Patents

Literature

47results about How to "Large amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

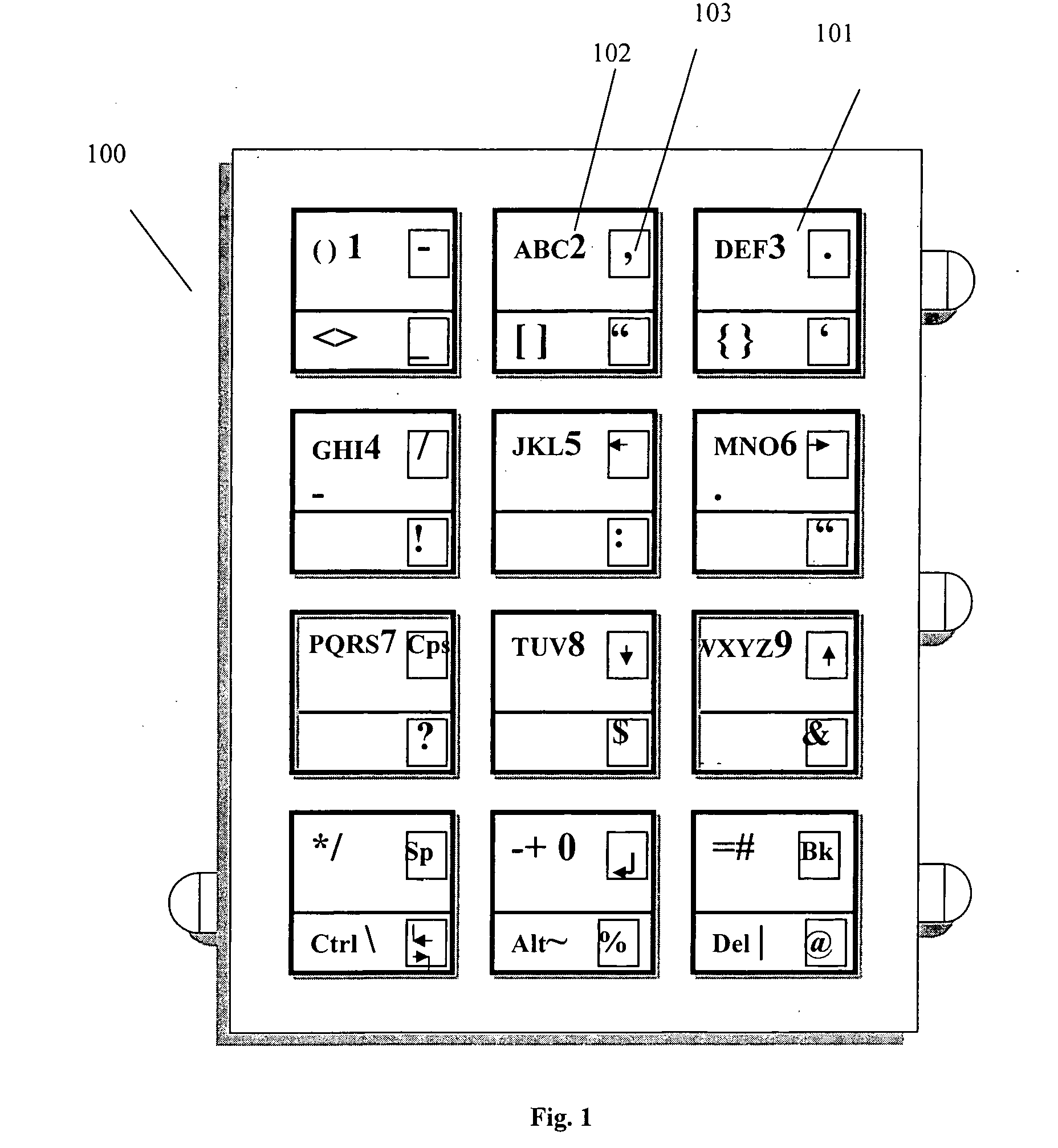

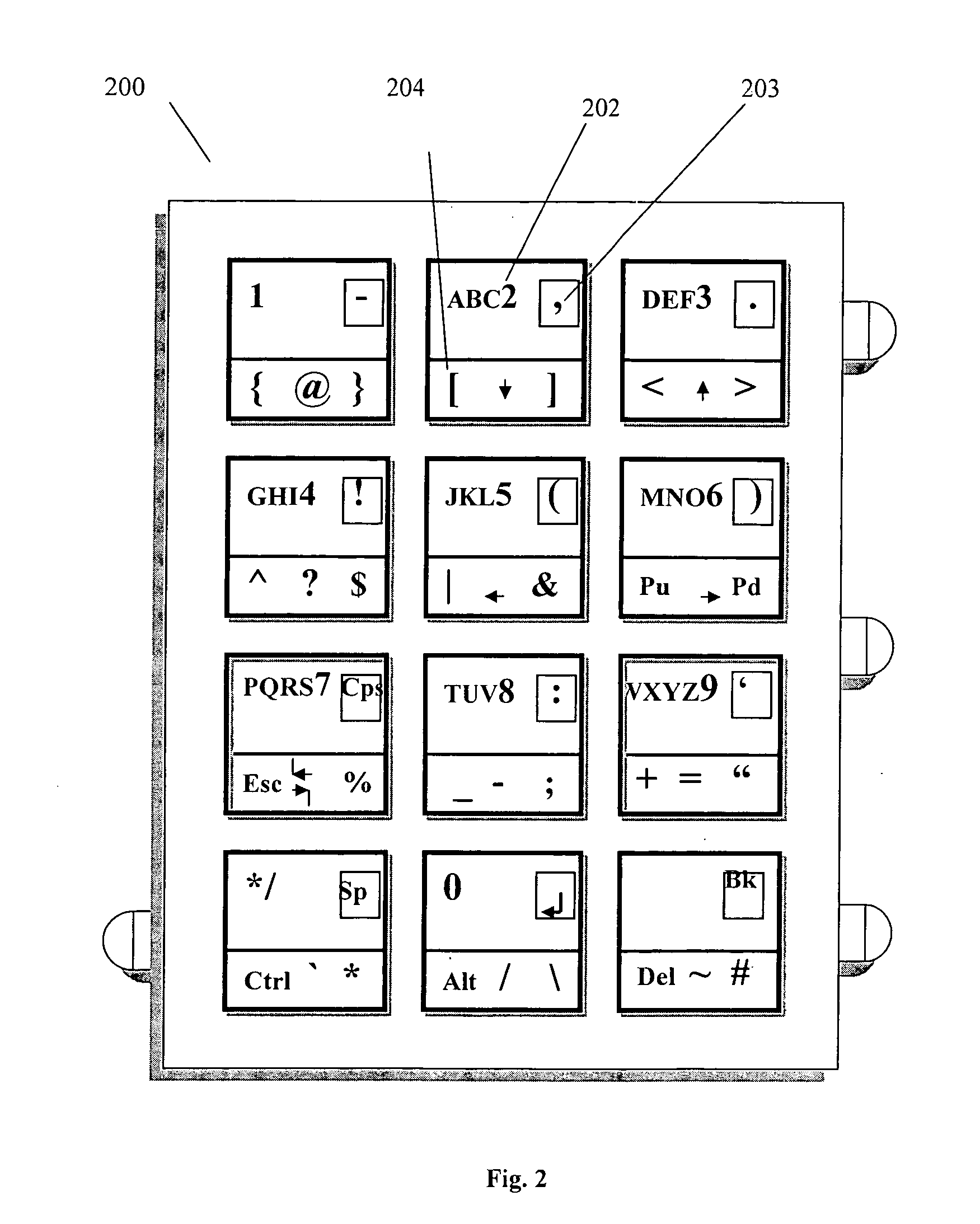

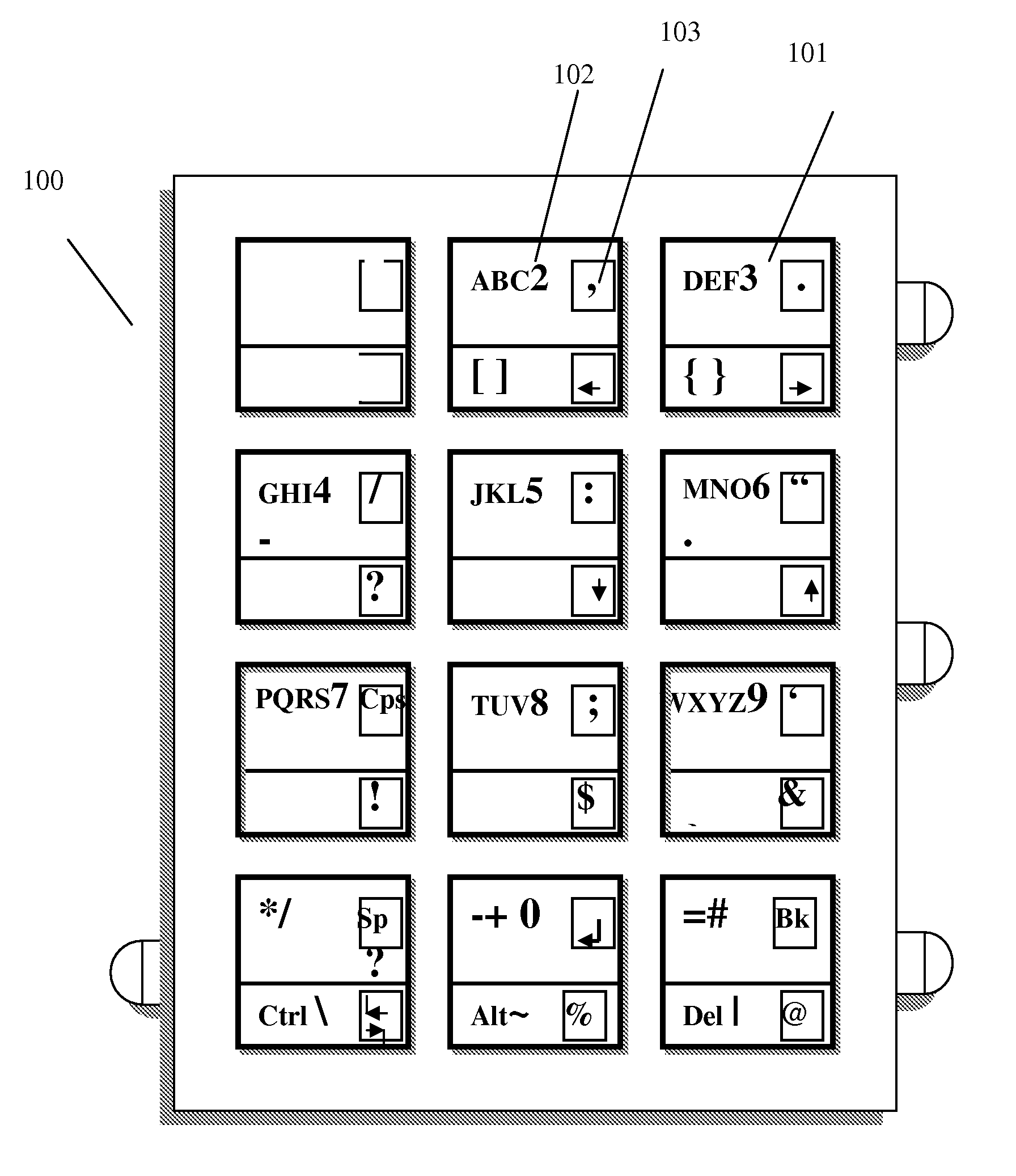

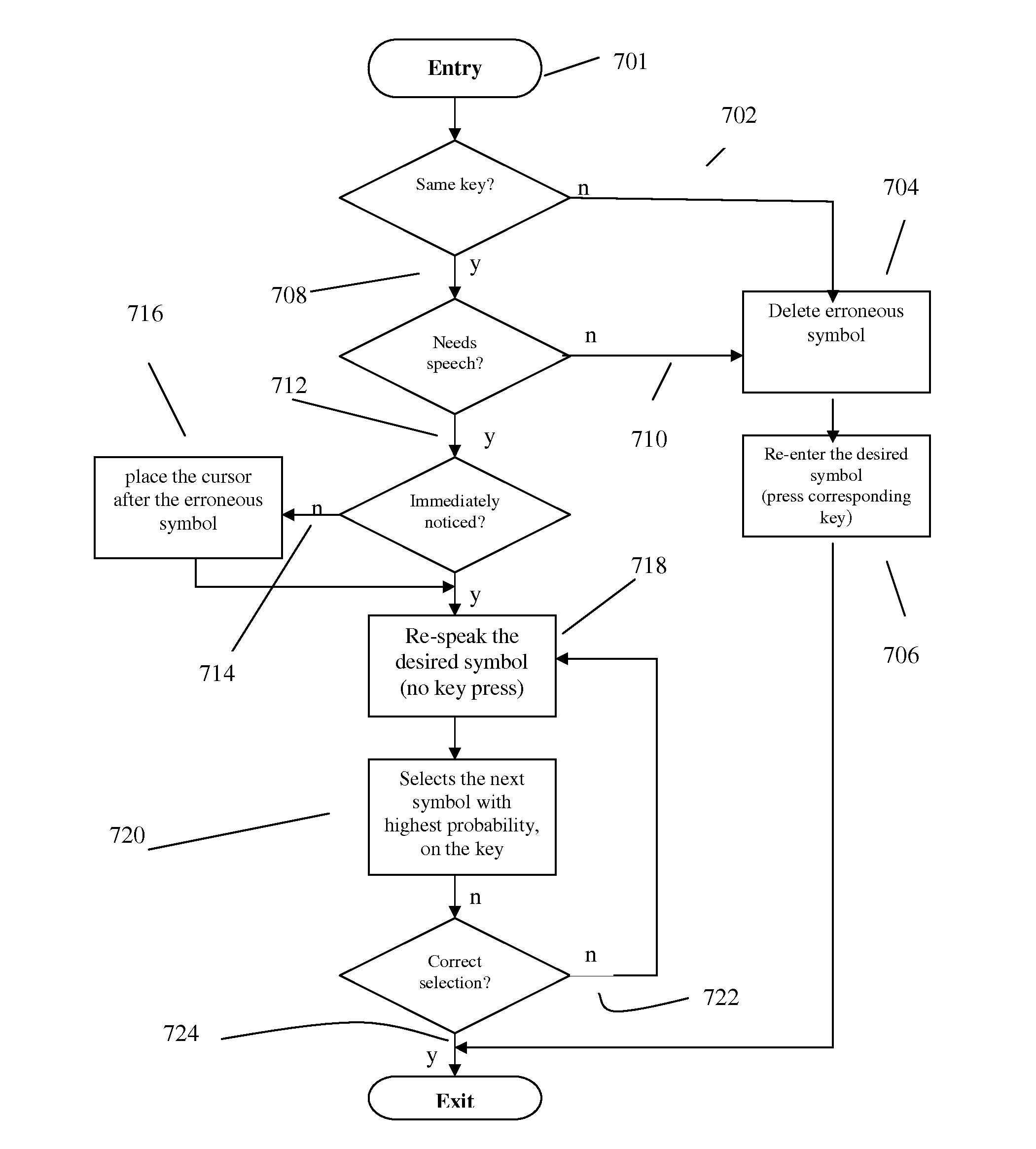

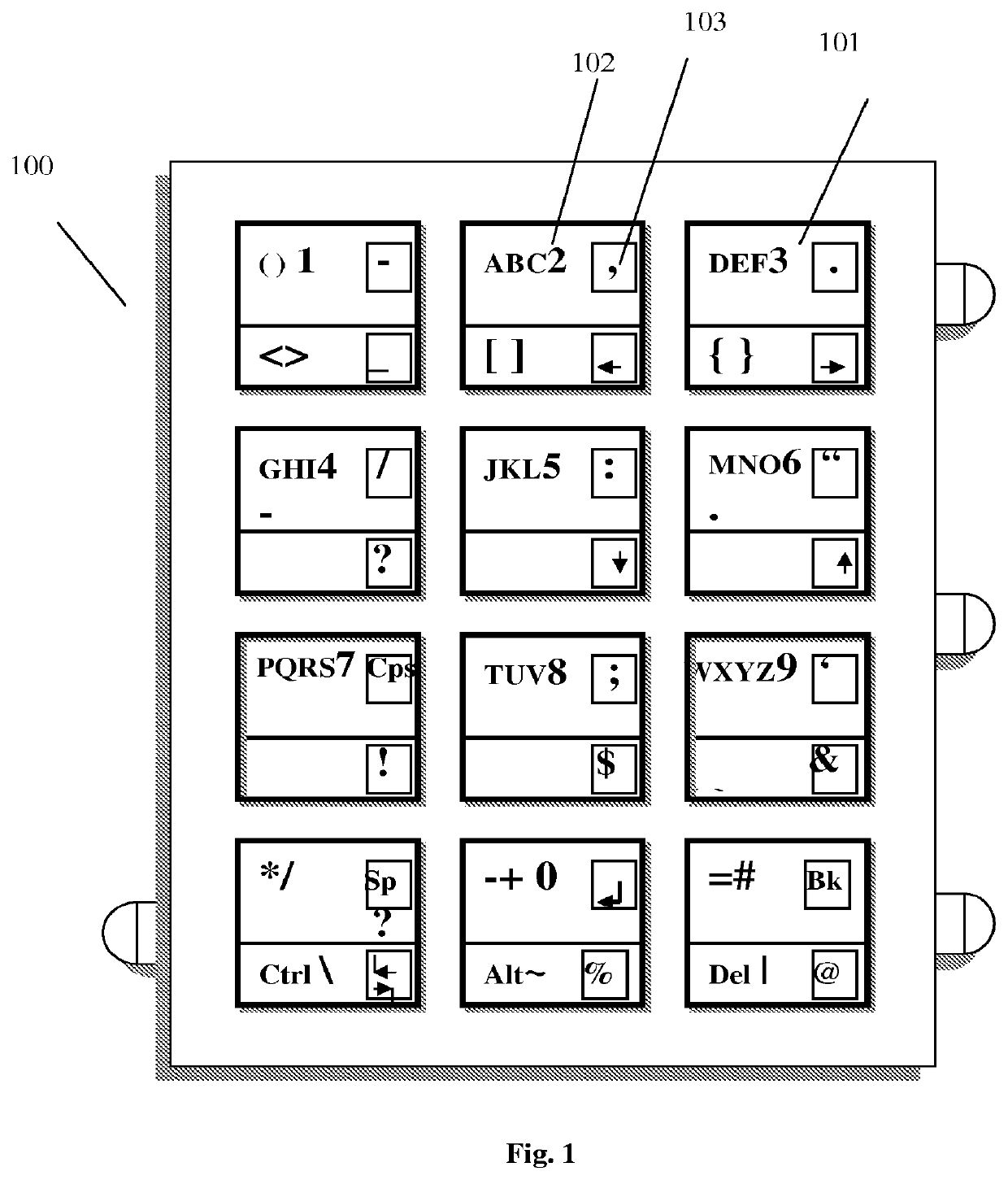

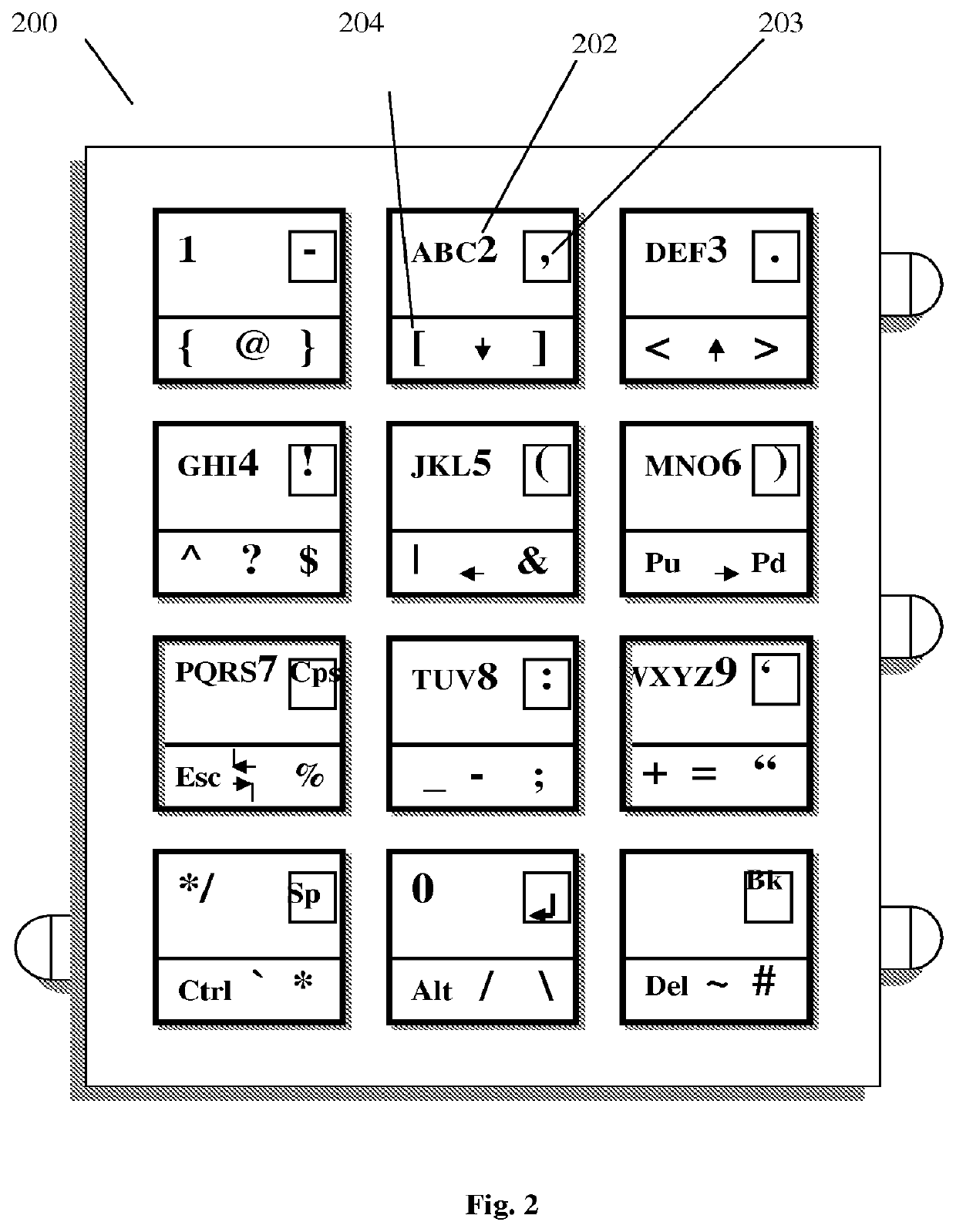

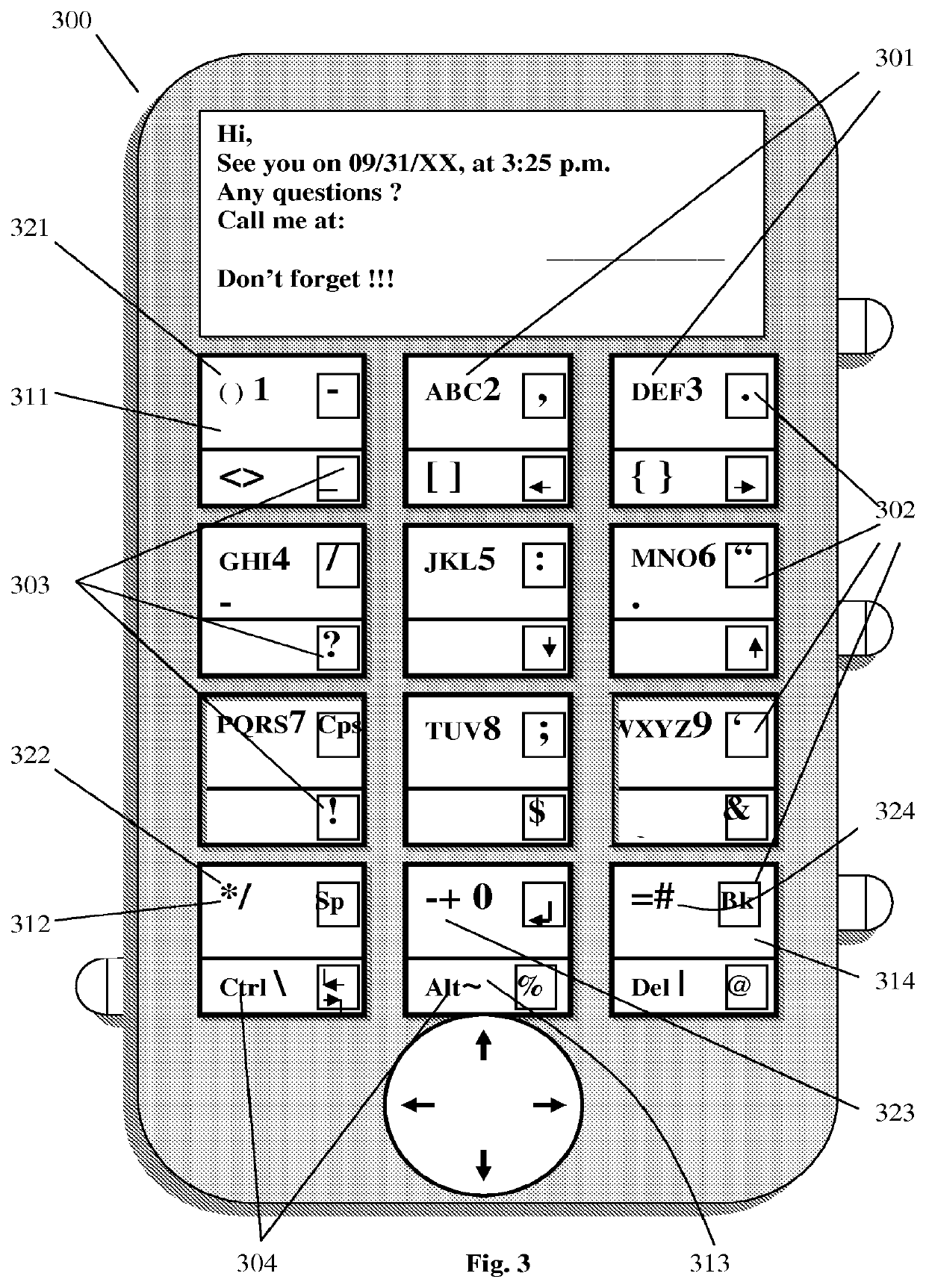

Systems to enhance data entry in mobile and fixed environment

InactiveUS20070182595A1Large of expenditureLarge amount of setInput/output for user-computer interactionElectronic switchingDisplay deviceArtificial intelligence

An electronic device includes a first means for entering characters coupled to the device for generating a first character input data. A second means for entering characters is also coupled to the device for generating a second character input data, where the second means for entering characters includes a system for monitoring a user's voice. A display displays the character thereon. A processor is coupled to the first and second means for entering characters configured to receive the first and second character input data such that the character displayed on the display corresponds to both the first and second character input data.

Owner:GHASSABIAN FIROOZ BENJAMIN

Systems to enhance data entry in mobile and fixed environment

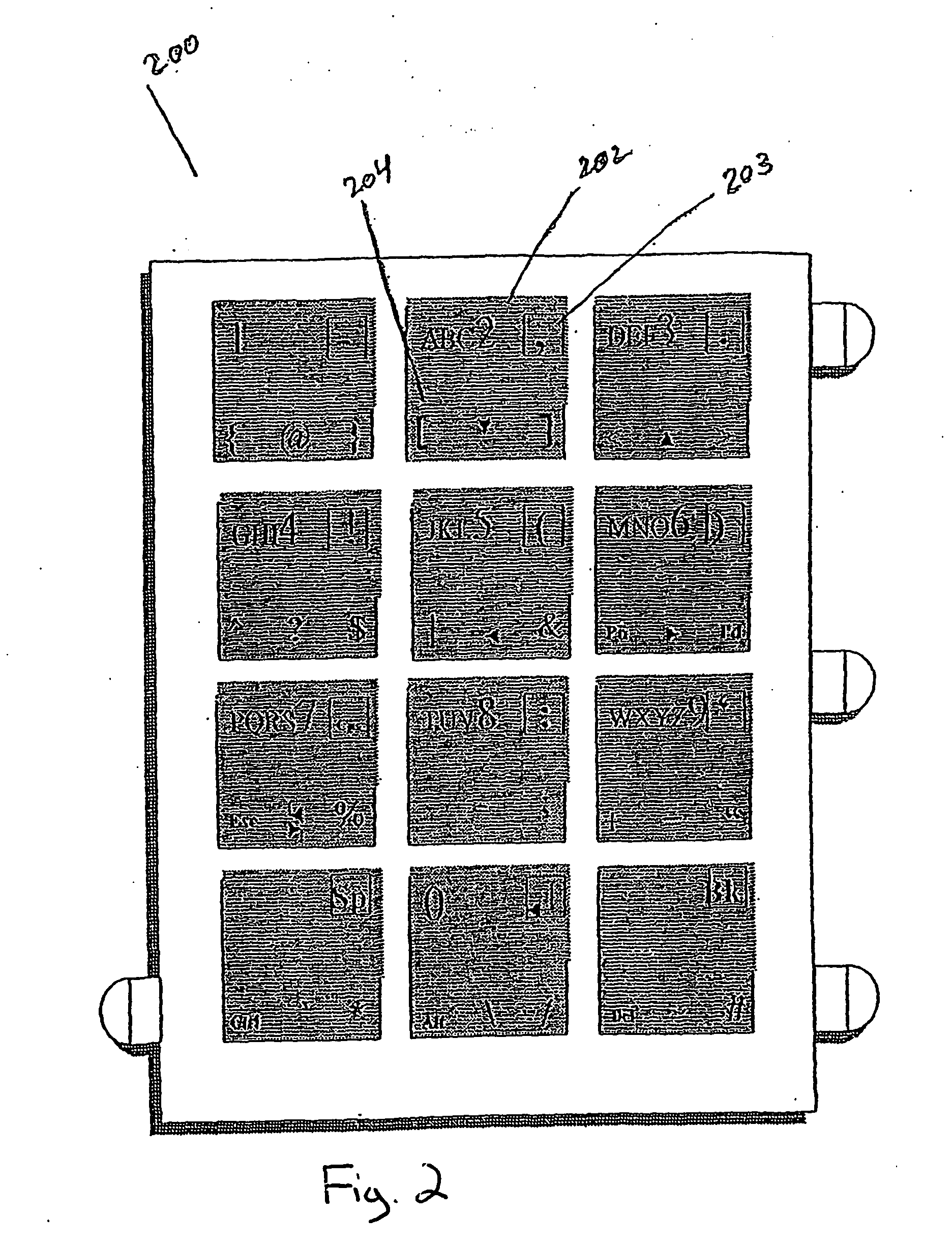

InactiveUS20090146848A1Large amountLarge of expenditureInput/output for user-computer interactionElectronic switchingText entryPointing device

A data entry system is provided using a virtual dynamic keypad having at least four keys, wherein to four of the keys at least substantially all of the letters of a language are distributively assigned and wherein the locations of the four letter keys relating to each other are dynamically defined during the entry of text. A text entry system is also provided using a virtual keypad having at least four keys wherein to four of its keys at least substantially all of the letters of a language are distributively assigned and wherein the locations of the four letter keys relating to each other are dynamically defined based on a calibrating procedure provided by the user. A data entry system is provided using a pointing device providing different pointing directions wherein each of the pointing directions duplicates a key of a predefined virtual keypad model wherein to at least some of its keys substantially all of the letters of a language are distributively assigned.

