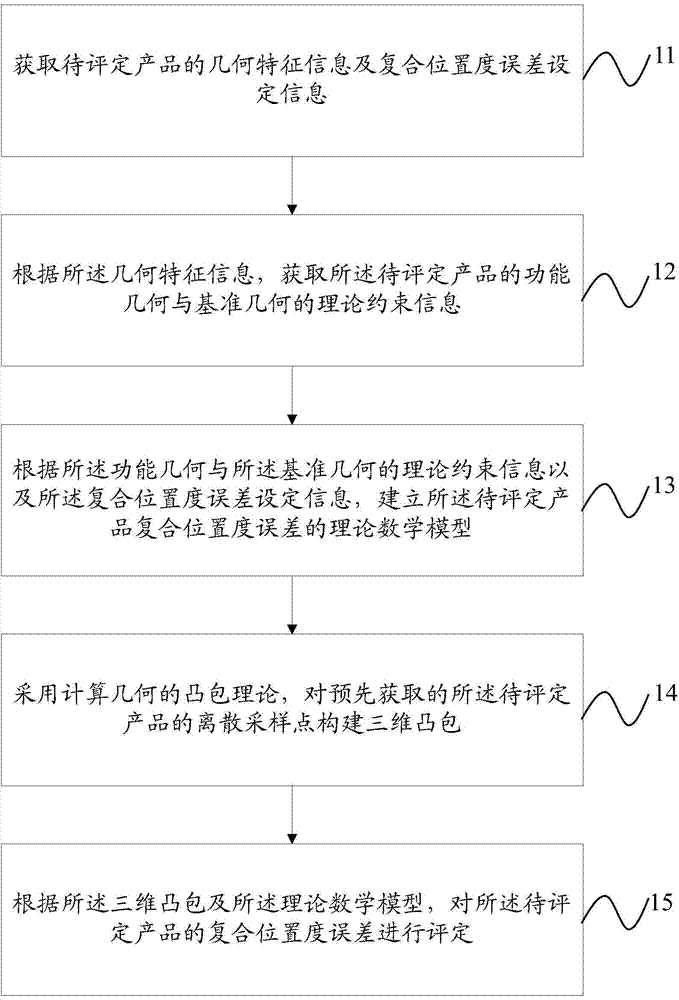

Method and device for composite position error evaluation

A composite position degree and error evaluation technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that the composite position degree error evaluation cannot be accurately realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

