Patents

Literature

44 results about "Composite Position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The location in the compositeSequence target's sequence to which a source compositeSequence maps. The association to MismatchInformation allows the specification, usually for control purposes, of deviations from the CompositeSequence's BioMaterial. (caMAGE)

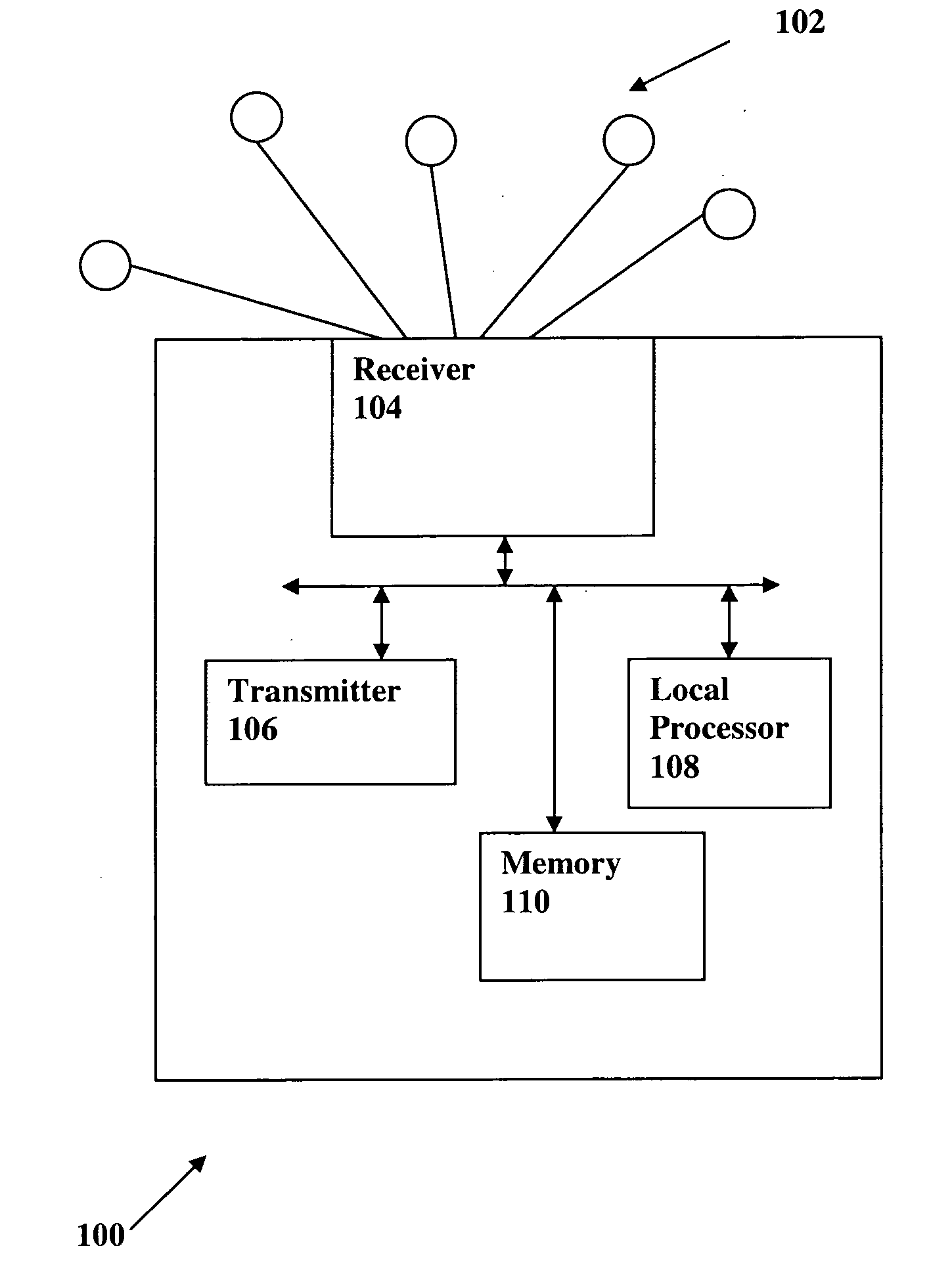

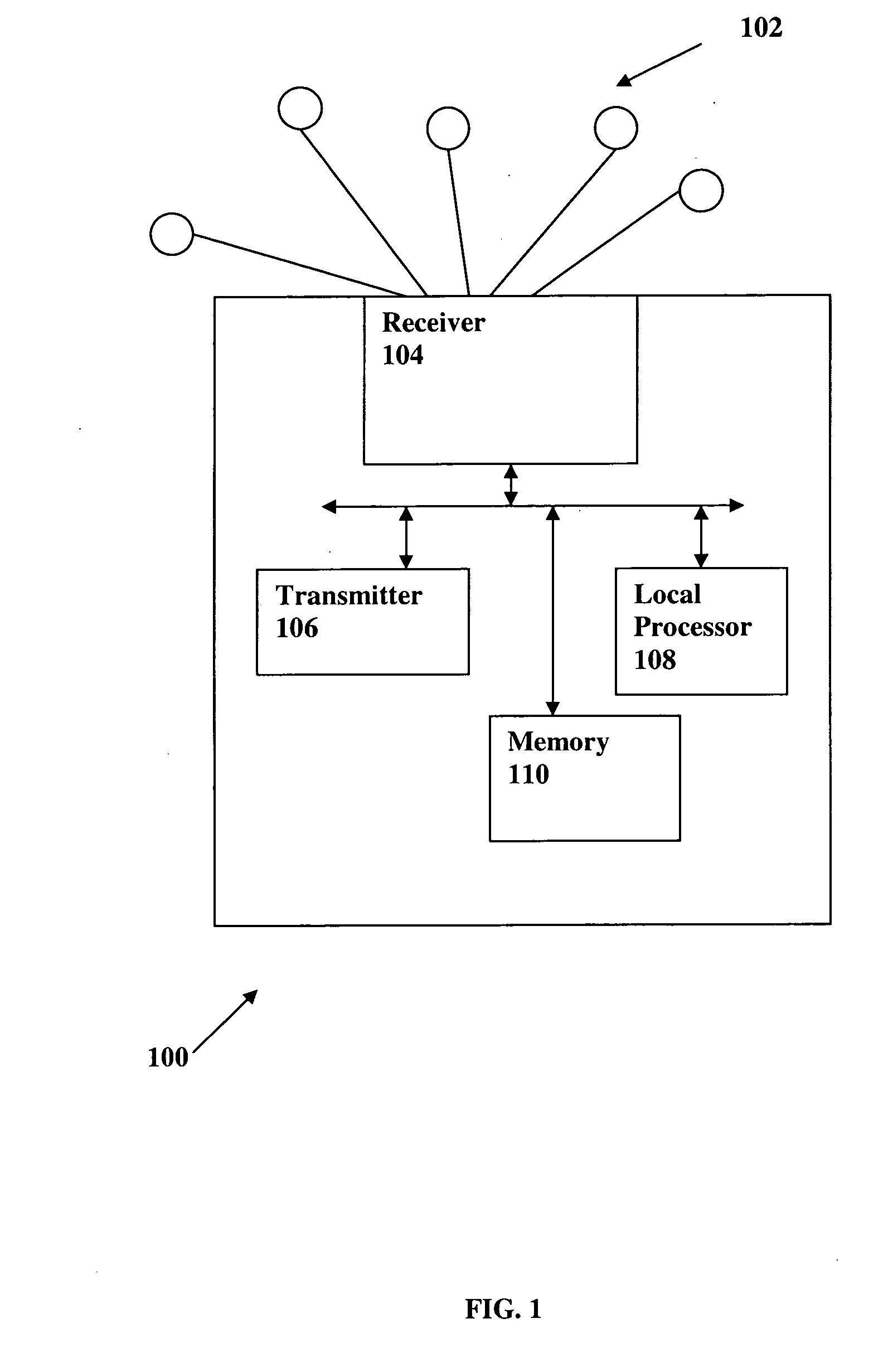

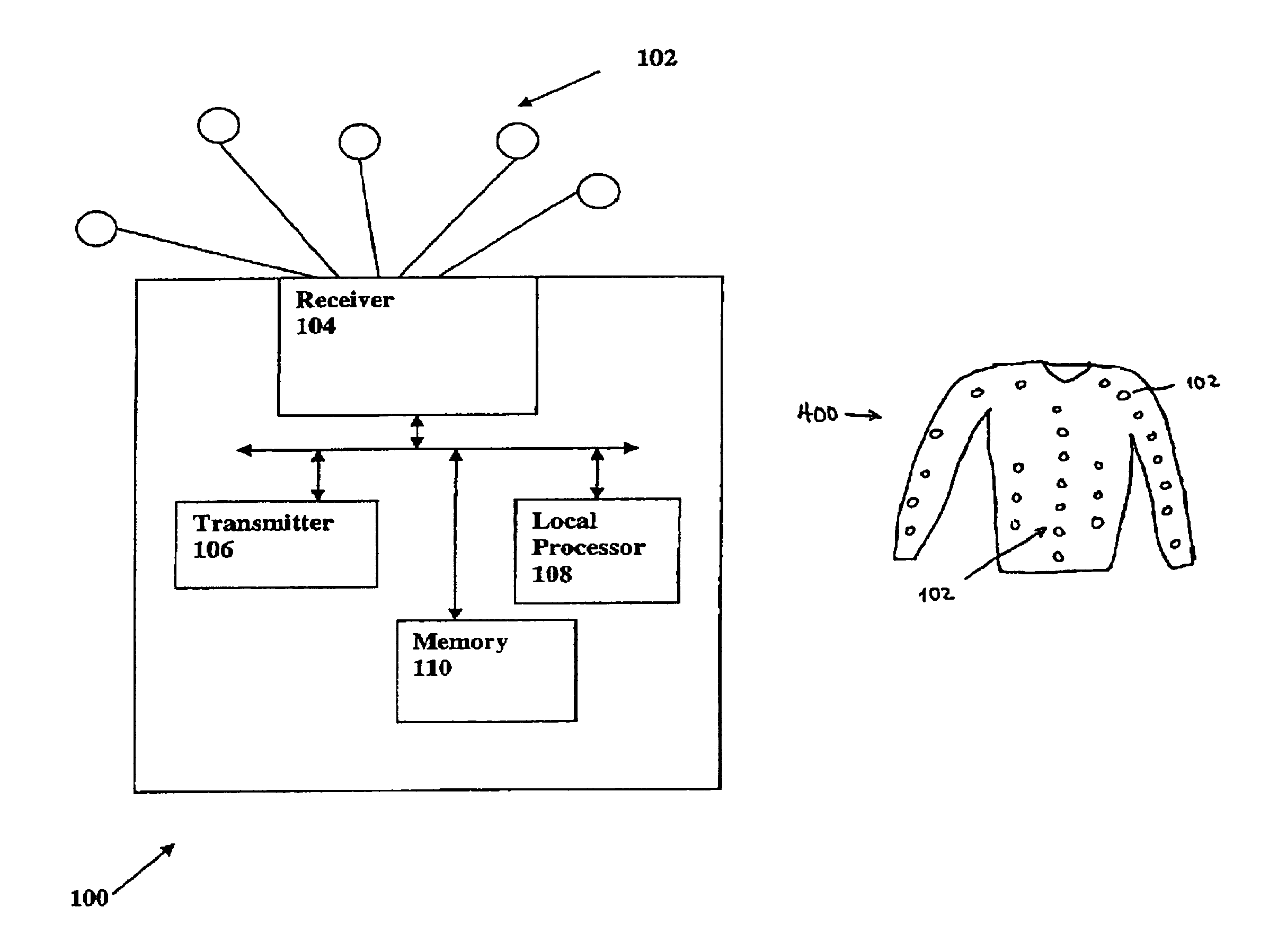

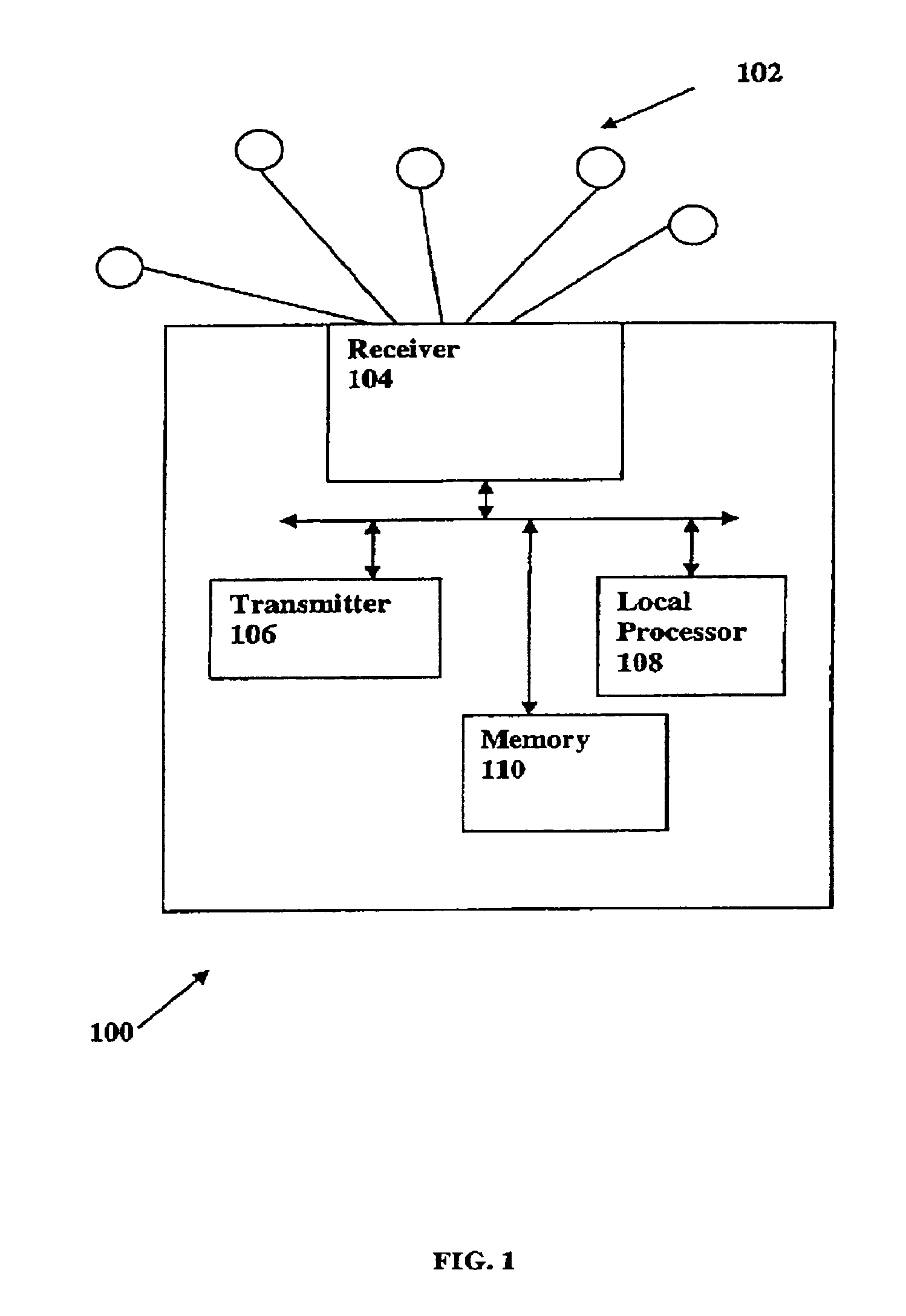

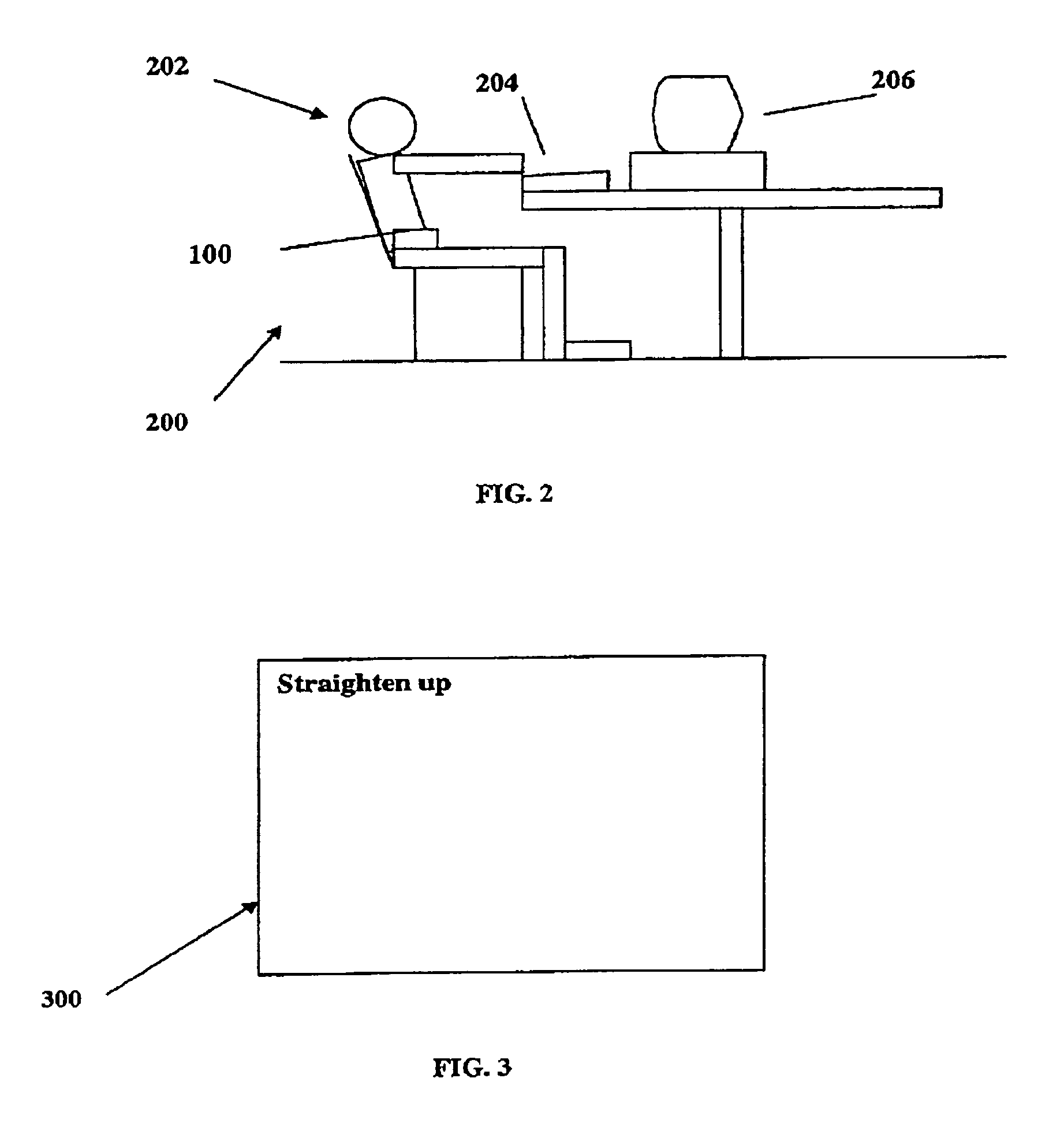

Device for monitoring a user's posture

A device, wearable by a user, includes: a plurality of sensor elements each for providing an indication of position of at least a part of the user's body; a receiver for receiving each indication of position provided by each of the plurality of sensor elements to provide a composite position signal. The individual sensor readings may all be transmitted to the external entity for further analysis. The sensors may be placed in different locations or positions for measuring the curvature of at least a part of the user's body.

Owner:IBM CORP

Device for monitoring a user's posture

A device, wearable by a user, includes: a plurality of sensor elements each for providing an indication of position of at least a part of the user's body; a receiver for receiving each indication of position provided by each of the plurality of sensor elements to provide a composite position signal. The individual sensor readings may all be transmitted to the external entity for further analysis. The sensors may be placed in different locations or positions for measuring the curvature of at least a part of the user's body.