Owner:KEYLESS SYST LTD

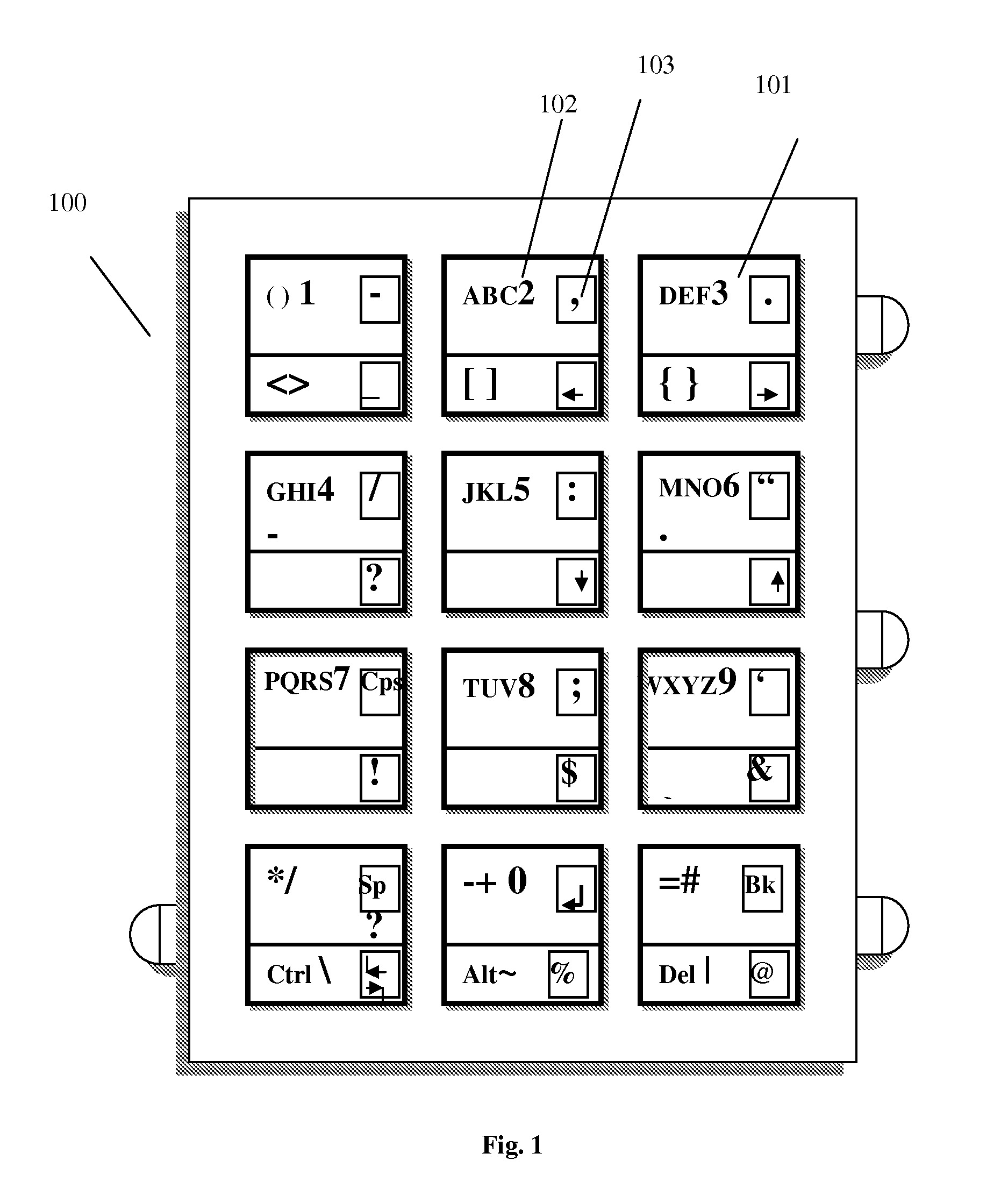

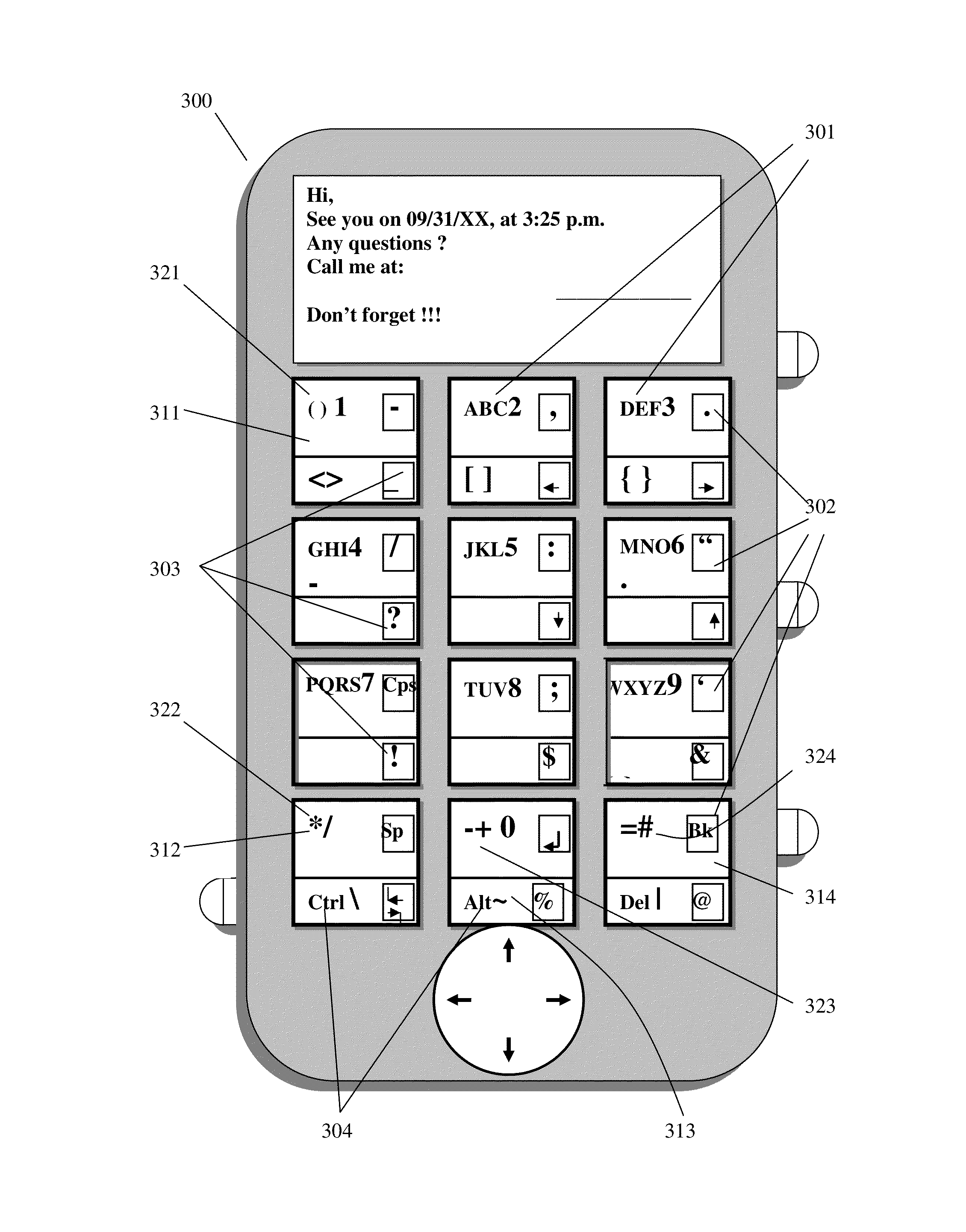

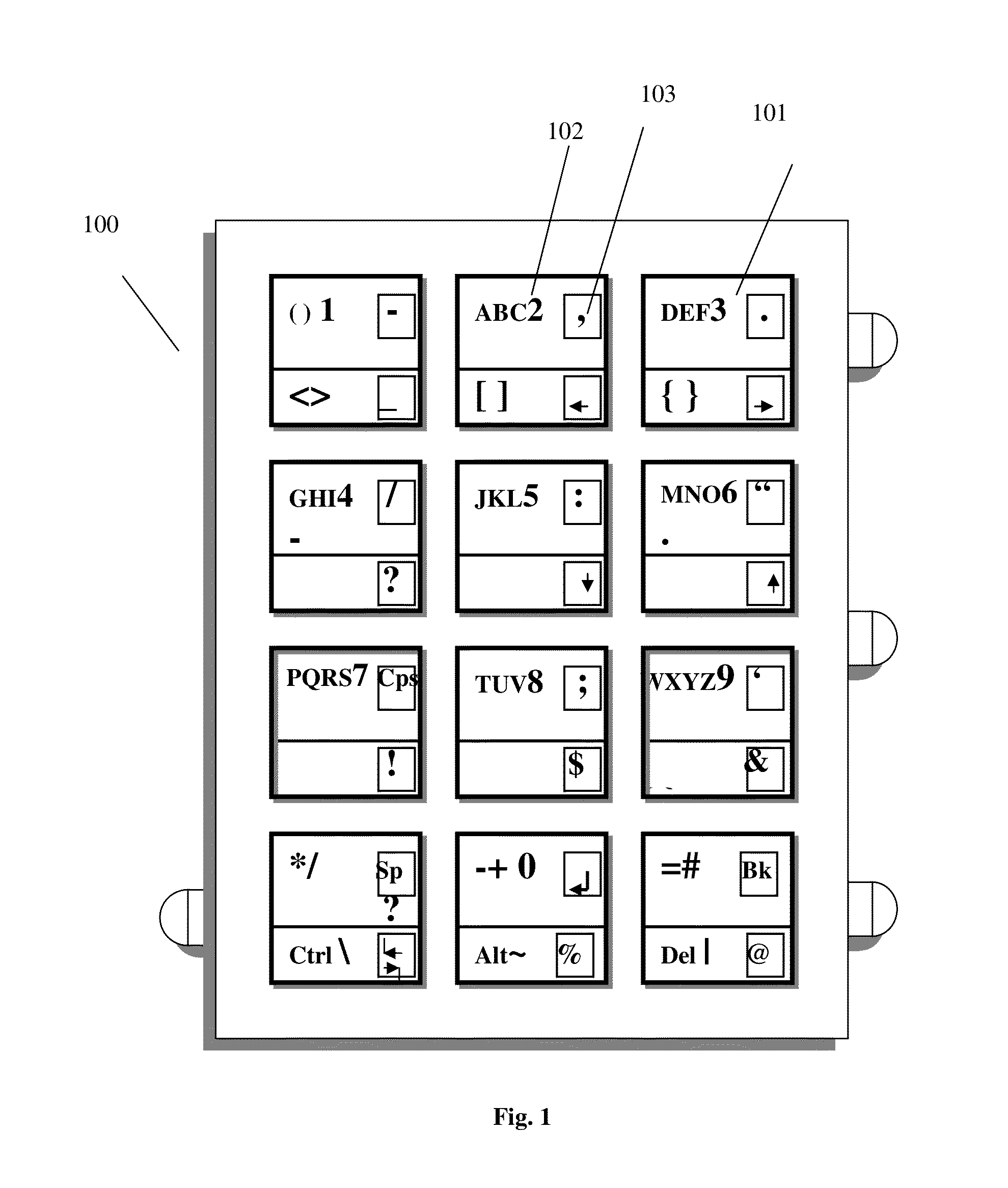

Systems to enhance data entry in mobile and fixed environment

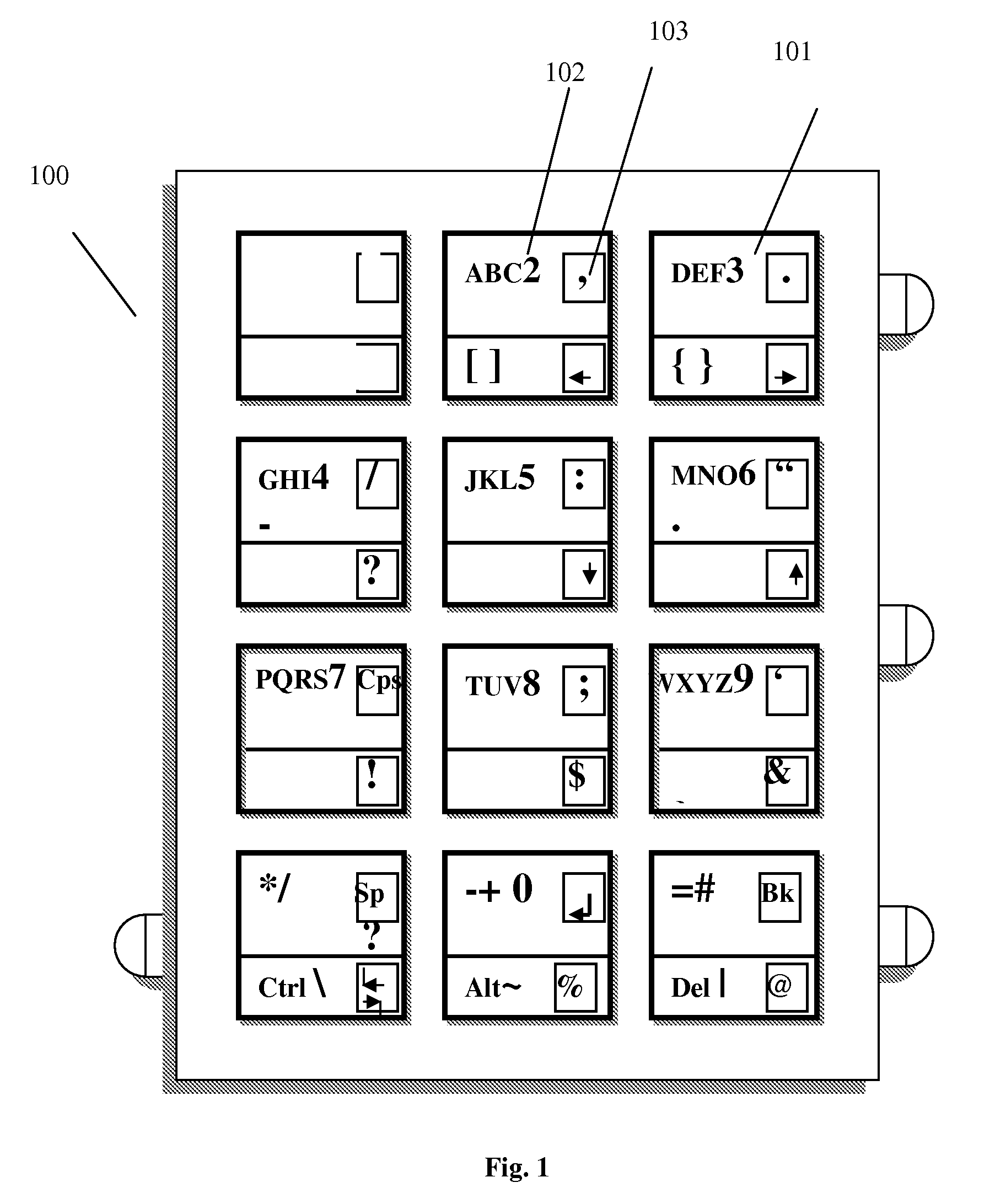

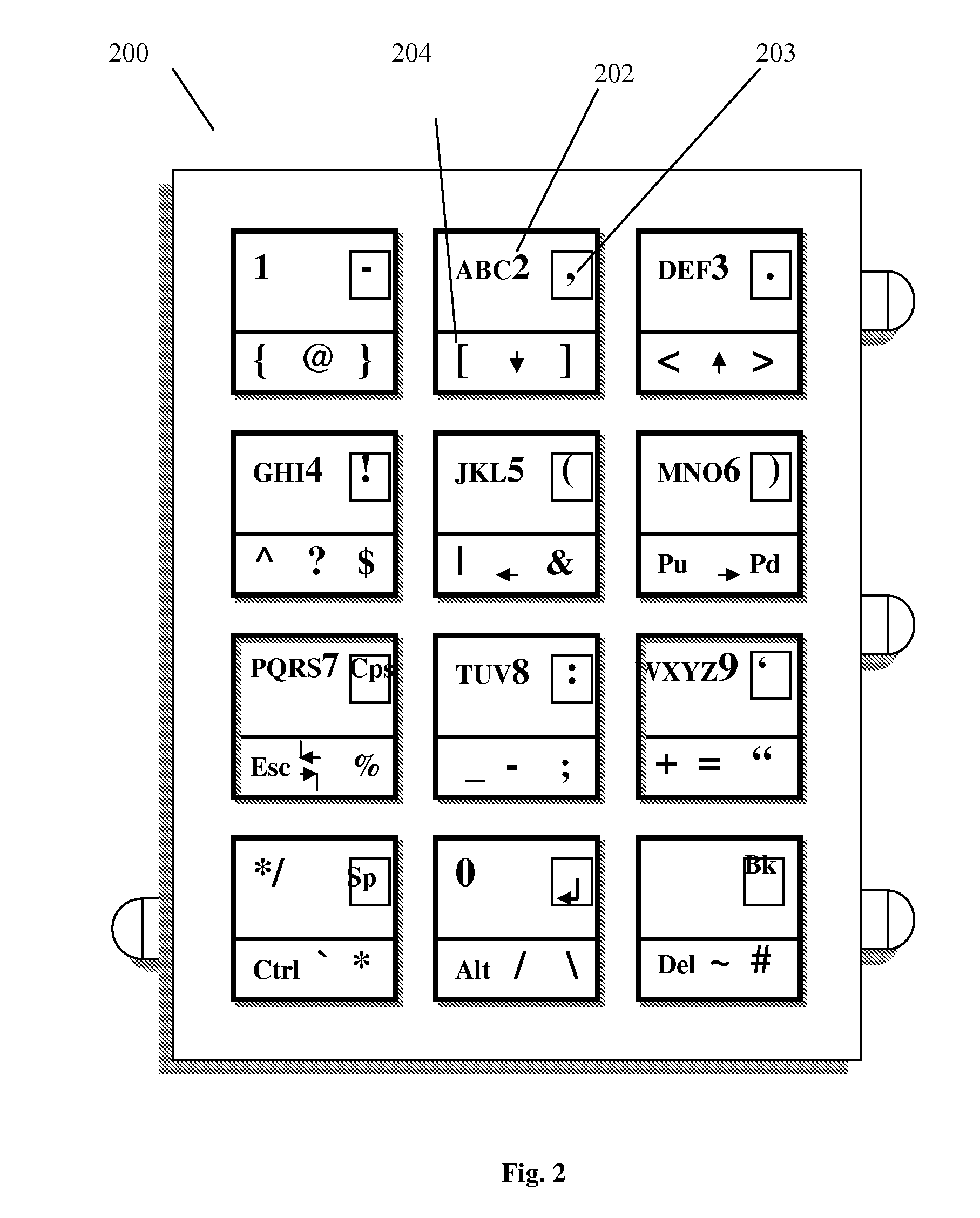

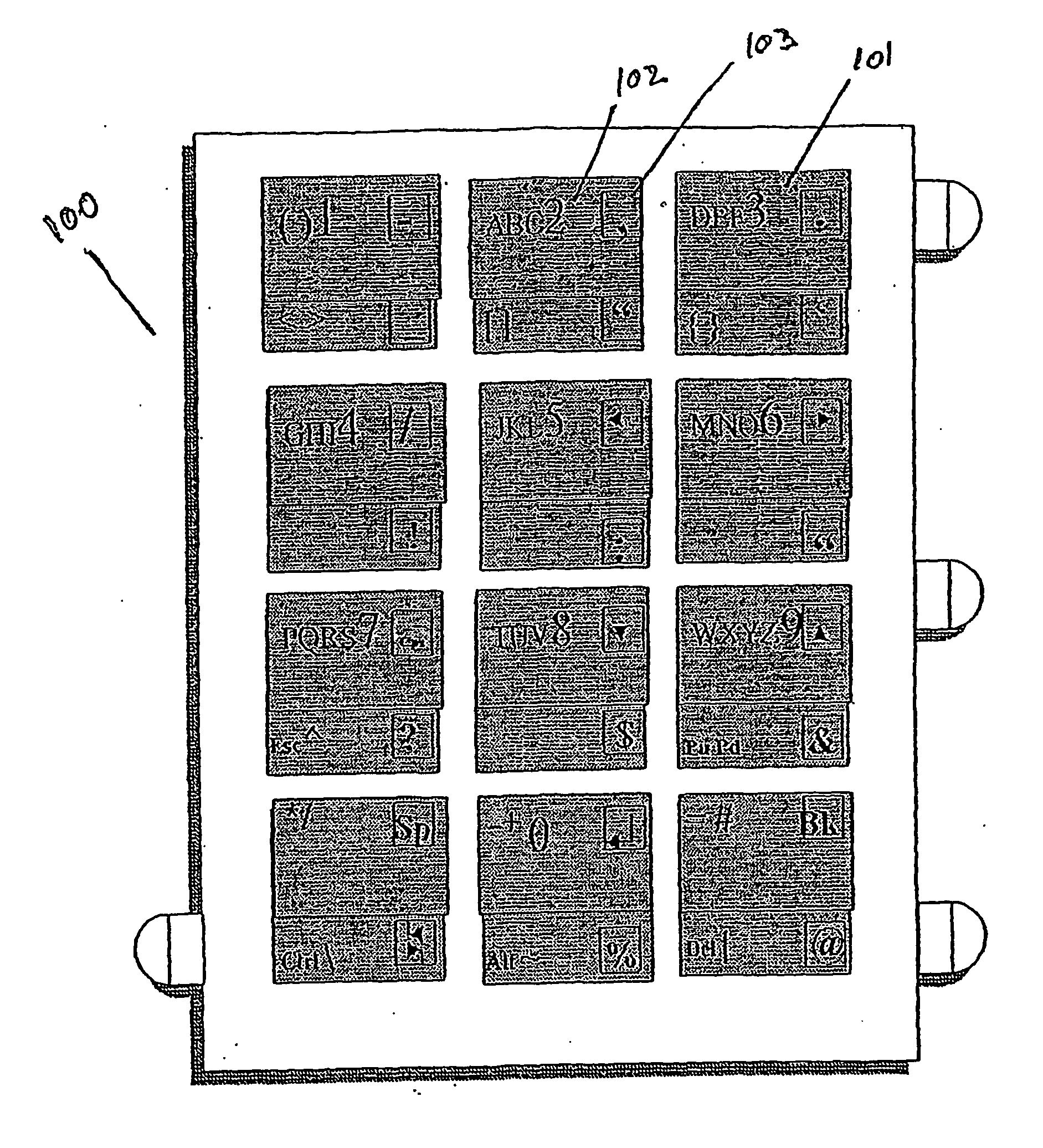

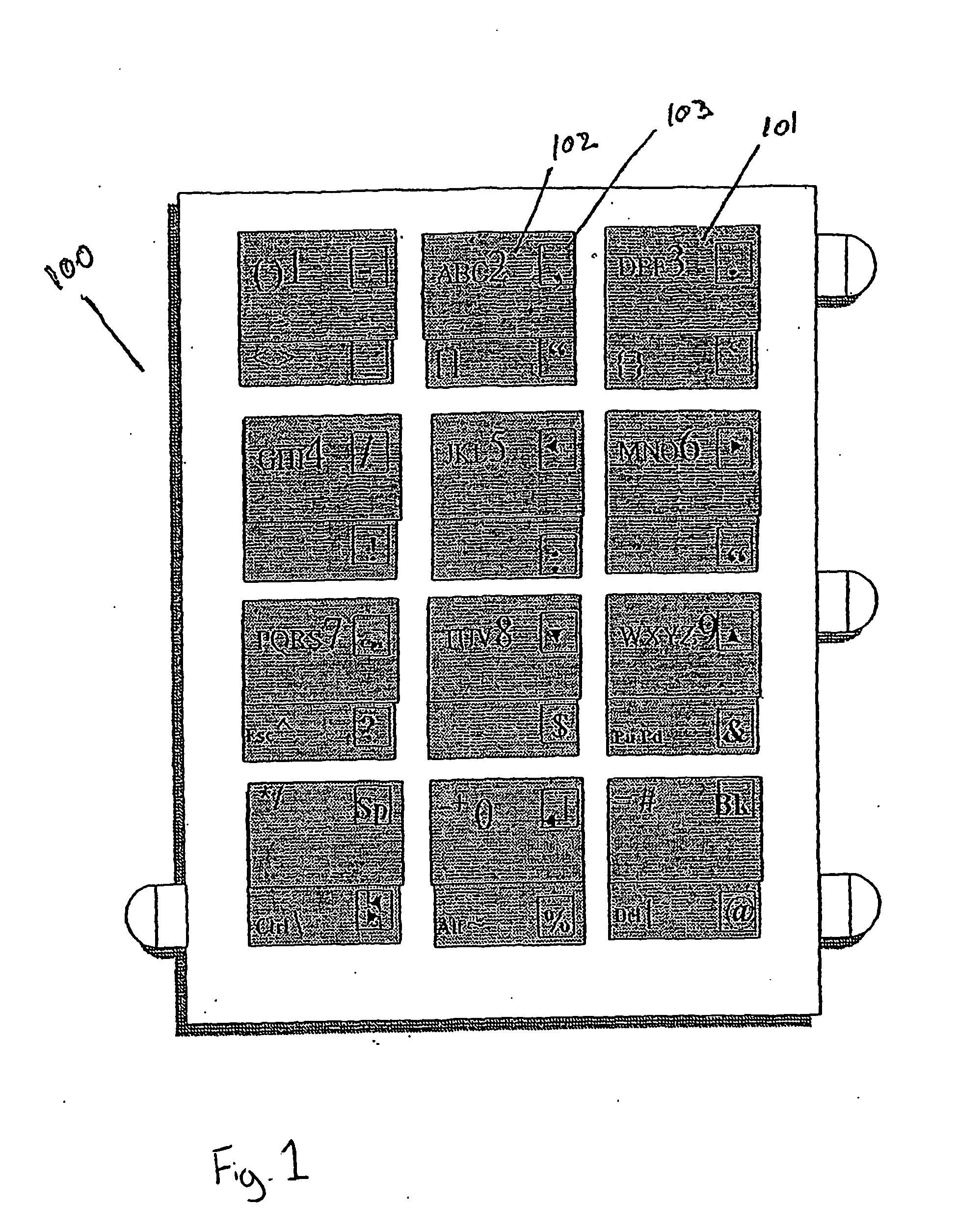

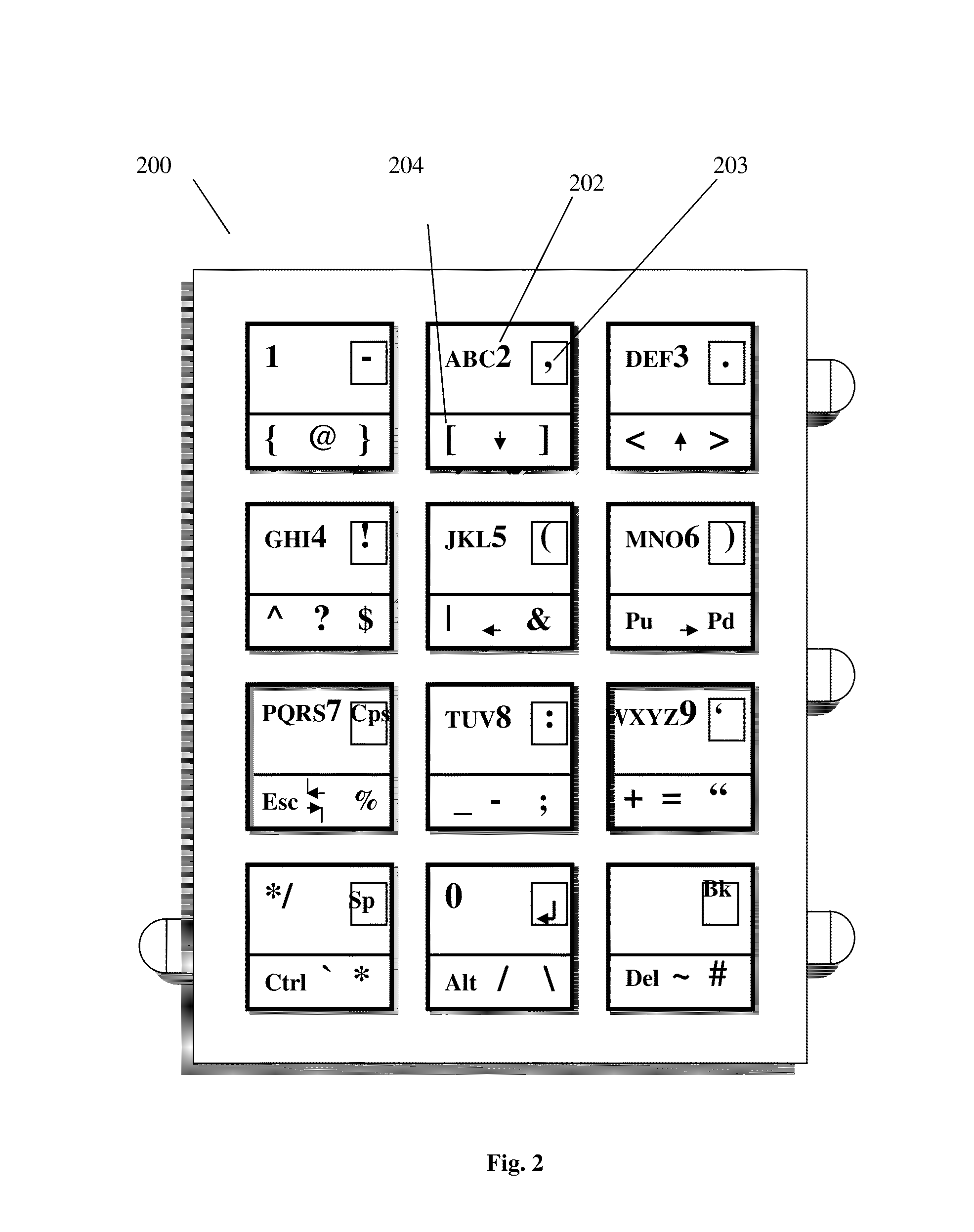

InactiveUS20070188472A1Large of expenditureLarge amount of setInput/output for user-computer interactionDevices with sensorRecognition systemData entry

A data input system having a keypad defining a plurality of keys, each key contains at least one symbol of a group of symbols. The group of symbols is divided into subgroups each having at least one of alphabetical symbols, numeric symbols, and command symbols, where each subgroup is associated with at least a portion of a user's finger. A finger recognition system is in communication with at least one key, where the key has at least a first symbol from a first subgroup and at least a second symbol from a second subgroup, The finger recognition system is configured to recognize the portion of the user's finger when the finger interacts with the key so as to select the symbol on the key, corresponding to the subgroup associated with the portion of the user's finger.

Owner:KEYLESS SYST LTD +1

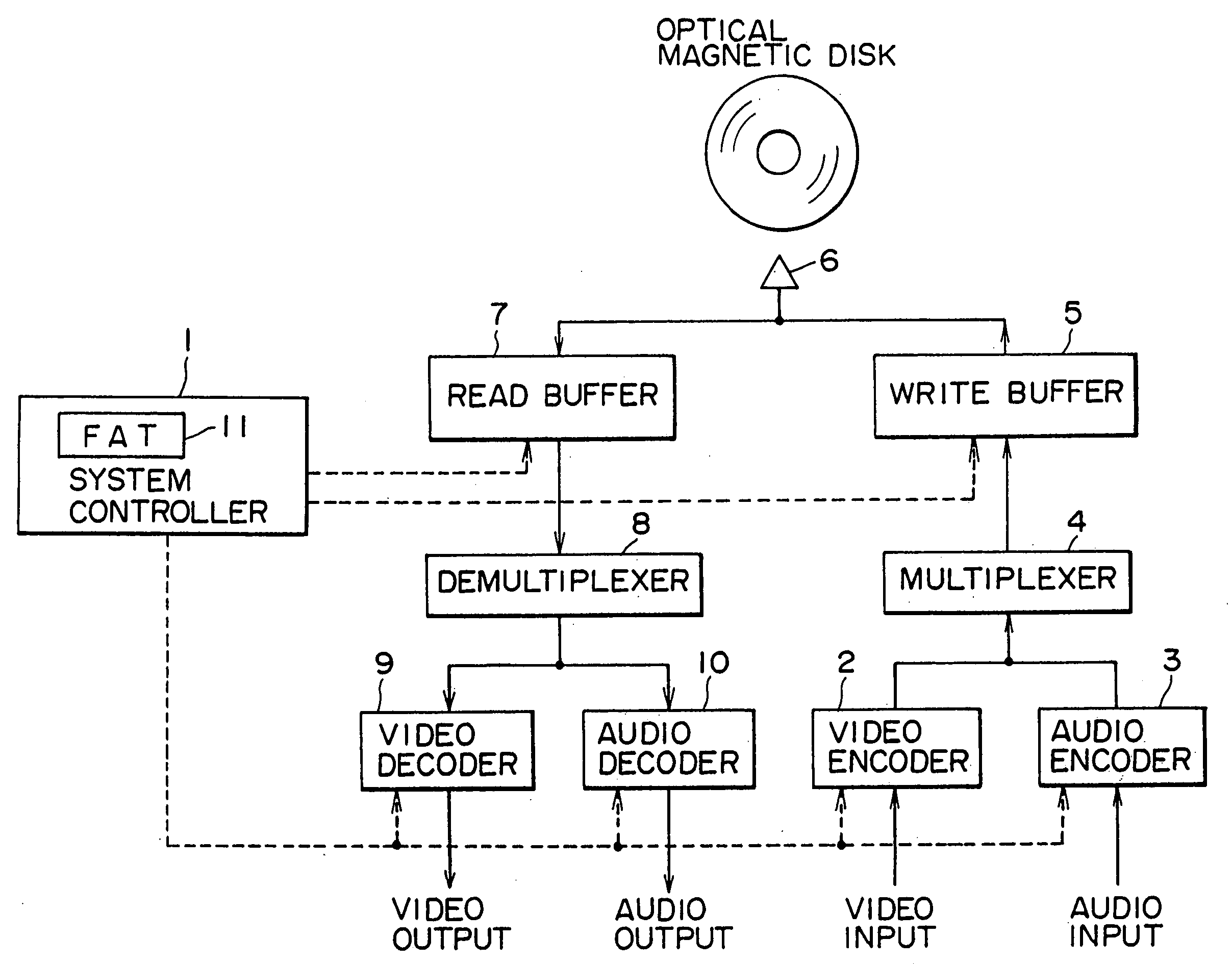

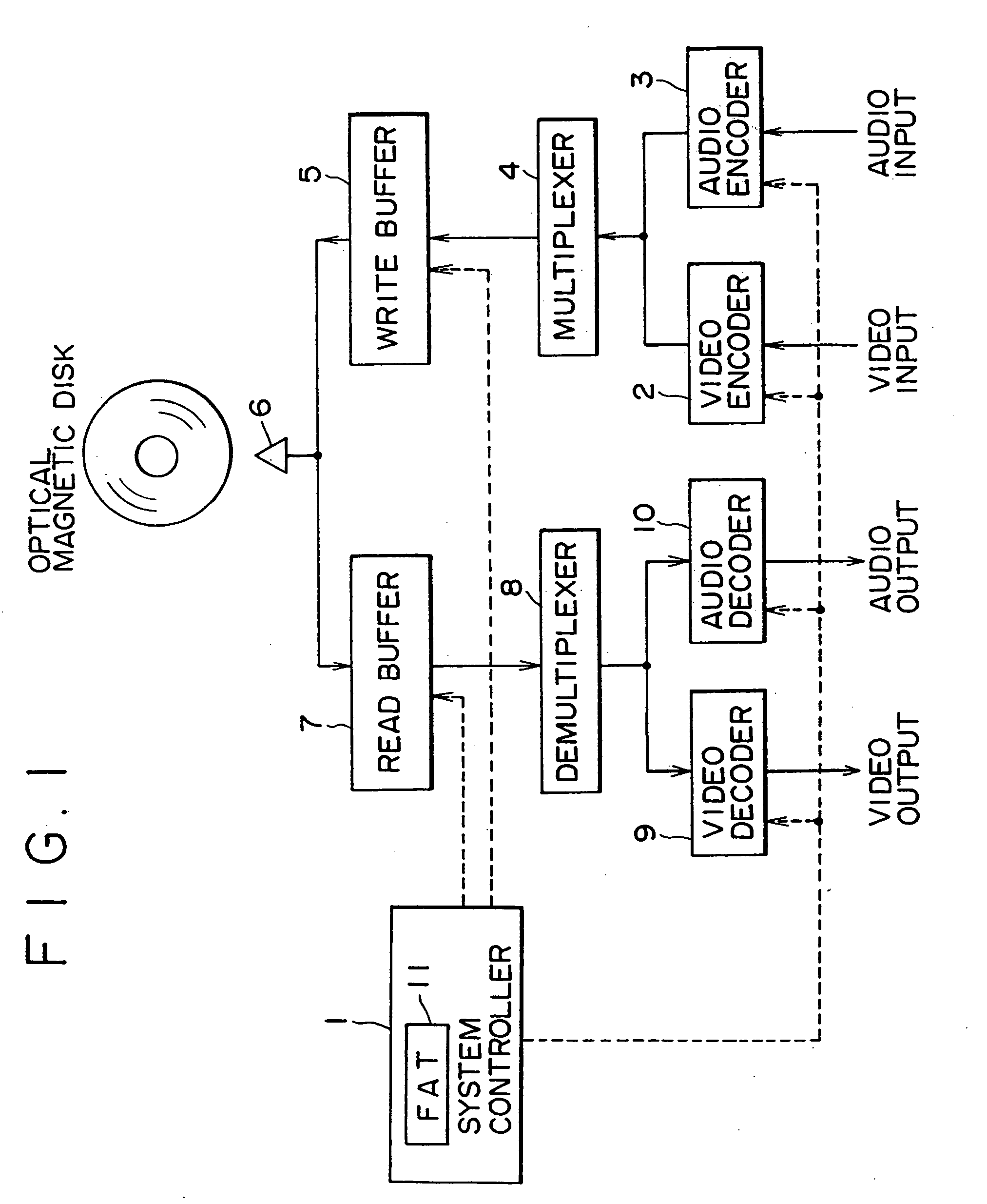

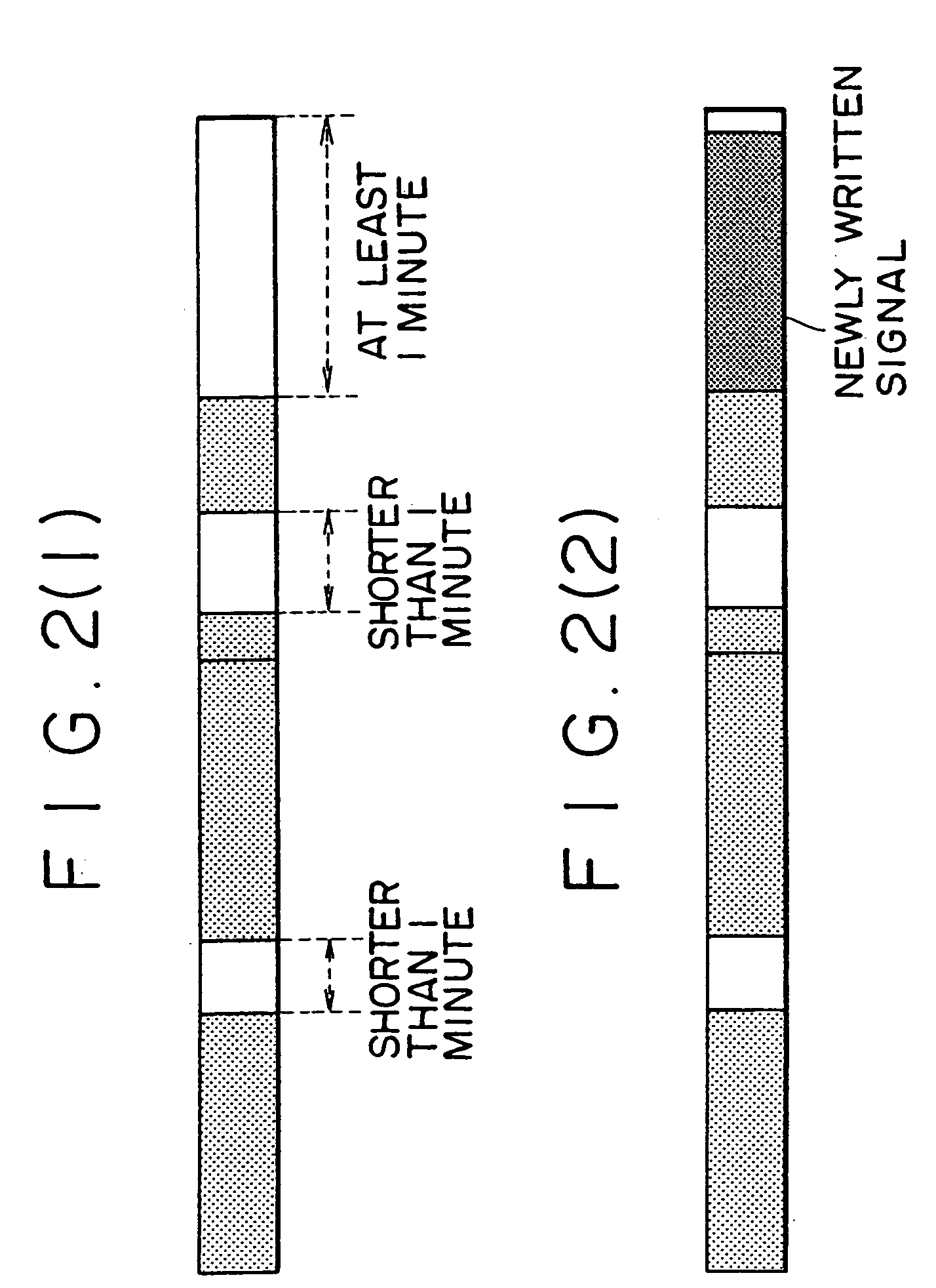

Signal recording method & apparatus, signal recording / reproducing method & apparatus and signal recording medium

