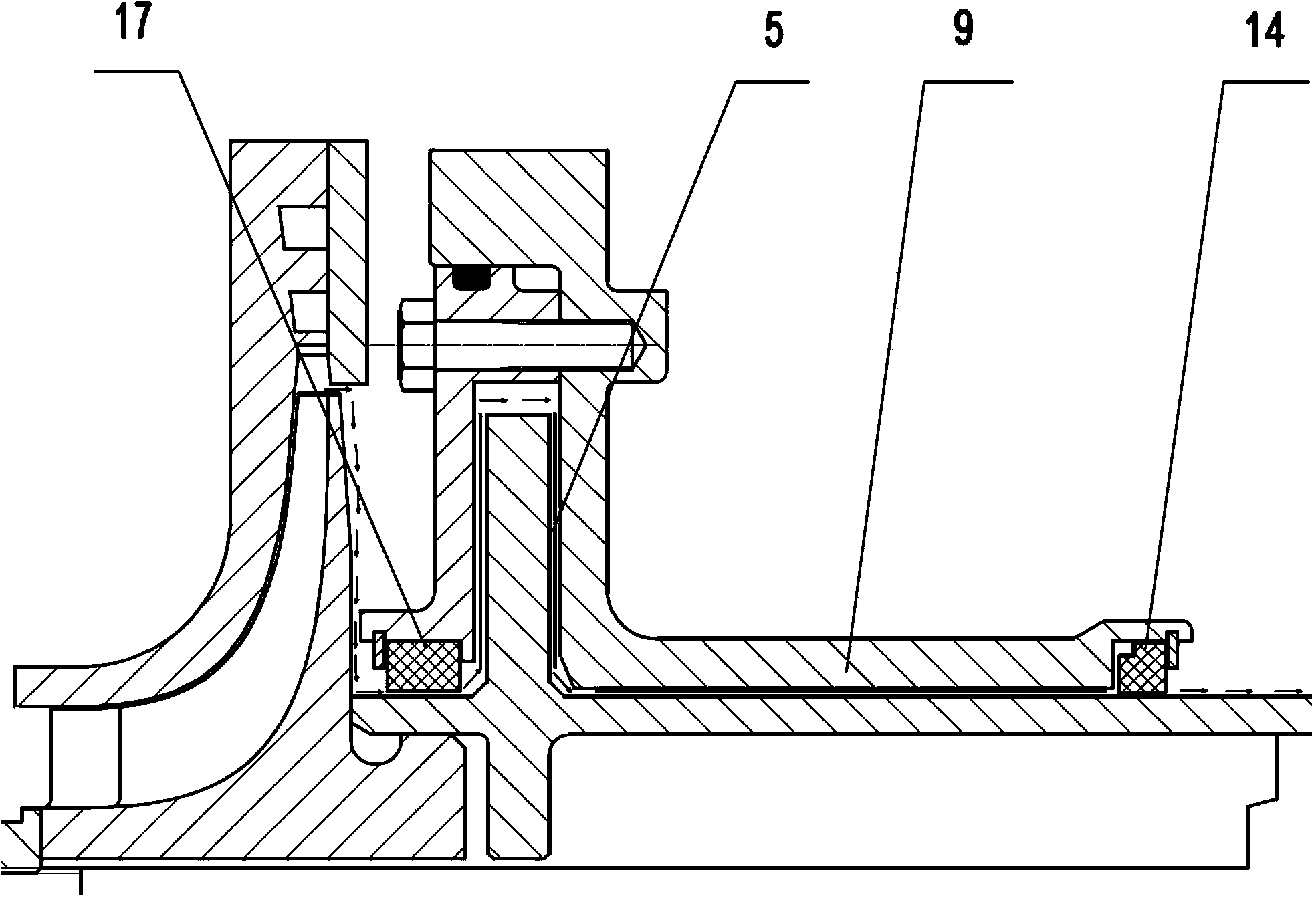

Power-driven gas compressor of novel structure

InactiveCN103671222ASimple structureImprove reliabilityPump componentsPump installationsElectricityCore product

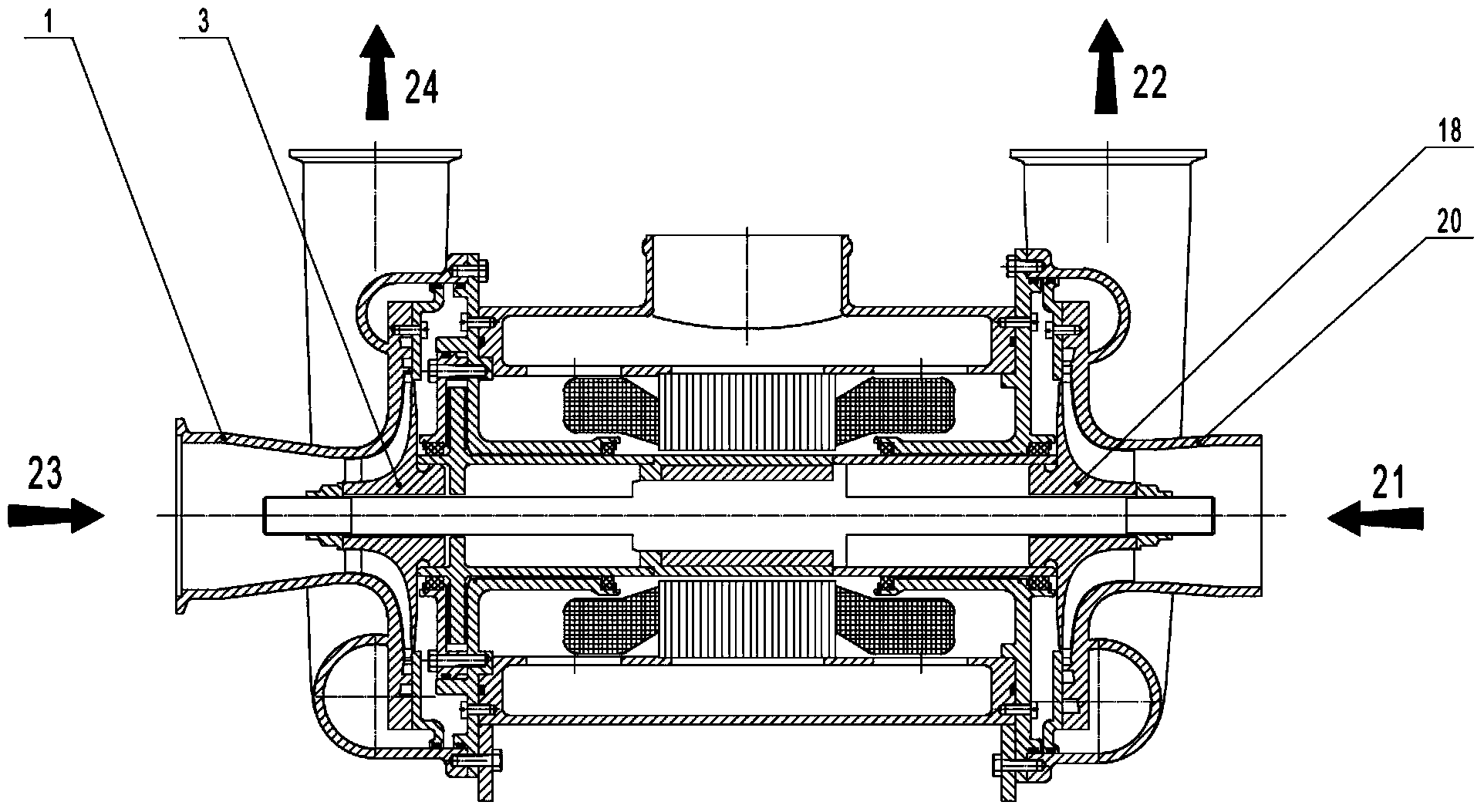

The invention relates to a power-driven gas compressor of a novel structure. The power-driven gas compressor serves as an important component of a power-driven environment control system, and is an indispensable core product of the power-driven environment control system applied to future all-electric aircrafts. A rotor system of a civil power-driven gas compressor is commonly supported with a ball bearing, and the power-driven gas compressor supported with the ball bearing needs a special oil supply structure to guarantee lubrication and cooling of lubricating oil to a bearing, so that the power-driven gas compressor is complex in structure, large in weight and poor in ball bearing reliability at the high rotation speed, and the requirements of the power-driven environment control system are difficultly met by the power-driven gas compressor of a traditional structure. According to the power-driven gas compressor of the novel structure, the rotor system is supported with an air bearing support. The power-driven gas compressor has the advantages of being simple in structure, high in reliability, good in high-temperature high-speed performance and the like, a two-stage compression structural mode is further adopted for the gas compressor, the high supercharging ratio can be obtained on the premise that the compact structures of products are guaranteed, and the compact, efficient and weight-reduction requirements and the like of the power-driven environment control system are accordingly met.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