Owner:IBM CORP

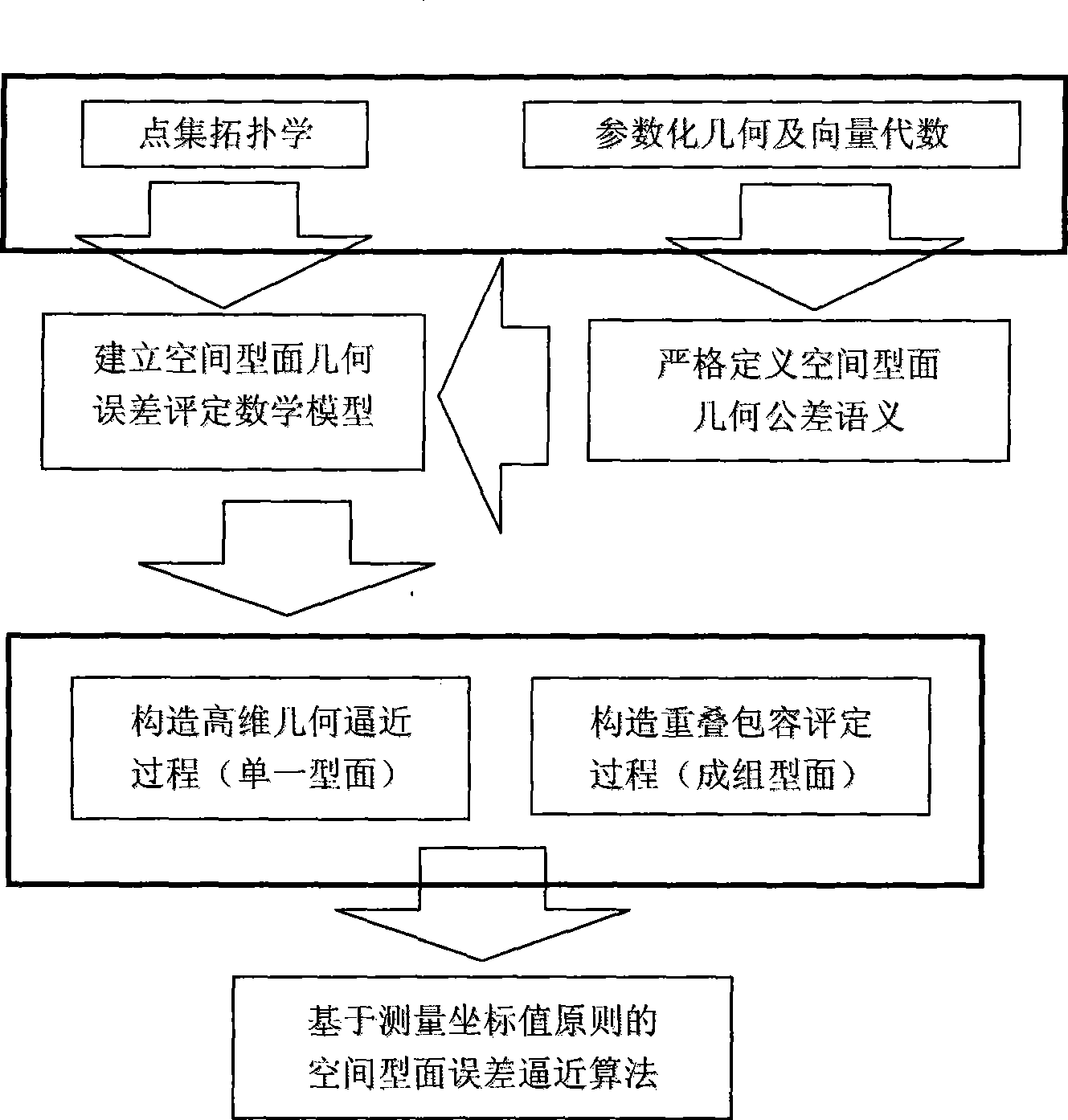

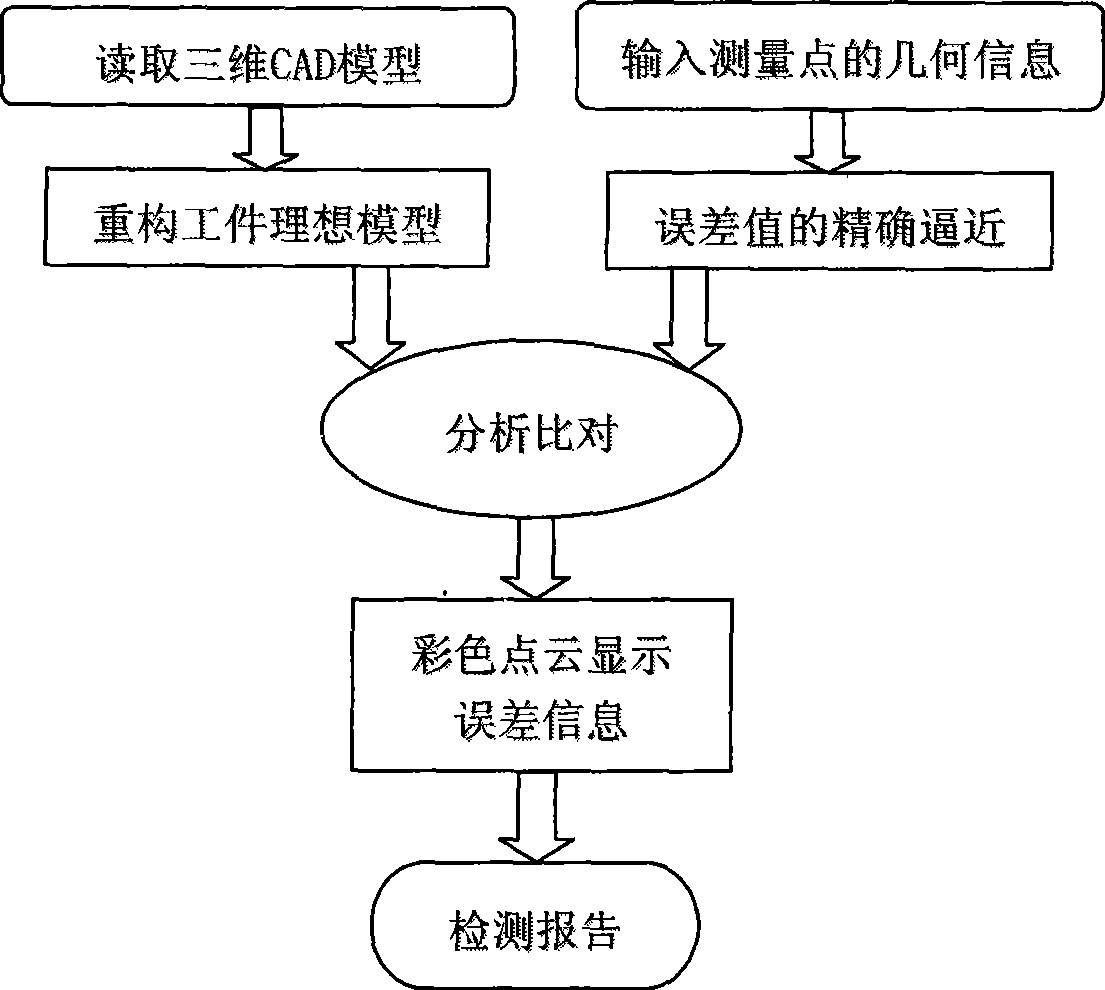

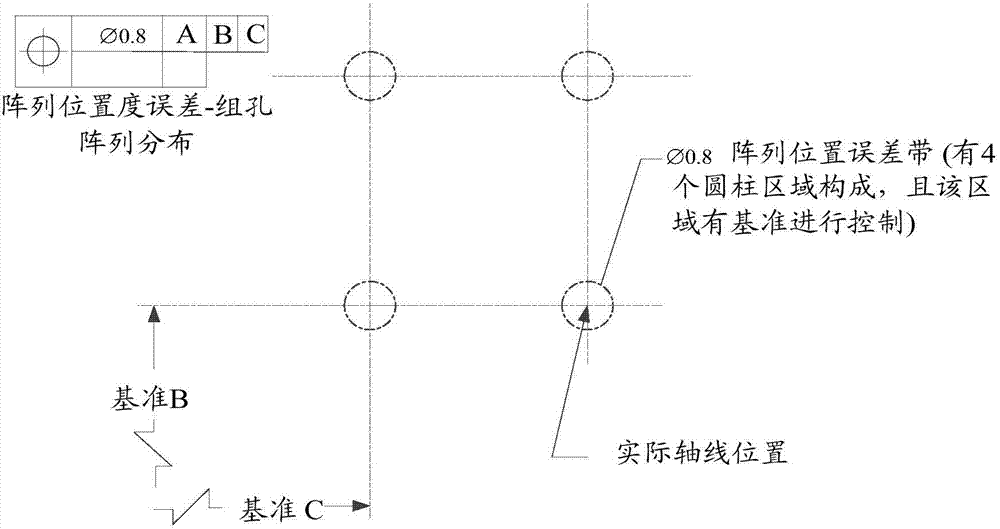

Method for assessing composite space type face geometric error

The invention relates to a method for evaluating geometrical error of a compound spatial moulding surface, belonging to the field of mechanic parts geometrical error evaluation. The method comprises the following steps: (1) a three-dimensional CAD model of a work piece to be evaluated is read and an ideal work piece model is reconstructed; (2) geometrical data of the work piece to be evaluated is measured to obtain the coordinate information of each measured point; (3) the error value of the measured moulding surface is calculated according to the geometrical error evaluation items of the work piece to be measured including spatial straightness accuracy, cylindricity and punch combination compound position; and (4) the error evaluation result is compared with the read ideal work piece model for analyzing, the processing error information is displayed by adopting colour cloud points, and the error evaluation report is obtained finally. The invention, by the approaching process for constructing minimum zone, realizes fast and accurate evaluation on the geometrical error of the compound spatial moulding surface.

Owner:TIANJIN UNIV

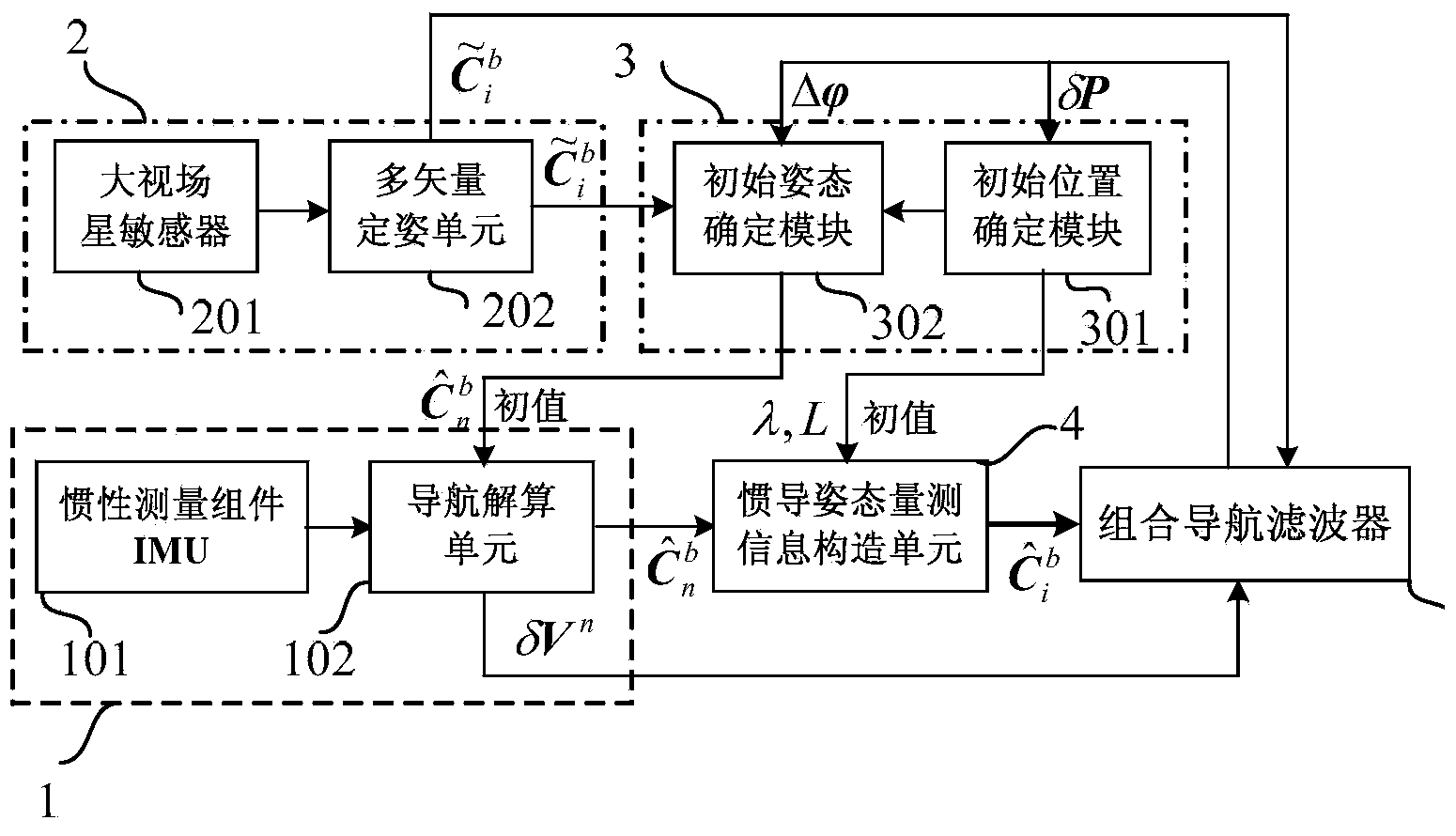

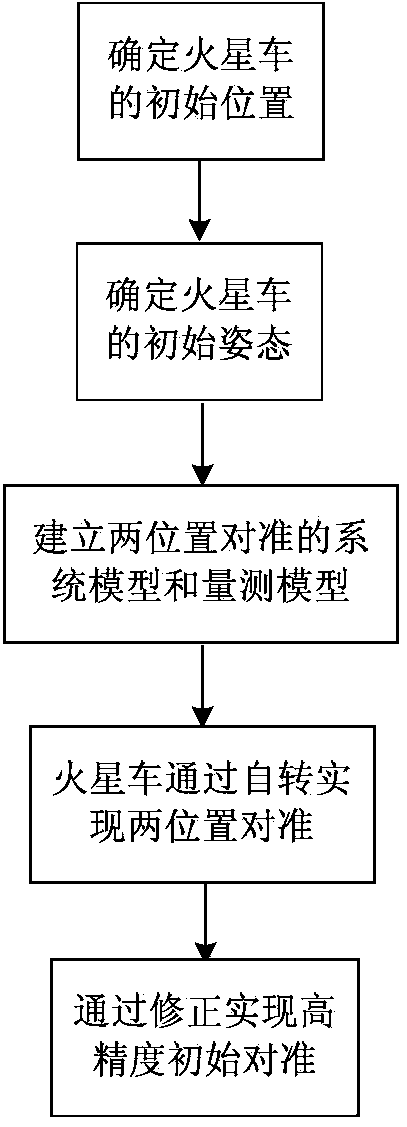

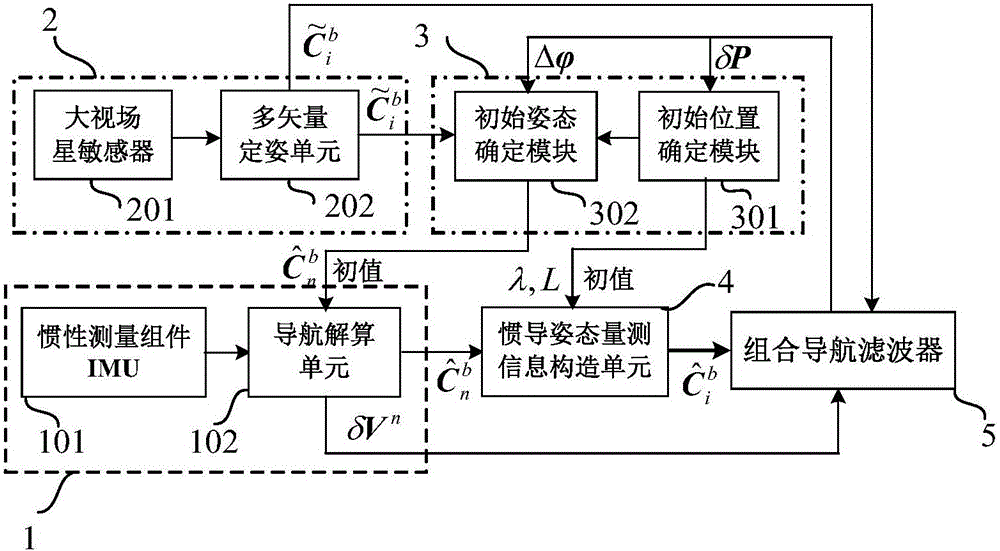

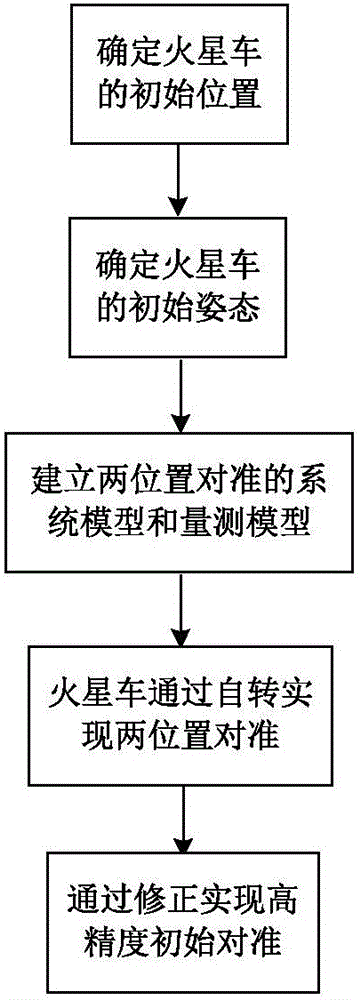

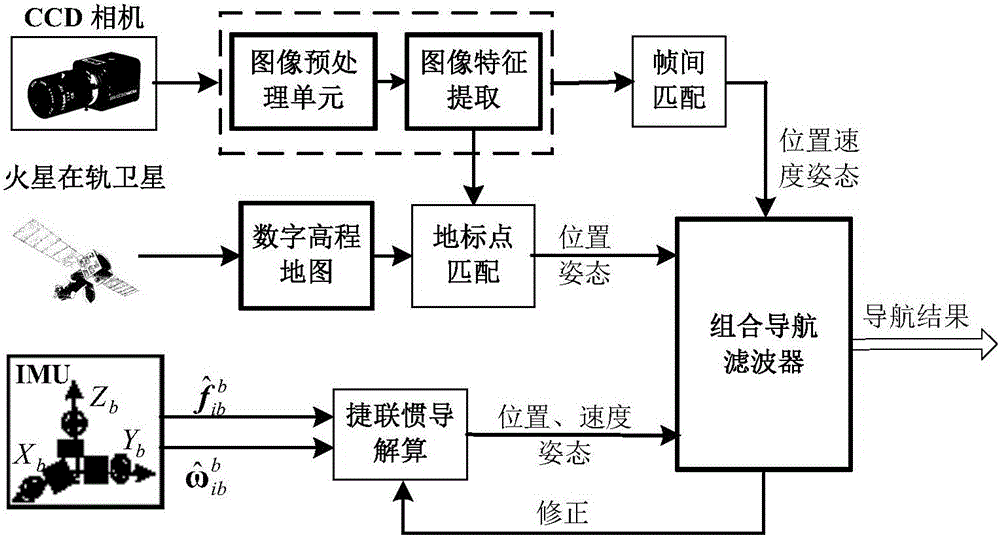

Method for aligning two composite positions with high accuracy and calibrating error of inertial navigation astronomy

InactiveCN103900611AQuick fixHigh precisionInstruments for comonautical navigationState modelComposite Position

The invention discloses a method for aligning two composite positions with high accuracy and calibrating error of inertial navigation astronomy. The method comprises the following steps: step one, taking a landing position determined by a landing machine as information of an initial position of a rover; step two, determining an initial attitude matrix of the rover according to the initial position of the rover and the inertia attitude matrix which is output by an astronomy navigation subsystem; step three, establishing a system state model and a measurement model for aligning two positions of the rover; step four, aligning the two positions by rotating the rover; step five, correcting initial position information of the rover to meet requirements of high-accuracy initial alignment. The method gives full play to the advantages of a serial inertial navigation system and the astronomy navigation subsystem, and is also applicable to other exploration rovers and wide in application prospect.

