Patents

Literature

175results about How to "Shorten the flow distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

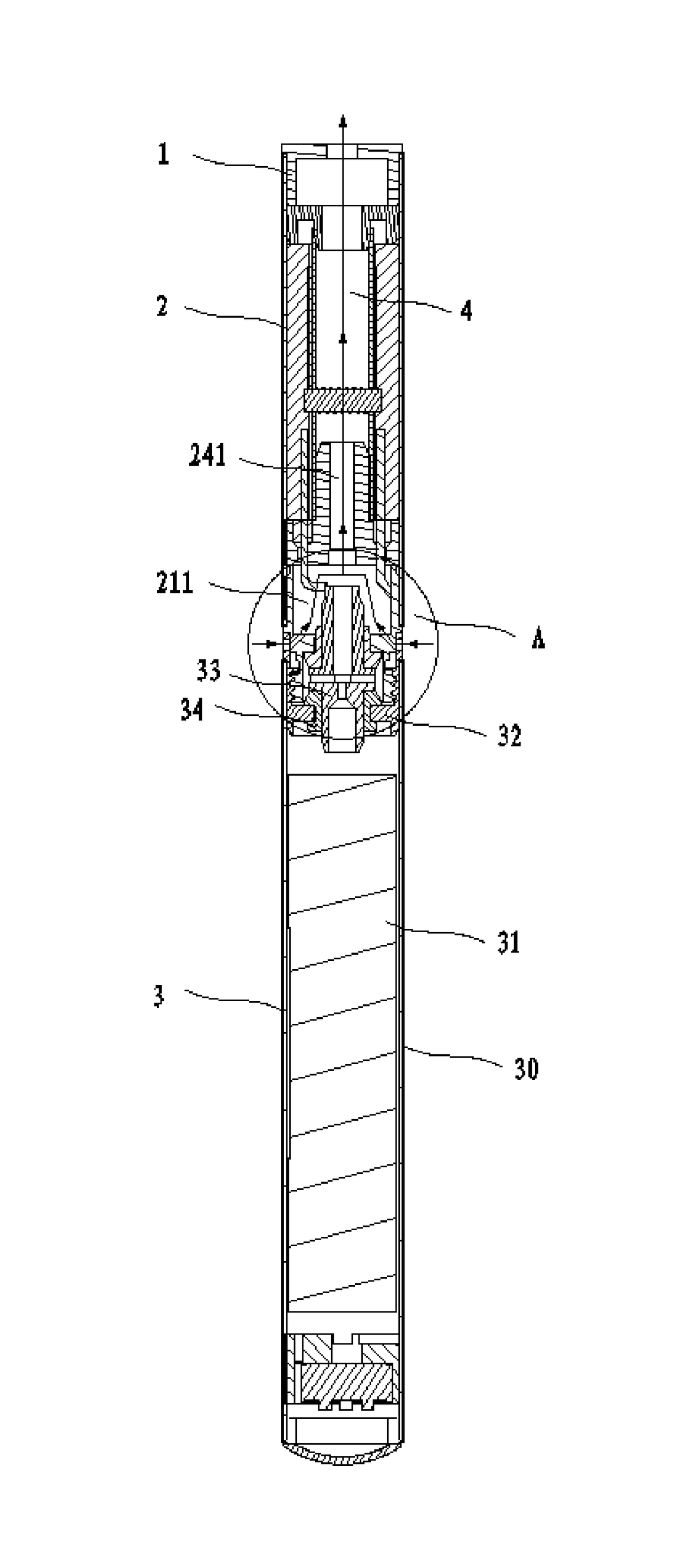

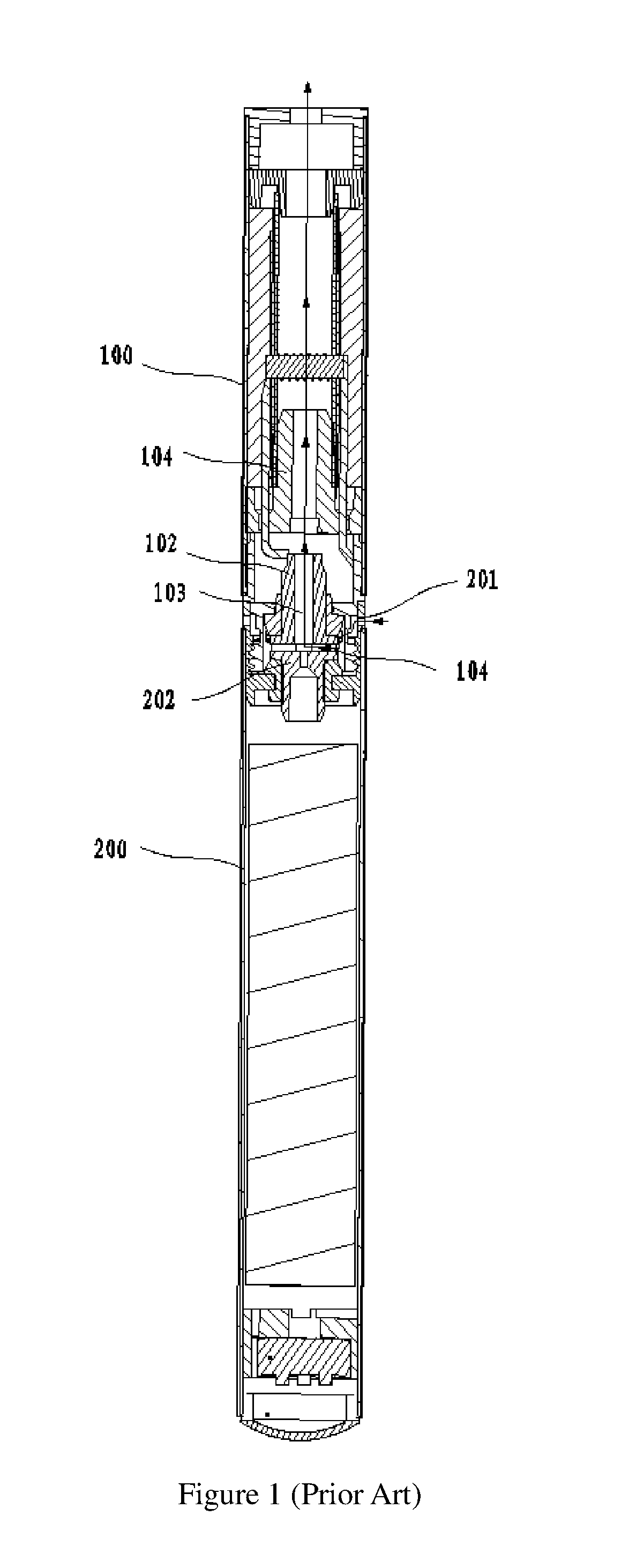

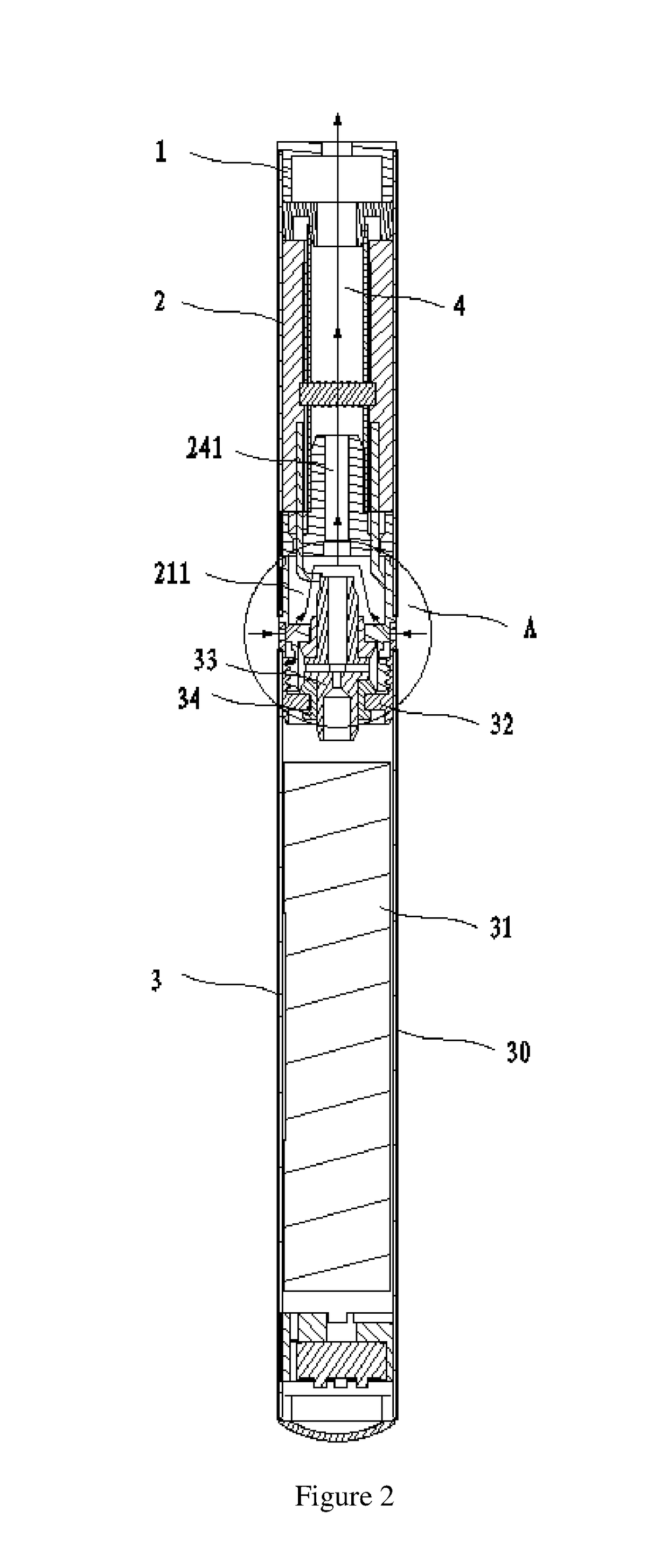

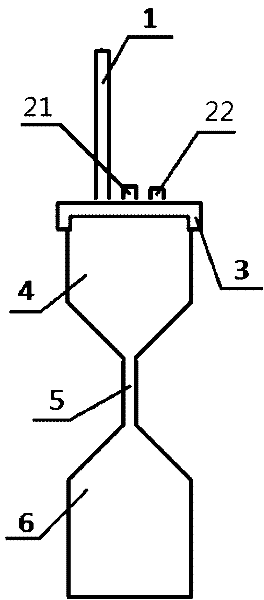

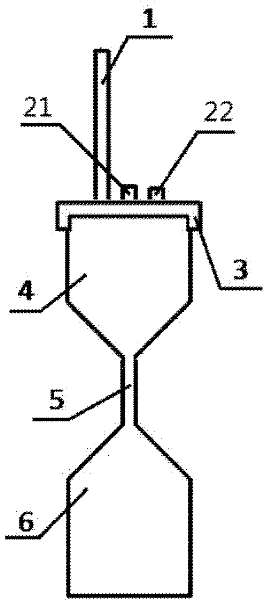

Electronic cigarette

InactiveUS20170208866A1Reduction of airflow passage bendingShorten the flow distanceTobacco pipesTobacco devicesElectronic cigaretteMechanical engineering

Provided is an electronic cigarette comprising a smoking end, an atomization assembly and a battery assembly; an airflow passage communicating with the smoking end is defined in the electronic cigarette; one end of the battery assembly is provided with a first connection sleeve connected to the atomization assembly; a peripheral wall of the first connection sleeve is provided with at least one first air inlet hole; a side wall of a first accommodation chamber is provided with at least one second air inlet hole communicating with first accommodation chamber and the first air inlet hole; thus it is unnecessary for the airflow to pass through the electrode before entering the smoking end, such that a circulation of the air flow is smoother, noise is reduced, and the battery assembly and atomization assembly are prevented from being mixed up during use.

Owner:HUIZHOU KIMREE TECH

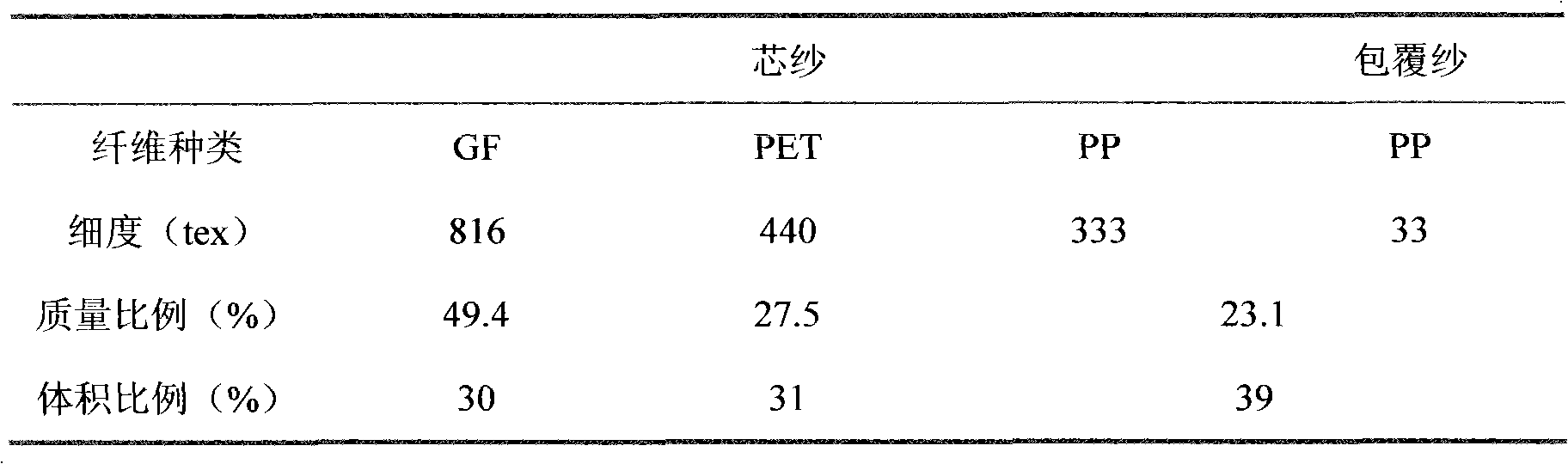

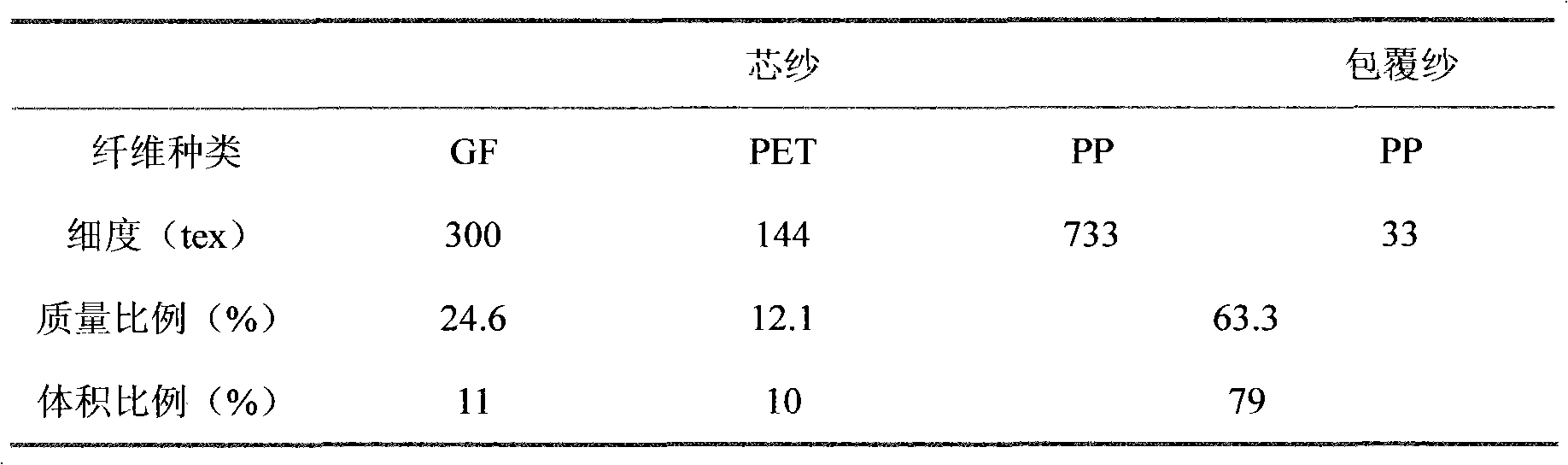

Method for preparing thermoplastic fiber-hybrid woven composite

ActiveCN102152554AGood protectionExcellent overall performanceSynthetic resin layered productsLaminationYarnThermoplastic composites

The invention discloses a method for preparing a thermoplastic fiber-hybrid woven composite and is characterized by comprising the following three steps: preparing thermoplastic fasciated yarns, weaving a pre-manufactured composite and molding the woven composite, wherein the thermoplastic wrapping yarns consist of strengthened fibers and thermoplastic resin fibers which are mixed according to the volume by adopting a fiber wrapping technology, the thermoplastic fibers are 40 to 80 volume percent and the strengthened fibers are 20 to 60 volume percent; and then the thermoplastic resin fibers are uniformly covered on the strengthened fibers to form the thermoplastic wrapping yarns. The thermoplastic composite is a big trend in the further composite development and has a bright development prospect.

Owner:ZHEJIANG MAGLIA CASHMERE FAMILY CO LTD

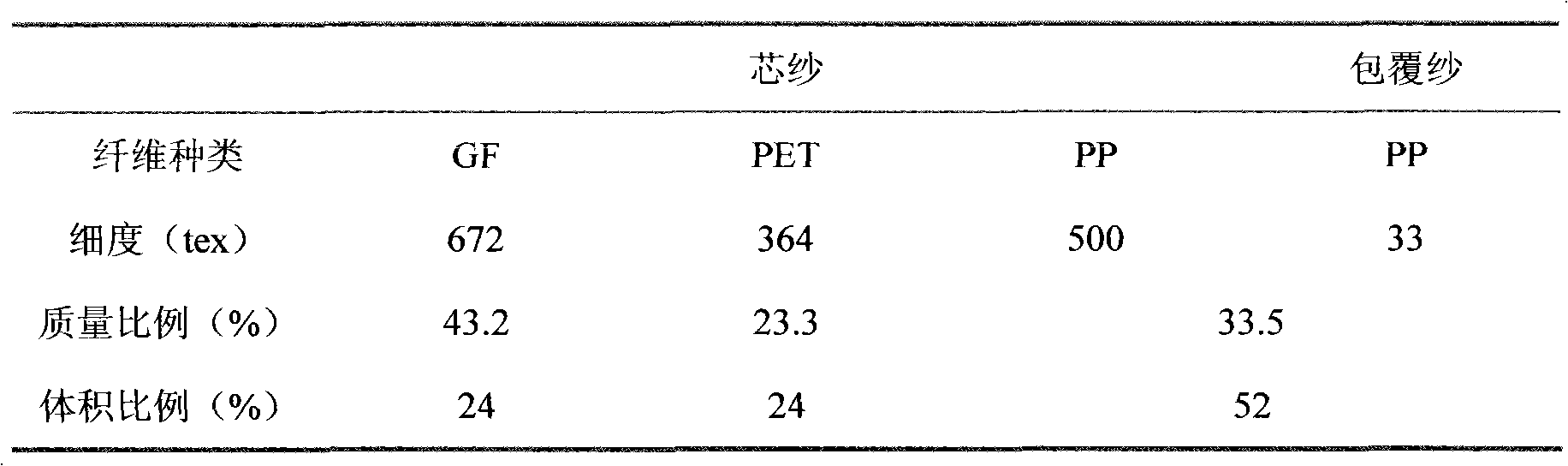

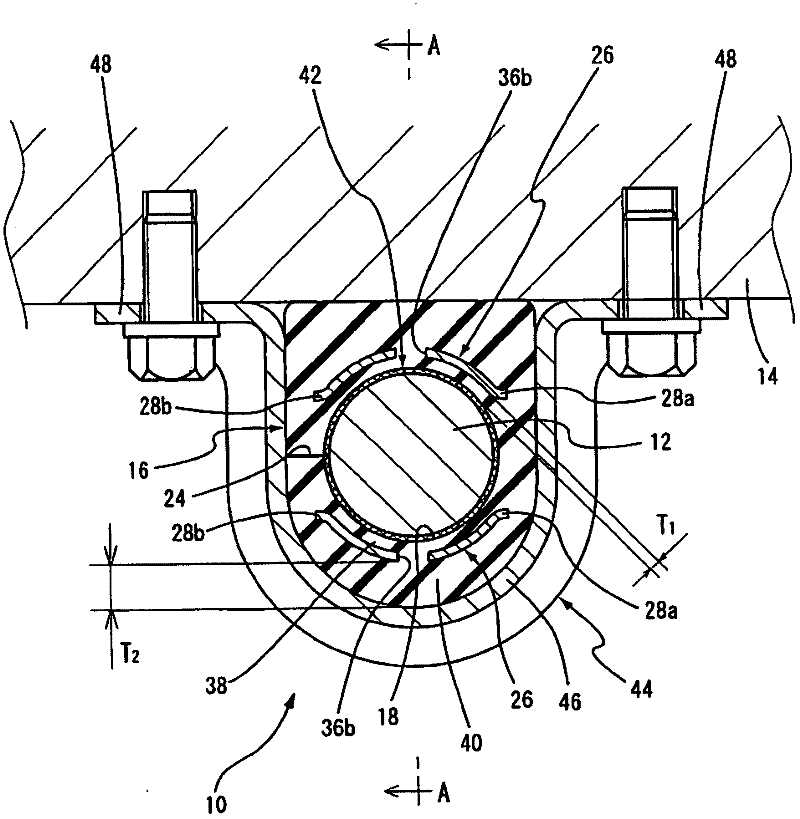

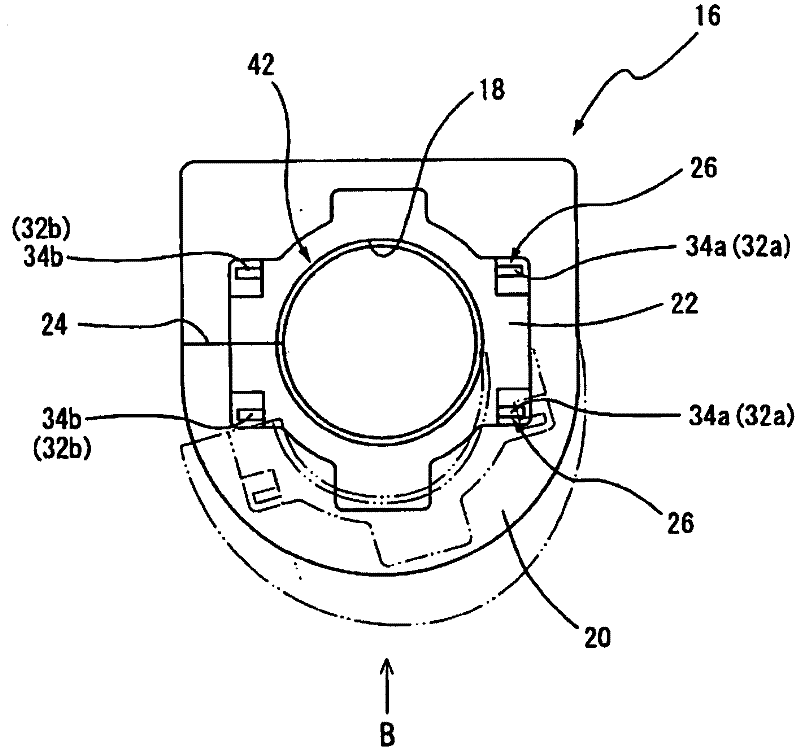

Vehicle stabilizer bushing

ActiveCN102470721AEliminate deflectionSmooth rotationSpringsNon-rotating vibration suppressionVulcanizationEngineering

Disclosed is a stabilizer bushing which more efficiently reduces torsional friction between a bushing main body and a stabilizer bar. A bushing main body (16) is formed from a cylindrical rubber elastic body to which a sliding member (42) is fixed to a surface of the inner circumference. In a middle area of the bushing main body (16) perpendicular to the axis thereof, two partition members (26, 26) are embedded so as to be positioned vertically, and are adhered by vulcanization. The bushing main body (16) is constituted from an inner rubber part (38) of a thickness so as not to allow elastic deformation by an input load, and an outer rubber part (40) thicker than said inner rubber part. Meanwhile, through-holes (36a, 36b and 36c) are formed only in positions that equally divide the partition members (26, 26) in the circumferential and axial directions.

Owner:SUMITOMO RIKO CO LTD +1

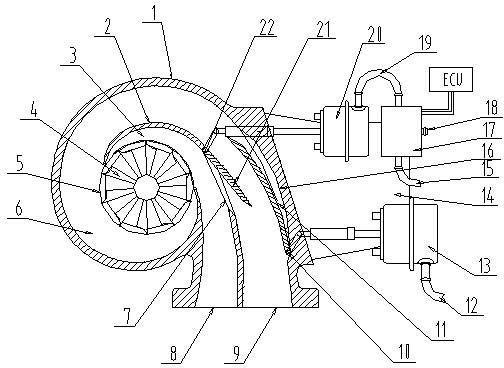

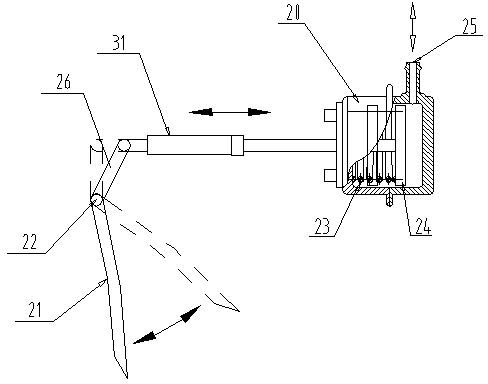

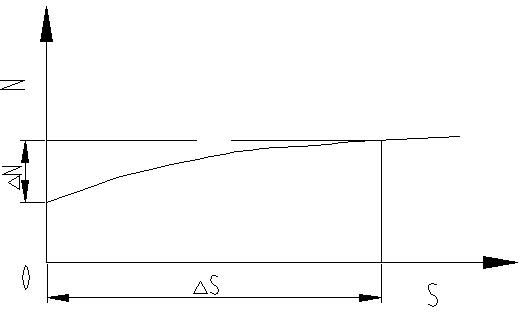

Staged flow-adjustable turbine shell

ActiveCN102536433AAvoid lateral flowReduce flow frictionInternal combustion piston enginesEngine componentsLow speedInlet flow

The invention discloses a staged flow-adjustable turbine shell, which comprises a turbine shell body. A turbine assembly and a waste gas inlet flow channel are mounted in the turbine shell body; an air inlet which is communicated with the waste gas inlet flow channel is arranged on the turbine shell body; an intermediate wall is disposed in the waste gas inlet flow channel and divides the waste gas inlet flow channel into an inner flow channel and an outer flow channel; a first valve device which can close the outer flow channel is disposed in the outer flow channel; and the intermediate wall is provided with a second valve device which can realize connection or disconnection of the inner flow channel and the outer flow channel. Waste gas energy is utilized sufficiently, rotation speed of a turbine rotor is increased, air inlet quantity of an engine in low speed work conditions is improved, so that the engine can apply more work, low speed torsion of the engine is increased, the low speed torque of the engine well matches with the low speed work conditions of the engine, and dynamic property and transient responsibility of the engine in low speed work conditions are improved.

