Method for manufacturing fiber-reinforced plastic product

A technology for reinforced plastics and fiber manufacturing, which is applied in the field of manufacturing fiber-reinforced plastic products, can solve problems such as implementation difficulties, dry glass fibers or white spots, and glass fiber air cannot be fully discharged, and achieves the effect of solving process and product quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

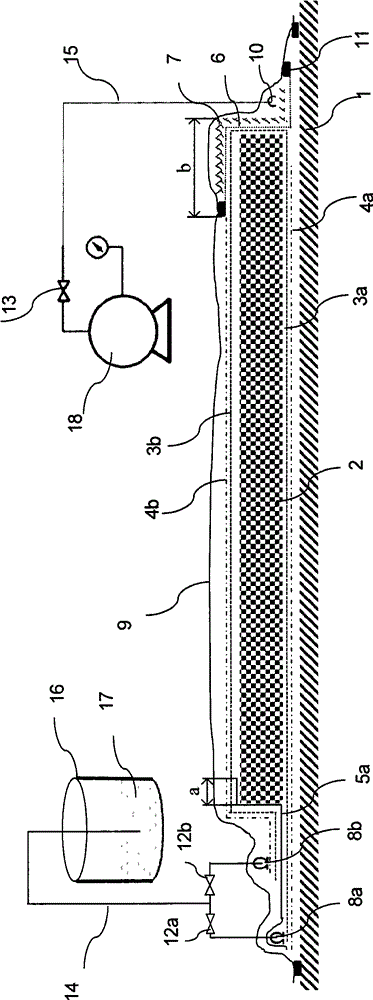

[0069] See figure 1 , which shows a first embodiment of the method of manufacturing a fiber-reinforced plastic article according to the invention.

[0070] The method for manufacturing fiber-reinforced plastic products disclosed in the present invention is especially suitable for fiber preforms that have a relatively large thickness or that are difficult for the resin to infiltrate. A fibrous preform that is difficult to fully wet through its entire thickness within a time period, depending on the nature of the resin used. In the present invention, the resin can be not only commonly used resins such as polyurethane resin and epoxy resin, but also any uncommon resin suitable for impregnating fiber preforms.

[0071] The steps of implementing the method for manufacturing fiber-reinforced plastic products according to the present invention using the above-mentioned system will be briefly described below.

[0072] (a) At first, lay the first or lower side guide net 4a on the mol...

no. 2 example

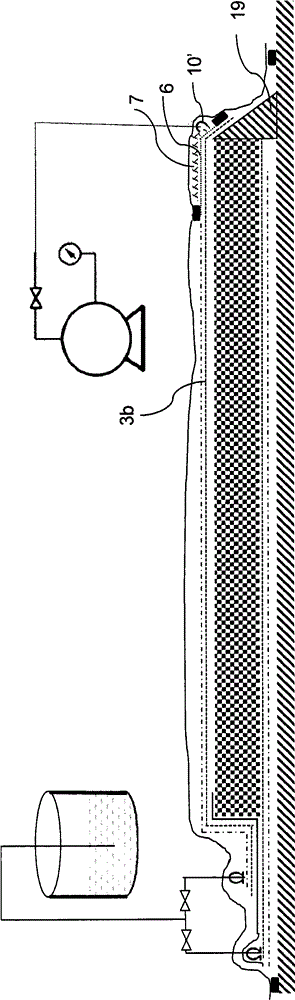

[0080] See figure 2 , which shows a second embodiment of the method of manufacturing a fiber-reinforced plastic article according to the invention.

[0081] Such as figure 2 As shown, a rib 19 is provided on the side of the mold 1 or the fiber preform 2 close to the gas extraction to replace the air felt 7 in the first embodiment. exist figure 2 In the above, the rib is triangular, but in practical applications, other appropriate shaped ribs are also optional.

[0082] Compared with the first embodiment, the second embodiment is except that the second release cloth 3b, the semi-permeable membrane 6 and the air felt 7 are laid on the sidewall 19 and the air suction port 10' is also arranged on the sidewall 19 , and the rest of the components are set in exactly the same way.

[0083]In the second embodiment, since the second release cloth 3b, the semi-permeable membrane 6 and the air felt 7 laid at the edge of the fiber preform 2 are replaced by the rib 19, the required s...

no. 3 example

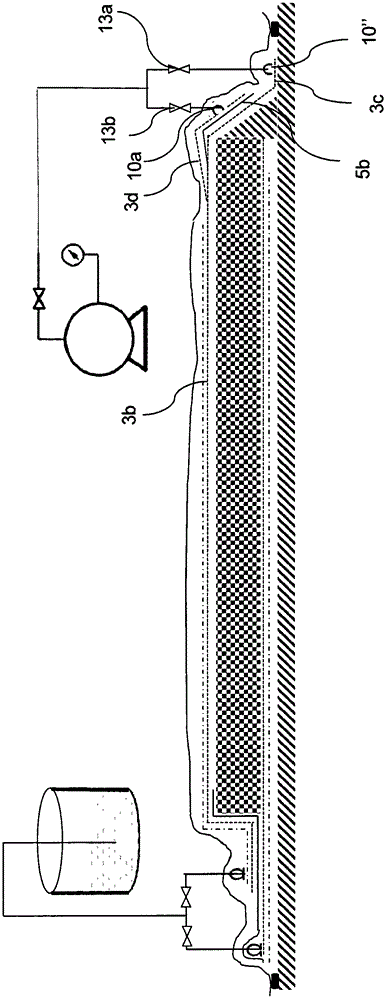

[0086] See image 3 , which shows a third embodiment of the method of manufacturing a fiber-reinforced plastic article according to the present invention.

[0087] On the basis of the step (c) of the second embodiment, it can be further extended to the sidewall 19 and the mold 1 when laying the second release cloth 3b to form a image 3 Release sheet extension 3c shown (in image 3 shown in dotted lines).

[0088] (d1) The air suction port 10 "is arranged above the release cloth extension section 3c, and partially or completely covers the release cloth extension section 3c and the air suction port 10" with the second film 5b and partially covers the fiber preform 2, which The width of the fiber preform to be covered may be 10% to 70% of the width of the area where the air guide net is not laid, preferably 20% to 50% of the width of the area where the air guide net is not laid.

[0089] (d2) Laying the third release cloth 3d on the second film 5b (in image 3 shown in dotte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com