Owner:BEIHANG UNIV

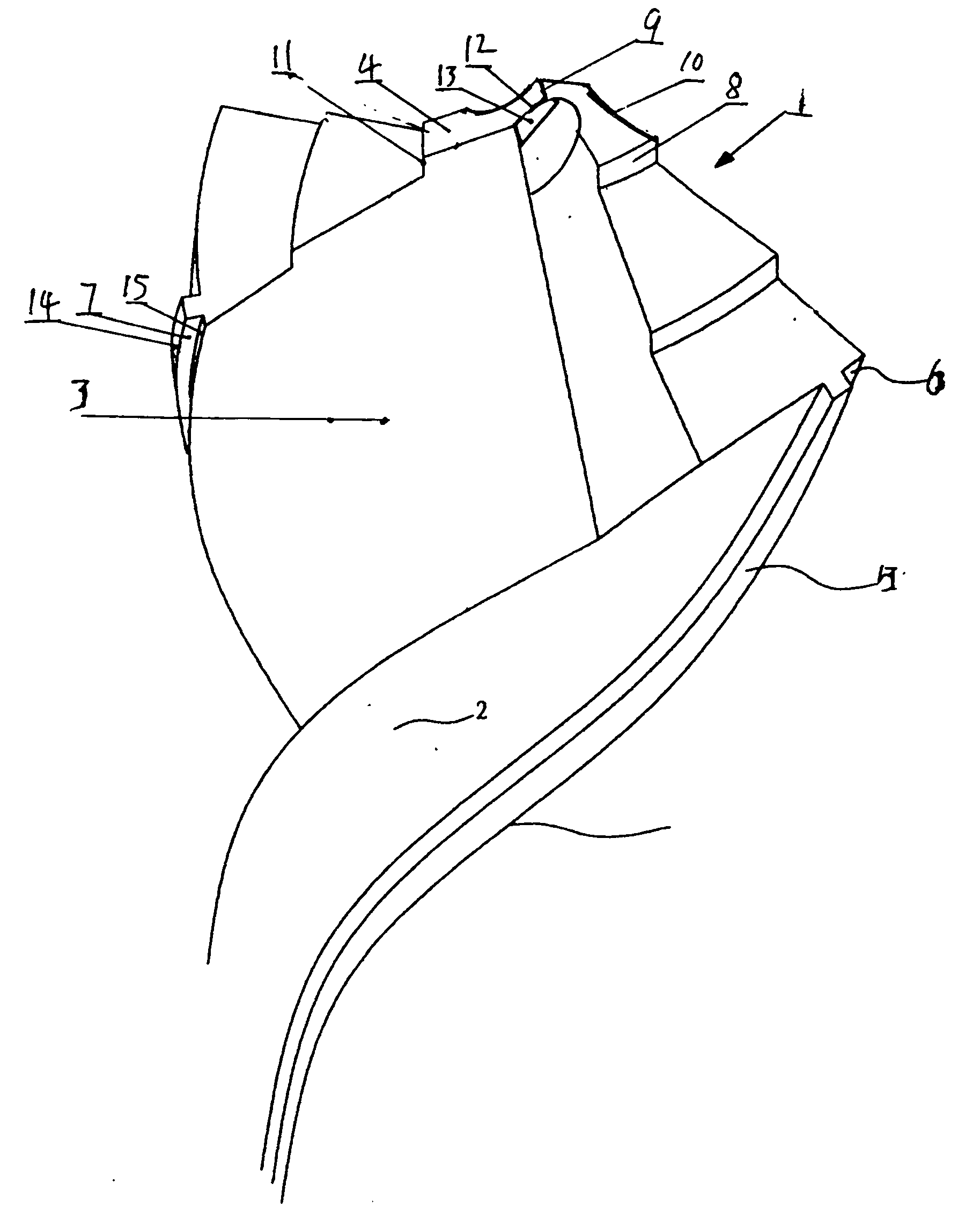

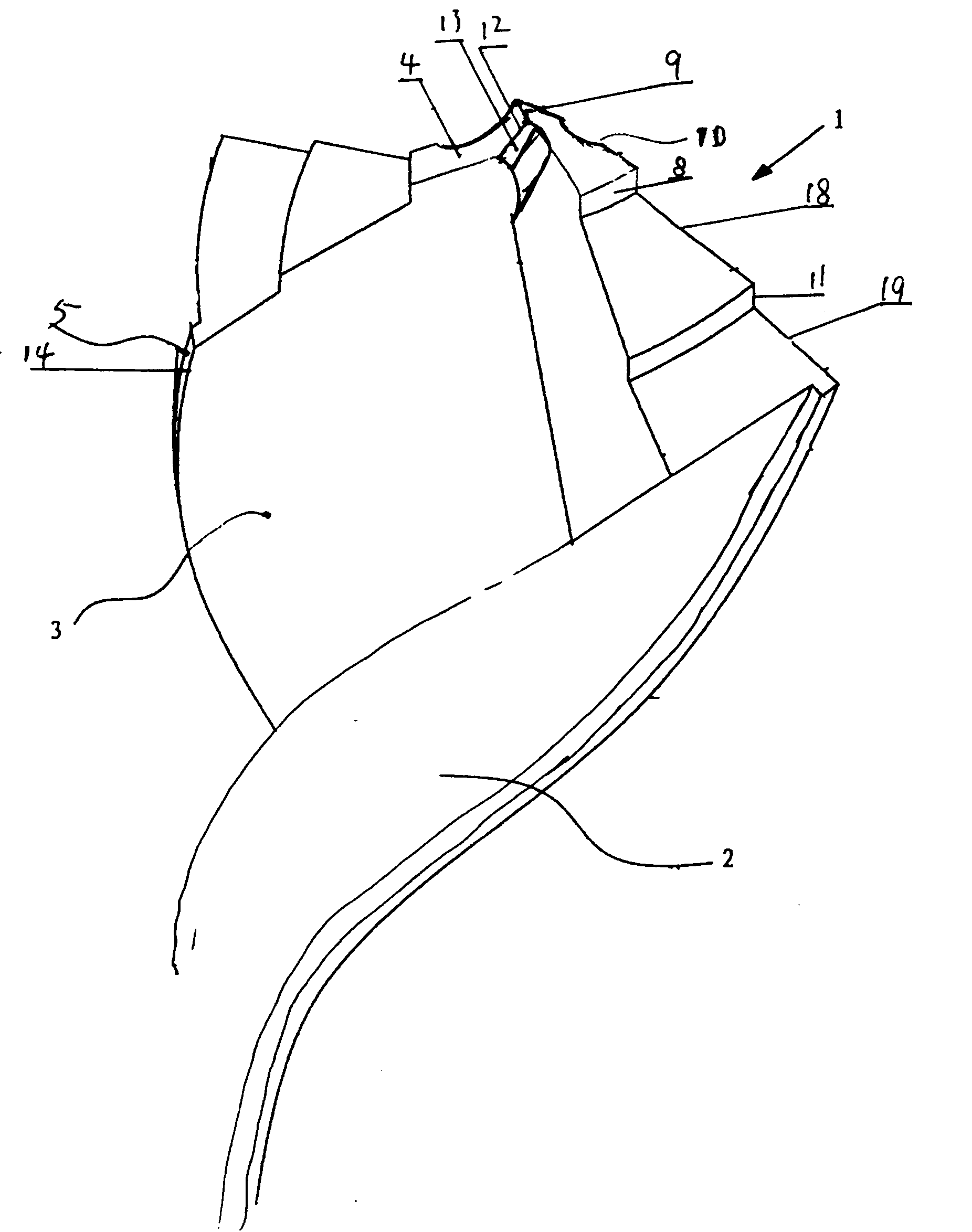

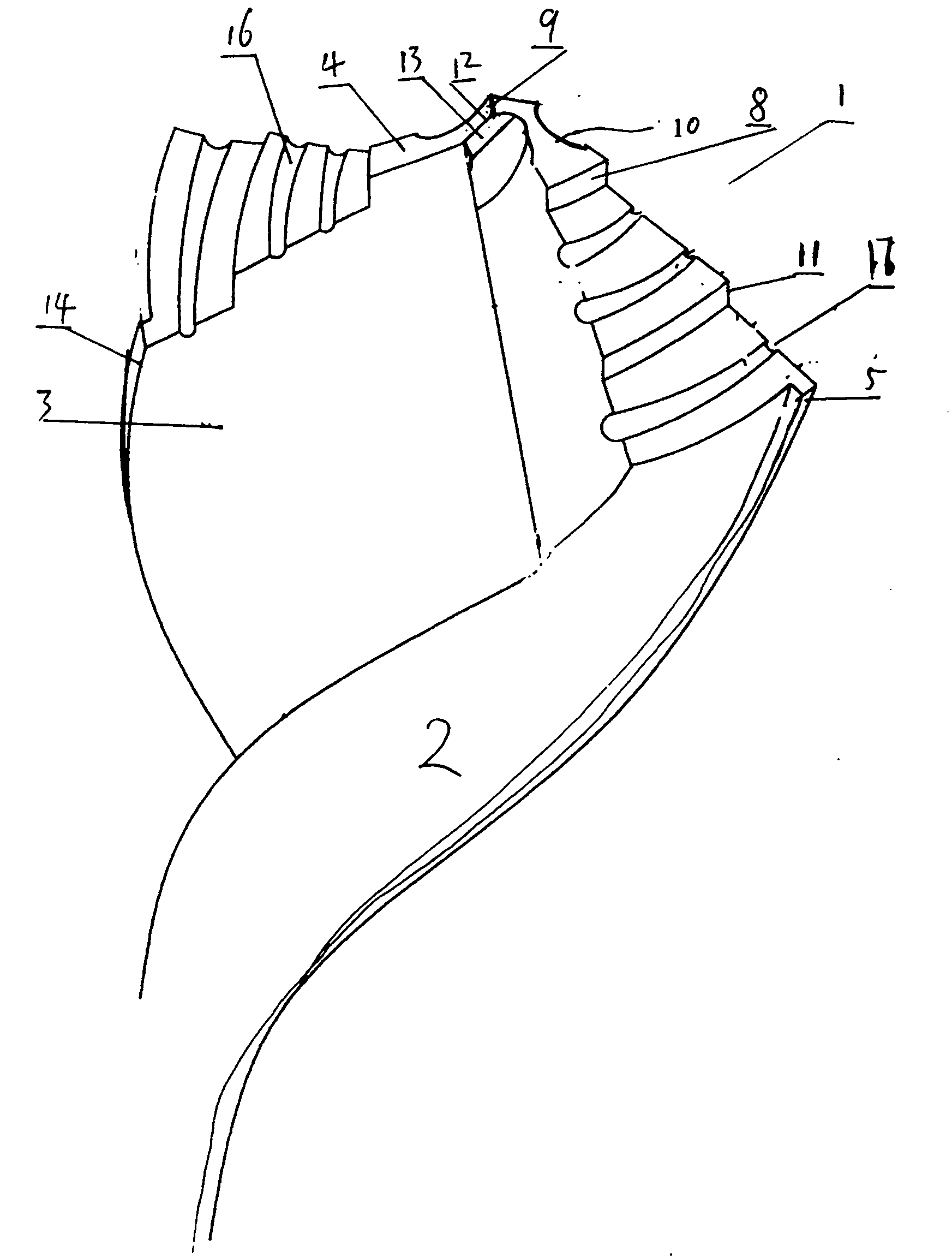

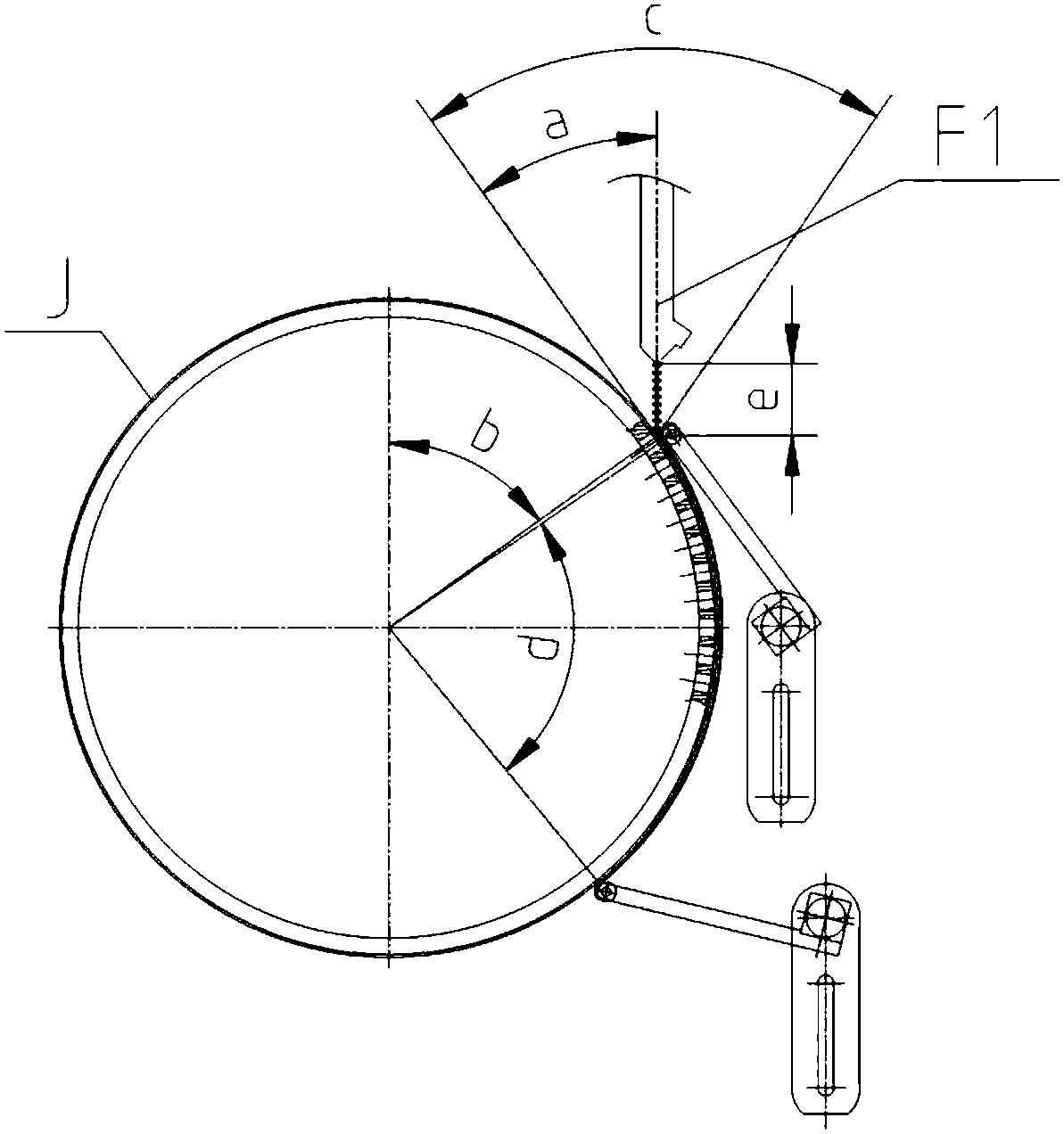

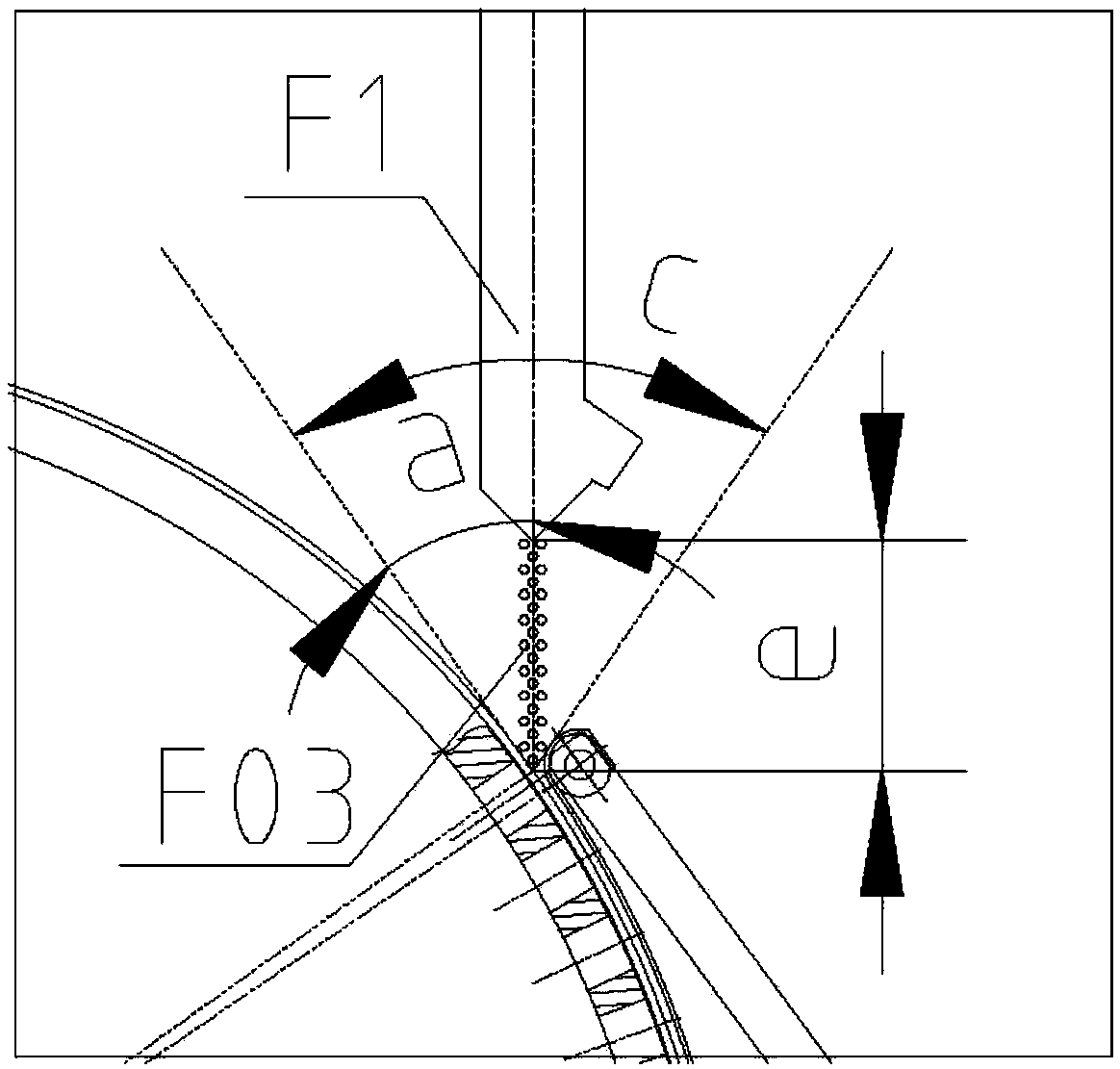

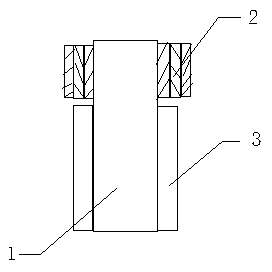

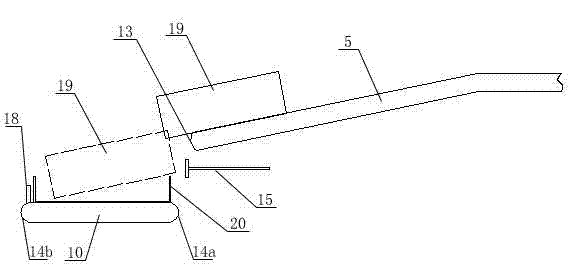

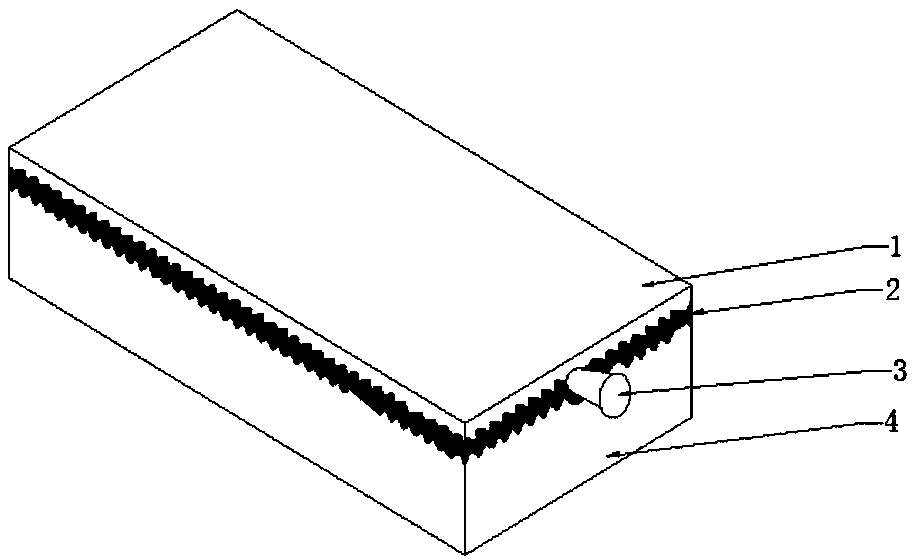

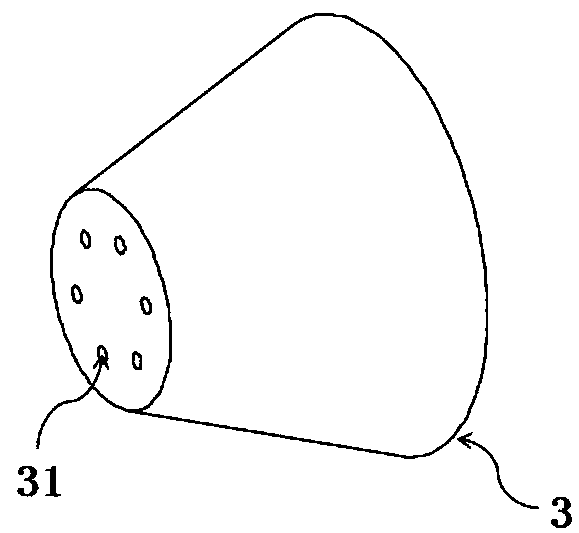

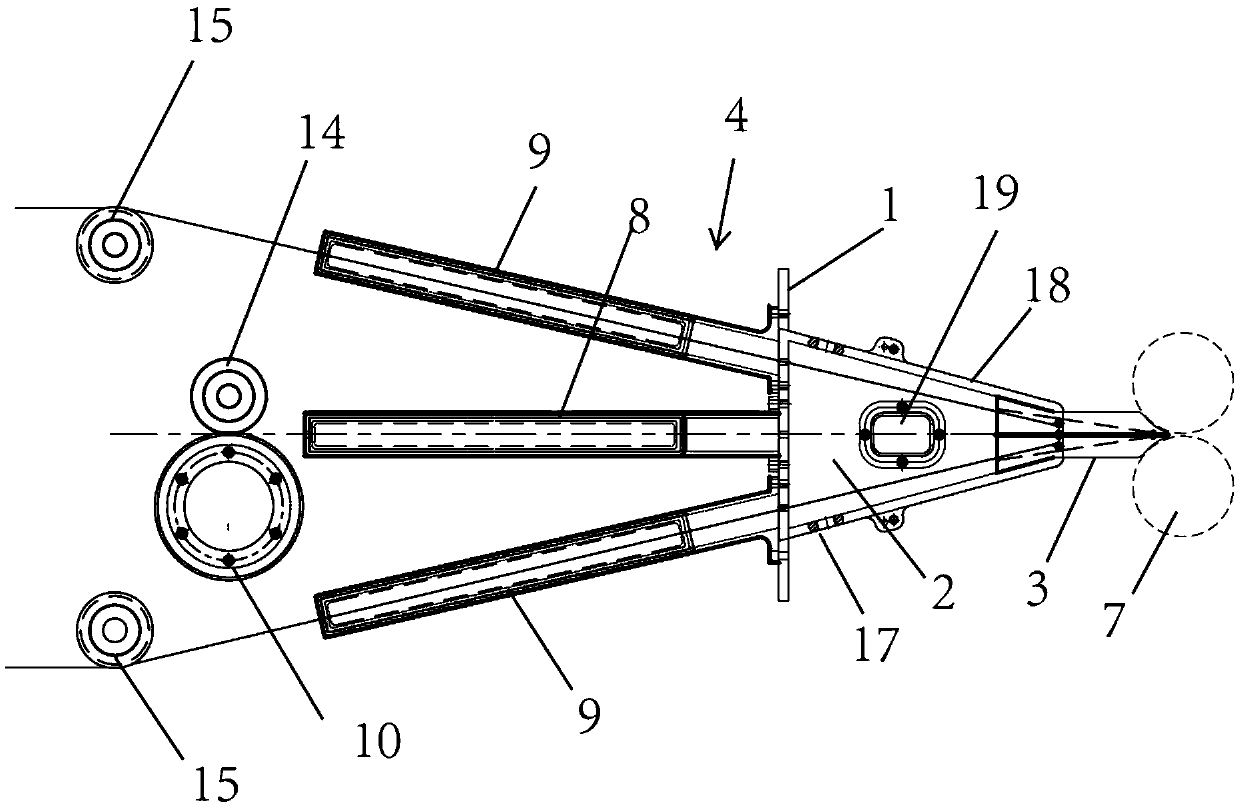

Spiral cutter for composite positioned cutting

The invention provides a spiral cutter for composite positioned cutting. The cutter has high stability, high radiating efficiency, and long service life and is easy to position in drilling processing. The cutter comprises a cutter head, and is characterized in that: at least stepped cutting edges, chamfering edges and chisel edges on two side of the spiral cutter 1 form S-shaped cutting edges 2; the stepped cutting edges or the chamfering edges are provided with at least one notch edge 3, and step parts of which the height is gradually reduced are formed towards two outer sides from the chisel edges on a rear cutting face; stepped edges 4 are formed on the stepped cutting faces of the cutting edges, and step parts of which the height is gradually reduced are formed towards two outer sides of the chisel edges on the rear cutting face; stepped edges are formed on the stepped rear cutting faces of the cutting edges; and at least one step of stepped edge is provided with at least one notch edge, and a groove distributed in an enlargement mode extends from the opening of the notch edge to the rear cutting face or the cutting faces.