Owner:康跃科技(山东)有限公司

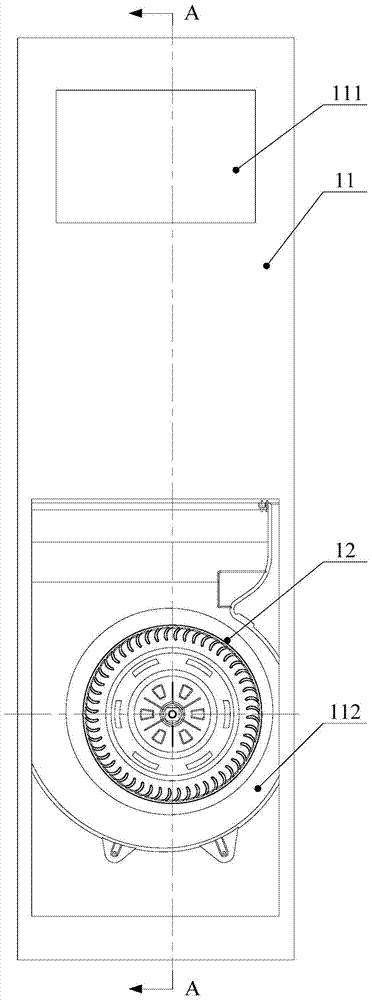

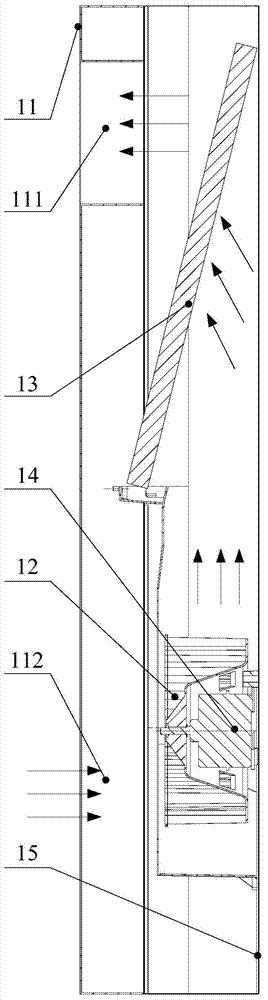

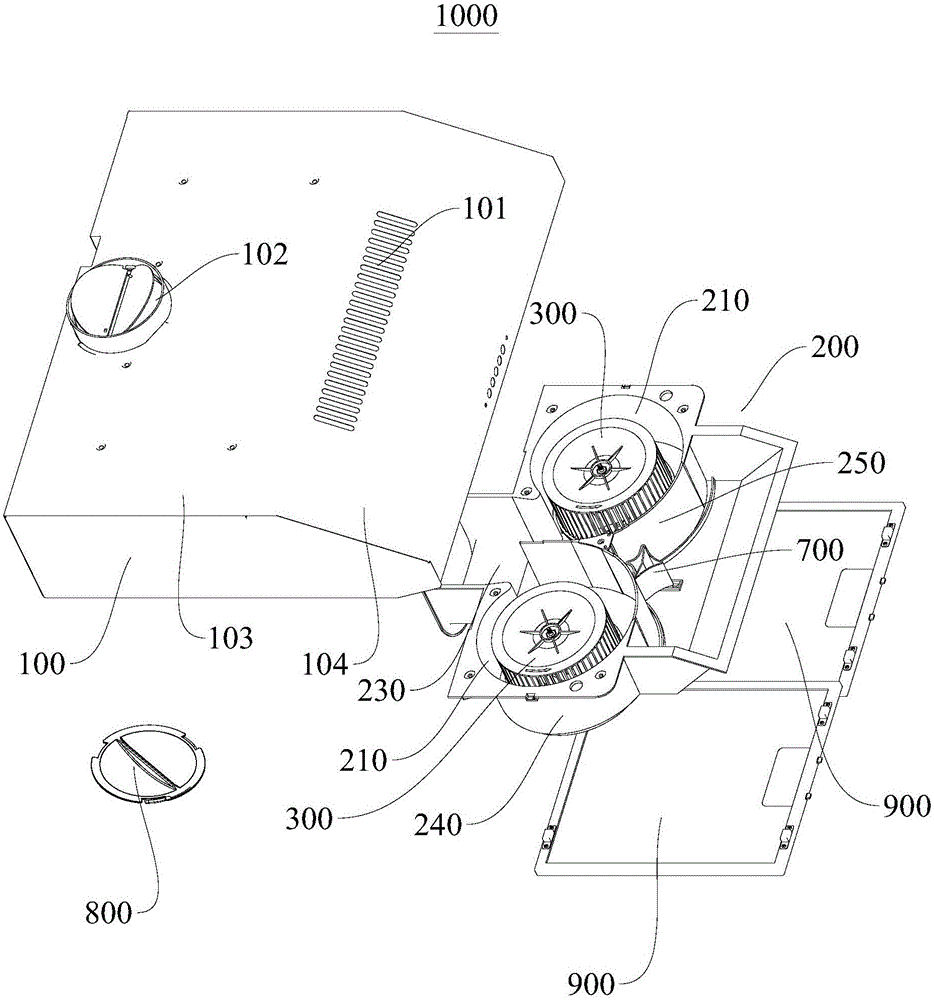

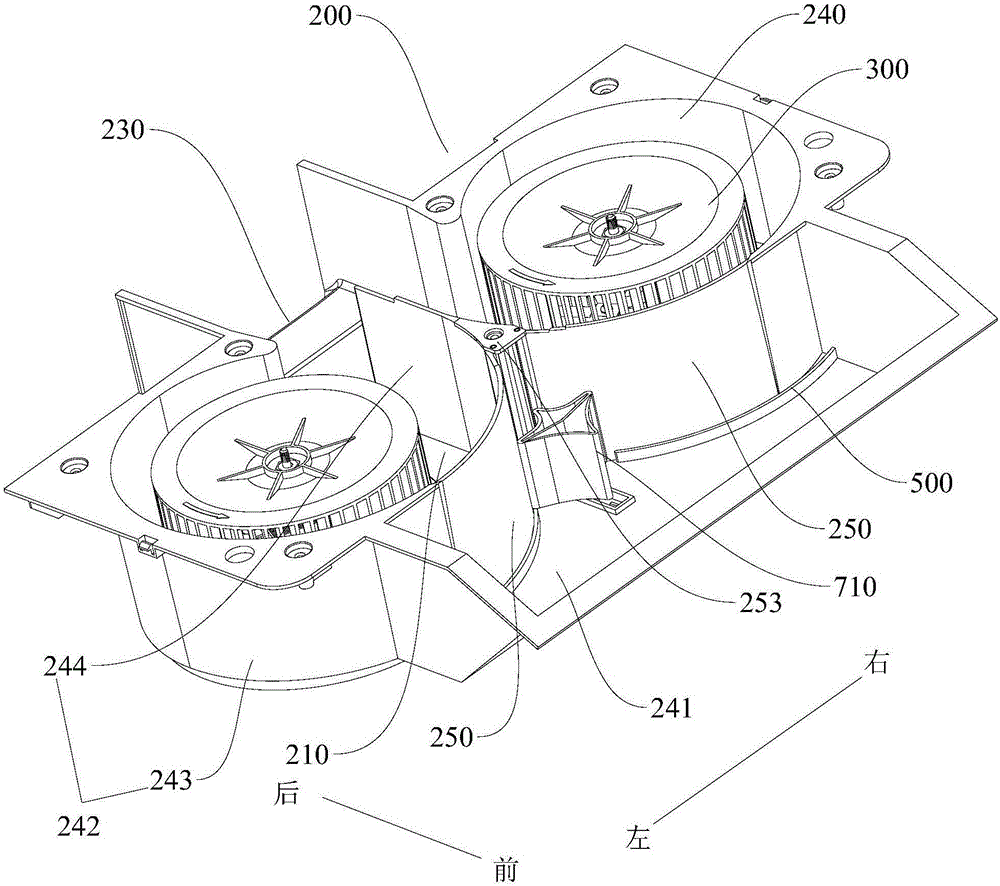

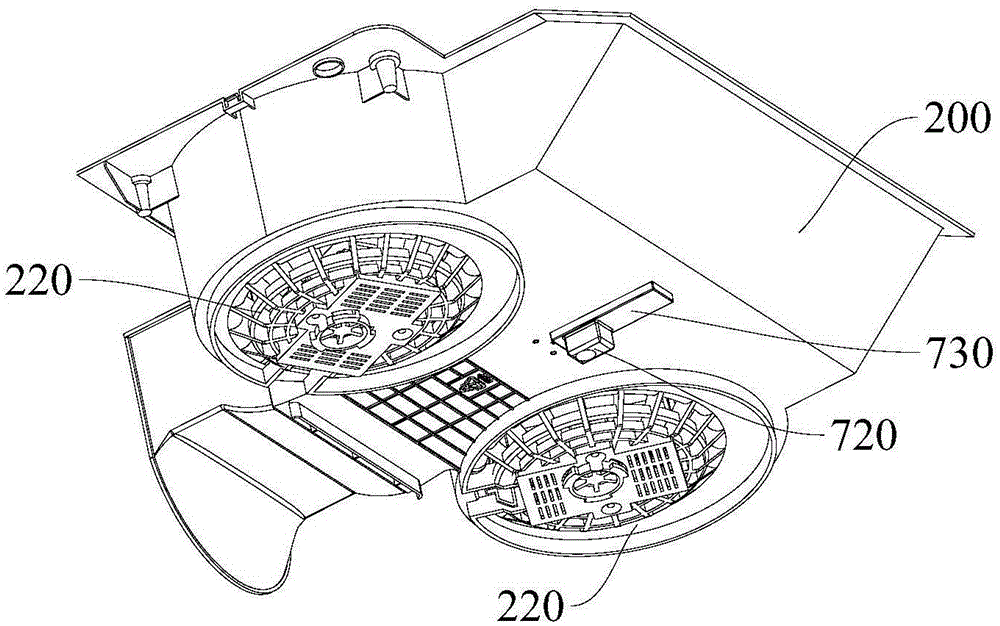

Indoor unit of split floor type air conditioner

InactiveCN104515196ARealize parallel air supplyAchieve entryMechanical apparatusSpace heating and ventilation safety systemsMixed flowEngineering

The invention provides an indoor unit of a split floor type air conditioner. The indoor unit comprises a front panel, a rear housing connected with the front panel to forming a receiving cavity, and a heat exchanger and fans both located in the receiving cavity, as well as a motor for driving the fan to run, wherein air outlets are formed in the front panel; the fans are axial-flow fans or mixed flow fans and are located between the heat exchanger and the front panel; at least two fans are arranged, and the indoor unit is provided with the air outlets as many as the fans; an air inlet is formed in the rear housing; the projections of the air outlets on the rear housing and the projections of the fans on the rear housing have overlapped parts with the air inlet. According to the indoor unit of the split floor type air conditioner, the airflow is capable of transversely passing through the indoor unit, the flowing distance of the airflow from the air inlet to the air outlet is shortened, and therefore, the energy loss is reduced and the overall operating efficiency is improved.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

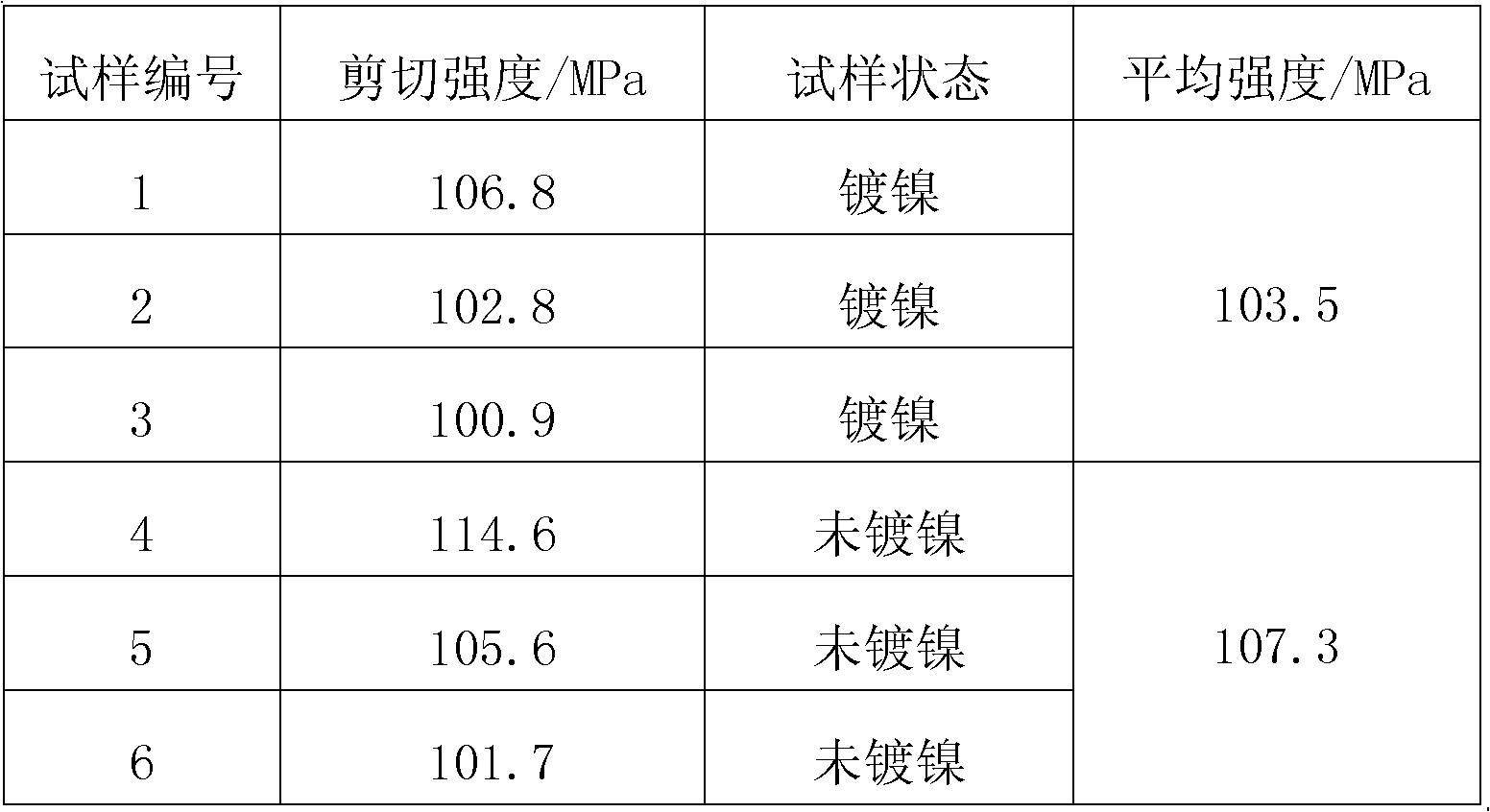

Vacuum brazing method for high-temperature alloy pipe parts

ActiveCN102500856APromote spreading wettingShorten the flow distanceSoldering apparatusBraze alloySuperalloy

The invention provides a vacuum brazing method for high-temperature alloy pipe parts. The method comprises the following steps: firstly coating nickel in the welding positions of pipe parts, secondly assembling high-temperature alloy pipe parts to be brazed in a way that the assembly gap is within the range of 0.03 mm to 0.08 mm, thirdly presetting an amorphous foil-like brazing alloy sheet with the thickness of 0.03 mm in the assembly gap of the high-temperature alloy pipe parts to be brazed, subsequently positioning the high-temperature alloy pipe parts by argon arc welding, and finally coating and injecting a solder paste made of powdery brazing alloy at the joint of the pipe parts and loading the high-temperature alloy pipe parts into a vacuum brazing furnace for vacuum brazing. The amorphous brazing alloy foil is preset in the assembly gap of the pipe parts to ensure welding and assembly gap. The amorphous brazing alloy foil and the powdery brazing alloy interact during the welding process, so as to facilitate spread and moistening of the brazing alloy and also reduce the flow distance of the powdery brazing alloy, thus obtaining a great improvement of welding quality.

Owner:AECC AVIATION POWER CO LTD

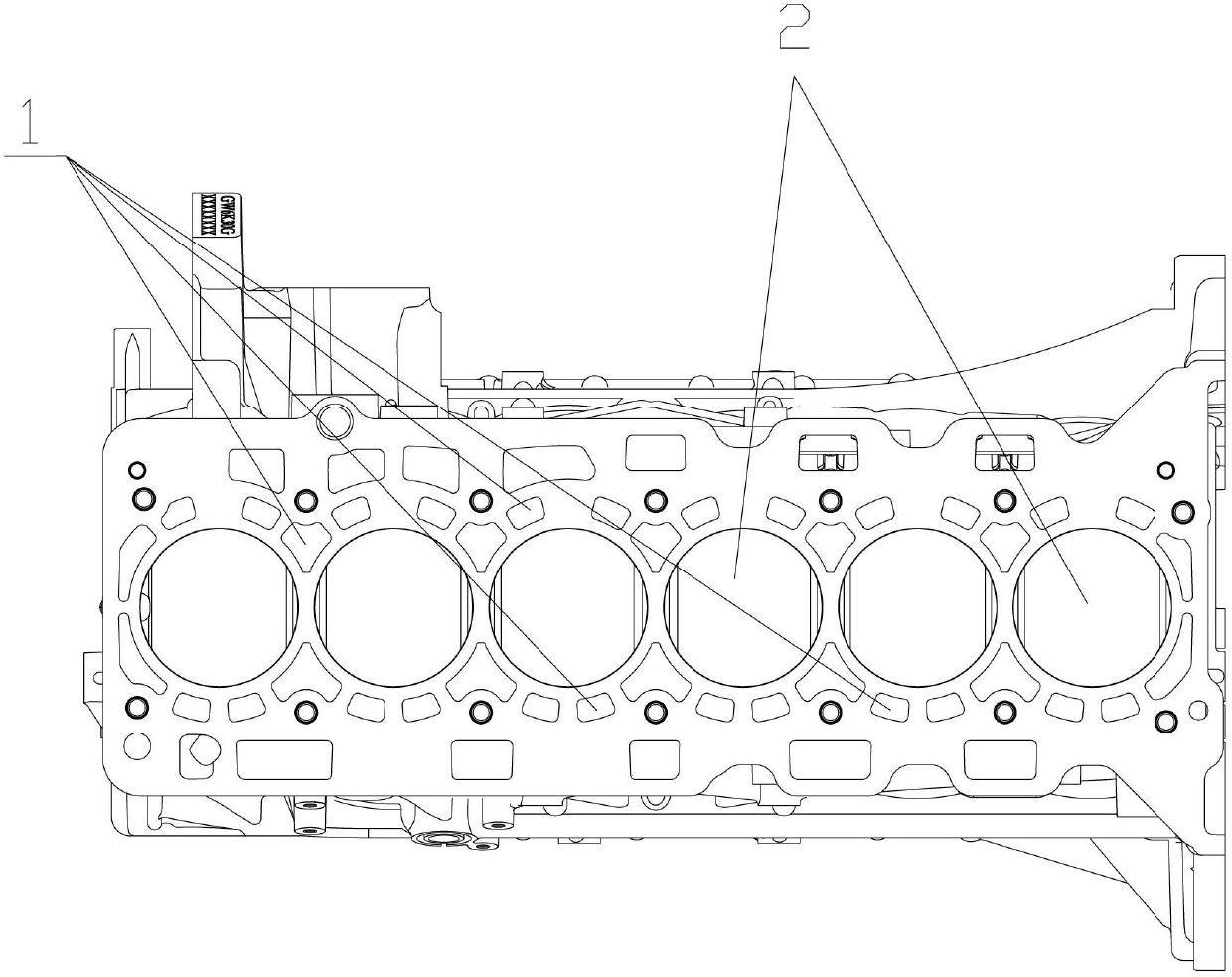

Engine

ActiveCN102678368AShorten the flow distanceUniform cooling waterCylinder headsCylindersCylinder blockWater jacket

The embodiment of the invention discloses an engine, relates to the technical field of automobiles and aims at improving the cooling effect of the engine. The engine comprises a cylinder body, a cylinder cover is covered on the cylinder body, a plurality of cylinder barrels and a cylinder body water jacket around the cylinder barrels are arranged on the cylinder body, the cylinder body water jacket is arranged on the cylinder cover, and the cylinder body water jacket comprises a water jacket on the air inlet side of the cylinder body and the water jacket on the exhaust side of the cylinder body, wherein the water jacket on the air inlet side of the cylinder body and the water jacket on the exhaust side of the cylinder body are mutually isolated, a water inlet is further arranged on the water jacket on the exhaust side of the cylinder body, a water outlet is arranged on the water jacket on the air inlet side of the cylinder body, and cooling water can enter into the water jacket on the exhaust side of the cylinder body from the water inlet, further enter into the cylinder cover water jacket from the water jacket on the exhaust side of the cylinder body, then enter into the water jacket on the air inlet side of the cylinder body from the cylinder cover water jacket and finally flow out of the water outlet. The engine disclosed by the invention is used for cooling the periphery of the cylinder barrels of the engine.

Owner:GREAT WALL MOTOR CO LTD

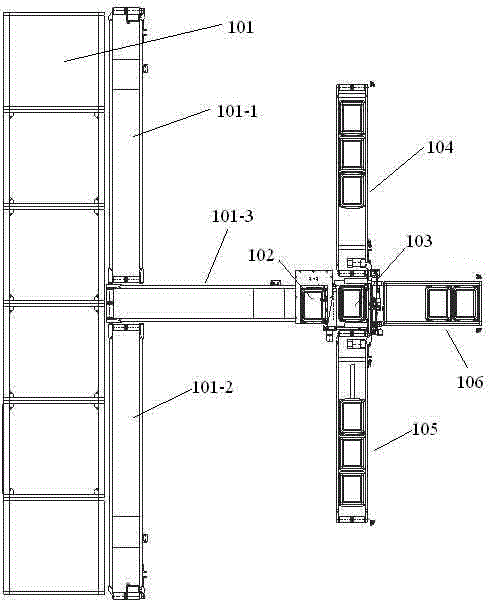

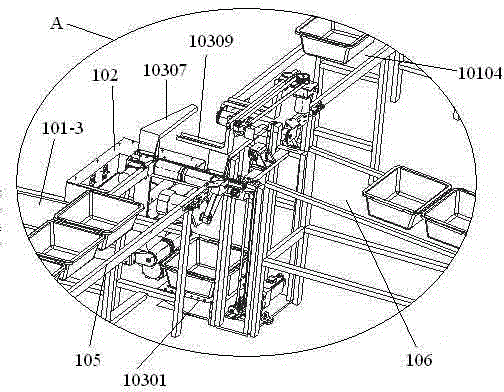

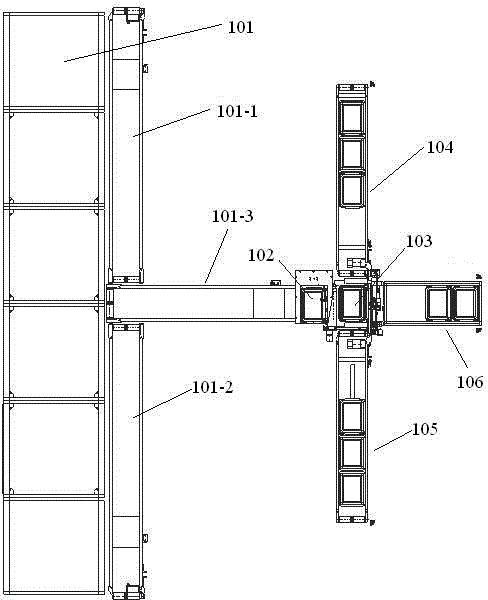

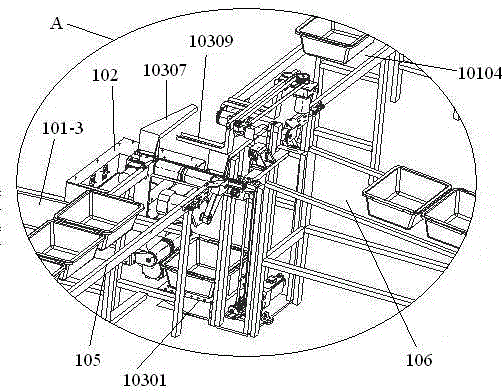

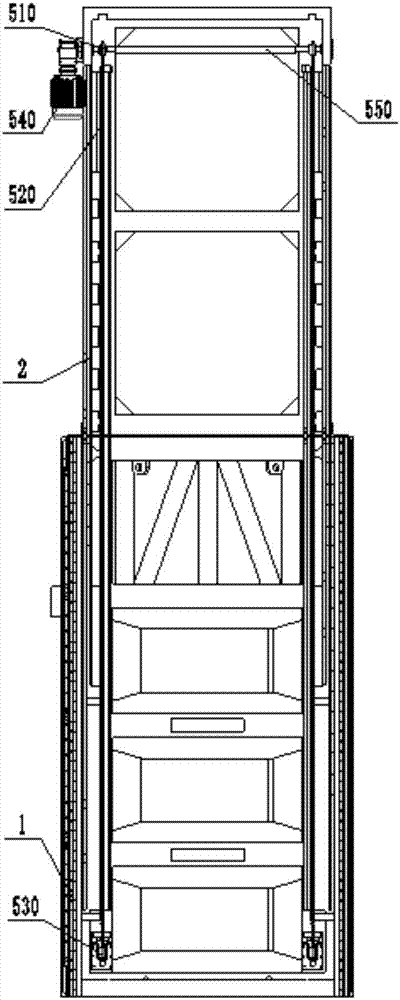

Intelligent medicine pushing and discharging device, dispensing control system and medicine management dispensing method

The invention discloses an intelligent medicine pushing and discharging device, a dispensing control system and a medicine management dispensing method. The intelligent medicine pushing and discharging device is used for an intelligentized dispensing control system, comprises a medicine slot capable of placing medicines and also comprises a pushing device for pushing medicines out of the medicine slot; when the medicines need to be discharged, the pushing device pushes the medicines towards the direction of a medicine outlet for discharging, and the moving distance of the pushing device is the distance, occupied in the medicine slot, of the medicines needing to be discharged; when the medicines do not need to be discharged, the pushing device does not form an enough thrust force to push the medicines out of the medicine slot. The intelligent medicine pushing and discharging device can be placed at a small angle or even a zero angle, the occupation space is smaller, the space utilization rate is greatly improved, the counting basis of medicine discharging is reliable, the medicine inventory information is in real time, real-time expiry date management of the medicines is realized, and the maintenance cost is low. Preferably, the pushing device comprises a motor and a pushing member; the middle of the medicine slot is hollowed to form a passage; the motor drives a pushing block on the pushing member to reciprocate and linearly move in the passage.

Owner:JIANGSU XUNJIE HARNESS TECH

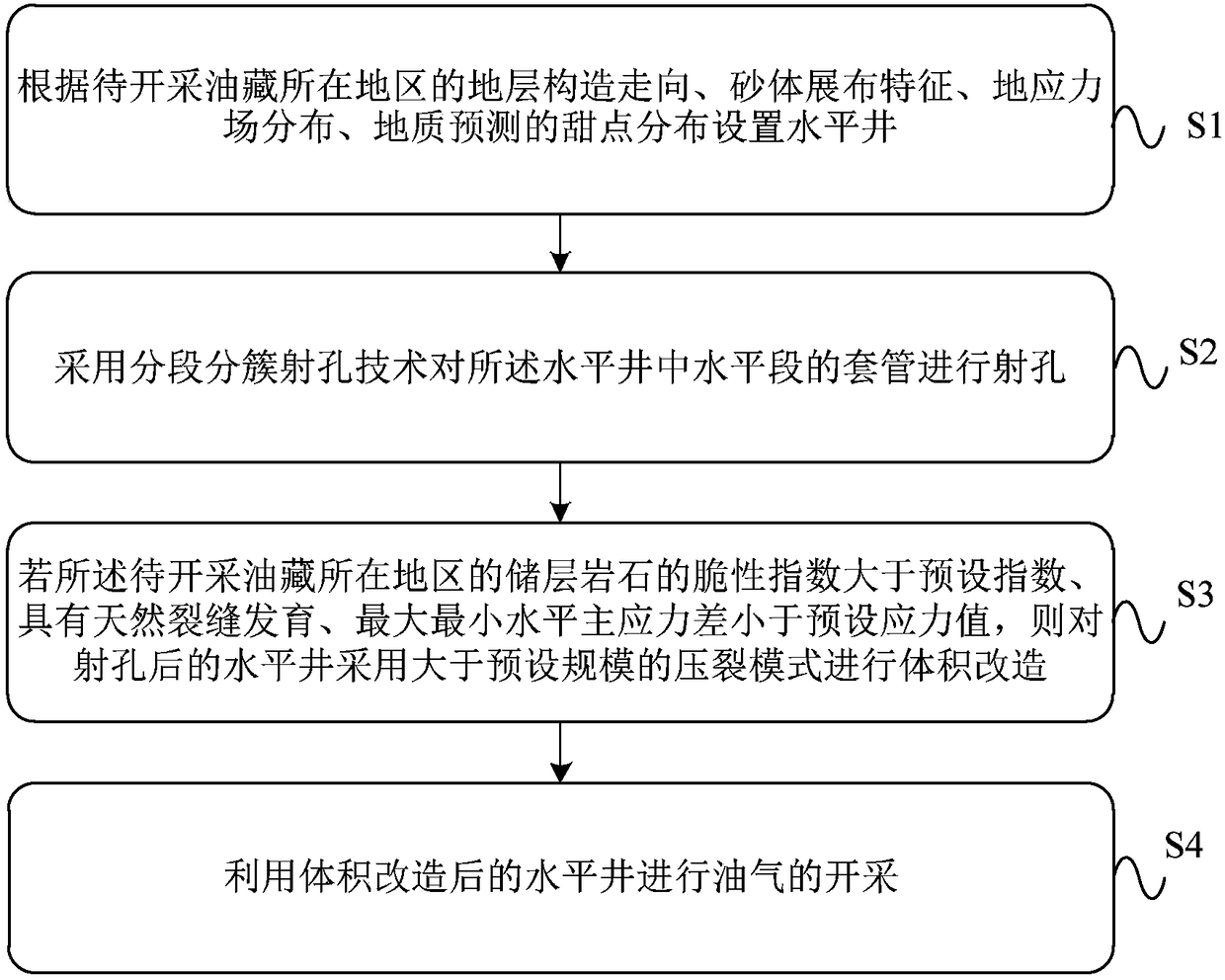

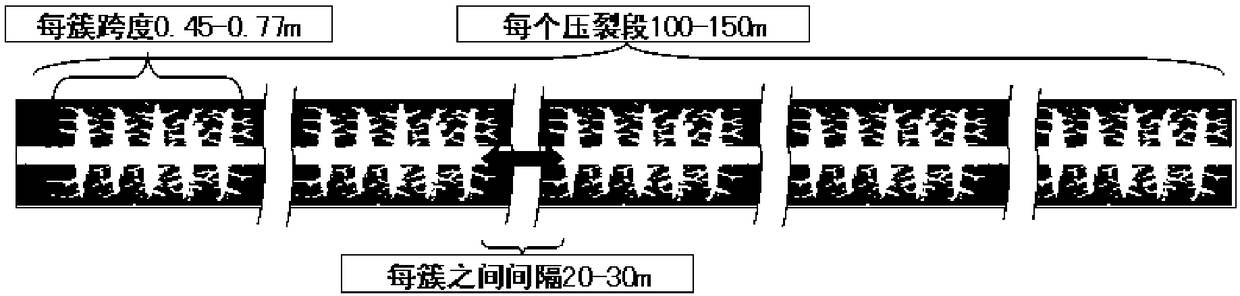

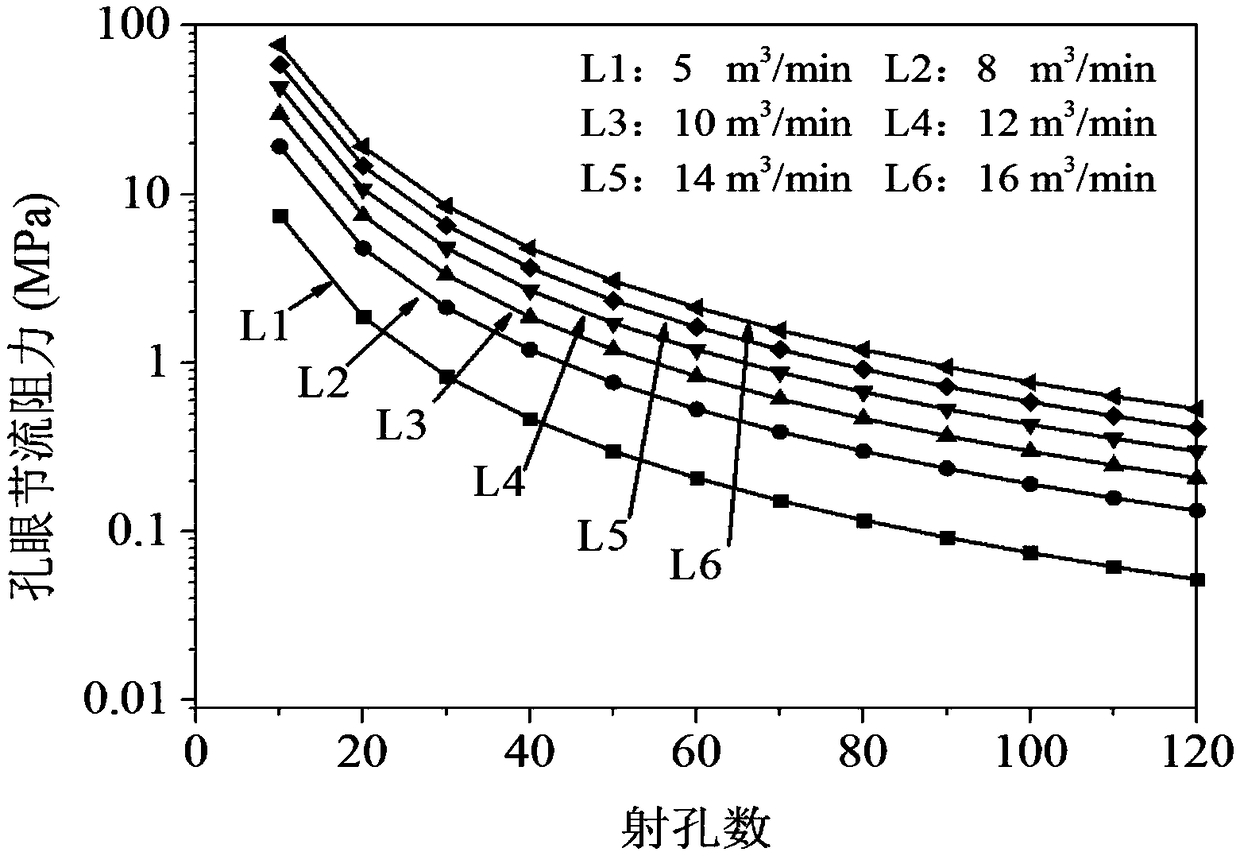

Oil and gas exploitation method for increasing recovery ratio through artificial crack control reserves