InactiveUS20050163468A1Reduce numberLarge amountTelevision system detailsMagneto-optical discsComputer hardwarePartial filling

By reducing the number of seek operations in an operation to play back a signal from a recording medium, the amount of data temporarily stored in a read buffer memory employed in a signal recording / playback apparatus is large enough to be output as a playback signal during a seek operation, allowing a continuous playback operation to be carried out. In order to reduce the number of seek operations, a signal is always recorded onto the recording medium in continuous free areas each having a size equal to or larger than a predetermined recording / playback time length which is typically set at 1 minute. If it is necessary to insert an additional signal having a length smaller than the predetermined recording / playback time length into a point of insertion in an area already occupied by an existing signal, a continuous free area with a size equal to or larger than the predetermined recording / playback time length is newly allocated to the additional signal. The additional signal is then recorded in the free area instead of being inserted into the point of insertion. Since the free area is larger in size than the length of the additional signal, the rest of the free area is filled up with a portion of the existing signal adjacent to the point of insertion.

Owner:SONY CORP

Systems to enhance data entry in mobile and fixed environment

InactiveUS20160005150A1Fast and reliableLarge amountGeometric image transformationAlphabetical characters enteringVirtual keyboardData entry

A data entry system is provided using a virtual dynamic keypad having at least four keys, wherein to four of the keys at least substantially all of the letters of a language are distributively assigned and wherein the locations of the four letter keys relating to each other are dynamically defined during the entry of text. A text entry system is also provided using a virtual keypad having at least four keys wherein to four of its keys at least substantially all of the letters of a language are distributively assigned and wherein the locations of the four letter keys relating to each other are dynamically defined based on a calibrating procedure provided by the user. A data entry system is provided using a pointing device providing different pointing directions wherein each of the pointing directions duplicates a key of a predefined virtual keypad model wherein to at least some of its keys substantially all of the letters of a language are distributively assigned.

Owner:GHASSABIAN BENJAMIN FIROOZ

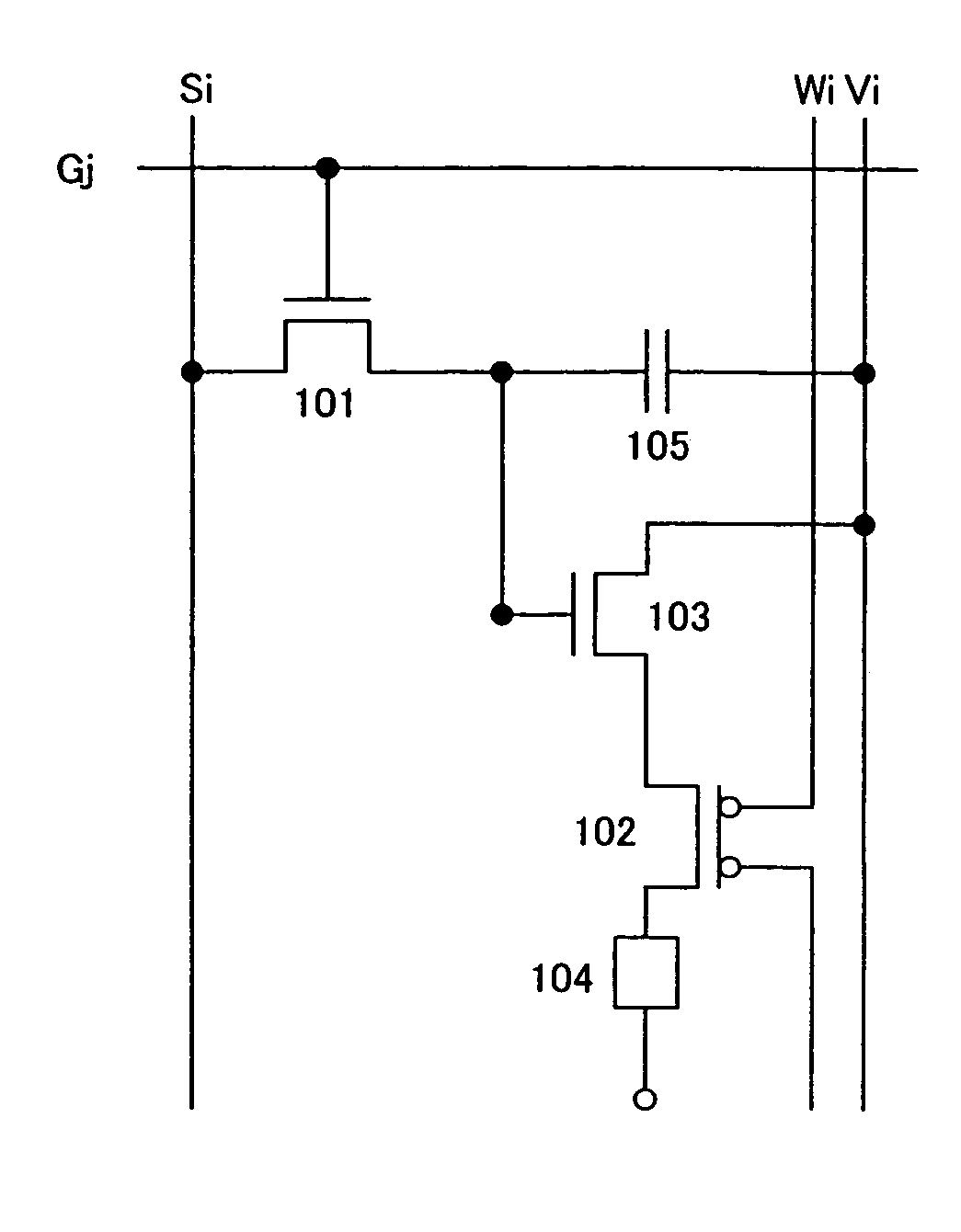

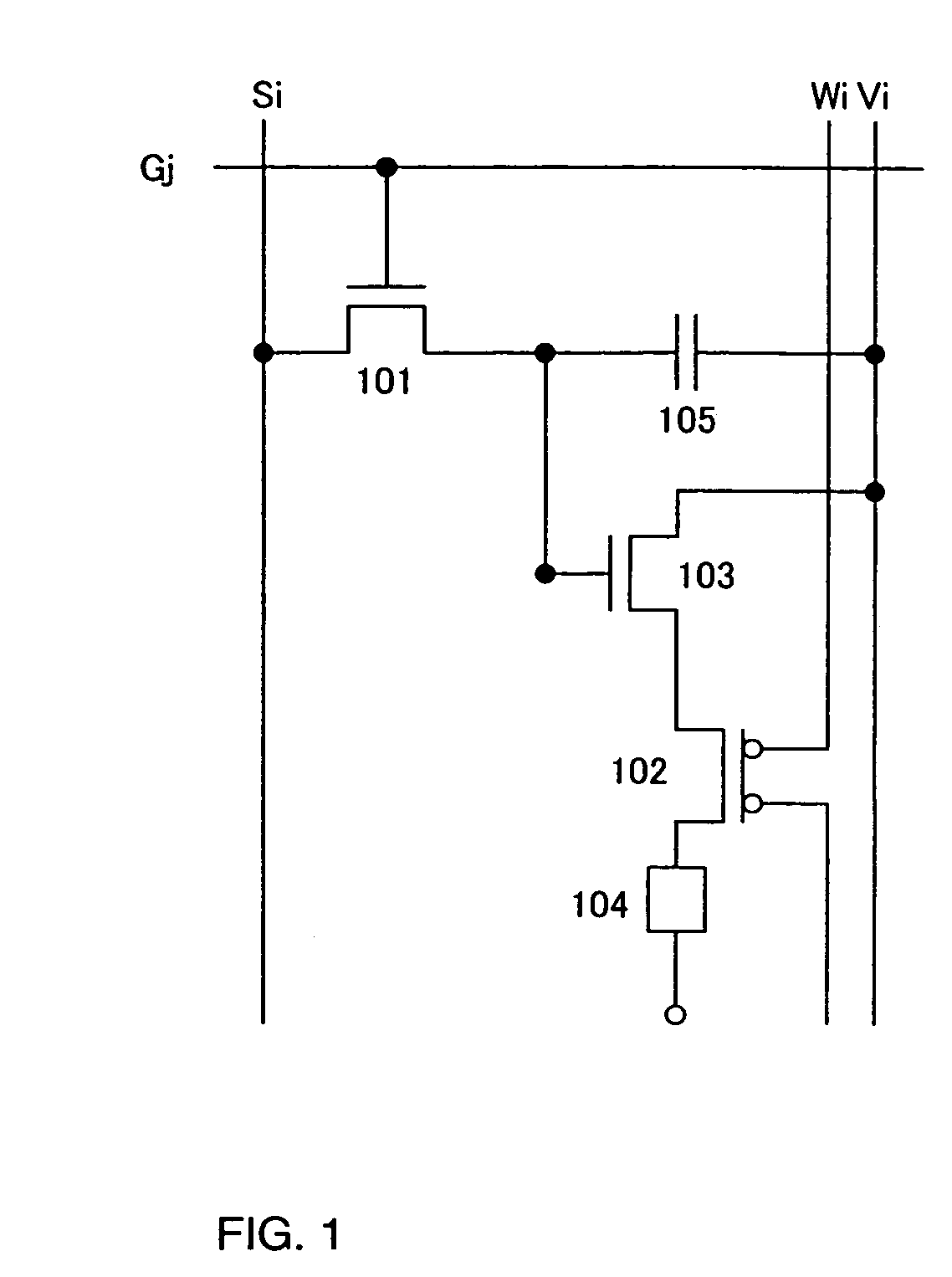

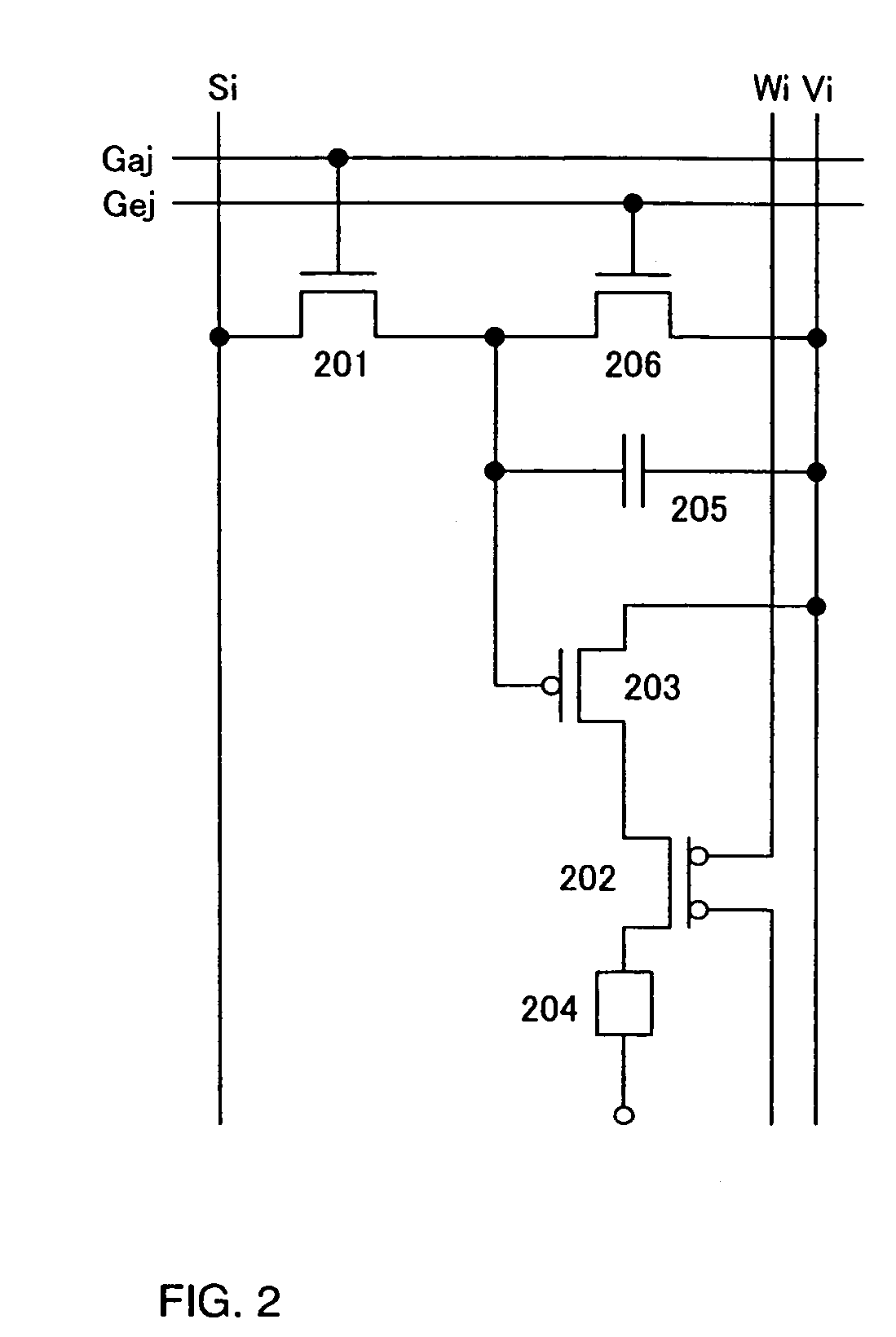

Element substrate and light emitting device

InactiveUS7122969B2High field-effect mobilityLarge amountElectroluminescent light sourcesSolid-state devicesLinear regionEngineering

No need of lowering off-current of a switching transistor, fewer luminance variations of a light emitting element between pixels due to characteristic variations of a driving transistor, and less risk of steps due to increase in the number of wirings. A video signal for light emission or non-emission of a pixel is input to a gate of a current controlling transistor operated in a linear region, which is connected in series with the driving transistor, through a switching transistor. Since a voltage Vds between a source and a drain of the current controlling transistor is small, small changes in a voltage Vgs between a gate and a source thereof do not affect a current flowing in a load. The current flowing in the light emitting element is determined by the driving transistor operated in a saturation region, and a fixed potential is input to the gate thereof during light emission.

Owner:SEMICON ENERGY LAB CO LTD

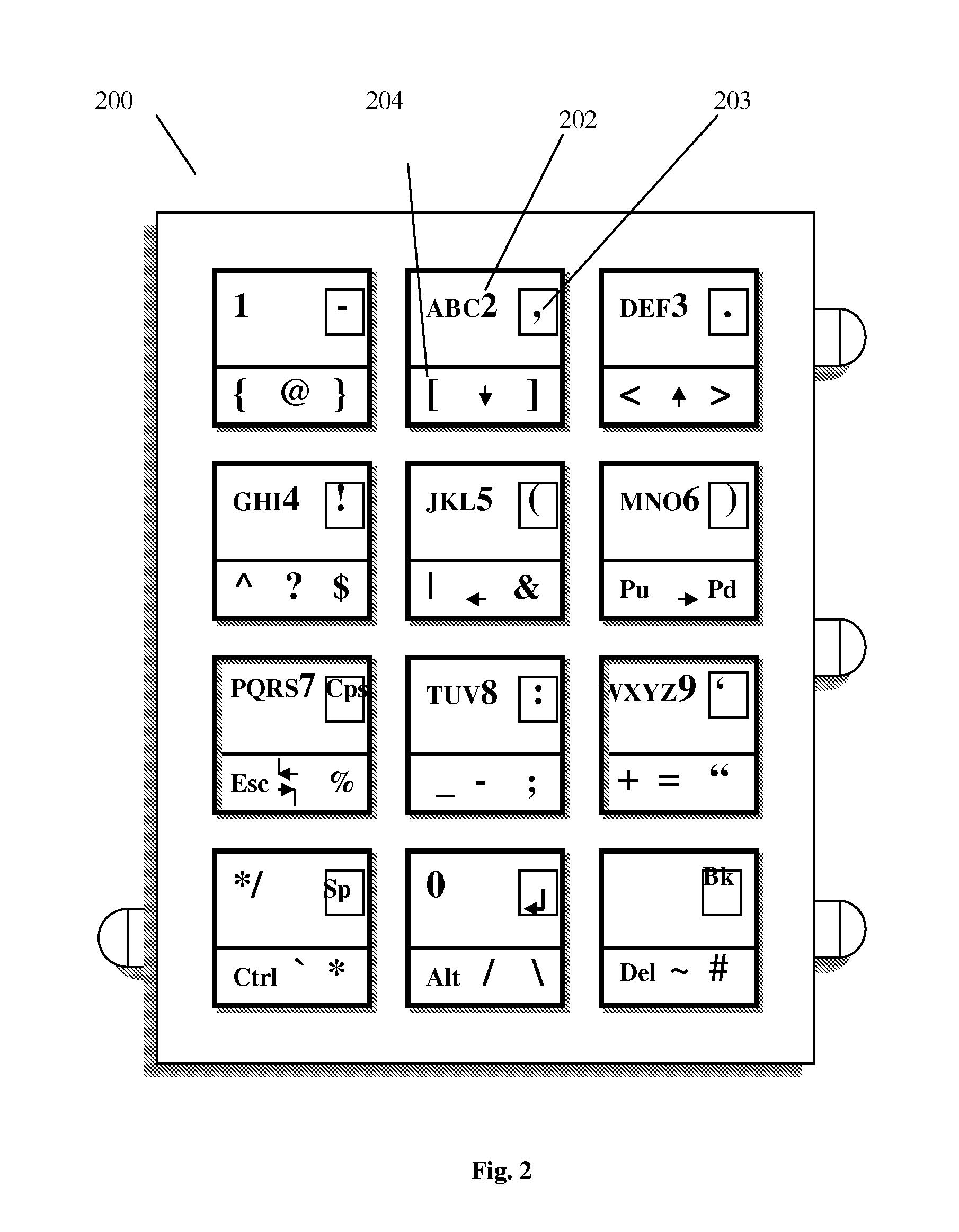

Systems to enhance data entry in mobile and fixed environment

InactiveUS20150261429A1Large of expenditureLarge amount of setSubstation equipmentInput/output processes for data processingHuman–computer interactionRecognition system

A data input system has a keypad defining a plurality of keys. Each key contains at least one symbol of a group of symbols. The group of symbols is divided into subgroups each having at least one of alphabetical symbols, numeric symbols, and command symbols, where each subgroup is associated with at least a portion of a user's finger. A finger recognition system is in communication with at least one key, where the key has at least a first symbol from a first subgroup and at least a second symbol from a second subgroup. The finger recognition system recognizes the portion of the user's finger when the finger interacts with the key so as to select the symbol on the key, corresponding to the subgroup associated with the portion of the user's finger.

Owner:GHASSABIAN BENJAMIN FIROOZ

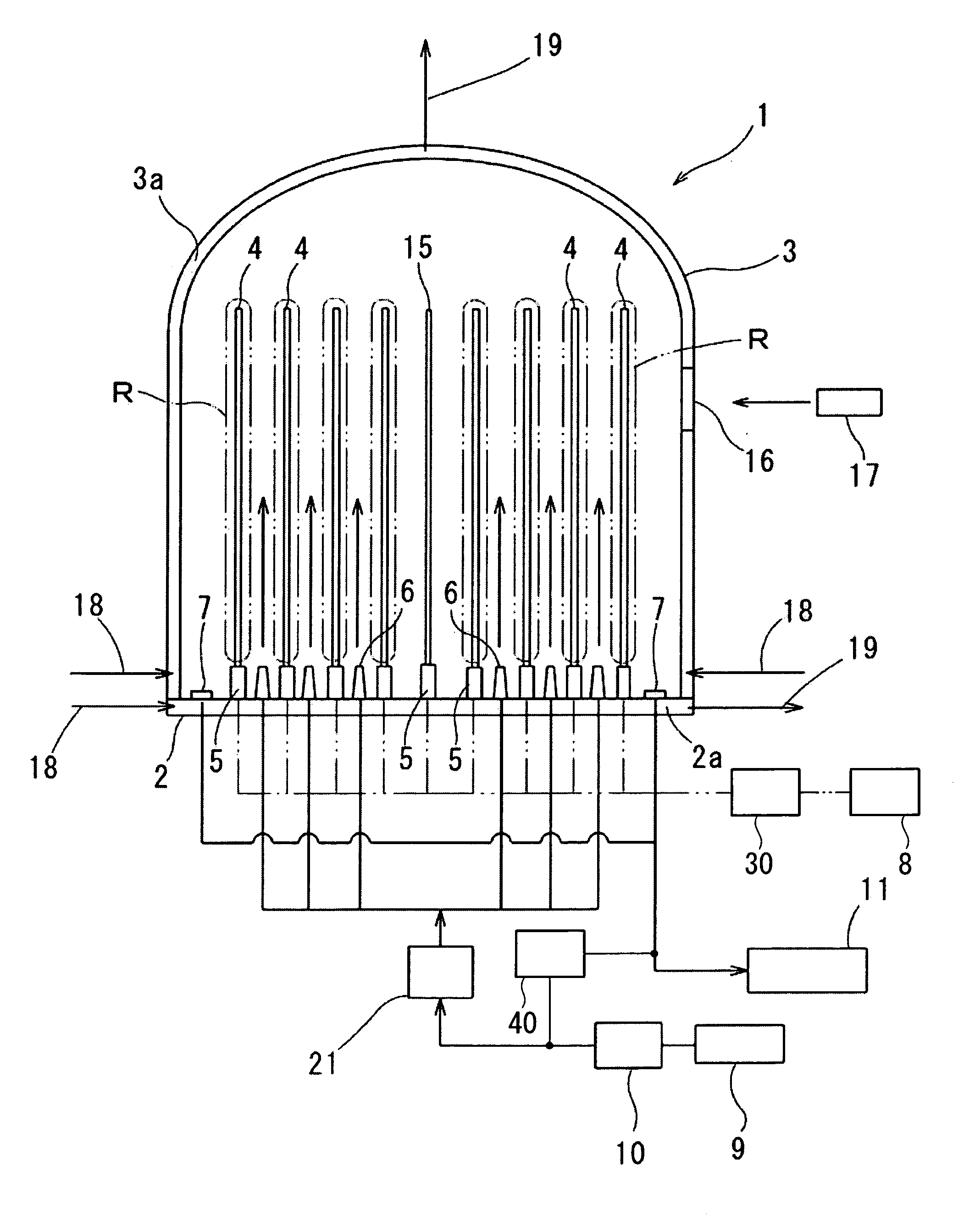

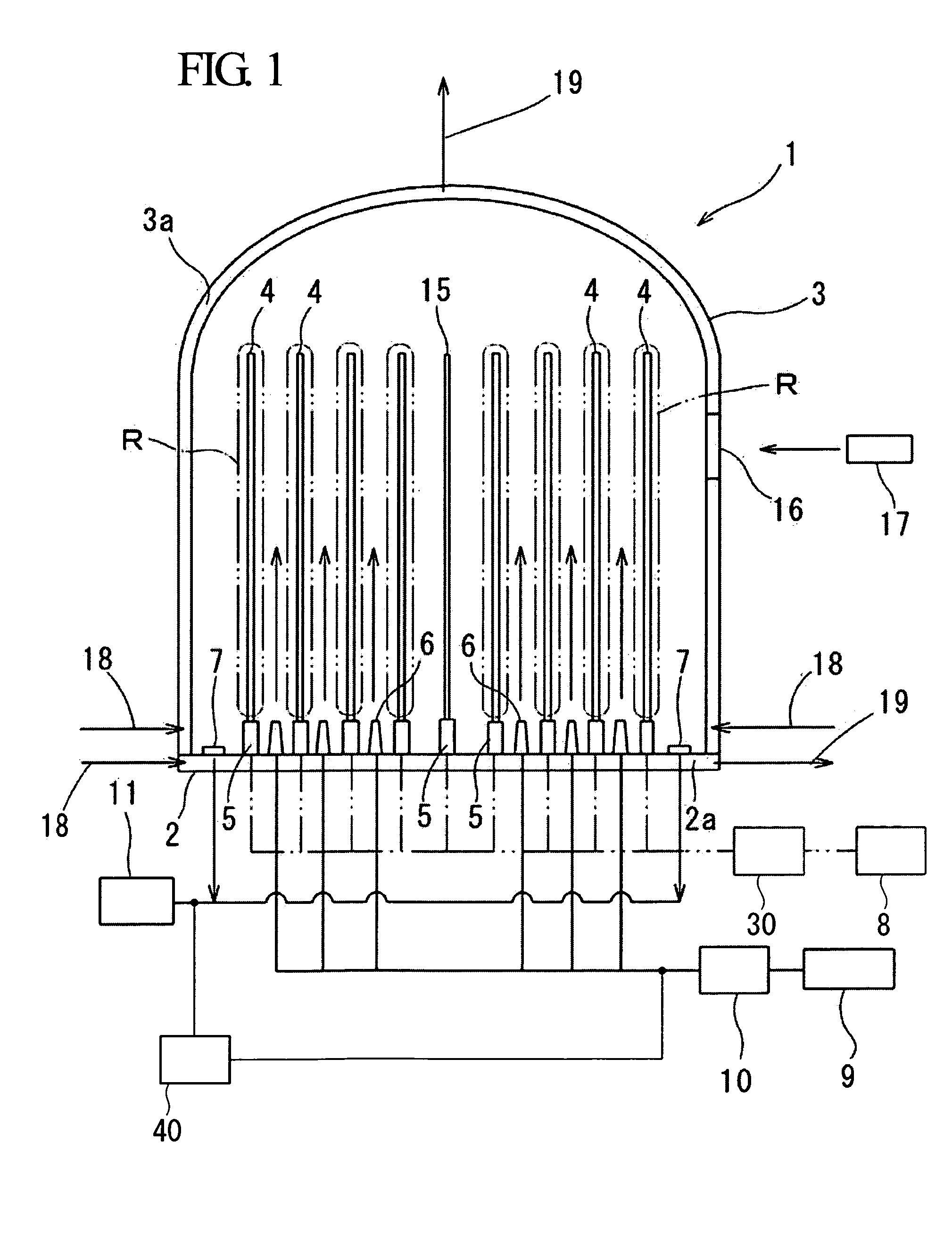

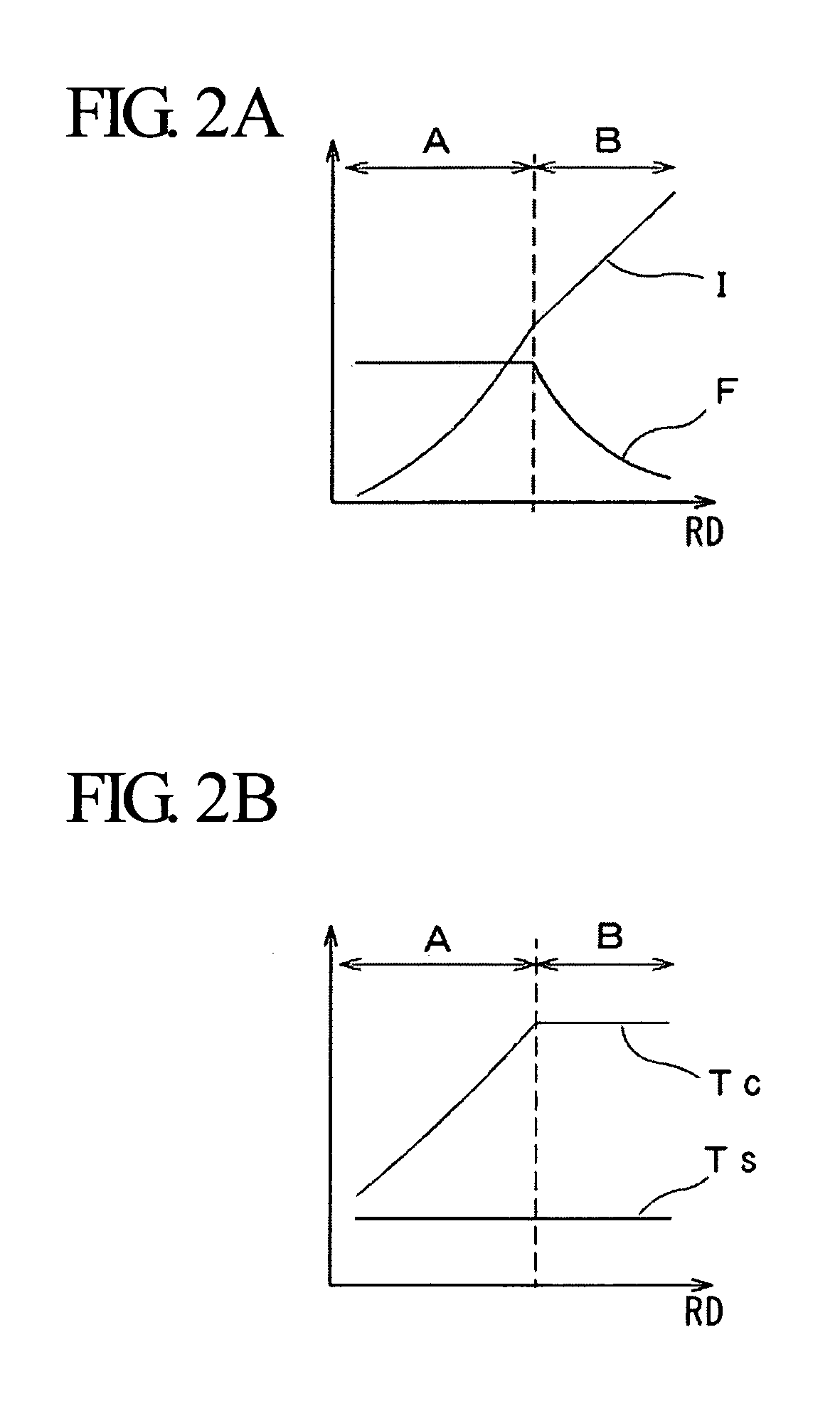

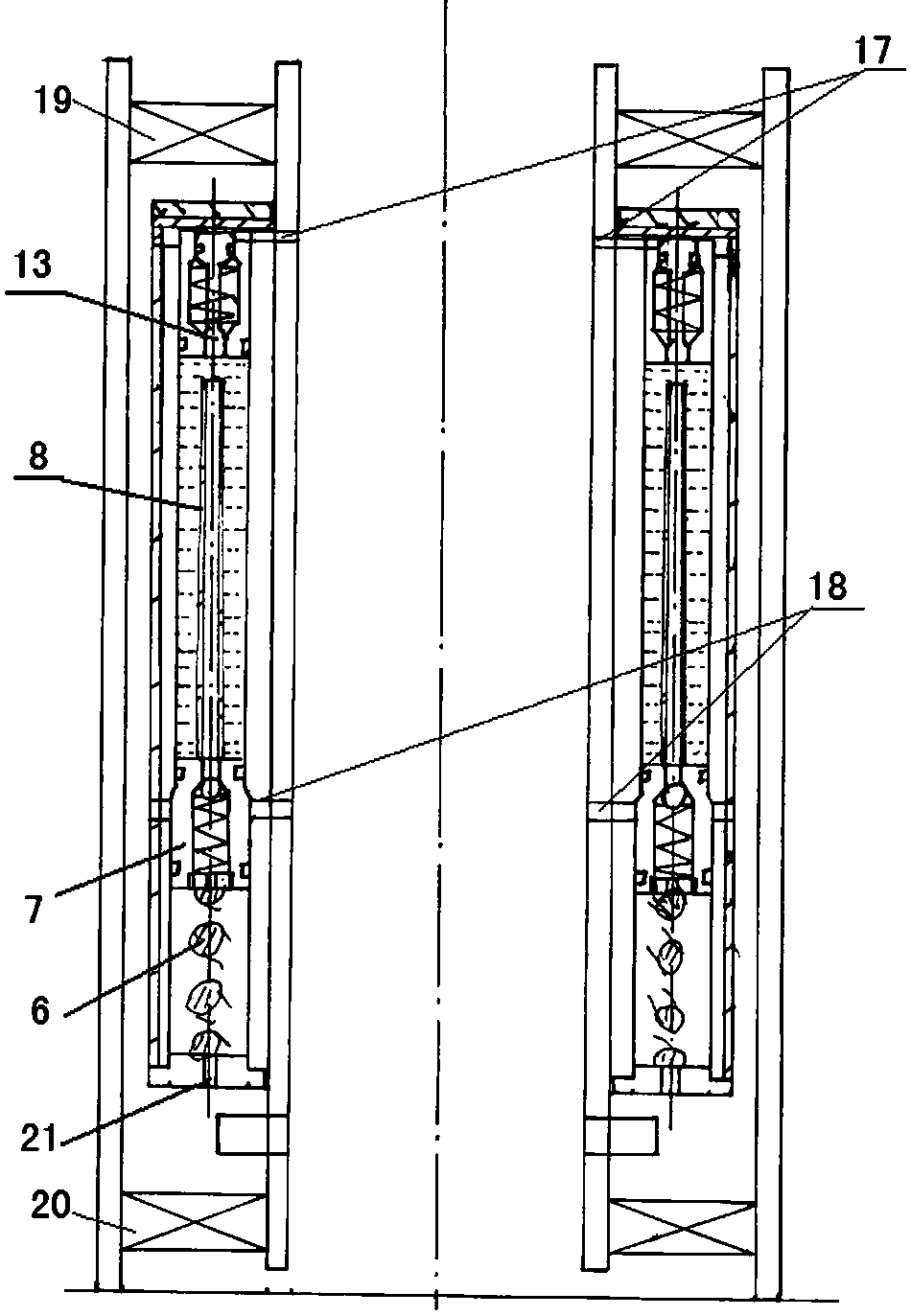

Polycrystalline silicon producing method, apparatus for producing polycrystalline silicon, and polycrystalline silicon

ActiveUS20110014468A1No longer growLarge amountFurnaces without endless coreDielectric heatingPolycrystalline siliconChlorosilane

A polycrystalline silicon producing method includes: the first process and the second process. In the first process, a surface temperature is maintained at a predetermined range by adjusting the current value to the silicon seed rod, and the raw material gas is supplied while maintaining a supply amount of chlorosilanes per square millimeter of the surface of the rod in a predetermined range until a temperature of the center portion of the rod reaches a predetermined temperature lower than the melting point of the polycrystalline silicon, and in the second process, a previously determined current value is set corresponding to a rod diameter and the supply amount of the raw material gas per square millimeter of the surface of the rod is decreased to maintain the surface temperature and the temperature of the center portion of the rod at predetermined ranges, respectively.

