Forming method of self-compacting concrete for pccp tube core

A technology of self-compacting concrete and forming method, which is applied in the direction of ceramic forming machines and manufacturing tools, can solve the problems of high pouring height and difficulty in ensuring the quality of finished tube cores to meet the standard requirements, so as to avoid vibration and noise, improve economic and social Benefits, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

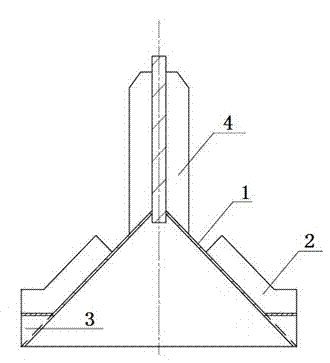

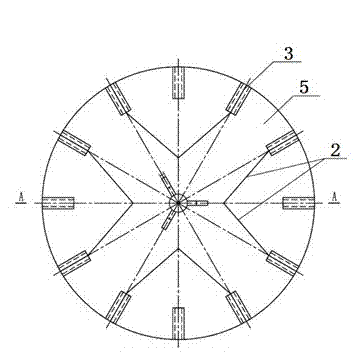

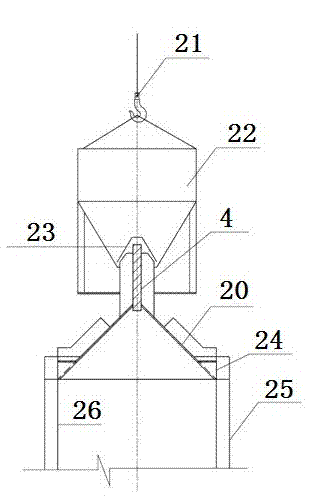

[0031] Such as figure 1 with figure 2 As shown, the structure of the homogenizer used in the present invention includes: a diversion cone 1, a diversion side plate 2, a fixed card 3, a push rod 4 and a discharge port 5.

[0032] Four or more guide side plates 2 are evenly distributed on the outer cone surface of the guide cone 1, and the guide side plates 2 are inverted V-shaped steel plates; The gap between them forms the feeding port 5, and twelve or more fixing clips 3 are evenly distributed on the bottom of the outer cone surface of the diversion cone 1, which are used to reliably fix the homogenizer on the top die; The cone top of the cone 1 is provided with a push rod 4, which is used to lift the top opening door of the hopper, so that the concrete material can leak from the hopper and start feeding; the concrete material passes through the outer cone surface of the diversion cone 1, along the diversion side plate The outer side of the pipe (that is, the feeding port ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com