ActiveCN108561106AImprove single well productionIncrease productionFluid removalPressure differenceMaterial Perforation

The invention provides an oil and gas exploitation method for increasing the recovery ratio through artificial crack control reserves. The method comprises the steps of arranging a horizontal well according to the stratum structure trend, distribution features of sand bodies, distribution of stress fields and the like of an area where a to-be-exploited oil deposit is located; adopting a segmentedand clustered perforation technology for perforating a casing pipe in the horizontal well; adopting a pressing crack mode of which the scale is larger than a preset scale for conducting capacity cracking transformation on the perforated horizontal well if the brittleness index of reservoir rocks of the area where the to-be-exploited oil deposit is located is larger than a preset index, the reservoir rocks have natural crack development, and the max-min primary stress difference is smaller than a preset stress value; adopting the horizontal well which is subjected to capacity cracking transformation for exploiting oil and gas. According to the embodiment, the mode of well control reserves is converted into the mode of crack control reserves, the contact area of a matrix and the cracks is increased, the distance of fluid in the matrix to flow to the cracks is reduced, the pressure difference for driving the fluid in the matrix to flow to the cracks is lowered, and the per-well yield andthe recovery ratio of oil and gas exploitation are increased.

Owner:PETROCHINA CO LTD

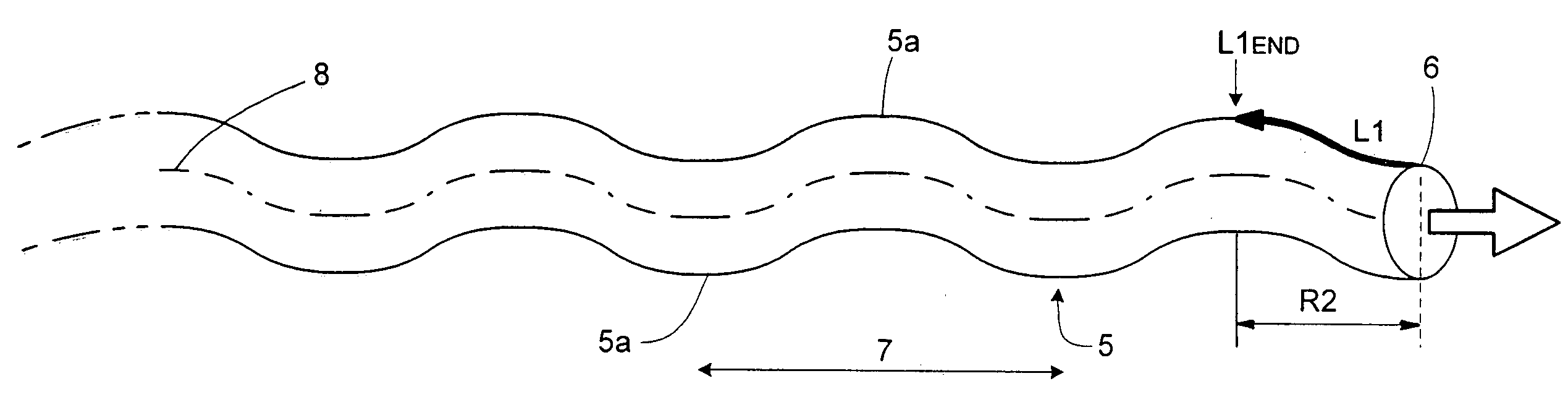

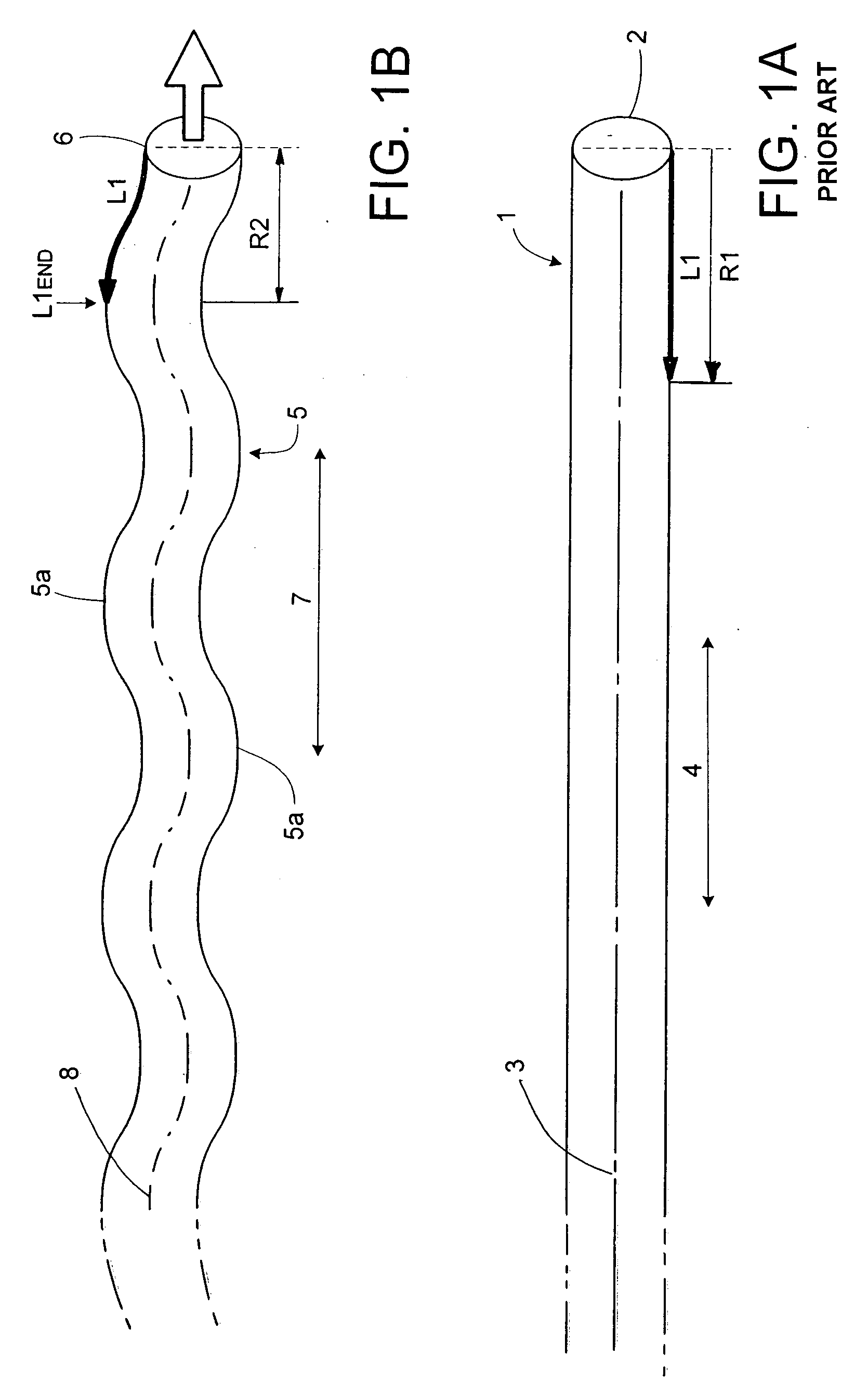

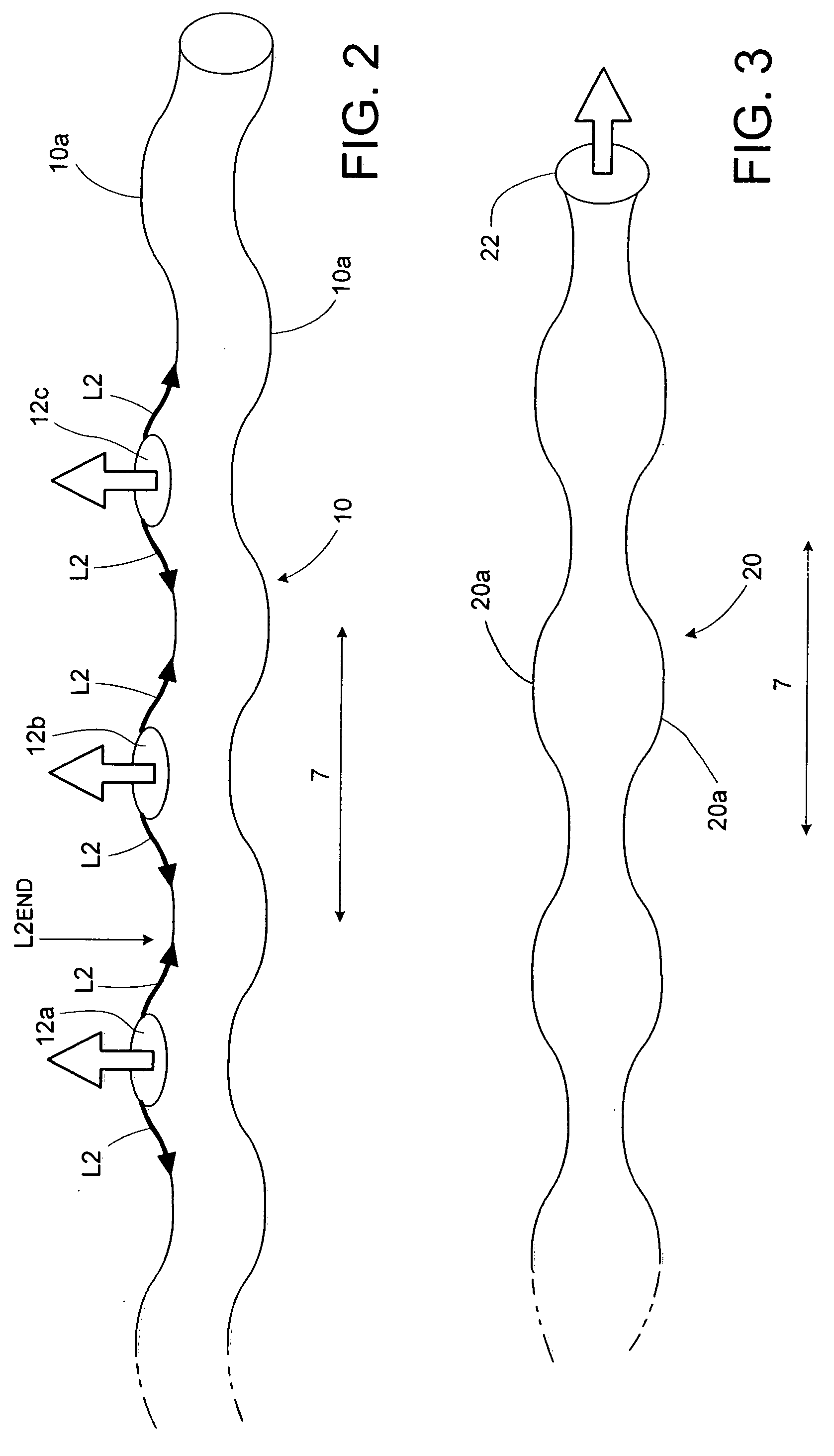

Intracranial catheter

InactiveUS20060253101A1Increase supplyImprove predictabilityCatheterPath lengthElectrical resistivity and conductivity

A catheter having an outer profile which is formed such that a path length along an outer surface of the catheter is greater than the corresponding length of the catheter, and to a method for determining the shape of a catheter, and wherein the elasticity and / or conductivity of the tissue into which the catheter is to be introduced is taken into account in order to determine the outer profile of the catheter.