Method for improving high-temperature properties of alumina based ceramic core

The invention provides a method for improving the high-temperature properties of an alumina based ceramic core for solving the problem that a domestic alumina based ceramic core has deflection difference at 1600 DEG C and fails to meet the requirement of pouring of single crystal blades at above 1550 DEG C, and belong to the technical field of alumina based ceramic core manufacturing. The method comprises the following steps: adding porous high-purity alumina to alumina based ceramic core powder, performing core pressing, primary roasting, primary strengthening by use of a high-temperature strengthening liquid, secondary roasting, secondary strengthening by use of the high-temperature strengthening liquid, third strengthening by use of the high-temperature strengthening liquid and primary strengthening by use of a low-temperature strengthening liquid, and finally roasting to obtain the core product. After the alumina based ceramic core is treated by use of the method, the deflection of the alumina based ceramic core is reduced to 0-0.5mm; after double roasting and double strengthening, the strength of the core is above 15Ma; after double roasting and triple strengthening, the strength of the core can be above 25Ma; as a result, the high-temperature properties of the alumina based ceramic core are greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

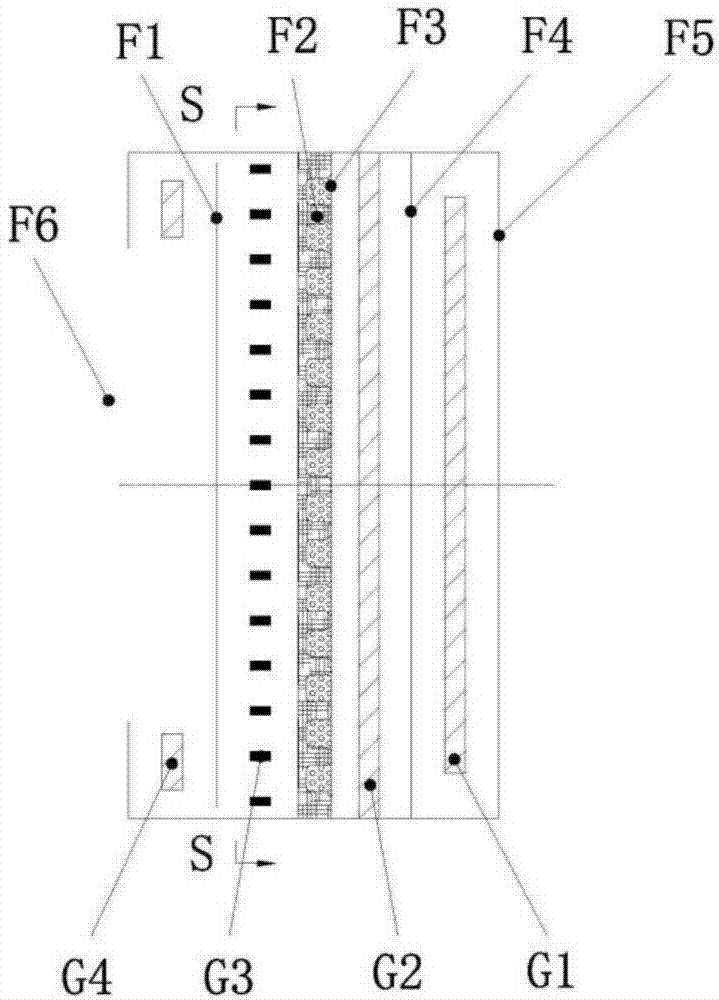

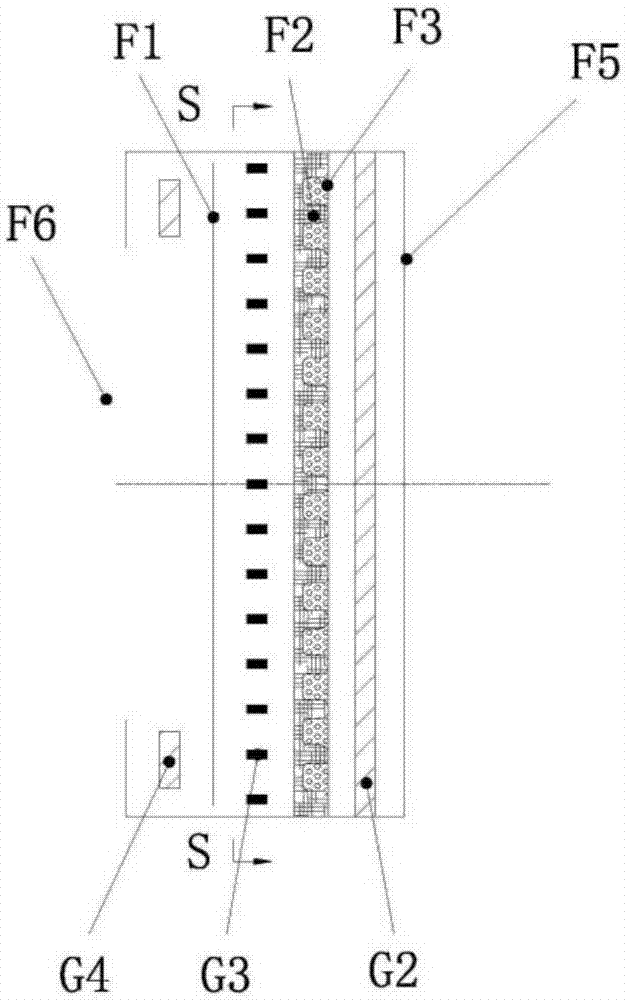

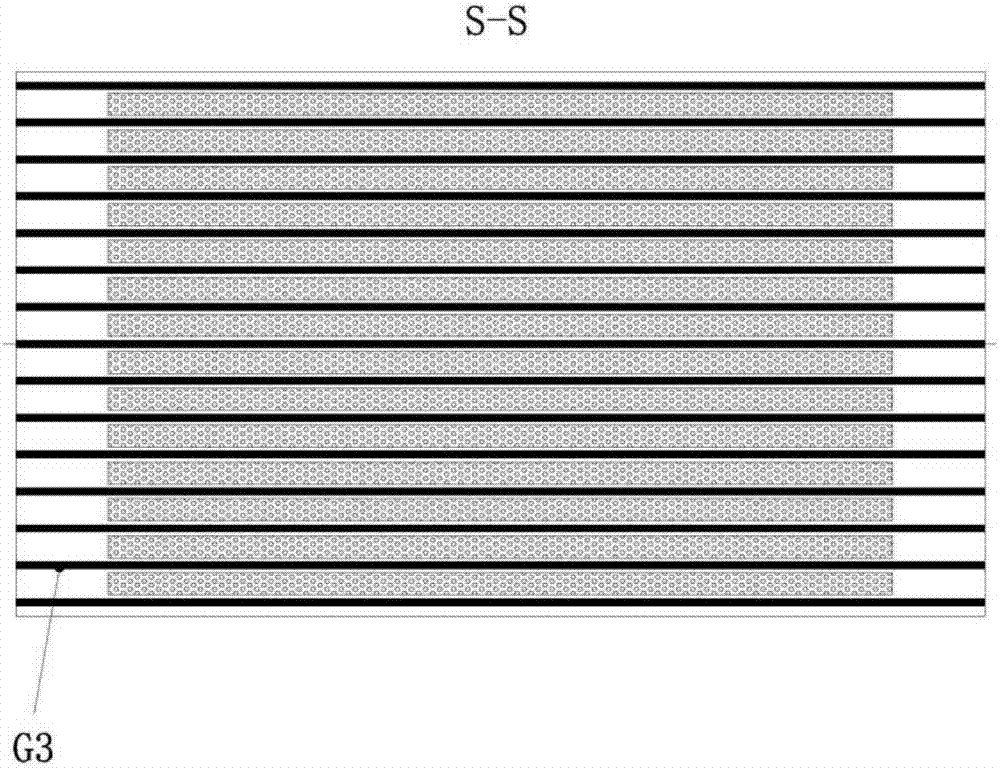

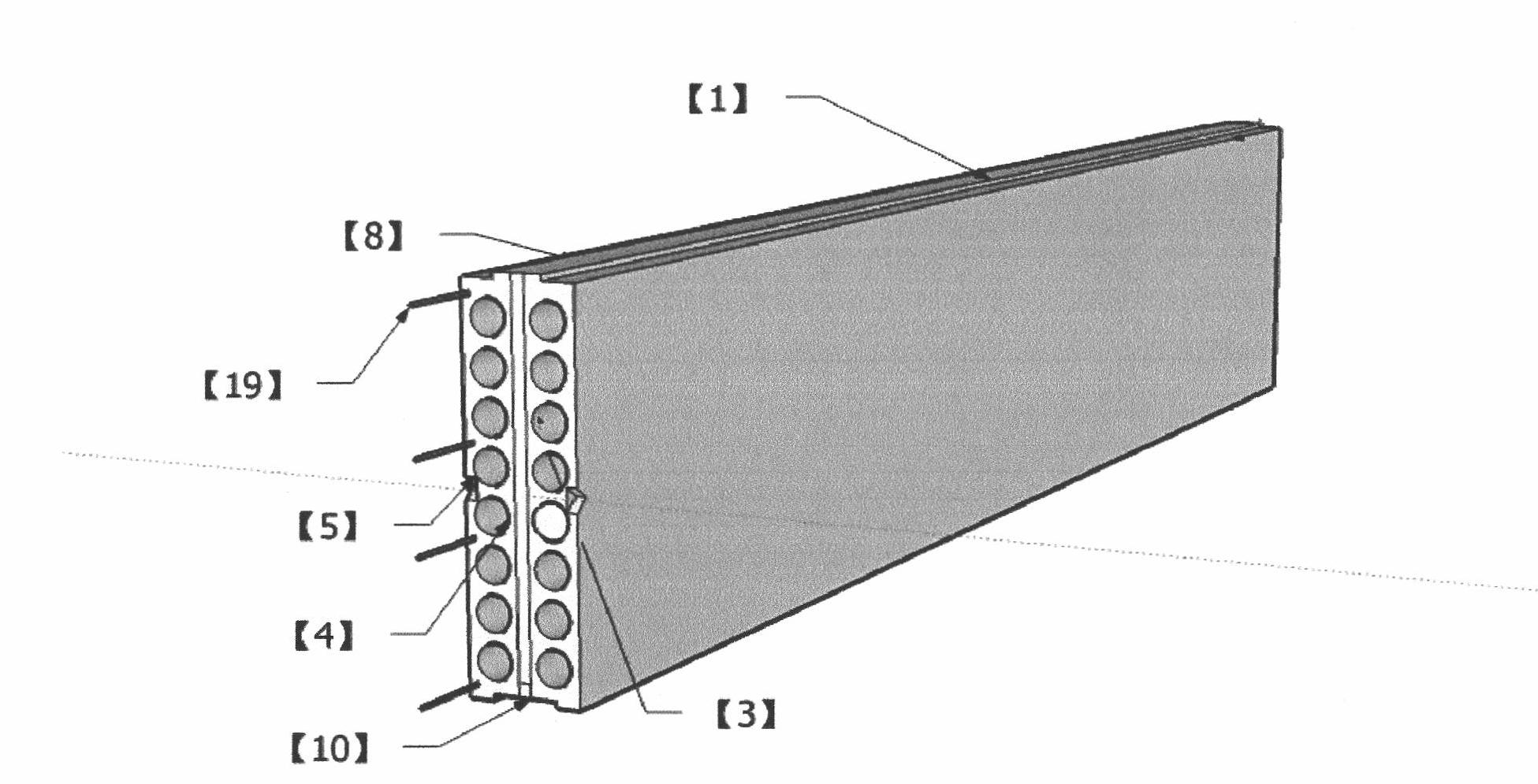

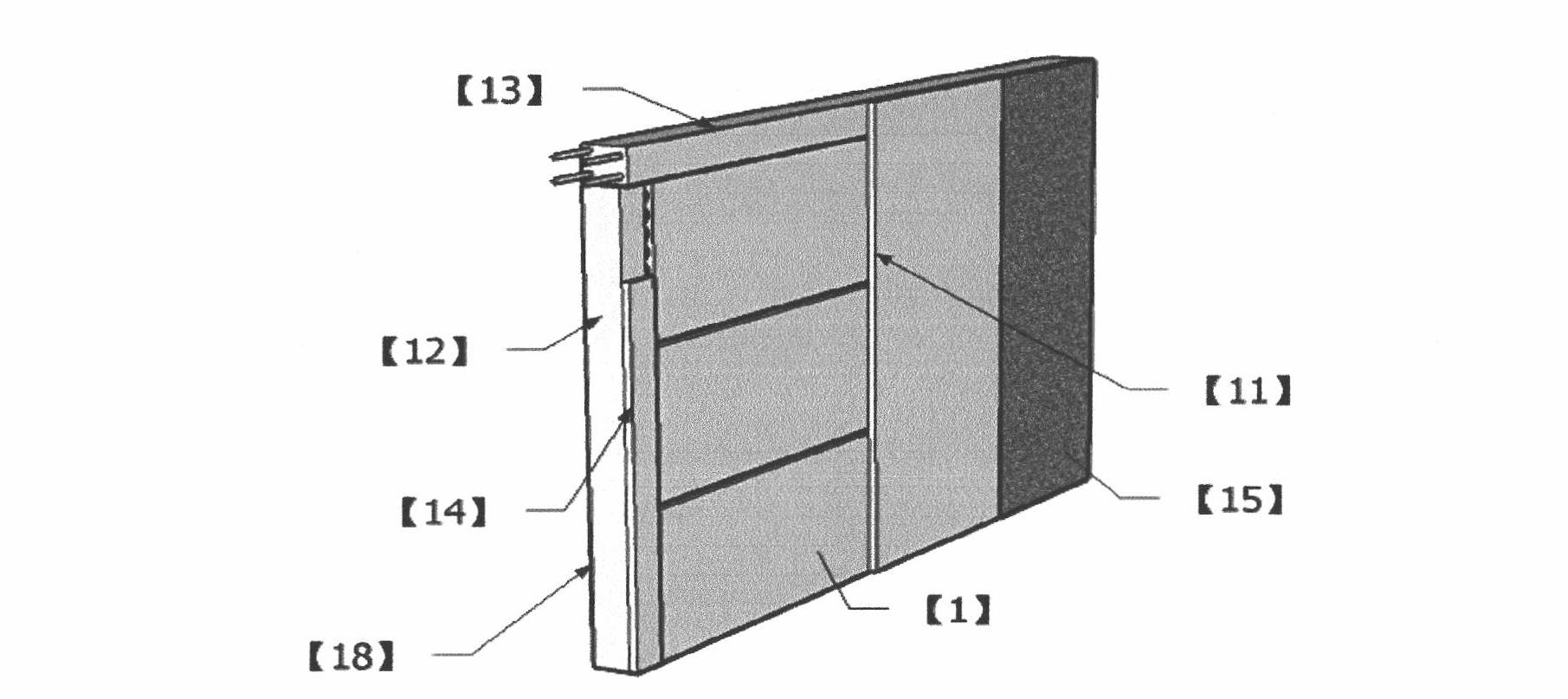

Heat preservation system for large-scale horizontal hole composite sandwich heat-preservation wallboard

ActiveCN102505777AImprove bindingImprove waterproof performanceWallsHeat proofingDouble rowCore product

