Heat preservation system for large-scale horizontal hole composite sandwich heat-preservation wallboard

A technology of sandwich insulation panels and insulation wall panels, which is applied in the direction of insulation, walls, building components, etc., can solve the problems of cumbersome process structure system, insulation effect, energy waste, and poor living environment, so as to prevent cold bridge condensation and improve Combined effect, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

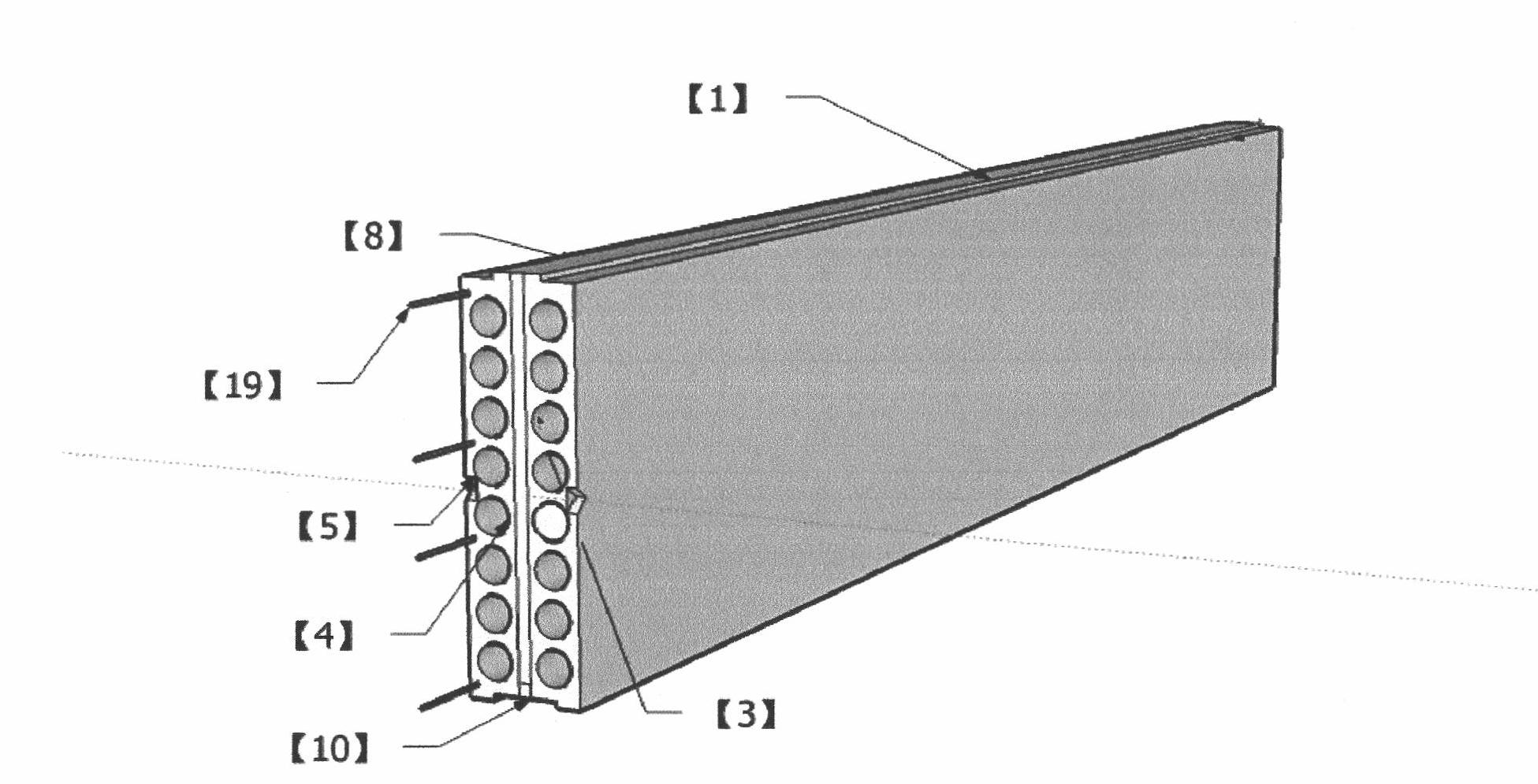

[0025] As shown in Figure 1: there are outer horizontal holes [3] and inner horizontal holes [4] inside the composite sandwich insulation wallboard [1] with large horizontal holes. There are hoisting gaps [5] and prestressed cold-drawn wires [19] at the end, waterproof convex grooves [8] are arranged above the wallboard, and waterproof grooves [9] are arranged below the wallboard.