Owner:BRAINLAB

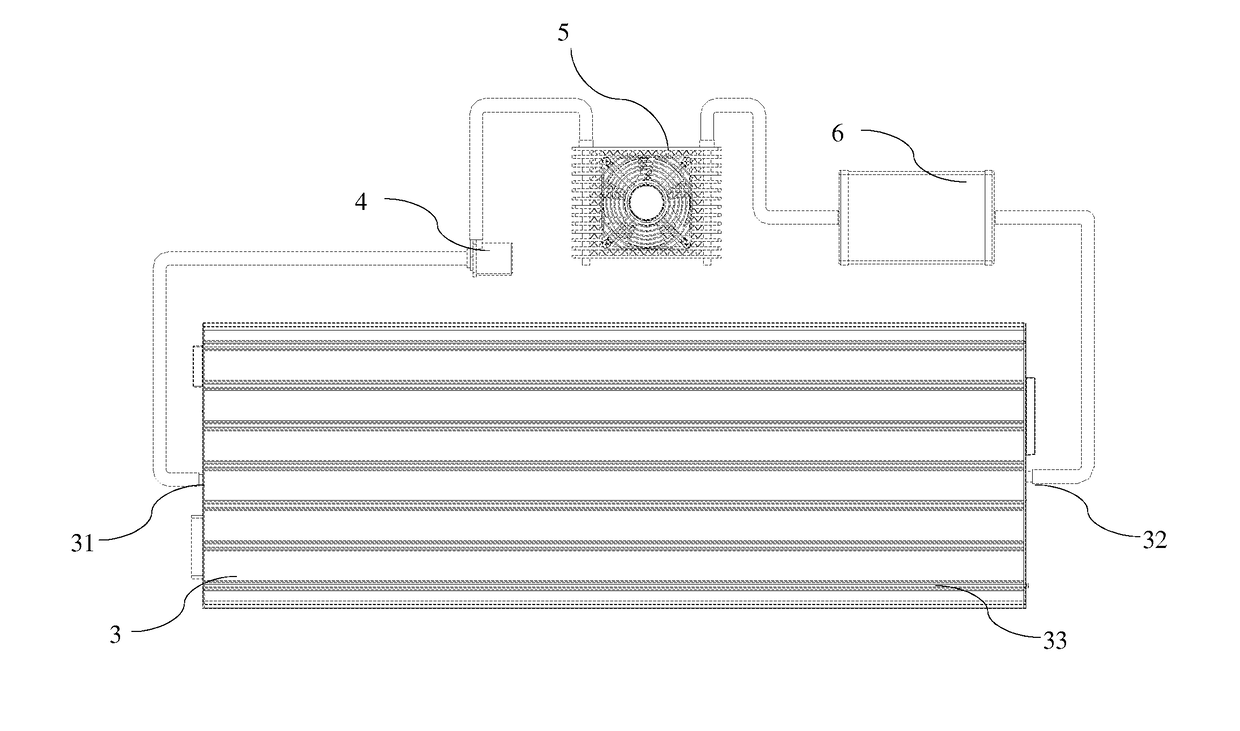

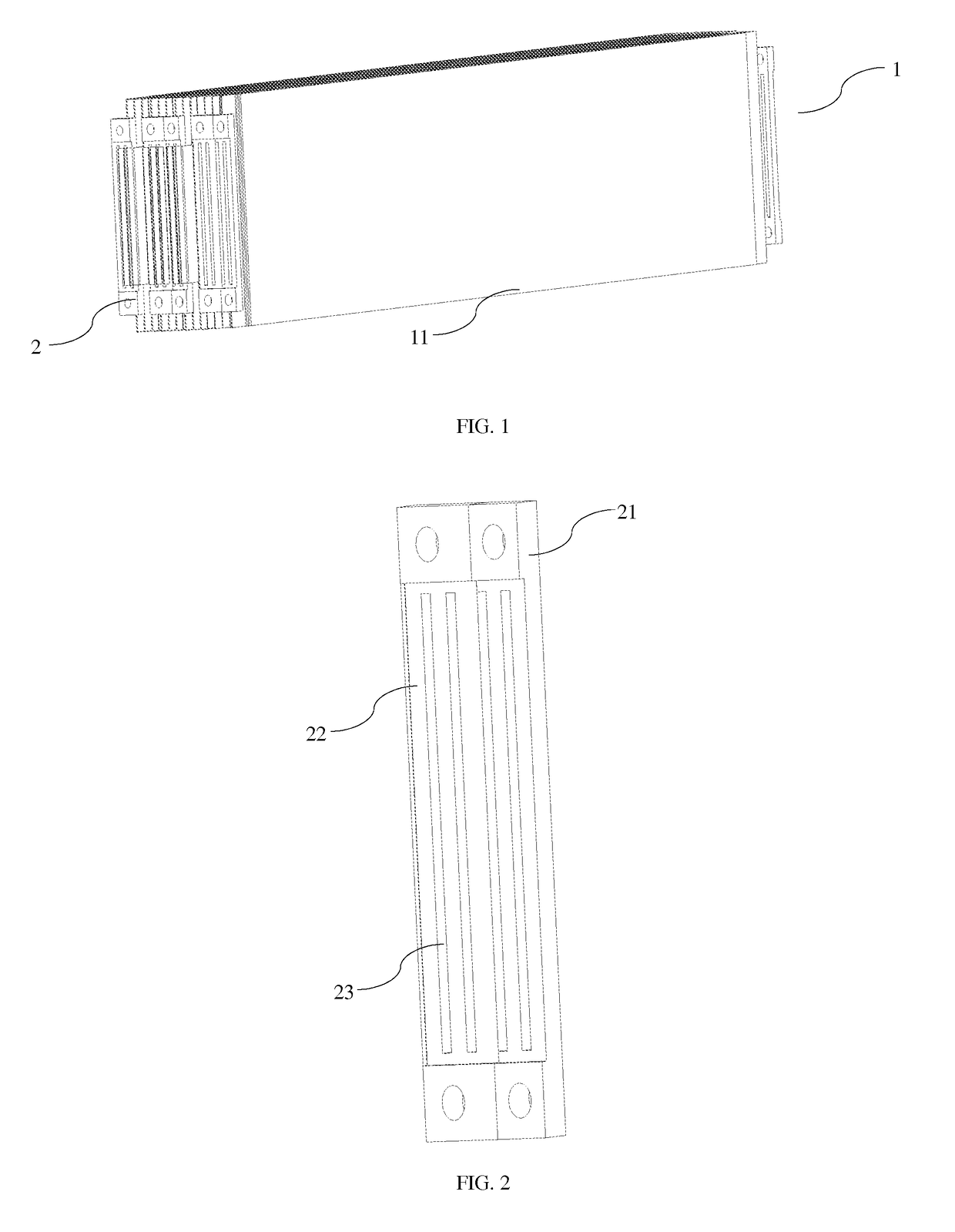

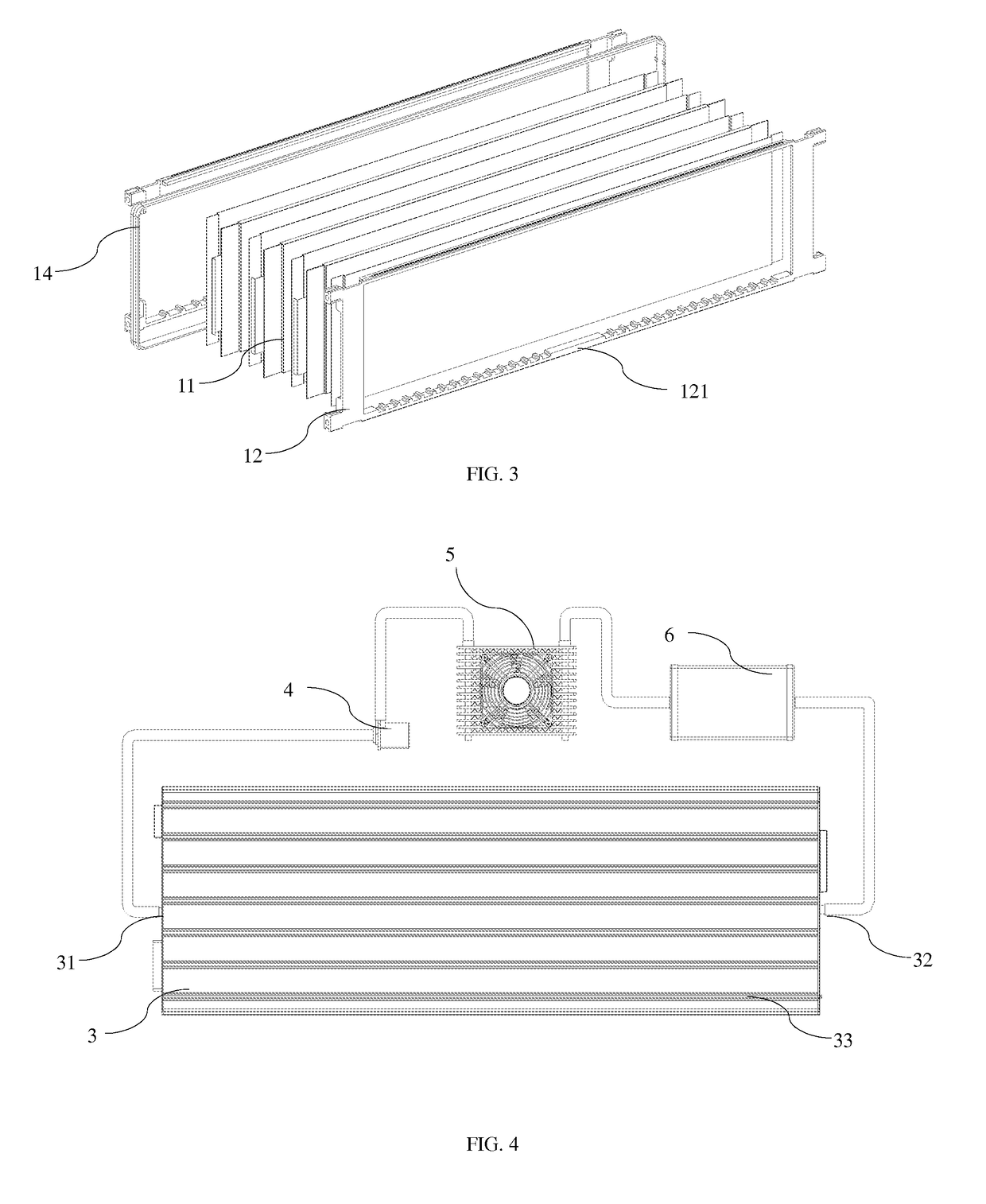

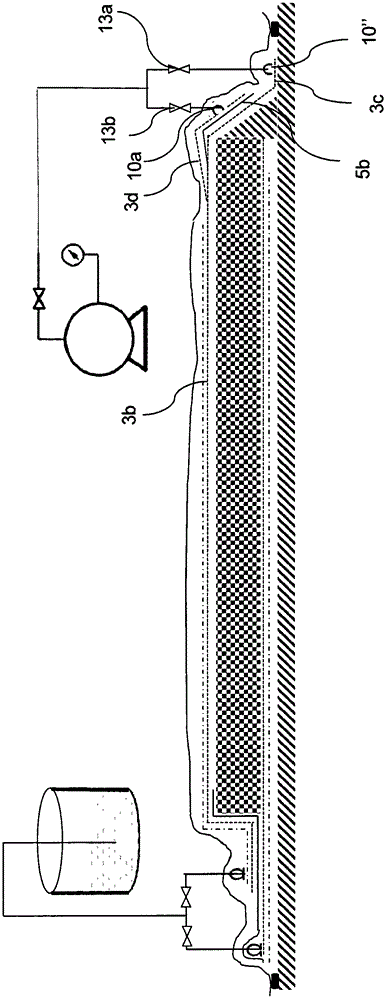

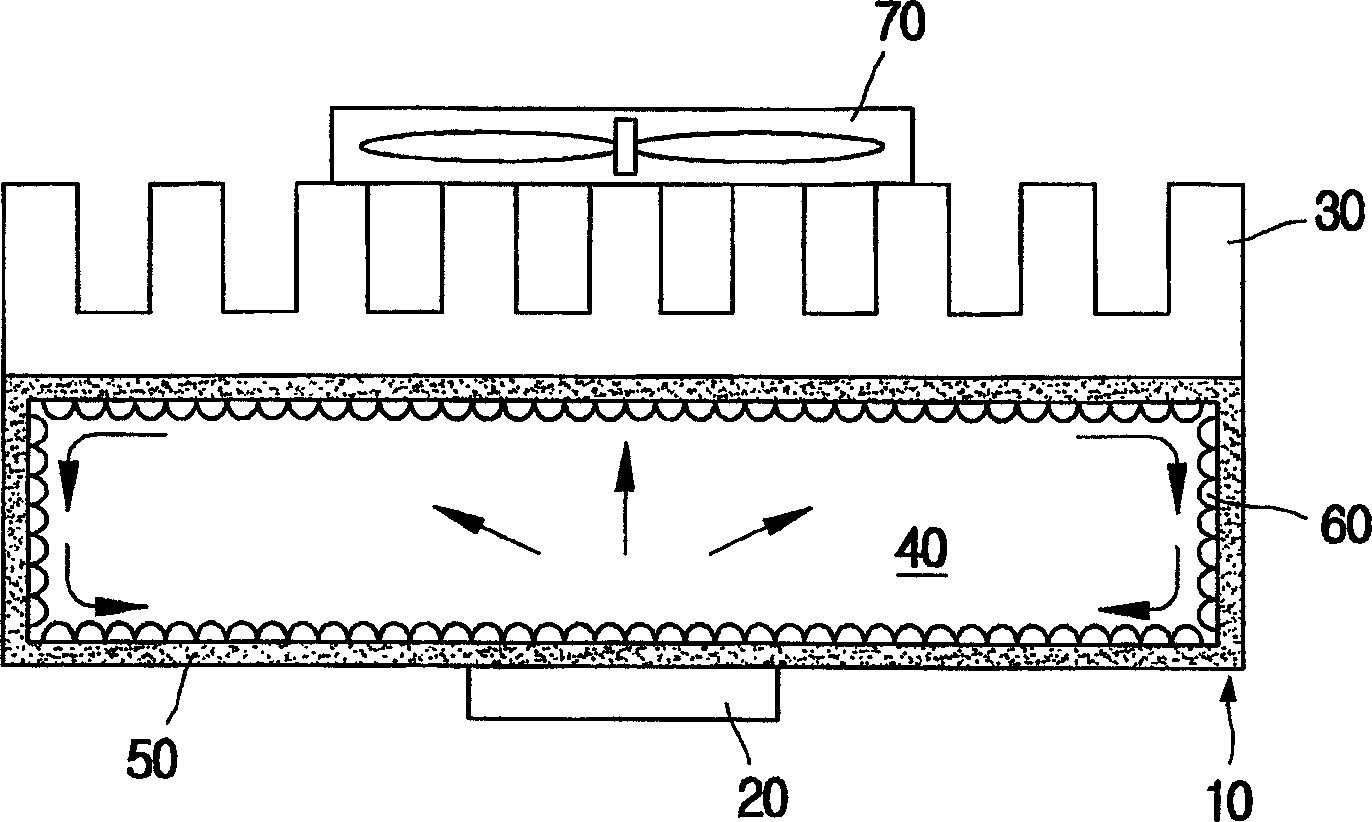

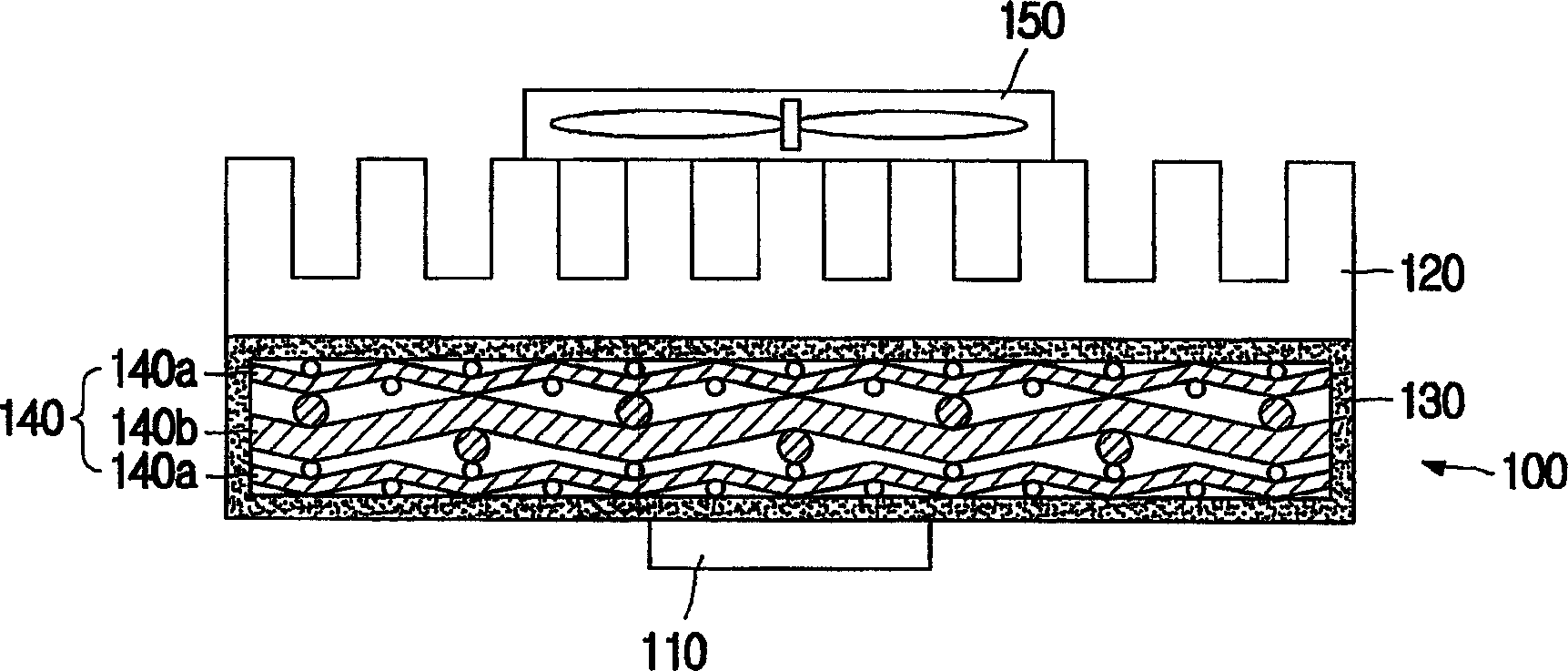

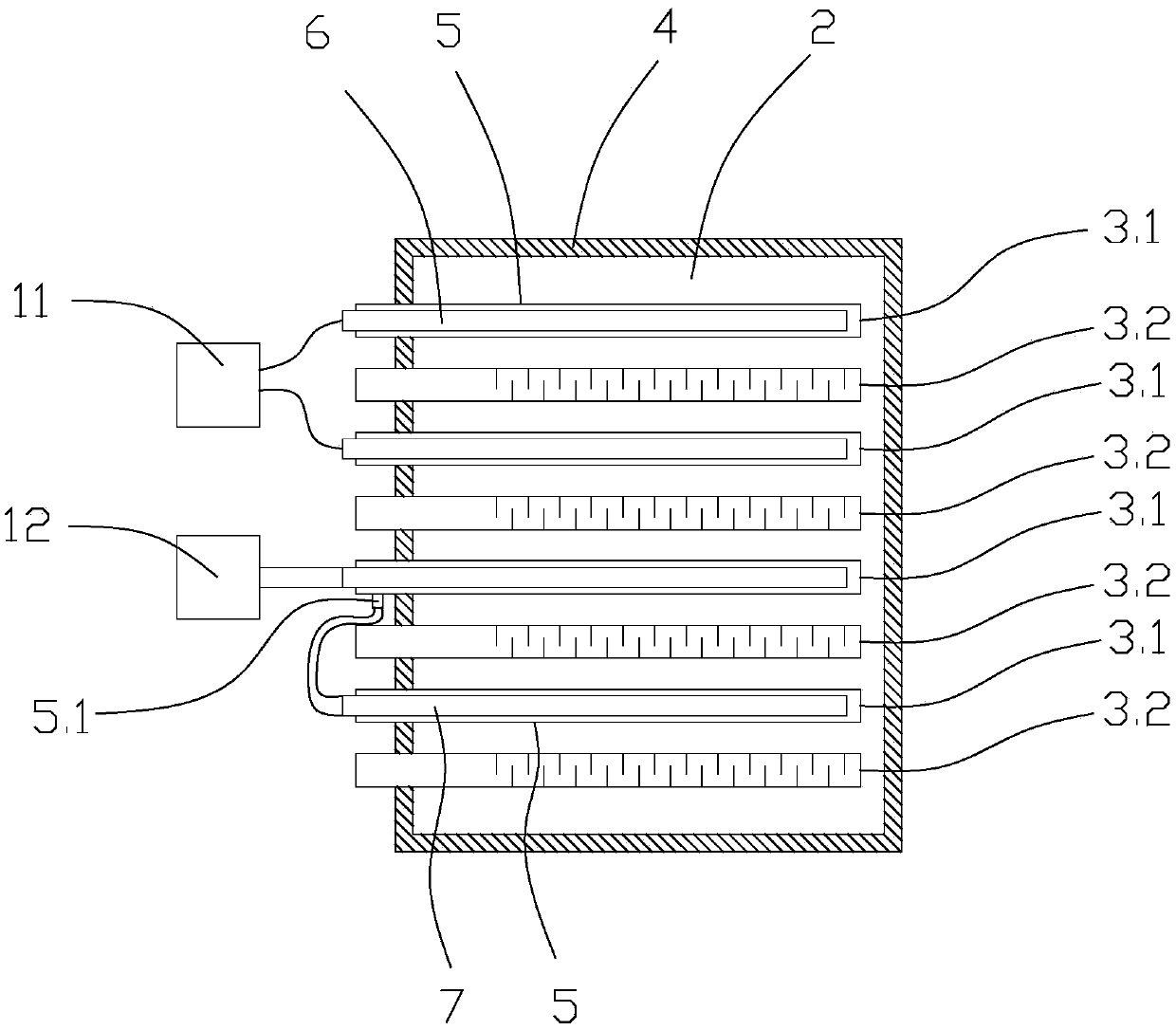

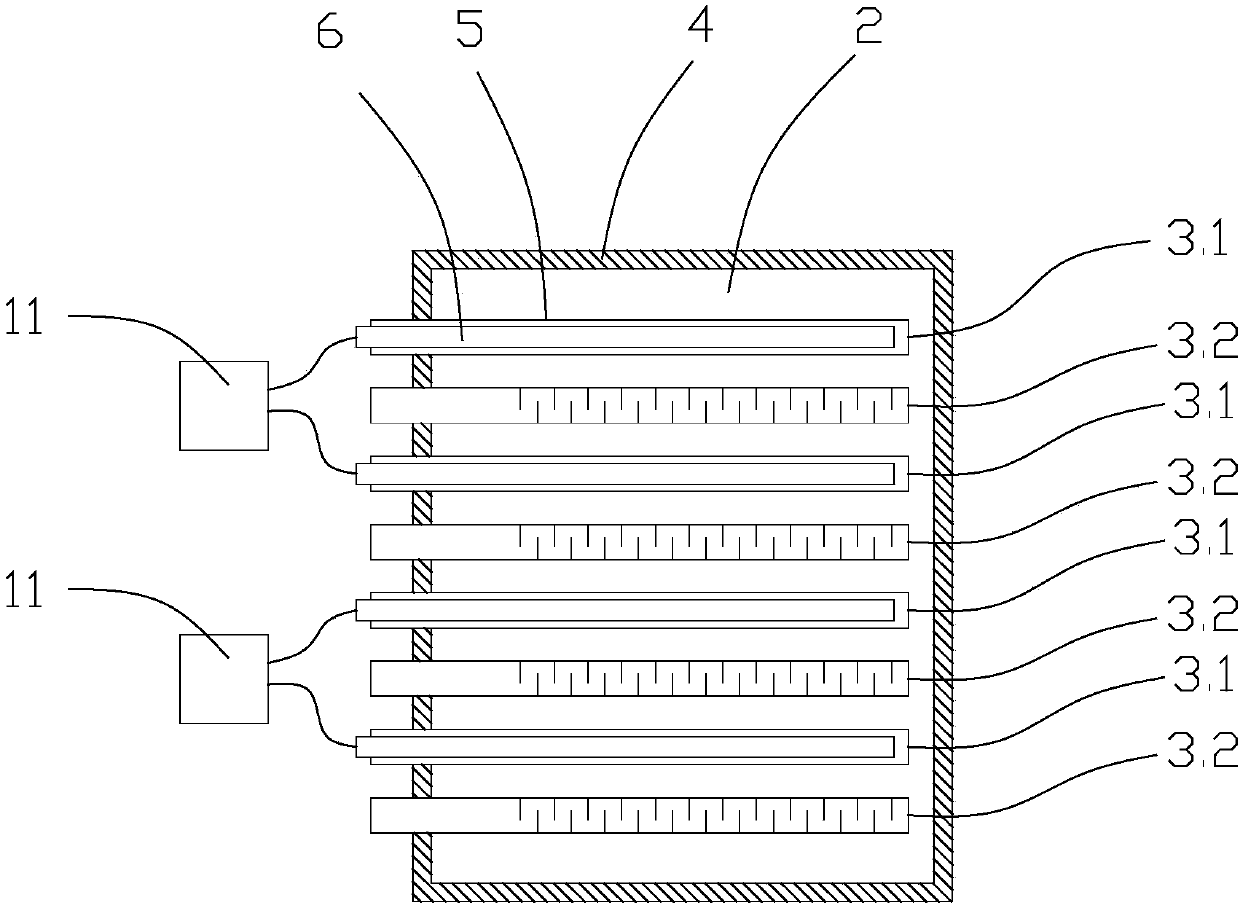

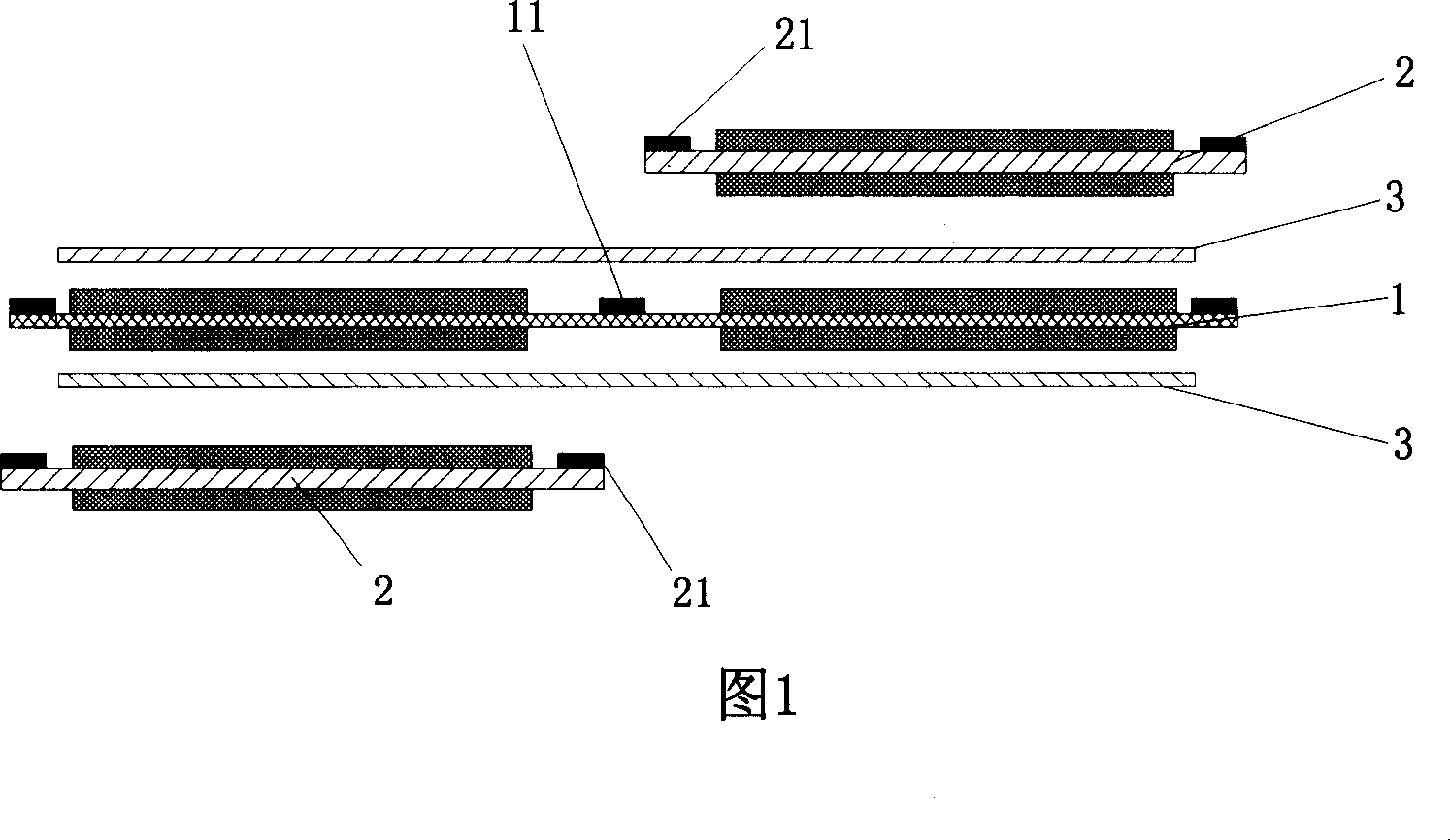

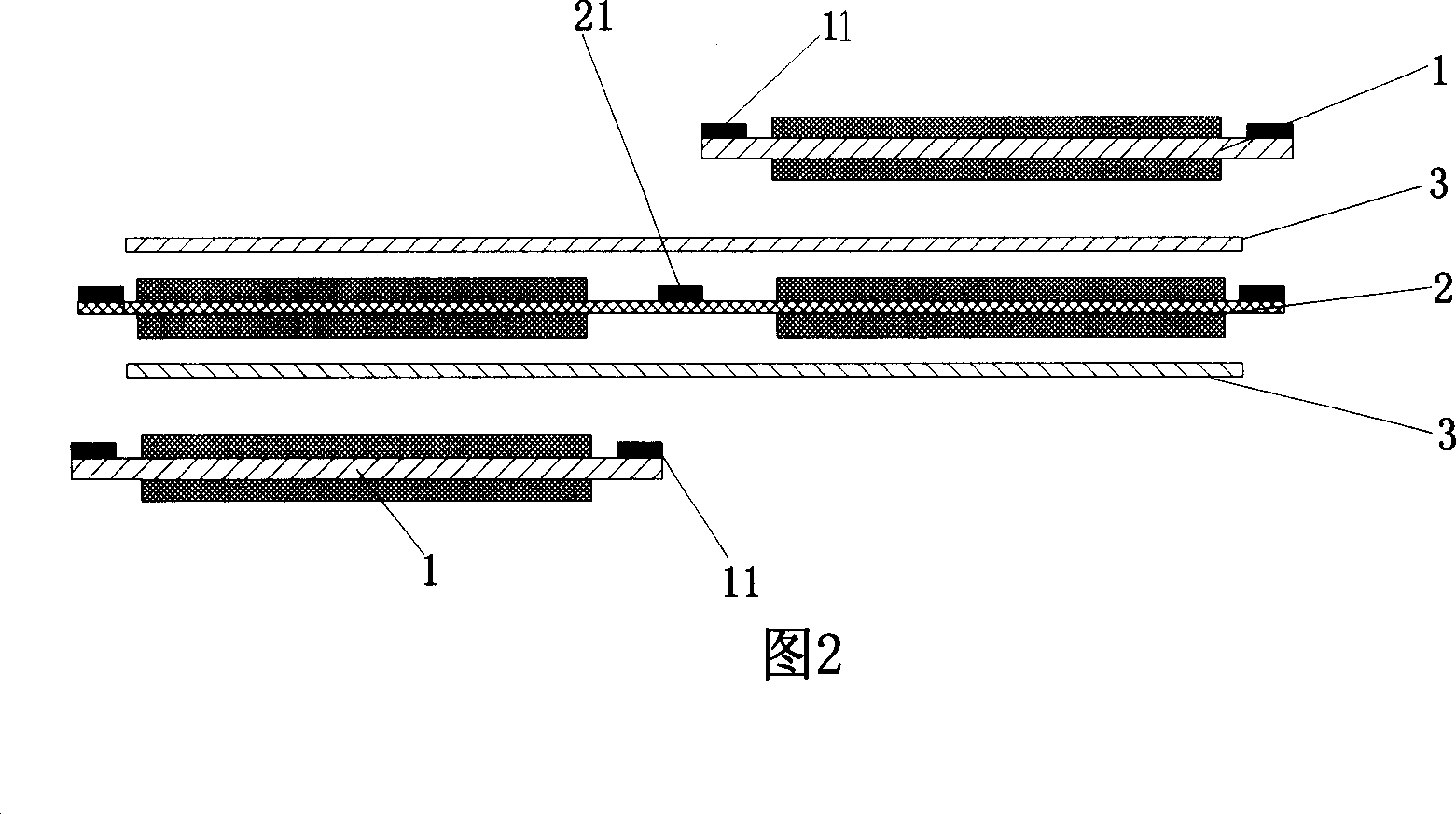

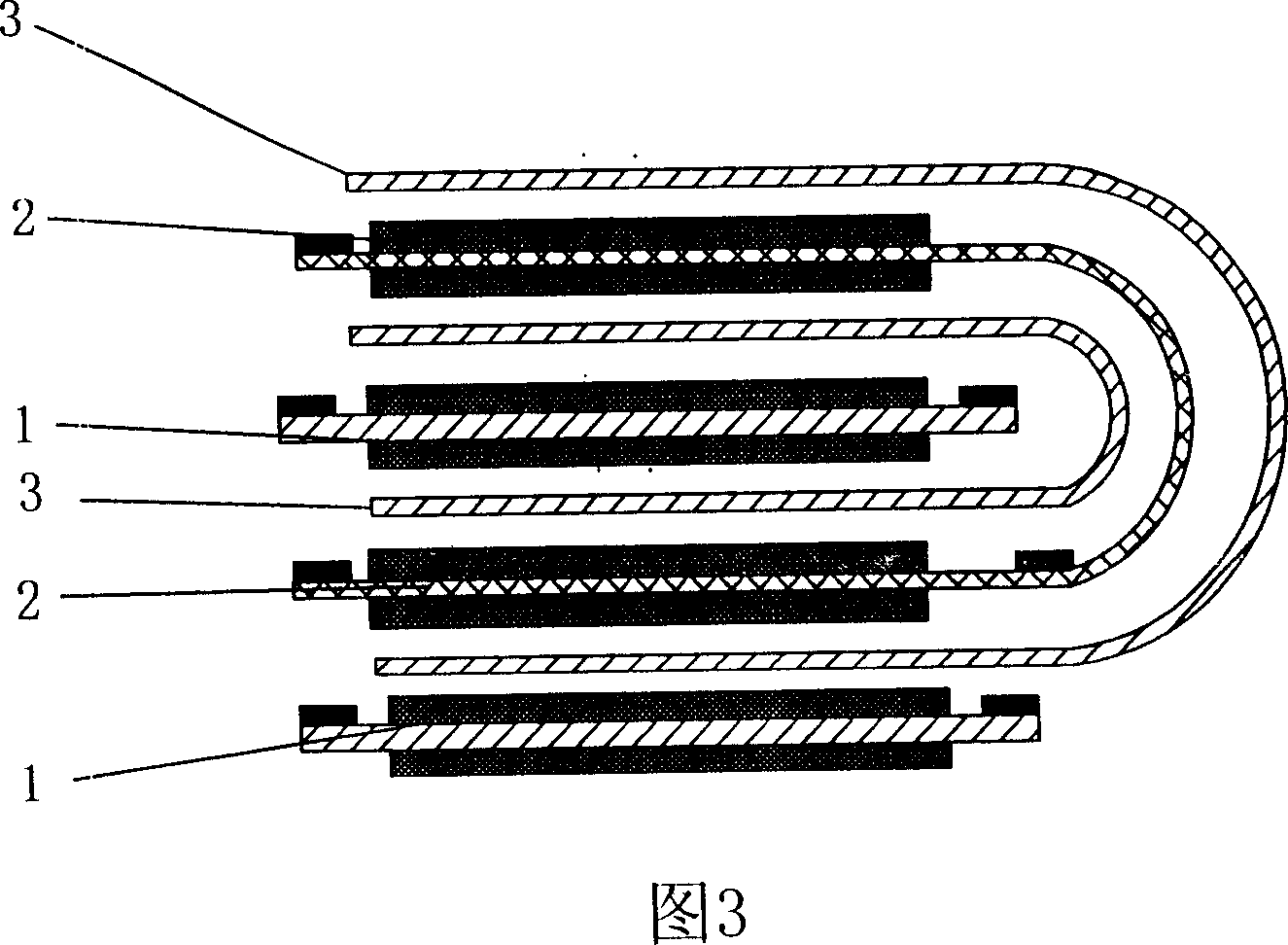

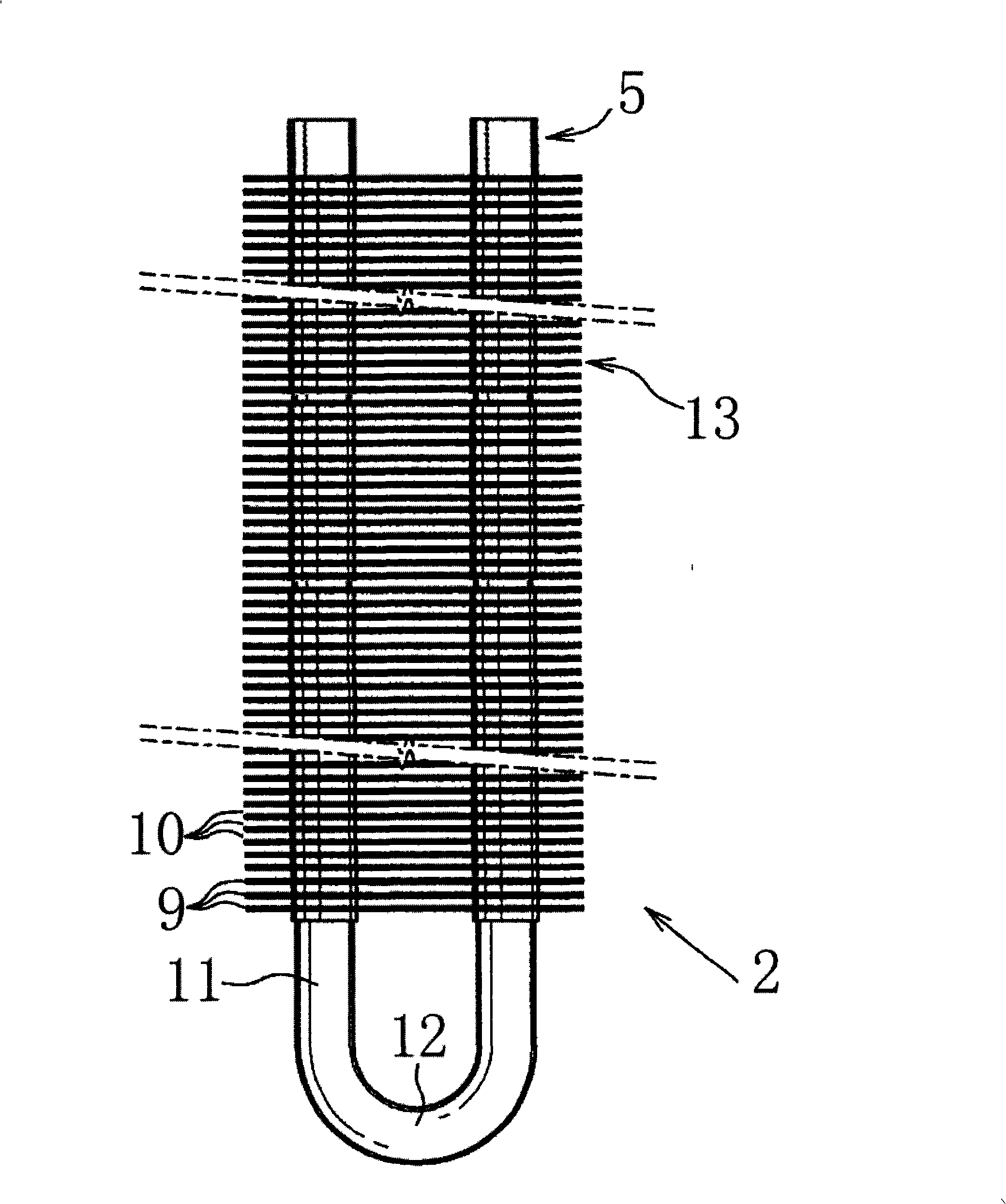

Liquid-cooled battery pack system

ActiveUS20170162923A1Improve securityIncrease energy densitySecondary cellsCell component detailsEngineeringDesoldering

The present invention provides a battery module and a liquid-cooled battery system that uses it, a battery cell and a current collector sheet, on the premise that the materials like the electrode and separator and so on are completely the same, energy density of the battery pack is greatly increased; the cell and the current collector sheet are fully welded connections, the joints are fewer and it is not prone to produce desoldering, also ensuring the stability of the of the cell tab and high current carrying capacity, and when putting the parallel battery module in series, the use of wires are avoided, thus reduces the volume of the battery pack; the innovative design for the liquid-cooled battery pack system, improves the thermal balance between the cells, and the heat-dissipation in battery pack distributes more evenly, the insulation property of the battery package is highly improved, controlling the heat-dissipation capacity of the system by adjusting the flow rate of the circulating pump, not only the unnecessary energy consumption can be avoided, but also have a better impact resistance.

Owner:MICROVAST

Intelligent medicine pushing and discharging plate turnover device

The invention discloses an intelligent medicine pushing and discharging plate turnover device, which is used for an intelligentized dispensing control system. The intelligent medicine pushing and discharging plate turnover device comprises a medicine slot capable of placing medicines; the middle of the medicine is hollowed to form a passage; the intelligent medicine pushing and discharging plate turnover device also comprises a pushing device for pushing medicines out of the medicine slot; when the medicines need to be discharged, the pushing device pushes the medicines towards the direction of a medicine outlet for discharging, and the moving distance of the pushing device is the distance, occupied in the medicine slot, of the medicines needing to be discharged; when the medicines do not need to be discharged, the pushing device does not form an enough thrust force to push the medicines out of the medicine slot; the pushing device comprises a motor, a turnover plate and a slider for pushing the turnover plate to linearly reciprocate and move along the passage; the turnover plate is movably connected with the slider; support plates are further arranged at two sides of the turnover plate and are placed at the edge of the passage; a containing chamber for containing the support plates is arranged at the bottom of the medicine adding port end of the medicine slot.