The invention relates to a design scheme of a novel heat preservation wallboard and in particular relates to a technology for producing a high-efficiency and heat-preservation concrete wallboard in a sandwich heat preservation manner. The invention provides a heat preservation system for an outer wall of a building, and the system is designed for reducing the heating and refrigerating energy consumption of the building, and further realizing the aim of the zero-energy-consumption running of the building. The external dimension of the large-scale horizontal hole composite sandwich heat-preservation wallboard taken as the core product of the invention has the height of about 1m, the length of 1-5 m, and the thickness of 0.2-0.3m. The large-scale wallboard takes the base design of internal / external double-row horizontal holes as a main part, takes the preset of a whole heat preservation plate material between the two rows of holes as a main means, and additionally takes the other various heat-preservation technologies as an auxiliary part, so that the heat-preservation coefficient of the composite wallboard is greatly improved on the basis of slightly increasing the whole thickness.

Owner:张宗楼

Core product cleaning process

ActiveCN103082781AMake up for cleaning needsFill the high requirements of additional cleaningPillowsStuffed mattressesSterile environmentCore product

The invention discloses a core product cleaning process. The core product cleaning process includes steps of 1) dust collection treatment; 2) cleaning treatment; 3) disinfection and sterilization; 4) disinfection treatment of personnel; 5) sterile nutrient feeding treatment; 6) drying treatment; 7) ironing treatment; and 8) sterilely packaging and warehousing, wherein the steps of cleaning treatment, disinfection and sterilization, disinfection treatment of the personnel, drying treatment, ironing treatment and sterile packaging are indispensable steps. The core product cleaning process is applicable to core products, meets the cleaning requirement of the core products in households, cleaning is realized in the sterile environment, pollution and bacterial propagation are avoided, the high requirement of the industry of household textiles for sterile caring cleaning is met, and cleaning efficiency is greatly improved and accessory special functions are achieved.