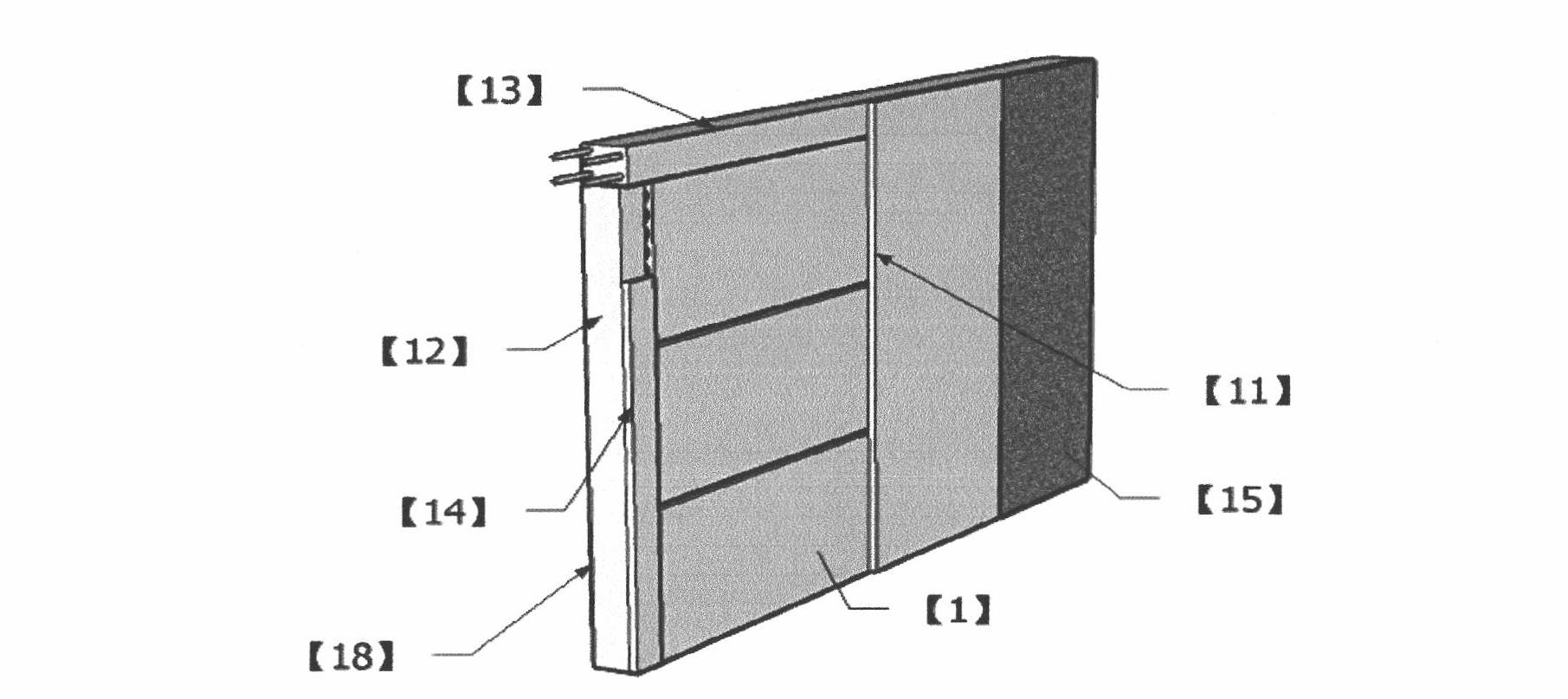

[0026] As shown in Figure 2: there are cast-in-place columns [12] and ring beams [13] at both ends of the large-scale horizontal hole composite sandwich insulation wall panel [1], and there are preset steel wire grid foam panels [14] on the outside ], on the outer surface of the wall, there is an external thermal insulation [11], and an exterior wall finish [15], and an interior wall decoration layer [18] is arranged on the interior wall.