Owner:JIANGSU XUNJIE HARNESS TECH

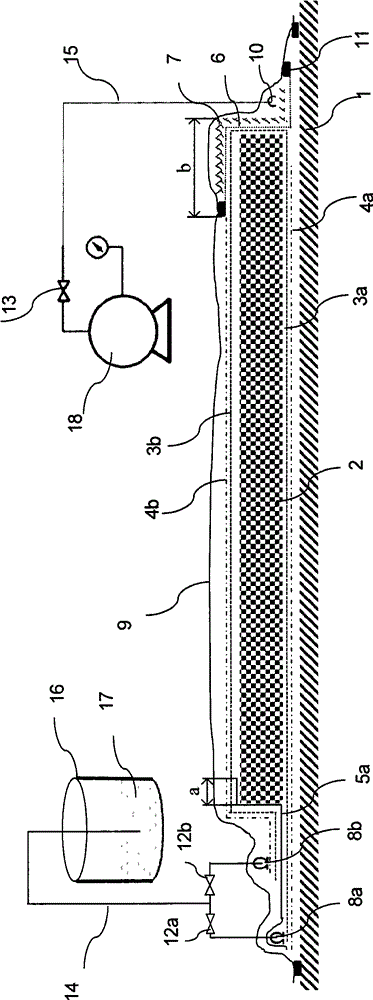

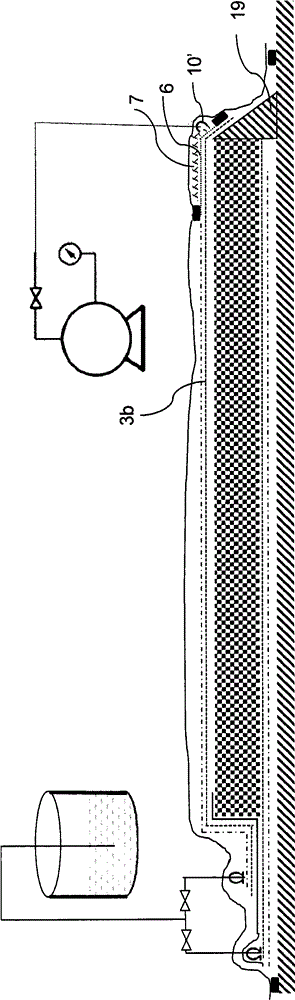

Method for manufacturing fiber-reinforced plastic product

ActiveCN106142593AShorten the flow distanceReduce flow timeMechanical engineeringFiber reinforcement

The invention relates to a method for producing a fiber-reinforced plastic product. The method for producing the fiber-reinforced plastic product comprises the following steps that a fiber preform is prepared on a mold; a first flow guide net, a second flow guide net, a first piece of demolding cloth and a second piece of demolding cloth are laid for the fiber preform; the fiber preform is sealed and made into a vacuum system through air extraction; resin is made to permeate the first piece of demolding cloth and soak the fiber preform from bottom to top by means of the first flow guide net; the resin is made to permeate the second piece of demolding cloth and soak the fiber preform from top to bottom by means of the second flow guide net; and the fiber preform soaked with the resin is obtained, and the fiber-reinforced plastic product is obtained finally. The method for producing the fiber-reinforced plastic product is characterized in that a first film is arranged on the side, close to the resin injection position, of the fiber preform so as to cover at least part of the first piece of demolding cloth, the first flow guide net and the fiber preform, and after the resin is supplied to the first flow guide net, the resin is supplied to the second flow guide net when the flowing area of the resin on the fiber preform is beyond the area covered by the first film.

Owner:COVESTRO DEUTSCHLAND AG

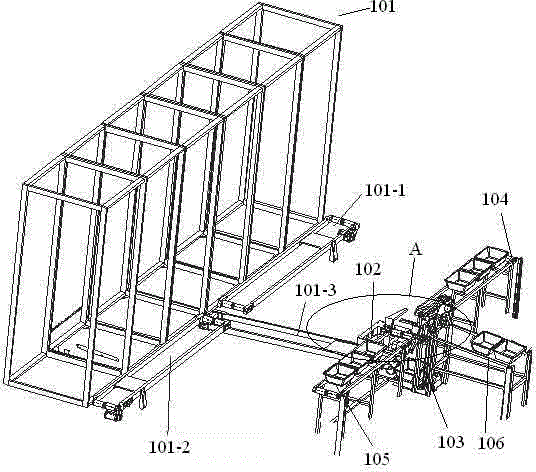

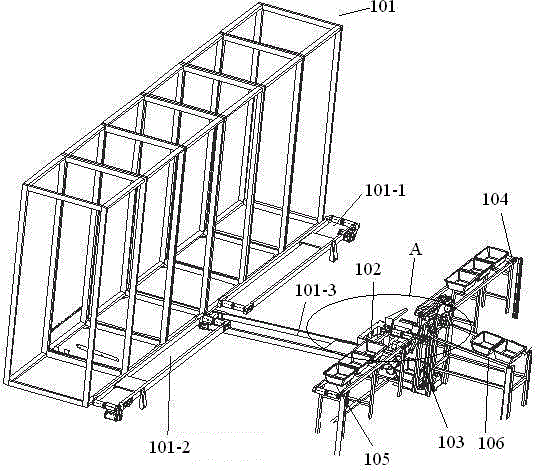

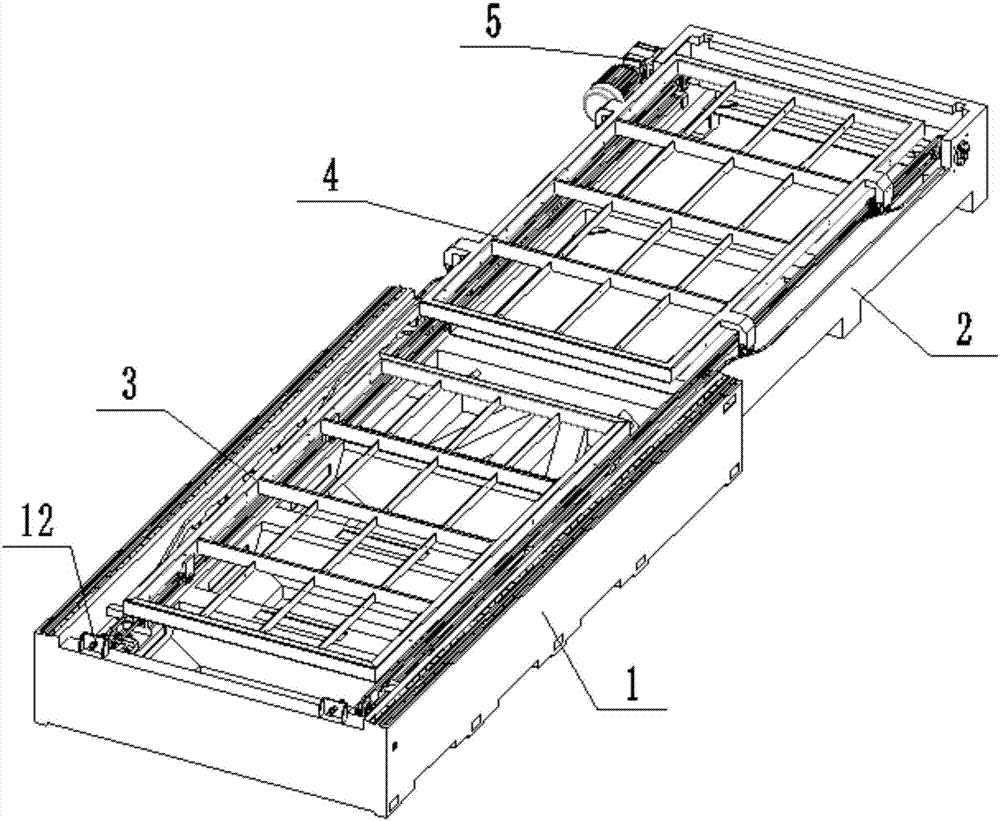

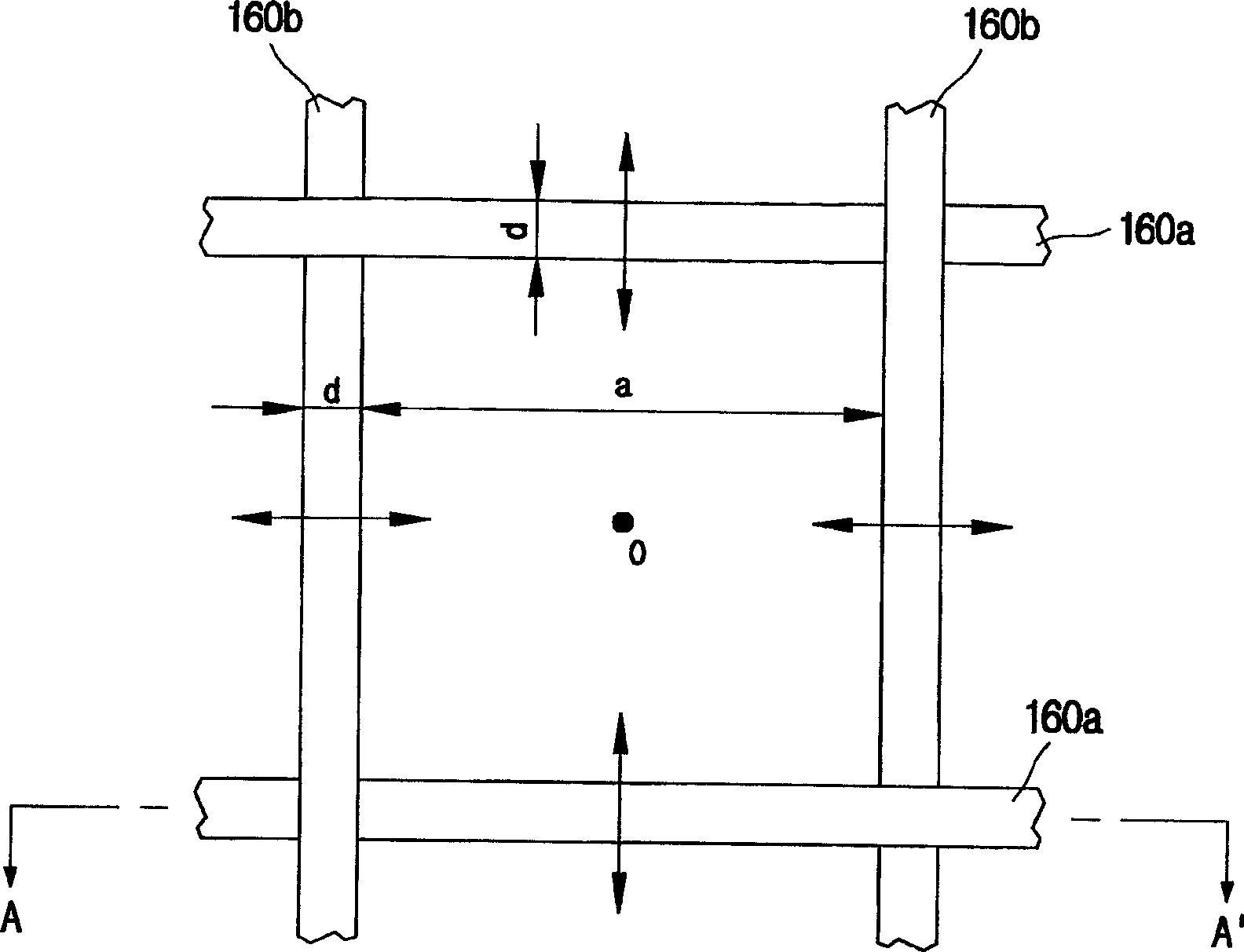

Double-worktable-exchange device of laser cutting machine

ActiveCN106862781AAvoid interferenceImplement the swap operationLaser beam welding apparatusManufacturing cost reductionEngineering

The invention discloses a double-worktable-exchange device of a laser cutting machine, and belongs to the technical field of laser cutting machines. The double-worktable-exchange device comprises a first worktable and a second worktable, wherein the first worktable and the second worktable are arranged on a worktable rail of a lathe bed, and position exchange of the two worktables is achieved through driving of a chain transmission mechanism. The worktable guide rail is divided into a lifting worktable outer guide rail with the middle high and the two ends low, a lifting worktable inner guide rail with the middle high and the two ends low, and a linear horizontal movement worktable guide rail, wherein transition of each middle high section and the corresponding low sections at the two ends is achieved through inclined sections. Two front side wheels at one end of the second worktable are arranged on the lifting worktable outer guide rail, and two rear side wheels at the other end of the second worktable are arranged on the lifting worktable inner guide rail. The first worktable is arranged on the horizontal movement worktable guide rail. The device does not need to be provided with a lifting mechanism, exchange between the two worktables can be completed by only reasonably designing the guide rails where the worktables operate, the structure is greatly simplified, the manufacture cost is reduced, and the double-worktable-exchange device has the beneficial effects of being convenient to operate and easy to maintain.

Owner:佛山汇百盛激光科技有限公司

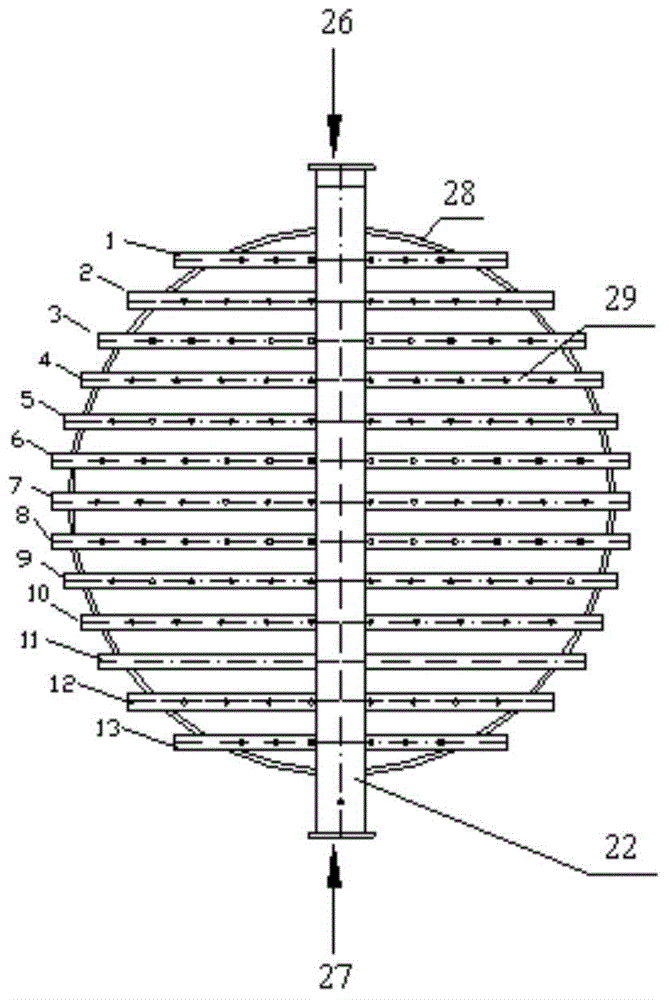

Tube heat exchange tube

InactiveCN102278901AExtend heat exchange timeReduce flow rateStationary tubular conduit assembliesAir conditioning systemsEngineeringExchange time

The invention discloses a casing type heat exchange tube, which comprises an inner tube and an outer tube, the inner tube is located in the outer tube, the upper end of the outer tube is connected with the medium inlet, the lower end of the outer tube is sealed, the upper end of the inner tube is connected with the medium The outlet is connected, and the lower end of the inner pipe is open. The sleeve-type heat exchange tube has the following advantages: 1) It increases the contact area with the surrounding filler or soil; 2) The flow velocity of the heat exchange medium in the outer tube is reduced, which increases the heat exchange time of the heat exchange medium; The heat exchange medium conducts heat exchange downwards by its own weight, and the flow distance of the heat exchange medium in the tube is shortened.

Owner:谢学军

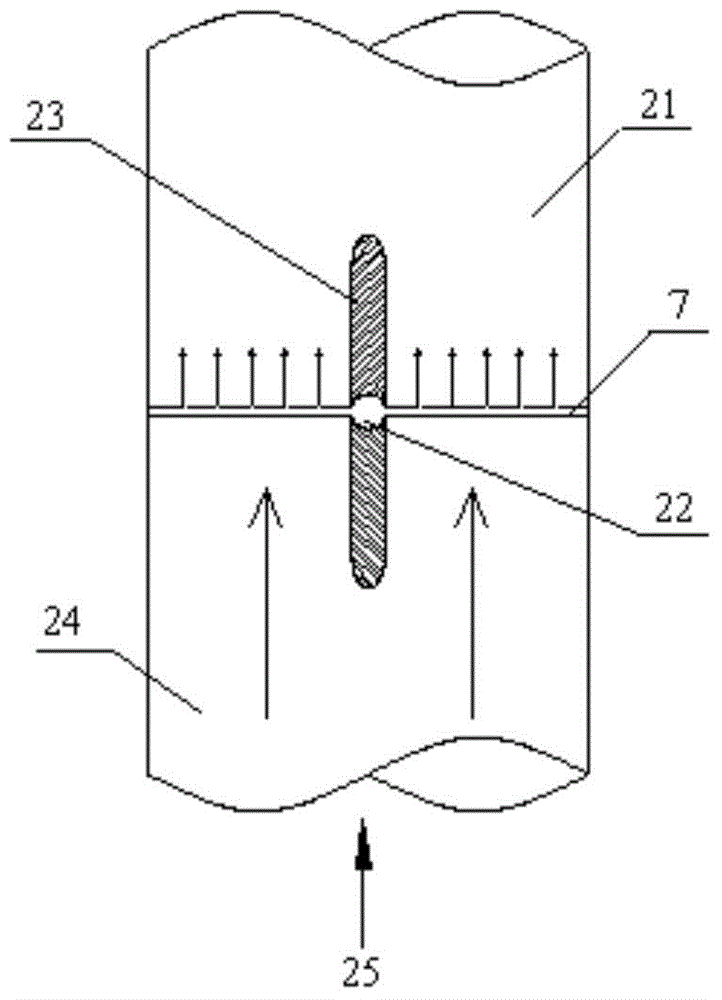

Ethylene and oxygen mixing method

ActiveCN104084065AStable supportPlay a supporting roleFlow mixersMixing gases with gases/vapoursPolymer scienceEthylene oxide

The invention relates to an ethylene and oxygen mixing method which is mainly used for solving the problem of an unsatisfactory mixing effect of ethylene and oxygen in the prior art. According to the technical scheme for solving the problem effectively, ethylene entering from a main runner and oxygen entering from a radially-arranged oxygen distributor are mixed in a mixer; the oxygen distributor comprises a central main pipe and at least one branch pipe; the central main pipe is vertically communicated with the branch pipe; the branch pipes are symmetrically arranged on the two sides of the central main pipe; small holes symmetrically distributed by taking the central main pipe as the center are formed in the branch pipes; the gas flow direction in the small holes is consistent with that in the main runner. The method can be applied to industrial production for producing ethylene oxide with a direct oxidization process.

Owner:SINOPEC SHANGHAI ENG +2

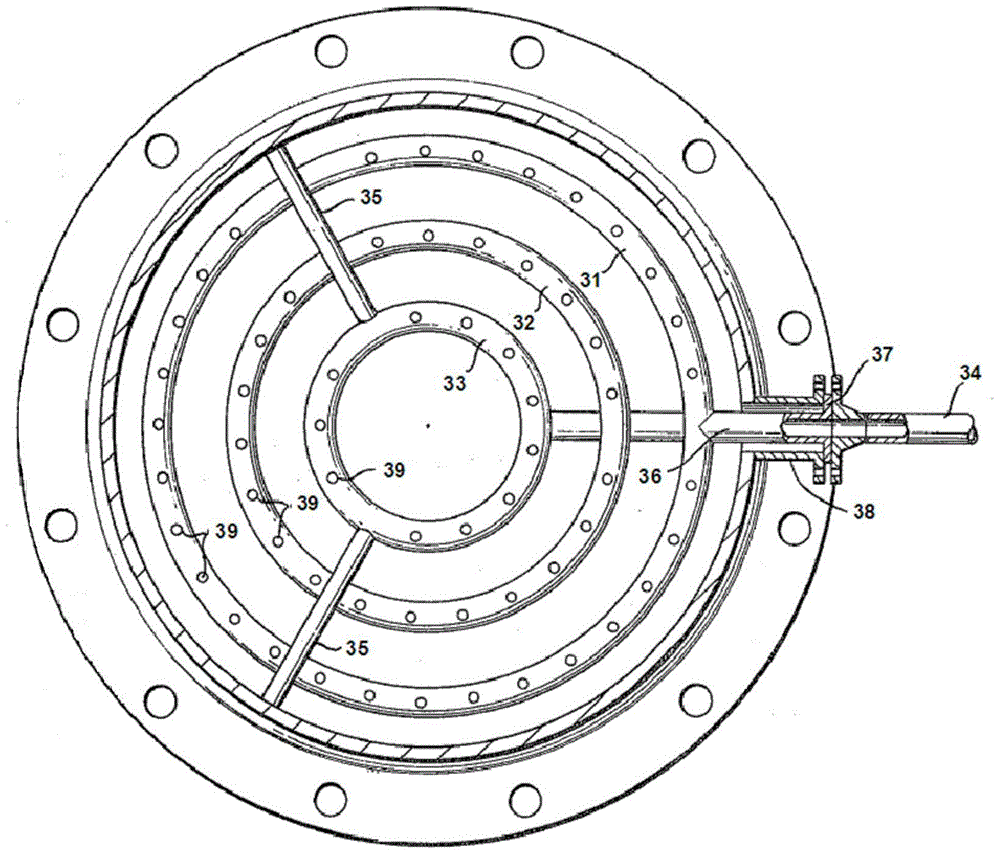

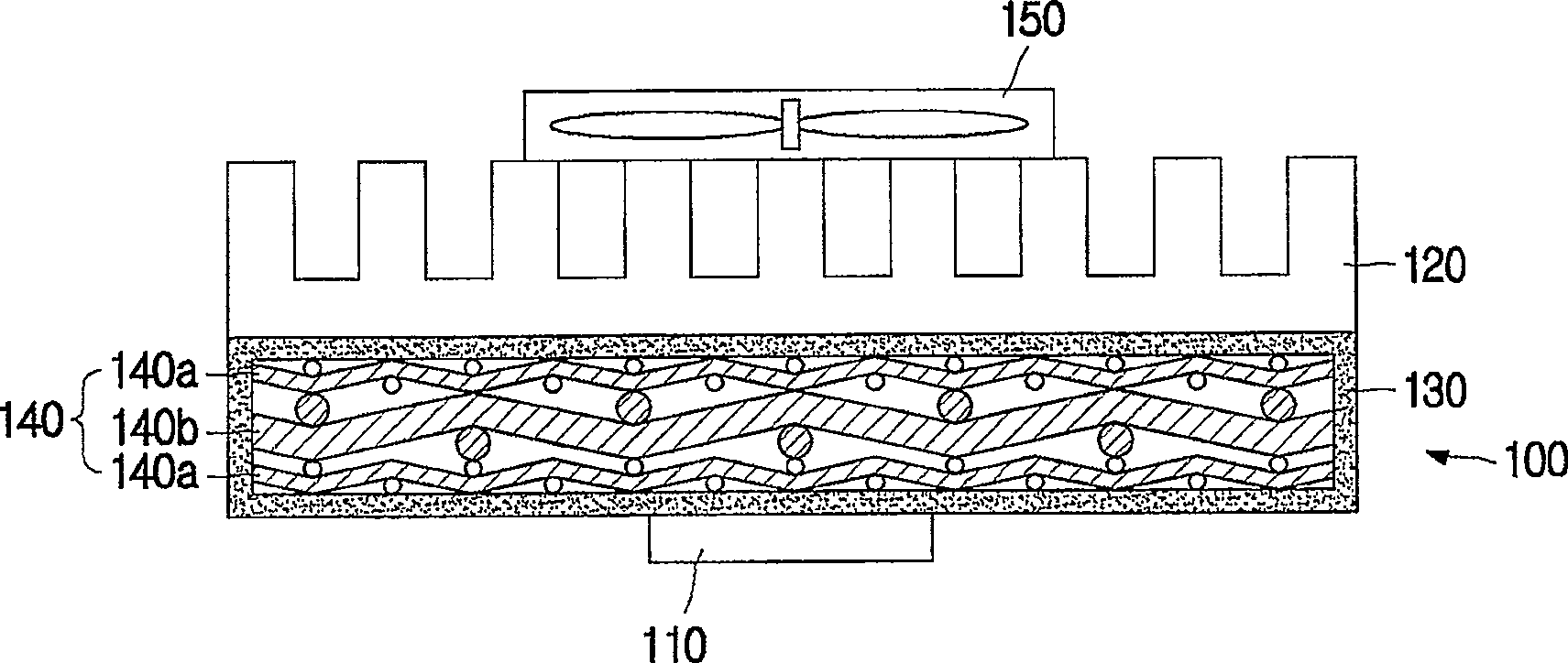

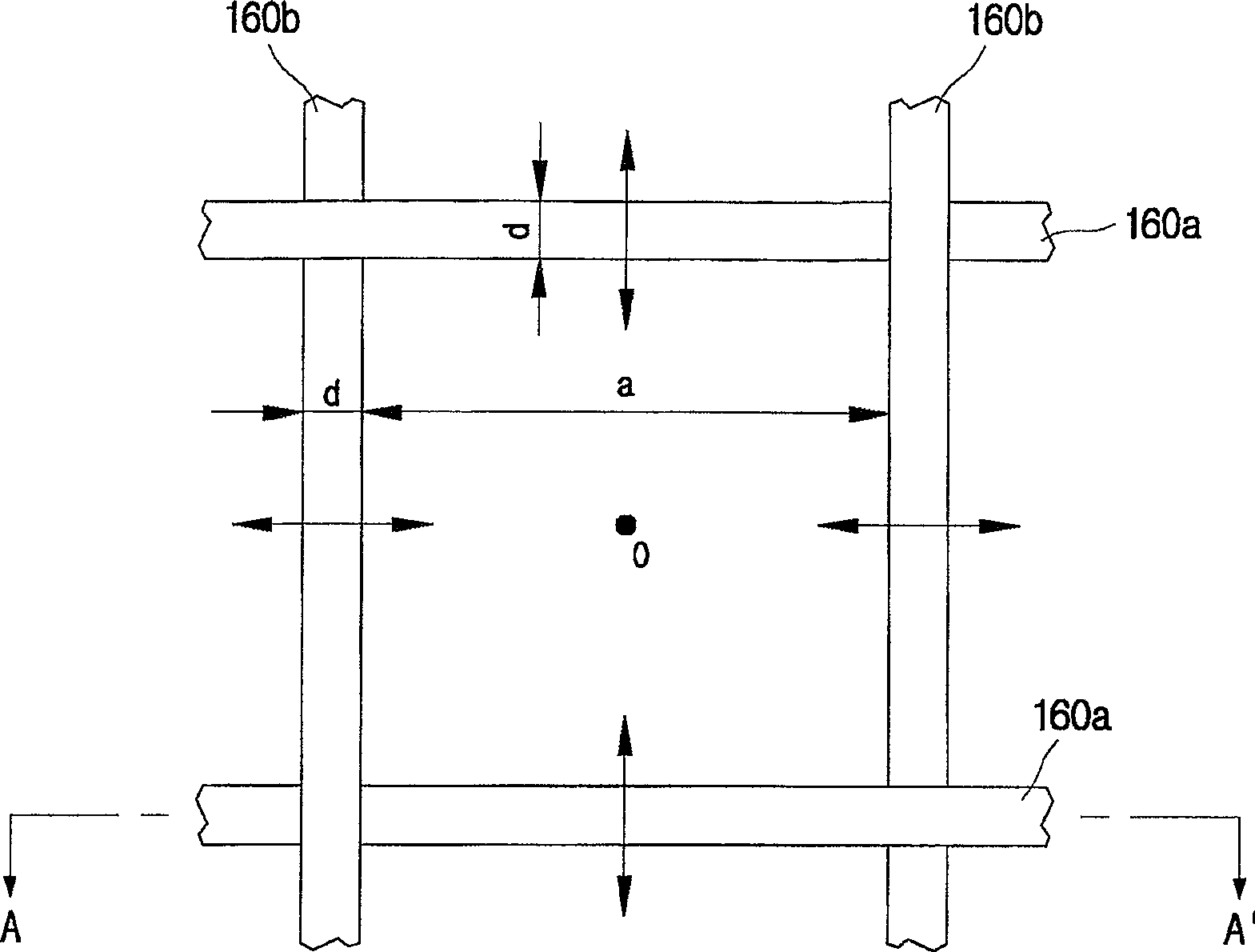

Flat plate heat transfer device

InactiveCN1887037AMaximize heat transferShorten the flow distanceWristbandsHatsWorking fluidCoarse mesh

Disclosed is a flat plate heat transfer device, which includes a thermally conductive flat case installed between a heat source and a heat emitting unit and containing a working fluid evaporated with absorbing heat from the heat source and condensed with emitting heat to the heat emitting unit; and a mesh layer aggregate installed in the flat case and having a structure that a fine mesh layer for providing a flowing path of liquid and a coarse mesh layer for providing a flowing path of liquid and a dispersion path of vapor simultaneously are laminated. On occasions, the coarse and the fine mesh layers are alternately laminated repeatedly, and the fine mesh layer is replaced with a wick structure. The coarse mesh layer is preferably a screen mesh layer with wire diameter of 0.2 mm ~ 0.4 mm and mesh number of 10 ~ 20. This device improves heat transfer performance.