Owner:MITSUBISHI MATERIALS CORP

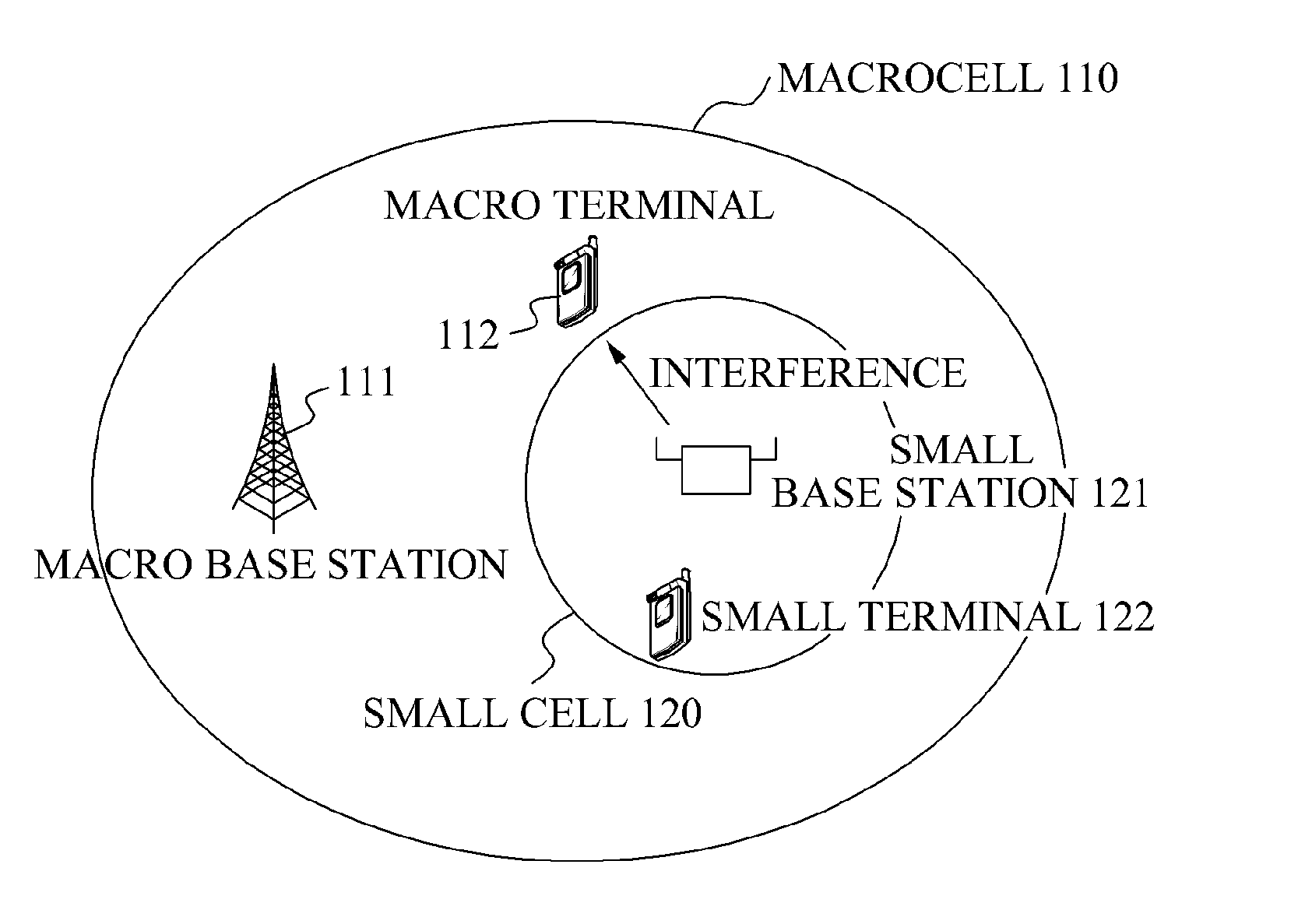

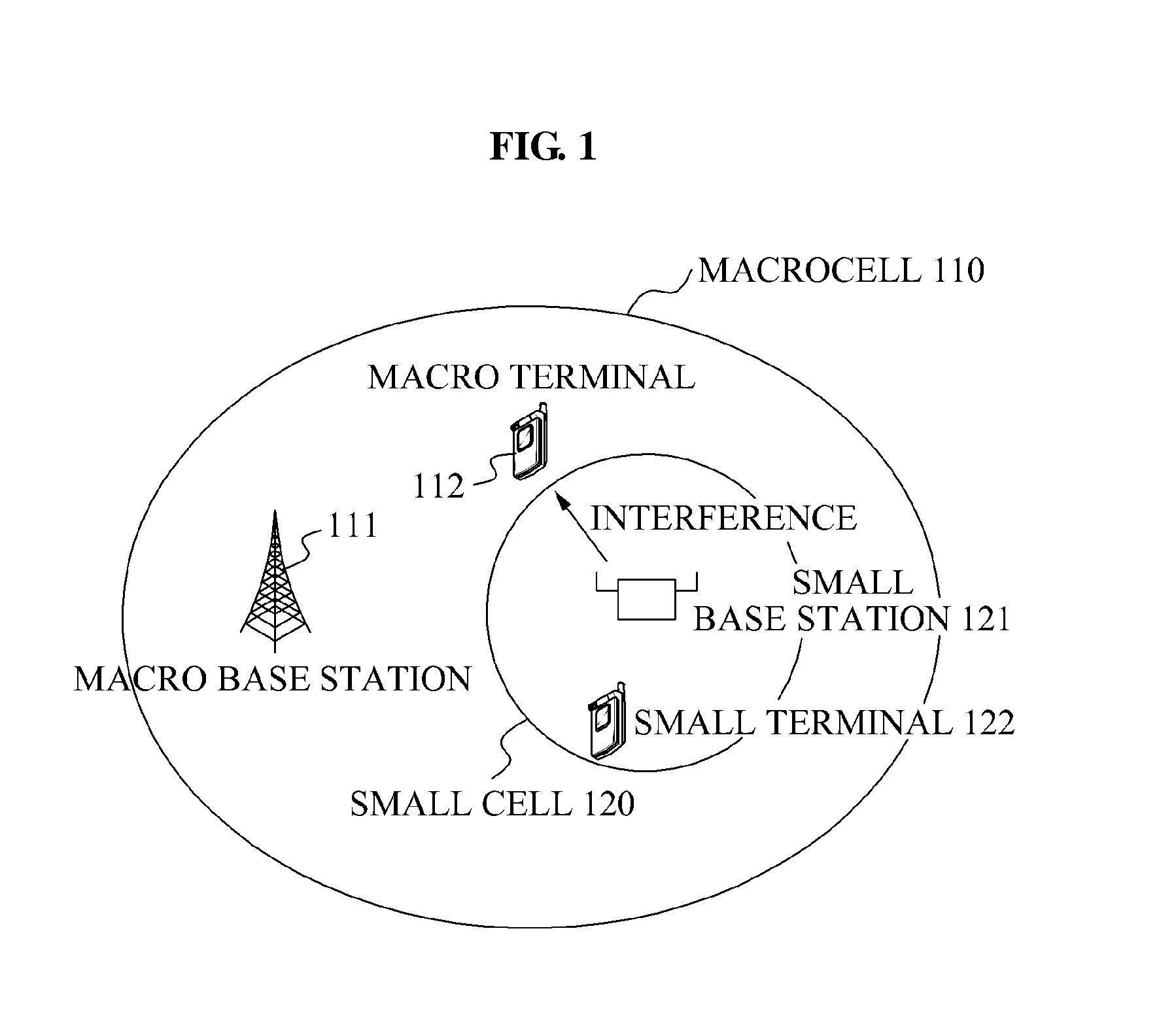

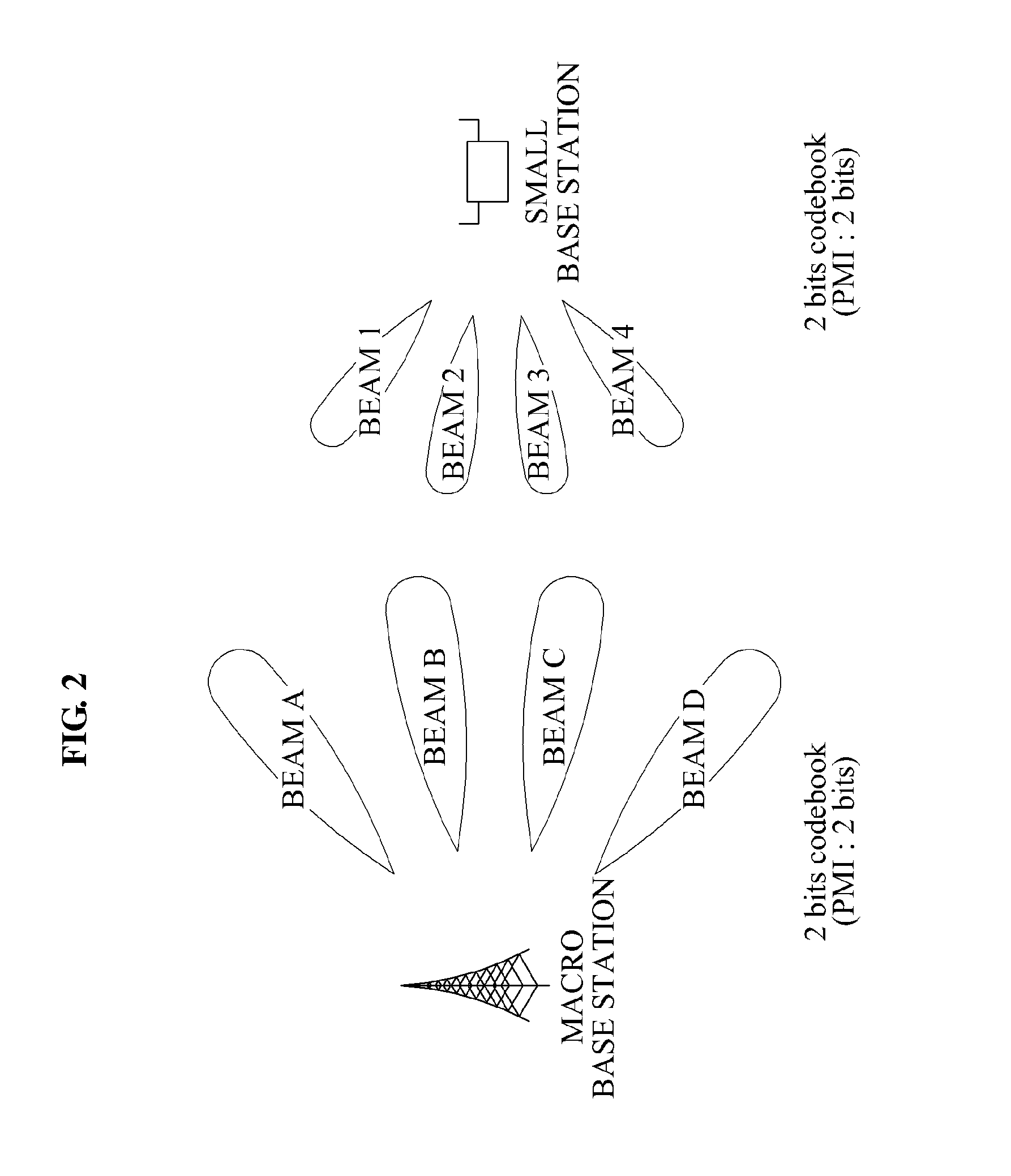

Hierarchical-cell communication system using asymmetric feedback scheme based on class of access network

ActiveUS20110128939A1Large amountPower managementCriteria allocationCellular communication systemsBeamforming

A small cell communication system may reduce interference occurring in a macro terminal through beamforming, even when using the same frequency resources as used by a macro communication system. For example, the small cell communication system may use a larger amount of radio resources than the macro communication system for transmission of feedback information in an uplink. For example, the small cell communication system may use a codebook having a larger size than a size of a codebook used by the macro communication system.

Owner:SAMSUNG ELECTRONICS CO LTD

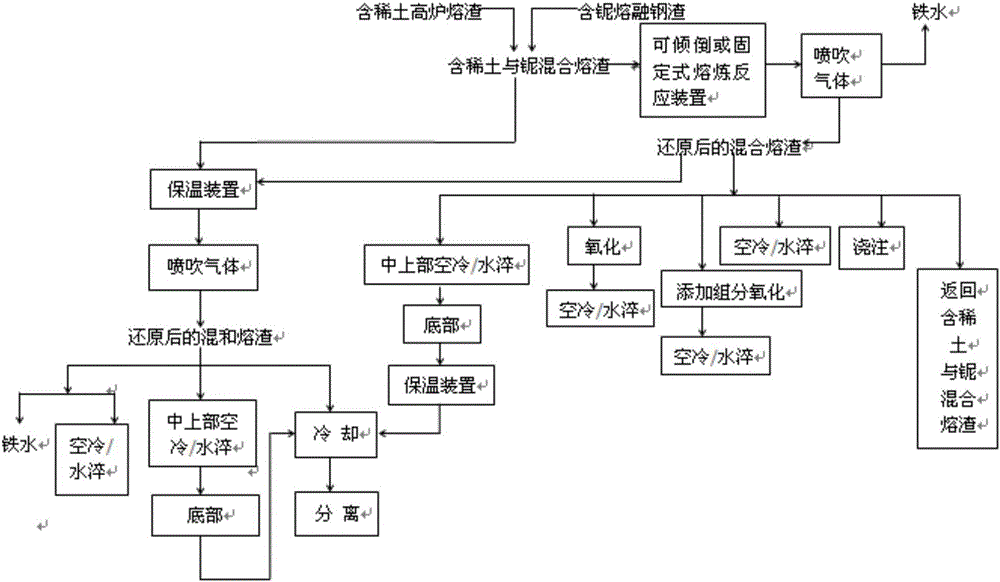

Smelting reduction recovery and thermal refining method for rare-earth-niobium-containing slag mixture

ActiveCN106048106AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementNiobiumSlag

The invention relates to a smelting reduction recovery and thermal refining method for a rare-earth-niobium-containing slag mixture and belongs to the field of non-blast furnace ironmaking and resource comprehensive utilization. The smelting reduction recovery and thermal refining method for the rare-earth-niobium-containing slag mixture comprises the following steps of (1) mixing rare-earth-containing blast furnace slag and niobium-containing molten steel slag to form the rare-earth-niobium-containing slag mixture and controlling the temperature of the rare-earth-niobium-containing slag mixture within a set temperature range; (2) injecting oxidative gas and conducting smelting reduction to reduce iron oxide into metallic iron fully; and (3) conducting separation and recovery according to different reaction devices. According to the method, the rare earth, the calcium component, the niobium component and the phosphorus component in the slag mixture can be efficiently recycled; cold-state niobium-rare-earth-iron-containing materials can be processed and at the same time thermal refining of the slag can be realized, so that the efficient resource comprehensive utilization can be achieved. The method is short in reaction time, high in metal recovery rate, low in production cost, strong in raw material adaptability, large in processing capacity, friendly with environment, high in economic income and capable of solving the problems of efficient recovery and utilization of metallurgical resources and heat energy effectively.