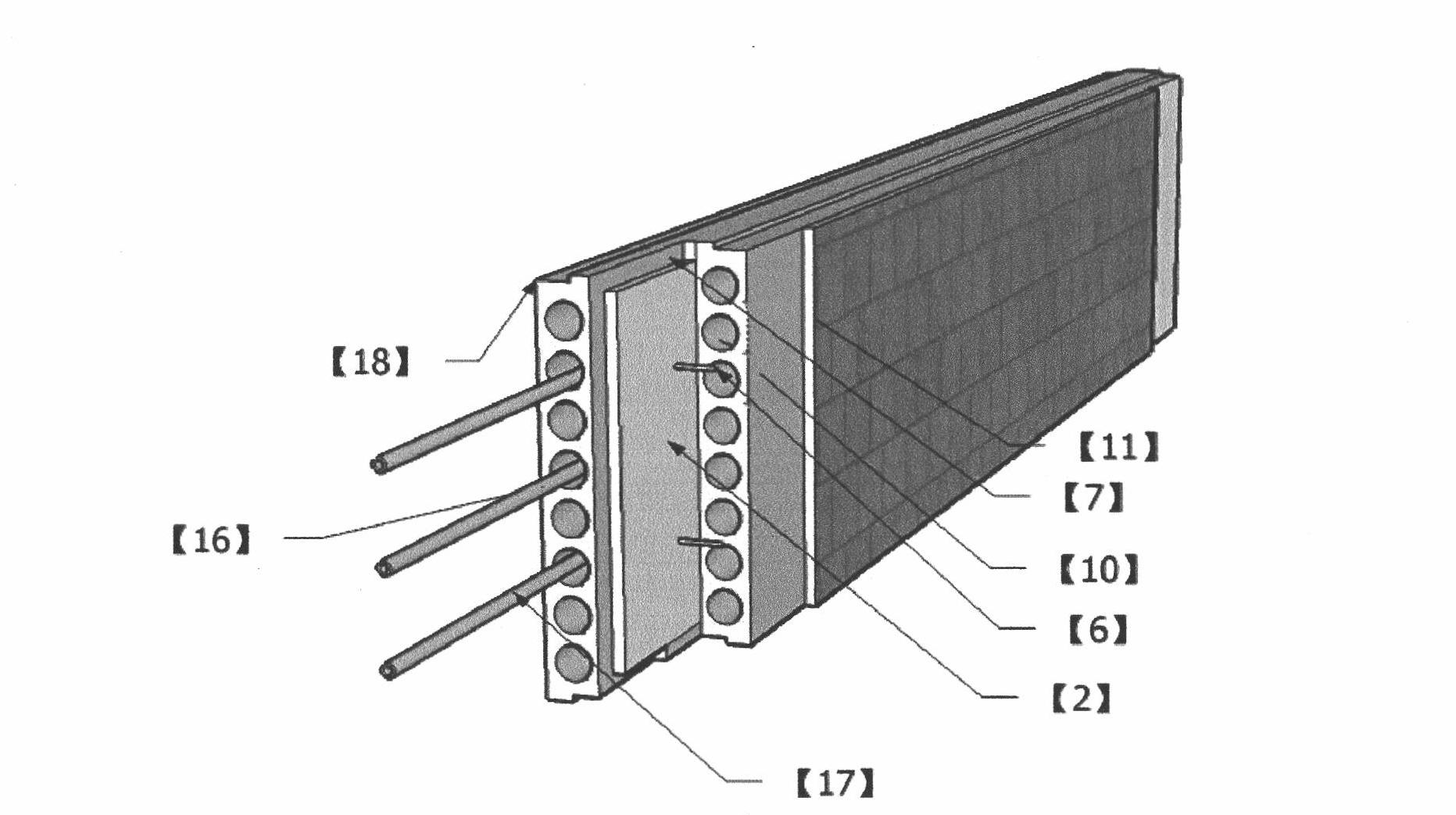

[0027] As shown in accompanying drawing 3: in the inb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com