Owner:LG CABLE LTD (KR)

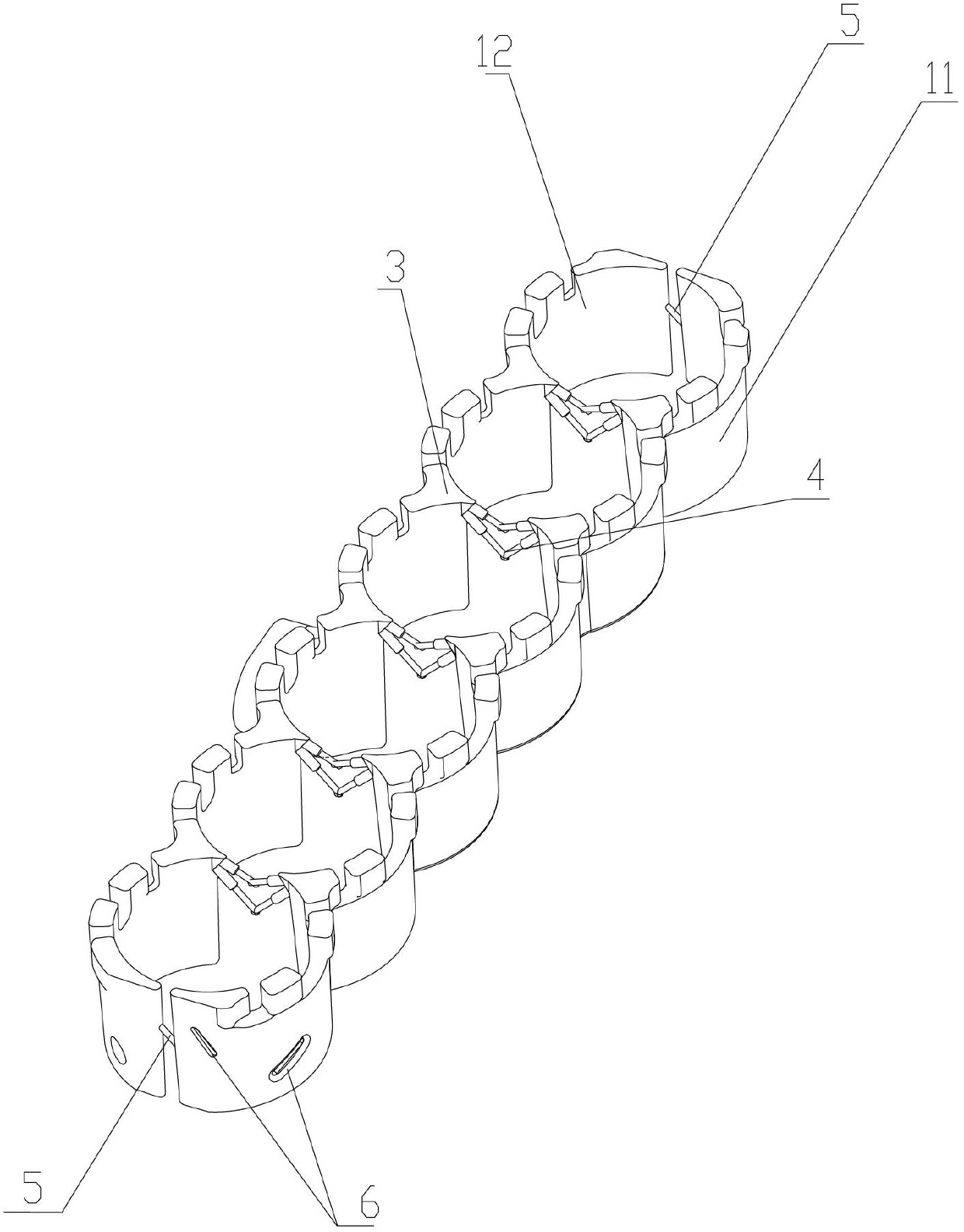

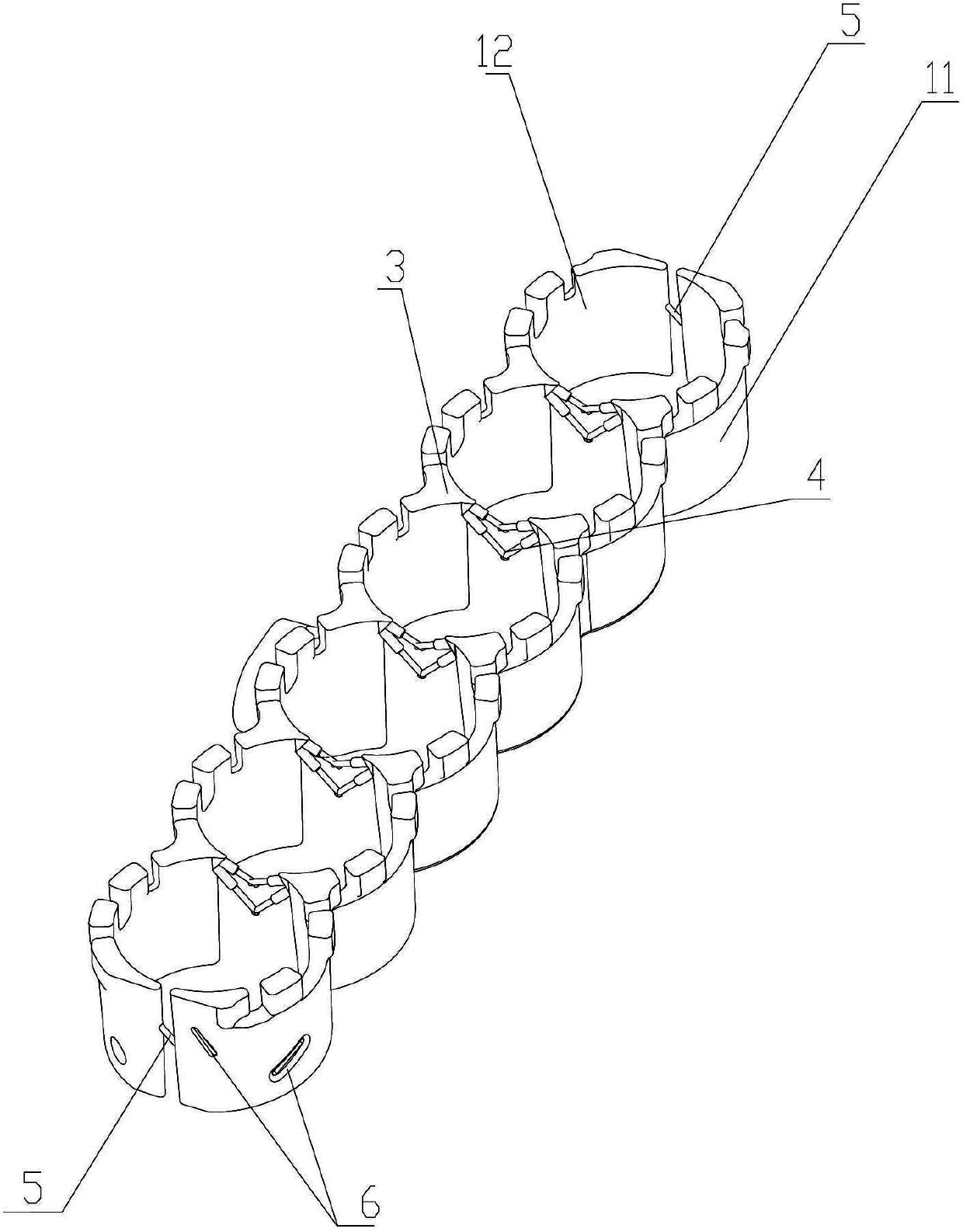

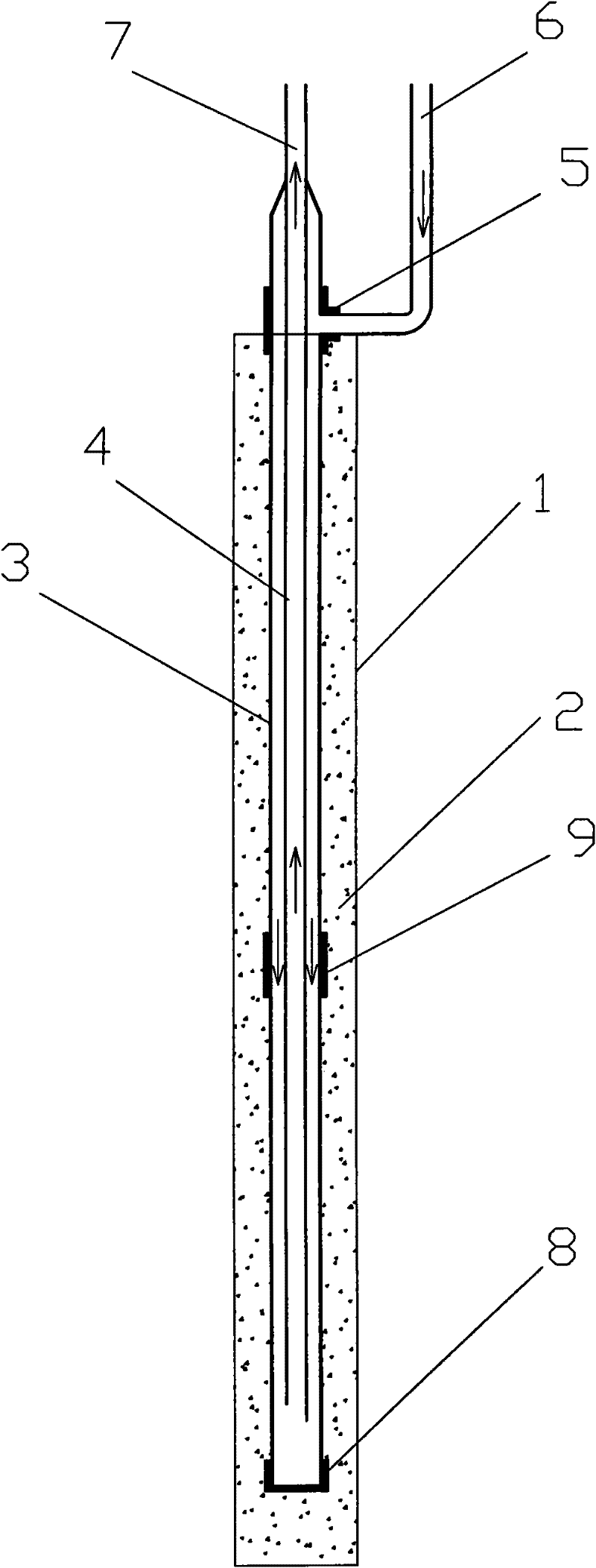

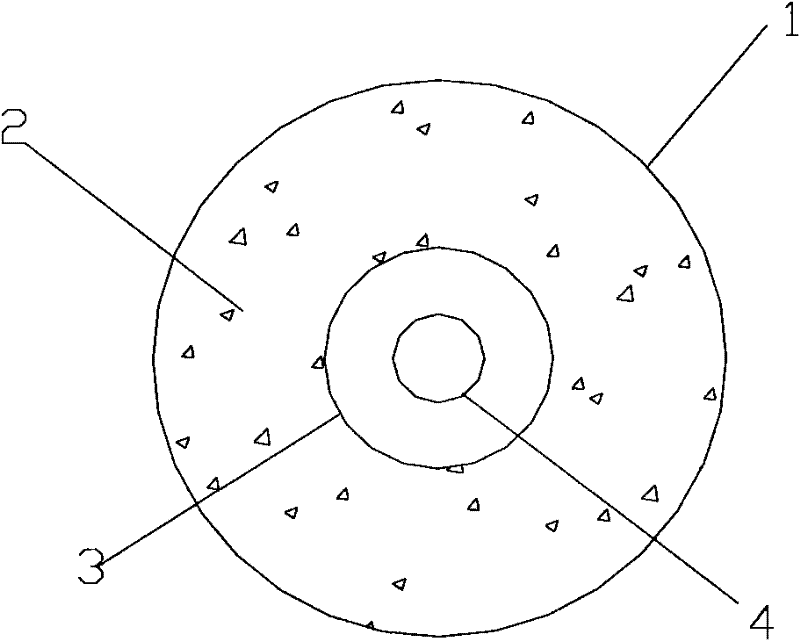

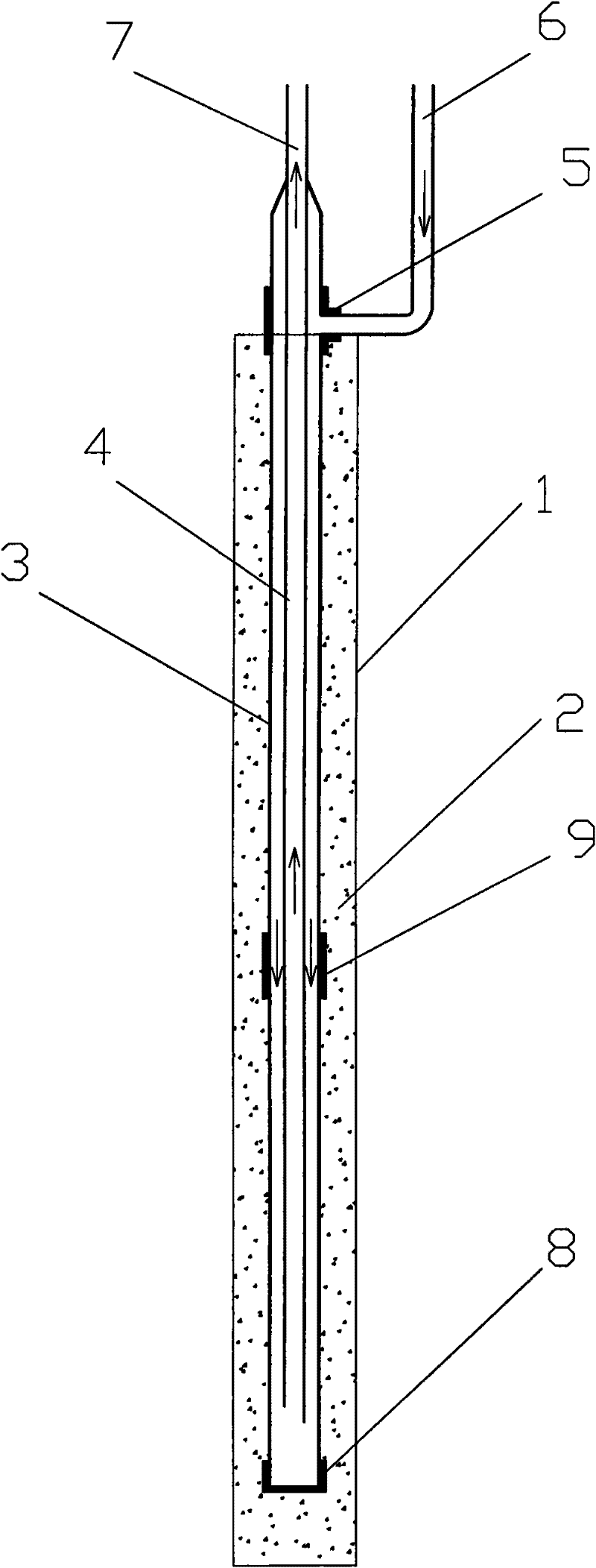

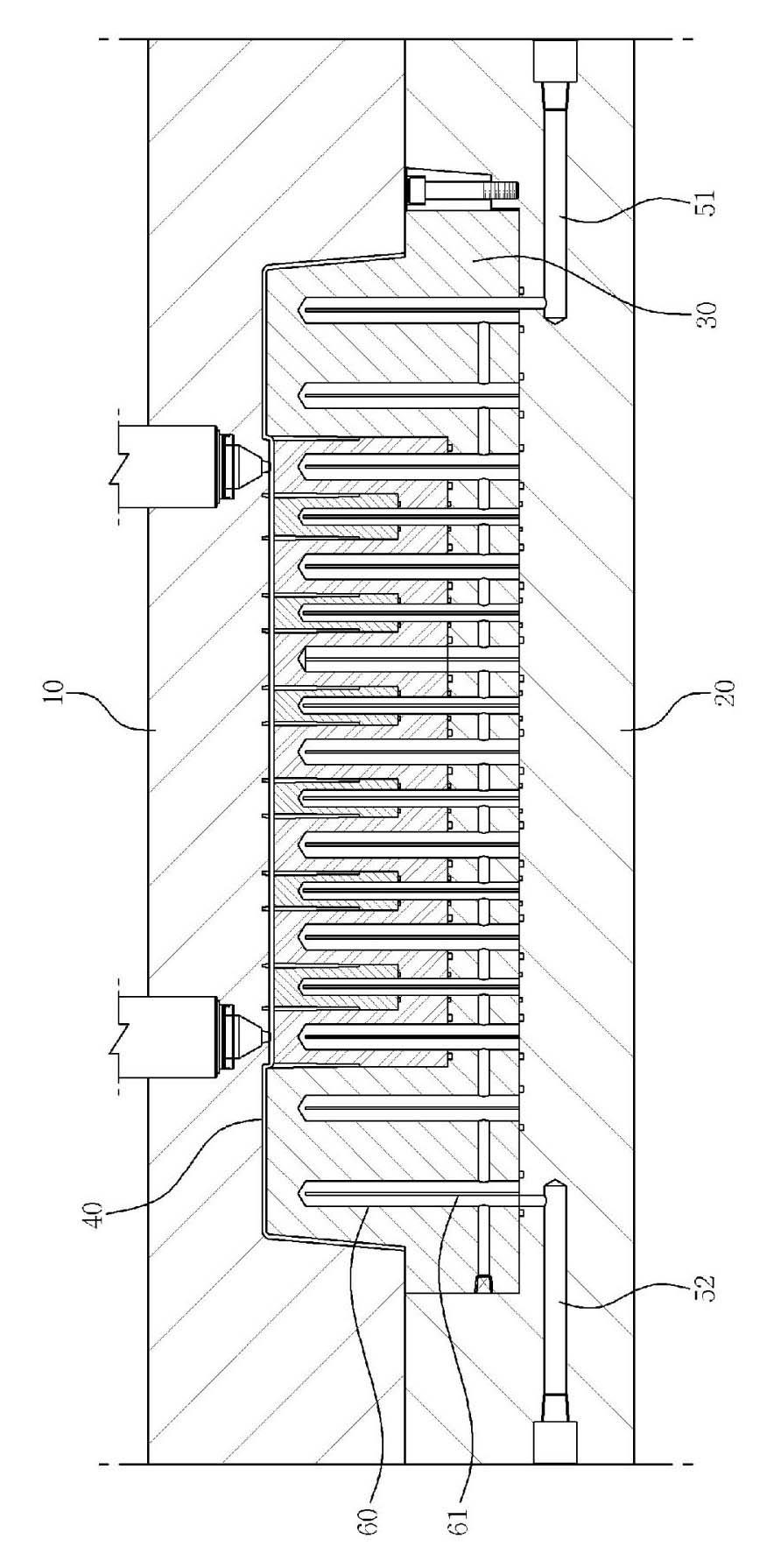

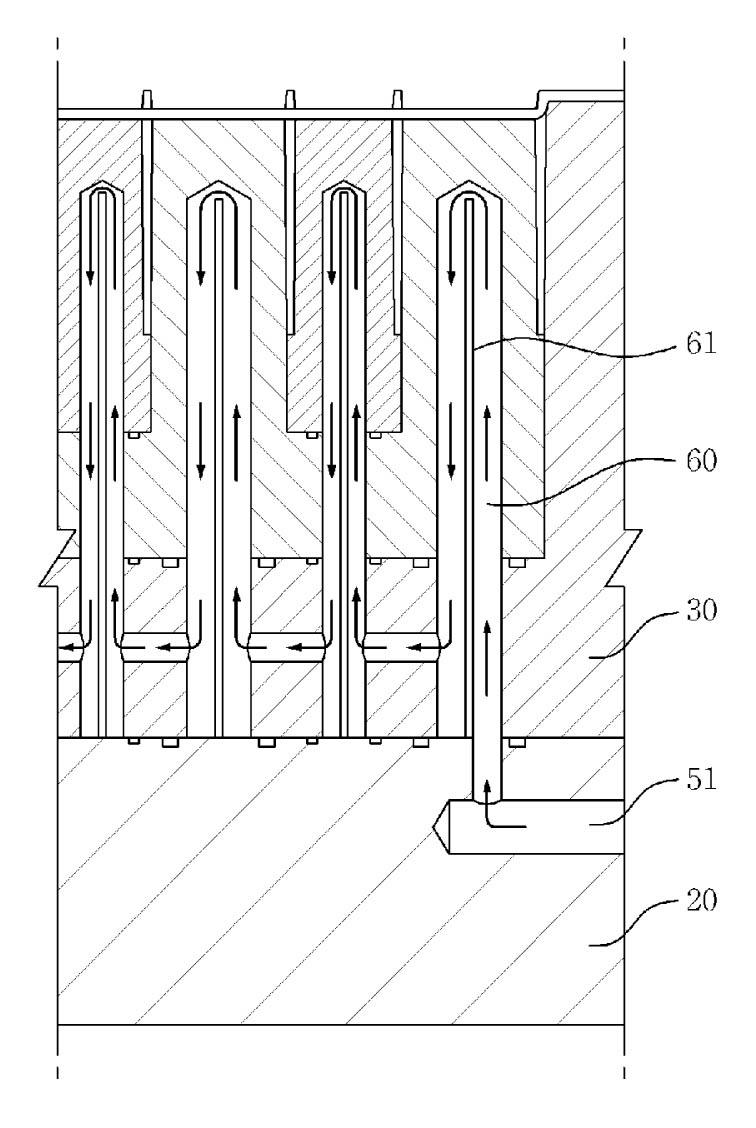

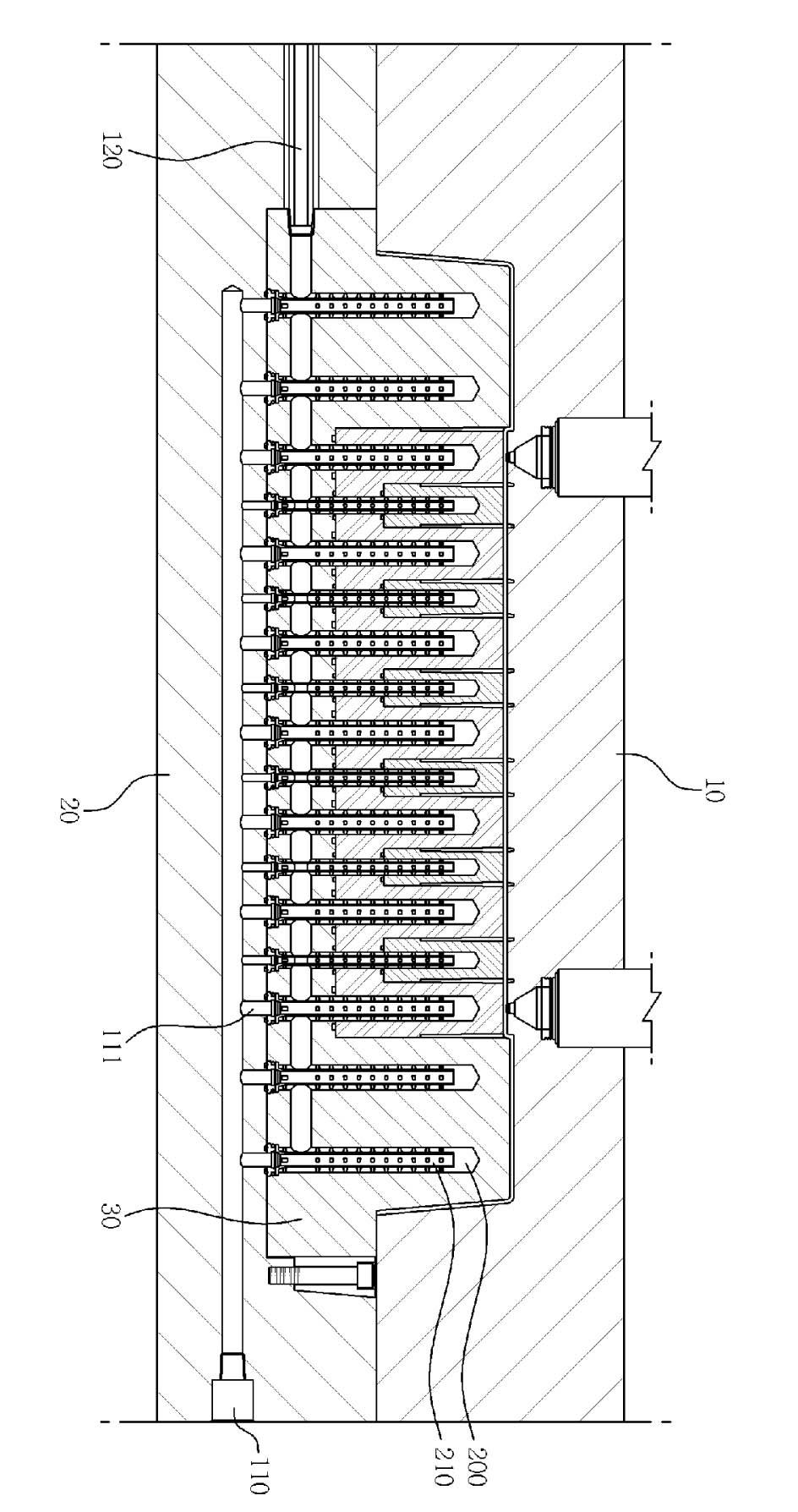

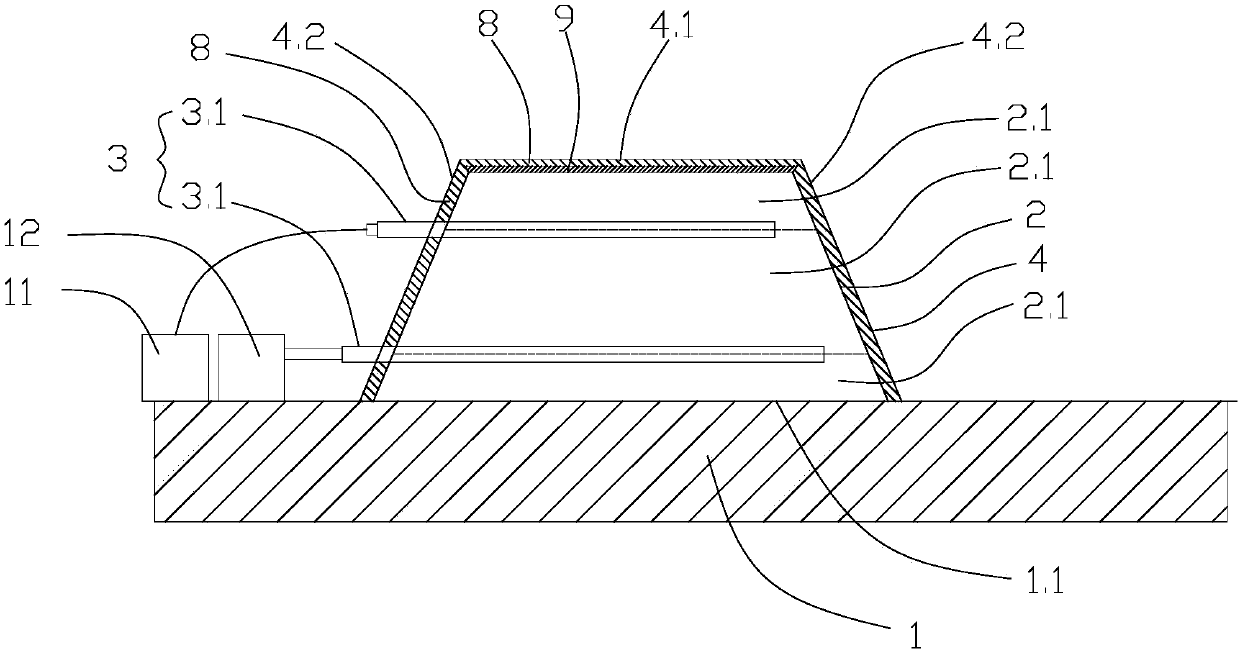

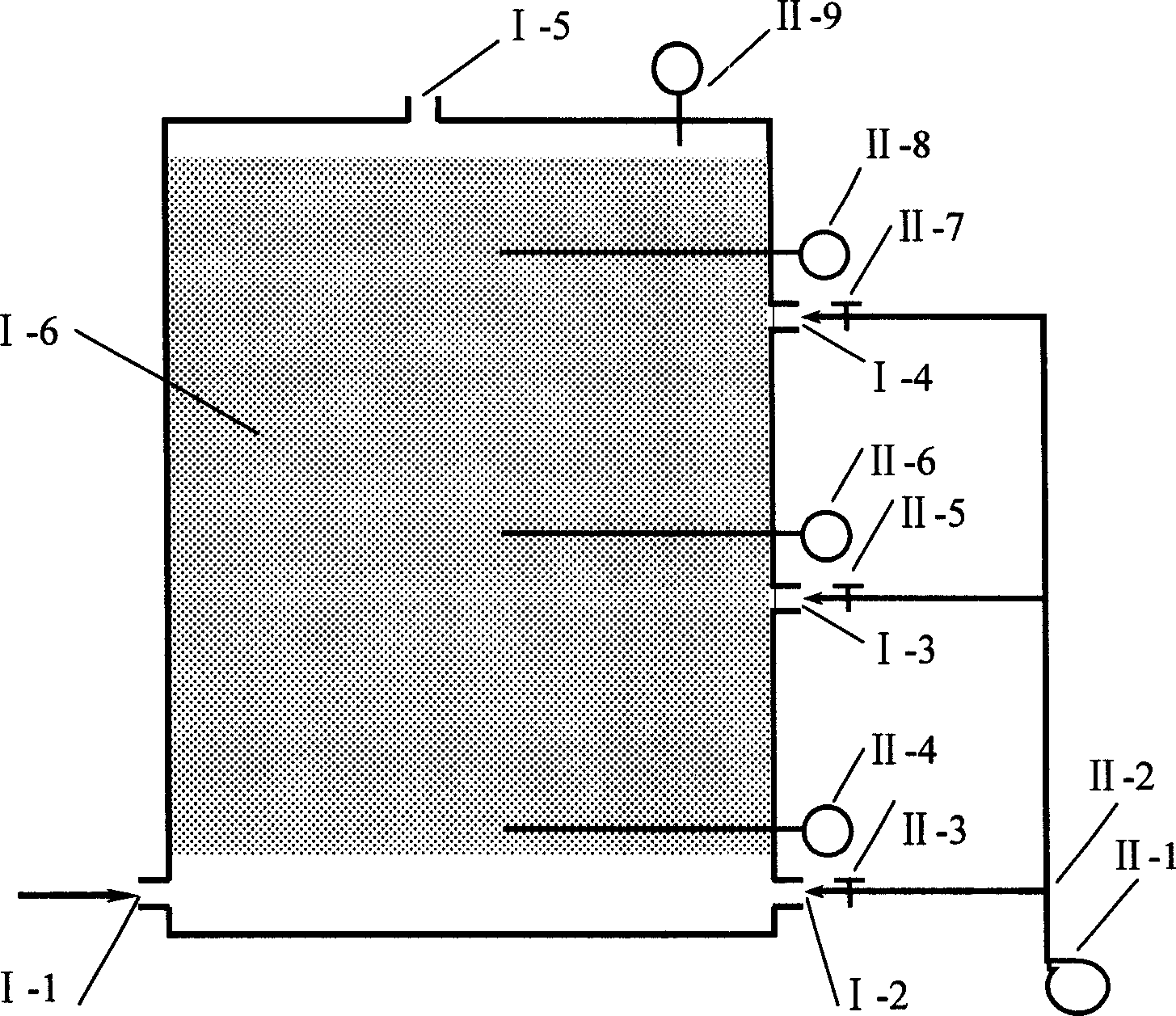

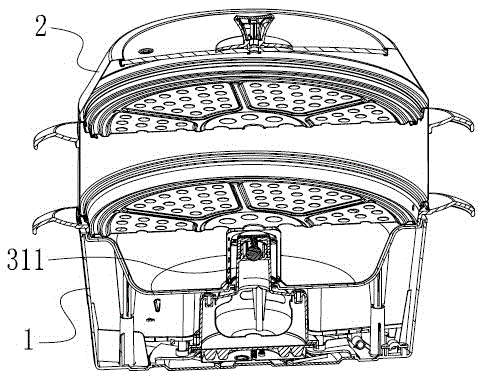

Baffle pipe and core-cooling device for an injection mold

The present invention relates to a core-cooling device for an injection mold which molds plastic injection-molded articles. More particularly, the present invention relates to a core-cooling device for an injection mold, wherein cooling water is efficiently supplied to circulate through a cooling water channel of a core and thus uniformly and quickly cool the core. The core-cooling device for an injection mold according to the present invention comprises: a basic cooling water pipe which is formed on a lower disk (20) and which includes a cooling water inlet (110) and a cooling water outlet (120); and core-cooling water pipes (200) in communication with the cooling water inlet (100) and the cooling water outlet (120) of the basic cooling water pipe so as to enable cooling water to circulate through the interior of a lower core (30).; Baffle pipes (210) divided into left and right sections are coupled to respective core-cooling water pipes (200). The cooling water inlet (110) of the basic cooling water pipe enables cooling water to be simultaneously fed into each of the core-cooling water pipes (200) via distribution pipes (111) connected to the lower ends of baffle pipes (210), respectively. The cooling water outlet (120) of the basic cooling water pipe is connected to lower portions of the core-cooling water pipes (200) so as to discharge, to the outside from the core-cooling device, the cooling water which is fed through the lower ends of the baffle pipes (210), discharged from upper portions of the core-cooling water pipes (200), and falling down toward the lower portions of the core-cooling water pipes (200) in order to cool the lower core (30).