Owner:NORTHEASTERN UNIV

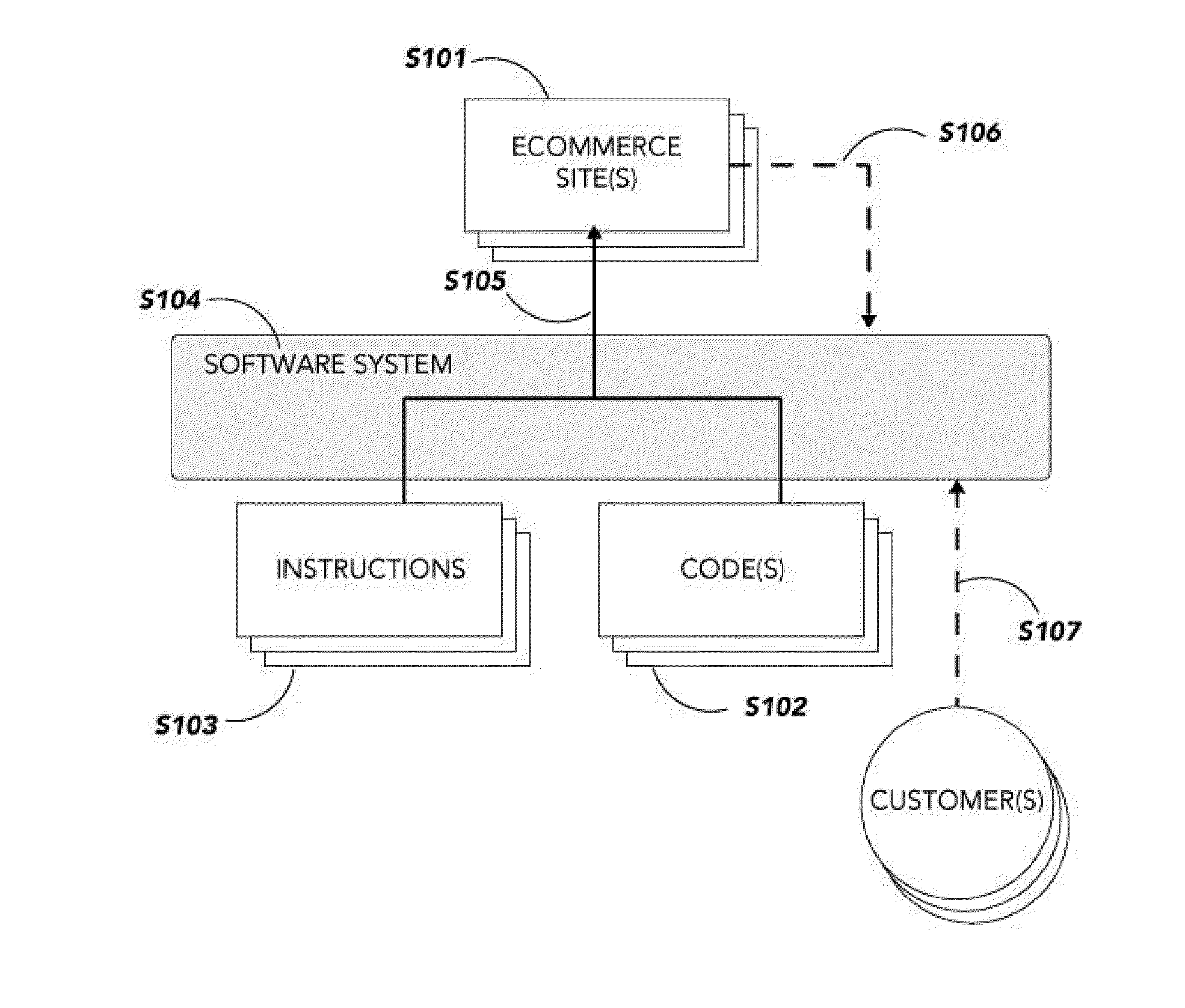

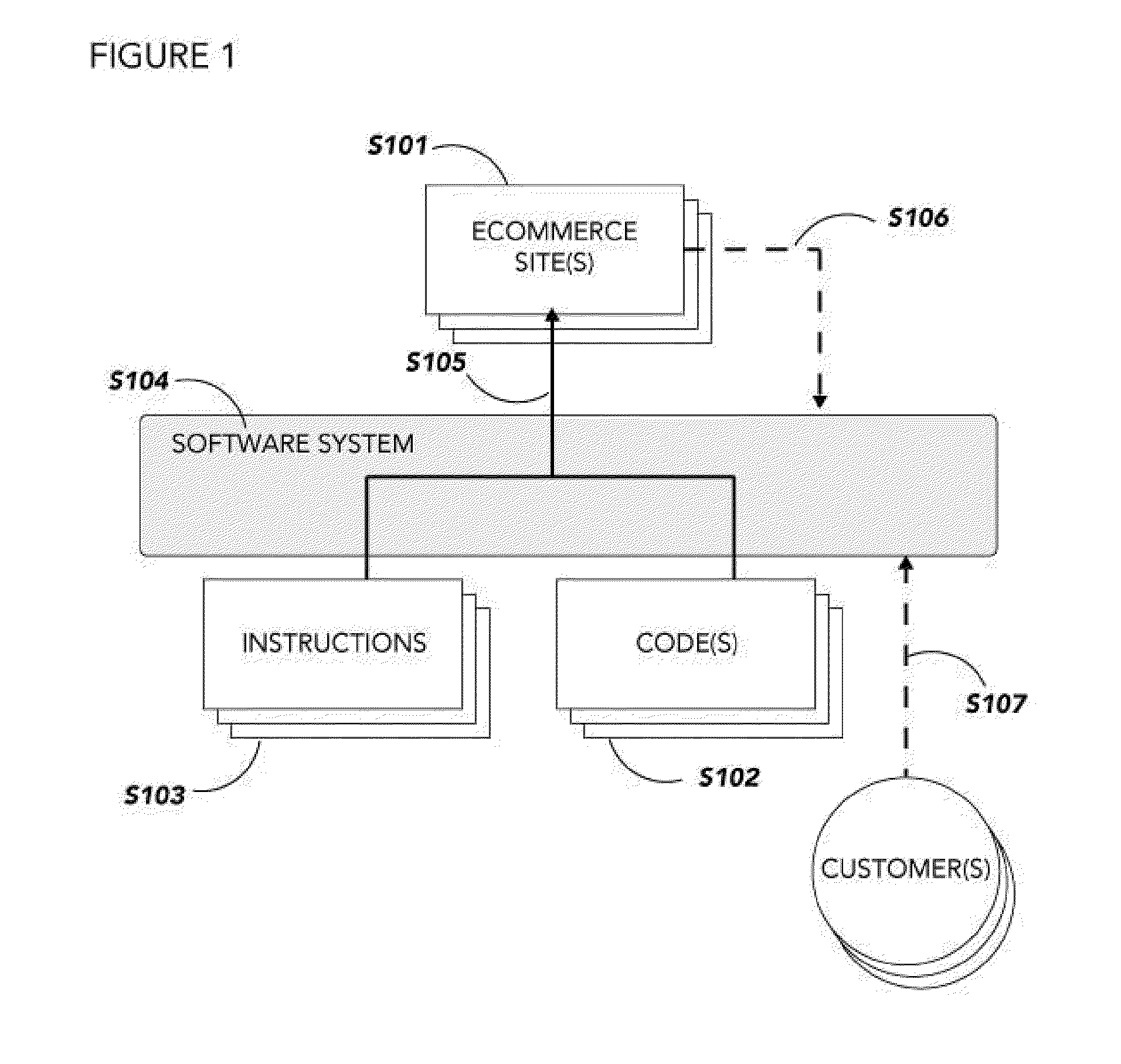

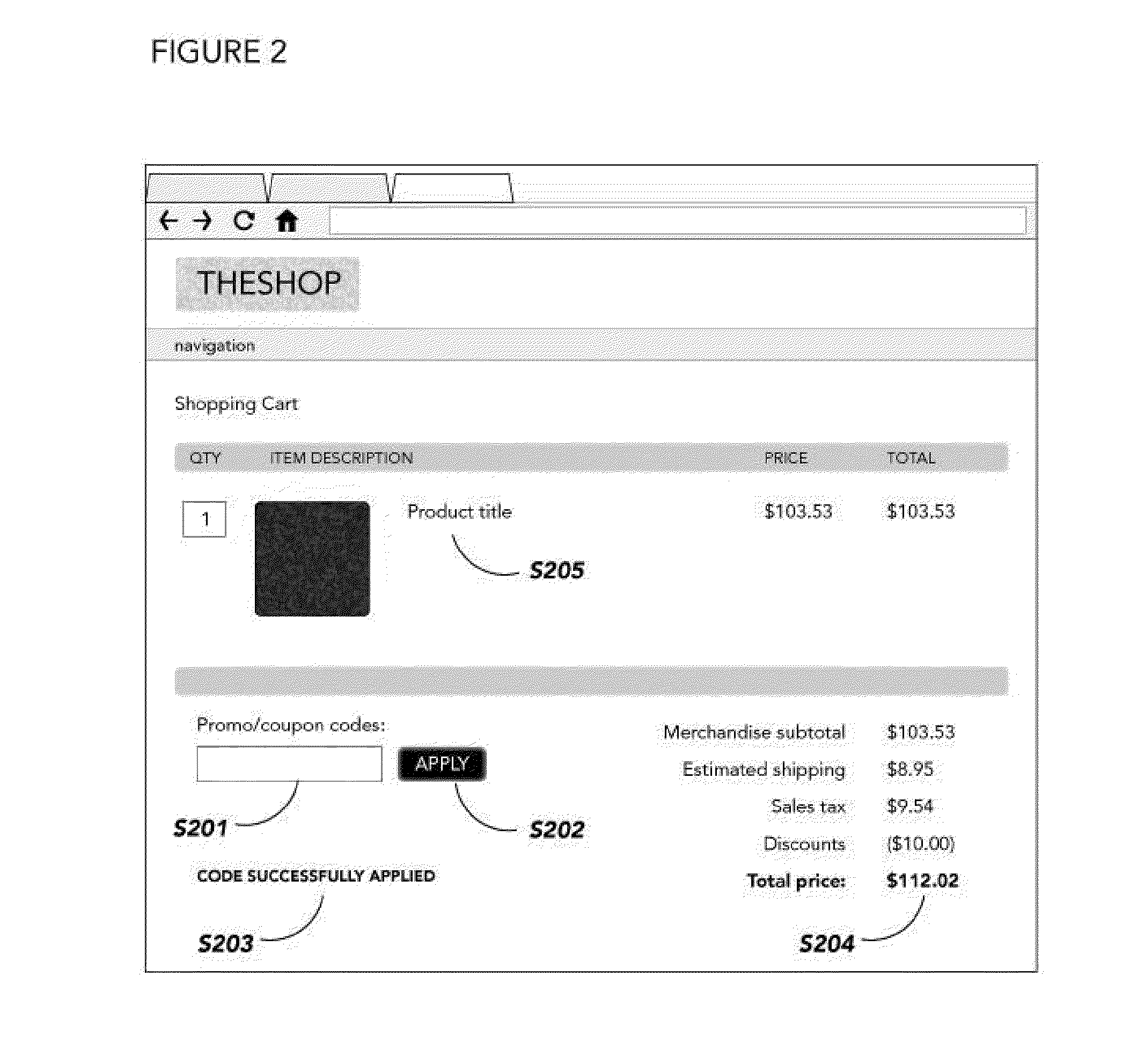

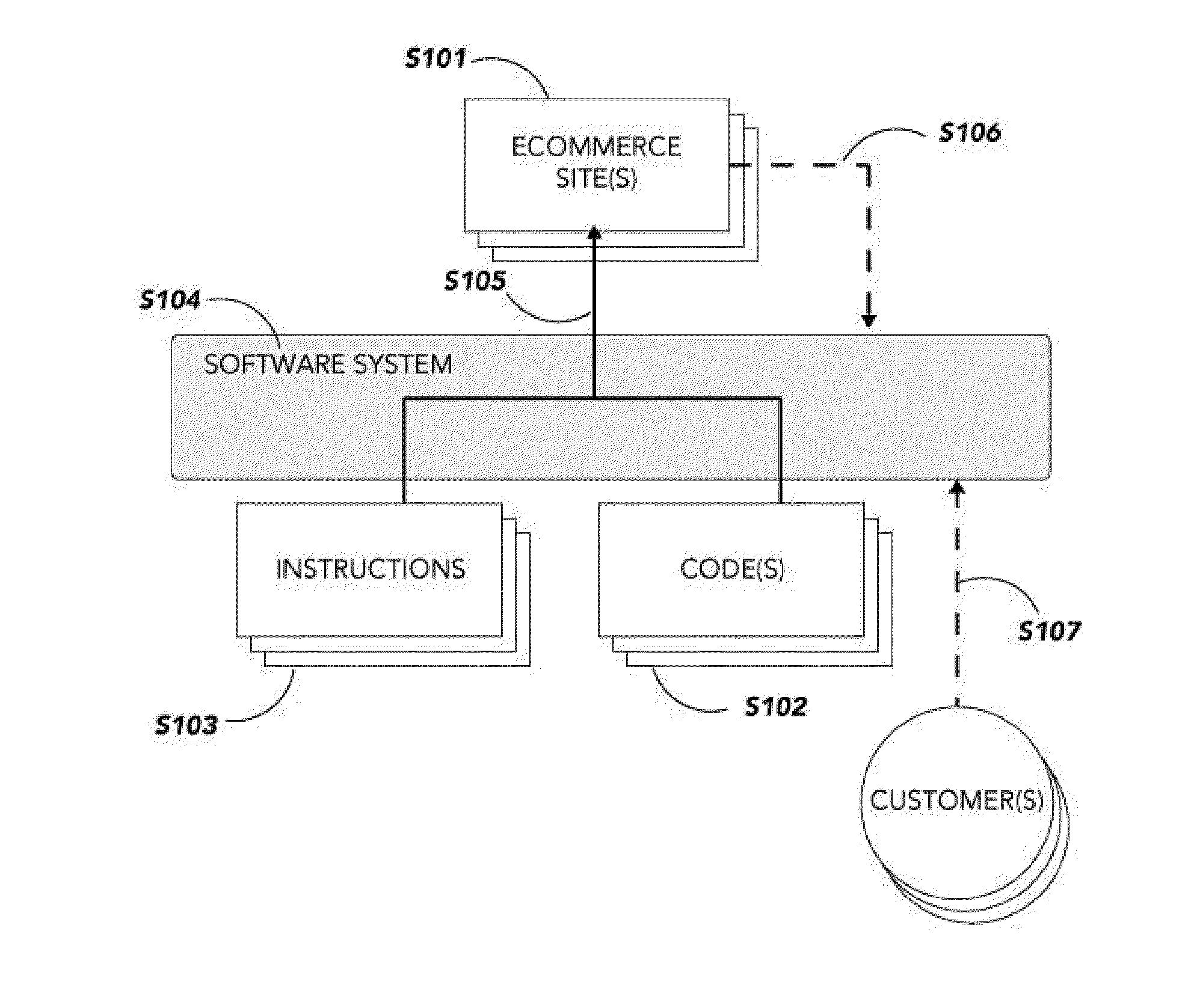

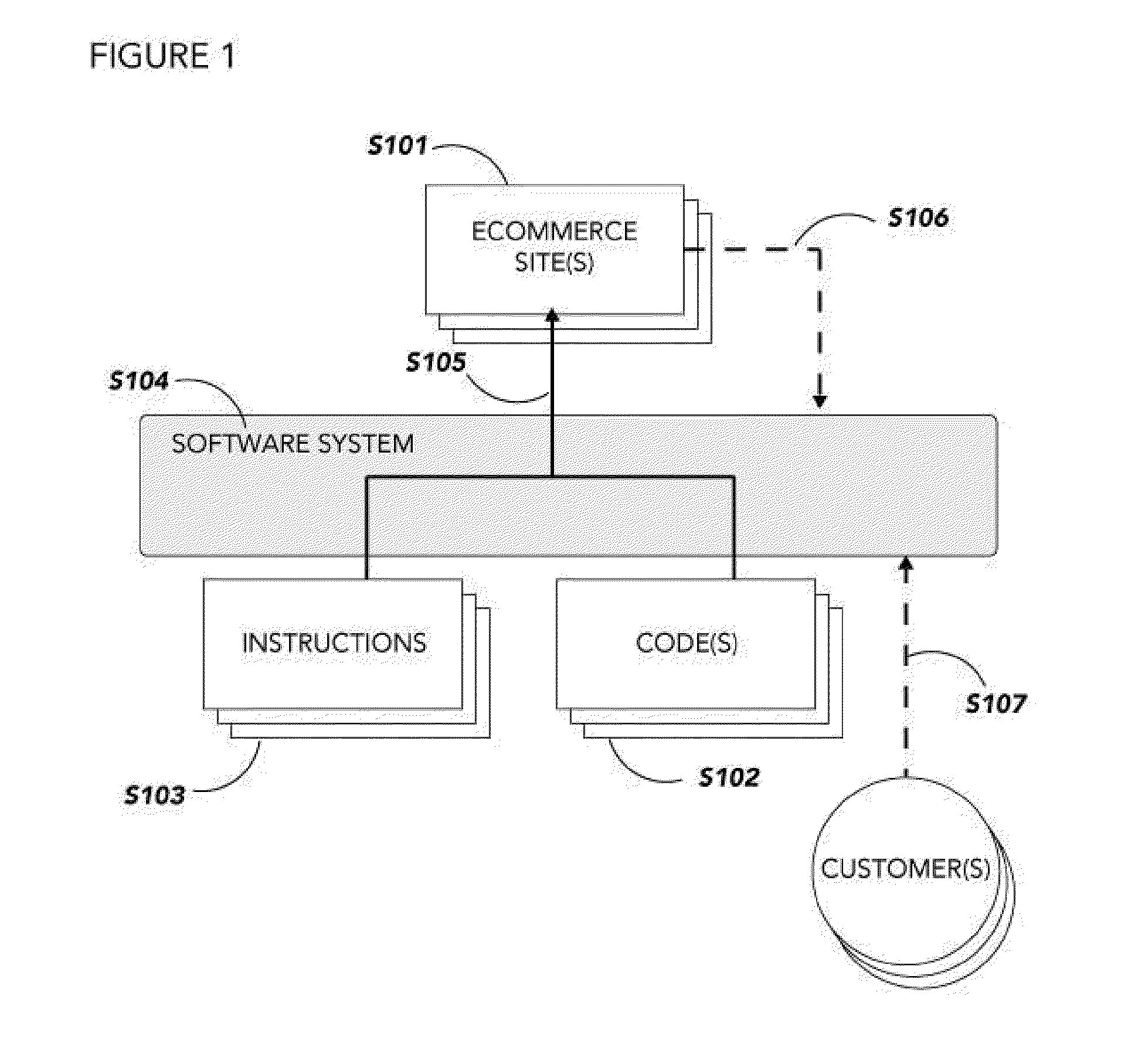

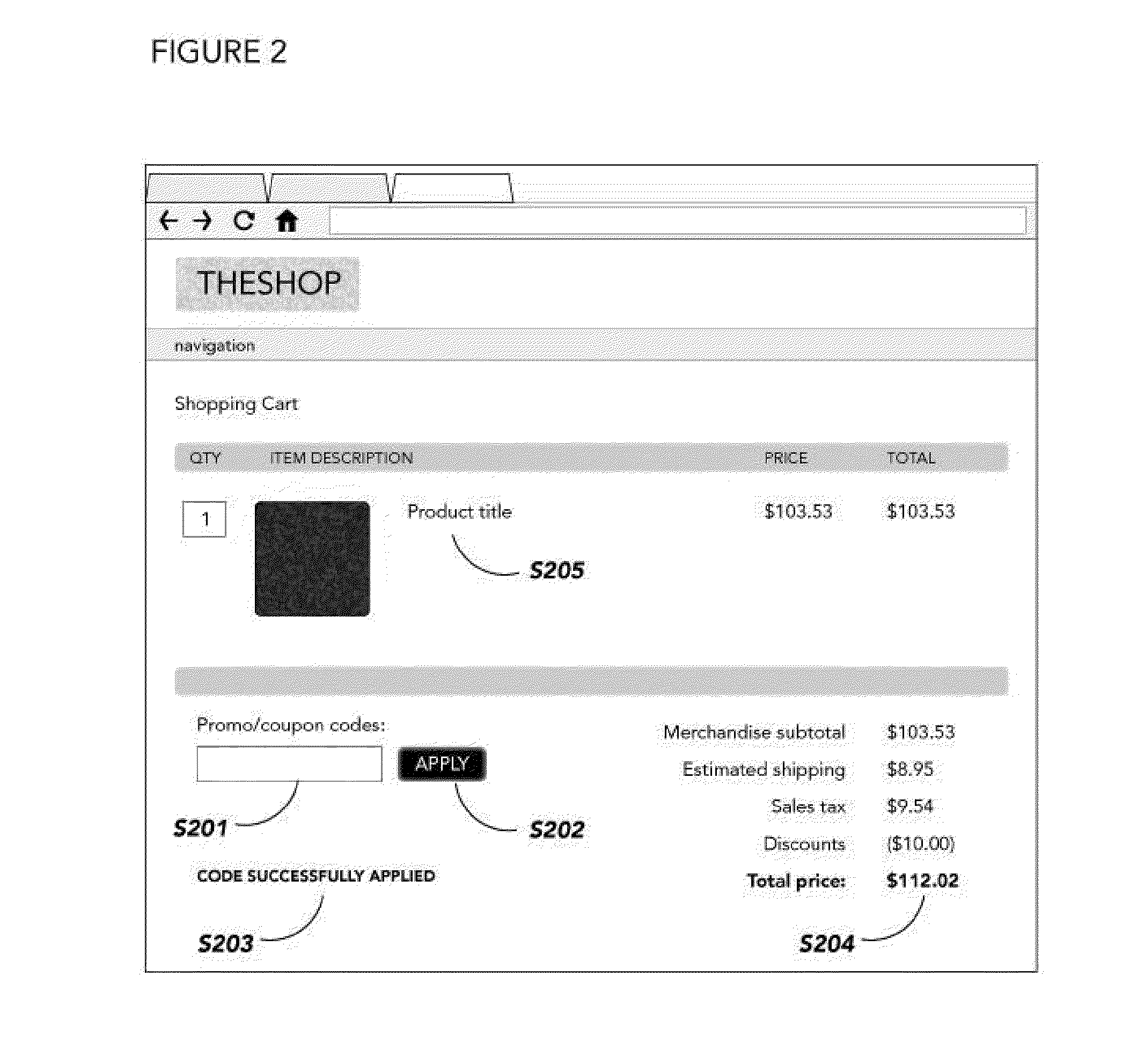

Cross-site online shopping assistant

A shopping assistant for online shopping. The invention provides for a software system to assist consumers in automatically locating and systematically applying discount codes to electronic commerce platforms to obtain reduced prices. In a preferred embodiment of the invention, discount codes are automatically located, evaluated against a user's shopping cart, and evaluated for the best results for the consumer. In the preferred embodiment, information about the utility of discount codes is recorded to machine readable storage.

Owner:PAYPAL INC

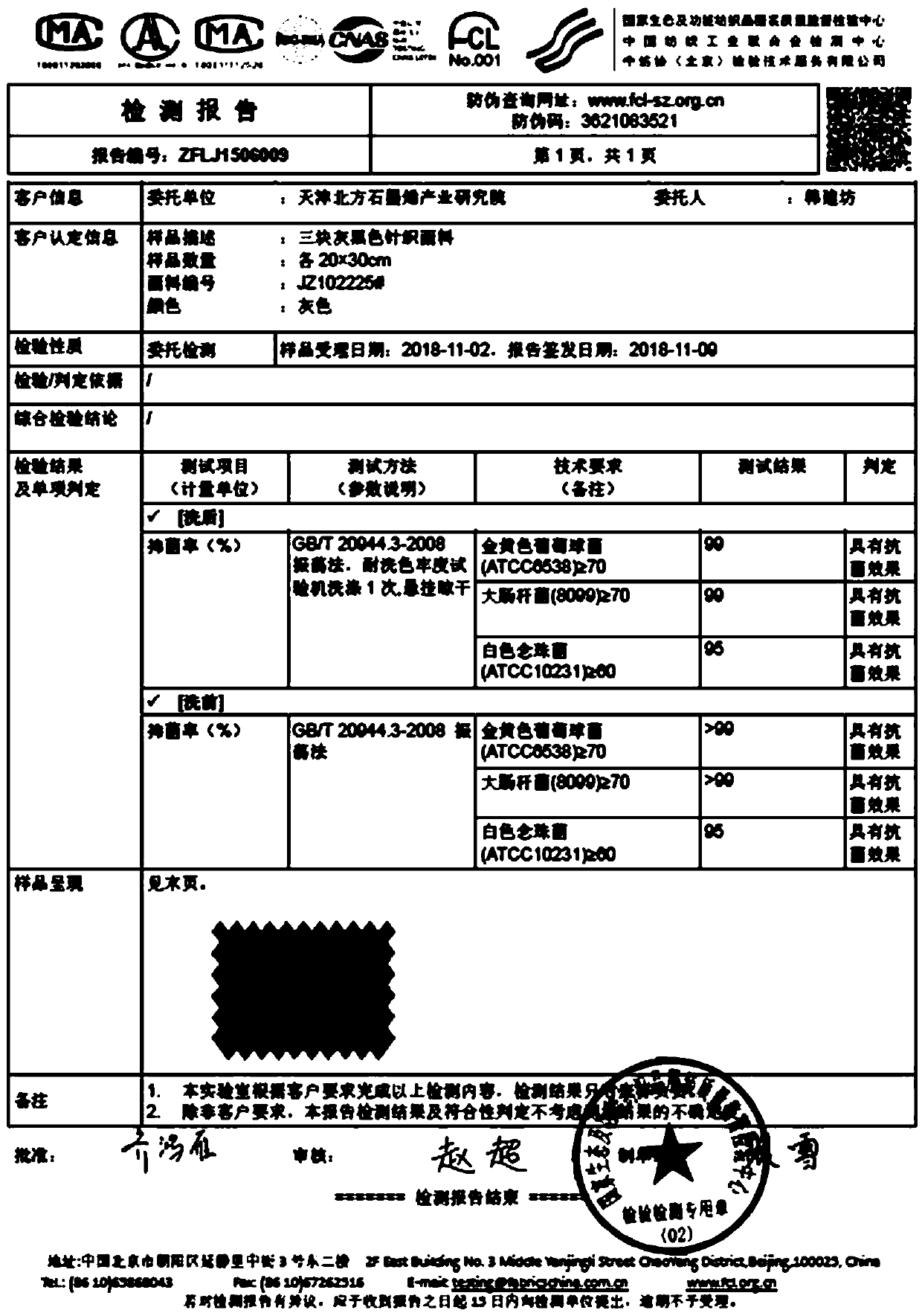

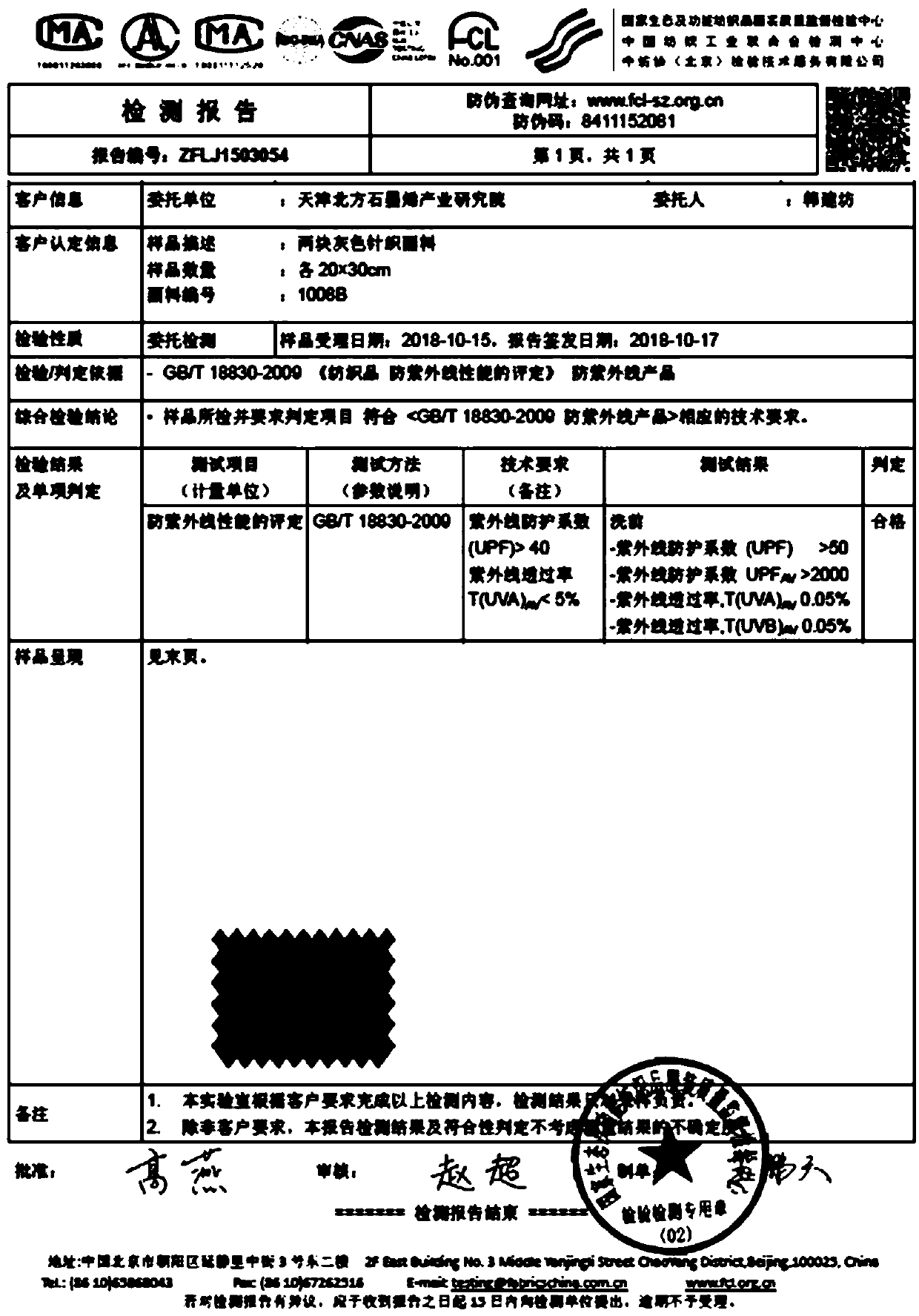

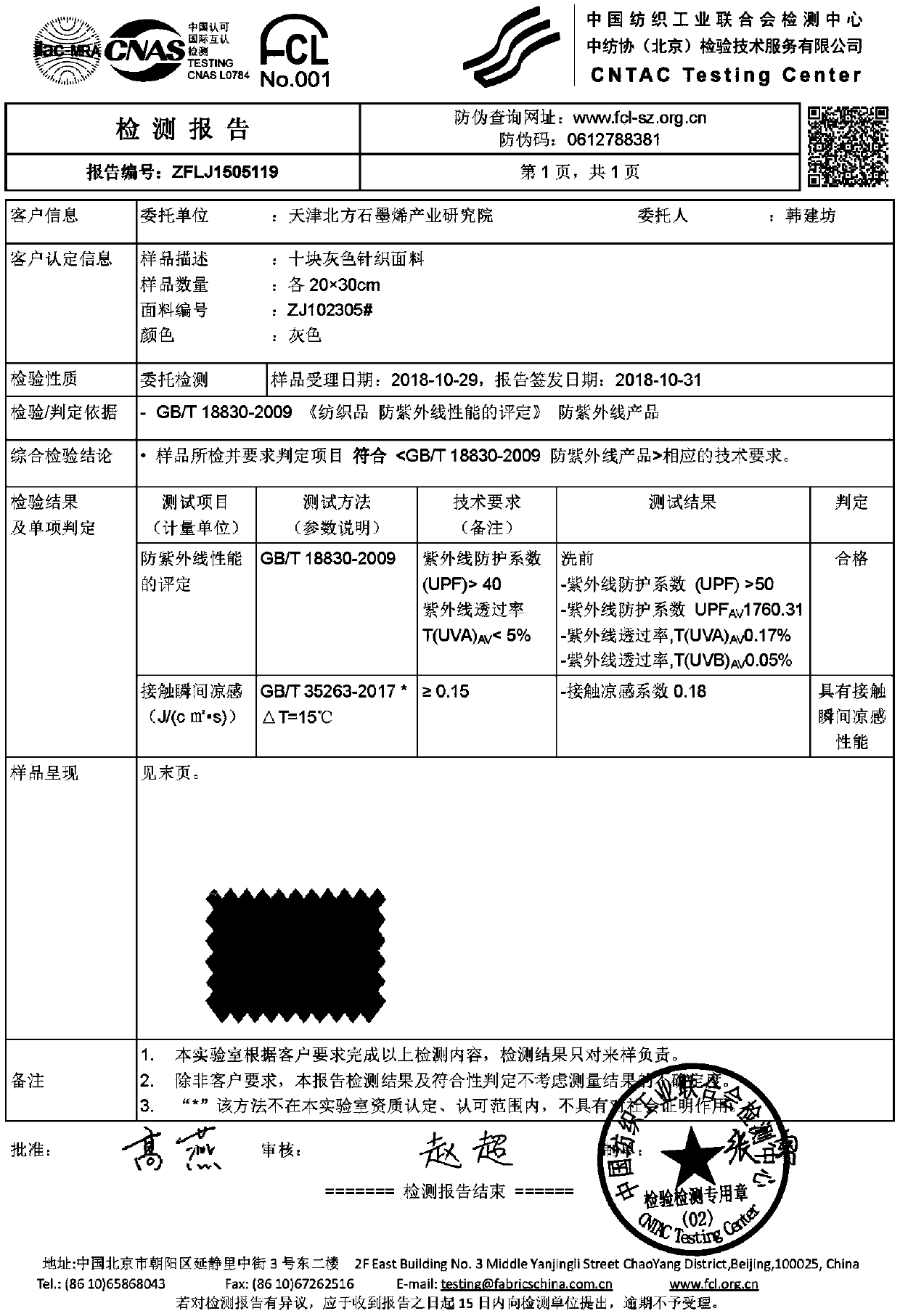

Graphene-based antibacterial fabric preparation method

ActiveCN109653005ASimple processEasy to operateBiochemical fibre treatmentLight resistant fibresCooking & bakingBenzyl benzoat

The invention provides a graphene-based antibacterial fabric preparation method which includes the steps: (1) fabric pretreatment: soaking a fabric by treatment liquid containing alkaline liquor and penetrating agents, and washing the fabric by water to reach neutral; (2) dyeing liquor preparation: diluting graphene oxide slurry by water, adding buffering solution and BB emulsion, uniformly mixingmixture to obtain dyeing liquor; (3) high-temperature dyeing: dyeing the fabric at high temperature by a temperature programming method according to a certain bath ratio; (4) drying and baking: drying the dyed fabric at the temperature of 110-150 DEG C, baking the dried fabric for 1-5 minutes at the temperature of 180-200 DEG C to obtain the antibacterial fabric based on the graphene. The BB emulsion is mixed emulsion of benzyl benzoate and polyoxyethylene castor oil. The antibacterial fabric preparation method based on the graphene is simple in process, easy to operate, the prepared textilefabric has excellent antibacterial and ultraviolet-proof functions, and a user instantly feels cool when contacting with the fabric.

Owner:天津北方石墨烯产业研究院

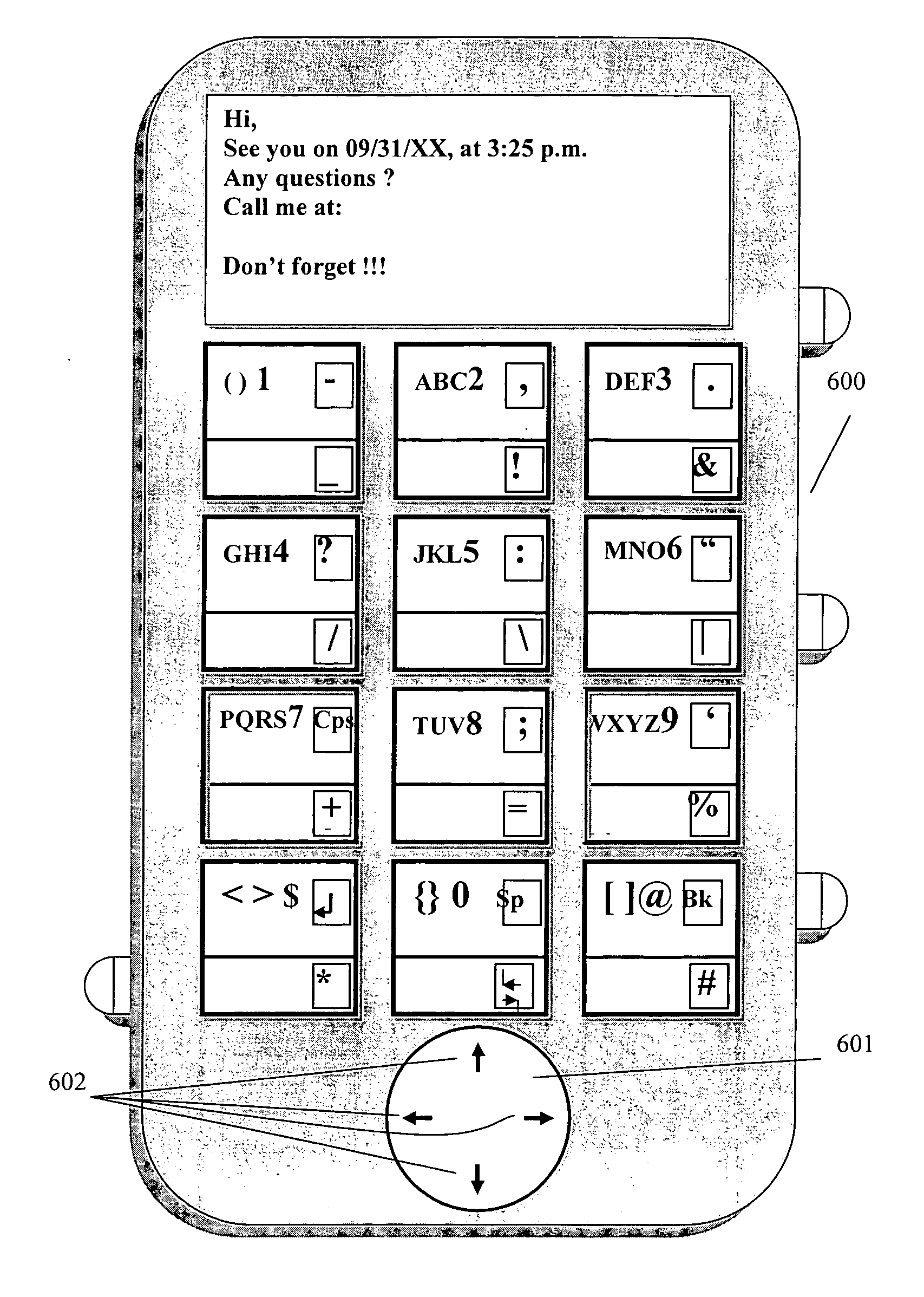

Systems to enhance data entry in mobile and fixed environment

ActiveUS20200228638A1Large of expenditureLarge amount of setInput/output for user-computer interactionDevices with voice recognitionMobile phoneData entry

A mobile phone device includes a housing having a substantially rectangular shape wherein its height dimension substantially corresponds to a distance between an ear and a mouth of a user and wherein its width dimension is less than its height dimension. A display unit is integrated within the front surface of the mobile phone device. The display unit substantially entirely covers the front surface of the mobile phone device. The mobile phone device does not include a physical key on the front surface.

Owner:GHASSABIAN BENJAMIN FIROOZ

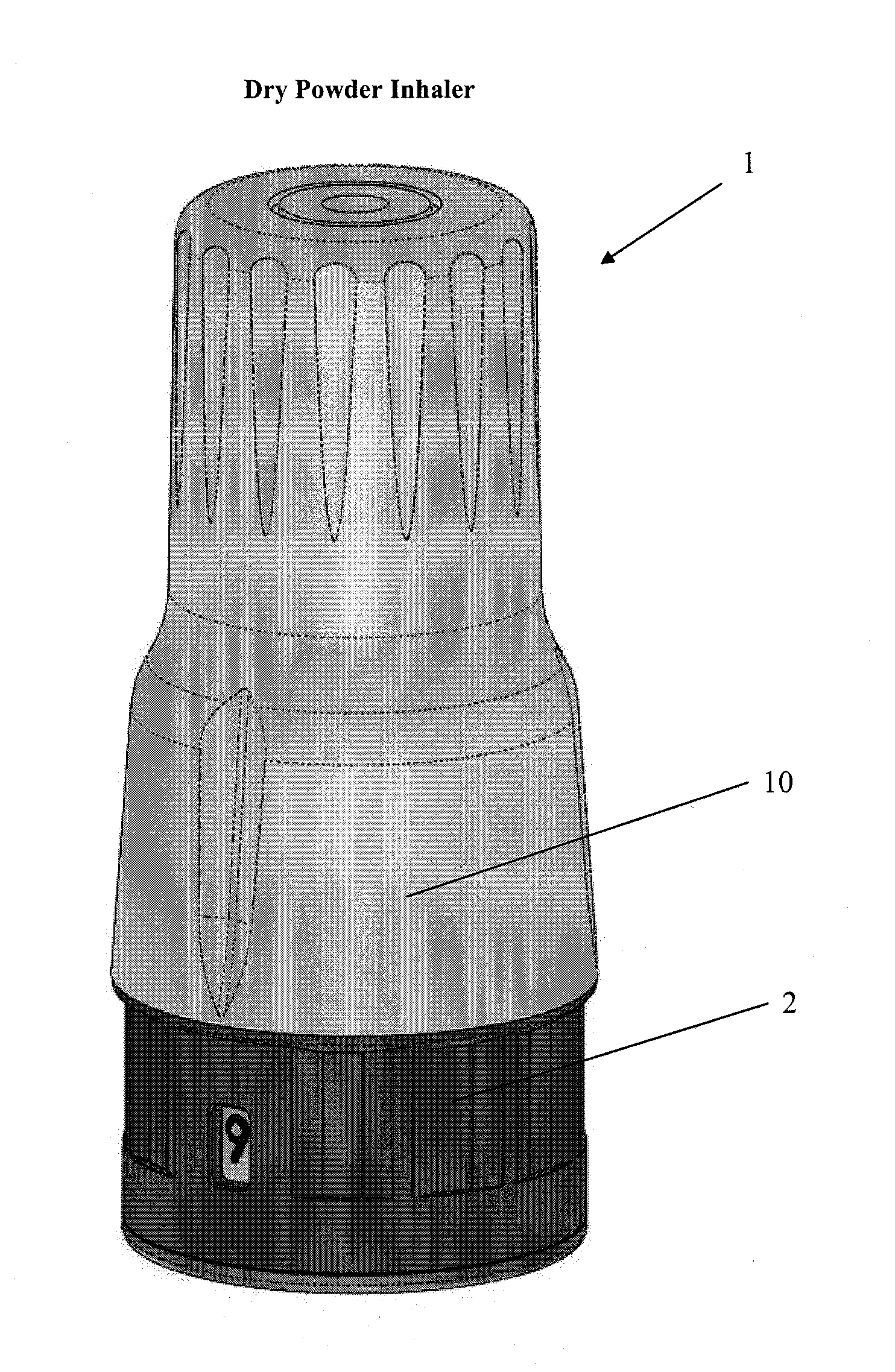

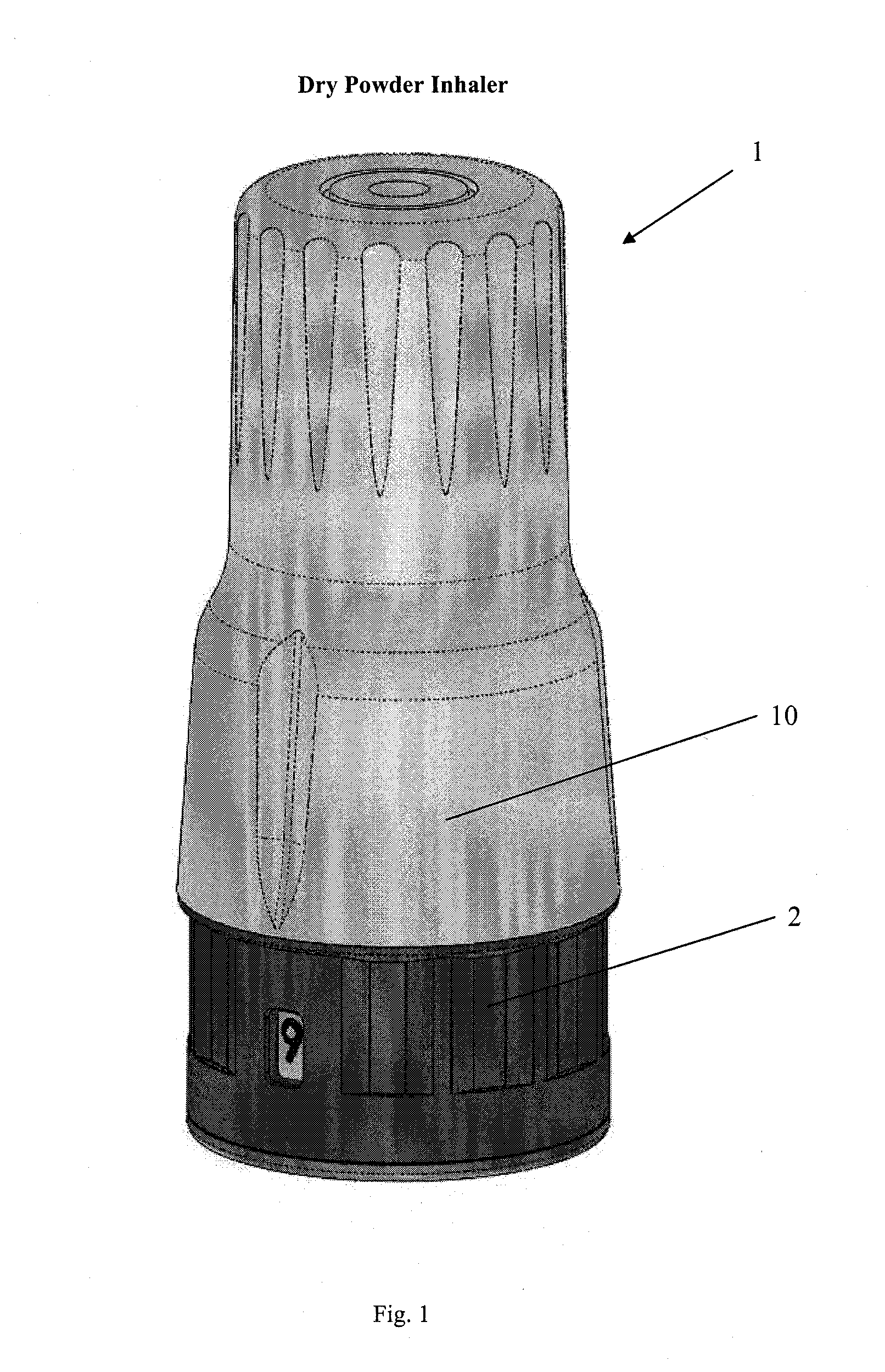

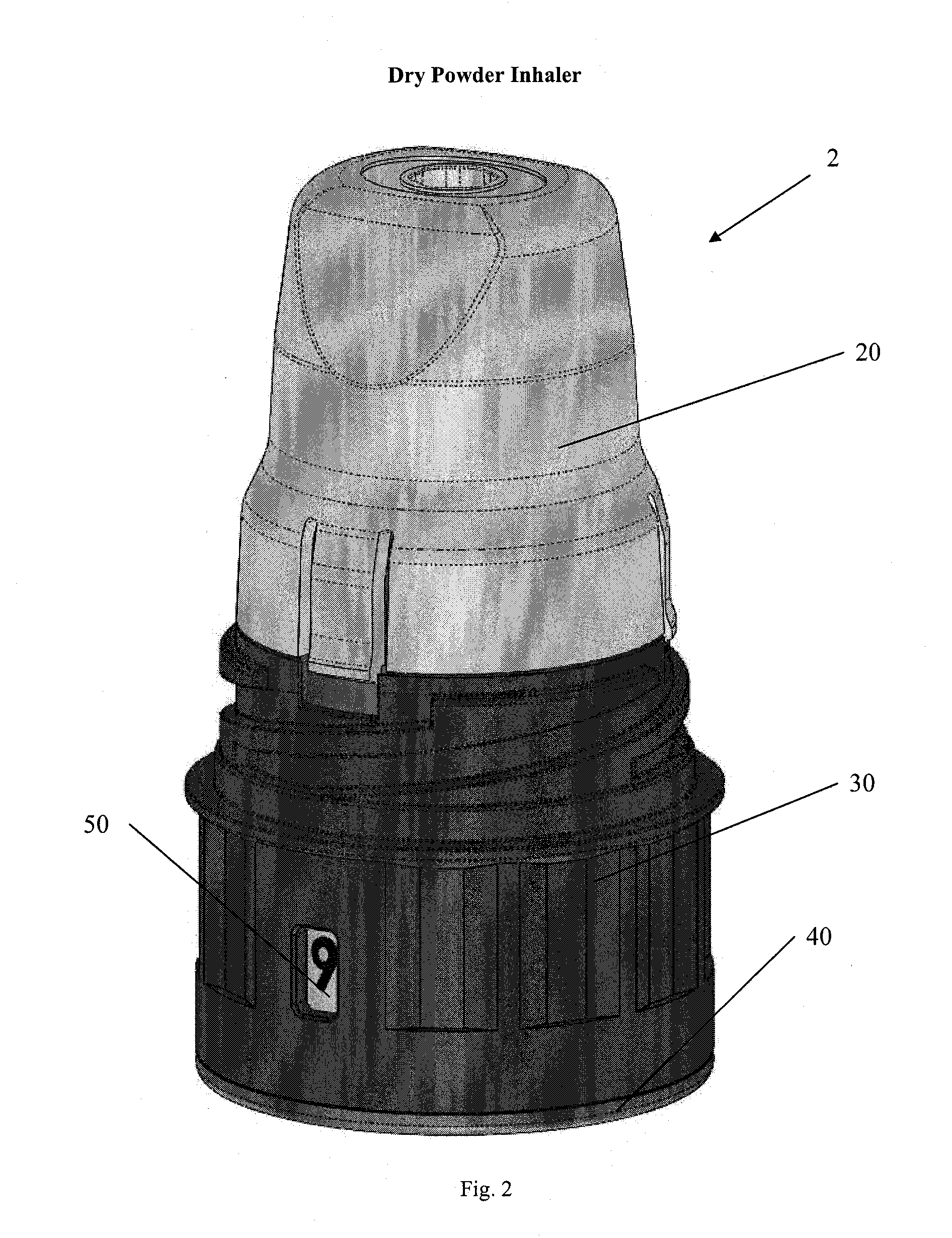

Dry powder inhaler with large capacity reservoir

InactiveUS20140014105A1Large amountA large amountRespiratorsLiquid surface applicatorsComposite materialBiomedical engineering

A dry powder inhaler is provided herein having a powder housing defined on an exterior by a generally cylindrical wall. Within the interior volume of the wall, a central passageway is provided through which certain components of the dry powder inhaler may pass. In addition, a powder reservoir is defined within the interior volume having a generally crescent-shaped profile formed along a substantial length of the wall. The powder reservoir terminates at end points between which is defined an isolated inhalation channel. With the configuration provided herein, the powder reservoir has a substantial working length exposed at its bottom to permit removal of medication therefrom. Advantageously, with this configuration, a relatively large amount of medication may be maintained, and obtained access to, in the powder reservoir.