Owner:李仕清

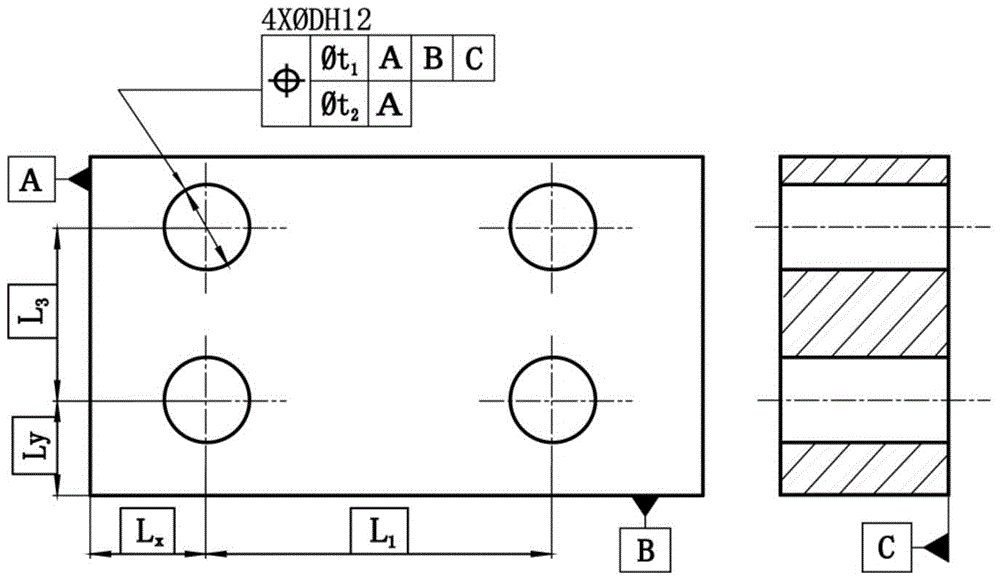

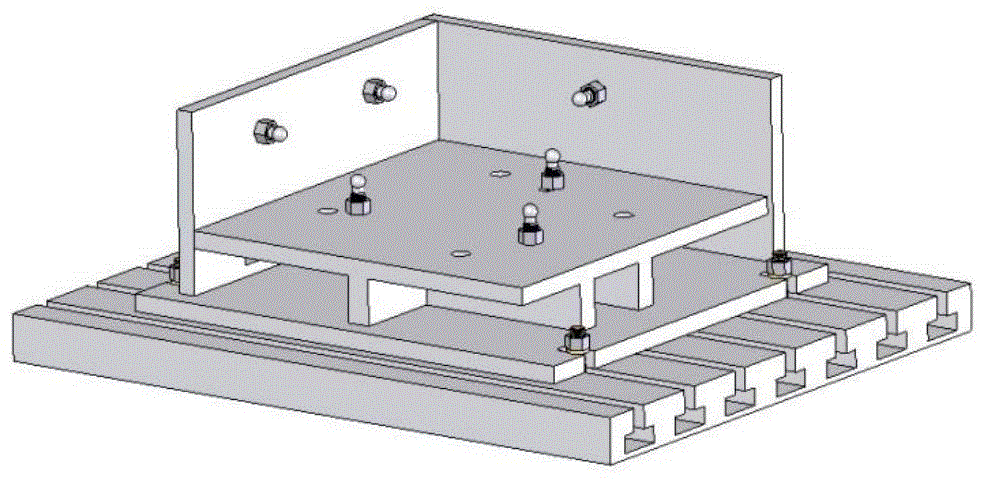

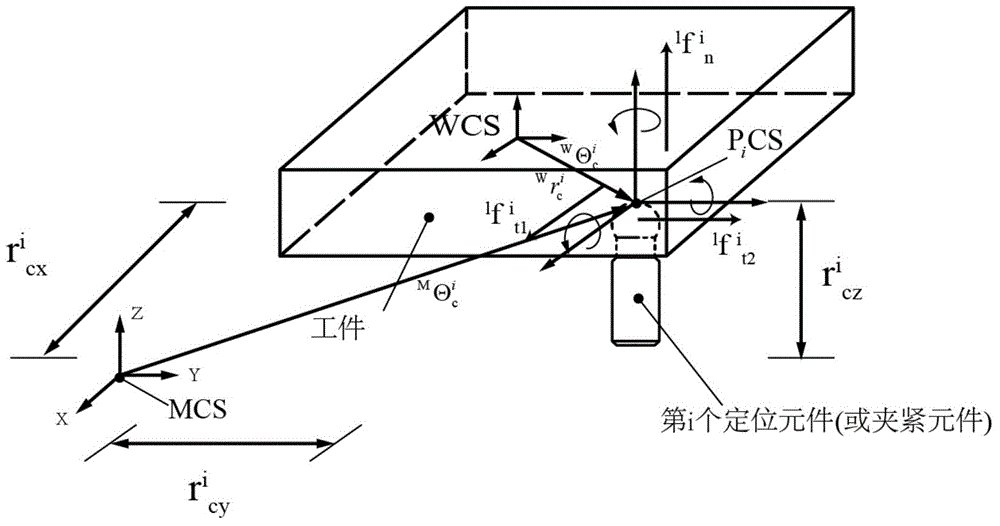

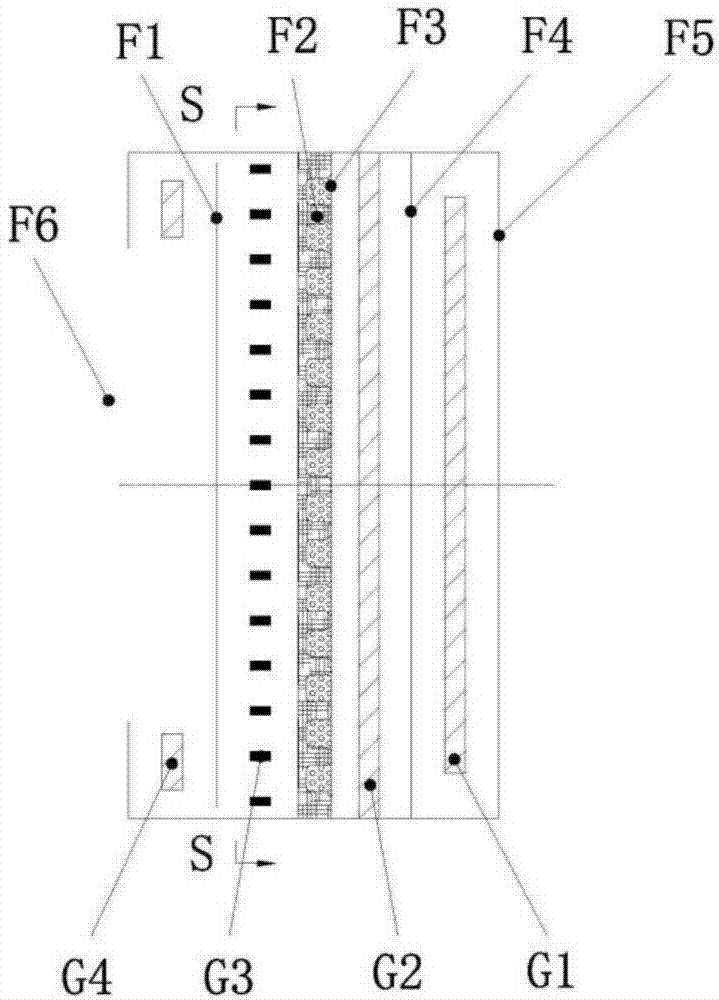

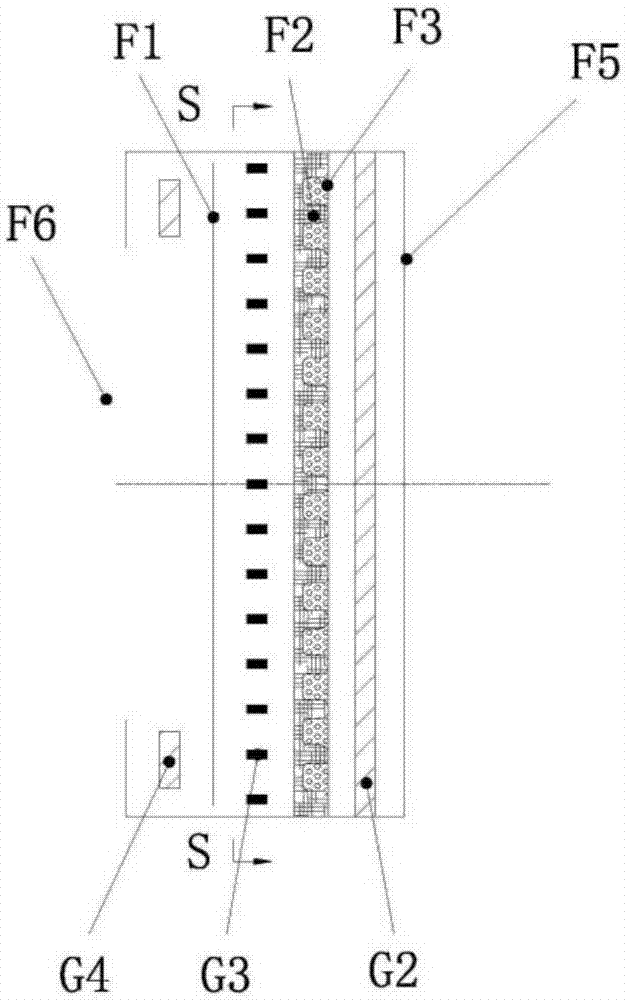

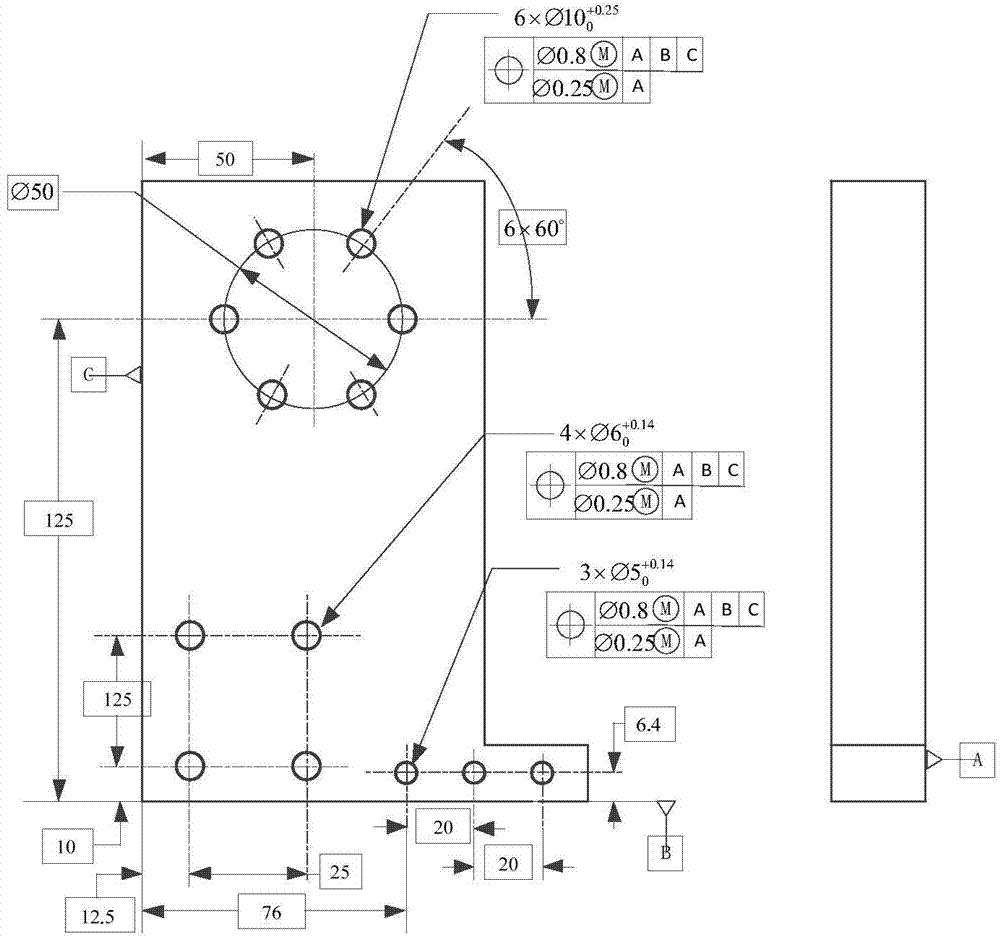

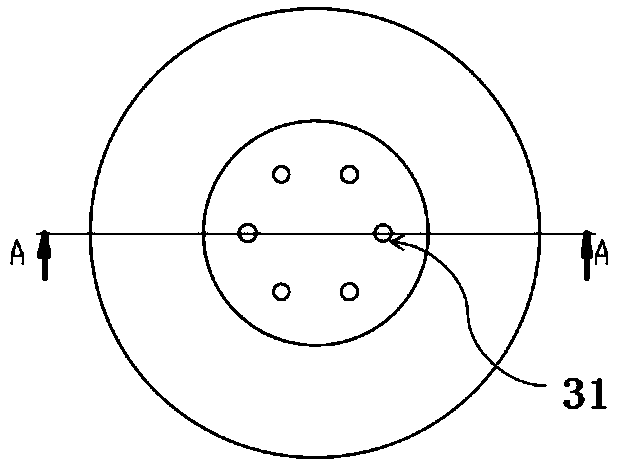

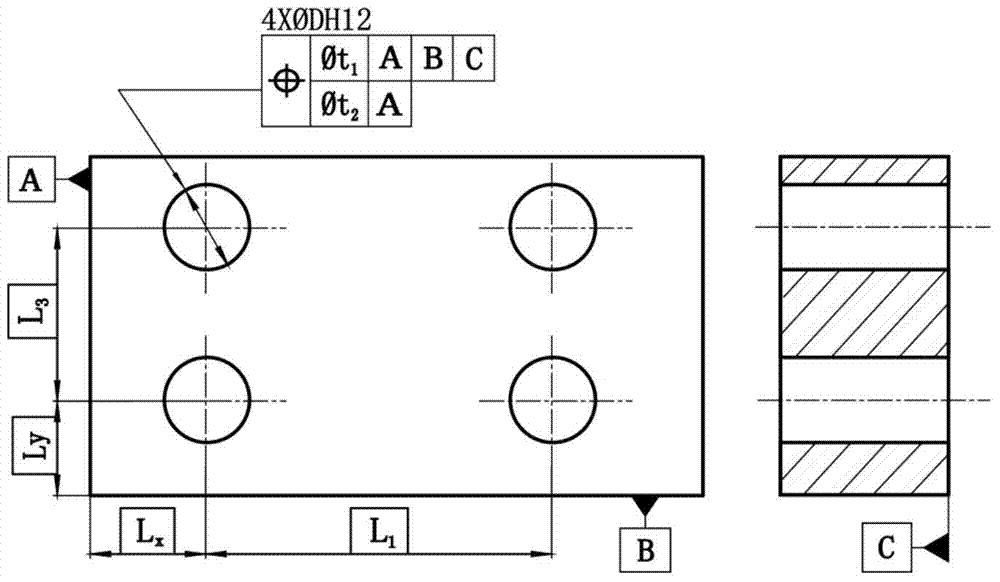

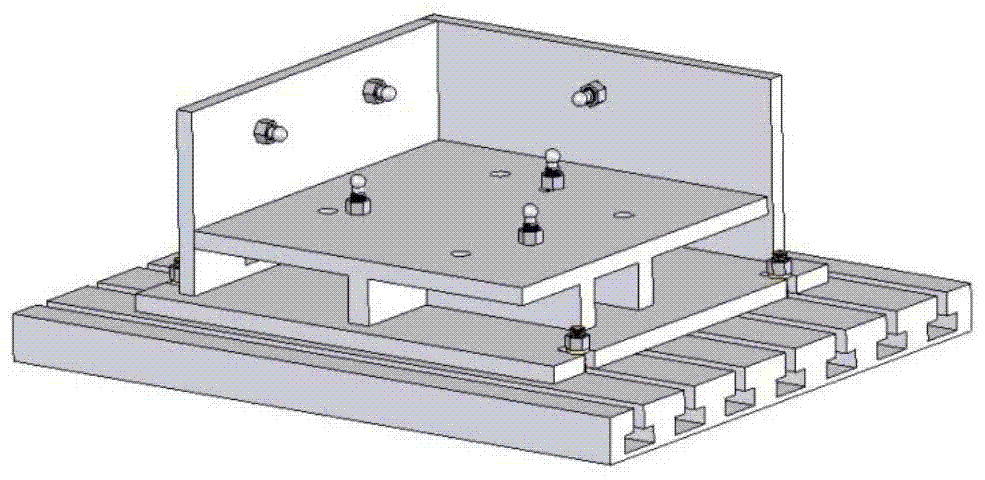

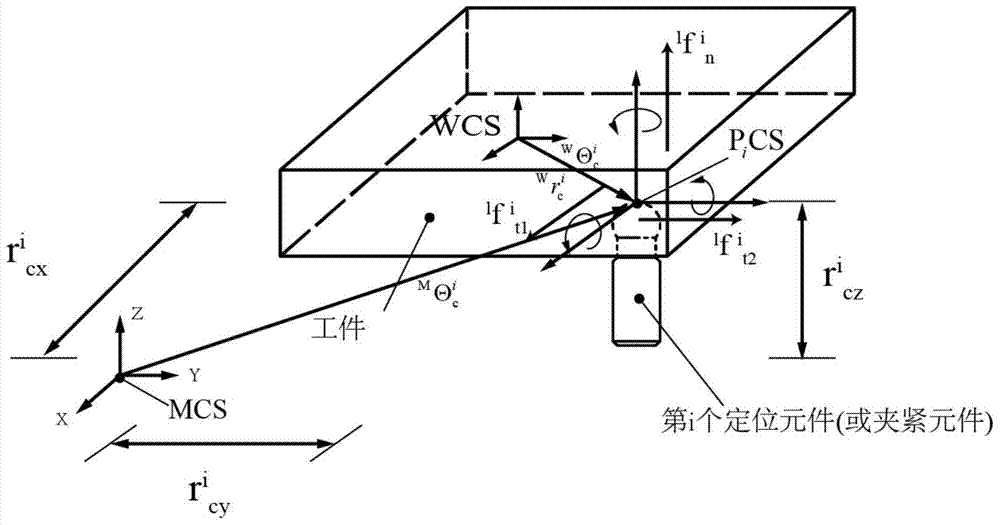

Method for controlling hole group composite position degree error through optimizing clamp layout

The invention discloses a method for controlling the hole group composite position degree error through optimizing the clamp layout. The method includes the following steps that a relation model of geometric errors of clamp positioning elements, positioning element positions and the working position error is established; a relation model of milling force, clamping force, the positioning element positions and the workpiece position error is established; a minimal hole group feature composite position degree error is an objective function, the clamp positioning element positions are optimization variables, the optimal positioning element position is searched for through an optimization algorithm, and the hole group composite position degree error is minimal. The clamp design method is high in universality and simple.

Owner:TIANJIN UNIV

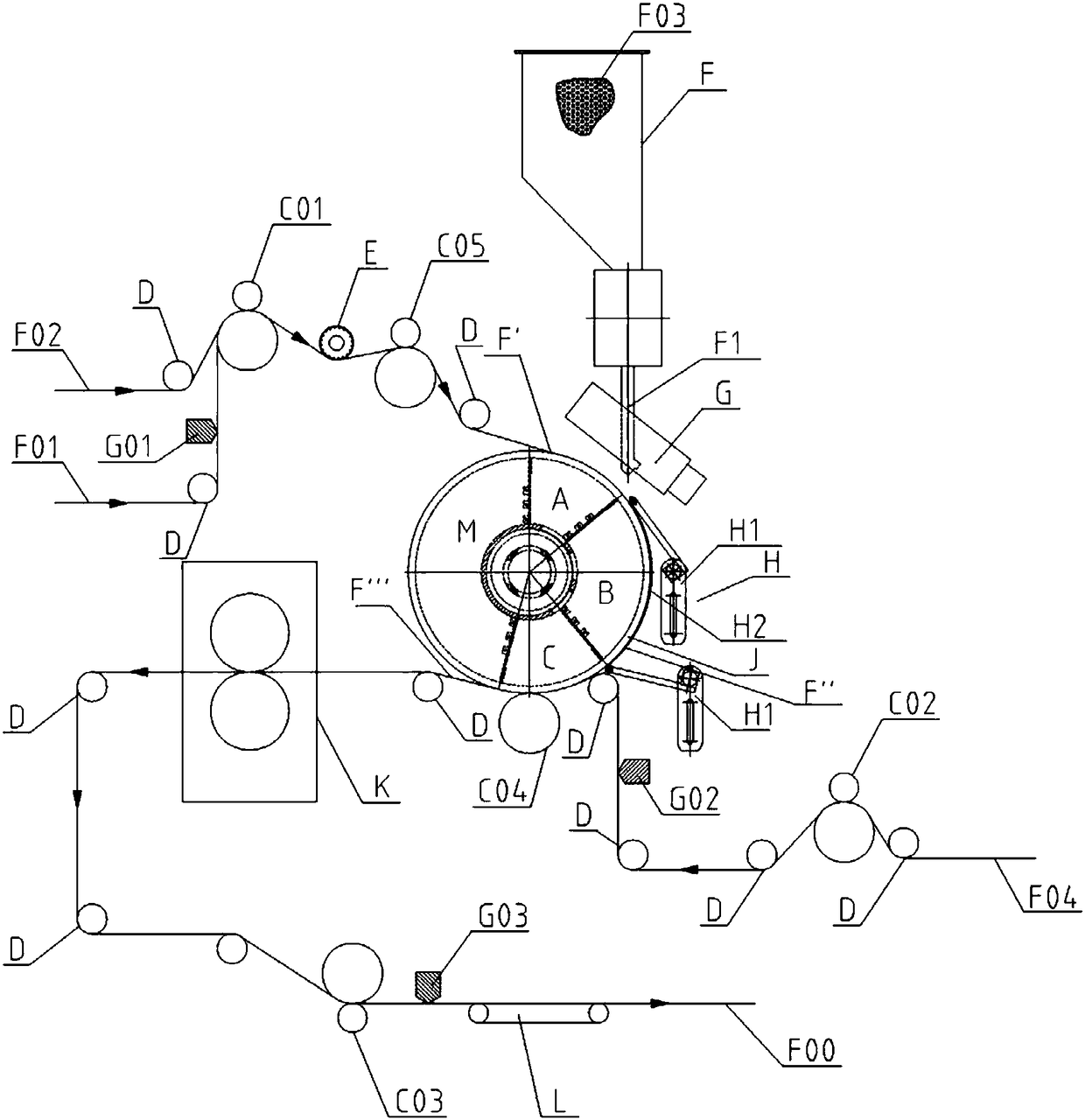

Ultrathin composite core product and production system thereof

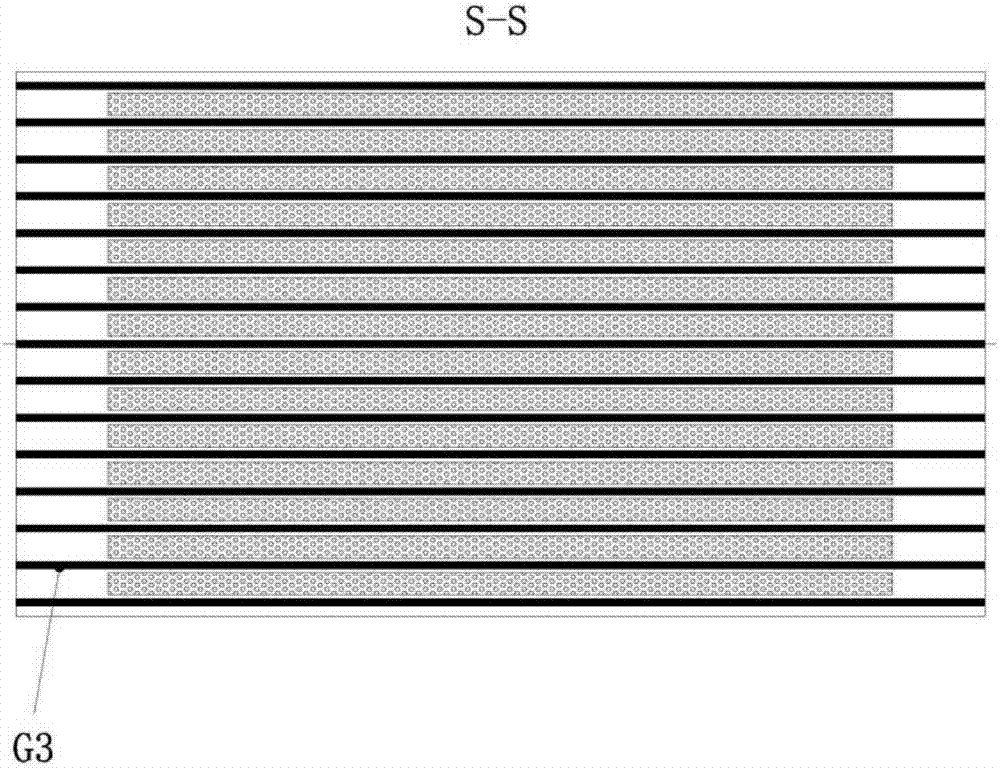

ActiveCN107280864AGood diversion and diffusion performancePromote absorptionAbsorbent padsBaby linensCore productReverse osmosis

The invention discloses an ultrathin composite core product, and a composite core comprises a hot-blast nonwoven, a fluffy hot-blast nonwoven, a polymer absorbent material and a cladding nonwoven which are successively laid from top to bottom. A production system for producing the ultrathin composite core product comprises a plurality of clamping driving rolls, a polymer feeding device, a composite drum device and a cladding device; the clamping driving rolls are disposed at the upstream side or downstream side of the composite drum device; the hot-blast nonwoven and the fluffy hot-blast nonwoven are gradually conveyed to the composite drum device after being clamped by a first pressing roll; a discharge port of the polymer feeding device is disposed at a product composite position on the composite drum device; the cladding nonwoven is gradually conveyed to the composite drum device; and a composite core is formed after a product composited by the composite drum device is claded by the cladding device. Compared with the prior art, the ultrathin composite core product has the advantages of good diversion diffusion performance, excellent absorption property, fast permeability speed and small reverse osmosis amount.

Owner:ZUIKO (SHANGHAI) CORP

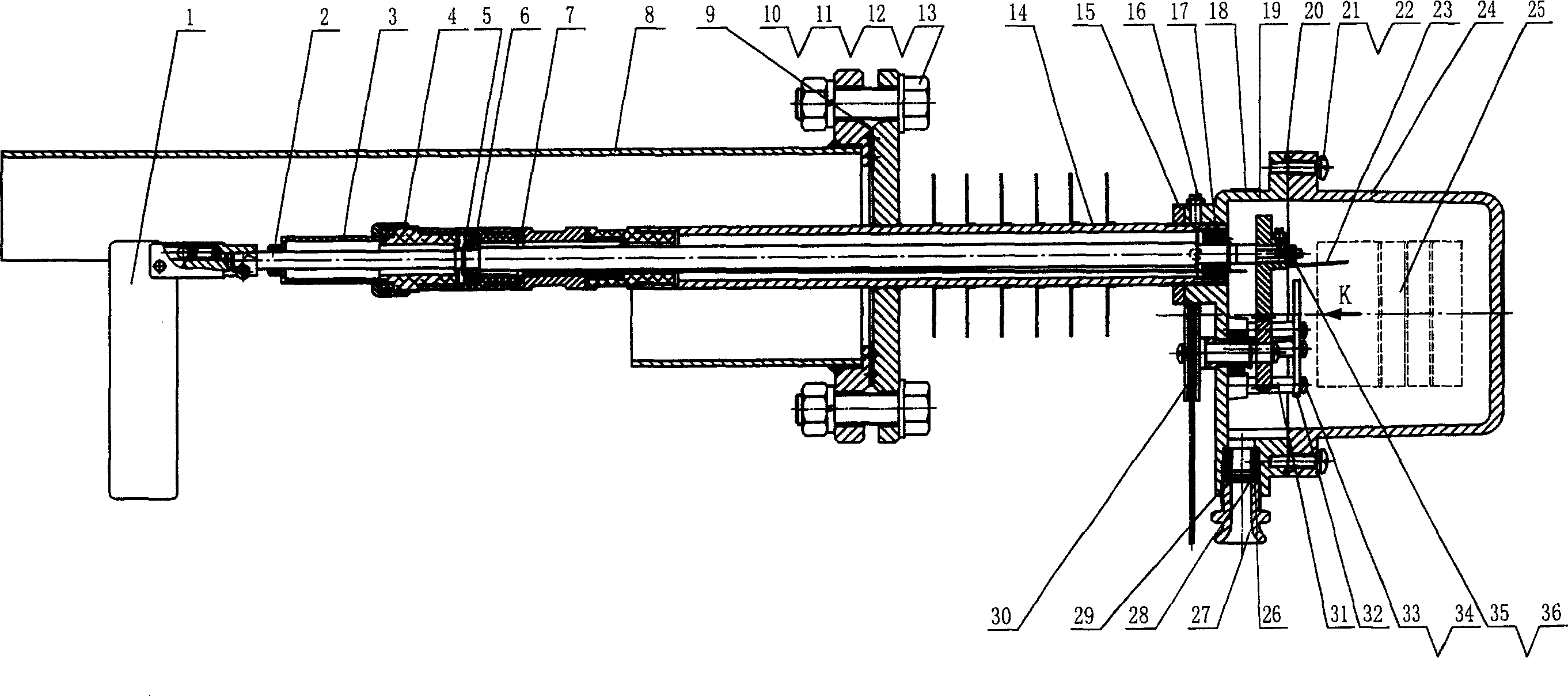

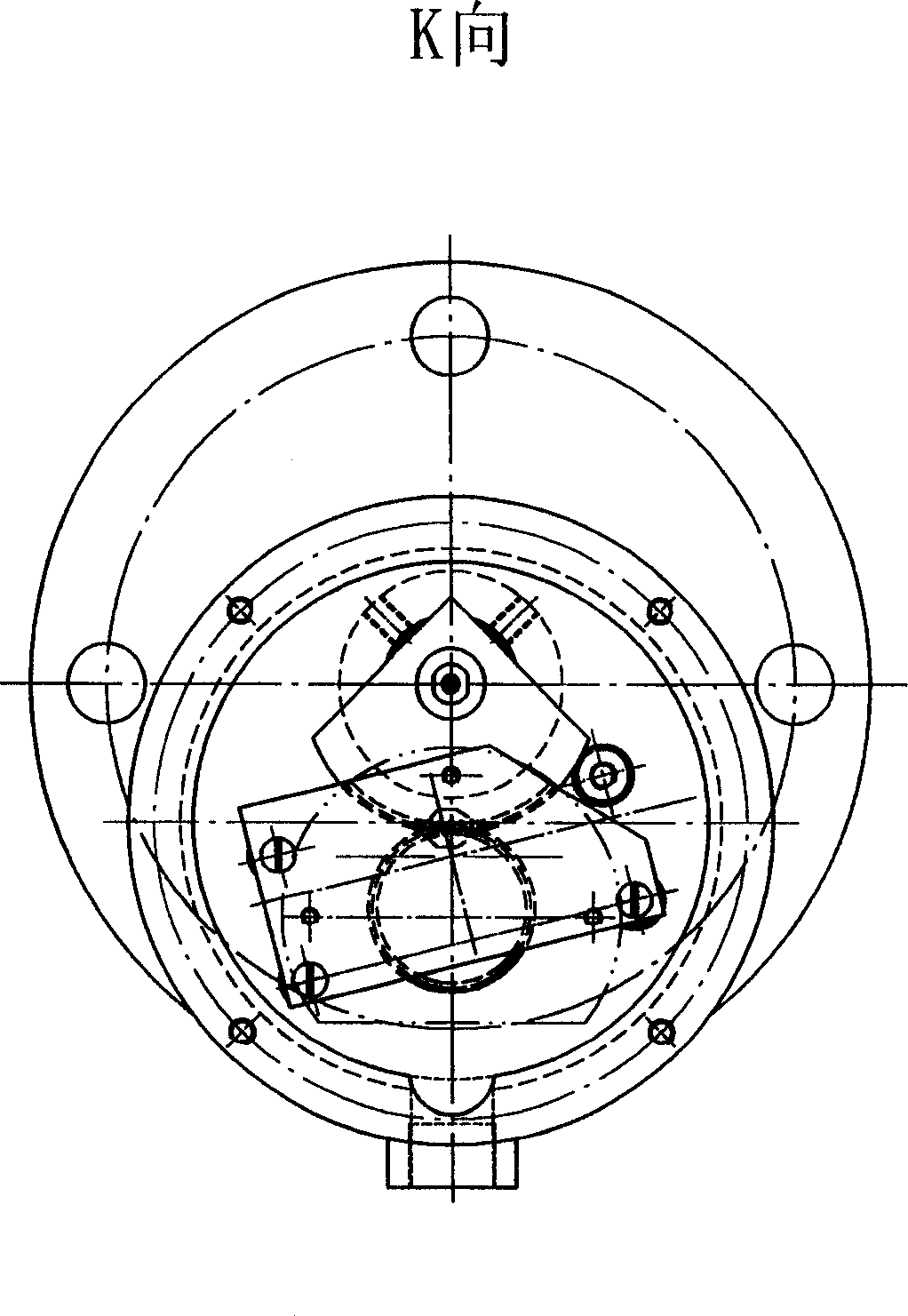

Novel composite position controller

InactiveCN1821917AImprove reliabilityEasy maintenanceLevel controlMachines/enginesTuning forkEngineering

This invention relates to a new type of compound position controller including a test board component, a master shaft, a sealing component, a compound detection pole component, a screen leading component, a protecting cover component, a beam barrel, a base seat, a detection pole lead, a top cover, a CB component and a manual component, in which, the insulation connector of the compound detection pole component is screwed in the beam barrel to be fastened, a screen pole is screwed on the bearing jacket of the compound detection pole compound and the bearing jacket is screwed on the casing cap of the compound.

