Patents

Literature

82results about How to "Reduce flow time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

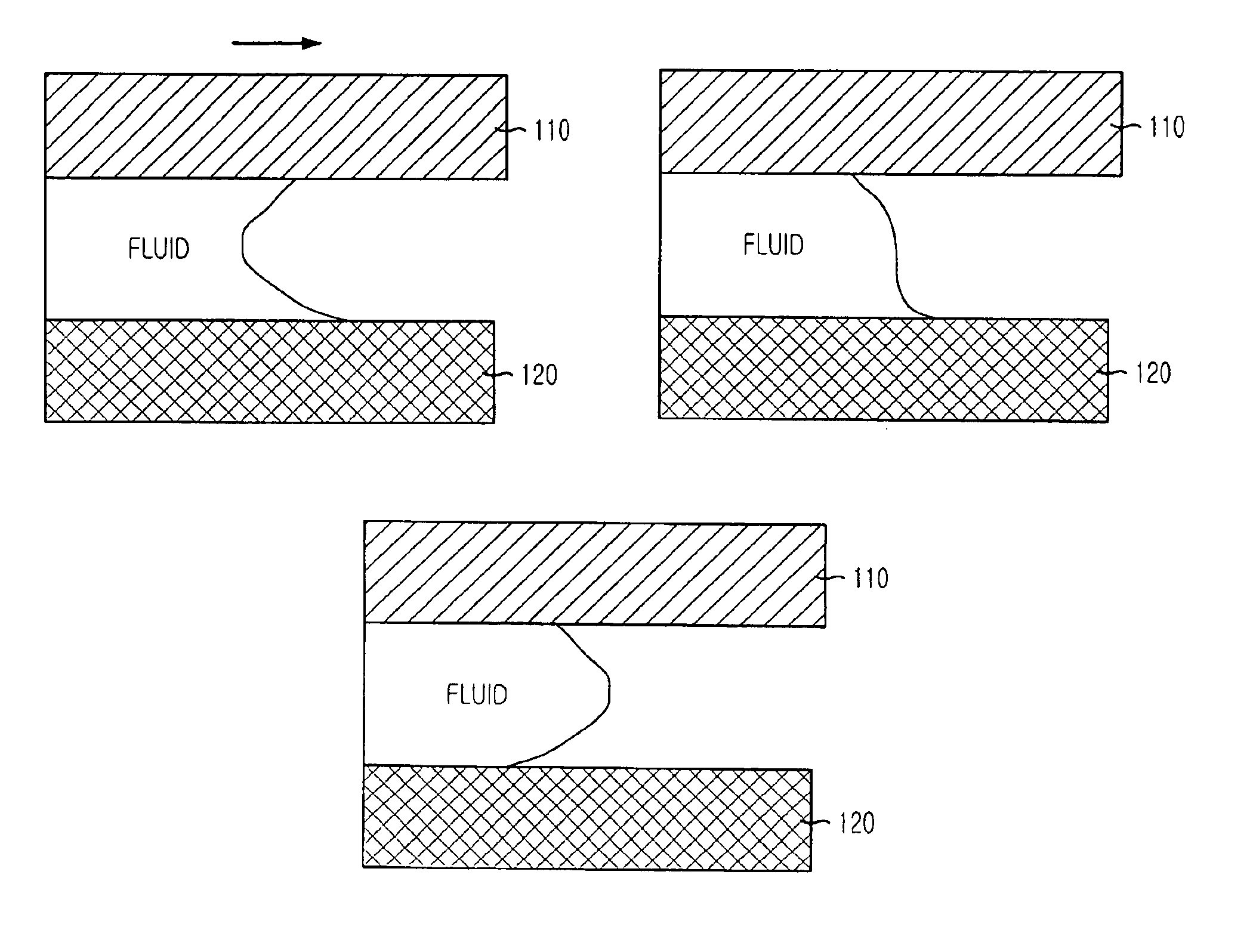

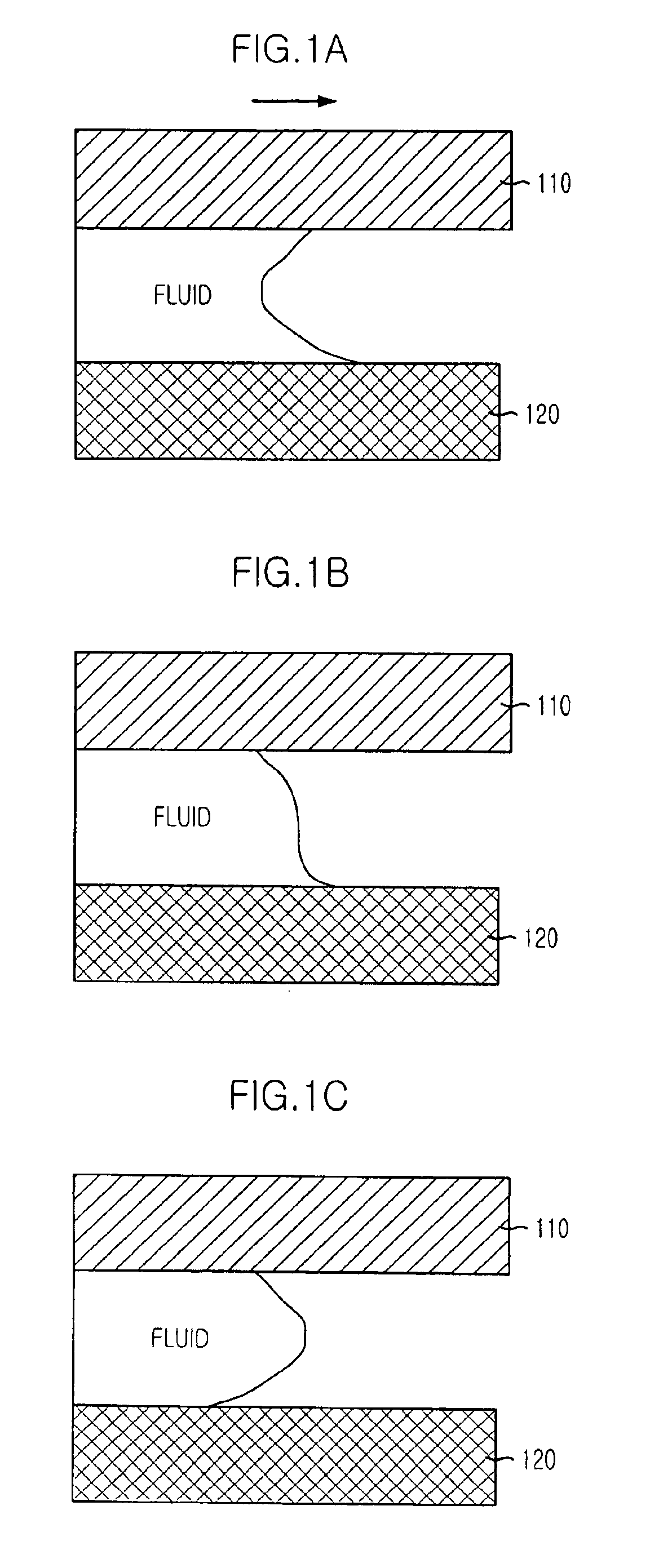

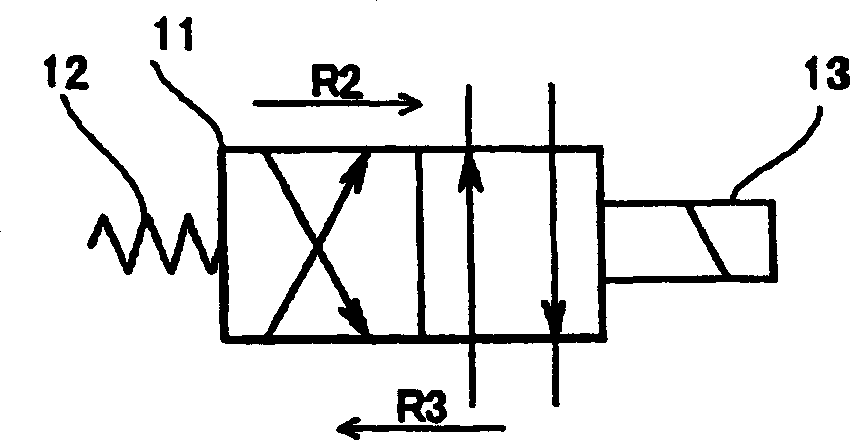

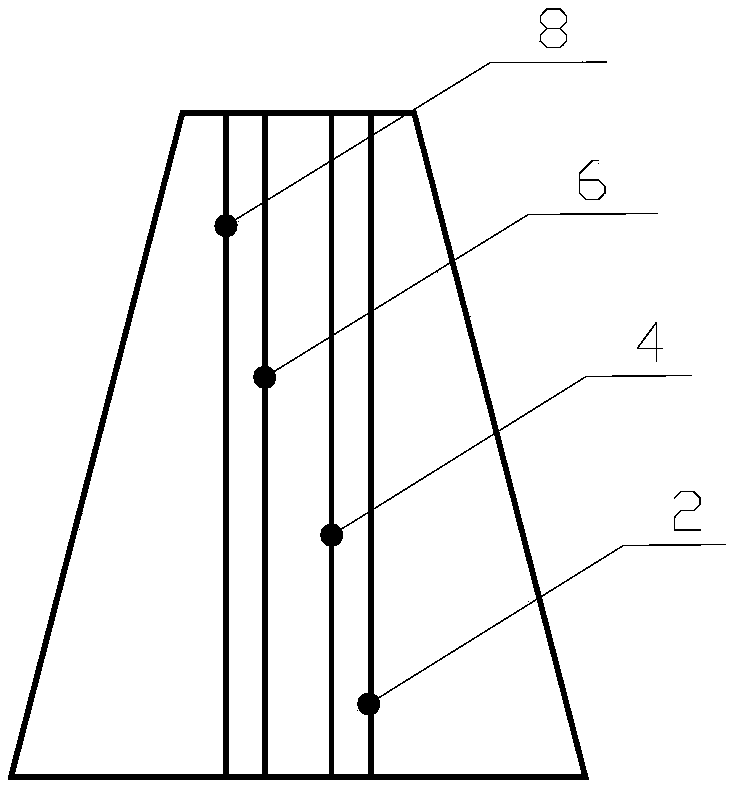

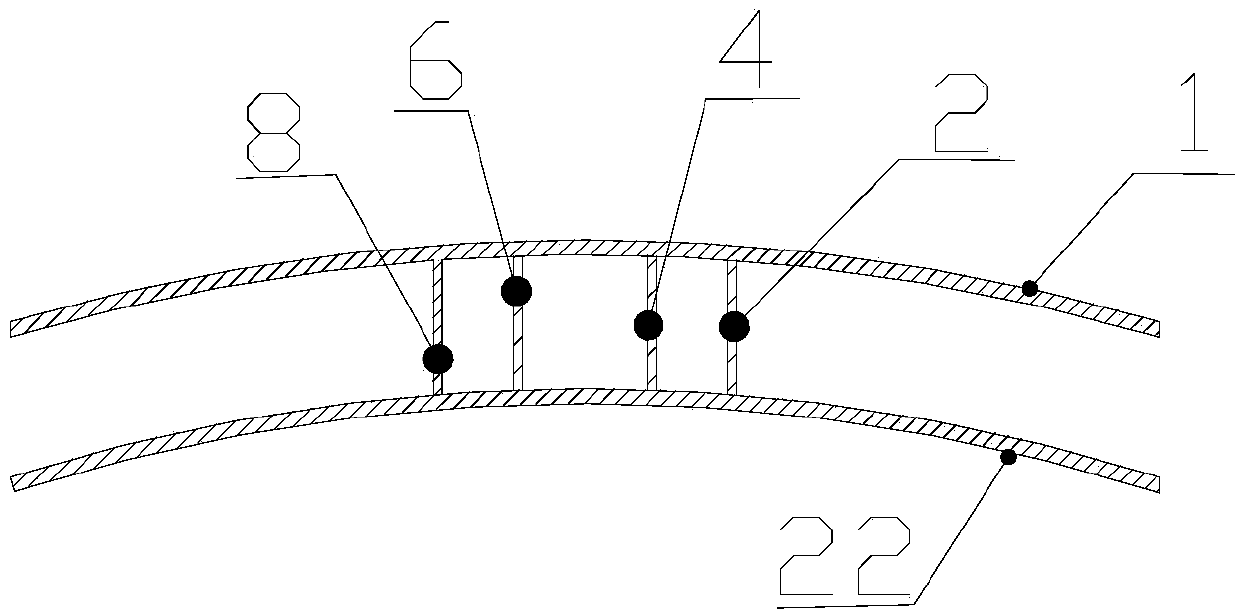

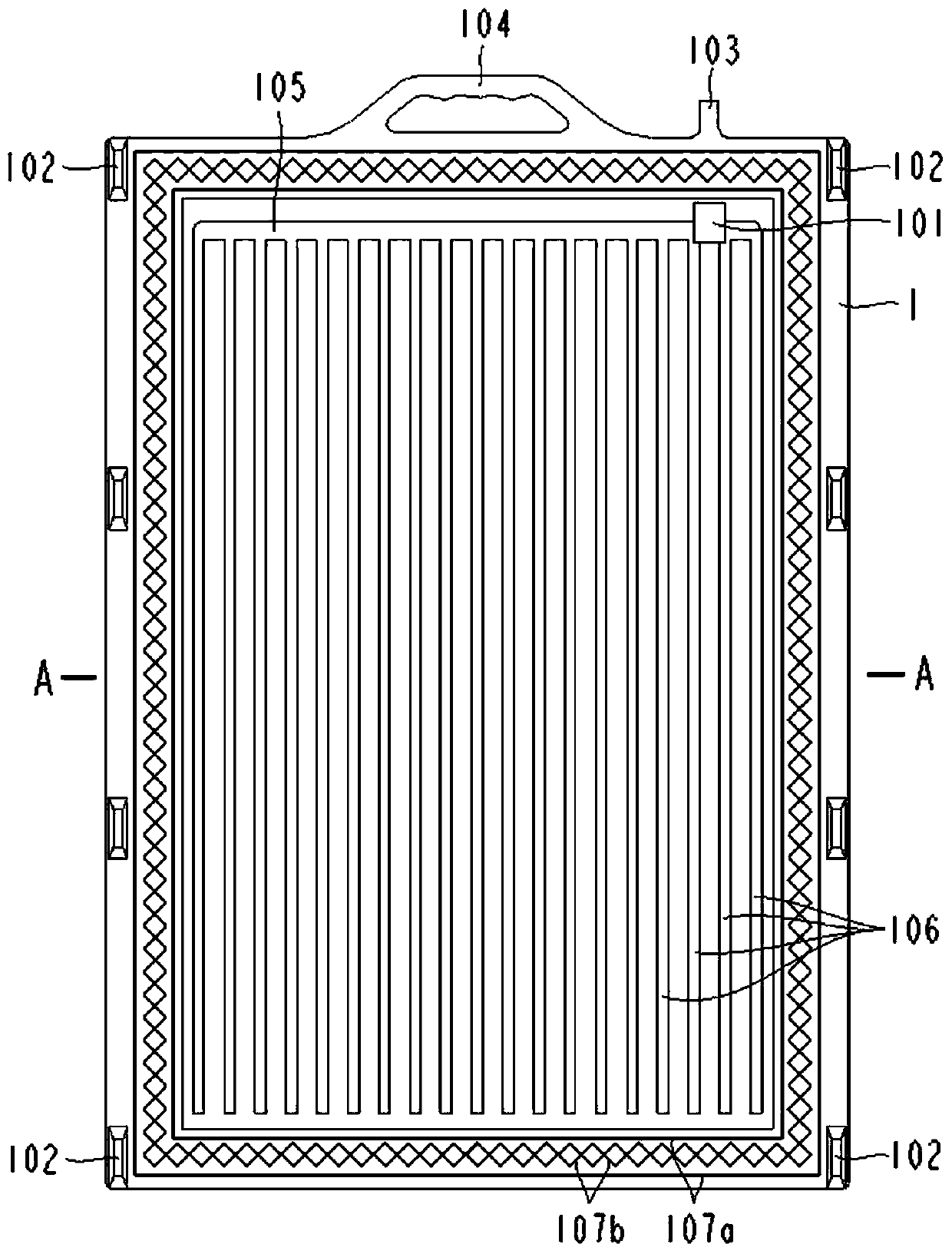

Micro fluidic device for controlling flow time of micro fluid

ActiveUS6901963B2Simple principleSimple structureAmpoule syringesCircuit elementsControl flowEngineering

Provided is a micro fluidic device that can control a flow time of micro fluid by using a capillary phenomenon. The micro fluidic device includes: a flow channel for flowing fluid, the flow channel being formed between a top substrate and a bottom substrate or between a top substrate, a bottom substrate, and a middle substrate; a flow blocking surface for stopping a flow of the fluid in the flow channel temporarily; and a hump for delaying the flow formed in the line of continuity with the flow blocking surface. The micro fluidic device of the present research can control the flow time in a simple manner.