Owner:VIOLET HOME TEXTILE TECH

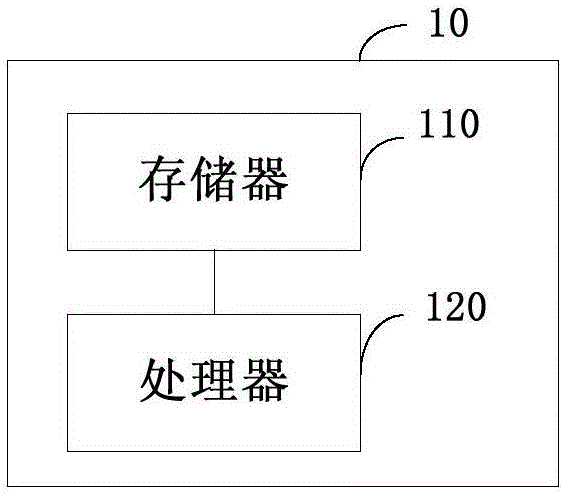

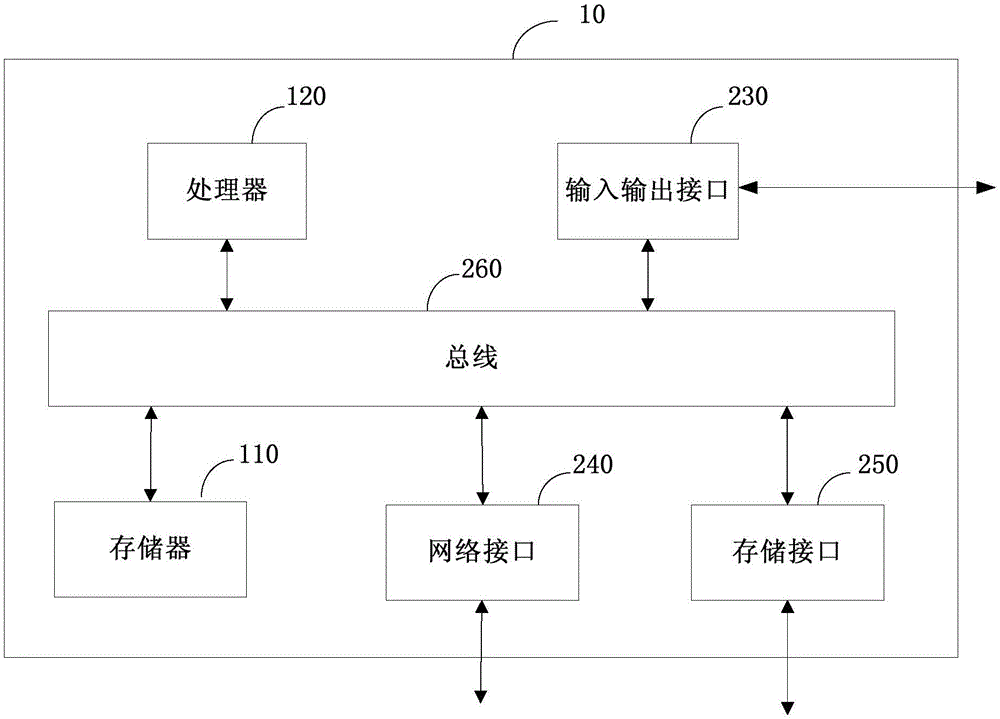

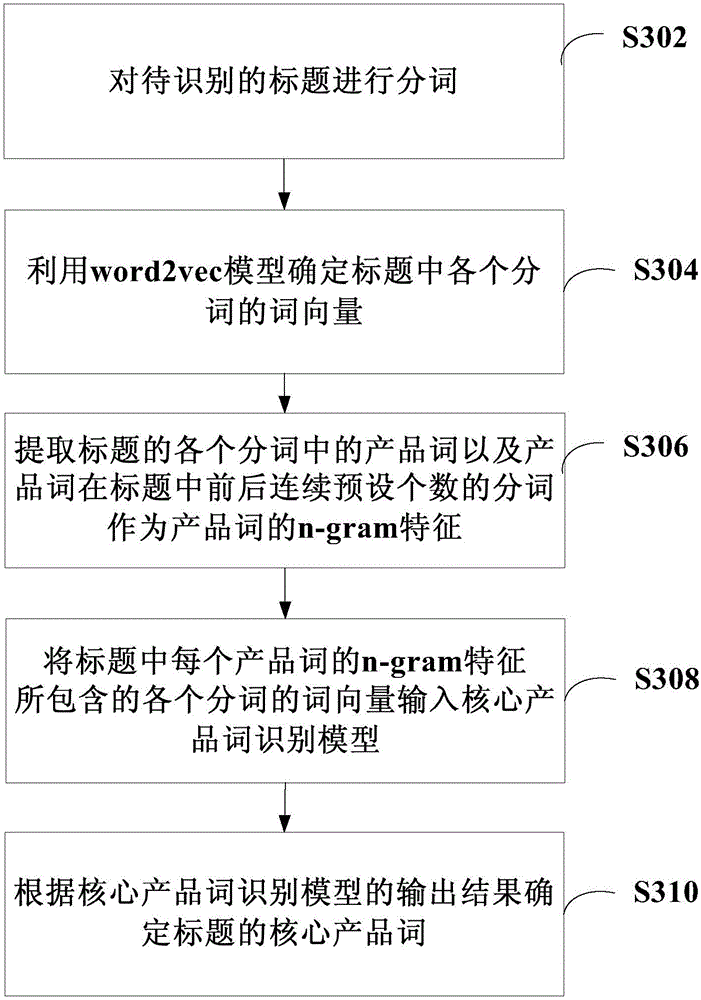

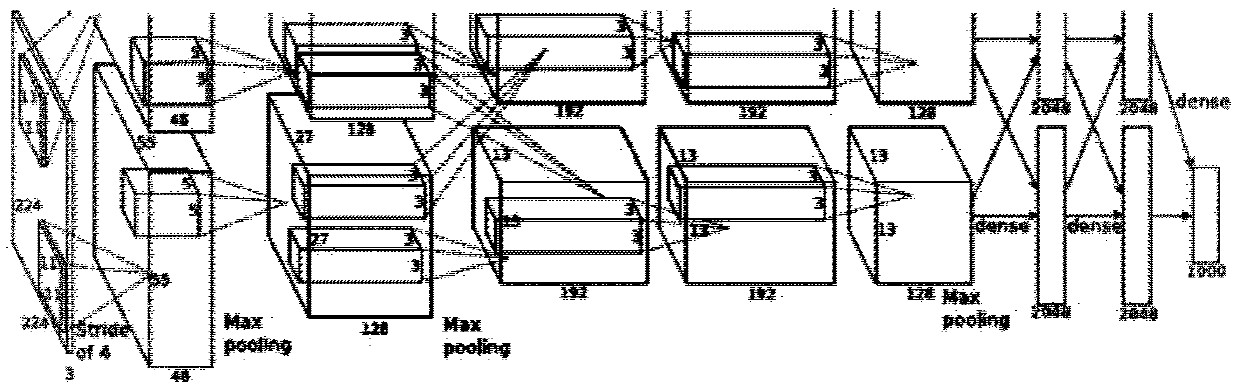

Identification method and device for core product word in title

ActiveCN106649276AImprove ambiguityImprove accuracyCharacter and pattern recognitionNatural language data processingCore productWord identification

The invention discloses an identification method and device for a core product word in a title, and relates to the technical field of computers. When a word2vec model generates a word vector of a word, previous and next words adjacent to the word or words near the word in the title can be referenced, and therefore word vectors generated by the same word in different contexts are different; meanwhile, the n-gram characteristics of the product word contain the previous and next words adjacent to the product word or the words near the product word in the title, the context of the product word can be expressed, and therefore the n-gram characteristics are obtained by the same word in different contexts are different; accordingly, word vector expressions for the n-gram characteristics are different, results obtained when identification is conducted through a core product word identification model are different, the ambiguity problem of identification of the core product word in the title is solved, and the accuracy rate is increased.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Preparation of individually coated edible core products

A method and apparatus for producing individually coated, baked, edible core products is disclosed. Individual edible cores are coated with a farinaceous dough and baked. The coated cores are agitated as their coatings expand to prevent them from clumping or agglomerating during baking. The baked, coated cores are individual core pieces with an expanded, crispy coating.

Owner:FRITO LAY TRADING CO GMBH

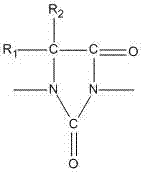

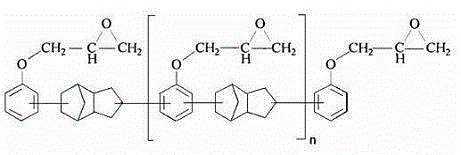

Method for synthesizing branched molecular gene carrier with the pentaerythritol derivative as core

InactiveCN1632126AImprove gene transfer efficiencyHigh densityVector-based foreign material introductionDendrimerEnd-group

The invention relates to the preparation technology of dendrite macromolecule gene carrier, in particular, the dendrite macromolecule whose number of active groups is three times that of the old nuclear product is synthesized by designing a new nuclear molecule. The technical scheme is to use trihydroxymethylaminomethane to form a new nuclear molecule pentaerythritol-dodecylamine with pentaerythritol-quaternary acid chloride derivatives after a simple organic reaction. Compared with the products of old nuclear generations, the surface charge density and the number of active amine end groups of the new generation of polymers synthesized by the new nuclei are three times higher, which is conducive to obtaining higher gene transfer efficiency. The surface of this kind of polymer is rich in amine groups, which can combine with negatively charged DNA to form a nano-supramolecular complex, which can be used as a gene carrier to transfer plasmid DNA into cells. Cell transfection experiments show that its efficiency is equivalent to that of commonly used liposome gene transfer reagents, but its cytotoxicity is far less than that of the latter. Good application prospects.

