Magnetic chitosan/nano Fe3O4 composite and preparation method and application thereof

A composite material and chitosan technology, applied in chemical instruments and methods, nuclear magnetic resonance/magnetic resonance imaging contrast agents, alkali metal compounds, etc., can solve problems such as unfavorable industrial production, cumbersome process steps, and narrow application fields, and achieve Reduce the cumbersome steps of preparation, the preparation process is simple, and the effect of fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

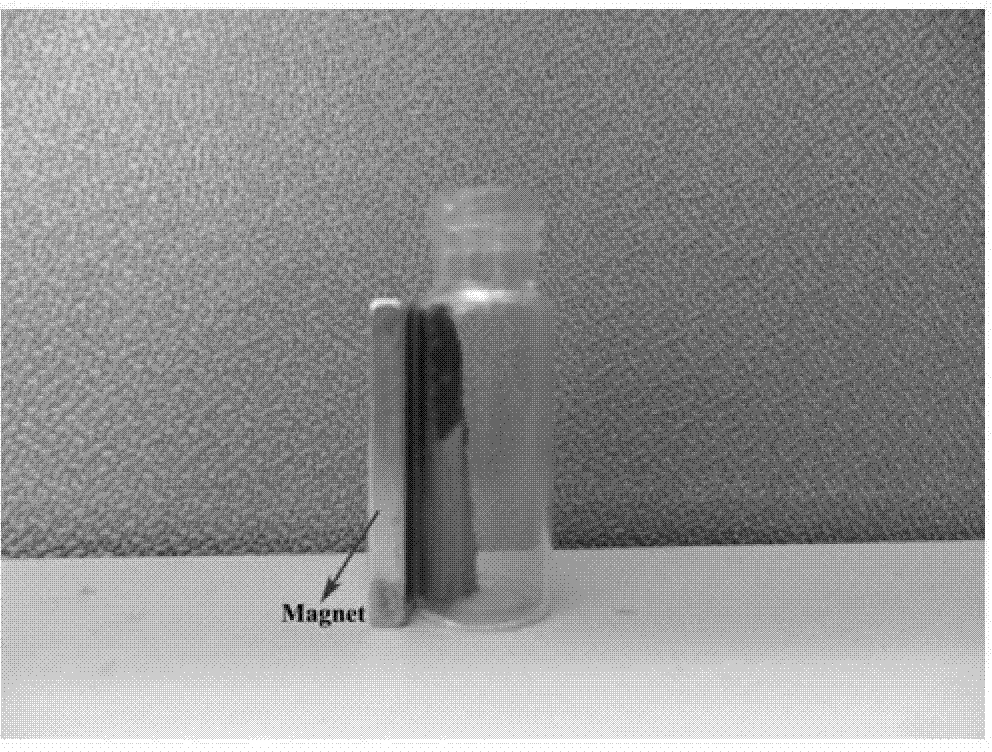

[0030] Using 2wt% acetic acid solution to accurately prepare 3wt% chitosan solution. 0.1mol / LNH 4 Fe(SO 4 ) 2 12H 2 O and 0.05mol / L (NH 4 ) 2 Fe(SO 4 ) 2 12H 2 O was dissolved in water in proportion, and 10ml was added dropwise to the chitosan solution while stirring. After 2-60 minutes, a uniform and stable orange flocculent colloid was obtained. At room temperature, put a small beaker with flocs on a glass dish, pour 25wt% concentrated ammonia solution into the glass dish, and the orange flocs will turn brown after reacting in an ammonia atmosphere for 0.1-12 hours. The product was washed with distilled water and absolute ethanol, and vacuum-dried for 24h to obtain chitosan / nano-Fe 3 o 4 composite material. Chitosan / nanometer Fe prepared by embodiment 1 3 o 4 Composite magnetic map see figure 1 .