Owner:INTELLECTUAL DISCOVERY CO LTD

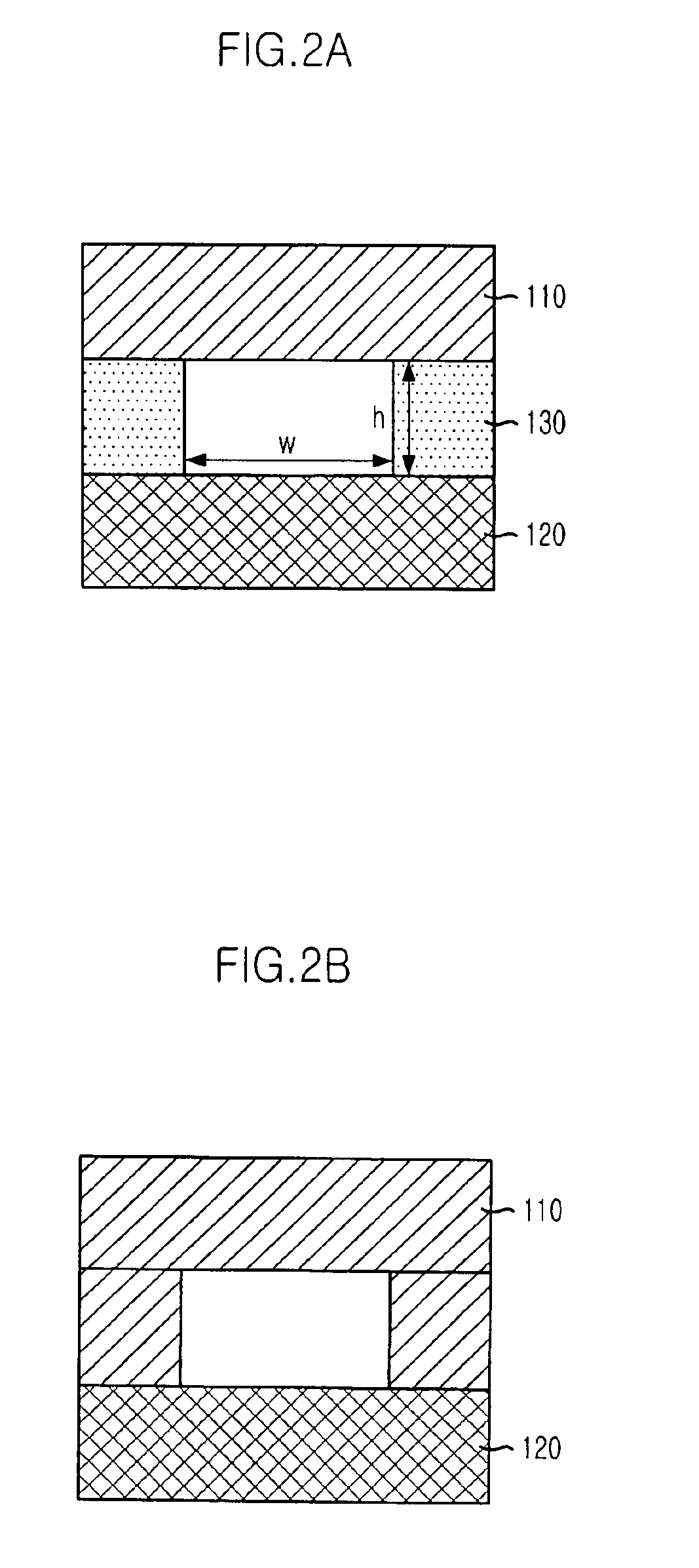

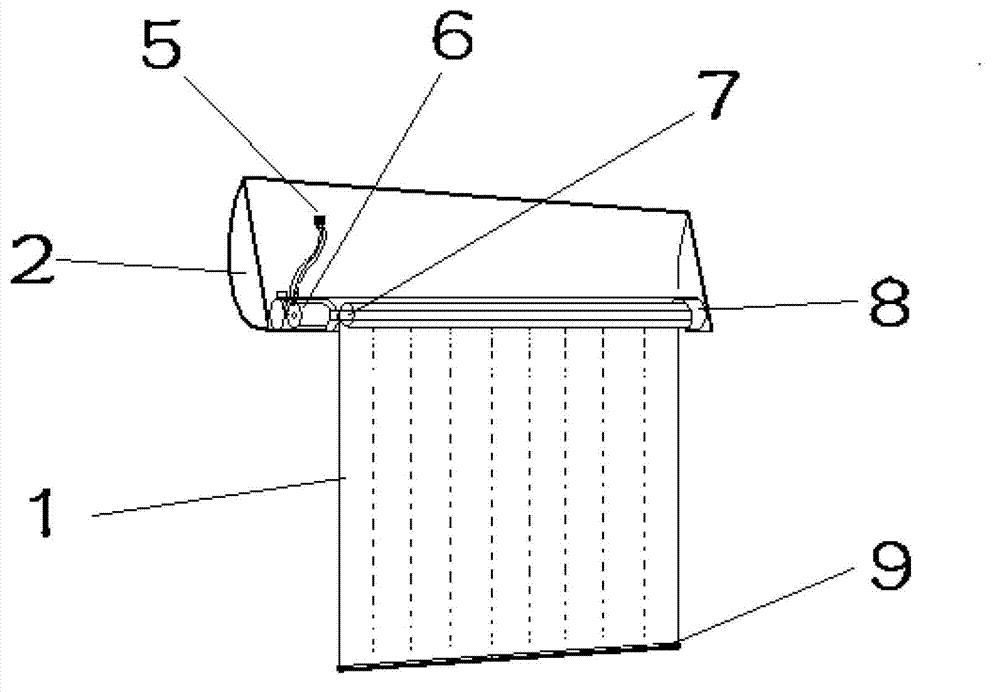

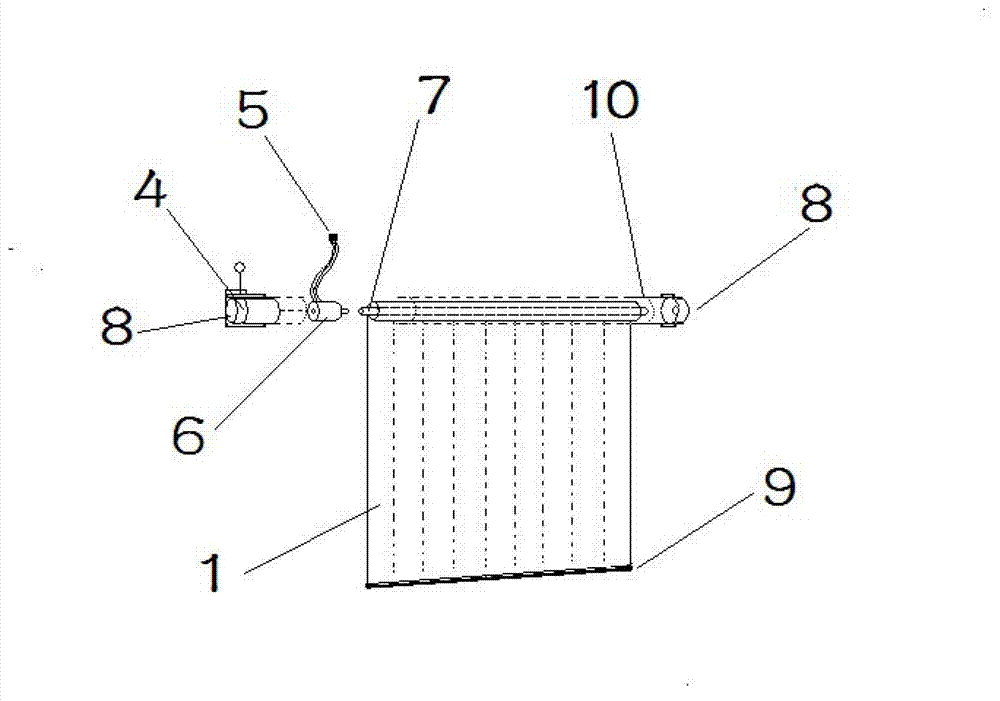

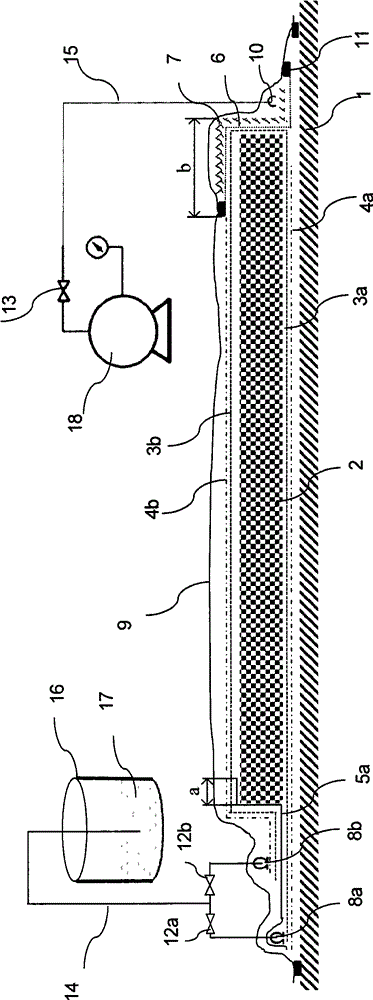

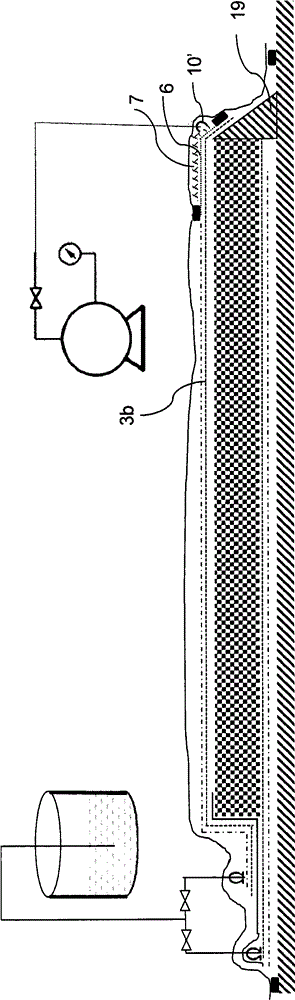

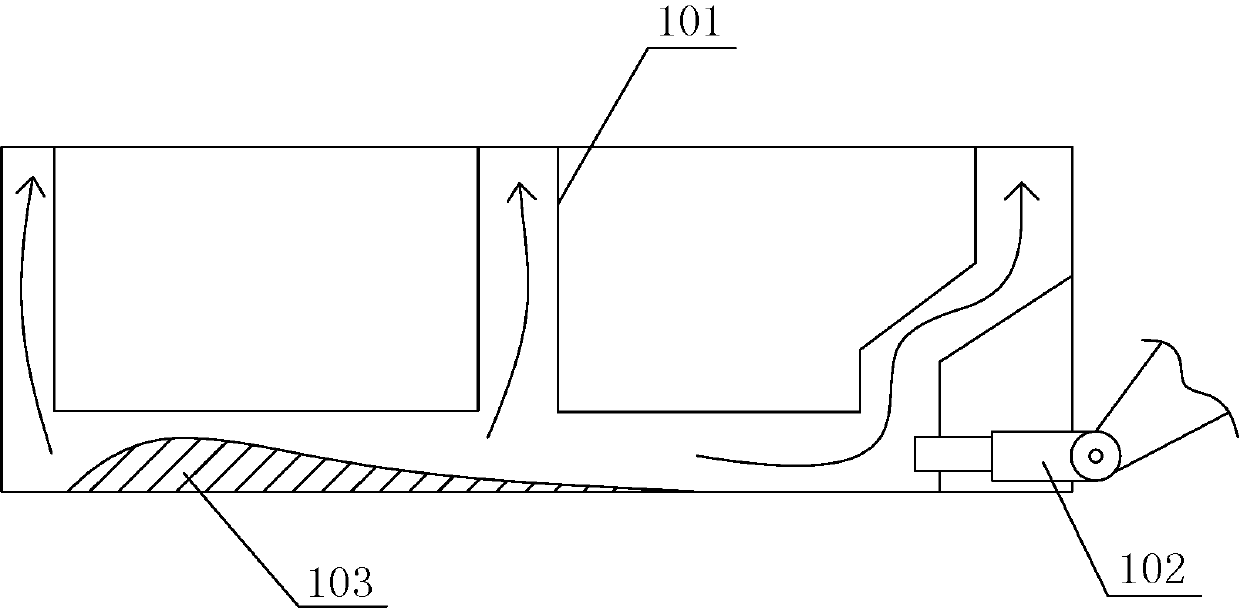

Air guide curtain of air conditioner

InactiveCN102967038AChange the air supply modeReduce flow timeSpace heating and ventilation safety systemsLighting and heating apparatusCold airSynchronous motor

The invention discloses an air guide curtain of an air conditioner. The air guide curtain is characterized in that one side of air curtain cloth of the air guide curtain is connected with a rolling blind shaft, and the other side of the air curtain cloth is connected with a curtain falling rod; one side of the rolling blind shaft is connected with a synchronous motor and is arranged in a rolling blind permanent seat on a left side, and the other side of the rolling blind shaft is arranged in a bearing connected in a rolling blind permanent seat on a right side and is arranged inside or outside an indoor unit surface cover through a rolling blind box; a left rolling blind permanent seat and a right rolling blind permanent seat are arranged; and a motor arranged in a controller is used for controlling a singlechip switch and a limiting switch, and is packaged in the left rolling blind permanent seat together with a receiving head. The air guide curtain of the air conditioner is simple in structure, and is easy to mount; functions of automatically starting up for falling the curtain during heating of the air conditioner and shutting down for rolling the curtain are designed, so that the conventional air supply mode of the air conditioner is changed; and an air deflector is prolonged through the air curtain cloth, so that hot air is guided to be lower side, cold air feel in a certain distance under the condition that central heating is started up in winter is avoided, the indoor temperature distribution is more uniform, and air-conditioning diseases are reduced.