Owner:NANKAI UNIV

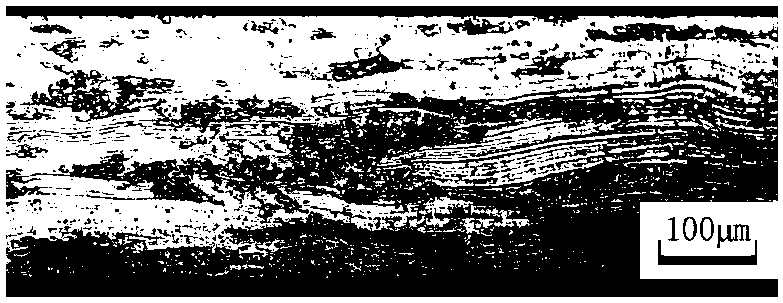

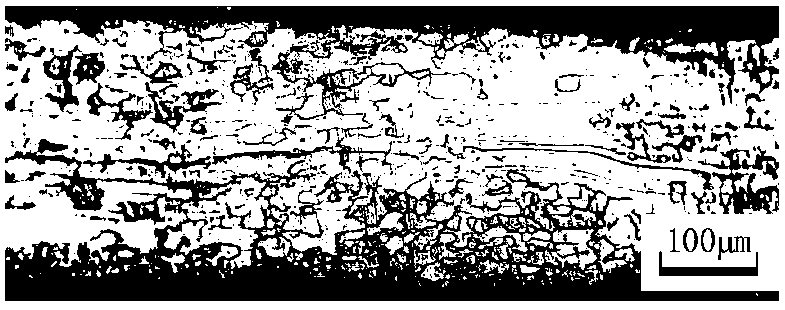

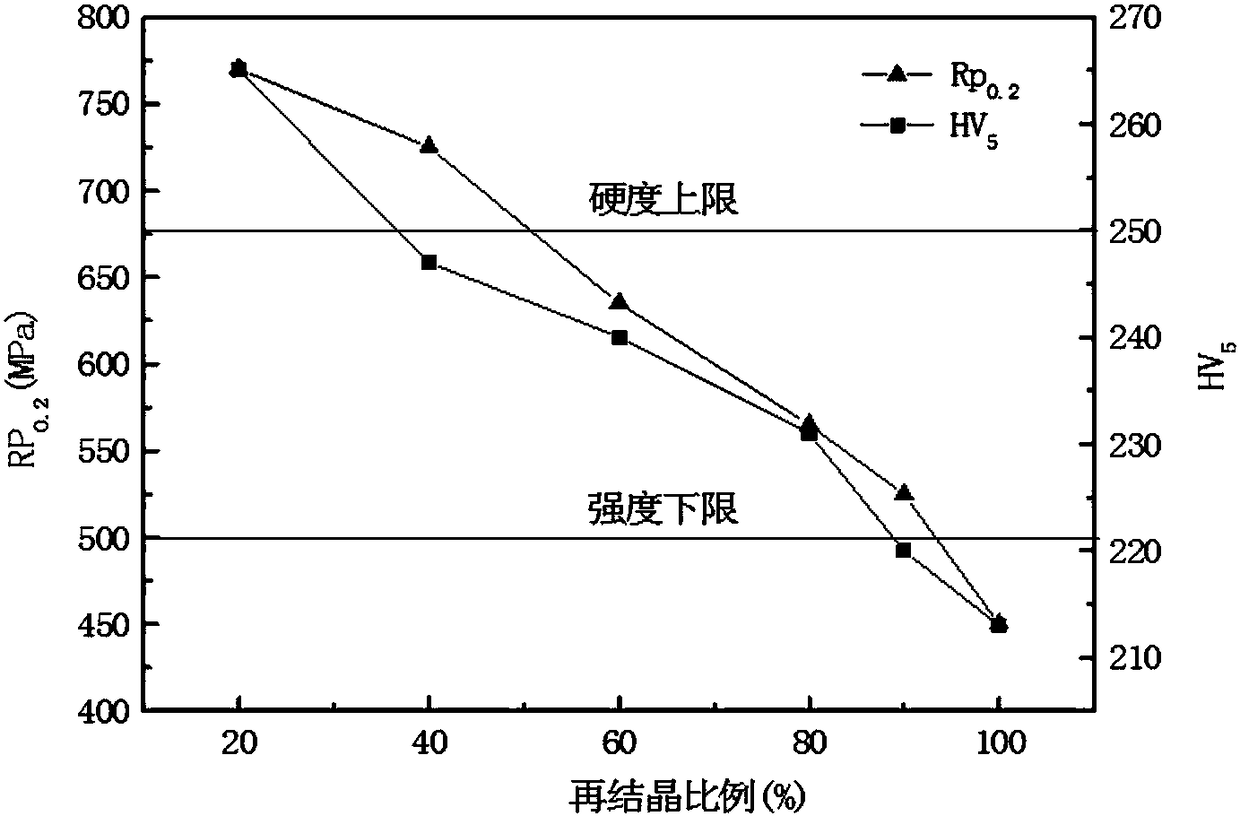

Non-oriented silicon steel for electric vehicle drive motor and preparation method thereof

The invention discloses non-oriented silicon steel for a drive motor of an electric automobile and a preparation method thereof. The performance of a silicon steel strip is controlled by optimizing chemical compositions and controlling the soaking time and soaking temperature of incomplete recrystallization annealing to regulate the recrystallization proportion. According to a rotor core made of the non-oriented silicon steel strip obtained after incomplete recrystallization annealing, the yield strength can reach 500 MPa or above, the Vickers hardness is 250 or below, and abrasion to a die is fully considered on the premise of guaranteeing the rotor strength. In addition, after stress annealing of the non-oriented silicon steel strip obtained after incomplete recrystallization annealing, a stator core manufactured from the steel strip is quite excellent in magnetic performance, i.e., the magnetic level of the stator core product after stress annealing is equivalent or even superior to that of a traditional full-process product.