Owner:李在福

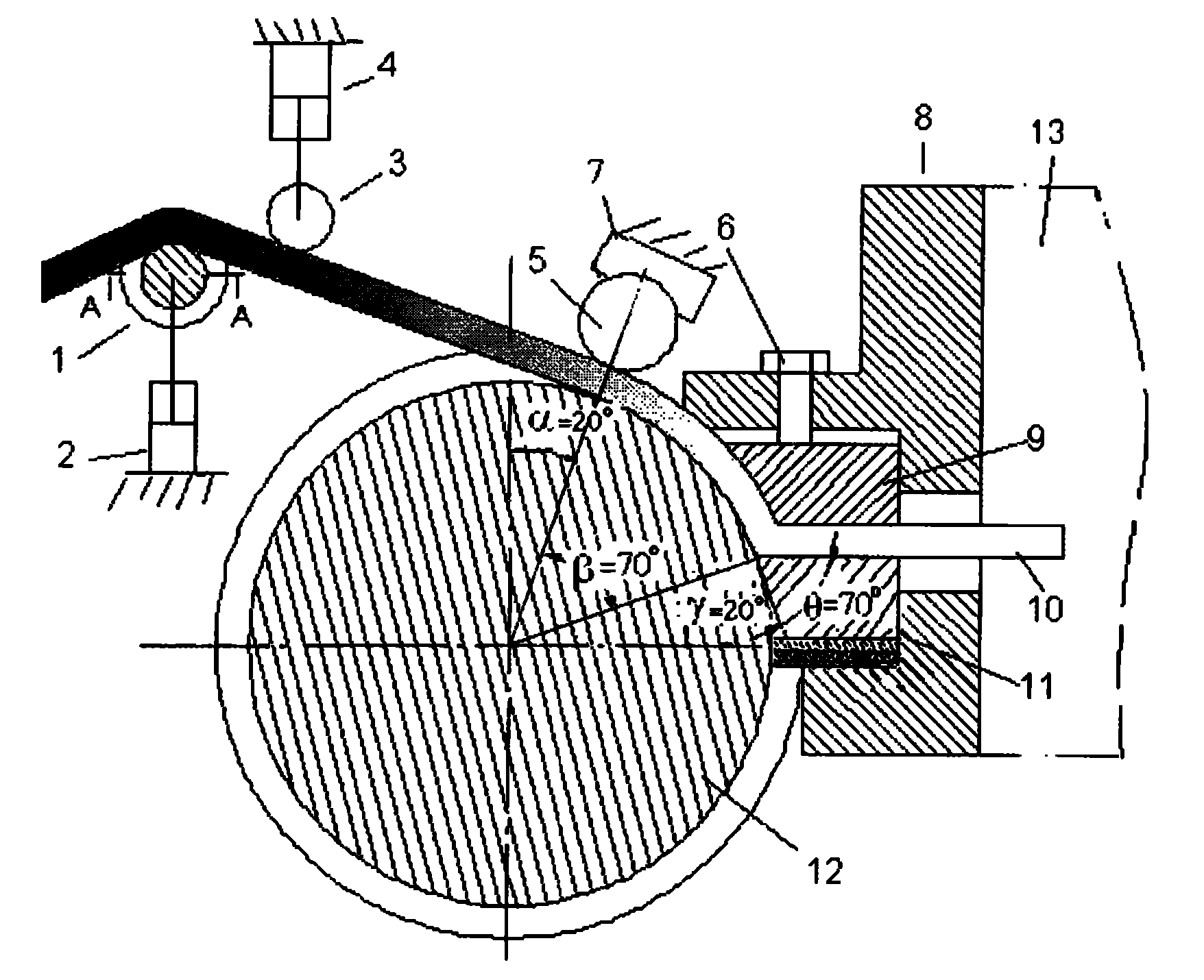

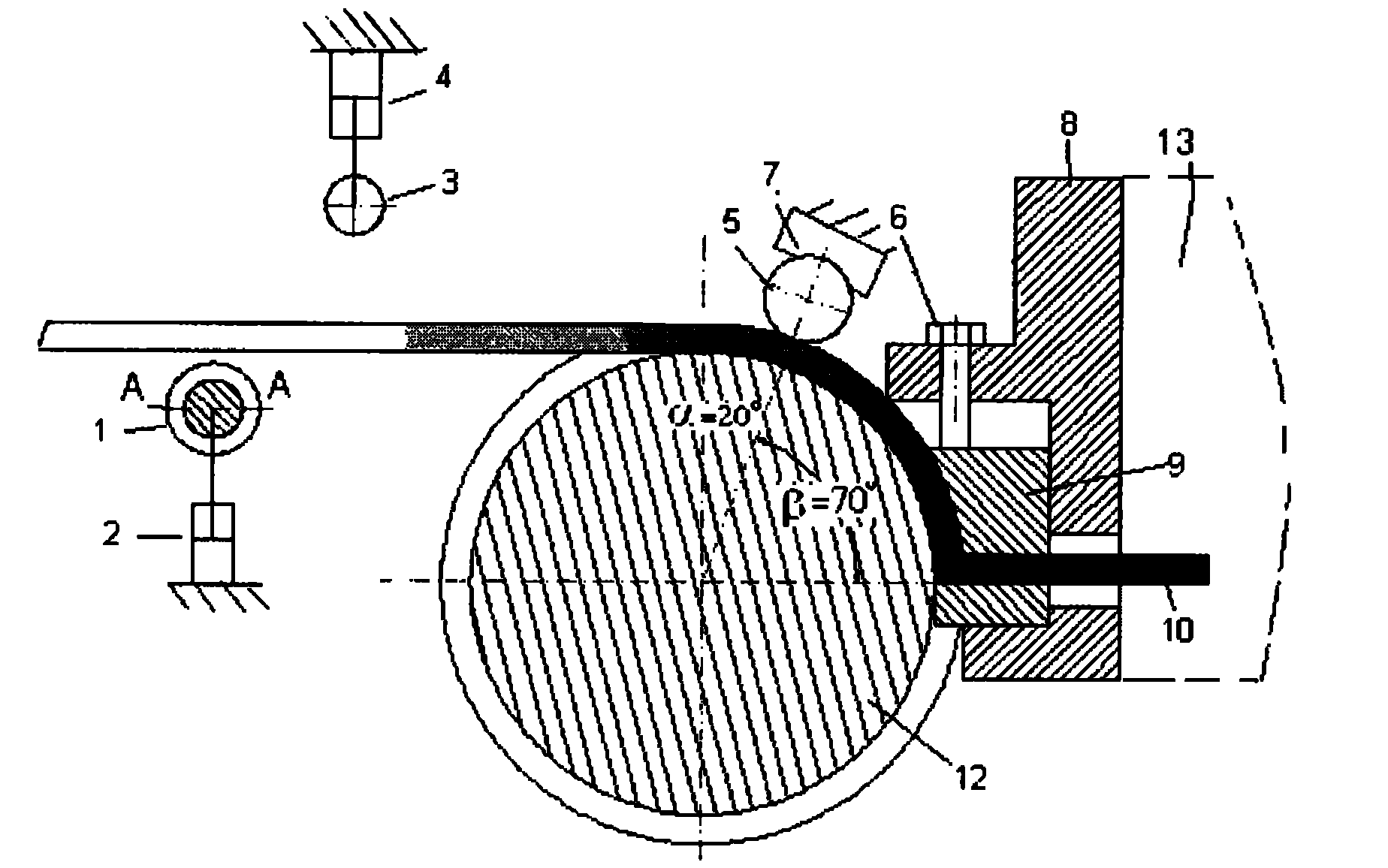

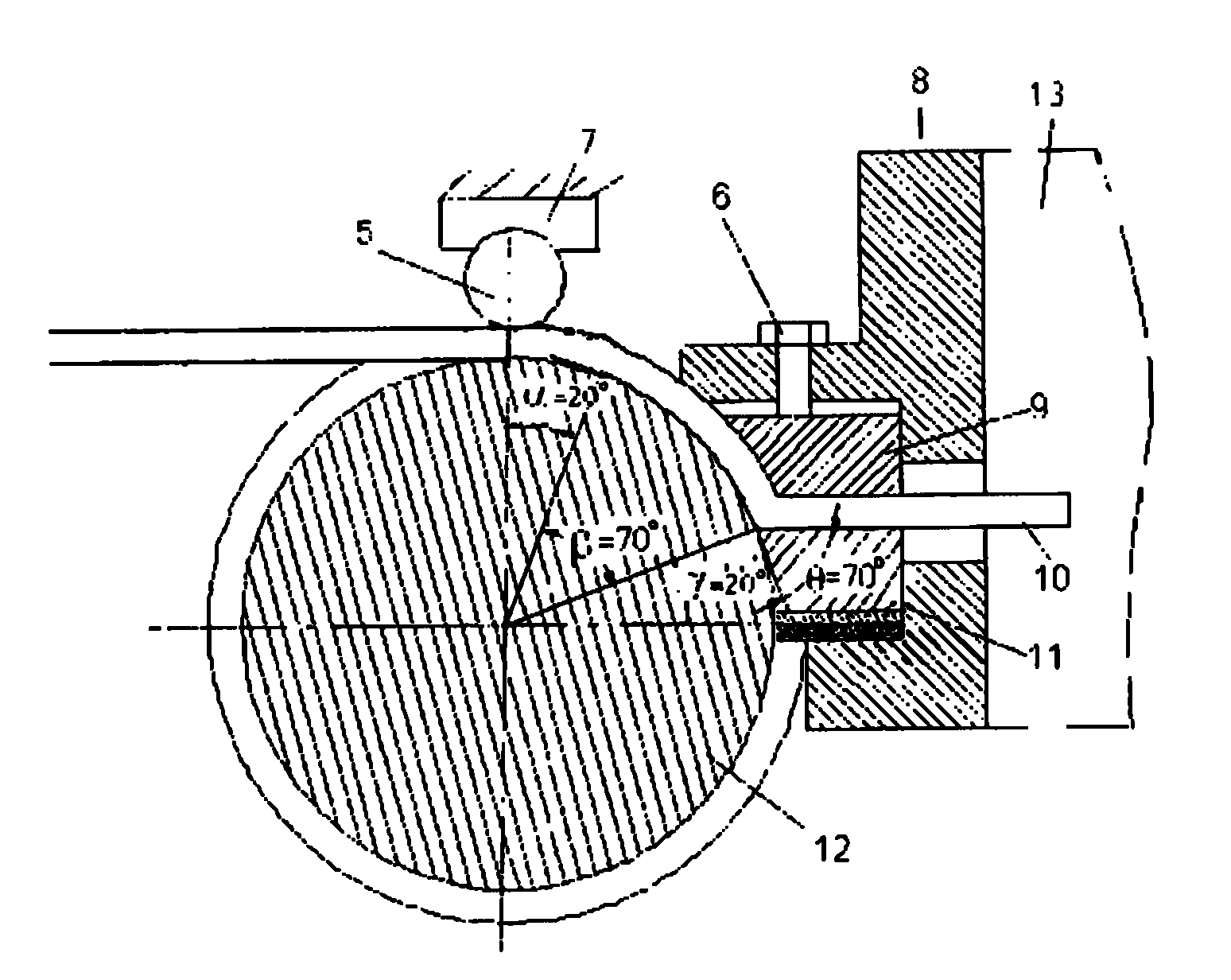

Extrusion device for shortening blank friction flow path

The invention relates to an extrusion device for shortening a blank friction flow path, which is suitable for continuous extrusion equipment. The extrusion device is characterized in that a blank friction flow path shortening device constituted by a wrap angle adjusting mechanism and an auxiliary blank gripping mechanism is arranged on a frame, and the wrap angle adjusting mechanism comprises a gripping wheel position adjusting component and an extrusion cavity position adjusting component; and the auxiliary blank gripping mechanism comprises a bending guide roller I, a bending guide roller oil cylinder I, a bending guide roller II and a bending guide roller oil cylinder II, so that the blank friction flow path can be shortened and the rotational angle of a blank can be reduced. According to the extrusion device disclosed by the invention, by adjusting the positions of a gripping wheel and an extrusion cavity, the blank flow path can be shortened, and the rotational angle of the blank can be reduced, so that the extrusion device can further reduce the extrusion load and deformation temperature of metal, not only save energy, but also prolong the service life of a tool and a mold; and particularly, the control of the deformation temperature can be realized by adjusting the blank flow path, which is very beneficial to preparation of high-performance nonferrous metal extruded products with fine-grained structures.

Owner:DALIAN JIAOTONG UNIVERSITY

Soil thermal desorption treatment system and method

InactiveCN107685074AReduce workloadFirmly connectedContaminated soil reclamationEnvironmental engineeringThermal desorption

The invention discloses a soil thermal desorption treatment system used for treatment of pollutants in soil of a site. The soil thermal desorption treatment system comprises a heap-shaped mound formedby the soil piled up on the site, a thermal desorption treatment assembly embedded in the mound and a sealing layer covering the surface of the mound; the thermal desorption treatment assembly comprises a heating pipe and an extracting pipe which are respectively used for heating the mound and discharging the pollutants desorbed at high temperature. The soil is piled up to form the mould directly, the heating pipe and the extracting pipe are arranged in the mould to have the soil heated and the pollutants in the soil discharged, arrangement of a thermal desorption treatment space of a staticpressure chamber and the like which are excavated in the site is not needed, and workload in thermal desorption treatment is reduced.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Reeling method for reel type secondary lithium ion battery

InactiveCN1929186AImprove alignment accuracyImprove winding efficiencyFinal product manufactureSecondary cellsEngineeringLithium-ion battery

This invention relates to secondary lithium ion battery field and to one rolling method of one chip rolling, which comprises the following steps: a, overlapping positive and negative electros and isolation film, wherein, positive electrode is in middle and isolation film on top and bottom with isolation film inside; b, folding the overlapped electrodes and isolation films by positive electrode.

Owner:DONGGUAN NEWPOWER ELECTRIC SCI & TECH

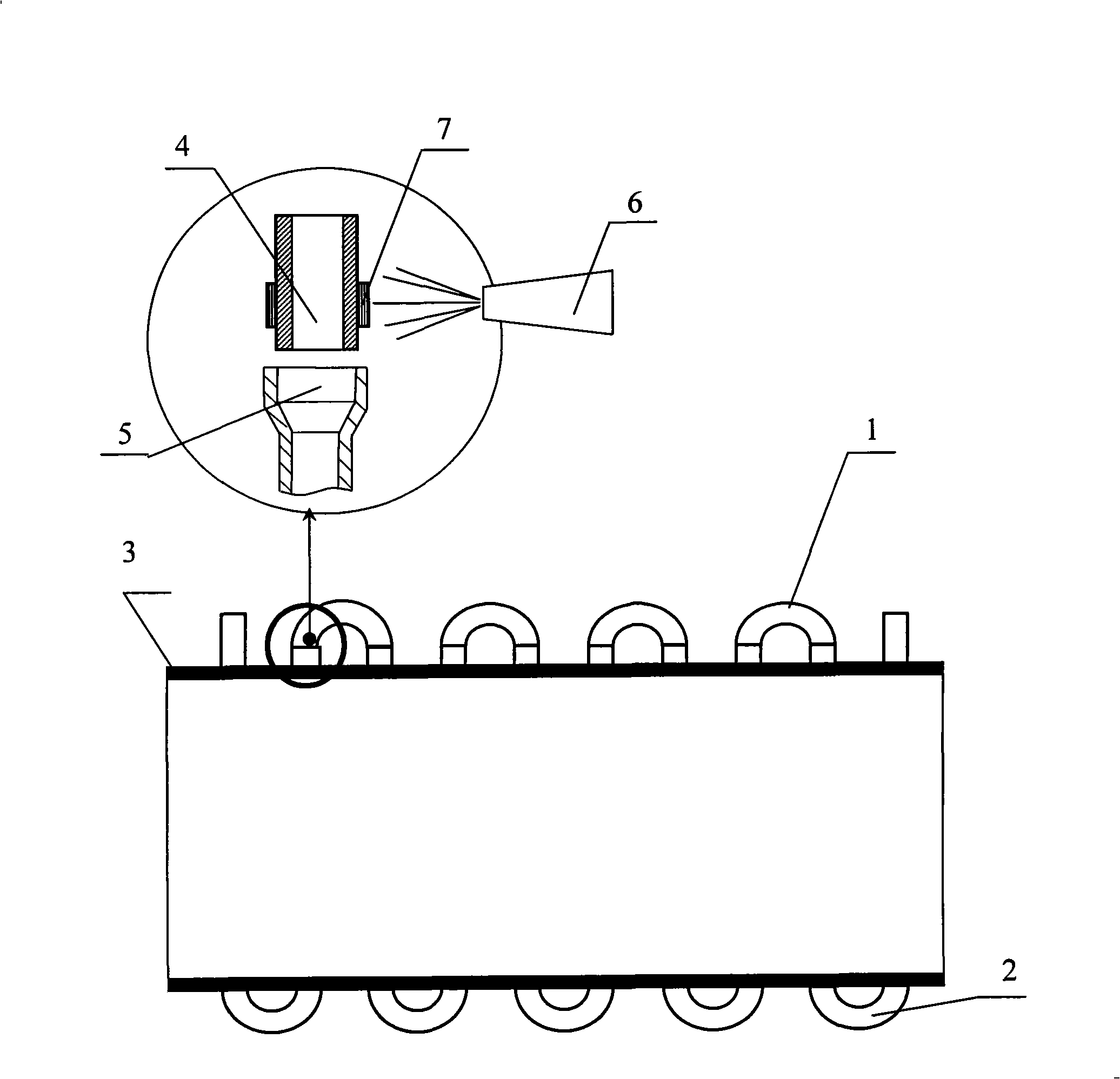

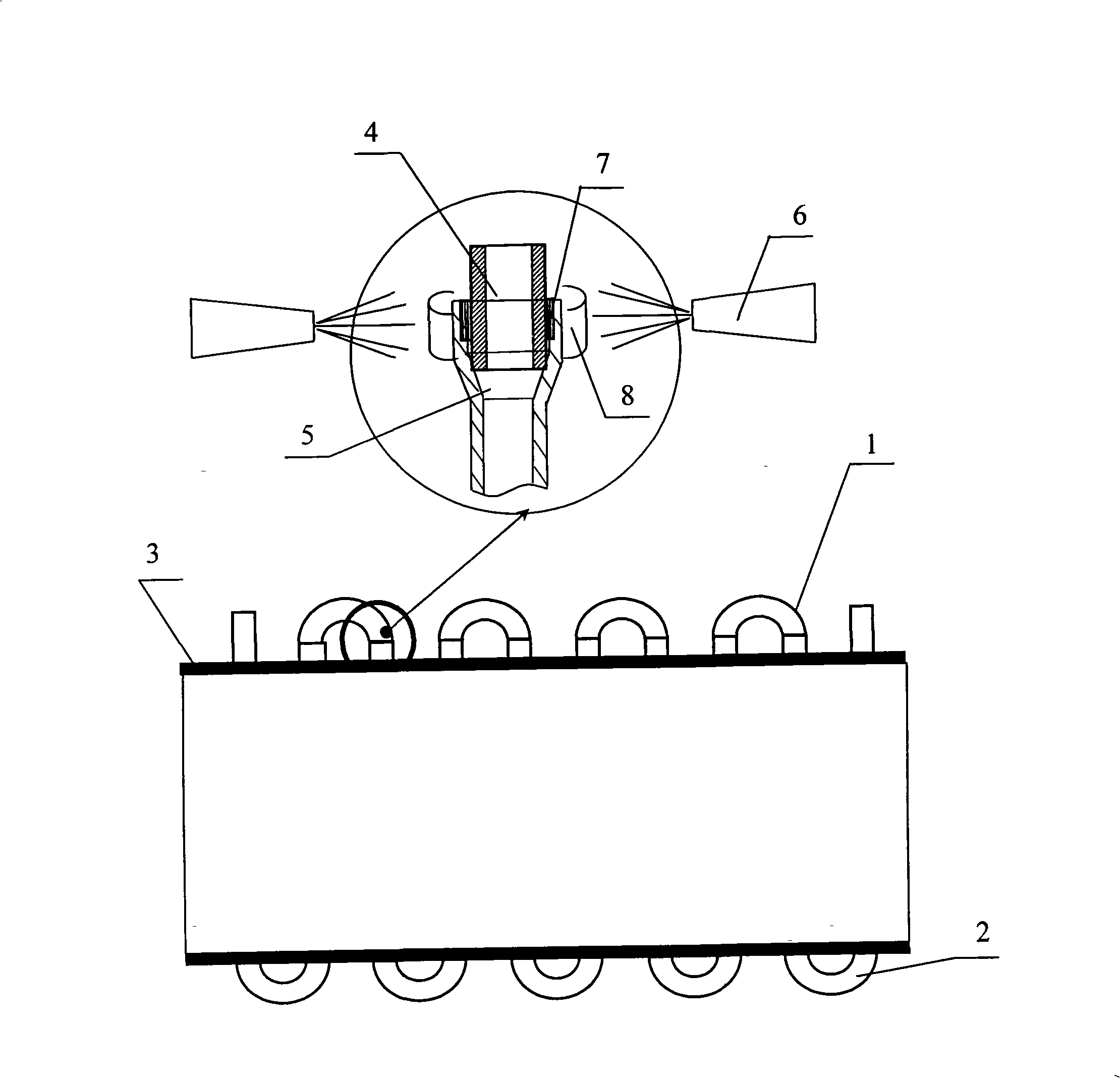

Connecting method of heat exchange aluminium tube

InactiveCN101301695AShorten the flow distanceEvenly heatedSoldering apparatusTubular elementsHeat resistanceEngineering

The invention discloses a connecting method for a heat exchanging aluminium pipe. A plurality of fins arranged in parallel form a rectangular fin group which passes through a group of lower U-shaped pipes; the diameter of a nozzle of the lower U-shaped pipe is larger than that of the nozzle of an upper U-shaped pipe. The method is characterized in that solder is firstly prepared as sheet-shape and wound at the external diameter of the nozzle of the upper U-shaped pipe till that the upper U-shaped pipe can be just plugged into the lower U-shaped pipe; finally, the U-shaped pipe is symmetrically heated at two sides by dual rows of flames; furthermore, a dismountable steel sleeve is arranged closely to the external side of the interface of the upper U-shaped pipe and the lower U-shaped pipe; the steel sleeve is made of material which can uniformly transmit the temperature; the steel sleeve is made of austenitic heat-resistance stainless steel; the connection of the heat exchanging aluminium pipe is completed by the heating of multi-class flames by times; the thickness of the solder is ranged between 0.5 and 1mm; the optimal thickness of the solder is 0.65mm.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

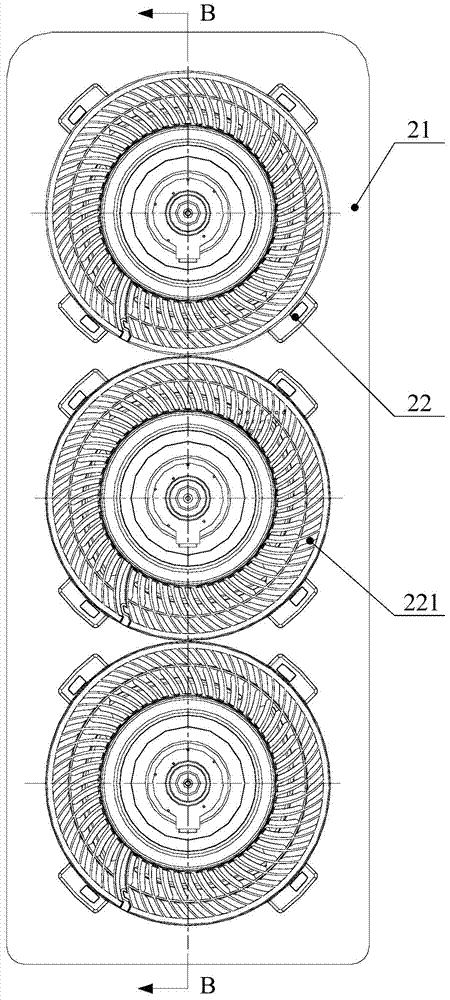

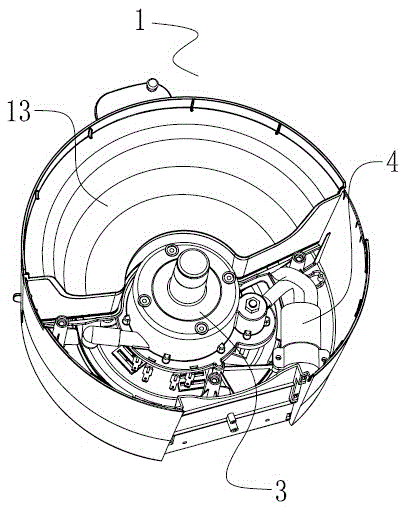

Volute for extractor hood

ActiveCN105091058AImprove emission efficiencyShorten the flow distanceDomestic stoves or rangesLighting and heating apparatusEngineeringFlue

The invention discloses a volute for an extractor hood. A volute air flue is arranged in the volute. The volute is provided with a volute air inlet and a volute air outlet. The volute comprises a fixed shell and a movable shell. The movable shell can move between the closing position and the opening position relative to the fixed shell. When the movable shell is located at the closing position, the fixed shell is matched with the movable shell, and air in the volute air flue is allowed to be discharged out of the volute air outlet. When the movable shell is located at the opening position, the movable shell is staggered relative to the fixed shell, so that a volute circulation air outlet is limited between the movable shell and the fixed shell. The volute circulation air outlet is arranged to allow air in the volute air flue to be discharged towards the indoor part through the volute circulation air outlet. According to the volute for the extractor hood, the flowing distance of air when the extractor hood exhausts towards the indoor part can be shortened.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Air supply system and method for accelerating methane biological oxidation

InactiveCN101016512AReduce global warming potentialSignificant global environmental effectsBioreactor/fermenter combinationsBiological substance pretreatmentsBiological oxidationGreenhouse

The invention discloses an air supply system to accelerate methane biological oxidation in greenhouse gases reduce-discharging domain, which is characterized by the following: depending on methane biological oxidizing reactor; dividing to multiple multistage followed with gas-flowing direction; settling separated air inlet port and assembling oxygen measurement set on each stage; composing air supply system with fan, gas pipe line and valve; connecting air supply system and reactor with air inlet port; providing air for each stage with oxygen measurement set and valve; dropping oxygen supply of air inlet port area; improving oxygen supply of outlet port area; reinforcing methane biological oxidation even property in the device; increasing stability of the device.