Owner:杜国凯

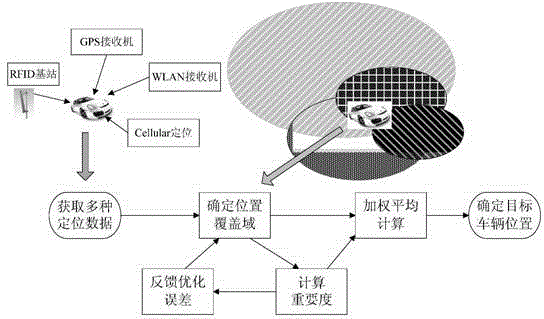

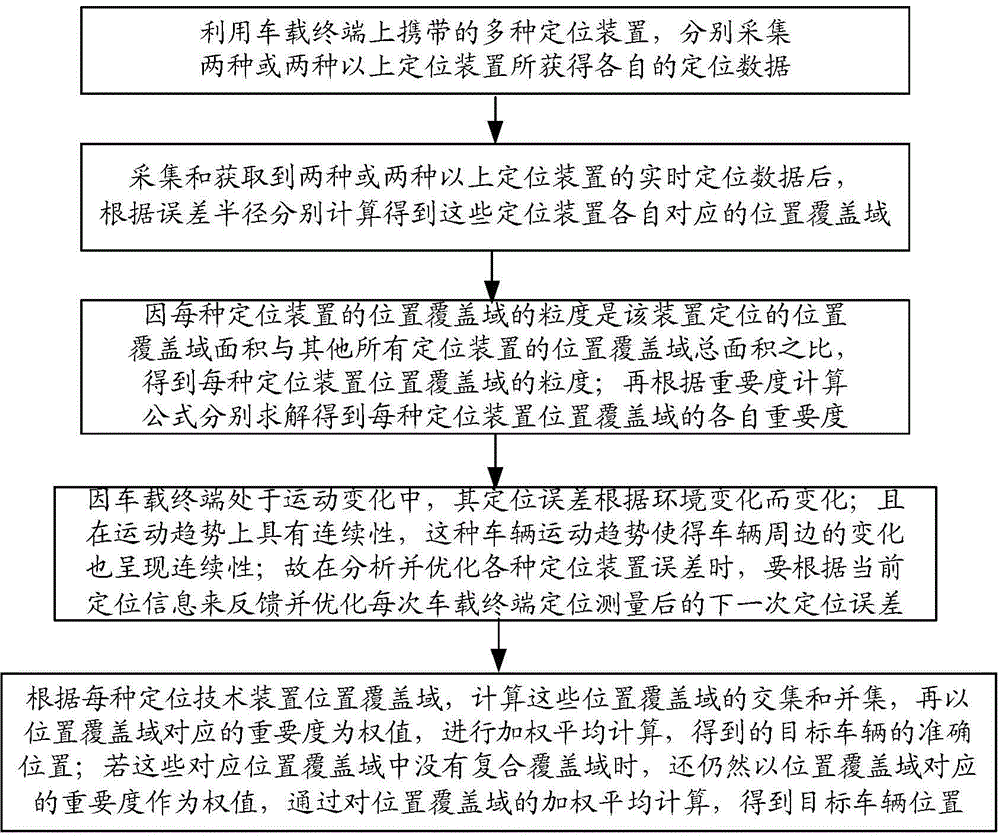

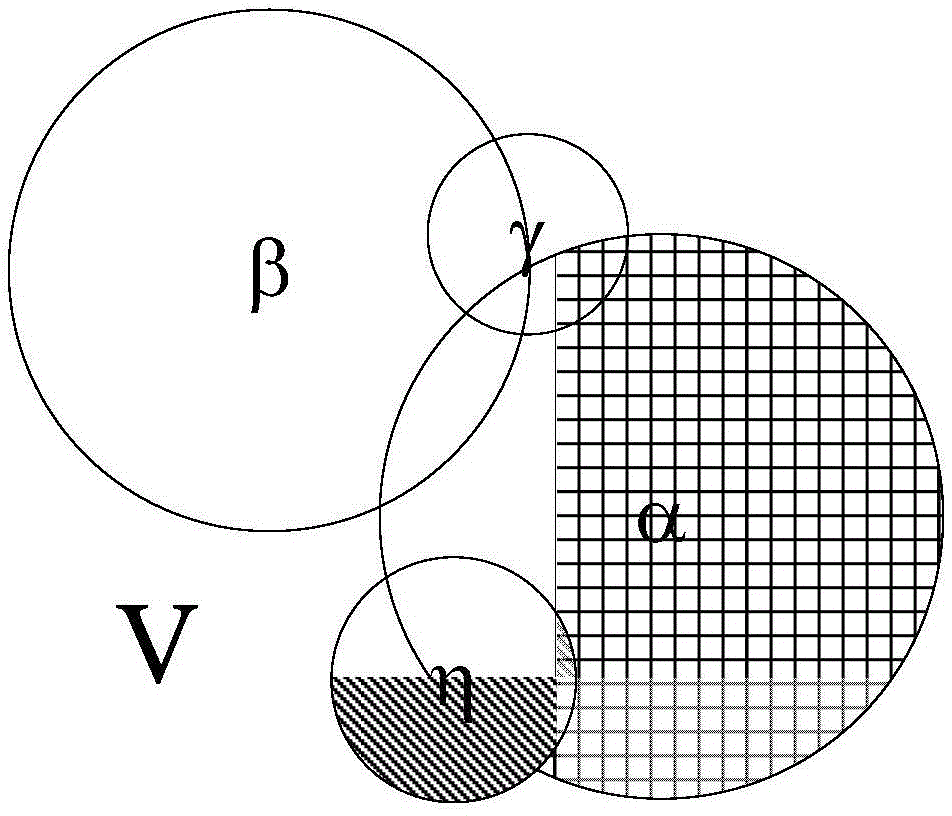

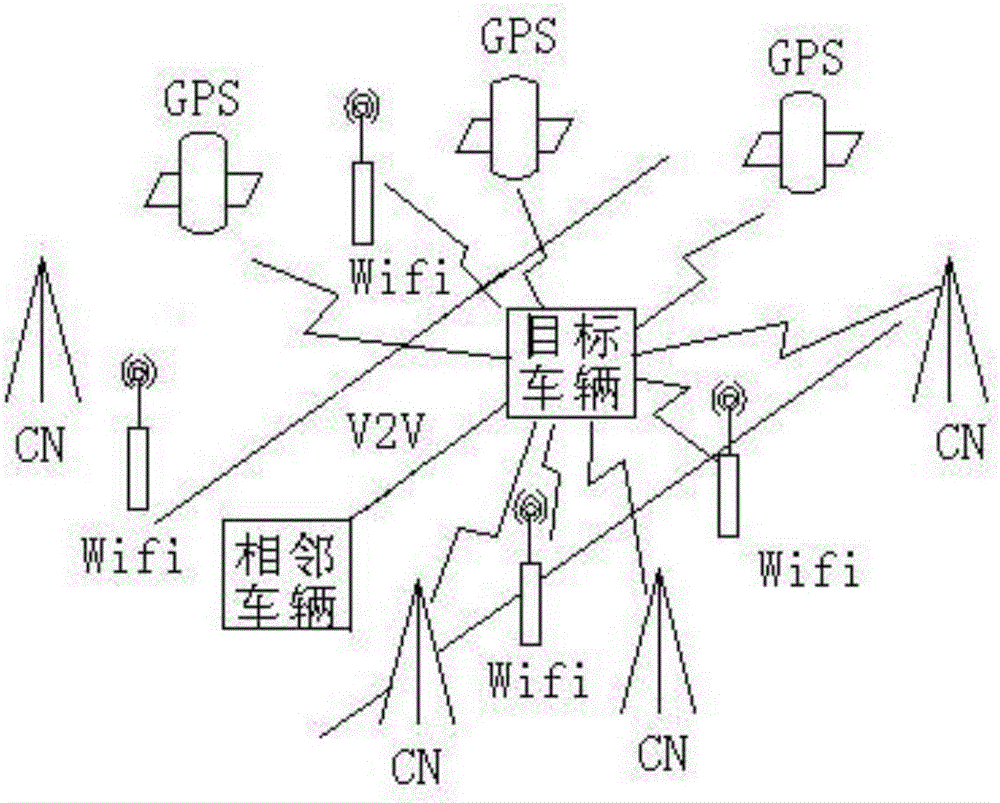

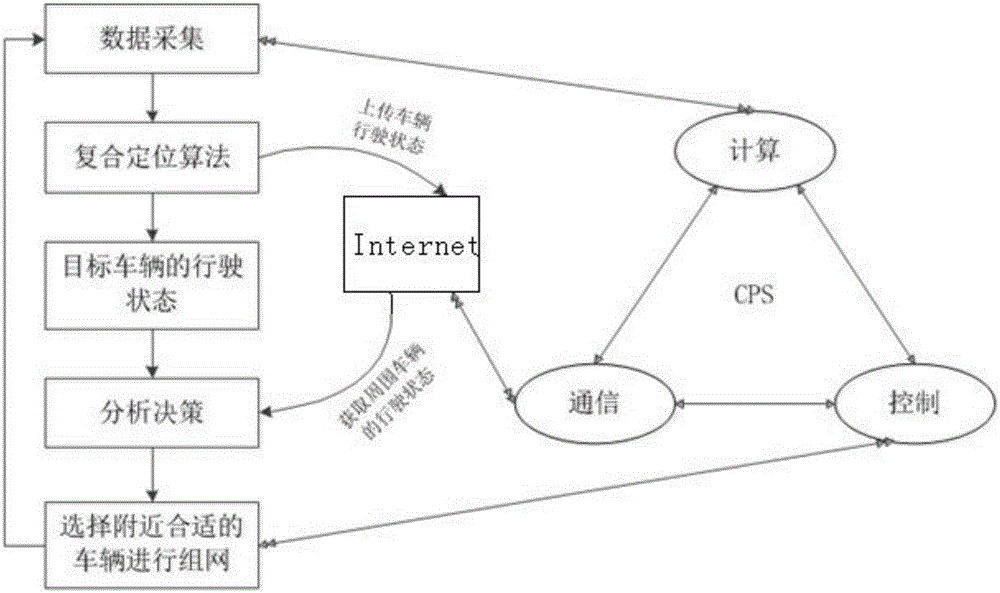

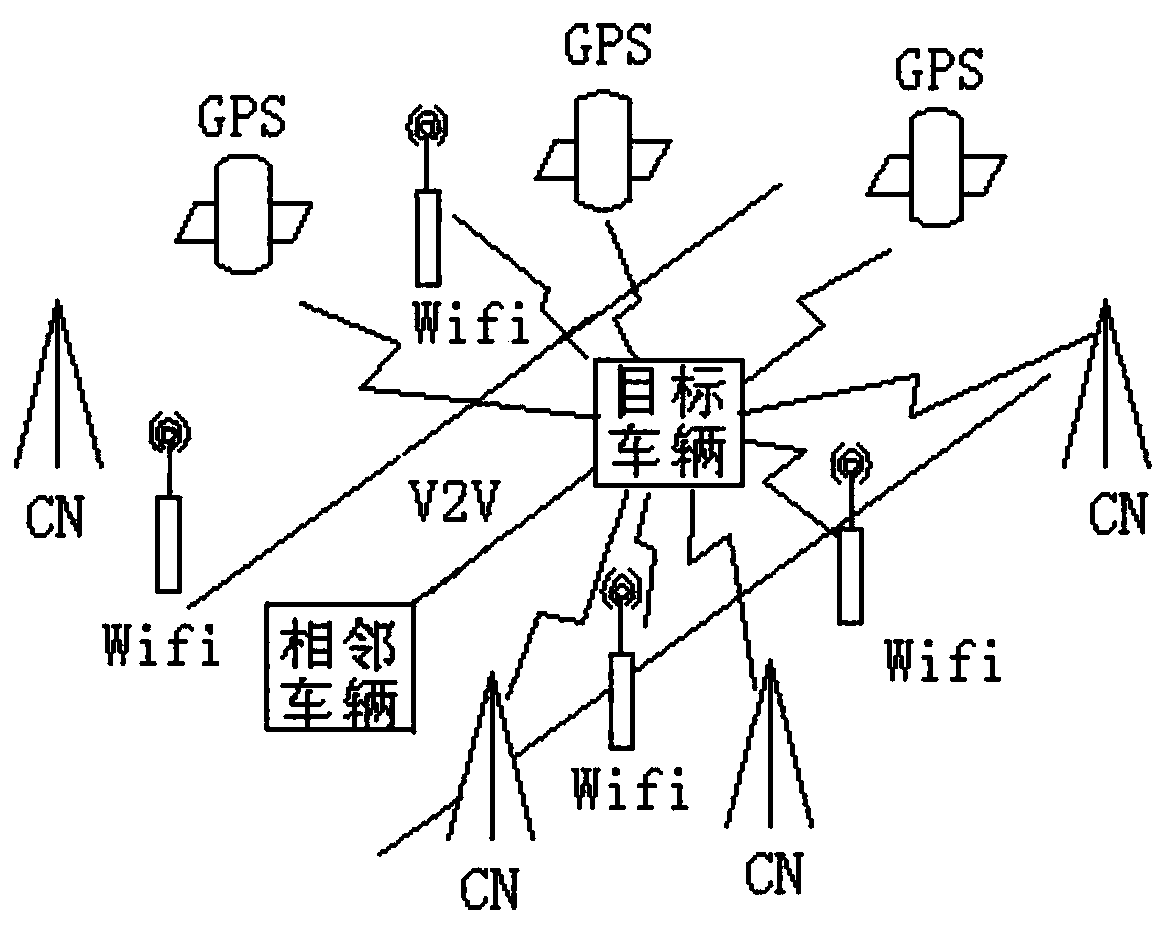

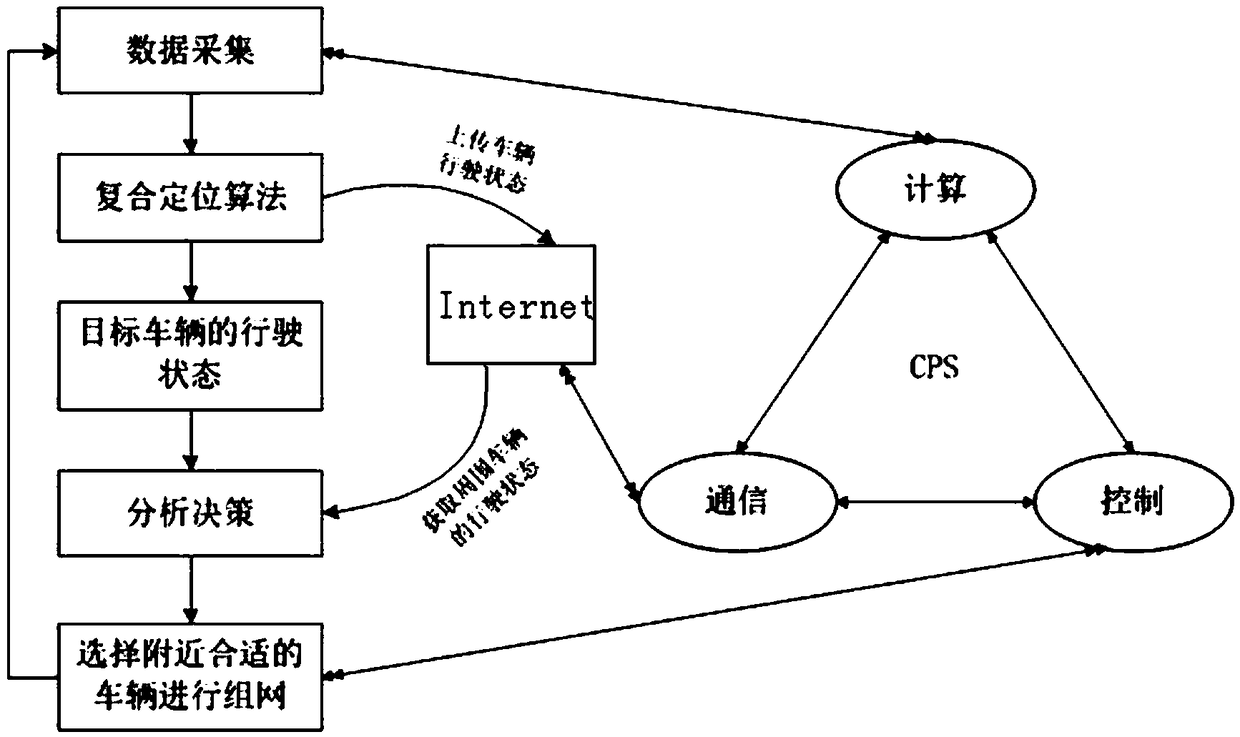

Variable importance degree-based vehicle real time positioning method

ActiveCN104132666AGuaranteed accuracyImprove rationalityInstruments for road network navigationPositioning technologyComposite Position

A variable importance degree-based vehicle real time positioning method comprises the following steps: obtaining respective positioning data of a variety of positioning technology devices on a vehicle terminal, and determining the position covering domains of a variety of positioning technologies through the error degree of each of the positioning technologies; analyzing and calculating the importance degree of each of the position covering domains of the positioning technologies according to an importance degree process, and optimizing the error degrees of the positioning technologies with the change of the importance degree as feedback; and carrying out weighted average calculation with each of the importance degrees of the position covering domains as the weight of a composite position domain to obtain the real time accurate position of a target vehicle. The method fusing the variety of vehicle positioning technologies and using the each of the importance degrees of the position covering domains as the weight during weighted average calculation improves the positioning technology fusion rationality. The variable importance degree-based vehicle real time positioning method has the advantages of simple operation steps, strong real time, use in different environments, high positioning calculation accuracy, small calculation amount, suitableness for a variety of positioning devices in a vehicle network, easy popularization and wide application.