Owner:MERCK SHARP & DOHME CORP

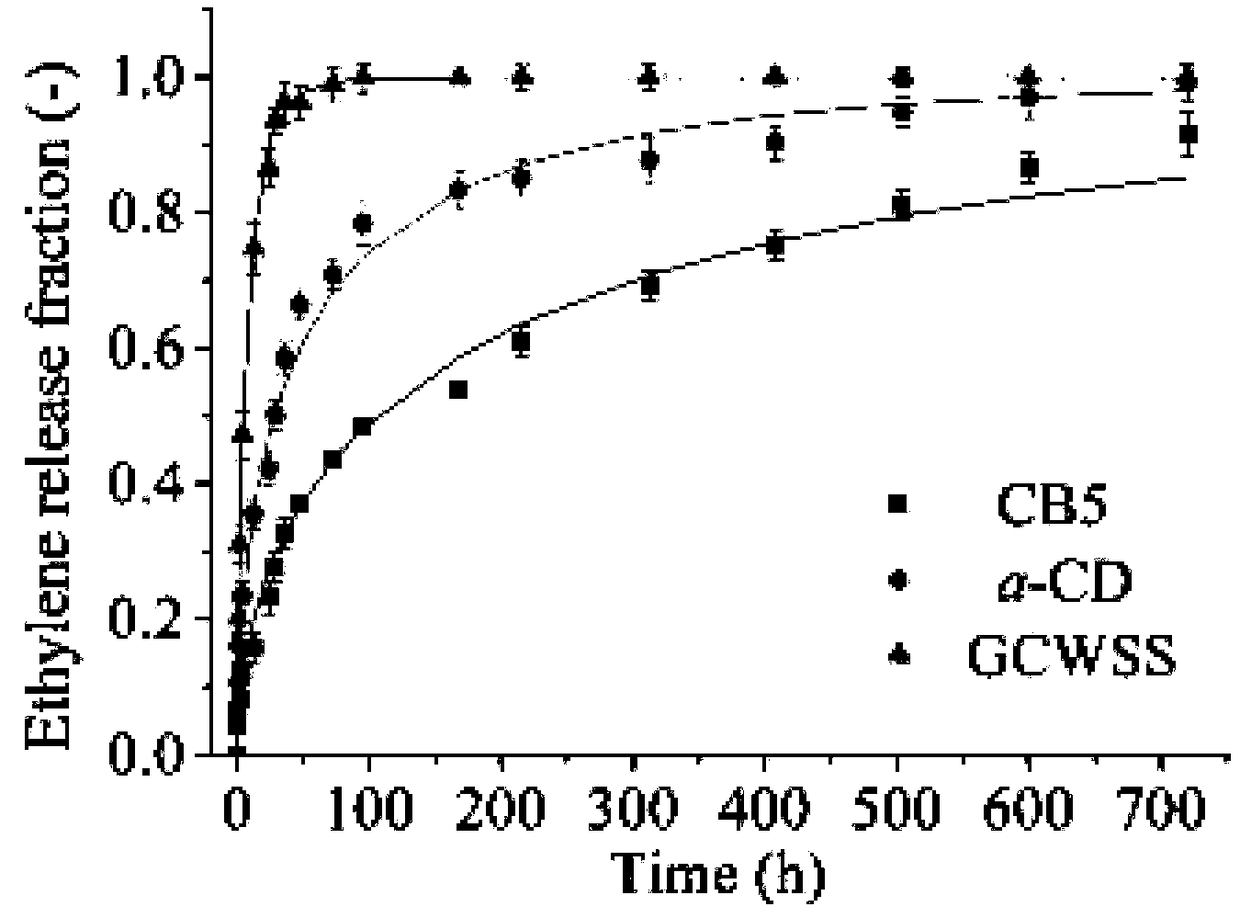

Ethylene gas embedding material with slow release performance and embedding method

InactiveCN108371180AHigh adsorption rateImprove stabilityBiocidePlant growth regulatorsHigh pressureEthylene

The invention discloses an ethylene gas embedding material with slow release performance and an embedding method. The embedding method comprises the steps: putting cucurbituril into a high-pressure reaction kettle, wherein the adding amount of the cucurbituril is 10% to 40% of the volume of the reaction kettle; vacuumizing the reaction kettle; introducing ethylene gas, wherein pressure intensity is controlled as 0.1 to 2.0Mpa; reacting for 8 to 48h under 15 to 35 DEG C; opening an air outlet valve of the reaction kettle after reaction finishes and absorbing unabsorbed ethylene to obtain an ethylene embedding product with the slow release performance. Tests show that the content of ethylene in the obtained product can reach 9.3% (w / w) or more, and the ethylene can be continuously released for 720h under 25 DEG C. To an ethylene adsorption technology, the method has the advantages of simpleness, high efficiency and low cost; composite can exist stably; the product has a wide applicationprospect in the field of controlled-atmosphere refreshment of fruits and vegetables.

Owner:SOUTH CHINA UNIV OF TECH

Accelerating agent and preparation method thereof

ActiveCN101973722AEvenly distributed holesLarge amountSolid waste managementMass ratioSuperplasticizer

The invention discloses an accelerating agent, which is characterized by consisting of the following raw materials in part by weight: 10 to 30 parts of limestone, 18 to 36 parts of bauxite, 3 to 5 parts of desulfurated gypsum residue, 25 to 50 parts of fly ash, 6 to 15 parts of high-efficiency water reducing agent and 0.05 to 0.1 part of exciting agent, wherein the high-efficiency water reducing agent is a naphthalene sulfonate high-efficiency water reducing agent, and the exciting agent is mixed by lauryl sodium sulfate and methylcellulose according to a mass ratio of 1:1. The accelerating agent has high impermeability and freezing resistance and low rebound rate, is easy, convenient and practicable to construct and has no harm to skin and eyes of a constructor. Meanwhile, the desulfurated gypsum residue is used as a raw material, the secondary utilization of the desulfurated gypsum residue is realized, resources are saved, the problem of treating solid waste residue in an electric power plant is solved and the environment is protected.

Owner:山西科腾环保新材料股份有限公司

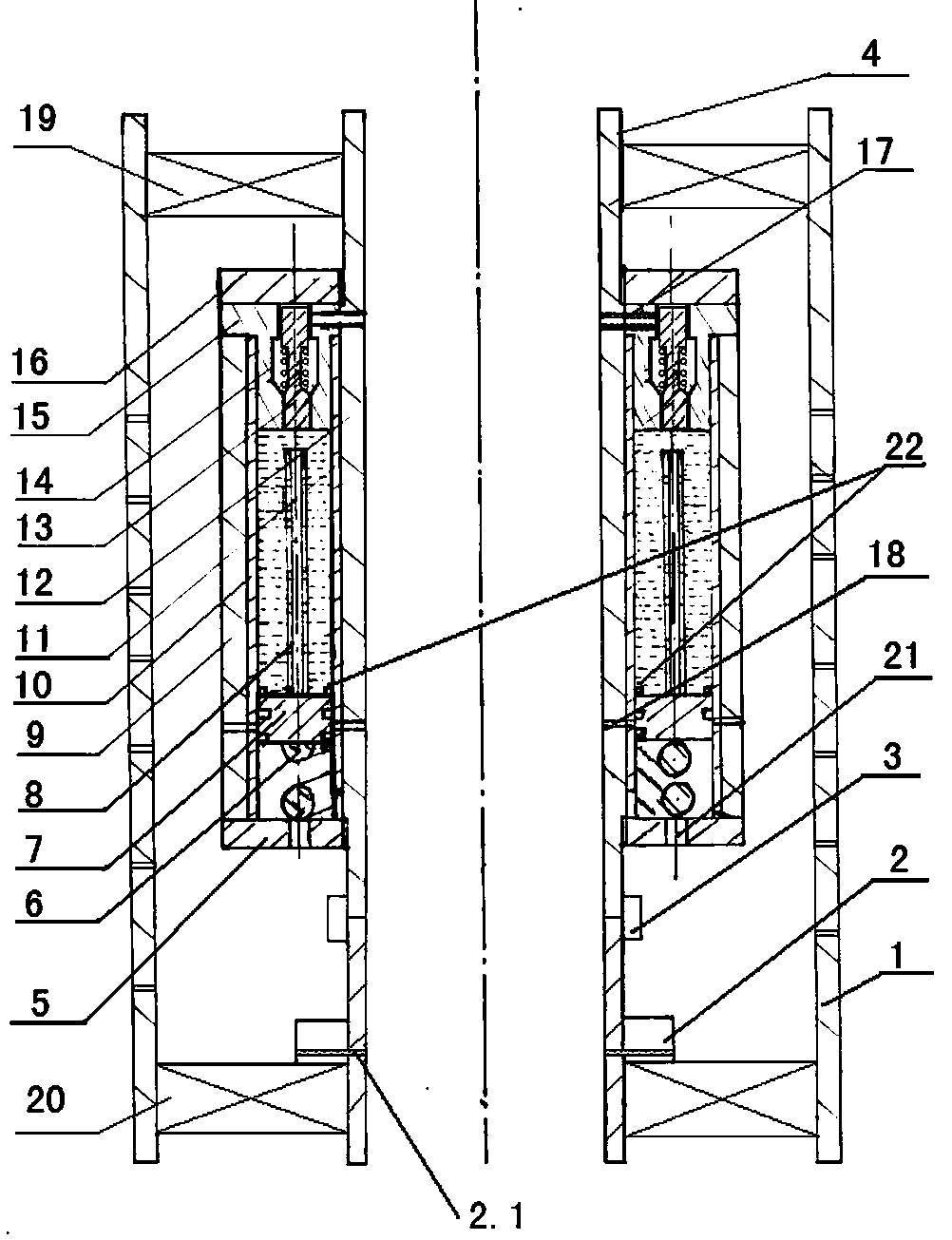

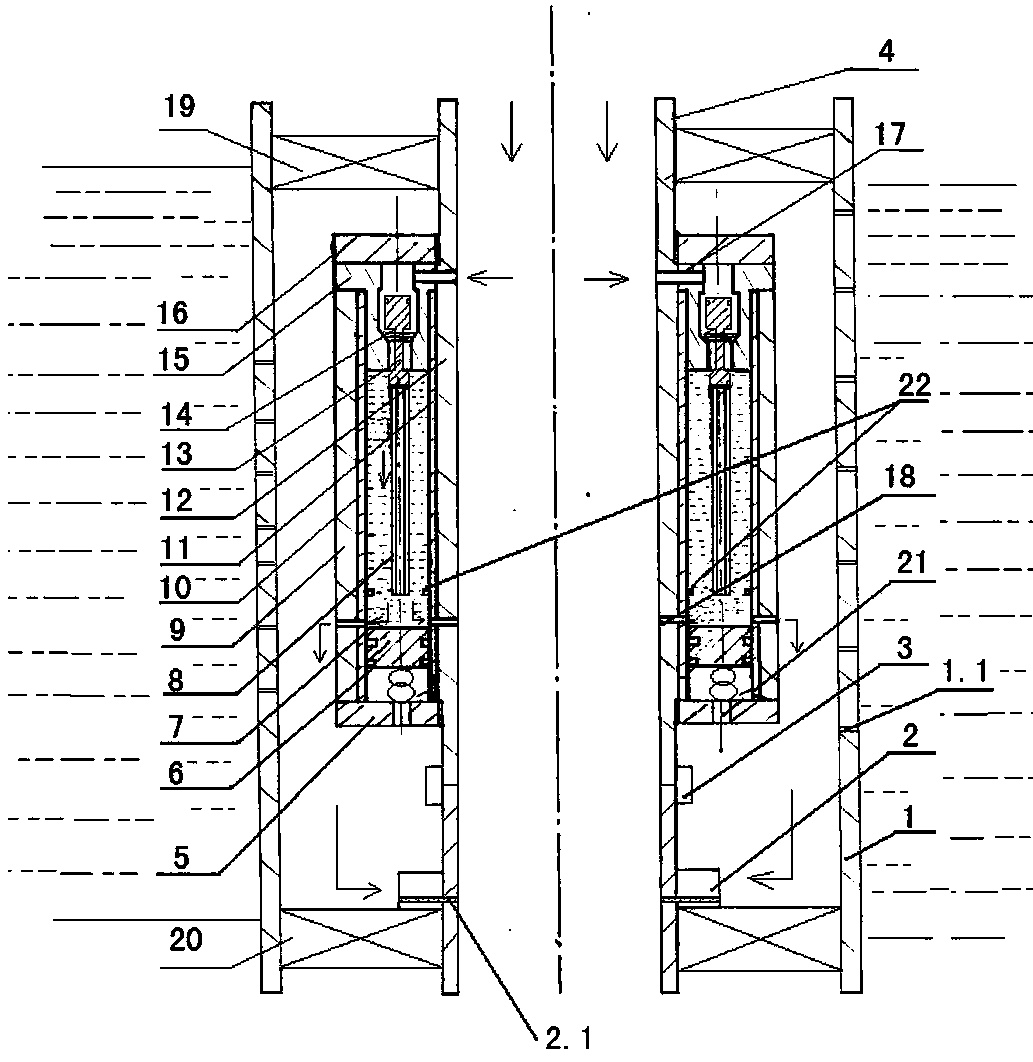

Water injection well bisalt anti-scaling descaling device

ActiveCN108716384ADon't worry about being damaged and leakingAvoid pollutionCleaning apparatusFluid removalCapillary TubingEngineering

The invention relates to a water injection well bisalt anti-scaling descaling device. According to the technical scheme of the device, an annular cavity is composed of a container outer pipe and a container inner pipe, basalt powder is put in the annular cavity, and a lower baffle ring is arranged at the bottom of the annular cavity; the upper side of the lower baffle ring is connected with a liquid outlet piston through a closing spring, a plurality of pressure transferring capillary tubes are arranged in the annular cavity, and a container pressing cover is arranged on the top of the annularcavity; a liquid inlet passage is arranged in the container pressing cover, the upper portion of the liquid inlet passage is communicated with an liquid outlet opening pipe of a central pipe, an opening piston is arranged in an inner cavity of the liquid inlet passage, and the upper portion of the opening piston is connected with a reset spring. The device has the advantages that by adopting thesolid basalt powder, under the same volume, much substance amount can be put in the device, opening and releasing structures of a container are replaced to prolong the anti-scaling time, the negativeinfluences which are caused by the fact that the anti-scaling descaling device is impacted and destroyed and are brought to a well site environment are reduced, and potential safety hazard is eliminated.

Owner:福州思琪科技有限公司

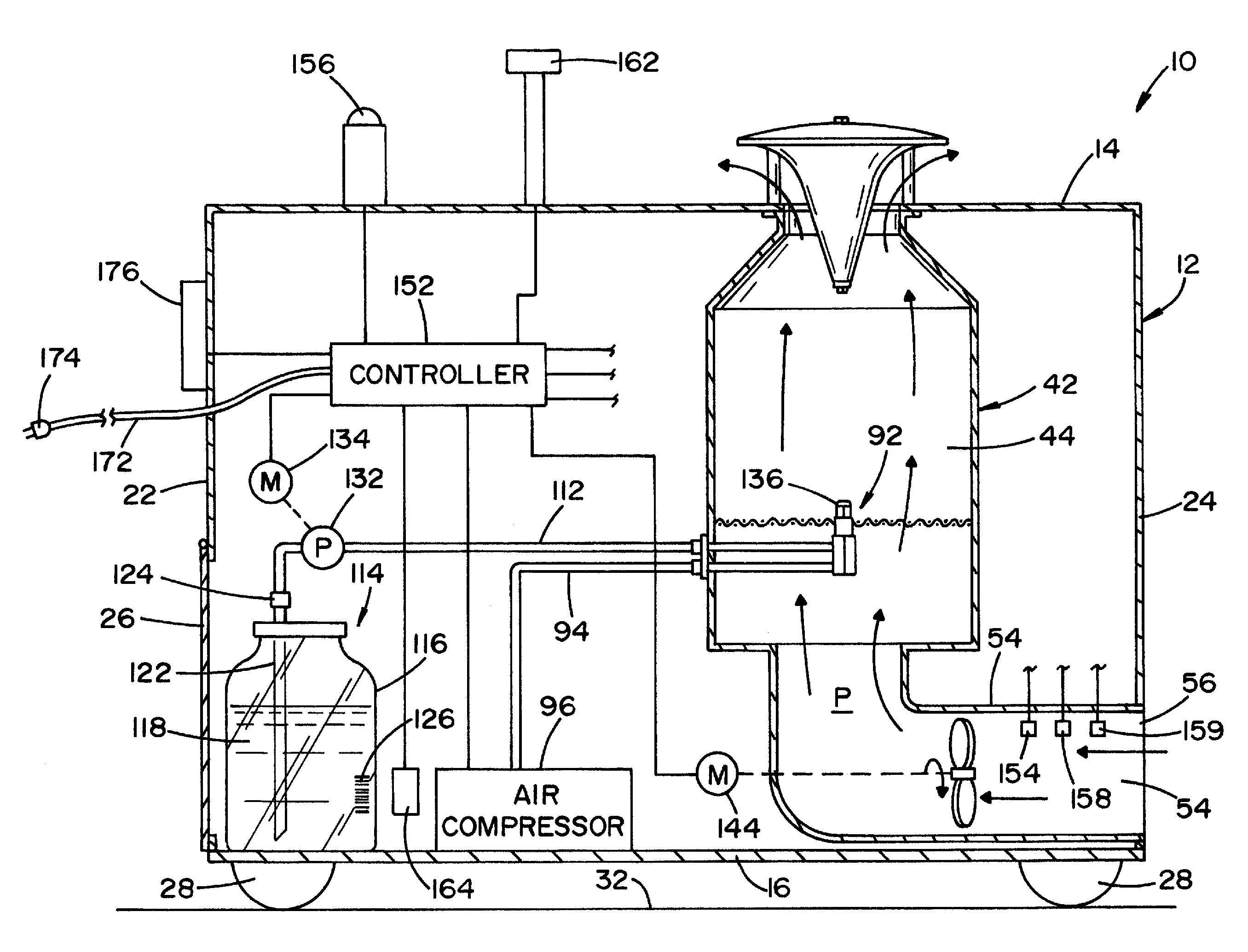

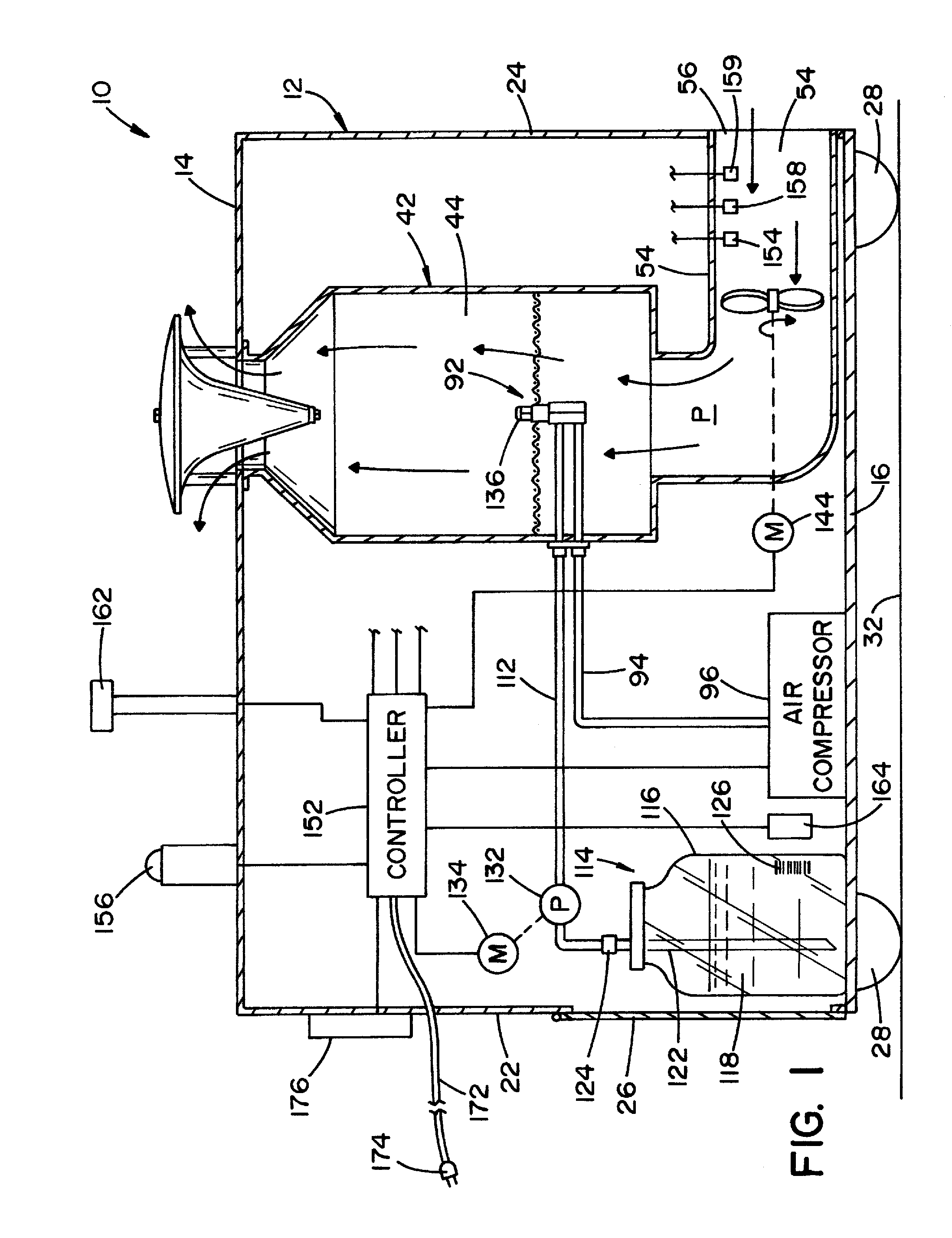

Cold-mist decontamination unit and method of operating same

A method of decontaminating a room or space, comprising the steps of providing a cold-mist decontamination device capable of generating an atomized mist comprised of a decontaminant and water, inputting into an internal processor the parameters of the room or space and the concentration of the decontaminant in the decontamination solution, measuring the temperature and humidity in the room or space, and determining the maximum amount of the decontamination solution that can be introduced into the room or space in atomized form without condensing the decontaminant on surfaces within the room or space.

Owner:AMERICAN STERILIZER CO

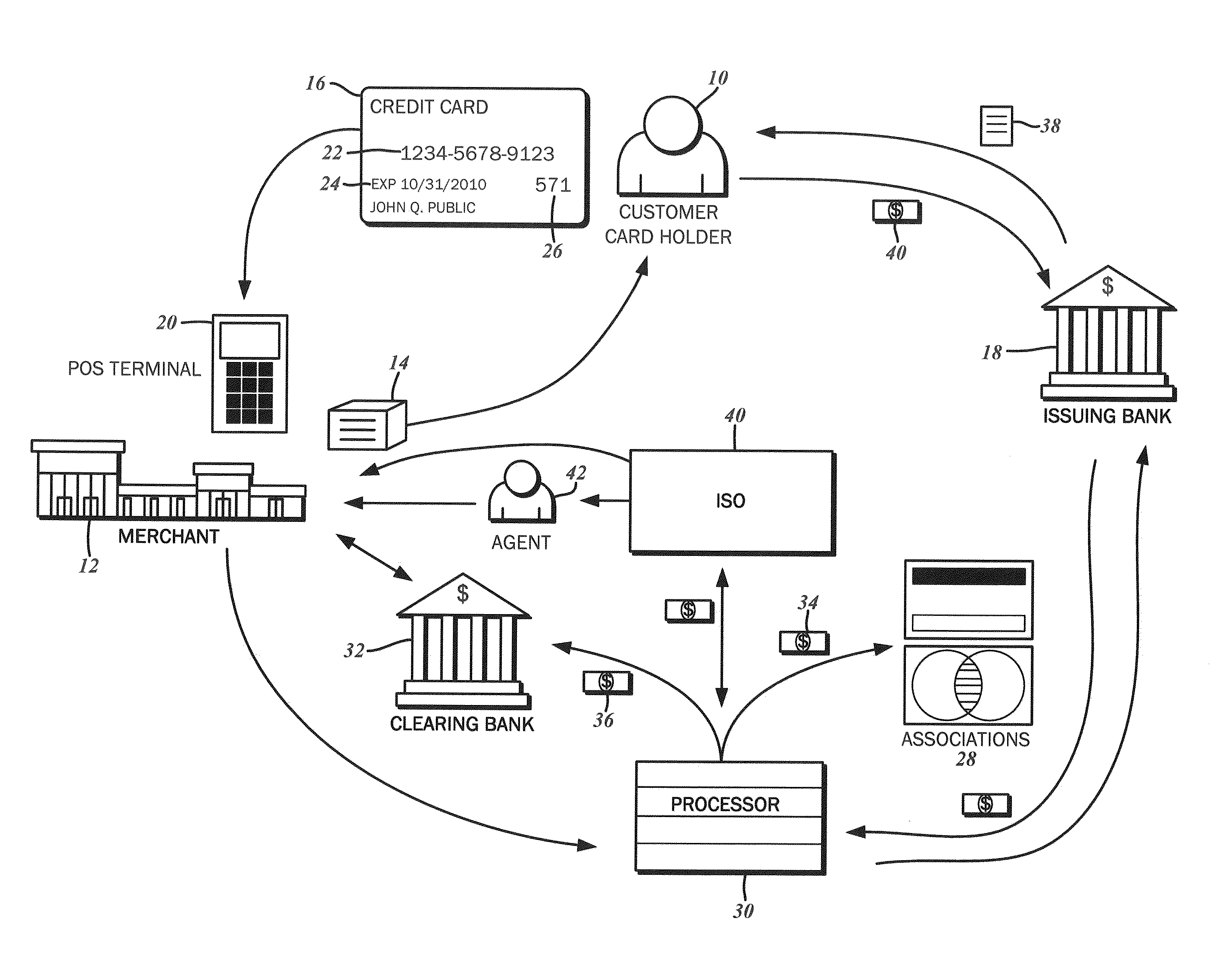

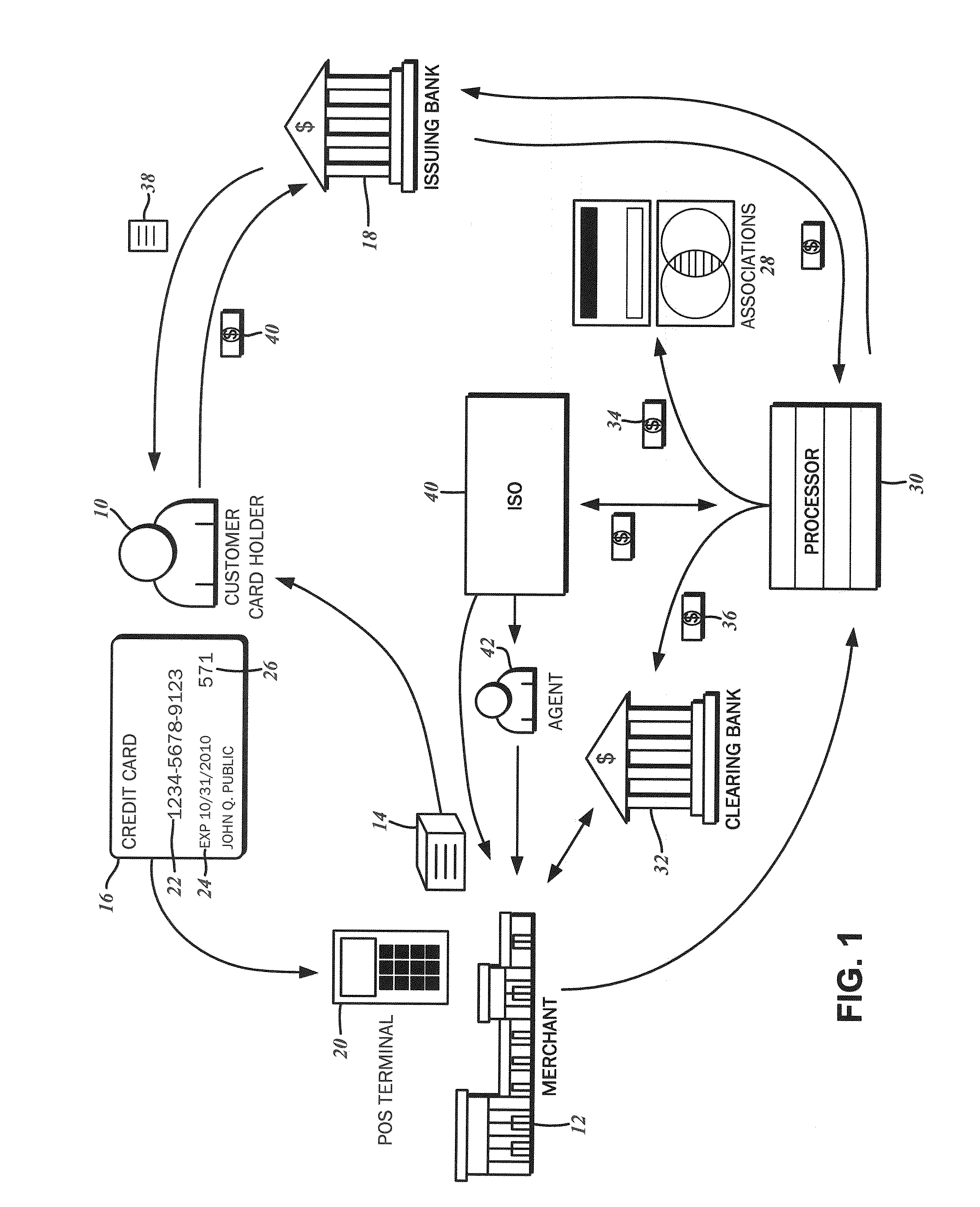

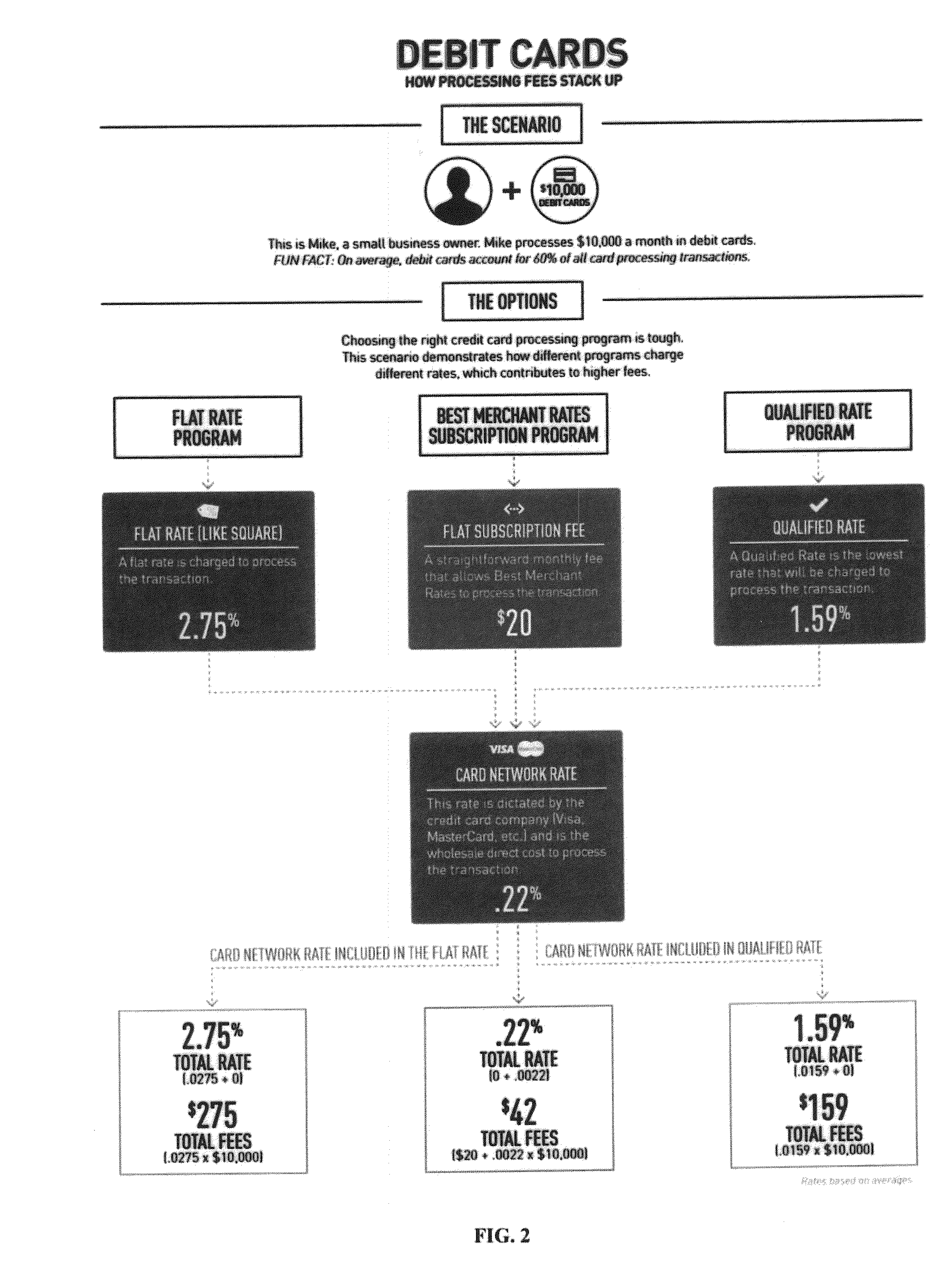

Subscription and membership based credit card processing system

InactiveUS20140279117A1Large amountSmall amountHand manipulated computer devicesCredit schemesFixed chargeComputer hardware

A method for implementing a flat fee structure for credit card processing, which simplifies the fees charged to a merchant from an ISO. The flat rate processing fee may cover processing for a particular merchant for a specified period of time.