Owner:武汉钢铁有限公司

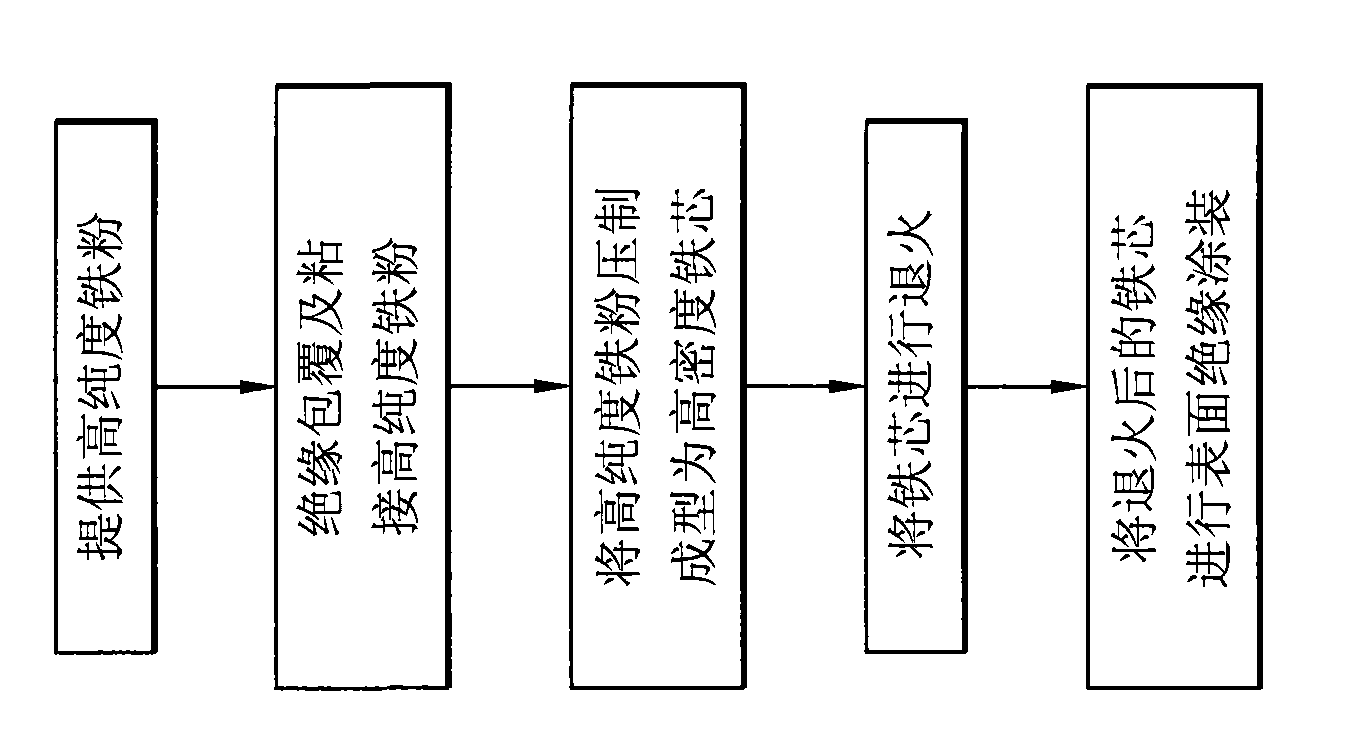

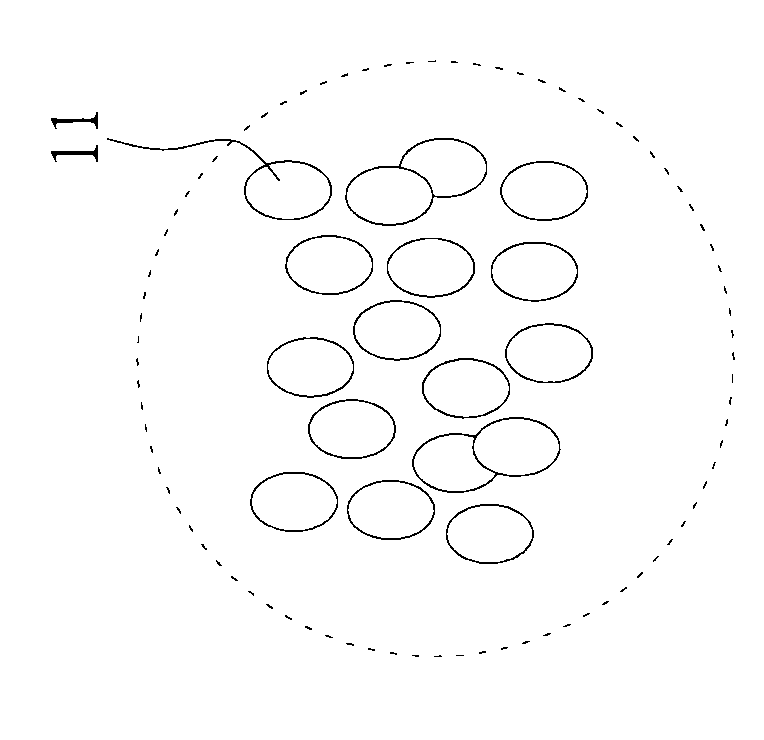

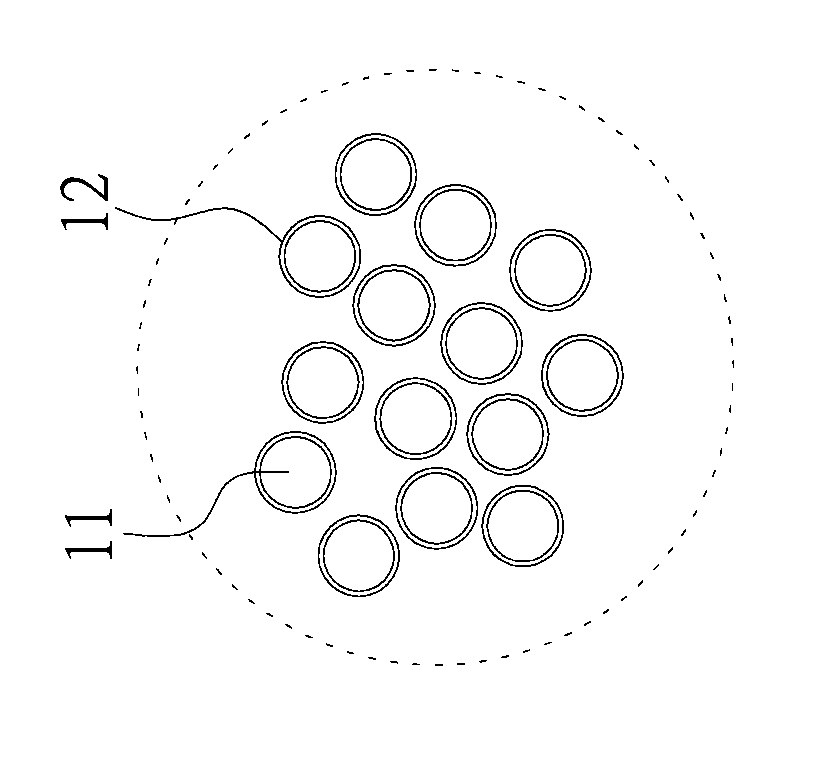

Method for manufacturing iron core and iron core product

InactiveCN101604885AFlat and smooth appearanceReduce eddy current lossManufacturing dynamo-electric machinesAdhesiveVolumetric Mass Density

The invention relates to a method for manufacturing an iron core, comprising the following steps: firstly, providing high-purity iron powder with the iron content of above 99 percent (weight); coating and splicing the high-purity iron powder with high temperature resistant isolating adhesive in an insulating mode; molding the high-purity iron powder into a high-intensity iron core; annealing the iron core; and coating the surface of the annealed iron core in an insulating mode. Therefore, the high-purity iron powder has excellent performances of high fill density, excellent liquidity and large compression. The eddy current loss of the iron core is less than that of the iron core of traditional silicon-steel plates, and the iron core can replace the prior iron core in both performance and cost at high-frequency environment, thereby satisfying the using requirement of motors and ensuring energy-saving effect. The invention also provides an iron core product.

Owner:乔智电子股份有限公司

Manufacture method of cable core

InactiveCN103093897AImprove mechanical propertiesExtend working lifeCable/conductor manufactureGlass fiberEpoxy

The invention relates to a manufacture method of a cable core. The manufacture cost of the cable core comprises the following steps: carbon fibers are led out of a creel, gum dipping is carried out to the carbon fibers after entering a first gum dipping area, and used epoxy resin is epoxy resin with heat-resisting high mechanical property; the carbon fibers after gum dipping enter a first curing oven to be precured, carbon fiber composite core are manufactured, the diameter of each carbon fiber composite core is 5mm to 12mm, and a curing degree reaches more than 85% by adjusting temperature; glass fibers on two sides are led out and respectively enter a second gum dipping area and a third gum dipping area, and used epoxy resin is high temperature resistant and weather resistant; the glass fibers after gum dipping pass through a winding area and are wound and cover the outer layers of the carbon fiber cores, the thickness of single side is 0.5mm to 2mm, and winding speed is synchronous with pultrusion speed by being controlled by a servo motor; and the carbon fiber composite cores and the glass fiber protective layers pass through the second curing oven after being compounded, and are fully cured by adjusting temperature. Composite material cable core products pass through a dragger and are wound up on the position of a winding disc.

Owner:STATE GRID CORP OF CHINA +1

Forming method of self-compacting concrete for pccp tube core

ActiveCN102267177AQuality assuranceAvoid vibration noiseCeramic shaping apparatusSocial benefitsFatigue damage

The invention discloses a self-compacting concrete moulding method for PCCP (prestressed concrete cylinder pipe) cores, and the method is implemented by designing, preparing and producing high-flowing self-compacting concrete applicable for PCCP core moulding, and pouring the self-compacting concrete at a uniform velocity in a unified material allocation mode. By using the method disclosed by theinvention, both the situation that the finished pipe core products meet the requirements for national standard quality can be ensured, and the vibration-free moulding can be realized, therefore, the vibration noise caused by using a plastic concrete moulding process is effectively avoided, no power consumption is produced for vibration, and no vibrator is arranged for generating a fatigue damage on a steel mould; and because a material homogenizer is adopted, the unified allocation of the self-compacting concrete can be realized, thereby reducing the occurrence of phenomenon that the construction quality of a vibration-free self-compacting concrete PCCP core is substandard because of high placing height and wide blanking width; meanwhile, the method can be used for night work. By using the method disclosed by the invention, the production process is simplified, the production efficiency is improved, the production cost is lowered, and excellent economic and social benefits can be produced.