Embodiment 2

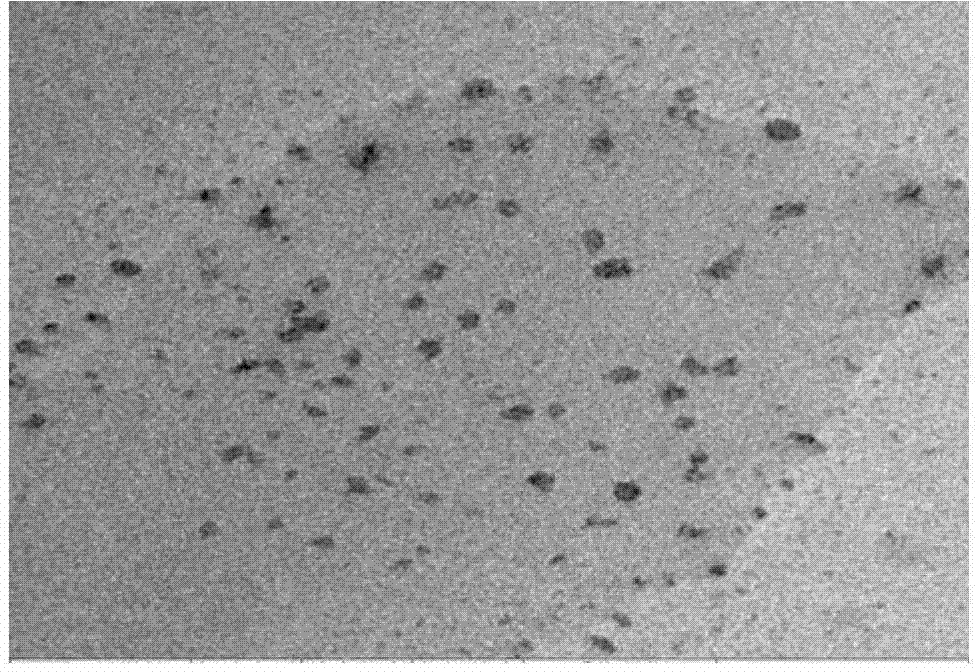

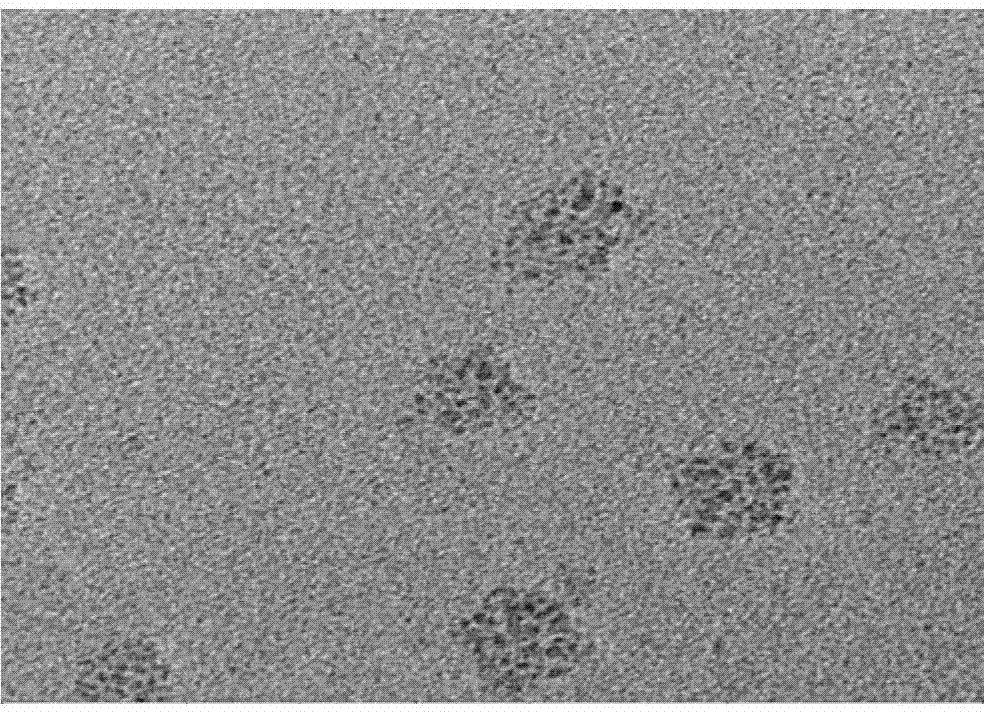

[0032] 0.2wt% chitosan solution was accurately prepared with 2wt% acetic acid solution. 0.1mol / LNH 4 Fe(SO 4 ) 2 12H 2 O and 0.05mol / L (NH 4 ) 2 Fe(SO 4 ) 2 12H 2 O was dissolved in water in proportion, and 10ml was added dropwise to the chitosan solution while stirring. After 2-60 minutes, a uniform and stable orange flocculent colloid was obtained. At room temperature, put a small beaker with flocs on a glass dish, pour 25wt% concentrated ammonia solution into the glass dish, and the orange flocs will turn brown after reacting in an ammonia atmosphere for 0.1-12 hours. The product was washed with distilled water and absolute ethanol, and vacuum-dried for 24h to obtain chitosan / nano-Fe 3 o 4 composite material. Chitosan / Fe 3 o 4 The nanocomposite product was dispersed in absolute ethanol, and then dropped onto a copper grid to dry and then observed under a field emission transmission electron microscope. Chitosan / nanometer Fe prepared by embodiment 2 3 o 4 TE...

Embodiment 3

[0034] 0.2wt% chitosan solution was accurately prepared with 2wt% acetic acid solution. 0.2mol / LNH 4 Fe(SO 4 ) 2 12H 2 O and 0.1mol / L (NH 4 ) 2 Fe(SO 4 ) 2 12H 2 O was dissolved in water in proportion, and 10ml was added dropwise to the chitosan solution while stirring. After 2-60 minutes, a uniform and stable orange flocculent colloid was obtained. At room temperature, put a small beaker with flocs on a glass dish, pour 25wt% concentrated ammonia solution into the glass dish, and the orange flocs will turn brown after reacting in an ammonia atmosphere for 0.1-12 hours. The product was washed with distilled water and absolute ethanol, and vacuum-dried for 24h to obtain chitosan / nano-Fe 3 o 4 composite material.

[0035] Chitosan / Nano Fe 3 o 4 The composite material is undergoing TG test, the condition is in nitrogen atmosphere, the heating rate is 10°C / min.

[0036] Chitosan / nanometer Fe prepared by embodiment 3 3 o 4 The thermal weight loss curve of composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com