Owner:BEIJING UNIV OF POSTS & TELECOMM

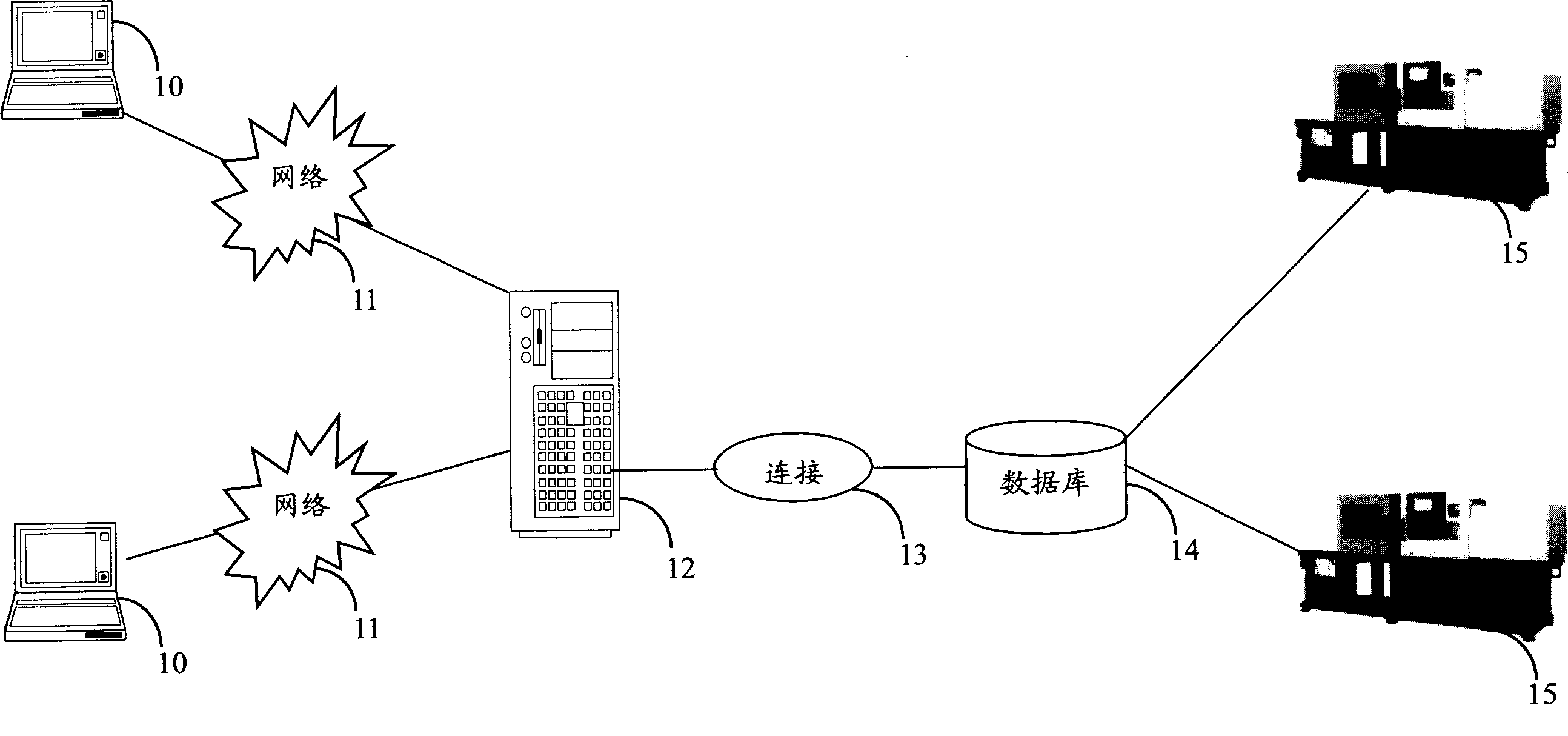

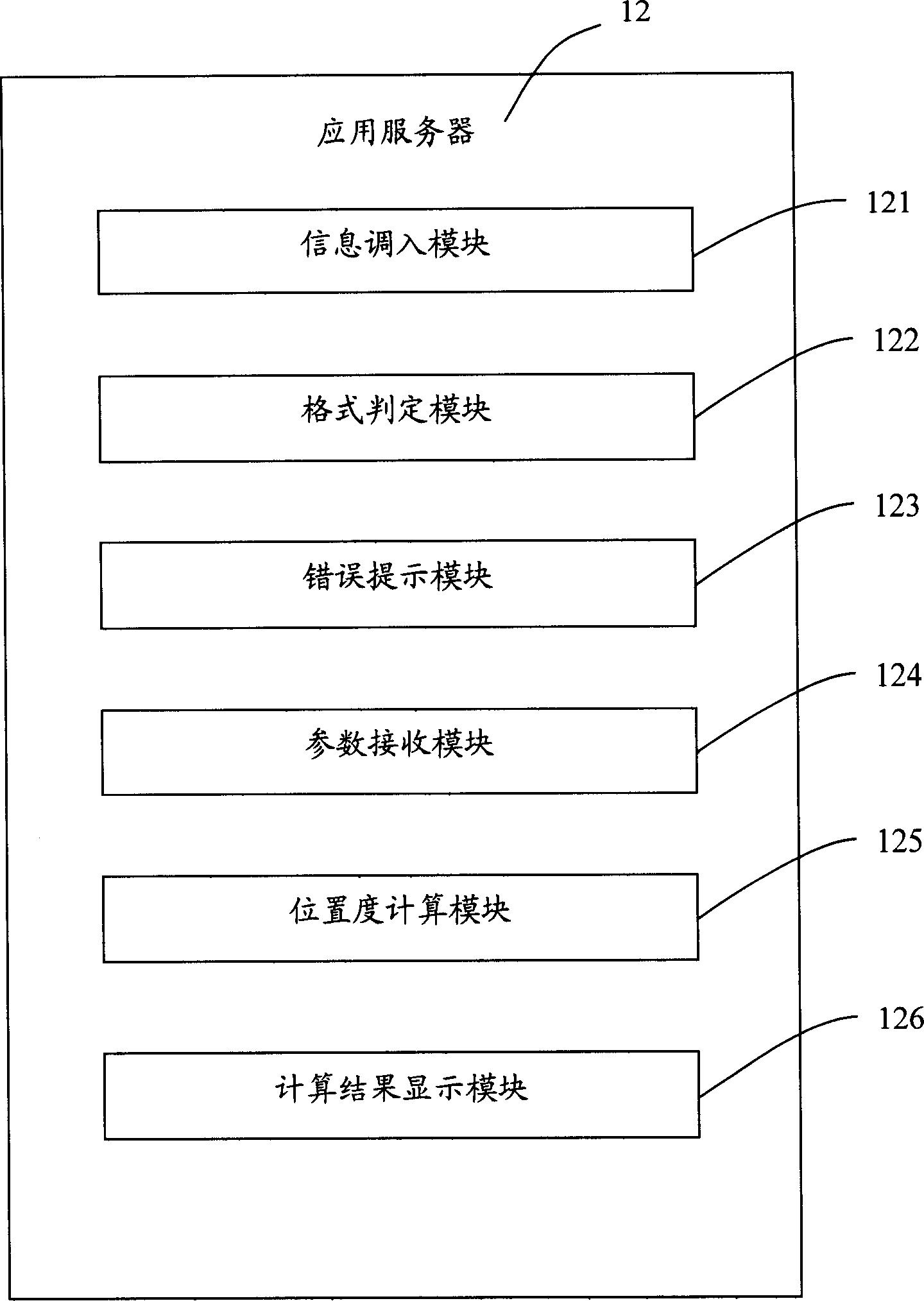

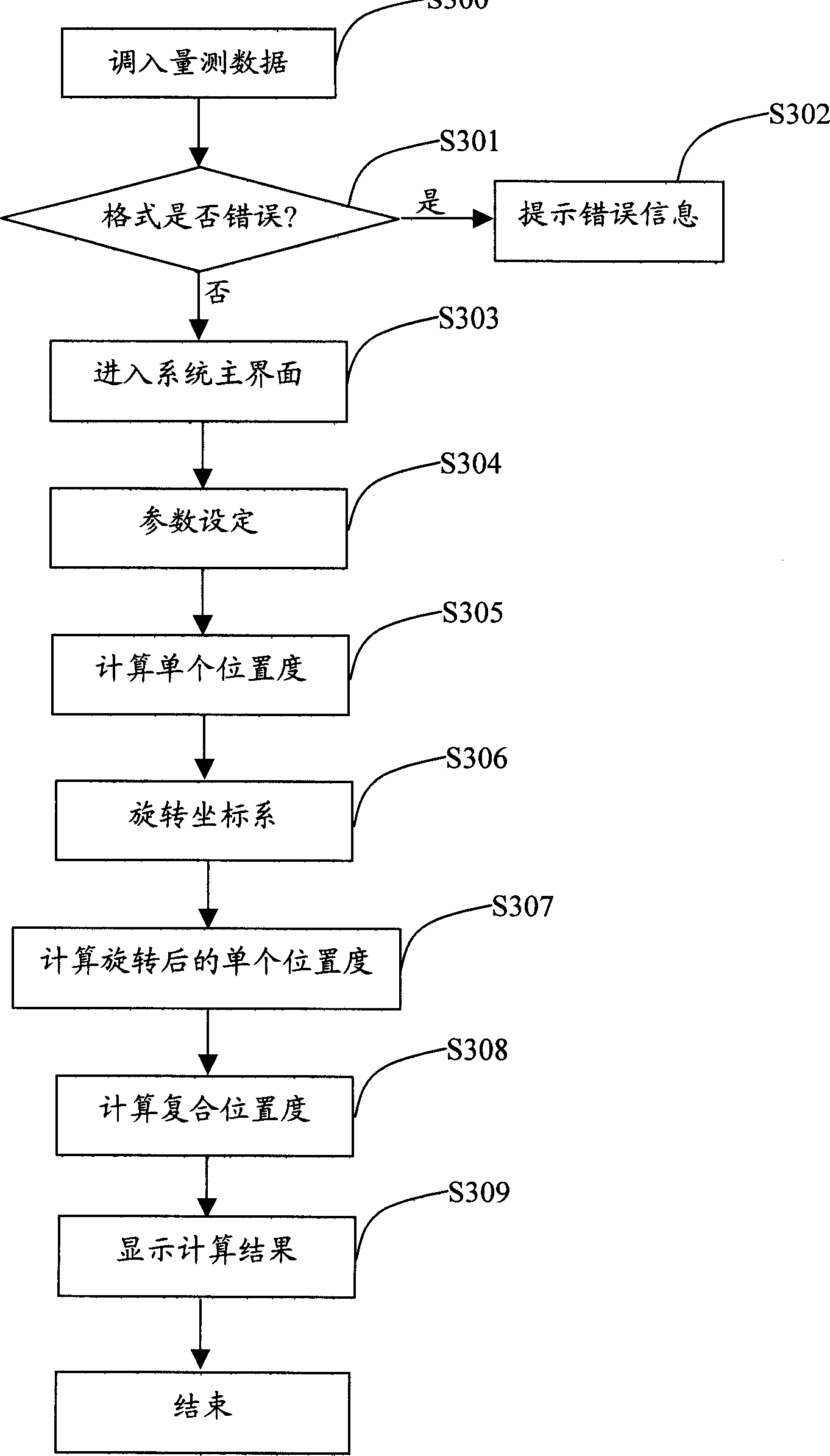

Complex position degree computing system and method

InactiveCN1773213ANo need to makeImprove calculation accuracyMeasurement devicesApplication serverClient machine

The present invention provides a complex position degree computing system and its method. Said system includes several customer terminal computers, an application server, a data base and several measurement instruments. The customer terminal computer can be used for providing an operation interface for user and dynamically displaying system operation state. The application server includes several software function modules for calling measuring information, receiving position degree computing parameter and computing complex position degree, and the data base is used for storing various data used or produced in the complex position degree computing process, including the information of measuring information, format standard, position degree theoretical value and allowable tolerance, etc.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

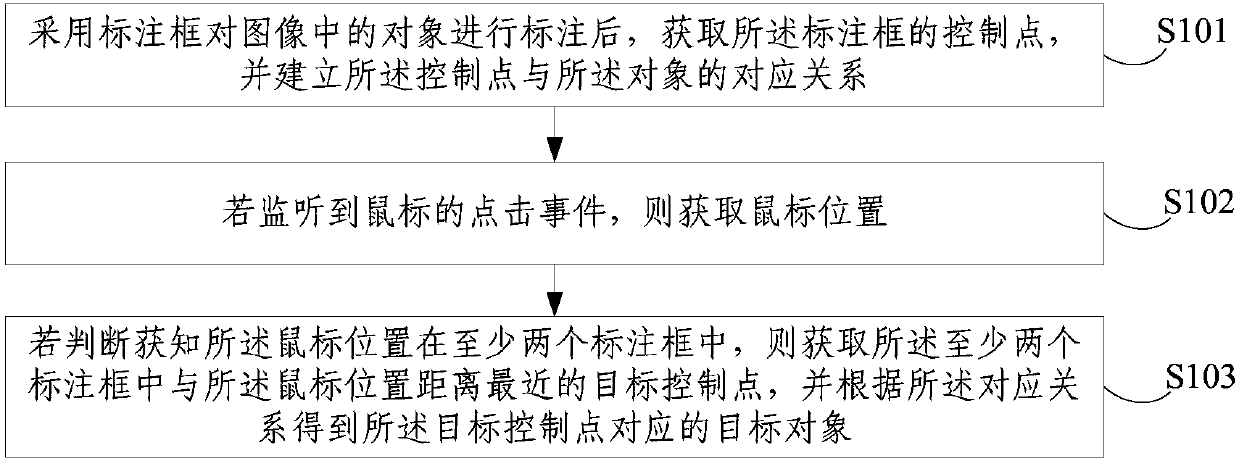

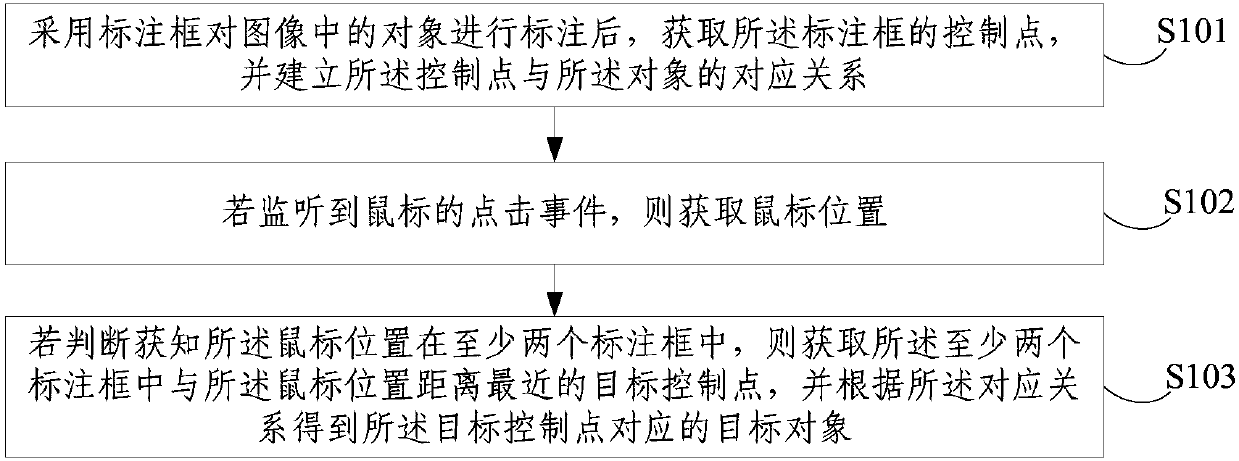

Tagged object control method

InactiveCN107704162AReduce the number of interactionsThe labeling process is simpleCharacter and pattern recognitionExecution for user interfacesPattern recognitionTarget control

An embodiment of the invention discloses a tagged object control method. The method comprises the steps of performing tagging on objects in an image by adopting tagging boxes, obtaining control pointsof the tagging boxes, and establishing corresponding relationships between the control points and the objects; if a clicking event of a mouse is monitored, obtaining a mouse position; and if it is judged that the mouse position is in at least two tagging boxes, obtaining a target control point closest to the mouse position in the at least two tagging boxes, and according to the corresponding relationships, obtaining a target objet corresponding to the target control point. The mouse position is obtained after the clicking event of the mouse is monitored; the target control point closest to the mouse position is calculated; and according to the corresponding relationships between the control points and the objects, the target object corresponding to the target control point is obtained, sothat the target object can be determined according to the mouse clicking position, the interactive frequency of a tagging tool and a user is reduced, the tagging process is simpler, and the tagging time is shortened.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

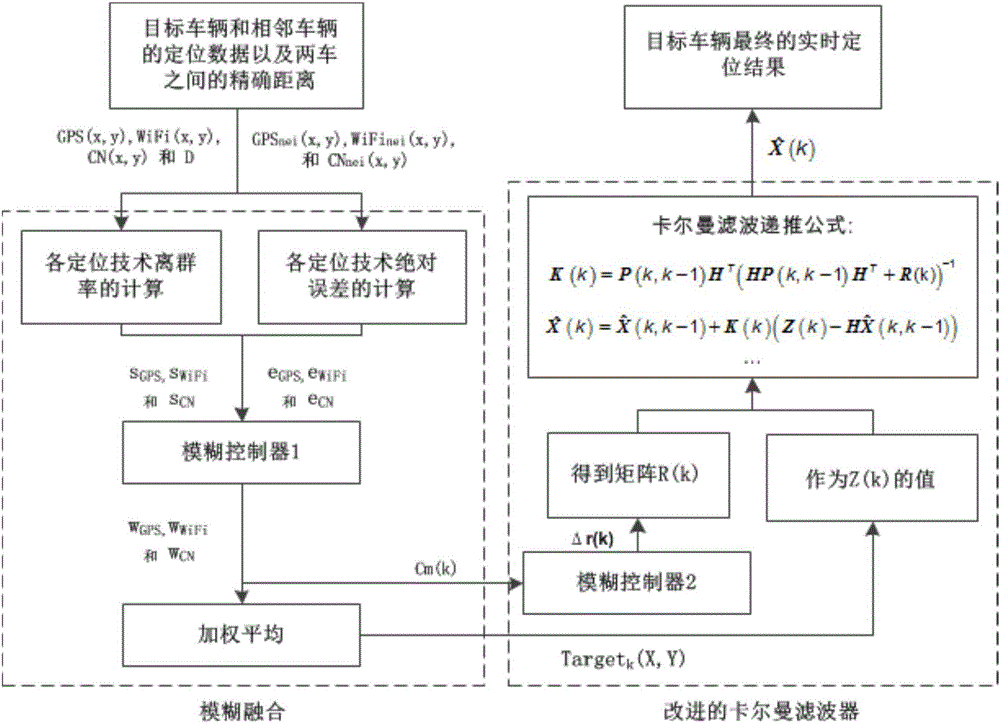

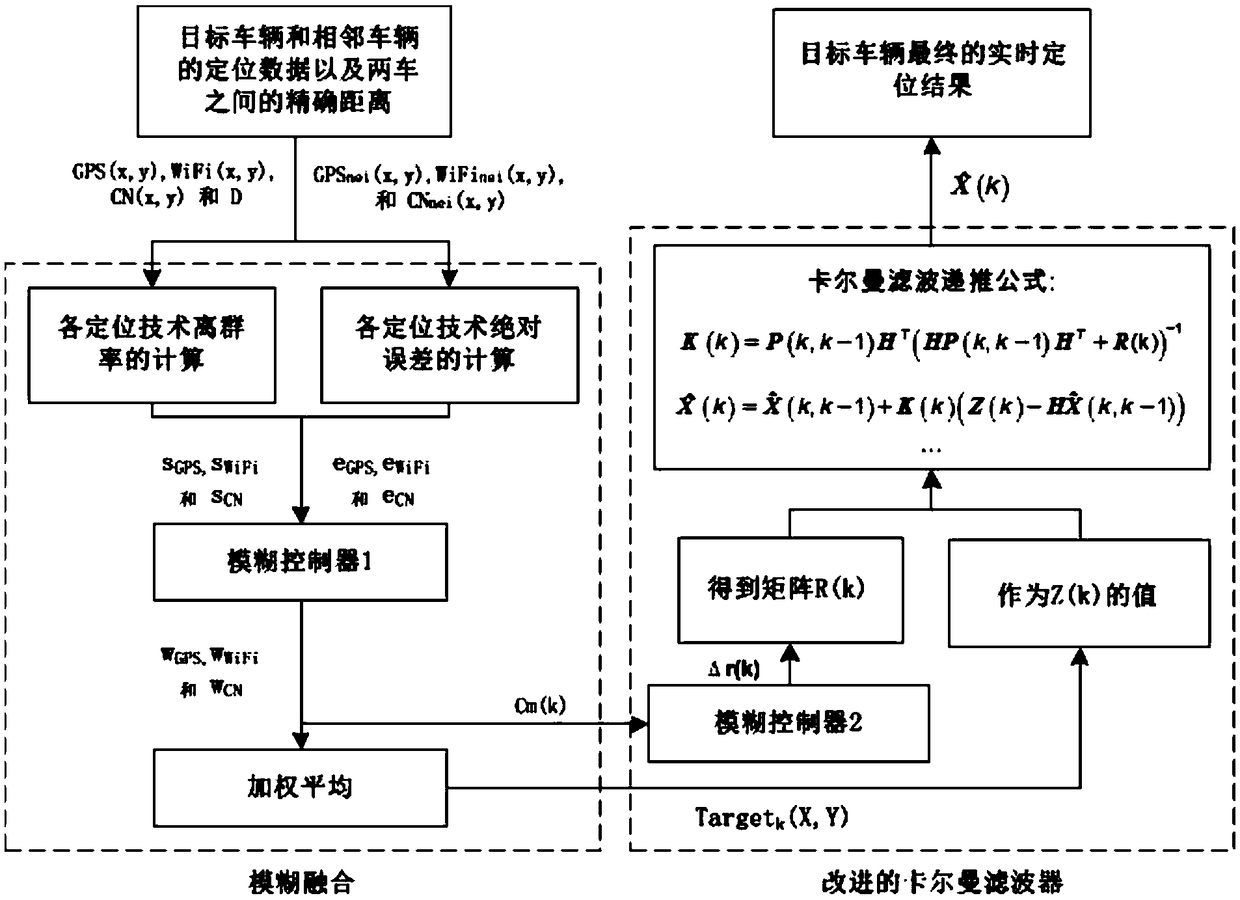

New compound positioning method based on fuzzy theory

ActiveCN106772516AImprove rationalityImprove accuracySatellite radio beaconingKaiman filterCovariance

The invention relates to a new compound positioning method based on fuzzy theory, belonging to the technical field of vehicle positioning. Based on vehicle cyber physical system technology, the positioning data of three positioning devices in a target vehicle and an adjacent vehicle is used, the error of each positioning technology is optimized by using the fuzzy theory and the positioning contribution of each positioning technology is obtained, and then with the positioning contribution as a weight, the fuzzy weighted calculation is carried out to obtain the composite position of the target vehicle. A Kalman filter of fuzzy variable measurement noise covariance is used to filter a composite position. According to the method, multiple vehicle positioning technologies are fused, two indexes of an outlier rate and an absolute error are constructed to reflect the reliability degree of each positioning technology, the rationality of positioning technology fusion is improved, at the same time, an improved Kalman filter is used to filter a fusion result, and the accuracy of positioning is improved.

Owner:HUNAN UNIV

Online composite process system and composite core product

PendingCN108608689ALarge amountTake into account absorbencyLamination ancillary operationsPersonal careSurface layerCore product

The invention discloses an online composite process system and a composite core product. The online composite process system comprises a composite drum device, a first semifinished product and a highmolecular material are composited at a first composite position of the composite drum device, a second semifinished product is formed after compositing, and a high molecular material supply device isarranged at a material receiving position of the composite drum device; a clamping and pressing roller is arranged at a downstream workstation of a second composite position of the composite drum device, a third semifinished product is arranged between the clamping and pressing roller and the composite drum device, and a coating device is arranged at a downstream workstation of the clamping and pressing roller and coats the third semifinished product to form a composite core. The composite core product comprises coating nonwoven cloth, fluffy nonwoven cloth, a high molecular material and a covering layer sequentially from bottom layer to surface layer. The online composite process system is high in production efficiency, negative pressure in the composite drum device can be utilized to suck macromolecule granules into the fluffy nonwoven cloth to be sufficiently mixed with the same, and product thickness is lowered effectively; the product prepared by the system is free of faultage, humping and hardening when expanding and high in quality and wearing comfort.

Owner:ZUIKO (SHANGHAI) CORP

Soft package power lithium ion battery cathode pole ear structure and preparation method

ActiveCN103178232AReduce contact resistanceEasy to weldCell component detailsElectrical batteryCopper

The invention discloses a soft package power lithium ion battery cathode pole ear structure and a preparation method, a pole ear base material is a copper strip with copper content of more than 99.99%; the pole ear is locally coated, and a pole ear glue with a multilayer structure is coated on an uncoated part of the pole ear. The prepared cathode pole ear can avoid the hidden trouble that a chronic corrosion leakage liquid is generated at a bimetallic composite position, the yield and consistency of cell production can be further enhanced, and the usage life of the cell can be simultaneously increased. The preparation method of the invention enables convenient operation, can realize large-scale production, and has the advantages of environmental protection and strong feasibility.

Owner:WANXIANG 123 CO LTD

Insulating and decorating composited board production technique and line

InactiveCN103206056AAutomated productionAutomated continuous productionCovering/liningsCeramic shaping apparatusProduction lineComposite Position

The invention discloses insulating and decorating composited board production technique and line. The production technique includes an insulating board production technique and a decorating board production technique. The production line comprises an insulating board production line and a decorating board production line. The insulating board production line sequentially comprises an automatic mixing platform, an insulating board production field, a cutting machine, a steam reactor and an insulating board positioning machine. The decorating board production line sequentially comprises an unrolling machine, a decorating board forming machine and a scraping machine. An output end of an insulating board conveying belt is correspondingly arranged above a decorating board conveying belt. The lap joint of the insulating board conveying belt forms at the composited position of an insulating board and a decorating board. Production process of insulating boards and decorating boards is designed into an automatic continuous production mode, automatic and accurate compositing of the insulating boards and the decorating boards which are finished is realized, and production ways of insulating and decorating composited boards are continuous and automatic. Compared with the production efficiency of the existing manual operation ways, production efficiency of the insulating and decorating composited boards is greatly improved, and production cost is reduced.

Owner:张晓武

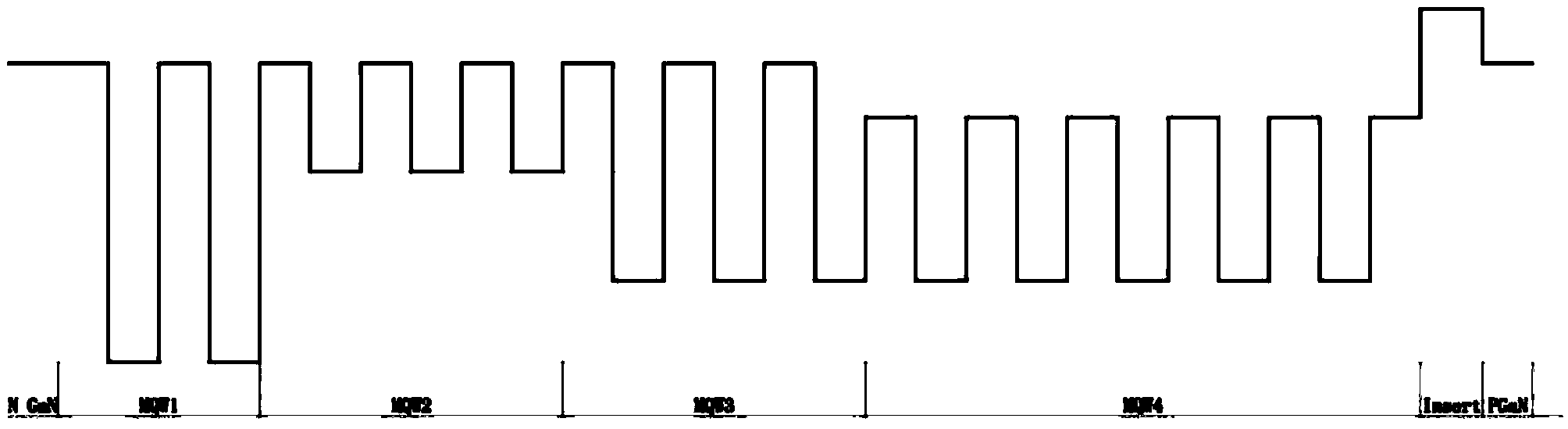

Multiple quantum well structure of high-brightness LED

InactiveCN103594573AImprove compound efficiencyReduce migration speedSemiconductor devicesElectron holeBrightness perception

The invention provides a multiple quantum well structure of a high-brightness LED to improve the whole performance of devices. The multiple quantum well structure comprises four multiple quantum well layers, the forbidden bandwidth of quantum wells in the first multiple quantum well layer is smallest, the forbidden bandwidth of quantum wells in the second multiple quantum well layer is largest, and the forbidden bandwidth of quantum wells in the third multiple quantum well layer and the forbidden bandwidth of quantum wells in the fourth multiple quantum well layer are between the forbidden bandwidth of the quantum wells in the first multiple quantum well layer and the forbidden bandwidth of the quantum wells in the second multiple quantum well layer. The forbidden bandwidth of quantum bases in the fourth multiple quantum well layer is smaller than the forbidden bandwidths of quantum bases of other multiple quantum well layers and larger than the forbidden bandwidth of the quantum wells of the fourth multiple quantum well layer. The multiple quantum well structure of the high-brightness LED obviously improves the optimized results of all the aspects such as the injection efficiency of an electron hole, the migration rate, concentration distribution and the composite position, and therefore the whole performance of the devices is greatly improved.