Owner:SICHUAN GUOTONG CONCRETE PROD +1

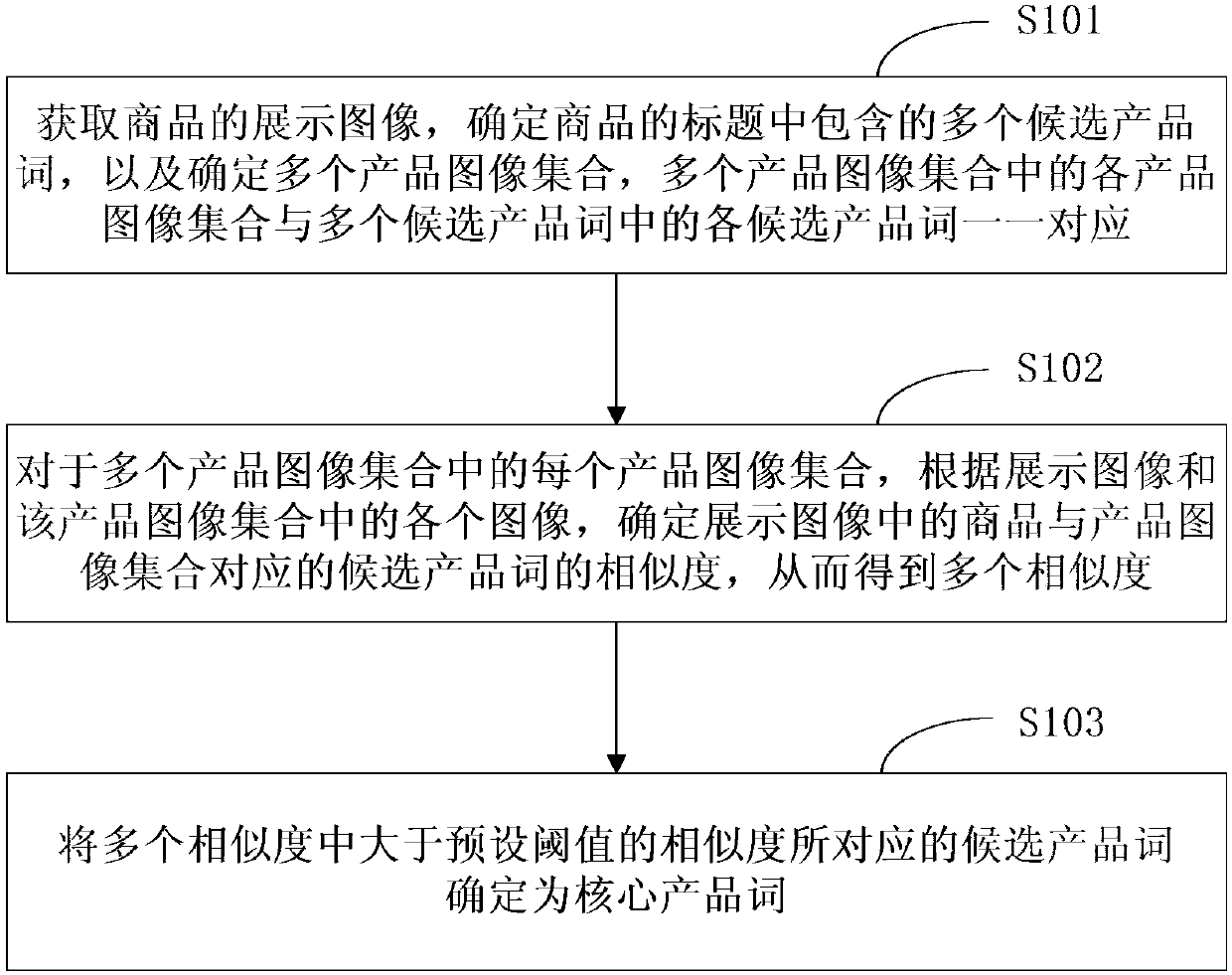

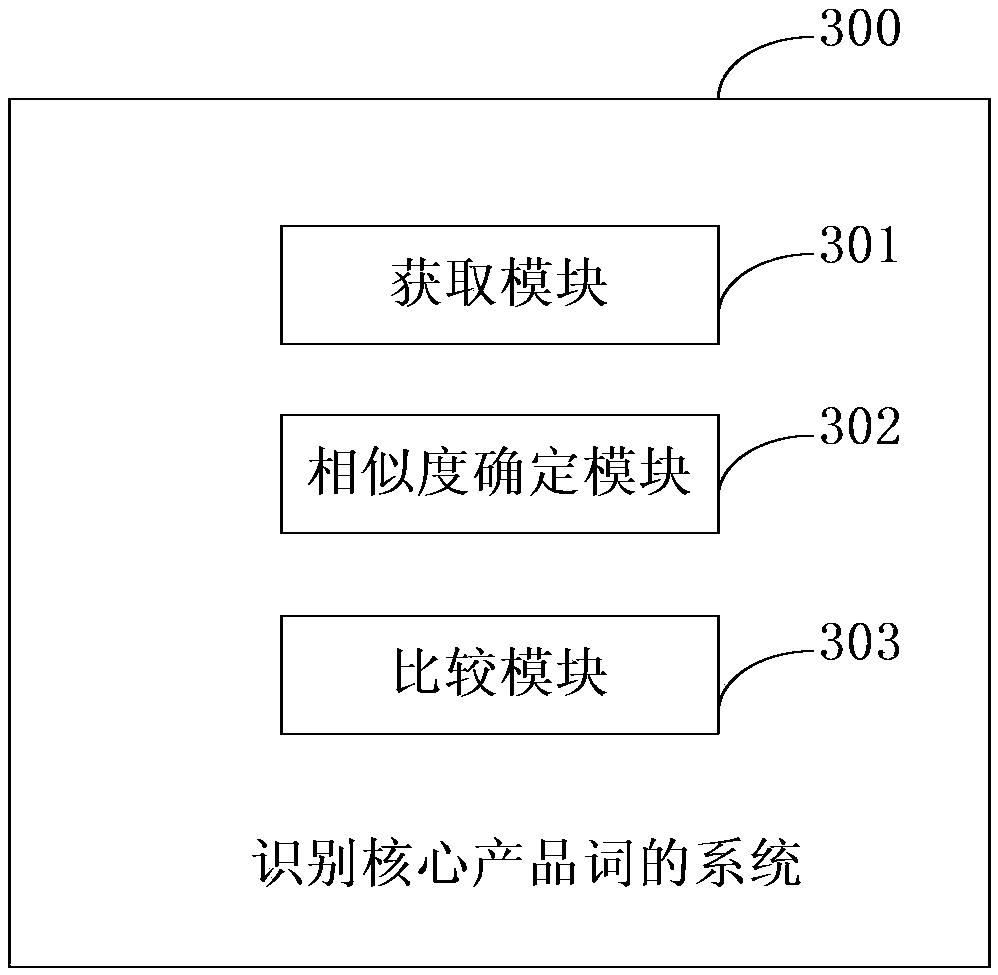

Method and system for identifying core product words

ActiveCN107832338AImprove recognition accuracyBuying/selling/leasing transactionsNeural learning methodsPattern recognitionCore product

The invention discloses a method and system for identifying core product words, and relates to the technical field of computers. The method includes the following specific steps of obtaining a displayimage of a product, determining a plurality of candidate product words contained in a title of the product, and determining a plurality of product image sets, wherein each product image set in the plurality of product image sets and each candidate product word in the plurality of candidate product words corresponds to each one; for each product image set in the plurality of product image sets, determining the similarity of the product in the display image and.the candidate product words corresponding to the product image sets according to the display image and each image in the product imagesets to obtain multiple similarities; and determining the candidate product words corresponding to the similarity greater than a preset threshold in the multiple similarities as the core product words. This method adds image information to the recognition of the core product words, so that the core product words of the product title is determined more intuitively and accurately.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Manufacturing method of carbon-fiber-contained composite material cable

InactiveCN105118575AImprove mechanical propertiesExtend working lifeInsulated cablesCable/conductor manufactureEpoxyGlass fiber

The invention relates to a manufacture method of carbon fiber composite cables. The manufacture method comprises the following steps: carbon fibers are led out of a creel, gum dipping is carried out to the carbon fibers after entering a first gum dipping area, and used epoxy resin is heat-resisting and high in mechanical property; the carbon fibers after gum dipping enter a first curing oven to be precured, carbon fiber composite cores are manufactured, the diameter of each carbon fiber composite core is 5mm to 12mm, and a curing degree is enabled to reach more than 85% by adjusting temperature; glass fibers on two sides are led out and respectively enter a second gum dipping area and a third gum dipping area, and used epoxy resin is high temperature resisting and weather resisting; the glass fibers after gum dipping pass through a winding area and are wound and cover the outer layers of the carbon fiber cores, the thickness of single side is 0.5mm to 2mm, and winding speed is synchronous with pultrusion speed by being controlled by a servo motor; and the carbon fiber composite cores and the glass fiber protective layers pass through a second curing oven after compounded together, and are fully cured by adjusting temperature. Composite material cable core products pass through a dragger and are wound up on the position of a winding disc.