Owner:BESTMERCHANTRATES COM

Cross-site online shopping assistant

A shopping assistant for online shopping. The invention provides for a software system to assist consumers in automatically locating and systematically applying discount codes to electronic commerce platforms to obtain reduced prices. In a preferred embodiment of the invention, discount codes are automatically located, evaluated against a user's shopping cart, and evaluated for the best results for the consumer. In the preferred embodiment, information about the utility of discount codes is recorded to machine readable storage.

Owner:PAYPAL INC

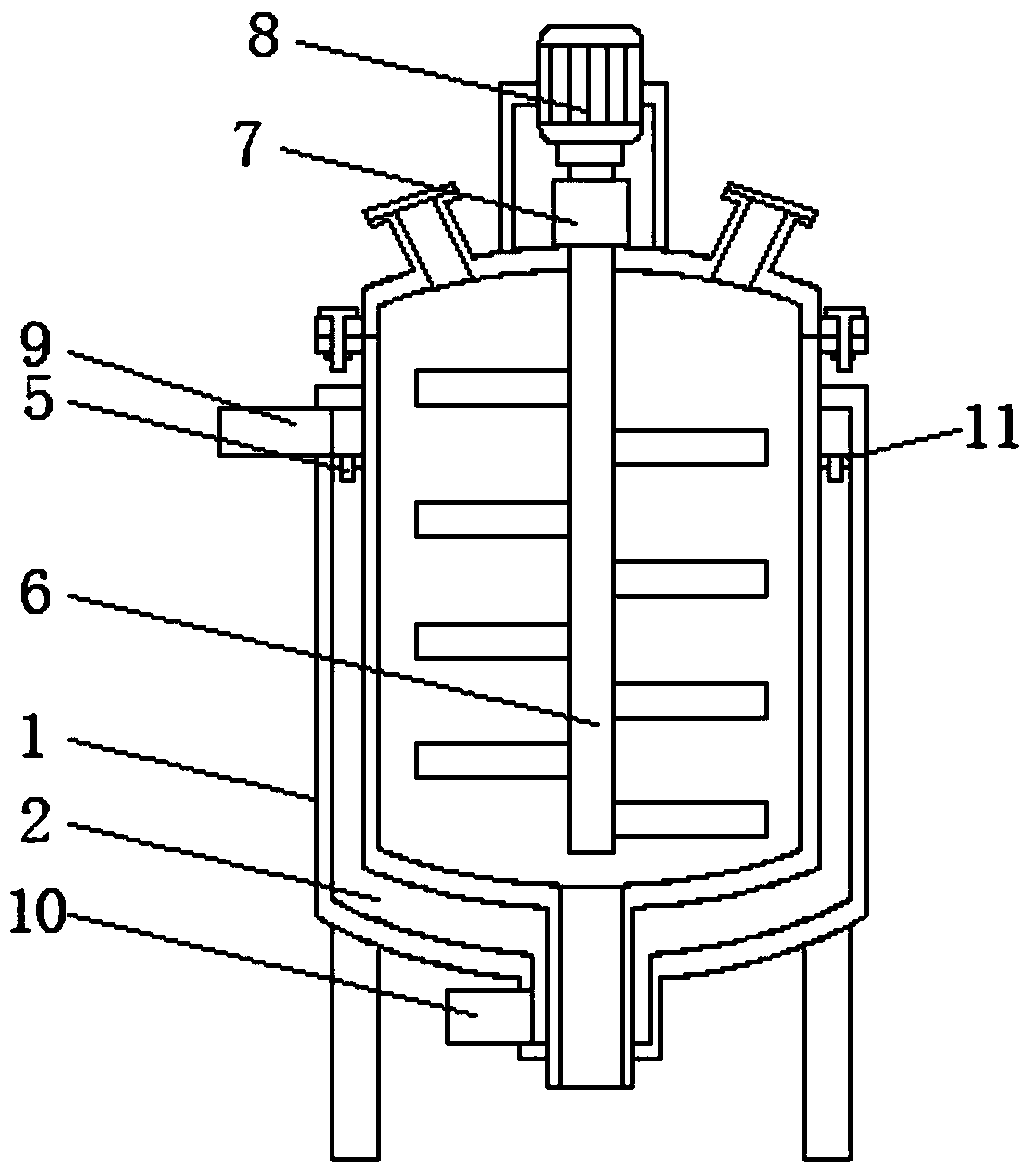

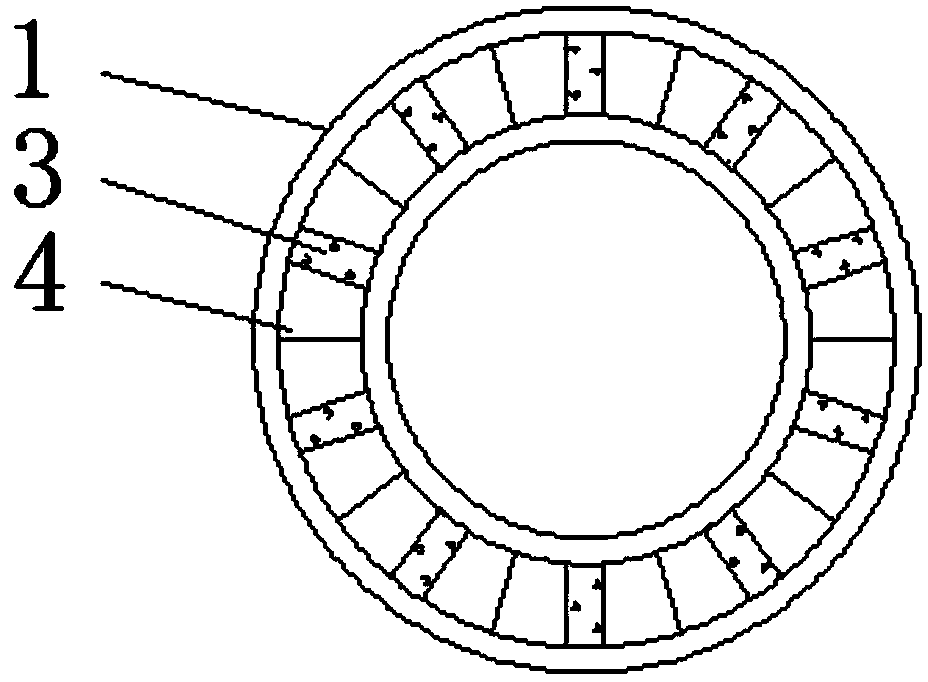

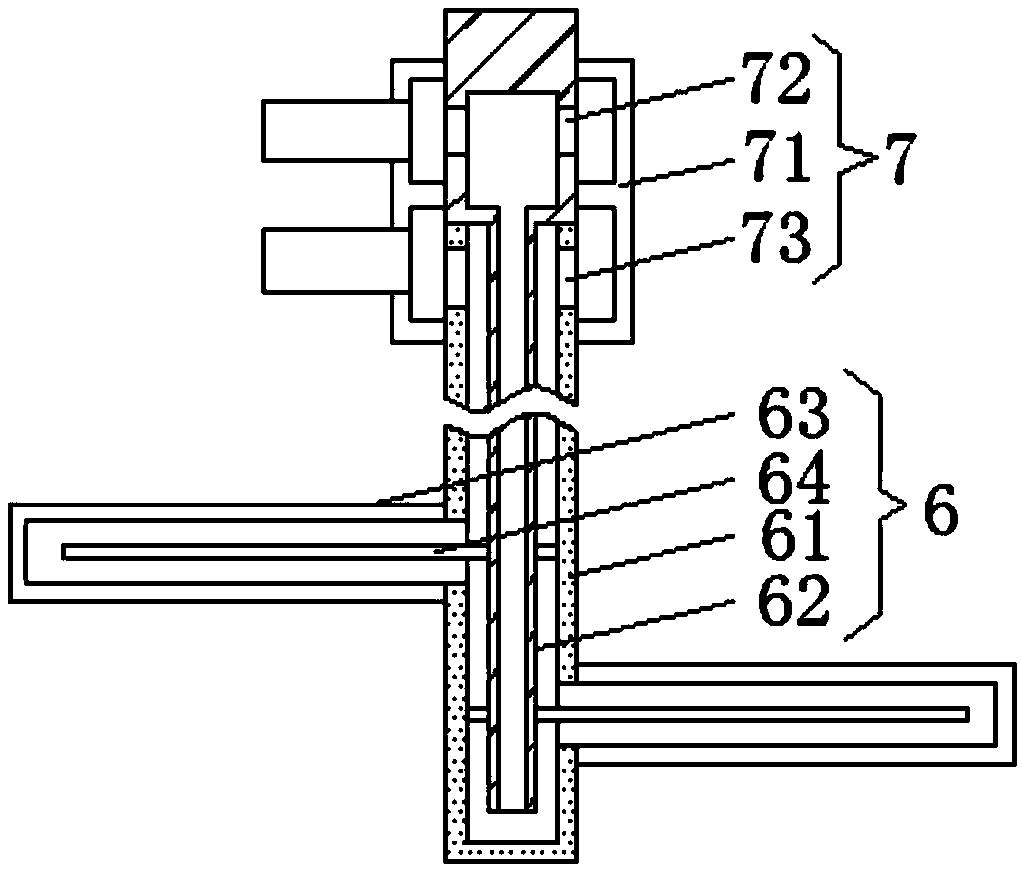

Novel reaction kettle

InactiveCN109248644AEasy to flow inShorten the flow distanceChemical/physical/physico-chemical stationary reactorsCooling effectEngineering

The invention discloses a novel reaction kettle and belongs to the technical field of reaction kettles. The novel reaction kettle comprises a kettle body, wherein a top plate is arranged at the top ofthe inner chamber of a heat exchange cavity, clapboards are uniformly arranged at the bottom of the inner chamber of the heat exchange cavity, a flow channel is formed between every two adjacent groups of clapboards, blocking devices matched with the flow channels are uniformly arranged on the top plate, and a stirring device is arranged in the inner chamber of the kettle body. When the pressureof water in the heat exchange cavity at the upper side of the top plate is larger, a cock body is separated from a pipe body; in order to enable cold water to flow into the inner chamber of each flowchannel, the material at the outer side in the kettle body is cooled, thereby ensuring that the amounts of cold water entering the flow channels close to and away from a water inlet pipe are equal, ensuring uniform heat exchange of different parts of the kettle body, and reducing the flow distance of cold water so as to achieve a better cooling effect. A part of cold water enters the inner chamberof a stirring sleeve through a water inlet and enters the inner chambers of stirring blades, and the internal material in the kettle body is cooled through the stirring blades, thereby enhancing thecooling effect.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

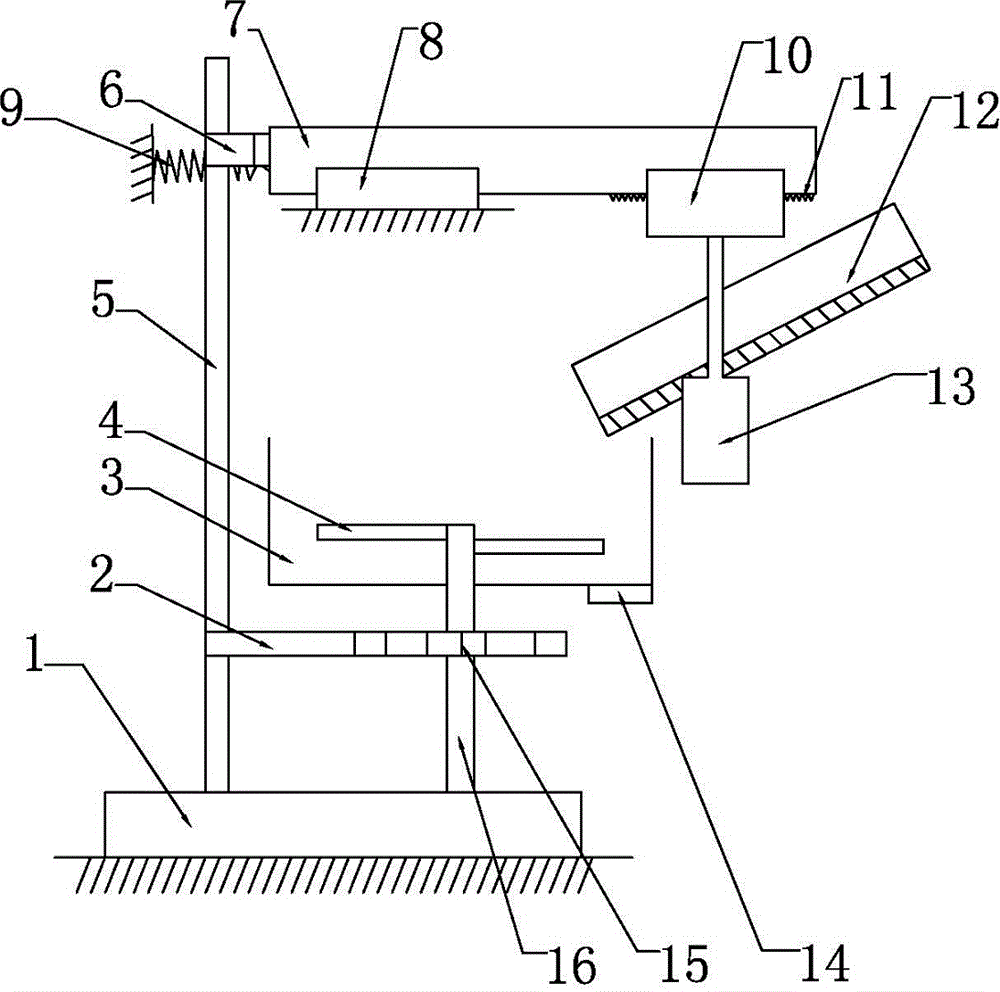

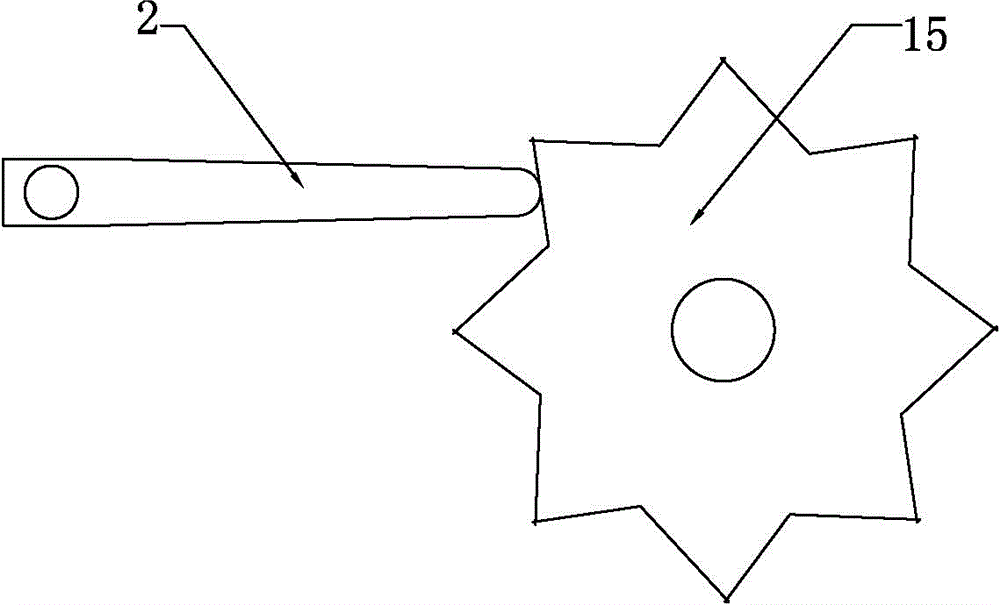

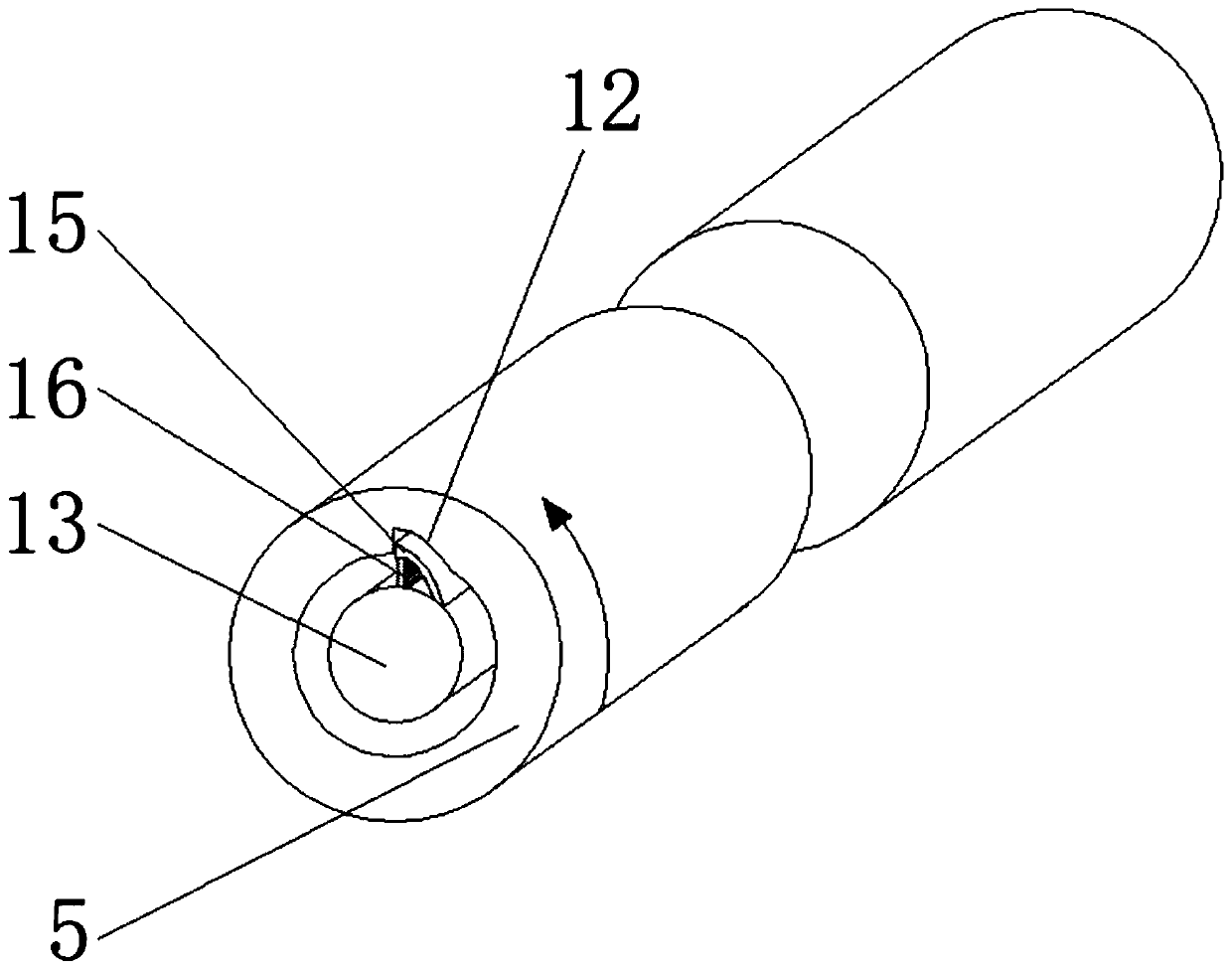

Grinding apparatus for cultivating edible fungus

InactiveCN105075671ASmall diameterLarge amountCultivating equipmentsMushroom cultivationEngineeringCam

The present invention relates to a crushing apparatus. The present invention discloses a grinding apparatus for cultivating edible fungus. The grinding apparatus comprises a pedestal; the pedestal is rotatably connected with a main rotating rod and a driving rotating rod; the driving rotating rod is fixedly connected with a cam; the main rotating rod is fixedly connected with a swing rod; one side of the swing rod is abutted with the cam; the main rotating rod is also fixedly connected with a bumping rod; one side of the bumping rod is provided with a sliding chute; a sliding block is slidably connected in the sliding chute; the sliding block is abutted with the bumping rod; the sliding block is provided with a spring in a bumping track of the bumping rod; the other end of the spring is fixed; one side, far from the bumping rod, of the sliding block is provided with sawteeth; a material tank controlled by a cylinder is disposed below the sawteeth; the driving rotating rod is provided with a rotating knife and an aggregate tank; the rotating knife is disposed in the aggregate tank; and an inclined guide tank is disposed below the material tank. The grinding apparatus, which is capable of directly grinding wood into scraps, for cultivating the edible fungus is provided for solving the problem that an existing crushing apparatus cannot crush the wood block directly.

Owner:重庆市洪欣食用菌有限公司

Preparation method of foaming agent of foam extinguishing agent

InactiveCN105664415ASolve usabilityResolution timeFire extinguisherEnvironmental resistanceFoaming agent

The invention relates to a preparation method of a foaming agent of a foam extinguishing agent, and belongs to the technical field of environment-friendly materials. The preparation method comprises the steps of: stirring and slag removal, filtration, alkali adding, hydrolysis, cooling and foaming. The foaming agent preparation method is simple, low in cost, easy to realize continuous production, stable in product quality, capable of obtaining more stable foaming agents fast in defoaming, free of polluting the environment, free of generating waste water and capable of realizing the waste recycling; and raw materials are wastes.

Owner:KUNMING UNIV OF SCI & TECH

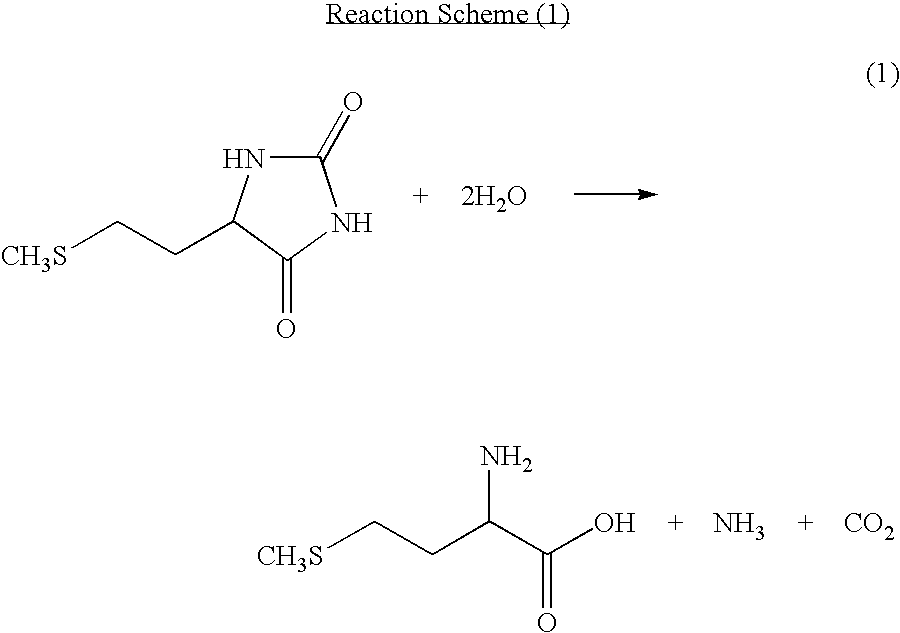

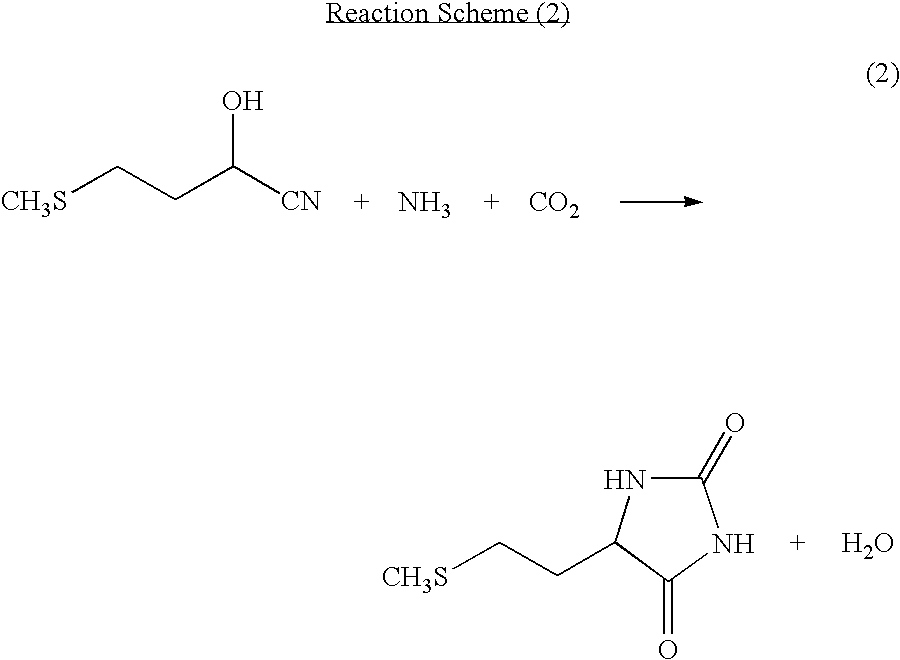

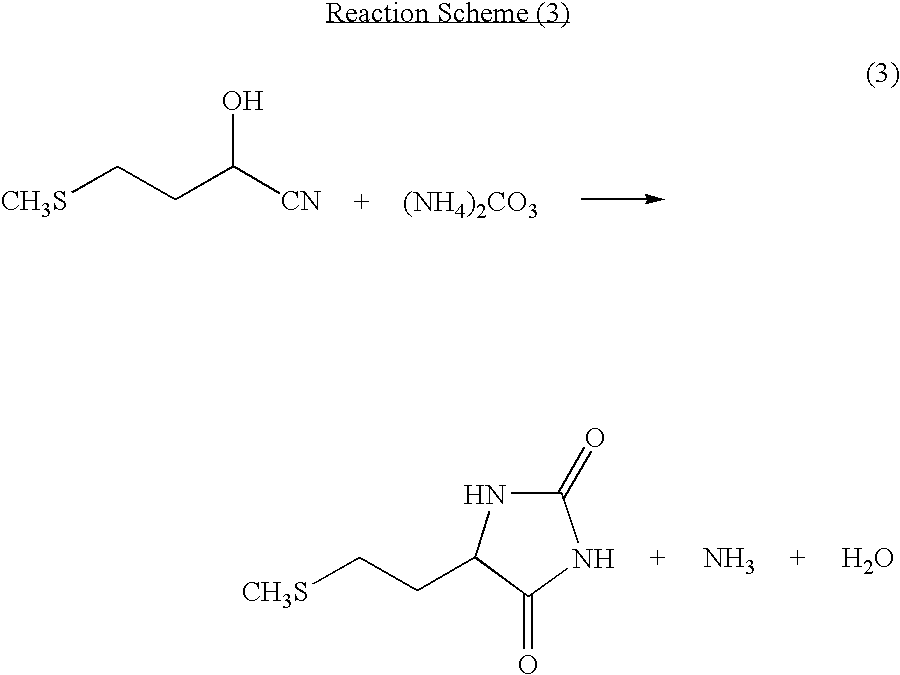

Process for producing methionine

InactiveUS20090306426A1Reduce amountLarge amountOrganic compound preparationSulfide preparationMethionine biosynthesisKetone

The present invention provides a process for producing methionine, which comprises steps of:hydrolyzing 5-[2-(methylthio)ethyl]imidazolidine-2,4-dione in the presence of a basic potassium compound in a non-stirred continuous first reaction tank, andheat-treating the reaction solution after hydrolysis in a second reaction tank. According to the process of the present invention, a methionine crystal with a higher bulk density can be produced.

Owner:SUMITOMO CHEM CO LTD

Method for extracting active ingredients

A method for extracting active ingredient(s) from a raw material to be extracted is provided. The method comprises the following steps: (1) mixing a raw material to be extracted with an aqueous solvent to provide a mixture; (2) conducting a homogenization to the mixture to obtain a first extract with active ingredient(s); and (3) conducting a high pressure homogenization to the first extract to obtain a second extract with active ingredient(s), wherein the homogenization in step (2) is conducted at a temperature ranging from normal temperature to 100° C.

Owner:TCI CO LTD

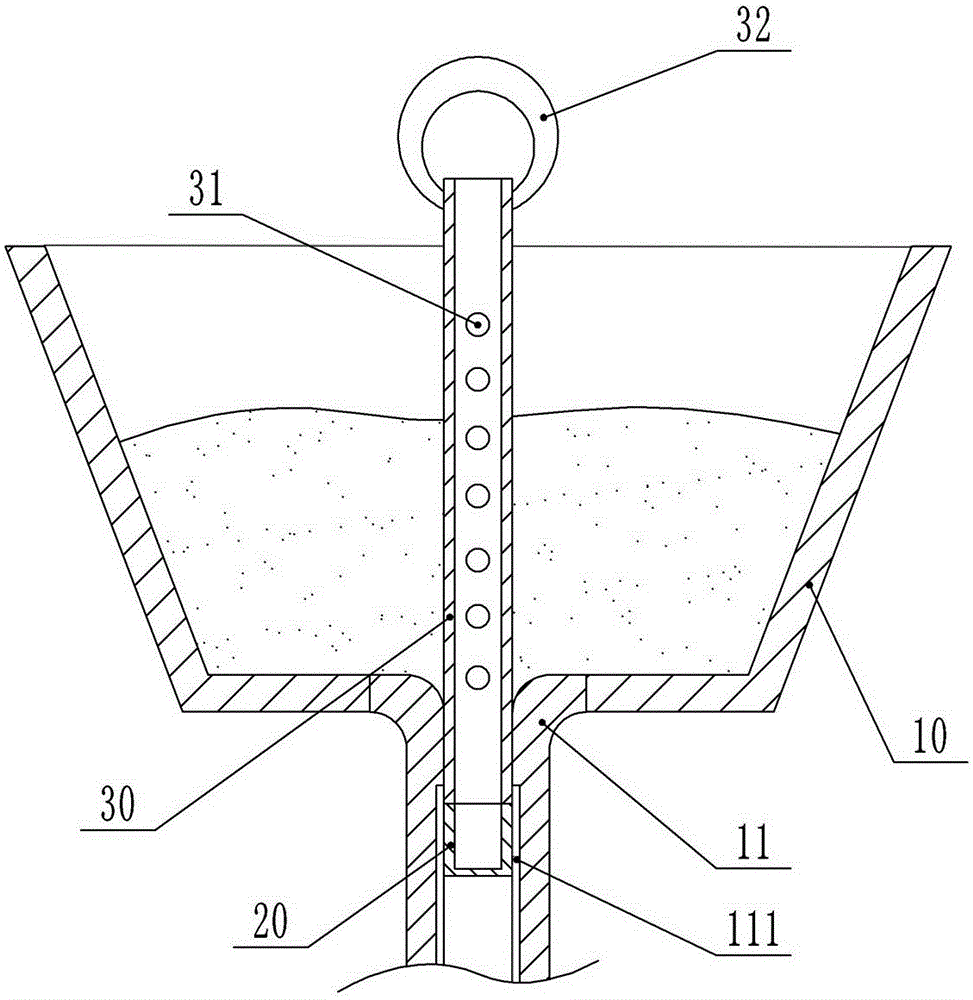

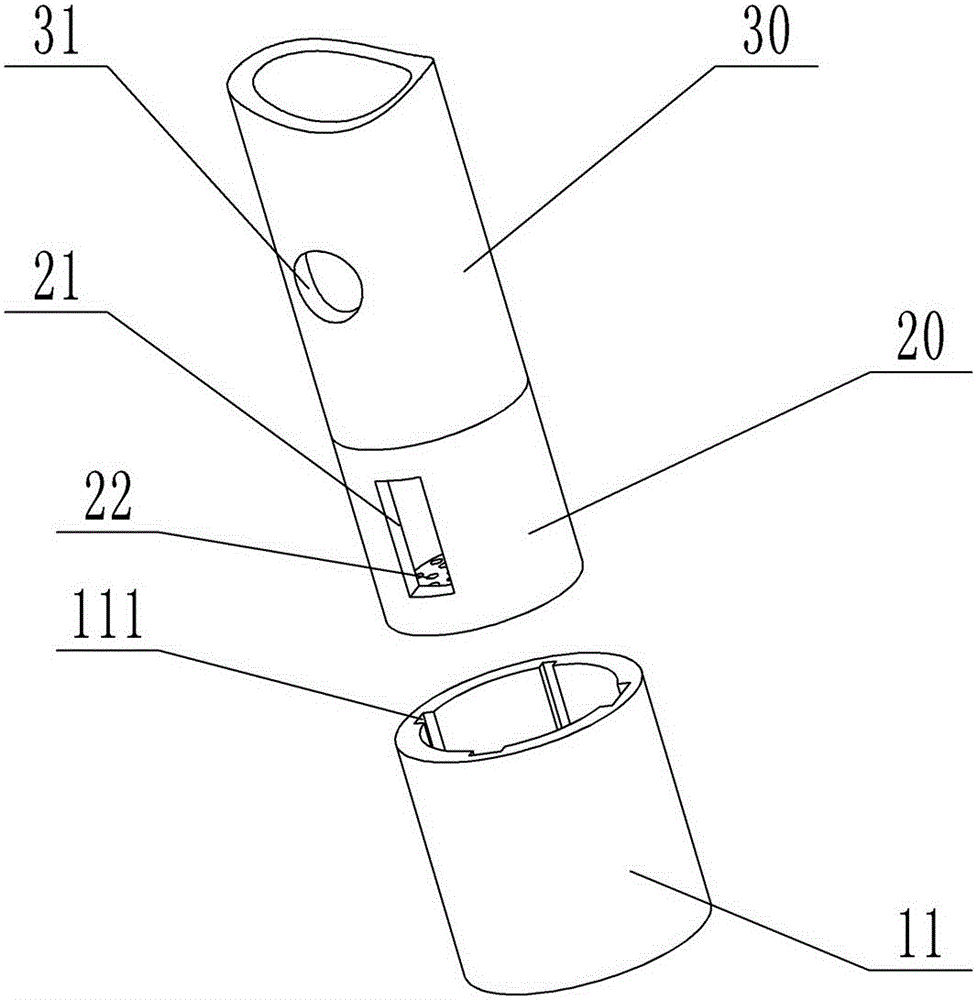

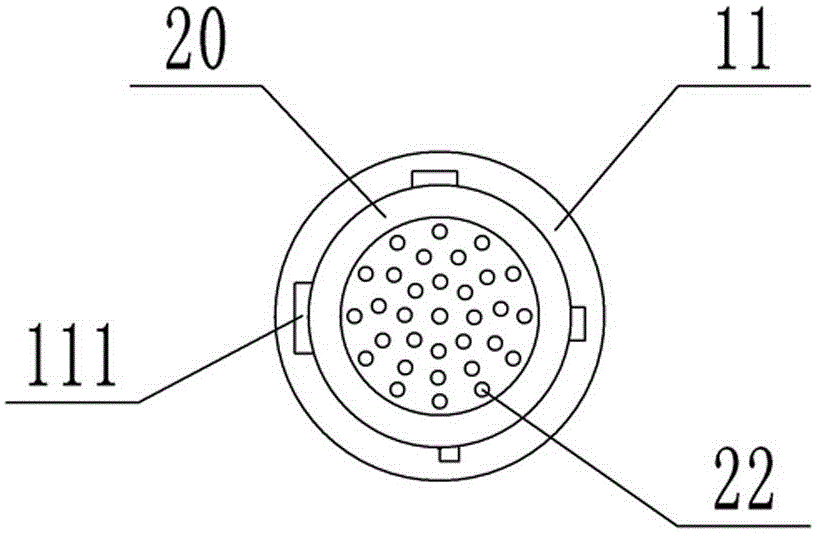

Tundish having speed regulation function

The invention belongs to the field of casting melt containers, and particularly relates to a tundish having a speed regulation function. The tundish comprises a tundish body and a stopper rod, and further comprises a liquid outlet pipe and a stop dog. A first cavity and a liquid outlet communicated with the first cavity are formed inside the stop dog. The liquid outlet pipe is arranged at the bottom of the tundish body. A plurality of liquid outlet grooves of different sizes are formed in the inner wall of the liquid outlet pipe and are smaller than the liquid outlet. The liquid outlet pipe is connected to the stop dog in a sleeved manner. A second cavity is formed inside the stopper rod which is further provided with a liquid inlet communicated with the second cavity. The stop dog is fixed to the stopper rod. The first cavity is communicated with the second cavity. Compared with a traditional stopper rod-water gap flow control structure, it is not needed to consider the relation between the vertical movement distance of the stopper rod and the open area of a water gap, and it is only needed to machine the liquid outlet grooves of certain sizes in the liquid outlet pipe in advance and rotate the stopper rod to make the liquid outlet of the stop dog communicated with one liquid outlet groove, so that operation is easy, and flow rate control is more accurate.