Owner:西安利科光电科技有限公司

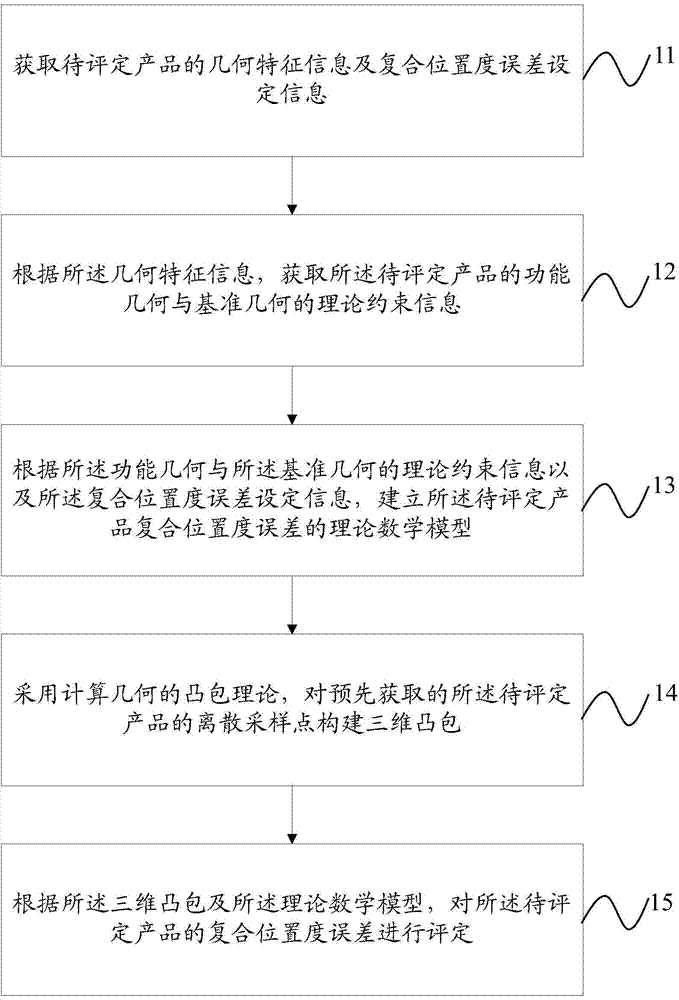

Method and device for composite position error evaluation

ActiveCN104750977AAccurate assessmentMeet the design requirementsSpecial data processing applicationsMathematical modelSimulation

The invention provides a method and device for composite position error evaluation, and relates to the field of mechanical engineering. The method and device solve the problem that in the prior art, the composite position error evaluation cannot be achieved accurately. The method for the composite position error evaluation comprises the steps of acquiring geometrical characteristic information and composite position error setting information of a to-be-evaluated product; acquiring function geometry and benchmark geometry theory constraint information of the to-be-evaluated product according to the geometrical characteristic information; building a composite position error theory mathematical model of the to-be-evaluated product according to the function geometry and benchmark geometry theory constraint information and the composite position error setting information; performing three-dimensional convex hull construction on pre-acquired discrete sampling points of the to-be-evaluated product by adopting the convex hull theory of computation geometry; evaluating the composite position error of the to-be-evaluated product according to a three-dimensional convex hull and the theory mathematical model. According to the scheme, the accurate evaluation of the composite position error is effectively achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

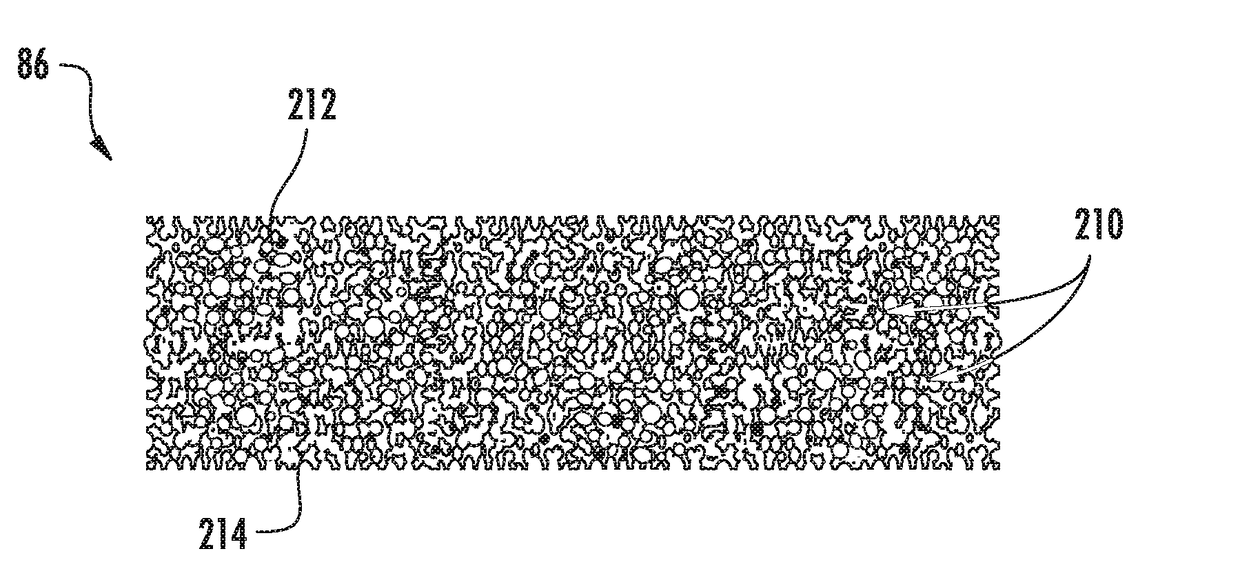

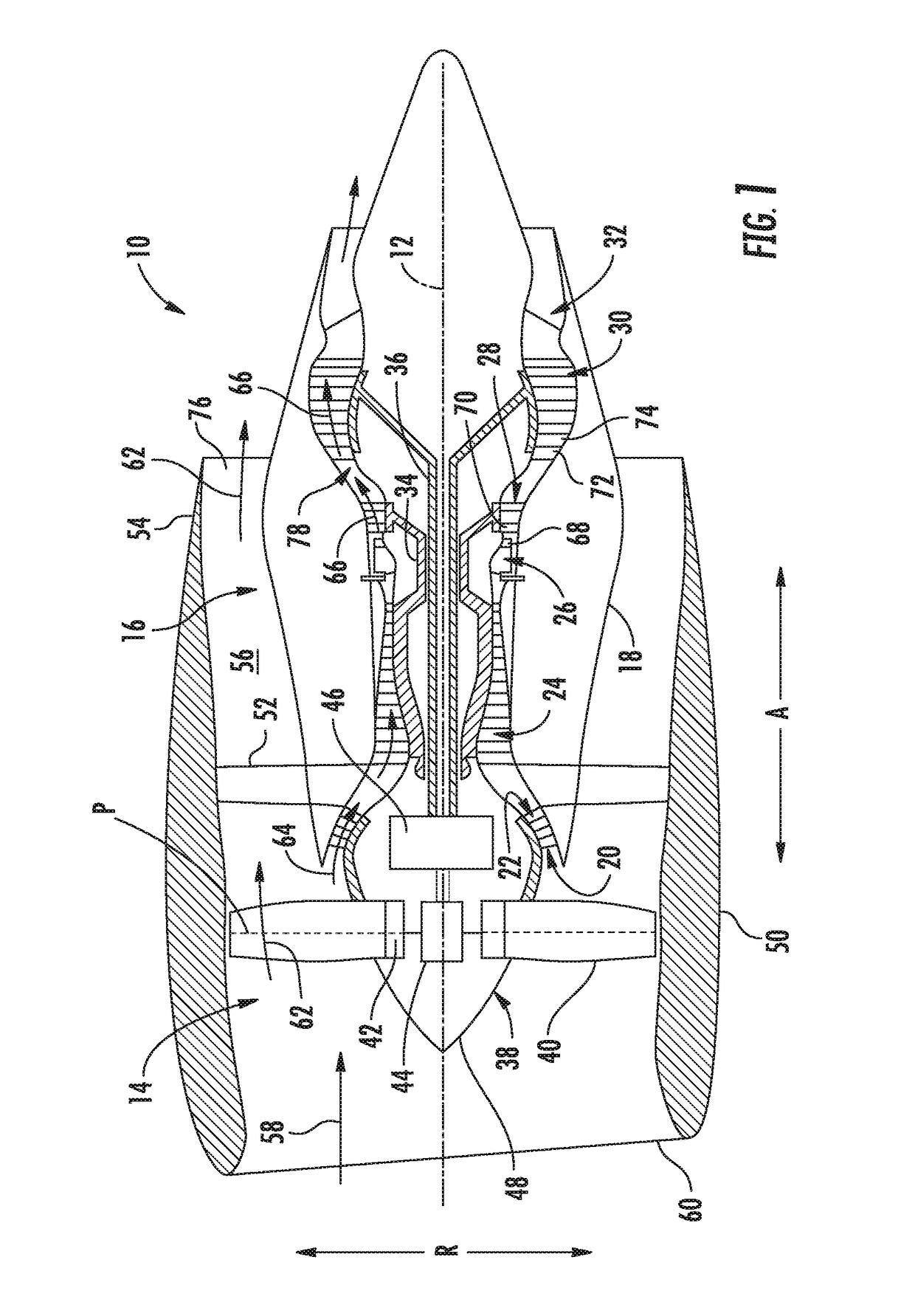

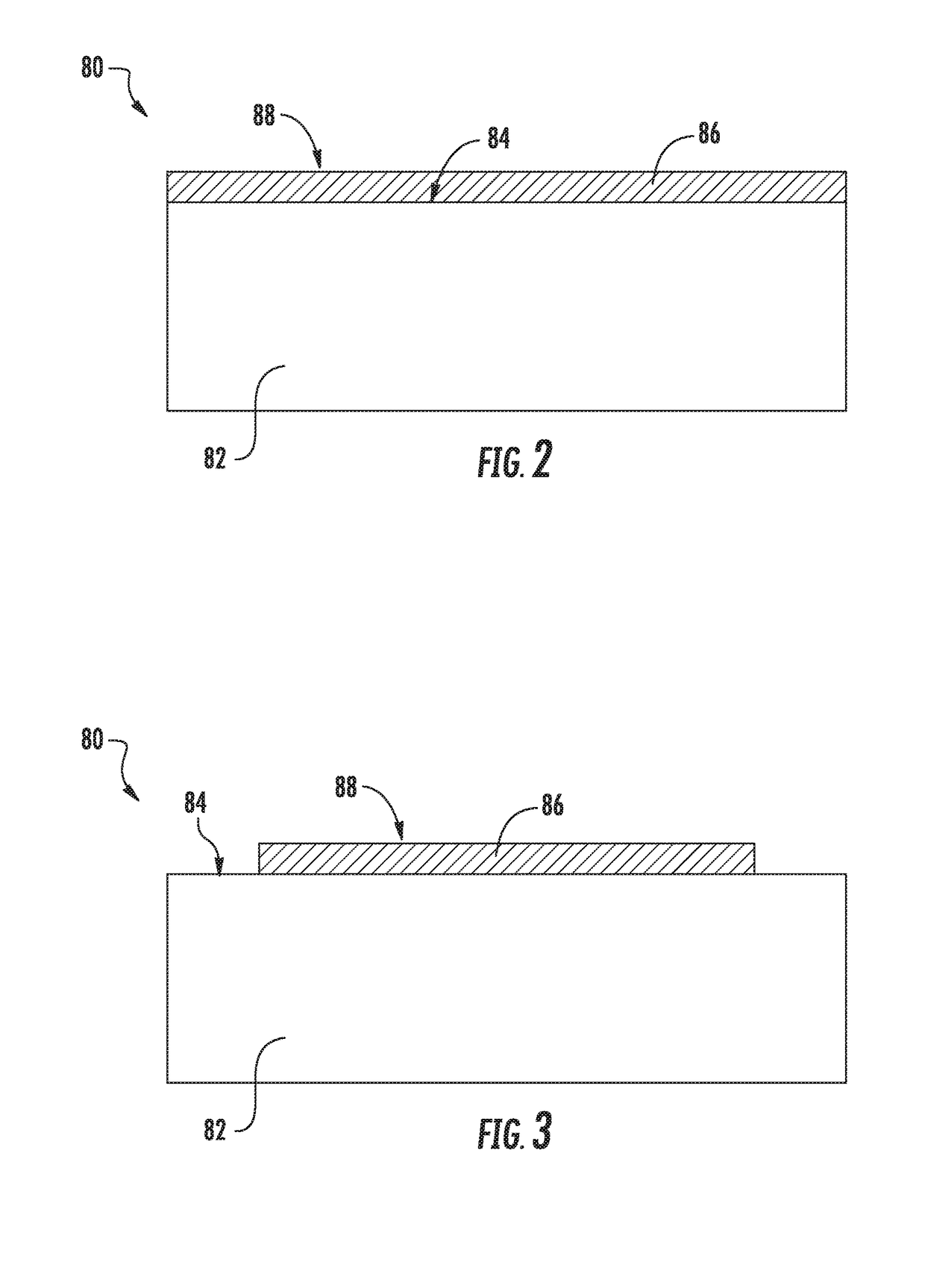

Foam based non-newtonian materials for use with aircraft engine components

An engine component for a turbine engine is provided. The engine component can include a substrate defining a surface, and an energy absorbing composite positioned on the surface of the substrate or within the substrate. The energy absorbing composite includes a shear thickening fluid distributed through a solid foamed synthetic polymer matrix.

Owner:GENERAL ELECTRIC CO

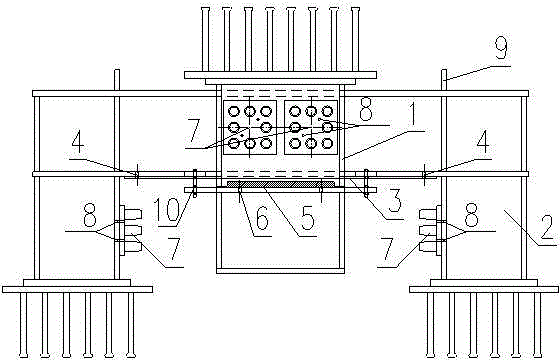

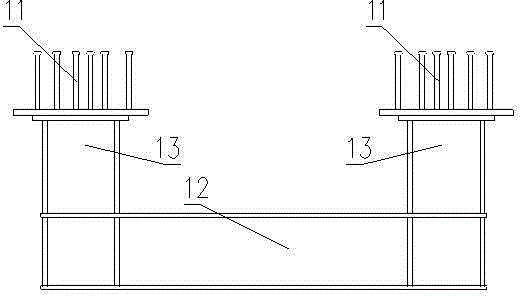

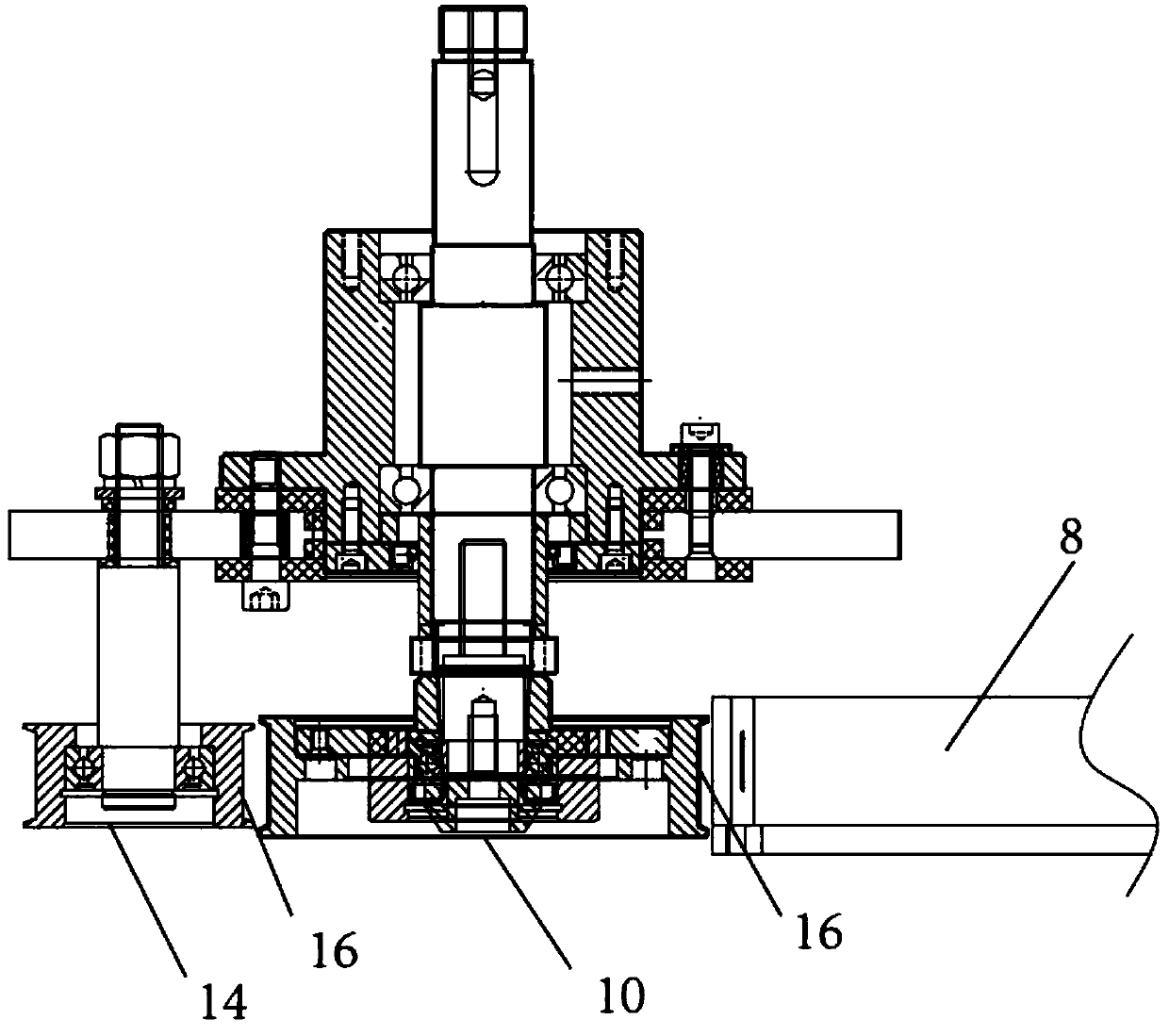

Three-direction composite position limiting device

PendingCN104313995AReduce volumeEasy to installBridge structural detailsBridge erection/assemblyEngineeringComposite Position

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Annotation object control device

InactiveCN107704163AReduce the number of interactionsThe labeling process is simpleCharacter and pattern recognitionInput/output processes for data processingTarget controlComposite Position

The embodiment of the invention discloses an annotation object control device. According to the device, after annotation boxes are adopted to annotate objects in an image, control points of the annotation boxes are acquired, and a corresponding relation between the control points and the objects is established; if a mouse clicking event is monitored, a mouse position is acquired; and if it is known that the mouse position is in at least two annotation boxes through judgment, target control points closest to the mouse position in the annotation boxes are acquired, and target objects corresponding to the target control points are obtained according to the corresponding relation. According to the embodiment, the mouse position is acquired after the mouse clicking event is monitored, the target control points closest to the mouse position are calculated, and the target objects corresponding to the target control points are obtained according to the corresponding relation between the control points and the objects. Therefore, the target objects can be determined according to the mouse clicking position, the number of interactions between an annotation tool and a user is reduced, the annotation process is simpler, and meanwhile annotation time is saved.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

Method for preventing interface oxidation of rolled metal composite plate

ActiveCN109647883AEasy accessEasy dischargeWork heating devicesAuxillary arrangementsComposite plateInterface bond

The invention discloses a method for preventing interface oxidation of a rolled metal composite plate, and belongs to the technical field of metal composite plate rolling. According to the method, toprevent interface oxidation of the rolled metal composite plate, an exhaust hole is formed in the interface composite position before heating and rolling are carried out, then a sealing plug is used for plugging the exhaust hole, so that the problem that the interface bonding strength of the composite plate is reduced due to the decline of the interface bonding rate caused by the fact that air between composite interfaces is heated and expanded in the heating and rolling process of the composite plate; and the method has the advantages of being simple in structure, reasonable in design and easy to operate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

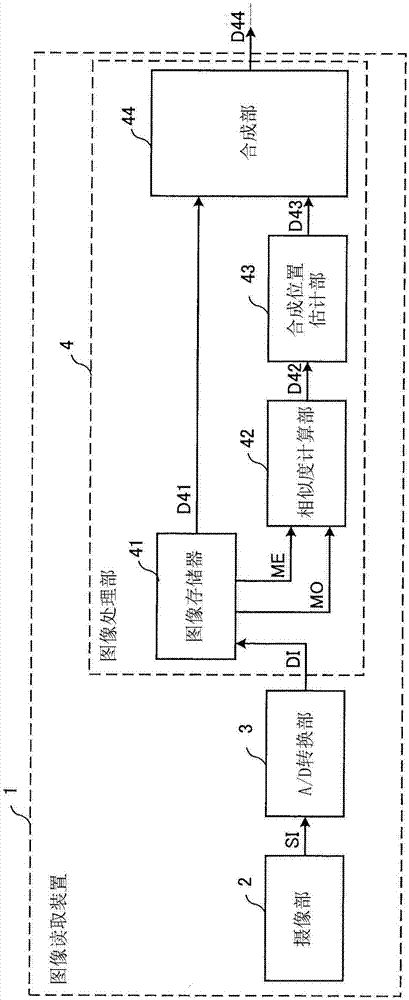

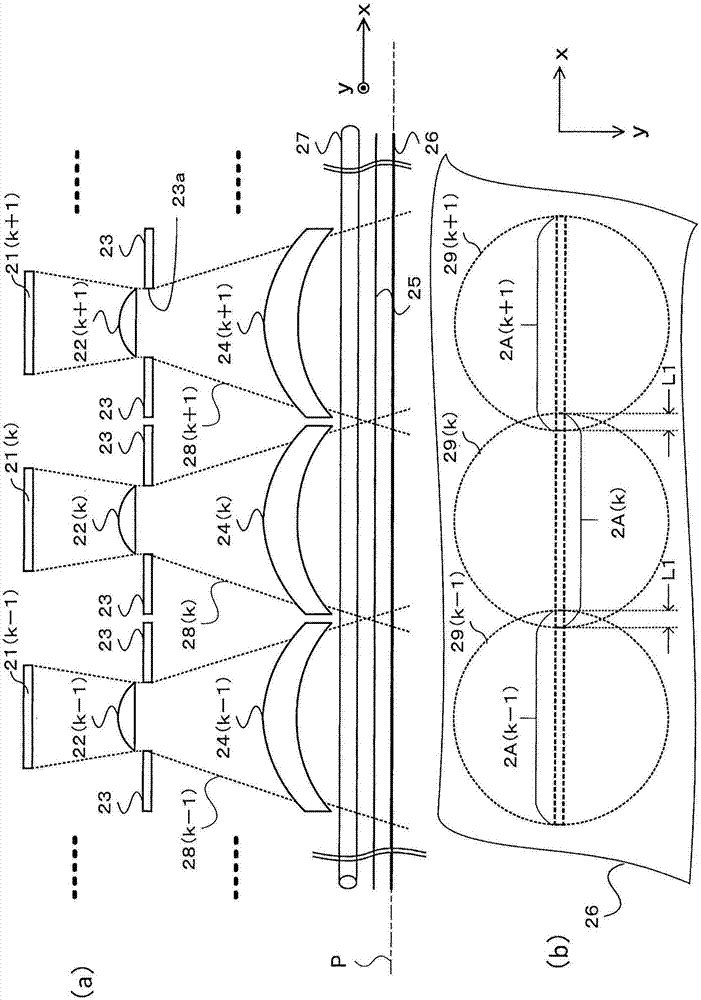

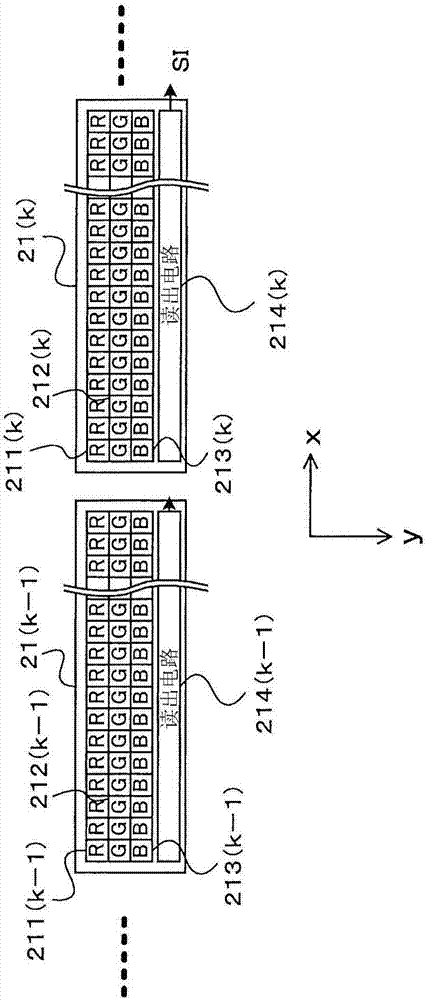

Image-reading apparatus and image-reading method

InactiveCN107409164AImprove picture qualityImage data processing detailsPictoral communicationImaging processingMagnification

An image-reading apparatus (1) is provided with: N sensor chips arranged in a first direction, each of the sensor chips having a plurality of imaging elements arranged in the first direction; N optical systems in which reduced images of N read ranges aligned in the first direction on a document are individually formed in the N sensor chips; and an image-processing unit (4) in which the position, in the first direction, of the overlapping areas of adjacent read ranges is determined using image data generated by the N sensor chips, the magnification of the read image and a compositing position are obtained from the position in the first direction thus determined, an image process is performed to correct the magnification in the first direction of the image data of the N read ranges, and the image data of the N read ranges subjected to the image process is combined to generate composite image data (D44), the image data being image data of the overlapping areas, the overlapping areas being areas in which there is an overlap between the adjacent read ranges in the image data of the N read ranges, and the compositing position being a position in which two items of image data are combined.

Owner:MITSUBISHI ELECTRIC CORP

Composite position error compensation method and device

ActiveCN110426991AHigh precisionIncreased complexityProgramme controlComputer controlCurve reconstructionData storing

The invention discloses a composite position error compensation method and device. The method comprises: correcting obtained original discrete actually-measured position data in a multi-dimensional non-uniform distributed manner into a plurality of sets of corrected position data storing error data that are generated by correction and are in a one-dimensional non-uniform distributed manner; carrying out curve reconstruction on the corrected position data in a one-dimensional non-uniform distributed manner in all sets to form corresponding corrected position data in a one-dimensional uniform distributed manner; carrying out curve reconstruction on all corrected position data in a one-dimensional uniform distributed manner, acquiring subdivision position data of uniform grid points, and thusacquiring a reconstructed curved surface; and generating a corresponding compensation table based on the reconstructed curved surface to realize composite position error compensation. According to the invention, the original discrete actually-measured position data in a multi-dimensional non-uniform distributed manner are corrected, error reconstruction is carried out based on the corrected data,and thus the compensation table is generated. Therefore, the high-precision and high-complexity composite position error compensation is realized.