Owner:张相锋

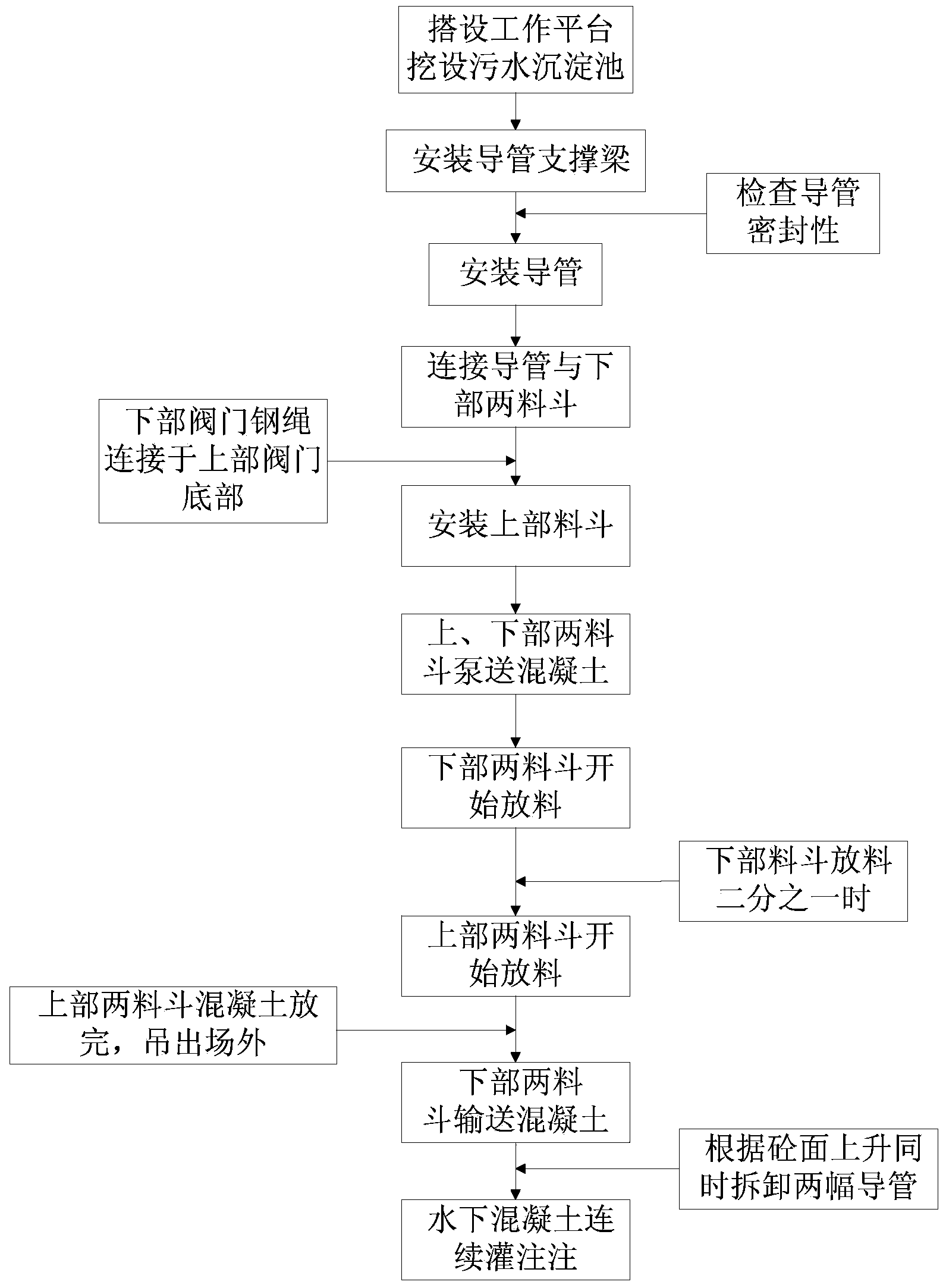

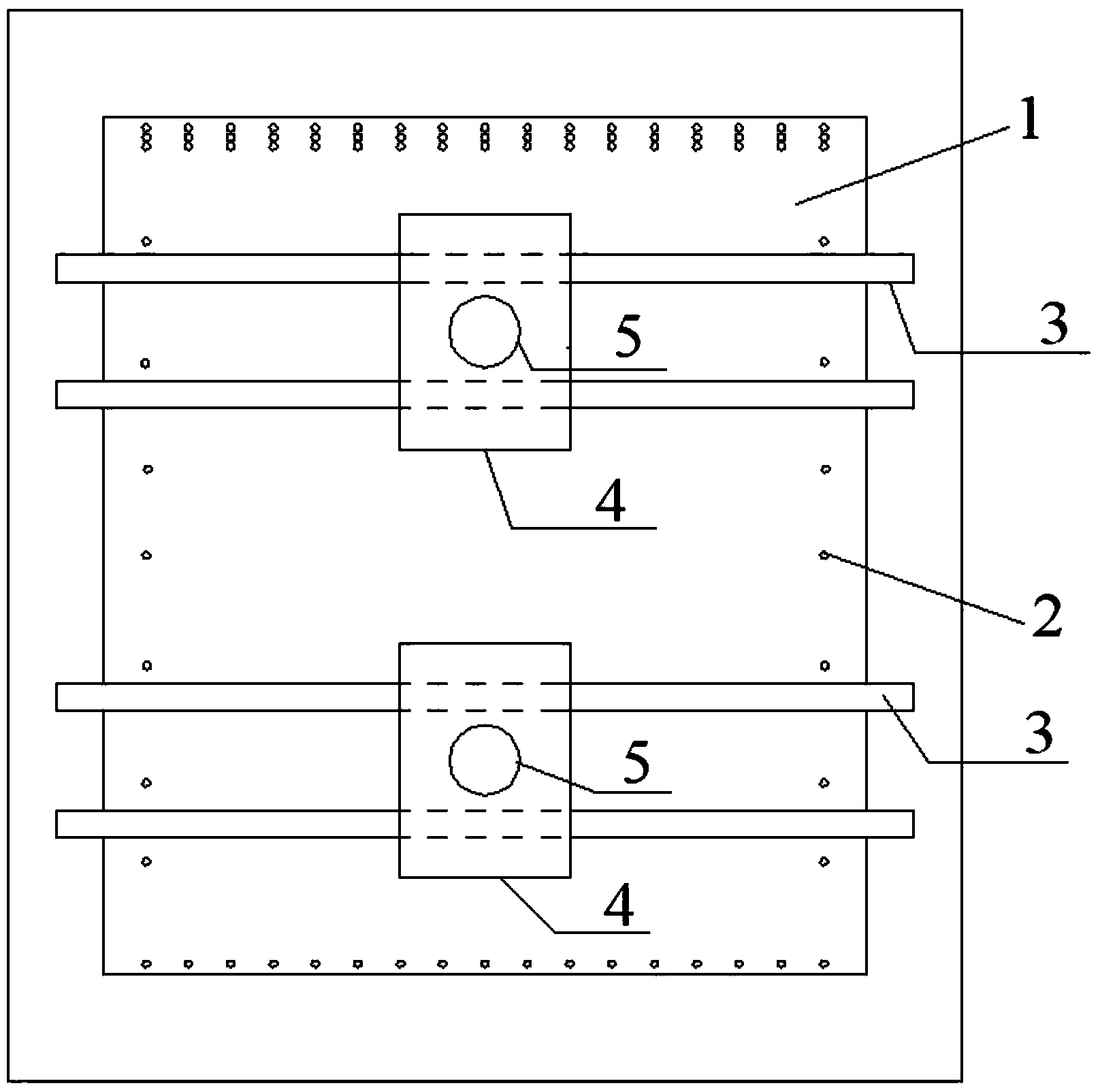

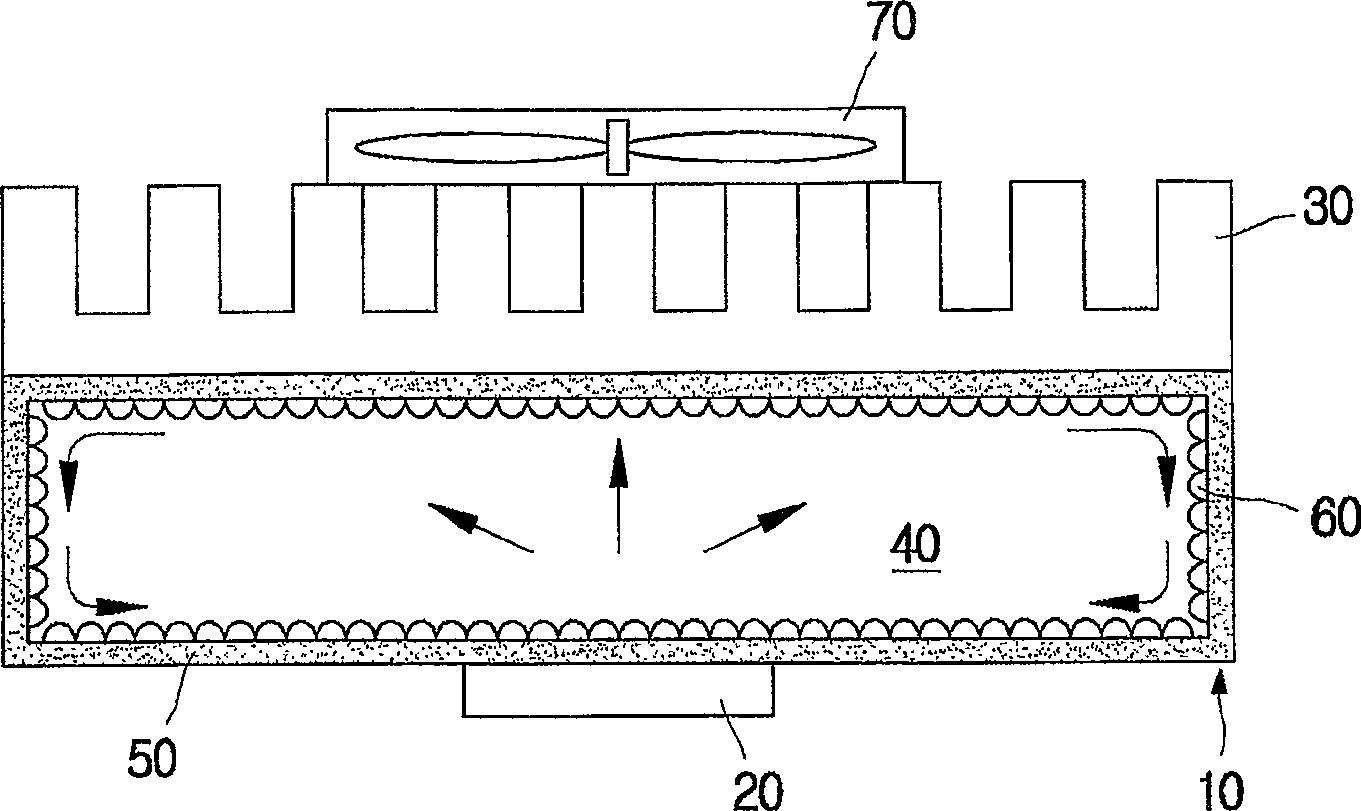

Underground concrete pouring construction technology based on double guide tubes and four hoppers

ActiveCN104032742AShorten the flow distanceSatisfy the requirement of buried depthFoundation engineeringGuide tubeBuilding construction

The invention discloses an underground concrete pouring construction technology based on double guide tubes and four hoppers. The underground concrete pouring construction technology based on the double guide tubes and the four hoppers comprises the following steps that (1) an operation platform is erected above a pile body; (2) two guide tube supporting beams are installed; (3) the two guide tubes are installed on the two guide tube supporting beams respectively; (4) the two lower hoppers are connected with the two guide tubes; (5) the two upper hoppers are lifted to the positions over the two lower hoppers respectively; (6) concrete is pumped into the four hoppers; (7) the lower hoppers start to discharge concrete; (8) when one second of the concrete in the lower hoppers is discharged, the upper hoppers start to discharge concrete; (9) the concrete continues to be pumped into the lower hoppers, concrete is poured continuously underground until underground concrete construction of the pipe body is ended. According to the underground concrete pouring construction technology based on the double guide tubes and the four hoppers, the method for continuously pouring concrete based on the double guide tubes and the four hoppers in a one-off mode is adopted, and the problem that the quality of underground concrete pouring on a large-area large-section pile body is poor is solved.

Owner:SCEGC MECHANIZED CONSTR GRP COMPANY

Flat plate heat transfer device

InactiveCN100508708CMaximize heat transferShorten the flow distanceWristbandsHatsWorking fluidCoarse mesh

Disclosed is a flat plate heat transfer device, which includes a thermally conductive flat case installed between a heat source and a heat emitting unit and containing a working fluid evaporated with absorbing heat from the heat source and condensed with emitting heat to the heat emitting unit; and a mesh layer aggregate installed in the flat case and having a structure that a fine mesh layer for providing a flowing path of liquid and a coarse mesh layer for providing a flowing path of liquid and a dispersion path of vapor simultaneously are laminated. On occasions, the coarse and the fine mesh layers are alternately laminated repeatedly, and the fine mesh layer is replaced with a wick structure. The coarse mesh layer is preferably a screen mesh layer with wire diameter of 0.2 mm ~ 0.4 mm and mesh number of 10 ~ 20. This device improves heat transfer performance.

Owner:LG CABLE LTD (KR)

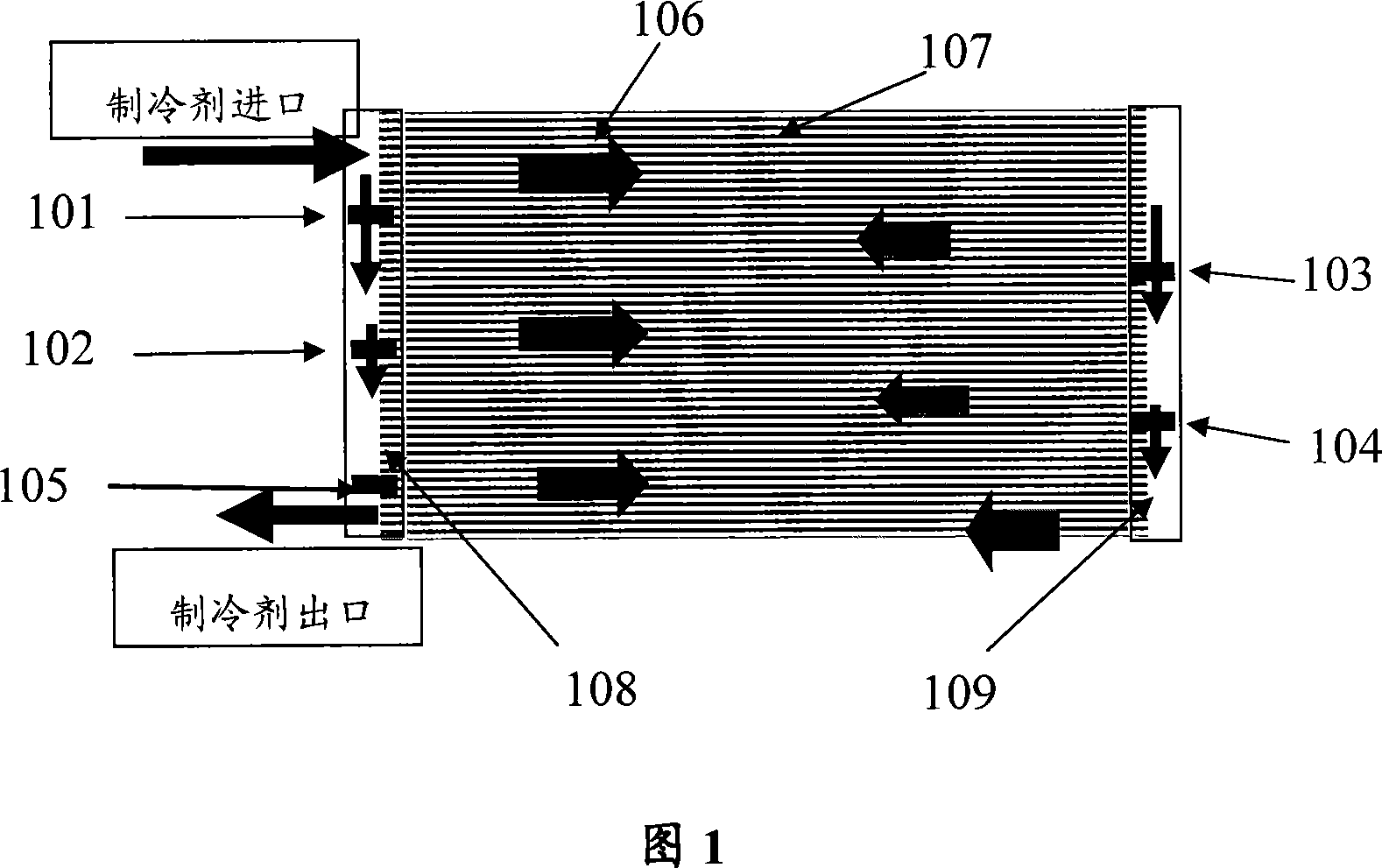

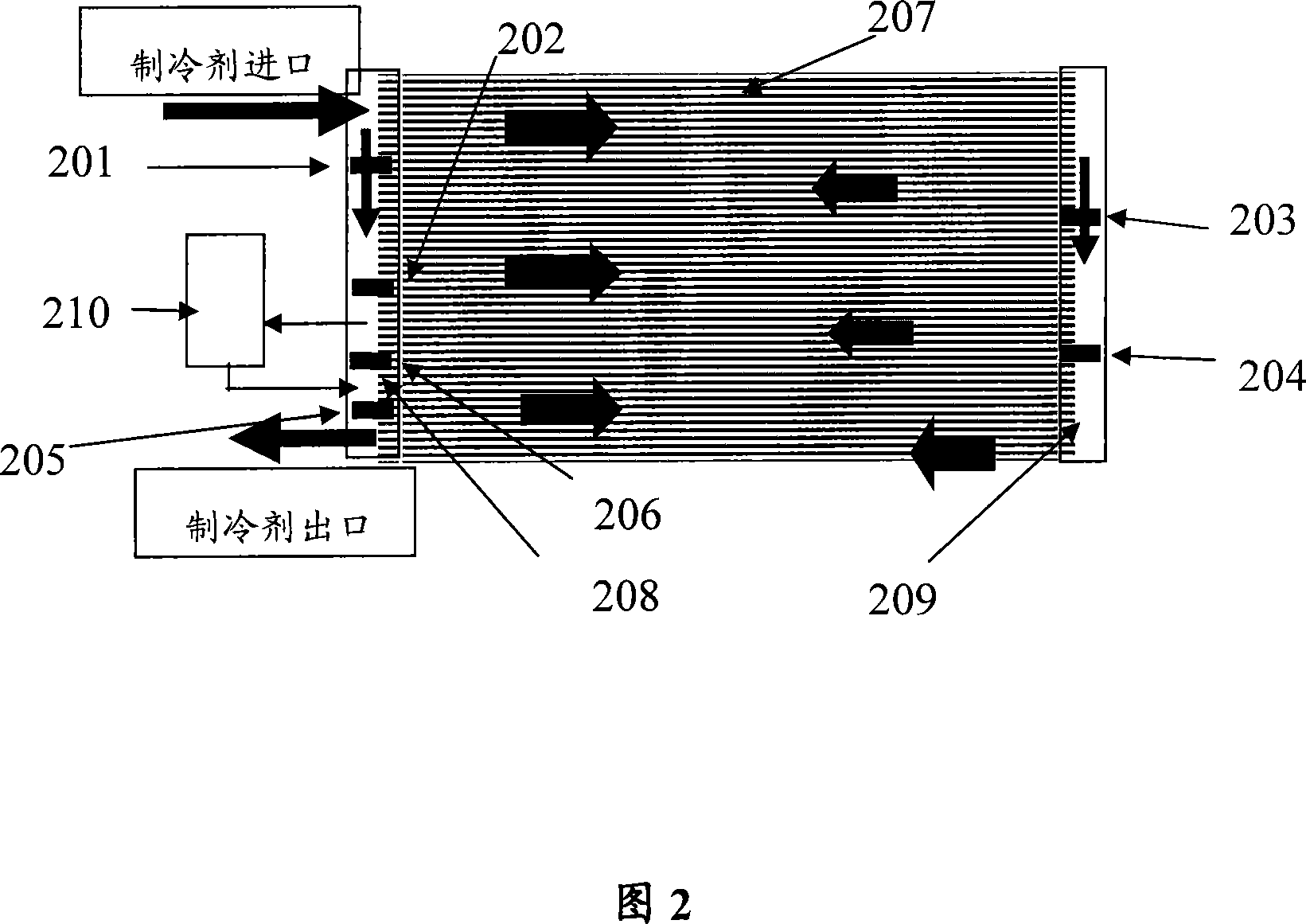

Condenser

InactiveCN101021376AImprove cooling effectLow flow resistanceEvaporators/condensersEngineeringRefrigerant

The invention discloses a non-overcooling condenser. It includes many regular arranged cooling tubes which the two ends are connected with two collecting mains. The inlet and outlet of the refrigerating medium are all set on the collecting tube which is set with much clapboard to make the medium turn over. At least one through-hole is opened in at least clapboard beside the clapboard which is near to the outlet. Also the invention discloses an overcooling condenser which opens the plume in part clapboard. The diversion controller is used in the invention to reach the mixing flow effect of the medium in condenser; actually, it is a series and parallel condenser. The invention has improved the radiator effect but not increased the volume and decreased the flow resistance of the medium in over heat area.

Owner:AIR INT THERMAL SYST R&D (SHANGHAI) CO LTD

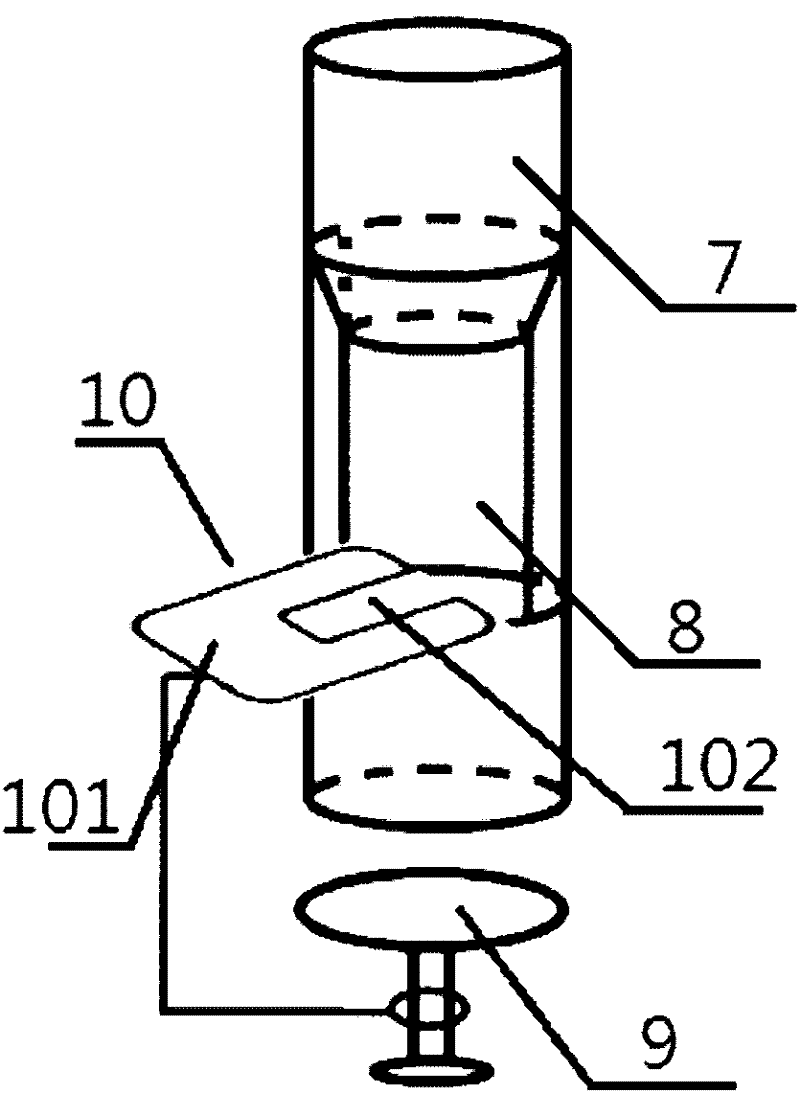

Totally-enclosed cell and cell factor preparation device and preparation method thereof

ActiveCN102242054AShorten the flow distanceReduce lossesBioreactor/fermenter combinationsBiological substance pretreatmentsCord blood stem cellMedicine

The invention discloses a totally-enclosed cell and cell factor preparation device which comprises an upper blood bag, a lower blood bag and a thin connecting pipe, wherein the upper blood bag is provided with an anti-coagulation inlet, a plasma sucking port for sucking plasma and an output port for outputting cells and cell factors; the bottom of the upper blood bag is conical; the top of the lower blood bag is conical; and the upper blood bag, the thin connecting pipe and the lower blood bag are formed into a dumbbell-shaped blood collecting bag. The cell and cell factor preparation method comprises the following steps of: introducing anti-coagulation blood, marrow and cord blood into the blood collecting bag, erecting the blood collecting bag on a hard sleeve, putting the hard sleeve into a centrifuge, and starting the centrifuge; separating the lower blood bag from the thin connecting pipe; fully mixing the plasma in the upper blood bag, and extracting the plasma in the upper blood bag for testing platelet concentration; reserving the plasma in the upper blood bag for later use; or centrifuging again to extract a plasma layer, and reserving centrifugally precipitated cells. The invention has the advantages of simplicity and convenience in operation, low loss of platelets, mononuclear cells and cell factors and high enrichment ratio, and obviously improves the safety and practicality.

Owner:ZHEJIANG XINGYUE BIOTECH

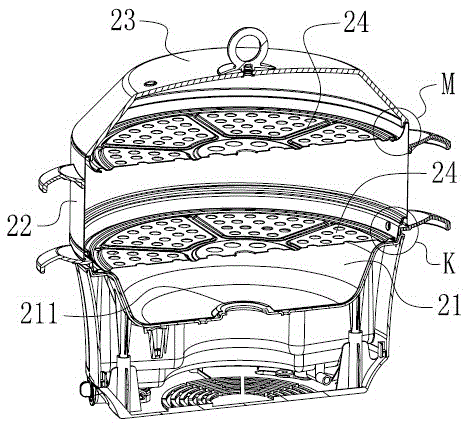

Micropressure steam hotpot

ActiveCN105615628AShorten the flow distanceReduce heat lossSteam cooking vesselsKitchen utensilsHeating efficiency

The invention relates to the technical field of kitchenware used for cooking food in steam and discloses a micropressure steam hotpot which comprises a base and a steamer placed on the base.A steam generator is arranged in the base, the steamer comprises a bottom pot and a pot cover, the steam generator comprises a shell, a steam outlet is arranged at the top of the shell, a pressure control valve blocks the steam outlet, a pressure control valve cover covers the steam outlet and covers the pressure control valve between the steam outlet and the top of the pressure control valve cover, the pressure control valve can move up and down, the pressure control valve cover is provided with steam flow holes, a through hole is formed in the bottom of the bottom pot, and after the steamer is placed on the base, the pressure control valve cover penetrates the through hole to extend into the bottom pot.The steam hotpot has effect of ejecting steam, thereby being conducive to the steamer to be quickly filled with the steam, and heating efficiency is improved.

Owner:BEIJING LIVEN SCI TECH

Preparation method of thermoplastic polyimide-based composite material structure member (cover)

The invention provides a preparation method of a thermoplastic polyimide-based composite material structure member (cover), which can be used for obviously improving the density and the toughness of products and forming an integrated skin cover member in one step. The method of the invention is realized by the following technical scheme comprising the steps of: at least laying one thermoplastic polyimide film the thickness of which is at least 0.001mm on the upper surface and the lower surface of carbon fiber or glass fiber fabric, and successively laminating the fiber fabric and the thermoplastic polyimide film in proportion; putting the laminated multilayer fiber fabric and the thermoplastic polyimide film into the skin part of a cover member mold cavity; adding thermoplastic polyimide-based chopped fiber composite material powder or granules at the reinforcing rib part of the mold cavity, and assembling the mold; after heating for 0.5-1 hour at300-400 DEG C on a molding press, applying 10-100MPa pressure , and keeping the pressure for 5-10 minutes; and then, cooling below 200 DEG C for demolding. The invention does not need to introduce solvents and has short cycle and low cost. The skin cover has light weight, high strength and high temperature resistance.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com