Owner:CHONGQING HAIDE METALLURGY MATERIAL CO LTD

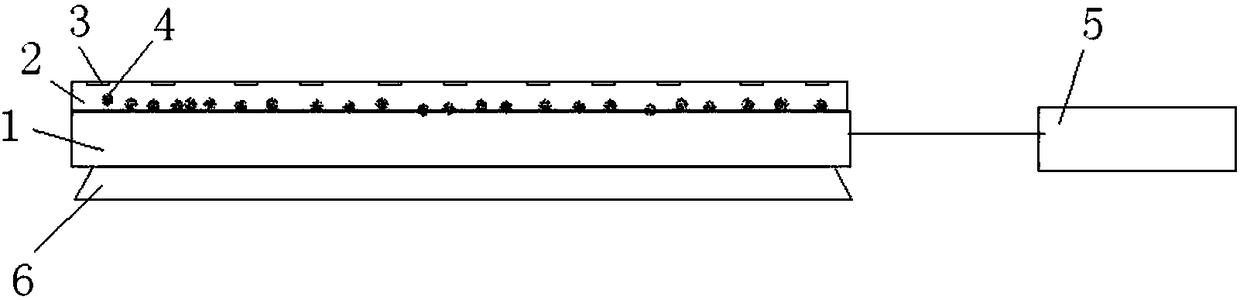

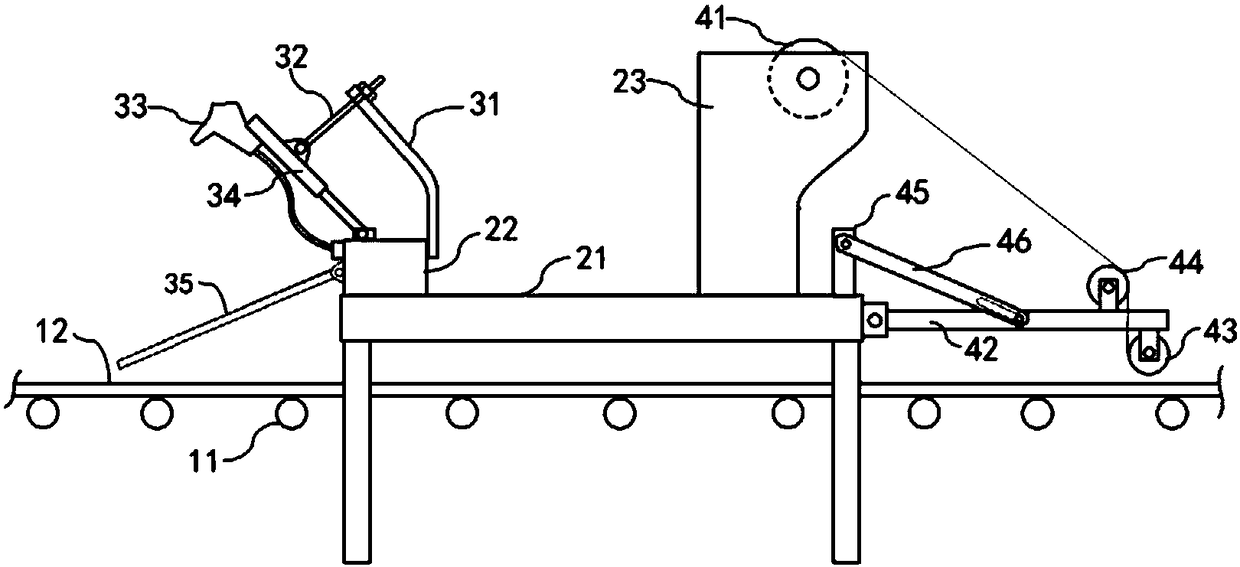

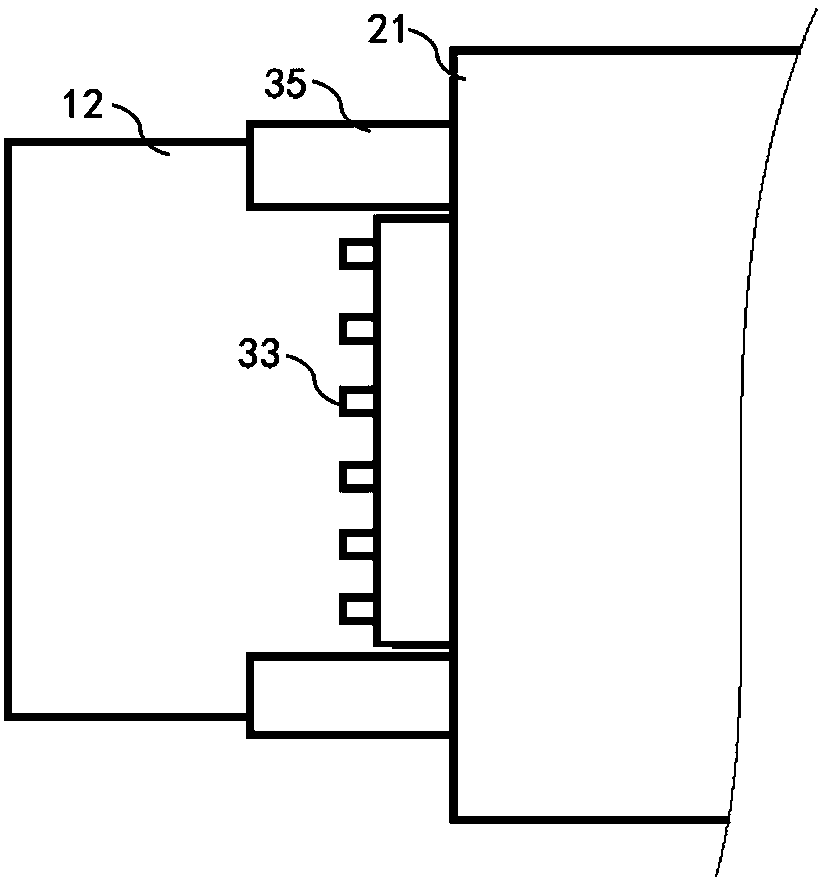

Rock wool on-line film laminating device and method

PendingCN108528003AEvenly distributedImprove fitLamination ancillary operationsLaminationEngineeringAluminum foil

The invention discloses a rock wool on-line film laminating device, and a method, and belongs to the field of rock wool processing. The rock wool on-line film laminating device comprises a glue spraying mechanism and a film supplying mechanism; the glue spraying mechanism and the film supplying mechanism are arranged on the two ends of a bearing platform along a rock wool transmission direction respectively; a plurality of spray guns are arranged in the glue spraying mechanism in parallel, and are used for spraying glue solution onto rock wool; aluminium foil in the film supplying mechanism islaminated onto the surface of rock wool through a film laminating roller. The rock wool on-line film laminating device is used for direct glue spraying onto rock wool plates, is capable of ensuring glue spraying uniformity, and then film laminating is carried out, so that preferable laminating of aluminium foil film onto rock wool plates is realized.

Owner:安徽力峦科技有限责任公司

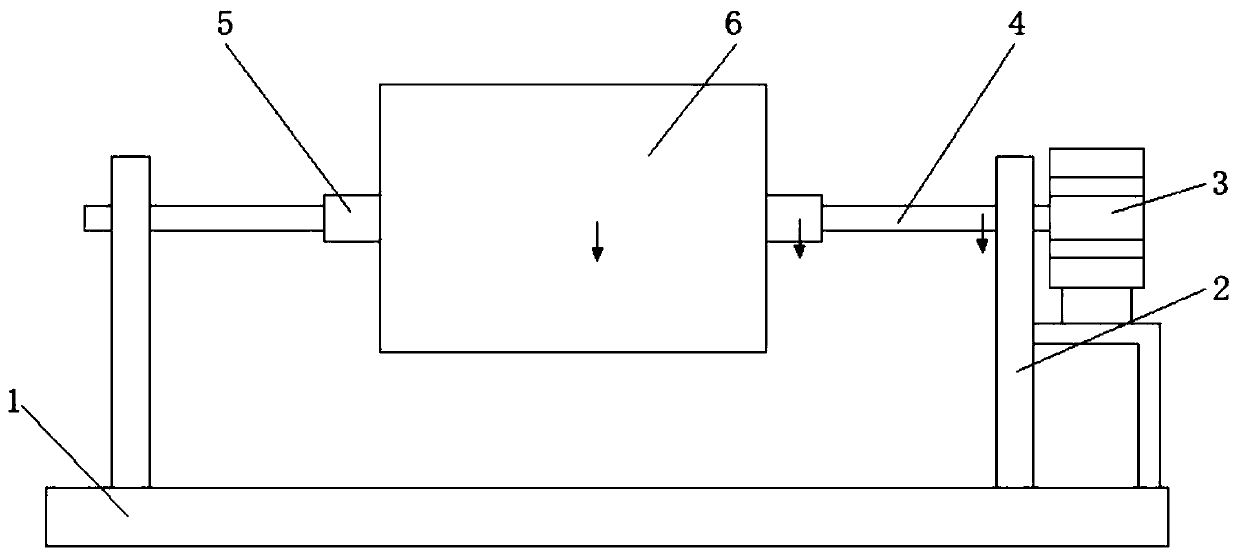

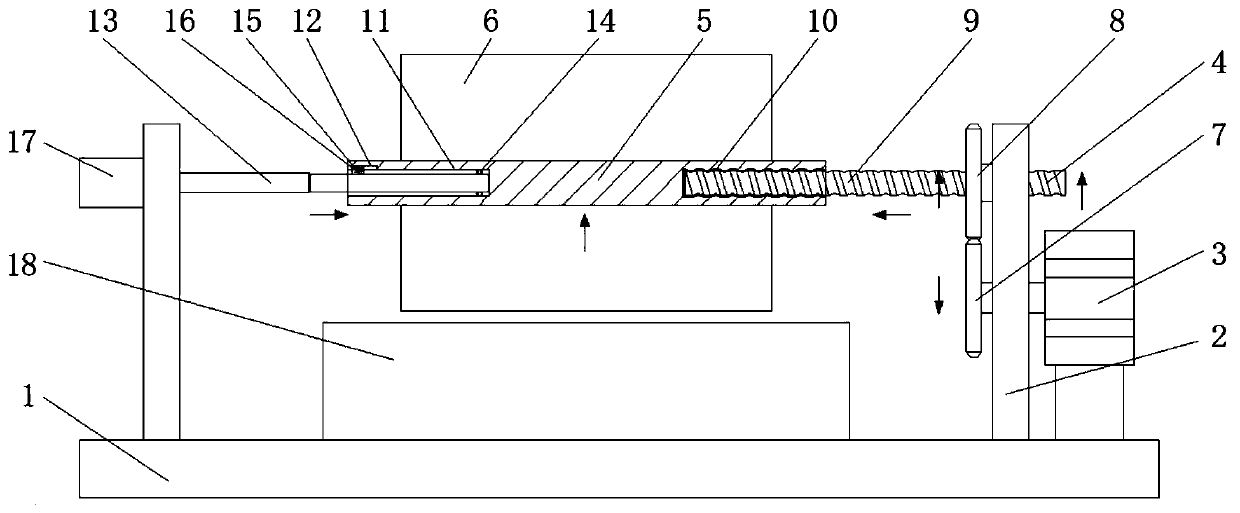

Composite cloth winding device

The invention relates to the technical field of textile machinery, and discloses a composite cloth winding device. The composite cloth winding device comprises a rack, wherein a supporting column is fixedly mounted on the upper surface of the rack; a magnetic powder brake is fixedly mounted on one side of the supporting column; a guide roller shaft is fixedly arranged in the middle of one side ofthe magnetic powder brake in a sleeving mode through the supporting column; and a guide roller sleeve is movably arranged in the middle of the outer surface of the guide roller shaft in a sleeving mode. Compared with the prior art, the composite cloth winding device adopting the abovementioned technical scheme has the advantages that the connecting mode of the guide roller shaft and the guide roller sleeve is changed, a threaded groove is in threaded fit with a threaded hole, and the rotating guide roller shaft transmits larger rotating torque to the guide roller sleeve, so that winding of cylindrical composite cloth is more stable; the connecting mode is optimized, and the rotating torque between the guide roller shaft and the guide roller sleeve is increased, so that the winding diameterof the cylindrical composite cloth is longer, and the amount of the wound cylindrical composite cloth is larger; and after the gravity is increased, transmission between the guide roller shaft and the guide roller sleeve cannot generate slipping.

Owner:嘉兴沃瑞科技有限公司

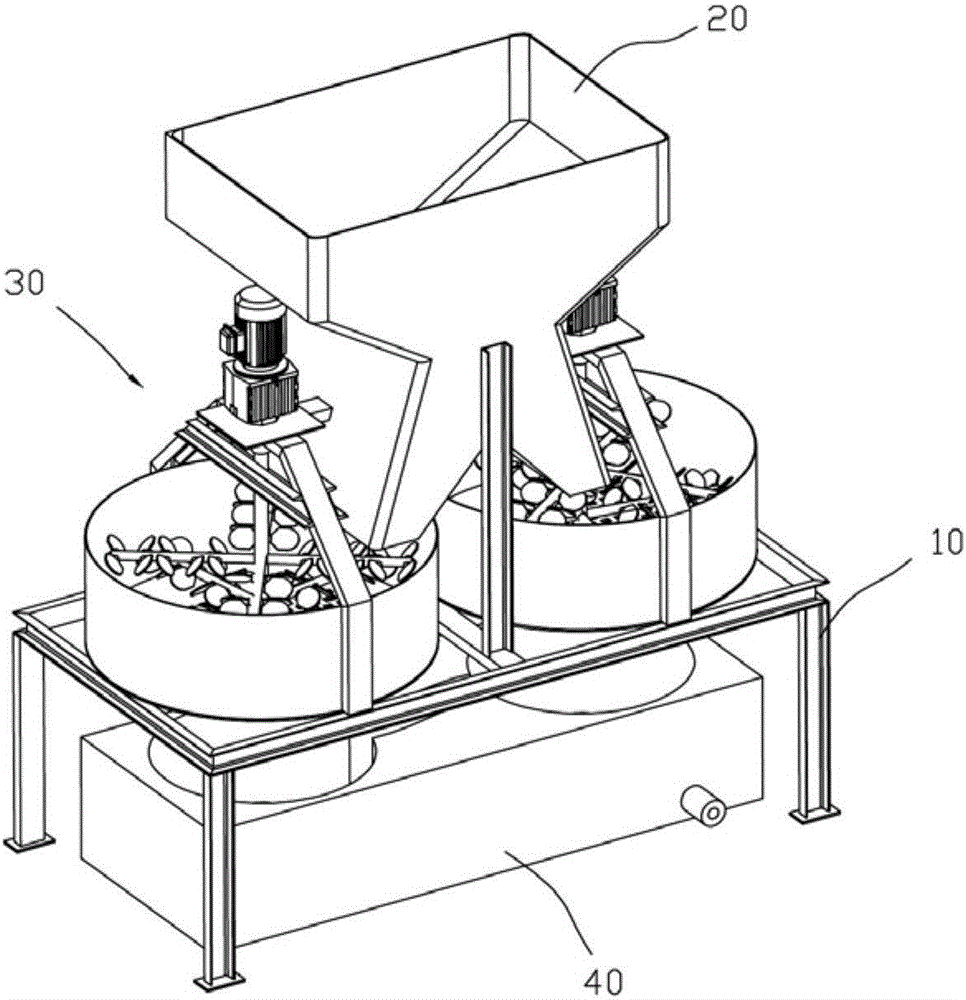

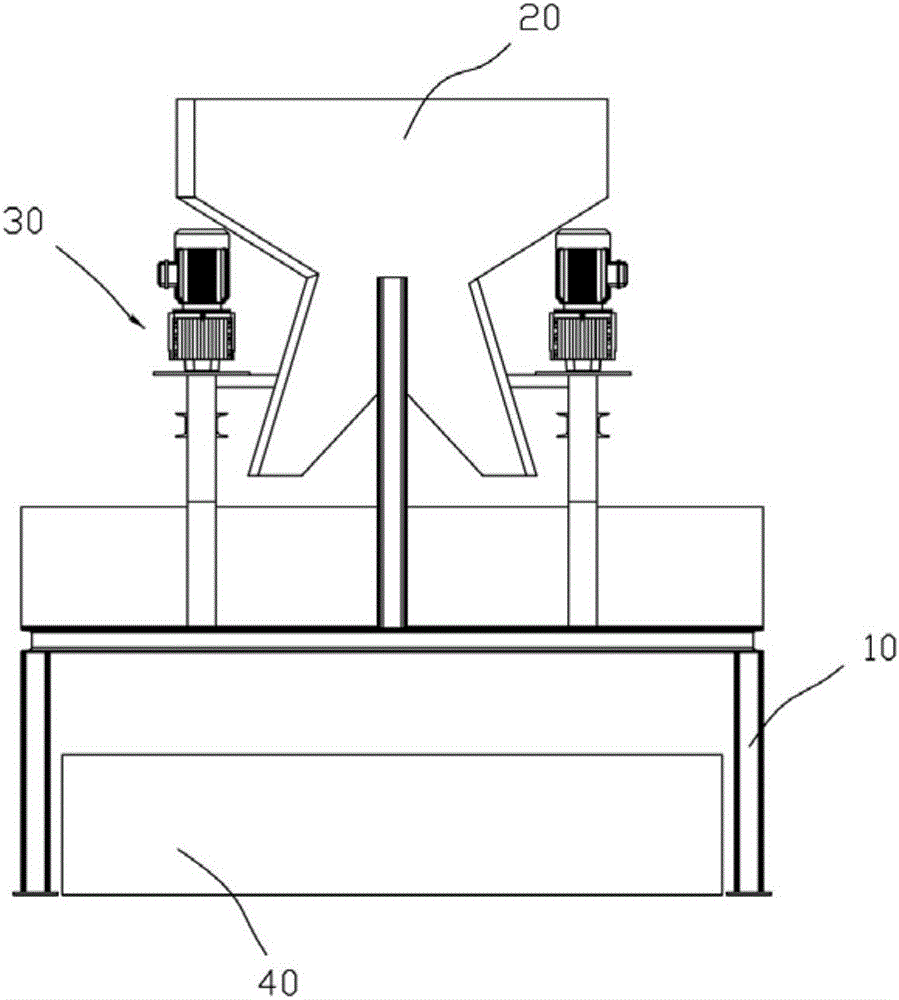

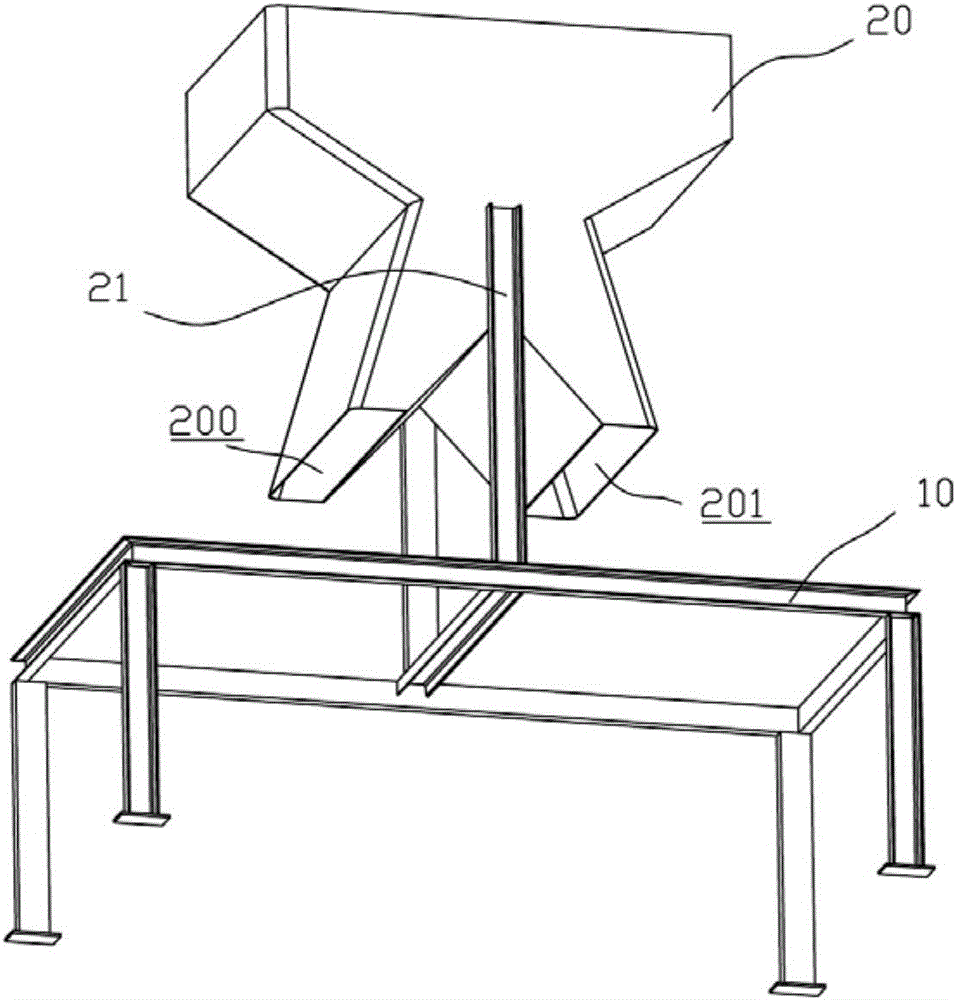

Sludge primary treatment equipment

The invention discloses sludge primary treatment equipment which comprises a bracket; a material distribution box is arranged above the bracket and is installed above the bracket through a material distribution box fixing plate; a first material release hole and a second material release hole are formed in the lower side of the material distribution box; stirring components, each of which is composed of an impeller component and a stirring barrel, are arranged under the first material release hole and the second material release hole respectively; and a collection box is arranged below the stirring barrels. According to the sludge primary treatment equipment, the traditional sludge primary treatment equipment is improved, the material distribution box is used to enable the amount of simultaneously treated sludge to be more, the double-layer impeller components are larger in stirring force to the sludge, and the stirring effect is better.

Owner:DONGGUAN BEIYANG IND DESIGN CO LTD

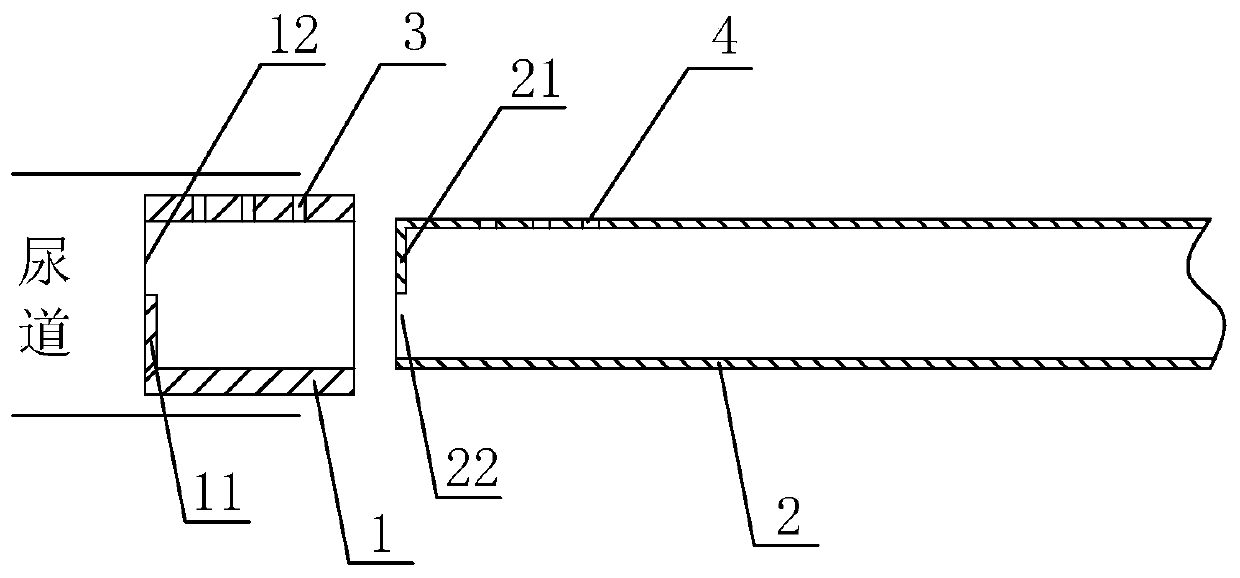

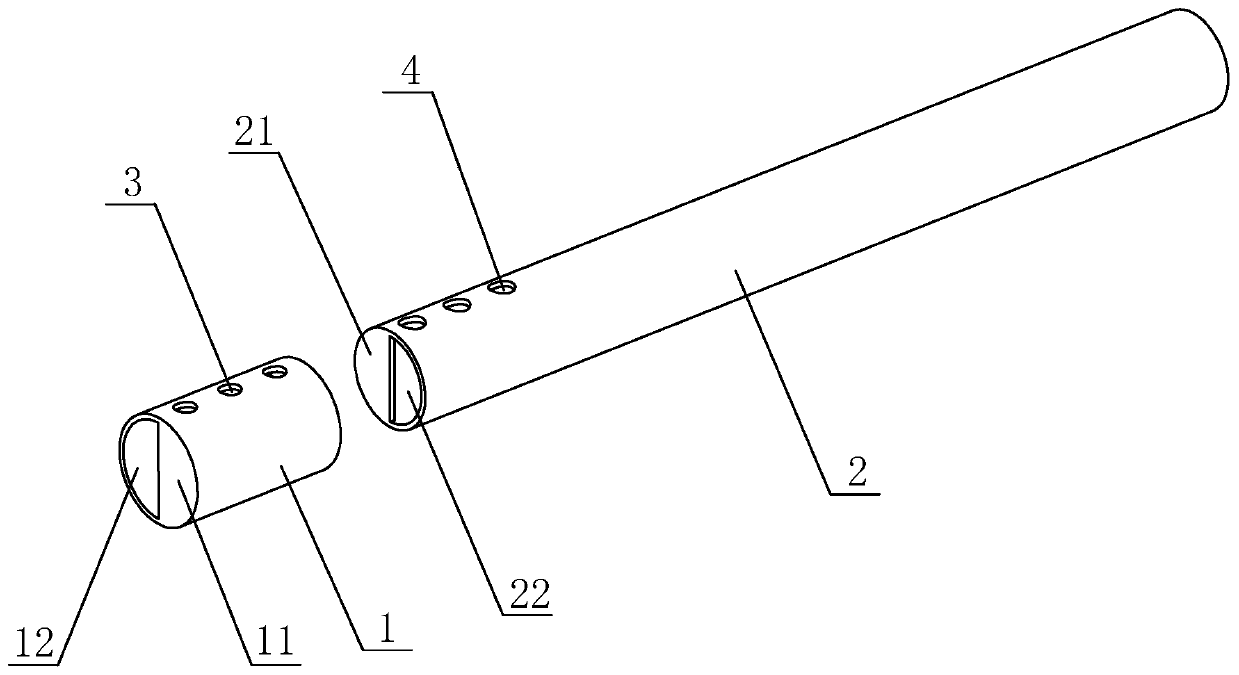

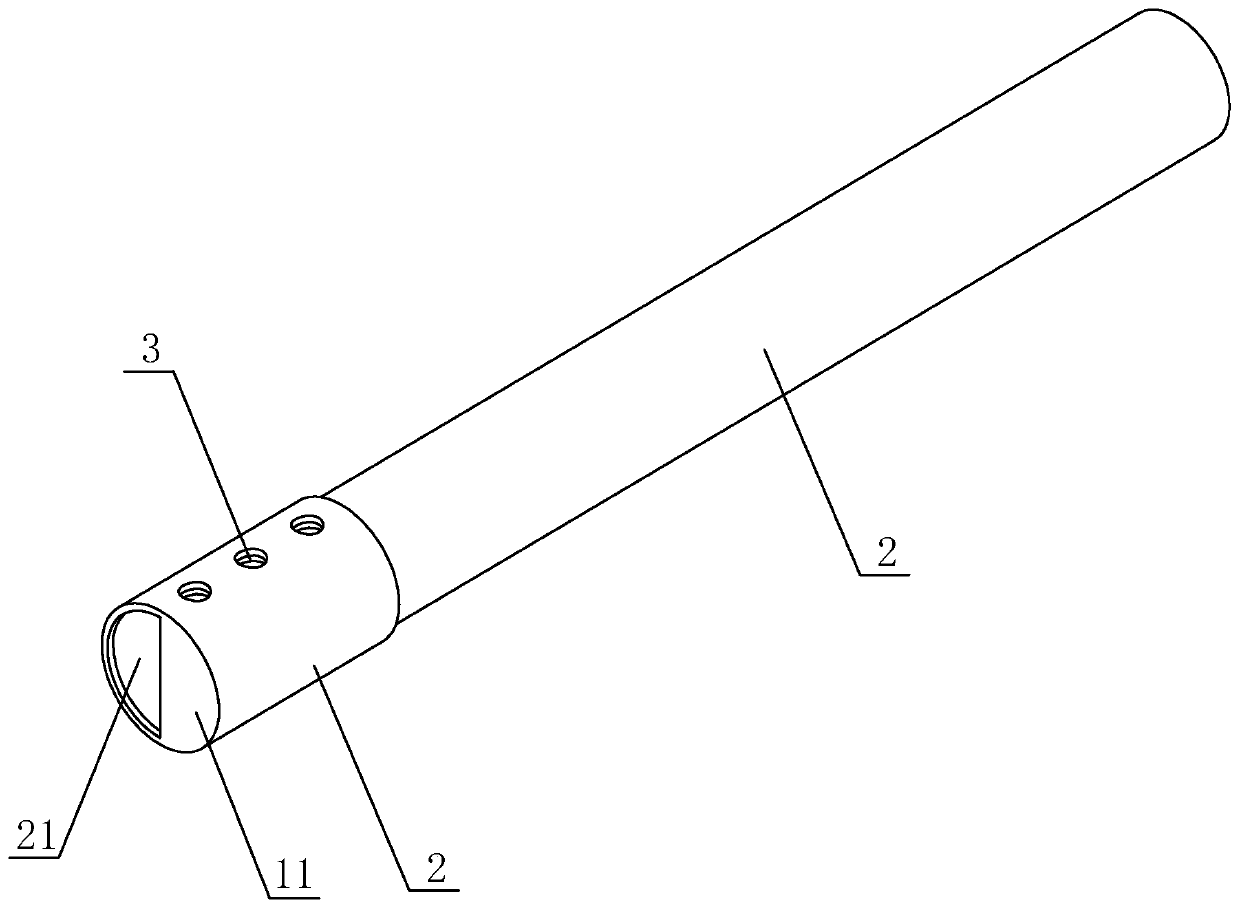

Novel urinary catheter and joint and cleaning method thereof

InactiveCN110935091AFlexible switching statusLarge amountCannulasEnemata/irrigatorsUrinary catheterSurgery

The invention relates to the technical field of urinary catheterization medical devices, and discloses a novel urinary catheter and joint and a cleaning method thereof. The novel urinary catheter andjoint includes a joint and a urinary catheter body, the urinary catheter body is detachably installed in the joint, a first cleaning opening is arranged in the side wall of the joint, a second cleaning opening is arranged in the peripheral side of the urinary catheter body, the urinary catheter body is placed in the joint, and when the urinary catheter body is rotated, the first cleaning opening communicates with the second cleaning opening; a first blocking piece is arranged in the joint, a first through opening is left between the first blocking piece and the inner wall of the joint, the endpart of the urinary catheter body is provided with a second blocking piece, and a second through opening is left between the second blocking piece and the inner wall of the urinary catheter body; when the first cleaning opening communicates with the second cleaning opening, the first blocking piece blocks the second through opening, and the second blocking piece blocks the first through opening for cleaning operation; and when the first cleaning opening and the second cleaning opening are not in communication, the first through opening communicates with the second through opening for urinarycatheterization.

Owner:上海蓓蕊医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com