Owner:胡妍

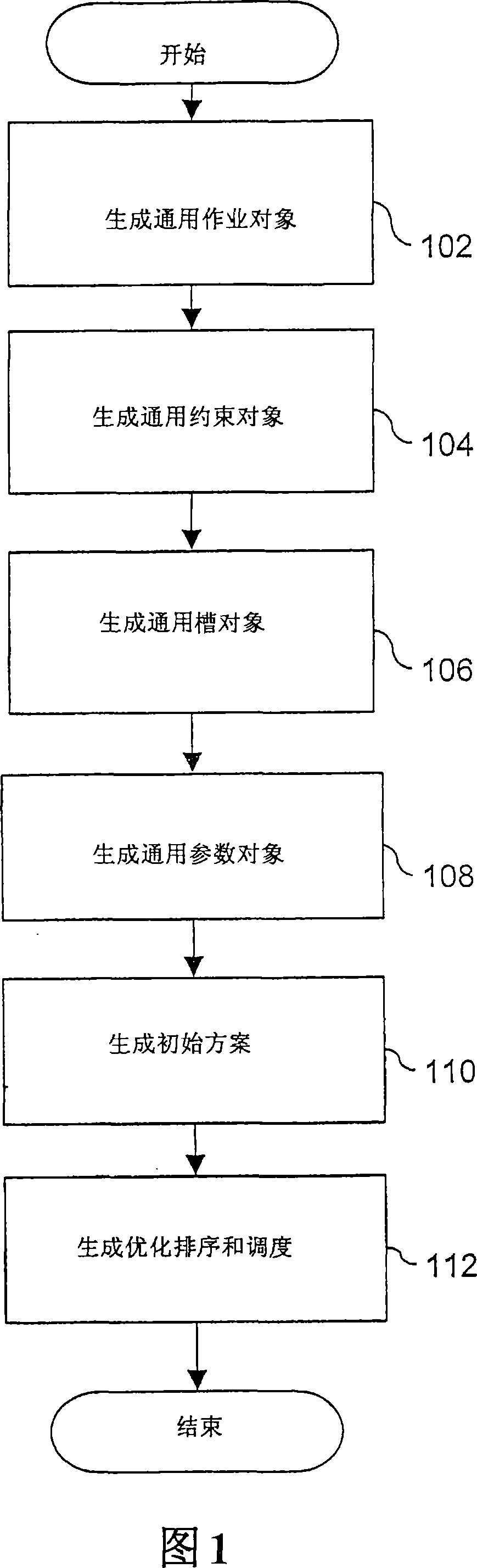

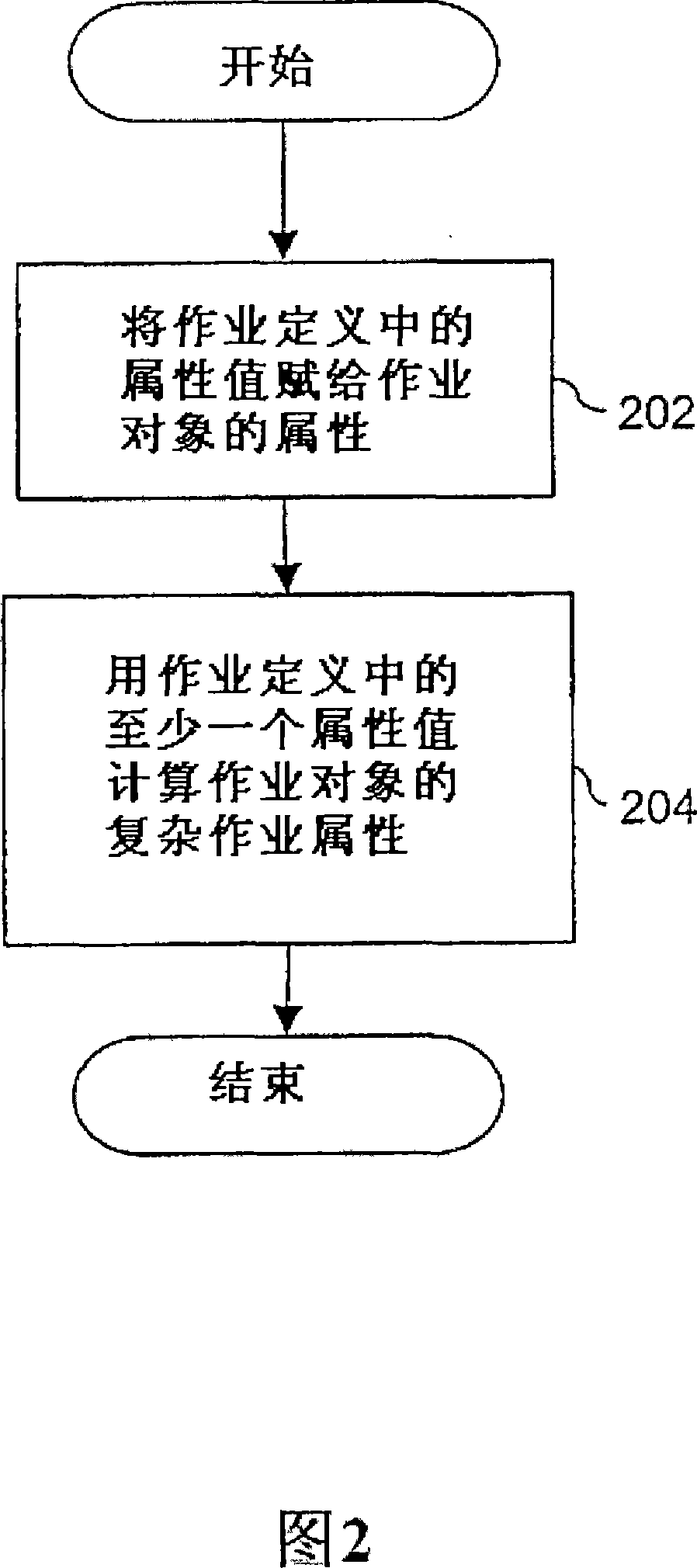

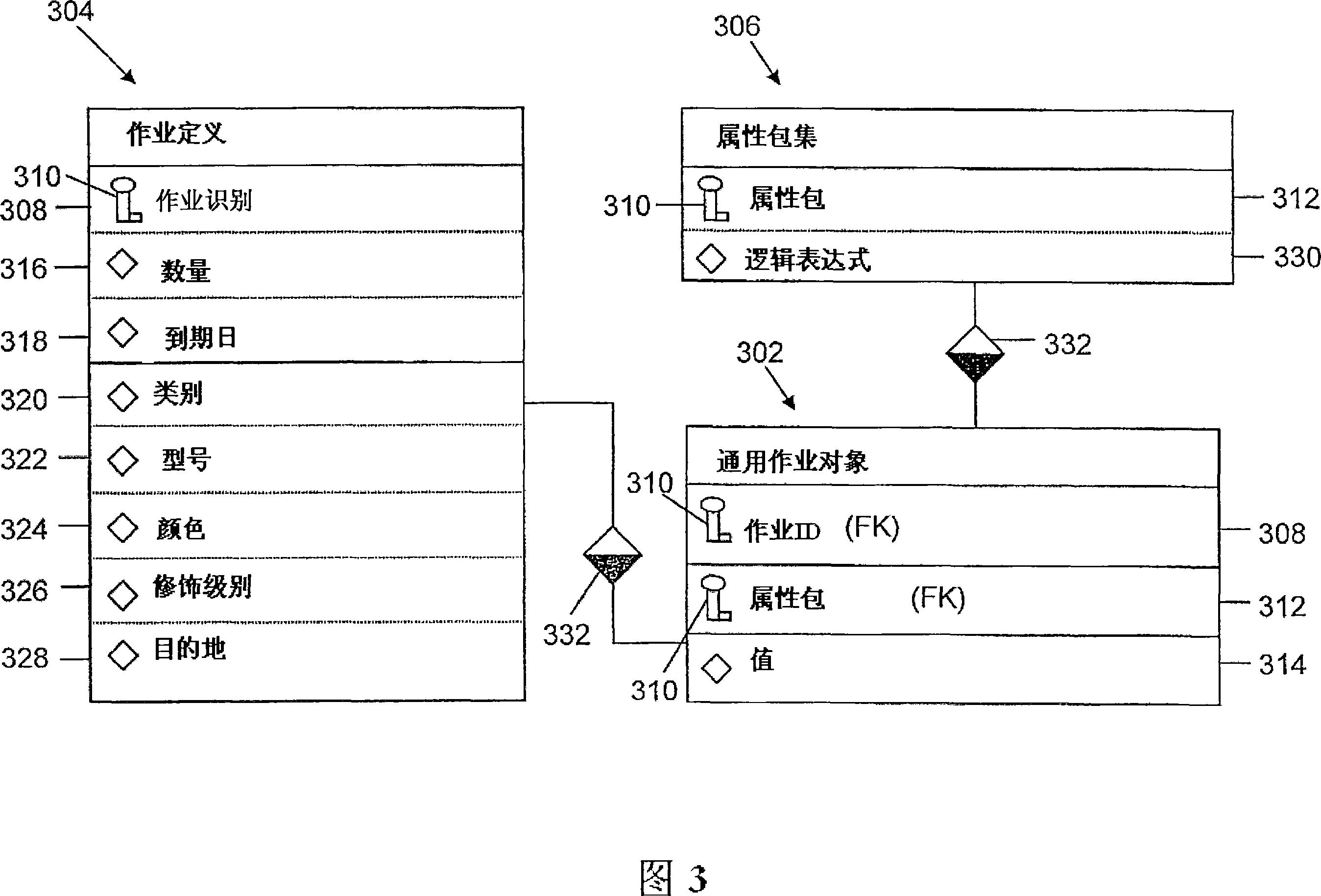

Method and system for sequencing and scheduling

A method and system as well as a computer program product for generating an optimized production sequence and schedule is provided. The method includes generation of a job object, a constraint object, a slot object and a parameters object that are used to generate the optimized production sequence and schedule. The system includes a configurable layer that stores the objects and a core product layer that generates the optimized sequence and schedule using the objects generated. The system may be used in conjuction with a variety of known optimization methodologies.

Owner:NETAPS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com