Owner:谢逢华

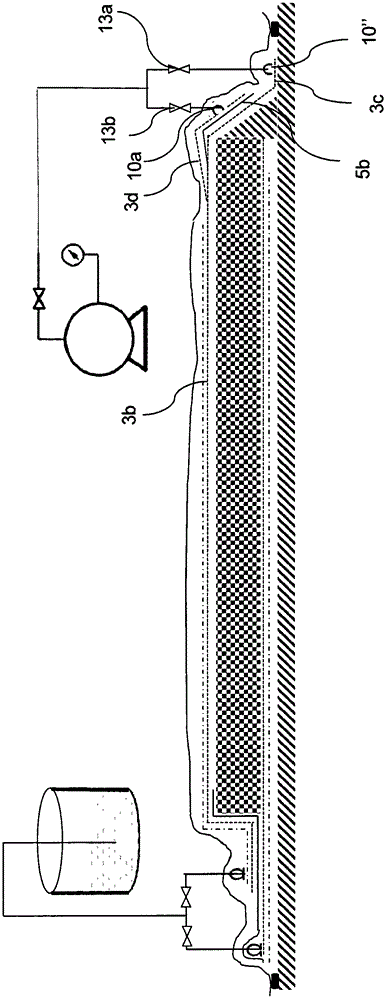

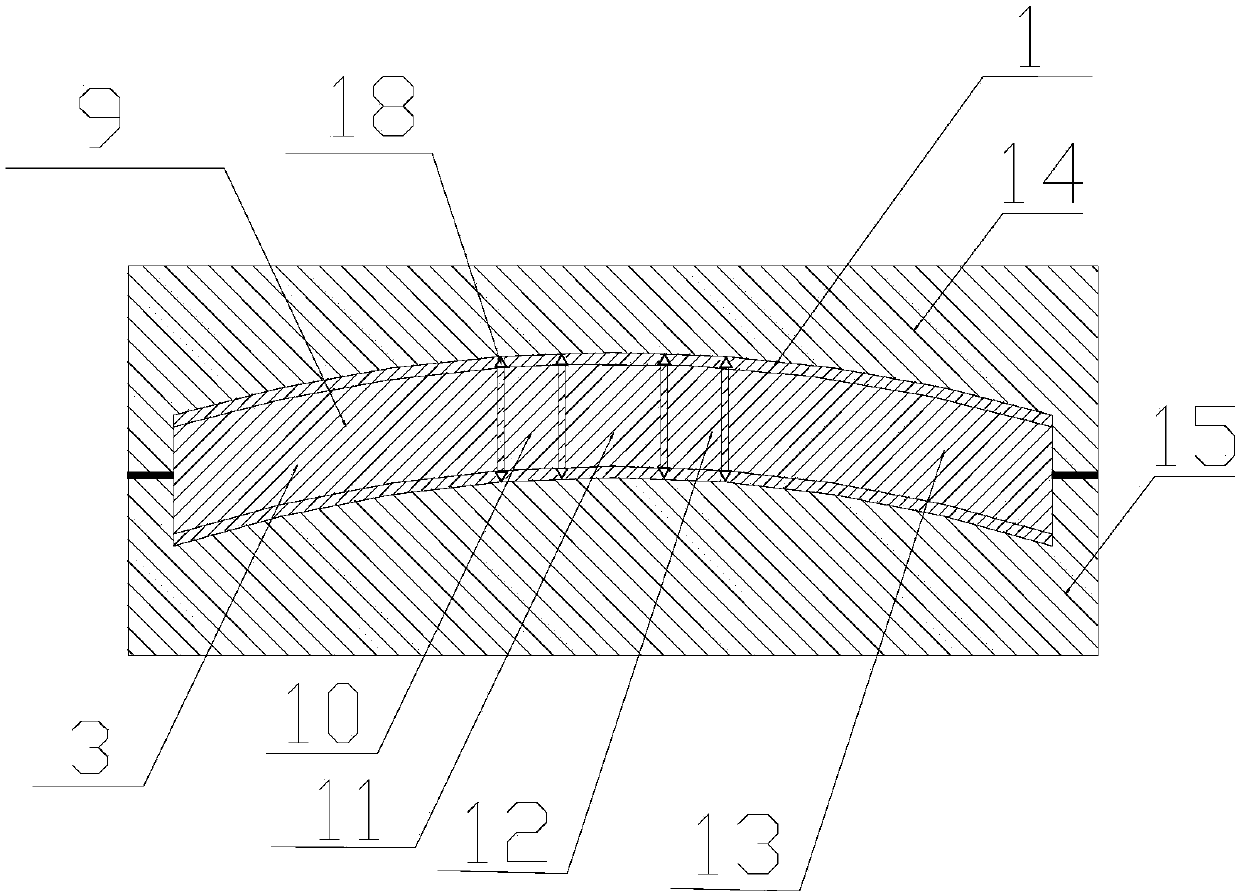

Method for manufacturing fiber-reinforced plastic product

ActiveCN106142593AShorten the flow distanceReduce flow timeMechanical engineeringFiber reinforcement

The invention relates to a method for producing a fiber-reinforced plastic product. The method for producing the fiber-reinforced plastic product comprises the following steps that a fiber preform is prepared on a mold; a first flow guide net, a second flow guide net, a first piece of demolding cloth and a second piece of demolding cloth are laid for the fiber preform; the fiber preform is sealed and made into a vacuum system through air extraction; resin is made to permeate the first piece of demolding cloth and soak the fiber preform from bottom to top by means of the first flow guide net; the resin is made to permeate the second piece of demolding cloth and soak the fiber preform from top to bottom by means of the second flow guide net; and the fiber preform soaked with the resin is obtained, and the fiber-reinforced plastic product is obtained finally. The method for producing the fiber-reinforced plastic product is characterized in that a first film is arranged on the side, close to the resin injection position, of the fiber preform so as to cover at least part of the first piece of demolding cloth, the first flow guide net and the fiber preform, and after the resin is supplied to the first flow guide net, the resin is supplied to the second flow guide net when the flowing area of the resin on the fiber preform is beyond the area covered by the first film.

