Ethylene gas embedding material with slow release performance and embedding method

A slow-release performance, ethylene technology, applied in the fields of botanical equipment and methods, pest control, animal repellants, etc., can solve the problems of weak binding of ethylene and starch, poor storage stability, unstable complexes, etc. Achieve the effects of easy storage and transportation, improved stability, and controllable release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

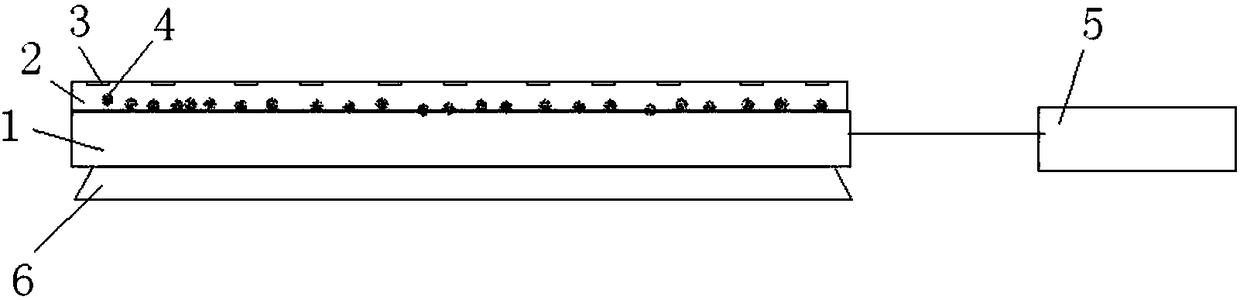

Method used

Image

Examples

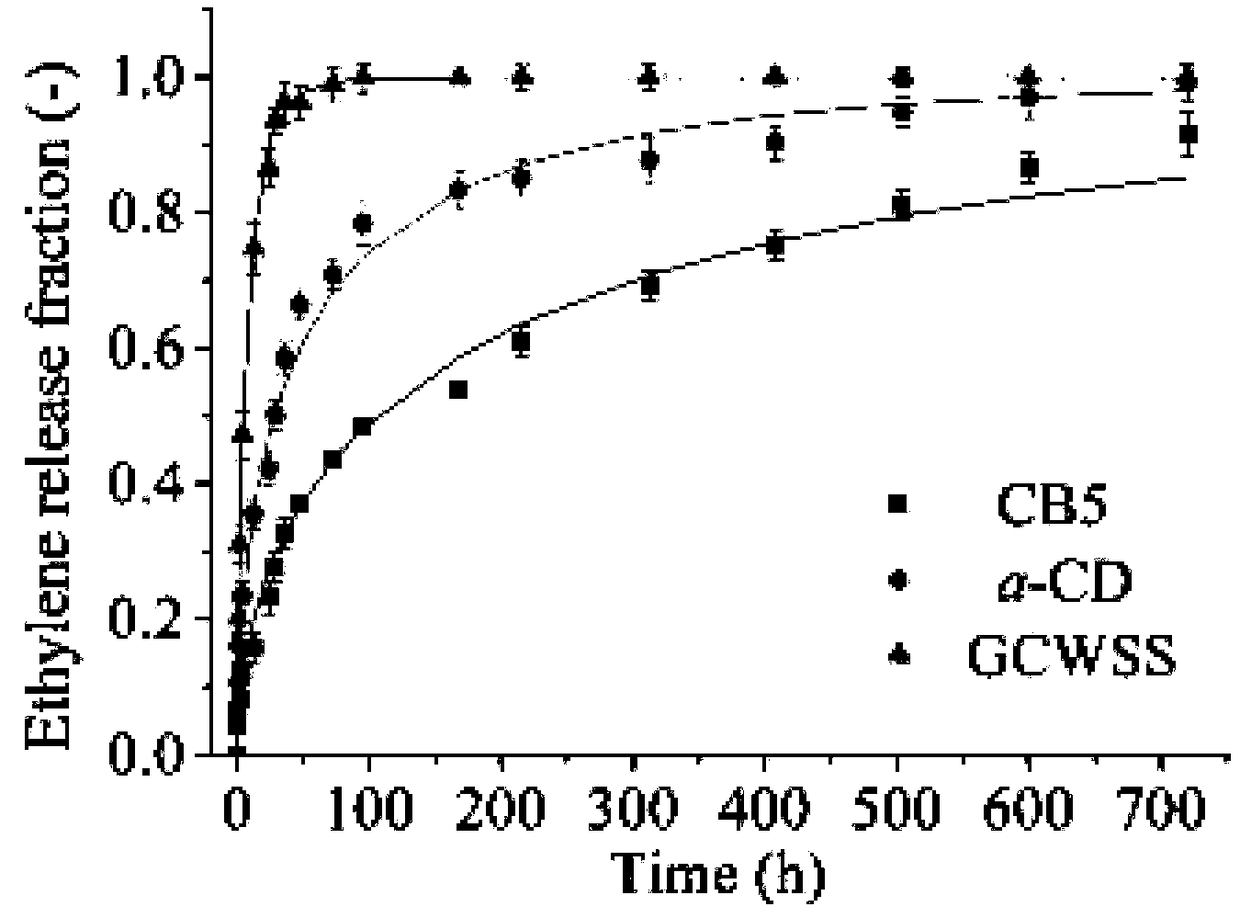

Embodiment 1

[0044] Cucurbit [5] urea (CB [5]) was placed in a miniature autoclave, the sample volume was 30% of the volume of the autoclave, and the autoclave was evacuated to -0.10Mpa. Introduce ethylene gas, react at 1.5Mpa, 25°C for 20 hours, open the outlet valve after the reaction, absorb unadsorbed ethylene with bromine water, and obtain cucurbituril powder product with ethylene adsorbed. The product is packed in a sealed bag and stored Store in dry, low temperature and dark conditions. The compound of 1.0g was weighed into a sealed bag and stored at 25°C for a period of time, and gas chromatography was used to detect the change of ethylene content in the compound during storage.

[0045] After testing, the recovery rate of the sample was 100%, and the adsorption rate of ethylene was 9.3% (w / w). The ethylene content in the composite is about 1% (w / w) after being placed at 25°C for 720 hours.

Embodiment 2

[0047] The experimental material used is cucurbit [6] urea (CB [6]), and other conditions are the same as in Example 1.

[0048] After testing, the recovery rate of the sample was 100%, and the adsorption rate of ethylene was 8.4% (w / w). The content of ethylene in the composite is about 0 after being placed at 25°C for 720h.

Embodiment 3

[0050] The experimental material used is cucurbit [7] urea (CB [7]), and other conditions are the same as in Example 1.

[0051] After testing, the recovery rate of the sample was 100%, and the adsorption rate of ethylene was 7.7% (w / w). The content of ethylene in the composite was zero after being placed at 25°C for 120 hours.

[0052] Due to space limitations, the parameters of the embedding method of this patent can be properly floated, and the floating range is as follows. The embedding method is to place cucurbitacin in a high-pressure reactor, and the amount added is 0% to 40% of the volume of the reactor. , evacuate the reactor, feed ethylene gas, control the pressure at 0.1-2.0Mpa, react at 15-35°C for 8-48 hours, open the outlet valve of the reactor after the reaction, absorb unadsorbed ethylene, and obtain release properties of vinyl-embedded products. After testing, the ethylene content in the obtained product can reach more than 9.3% (w / w), and it can release con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com