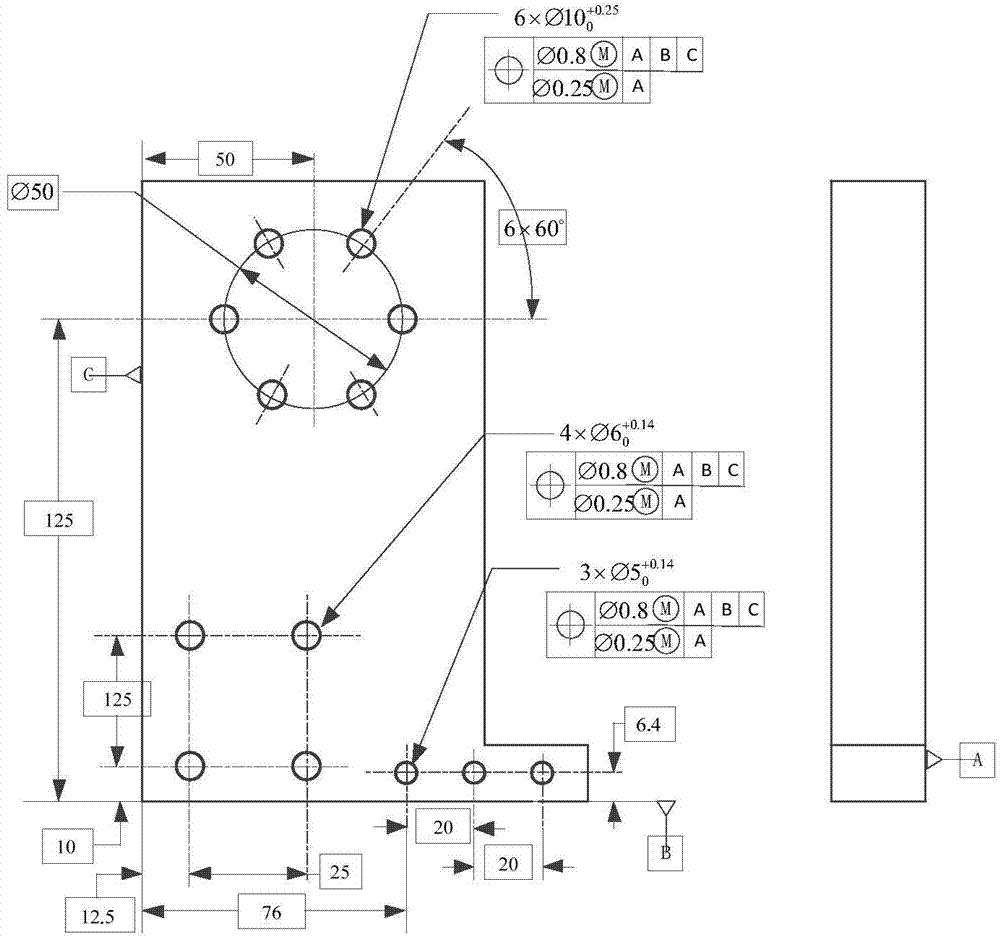

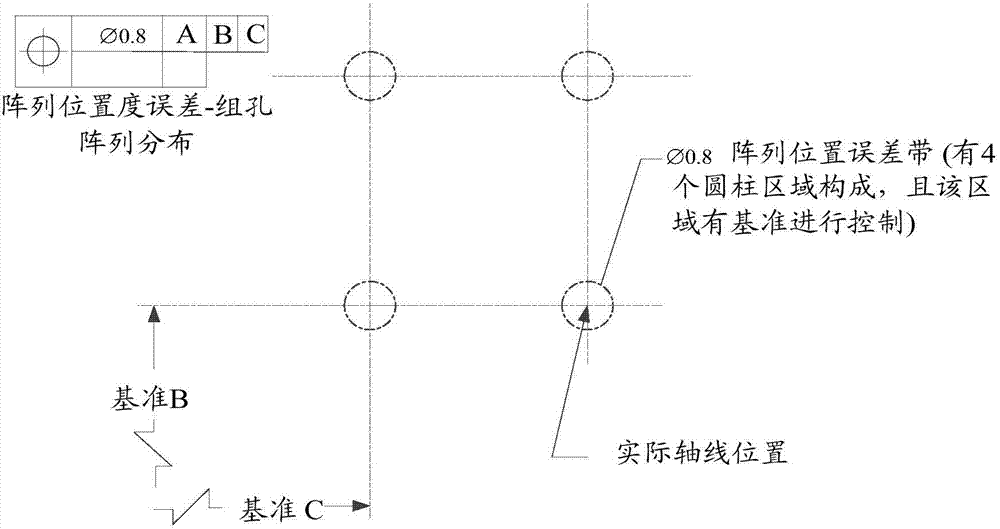

[0057] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0058] According to the definition of compound position error in ASME (American Society of Mechanical Engineers, American Society of Mechanical Engineers), the compound position error is the allowable variation of each actual element between each other or with respect to one or more reference positions, that is, The limit range that the actual position after processing is allowed to deviate from the ideal position specified by the design. In the prior art, with the development of CMM (Coordinate Measuring Machining, Coordinate Measuring Machine) technology, it becomes possible to use a geometric algorithm to realize compound error degree error evaluation for discrete measurement points based on CMM.

[0059] At present, scholars have proposed a large num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com