Owner:COVESTRO DEUTSCHLAND AG

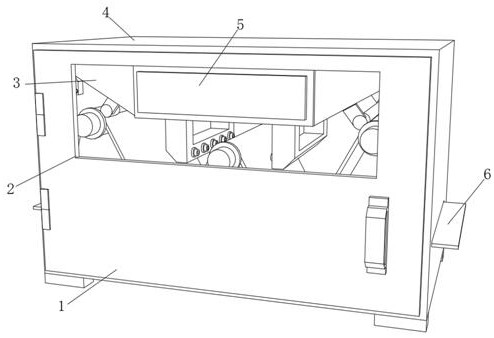

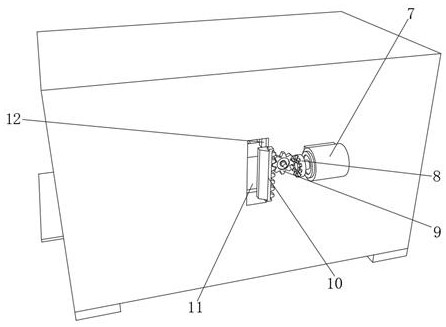

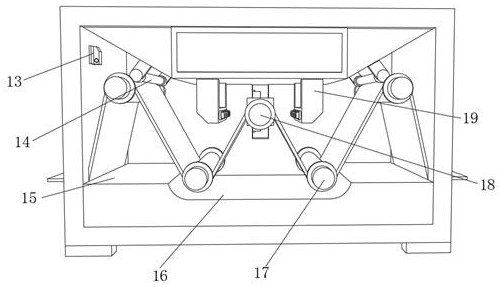

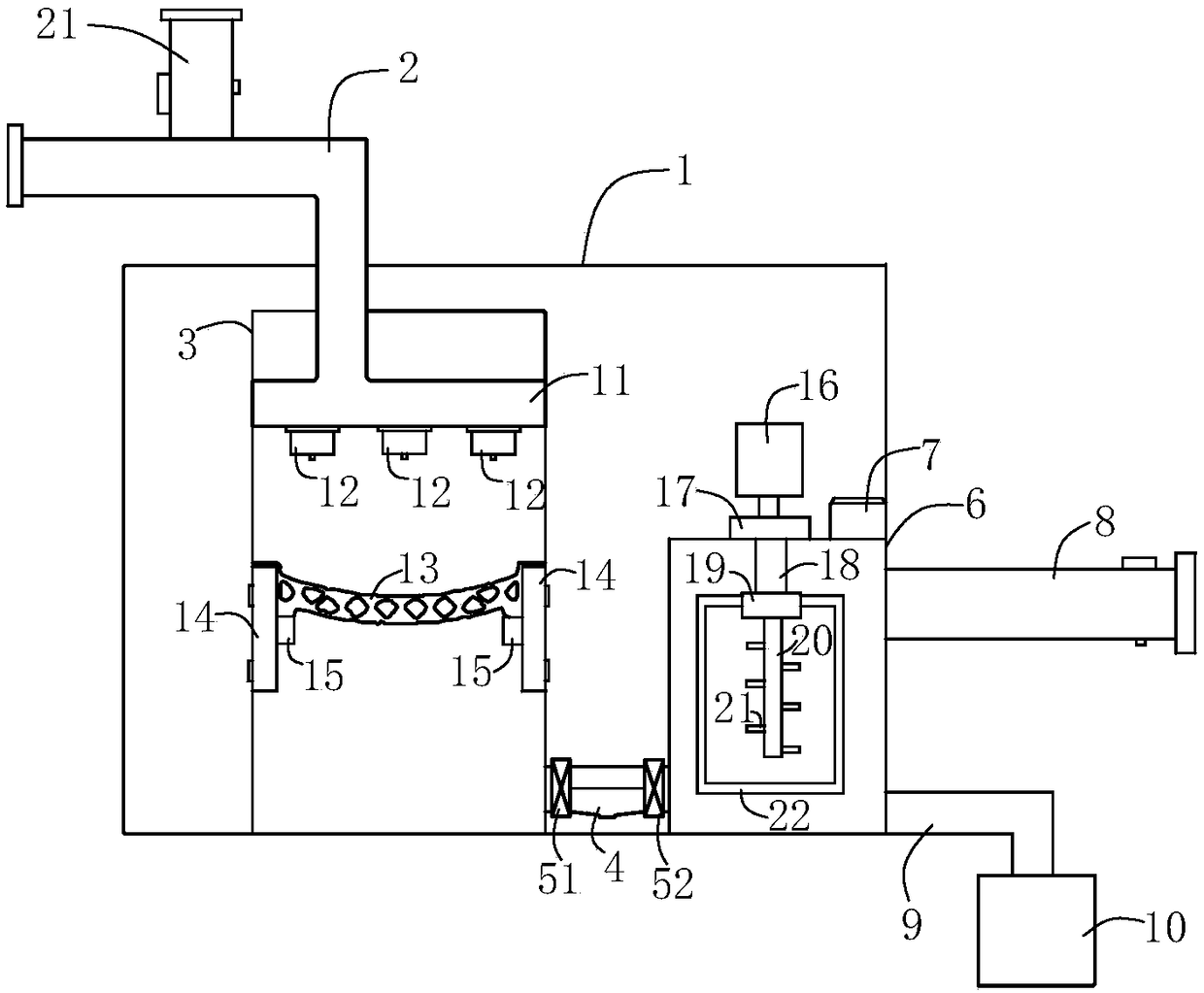

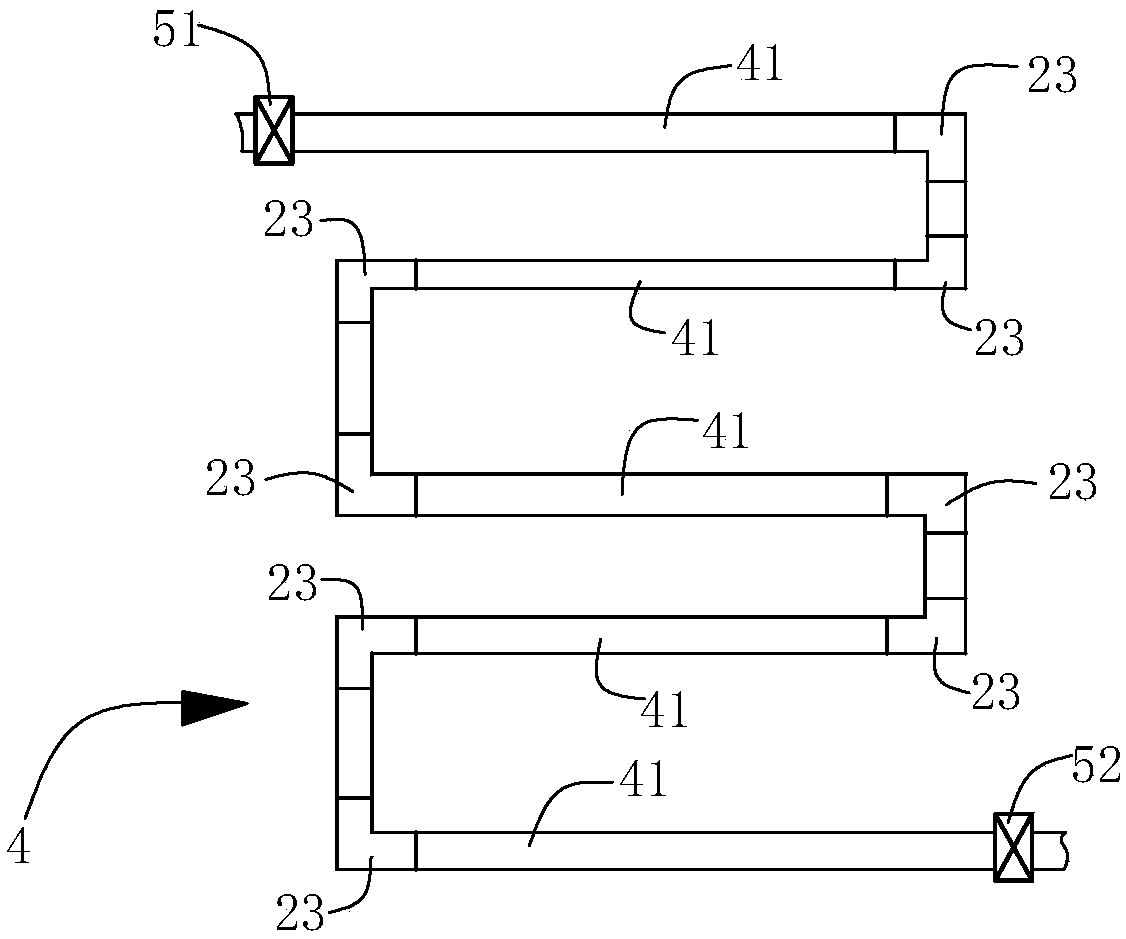

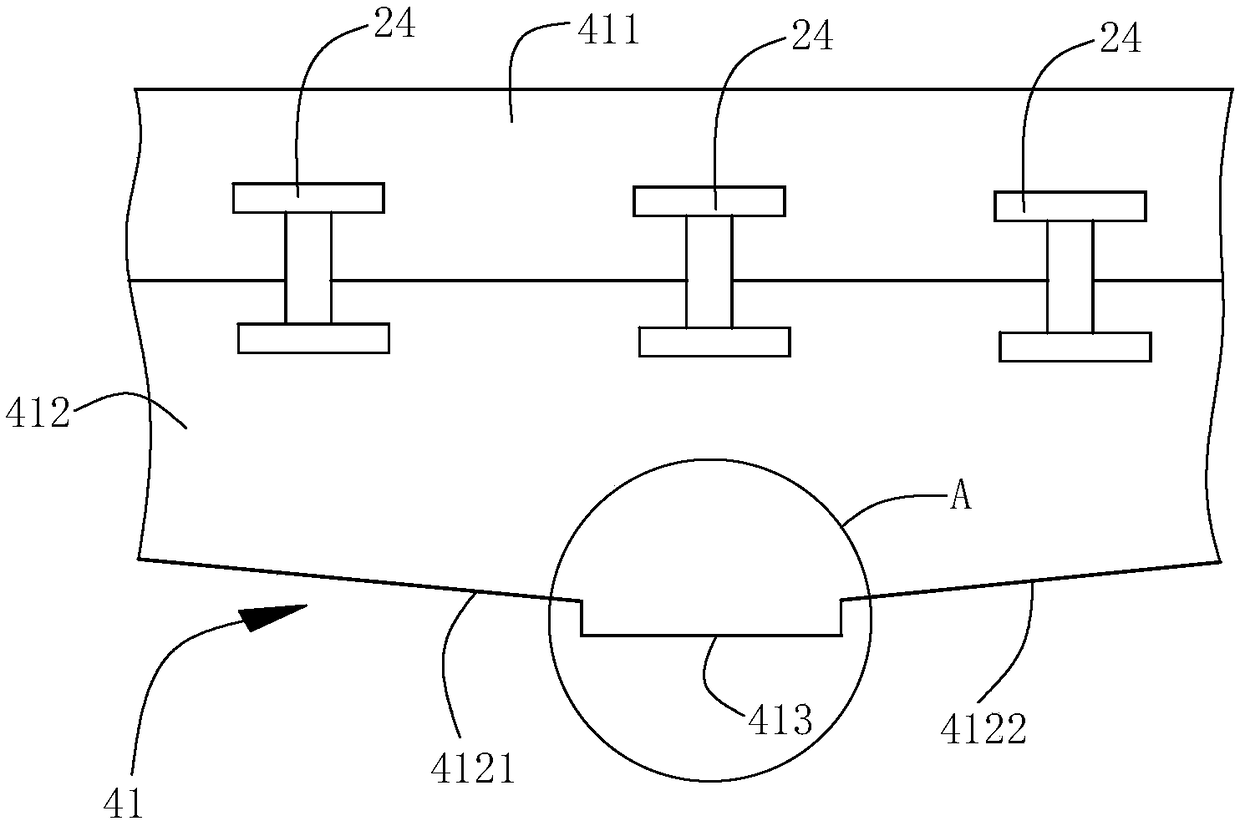

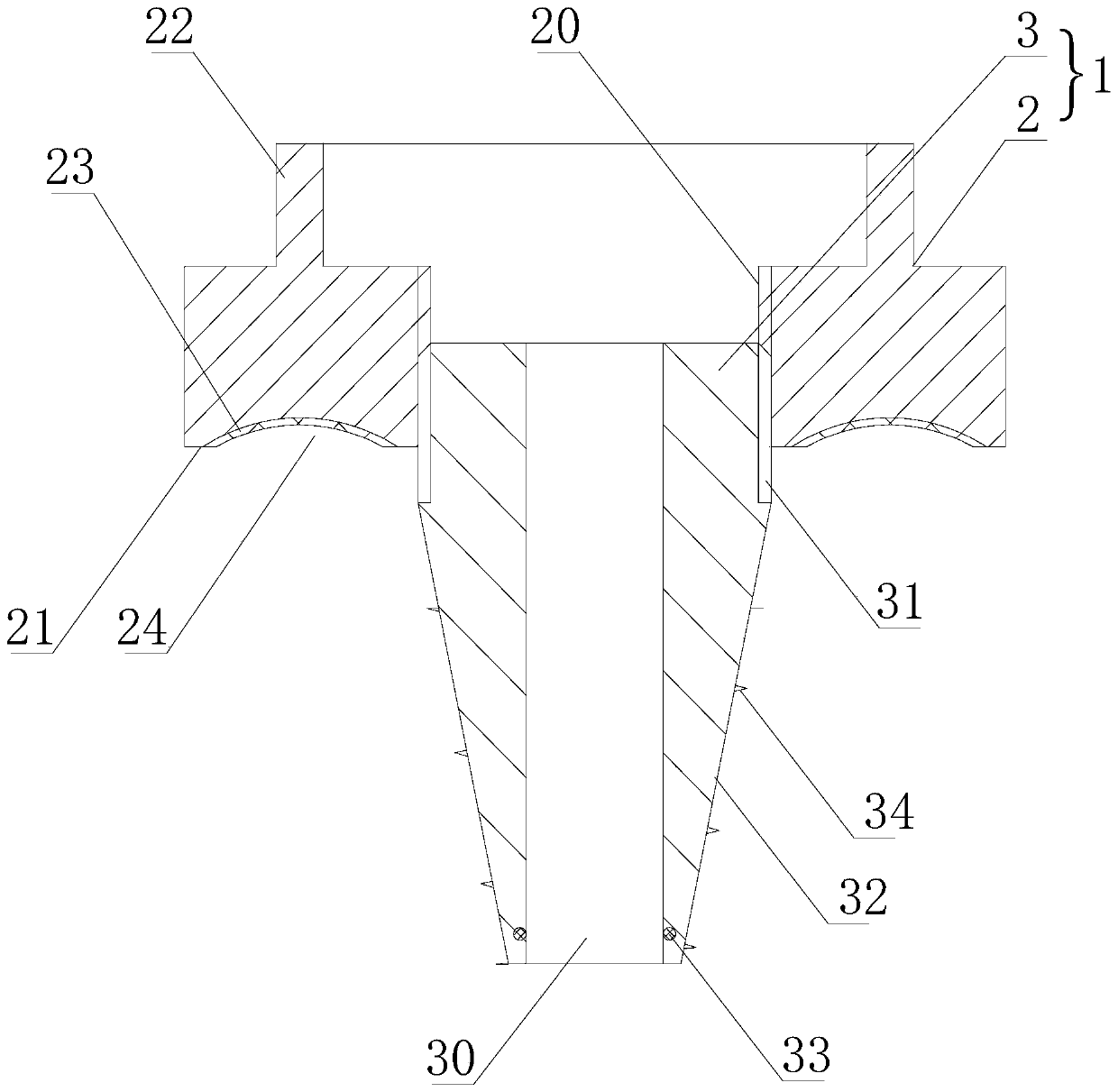

Vacuum-induction centrifugal casting device and titanium alloy casting method

The invention discloses a vacuum-induction centrifugal casting device comprising a furnace body, wherein the upper end of the furnace body is provided with a furnace cover, a