Owner:苏州行远志成自动化科技有限公司

An inertial navigation astronomical high-precision compound two-position alignment and error calibration method

InactiveCN103900611BQuick fixHigh precisionInstruments for comonautical navigationState modelComputer science

The invention discloses a method for aligning two composite positions with high accuracy and calibrating error of inertial navigation astronomy. The method comprises the following steps: step one, taking a landing position determined by a landing machine as information of an initial position of a rover; step two, determining an initial attitude matrix of the rover according to the initial position of the rover and the inertia attitude matrix which is output by an astronomy navigation subsystem; step three, establishing a system state model and a measurement model for aligning two positions of the rover; step four, aligning the two positions by rotating the rover; step five, correcting initial position information of the rover to meet requirements of high-accuracy initial alignment. The method gives full play to the advantages of a serial inertial navigation system and the astronomy navigation subsystem, and is also applicable to other exploration rovers and wide in application prospect.

Owner:BEIHANG UNIV

A New Method of Composite Positioning Based on Fuzzy Theory

ActiveCN106772516BImprove rationalityImprove accuracySatellite radio beaconingPattern recognitionKaiman filter

The invention relates to a new compound positioning method based on fuzzy theory, belonging to the technical field of vehicle positioning. Based on vehicle cyber physical system technology, the positioning data of three positioning devices in a target vehicle and an adjacent vehicle is used, the error of each positioning technology is optimized by using the fuzzy theory and the positioning contribution of each positioning technology is obtained, and then with the positioning contribution as a weight, the fuzzy weighted calculation is carried out to obtain the composite position of the target vehicle. A Kalman filter of fuzzy variable measurement noise covariance is used to filter a composite position. According to the method, multiple vehicle positioning technologies are fused, two indexes of an outlier rate and an absolute error are constructed to reflect the reliability degree of each positioning technology, the rationality of positioning technology fusion is improved, at the same time, an improved Kalman filter is used to filter a fusion result, and the accuracy of positioning is improved.

Owner:HUNAN UNIV

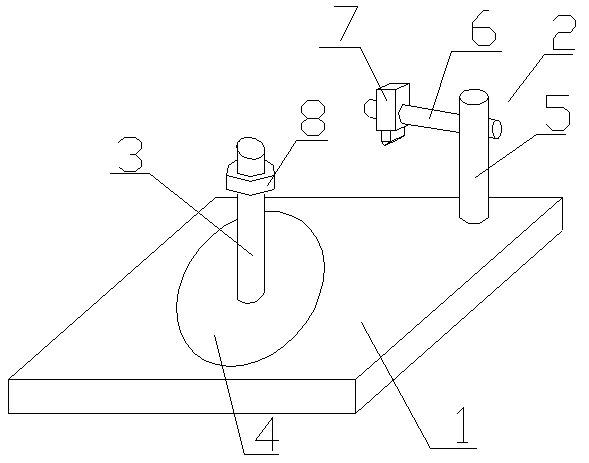

Semi-automatic edge printing machine

The invention provides a semi-automatic edge printing machine, which comprises a base and an edge printing device, wherein a center shaft is arranged above the base, a rotating disc is arranged under the center shaft, and the edge printing device is arranged at the right side of the upper side of the base. Through the arrangement of the center shaft and a positioning block, a wheel is positioned, then, the printing machine is regulated to a composite position through a rotating arm, the wheel is rotated, the wheel is subjected to edge printing treatment, the work efficiency of the wheel edge printing is improved, the work time is reduced, in addition, the operation is simple, and the learning is easy.

Owner:ANHUI YONGCHANG METAL PROD

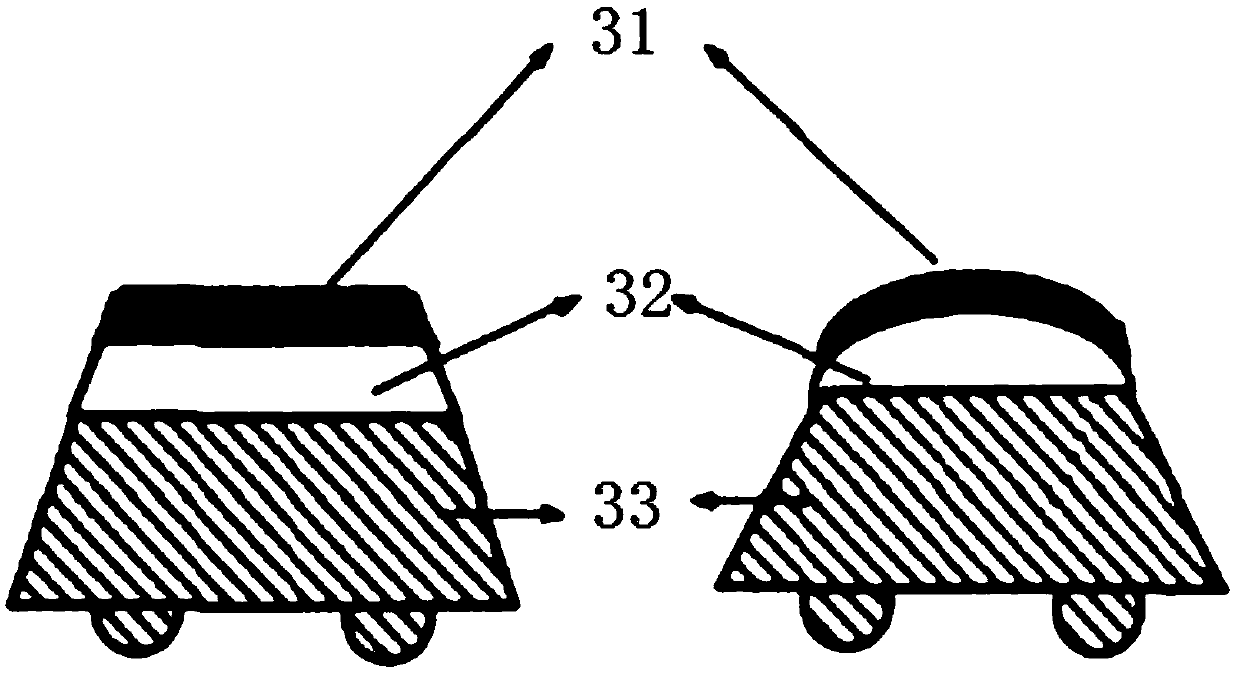

A lateral composite guide device for three-layer composite materials

ActiveCN106180179BReduce mutual interferenceReduce difficultyGuiding/positioning/aligning arrangementsFurnace typesComposite PositionMachining

The invention discloses a lateral composite position guide device for a three-layer composite material. The lateral composite position guide device comprises a composite body, wherein a cavity is formed in the composite body; a wire guide nozzle is arranged on one side of the composite body, and a plurality of wire feeding rails are arranged on the other side of the composite body; a cavity penetrates through a wire guide channel of the wire guide nozzle and wire feeding channels of the wire feeding rails; a plurality of guide arrangement assemblies are arranged in the wire guide channel of the wire guide nozzle; and a composite rolling part is arranged on one side of the wire discharging end of the wire guide nozzle. The lateral composite position guide device is reasonable in design and compact in structure, can quickly enable three strips to be laterally and closely attached together, and can provide a basis for subsequent machining.

Owner:SUZHOU CHUANGHAO NEW MATERIAL TECH CO LTD

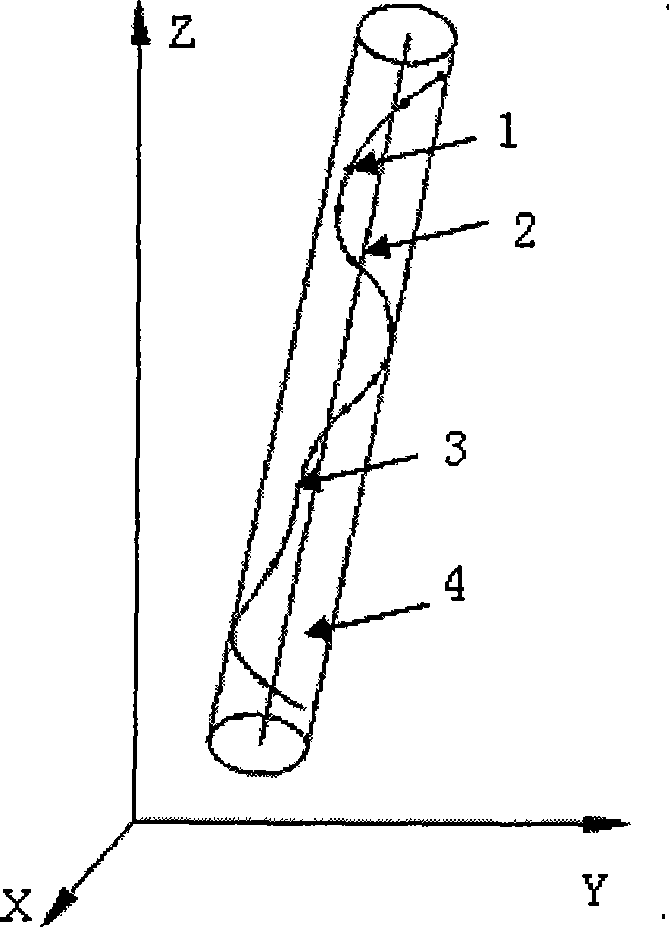

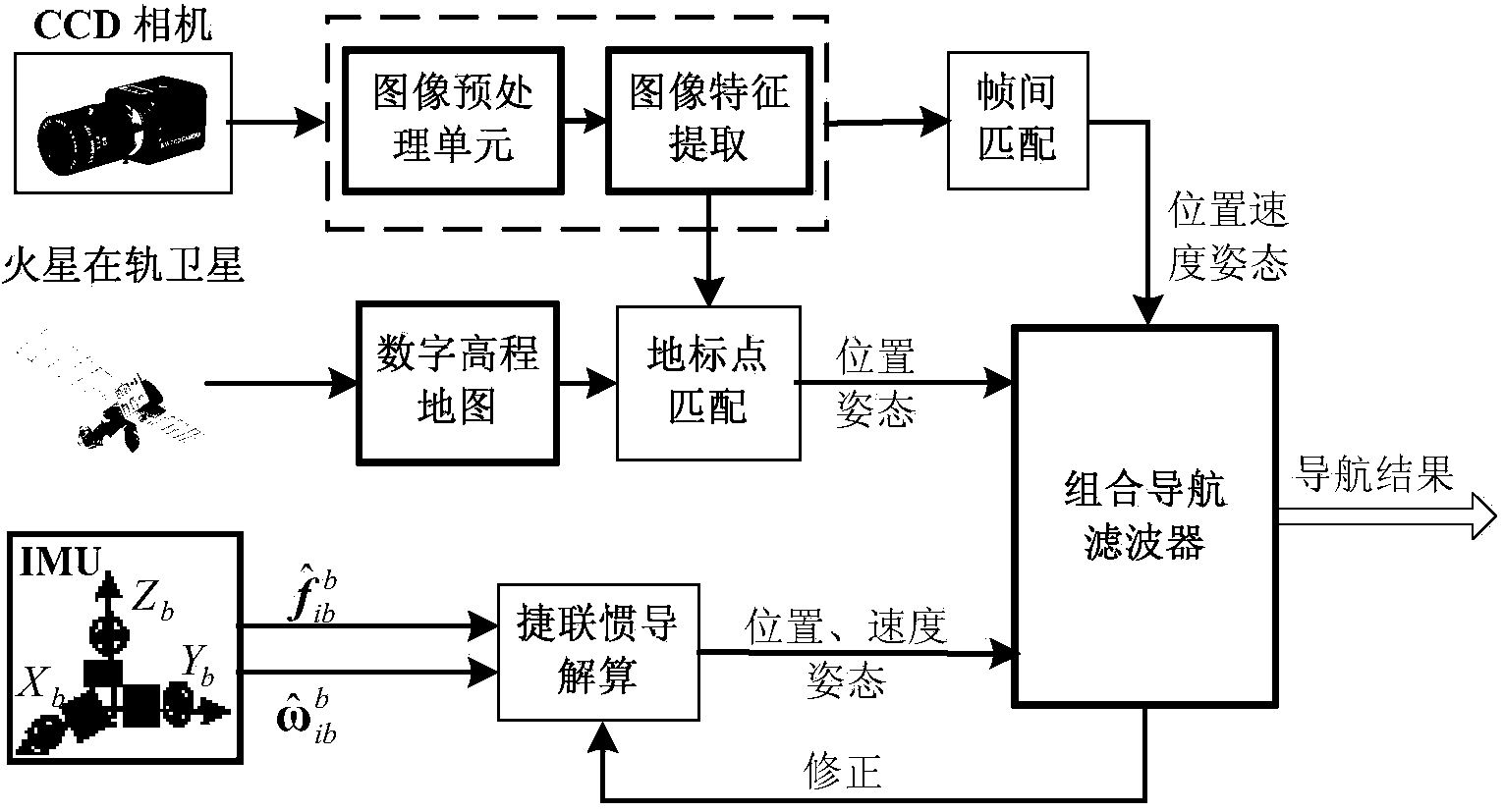

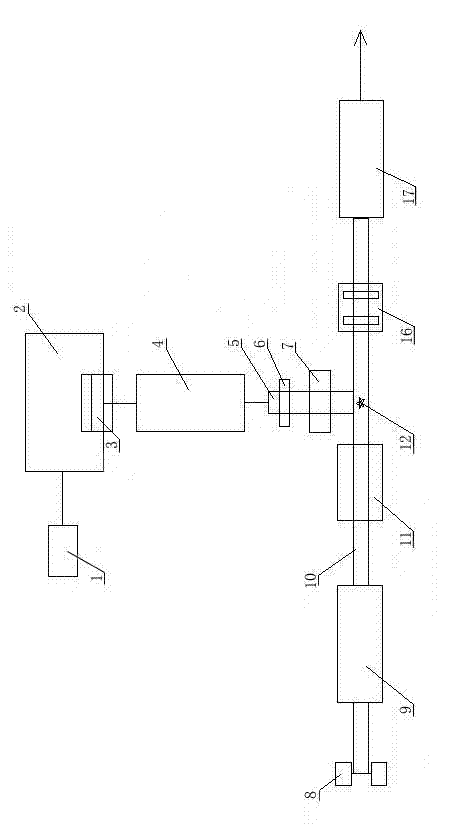

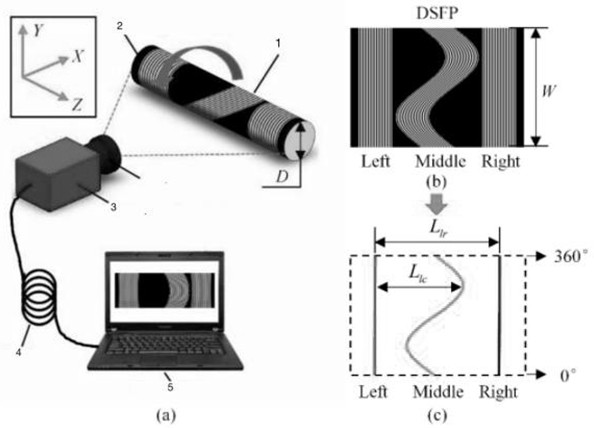

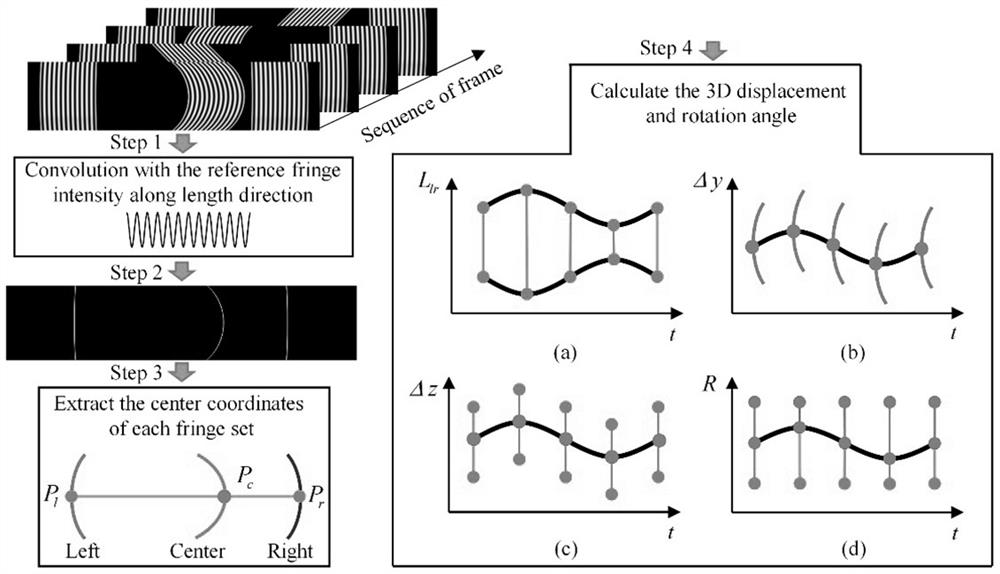

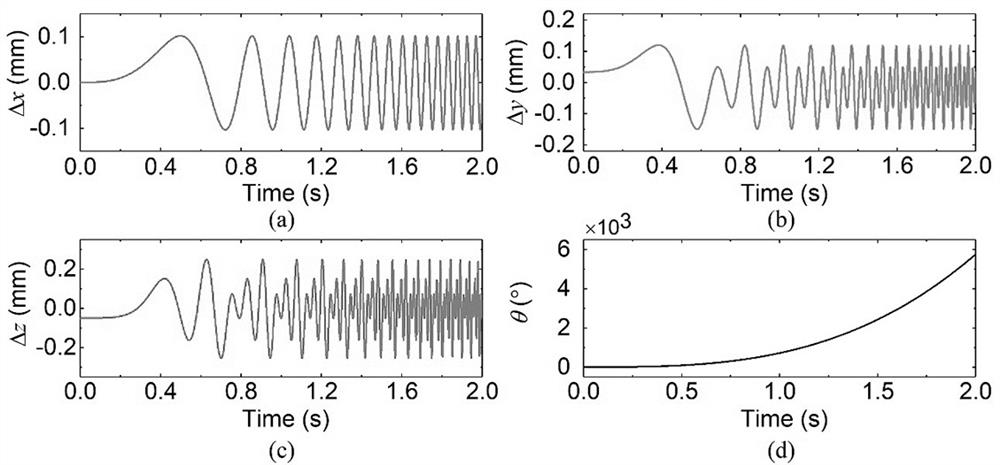

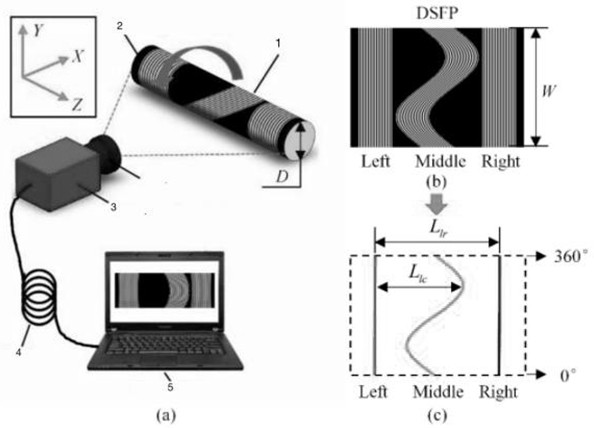

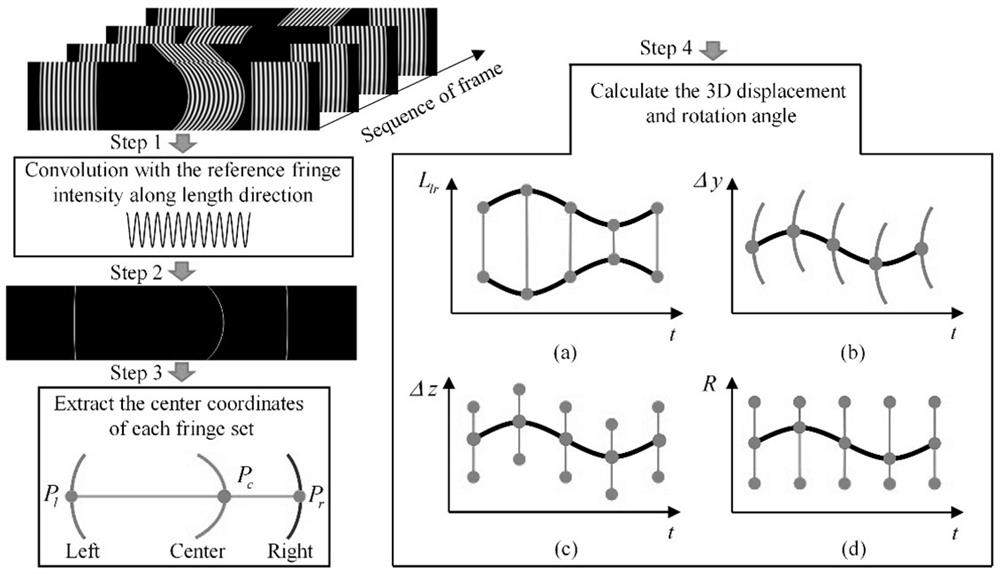

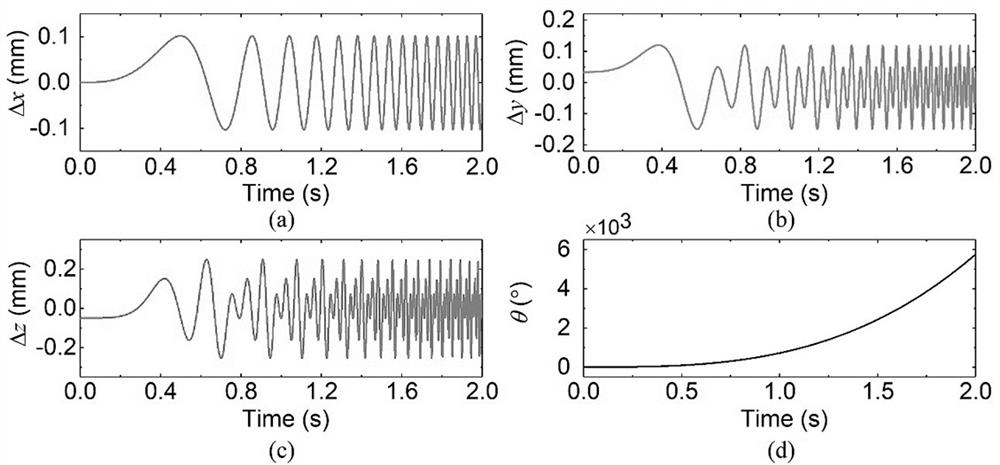

System and method for realizing order analysis of a rotating shaft by adopting visual composite position sensing stripes

ActiveCN113758695ALow costModal parameters will not be changedSubsonic/sonic/ultrasonic wave measurementMachine bearings testingRotational axisTime domain

Provided are a system and a method for realizing order analysis of a rotating shaft by adopting visual composite position sensing stripes. Artificial composite position sensing stripes are used as a three-dimensional vibration sensor and a rotating angular displacement sensor, and can be printed by a common printer and adhered to the periphery of the surface of the shaft. A high-speed camera is adopted as a detector, an image sequence of the composite position sensing stripes is obtained, and time-domain three-dimensional vibration and rotation angular displacement signals can be obtained at the same time through a proposed image processing algorithm. Therefore, simultaneous measurement of the three-dimensional displacement and the rotation angle is realized, and the system and the method are suitable for order analysis. Compared with a traditional system based on three eddy current sensors and one rotation angle sensor, the system has the advantage that the efficiency and robustness of the system are improved. Therefore, the provided composite position sensing stripe and vision-based system can be used for rotating shaft state monitoring and fault detection in practical engineering application.

Owner:FUZHOU UNIV

A Method of Controlling the Composite Position Error of Hole Groups by Optimizing Fixture Layout

The invention discloses a method for controlling the composite position error of a hole group by optimizing the layout of a fixture. The method comprises the following steps: establishing a relationship model between the geometric error of the fixture positioning element, the position of the positioning element and the position error of the workpiece; establishing the milling force, The relationship model between the clamping force, the position of the positioning element and the position error of the workpiece; the objective function is to minimize the composite position error of the hole group feature, and the position of the fixture positioning element is the optimization variable. Combined compound position degree error is the smallest. The fixture design method has strong versatility and simple design method.

Owner:TIANJIN UNIV

System and method for realizing order analysis of rotation axis using visual composite position-sensing stripes

ActiveCN113758695BLow costModal parameters will not be changedSubsonic/sonic/ultrasonic wave measurementMachine bearings testingRotational axisTime domain

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com