smelting cavity and a centrifugal casting cavity are symmetrically arranged in the furnace body, a smelting device is arranged in the smelting cavity, a centrifugal heating and casting device is arranged in the centrifugal casting cavity, and an overturning space for the smelting device is respectively arranged between the upper parts of the smelting cavity and the centrifugal casting cavity and the furnace cover. The invention further discloses a titanium alloy casting method by utilizing the vacuum-induction centrifugal casting device, wherein the titanium alloy casting method comprises the following steps that after titanium alloy is molten into liquid metal in a crucible, the crucible is overturned so that the liquid metal flows into a rotating casting liner, and a heating and heat-insulating device is further mounted outside the casting liner, finally a thin-wall titanium alloy casting is obtained. The vacuum-induction centrifugal casting device disclosed by the invention can cast flawless-surface thin-wall metal components.

Owner:XI'AN POLYTECHNIC UNIVERSITY

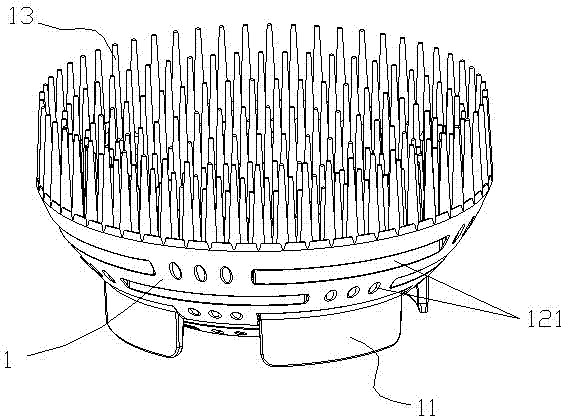

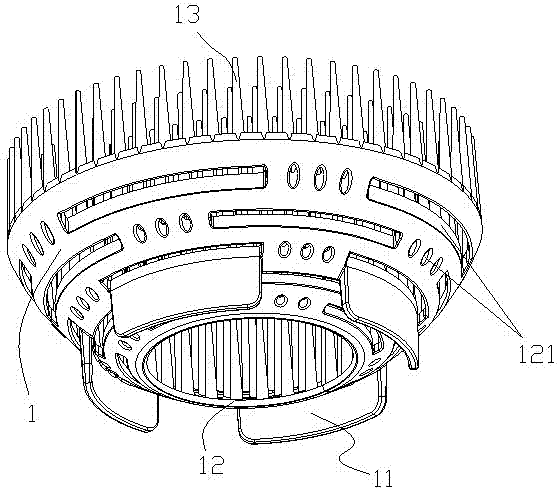

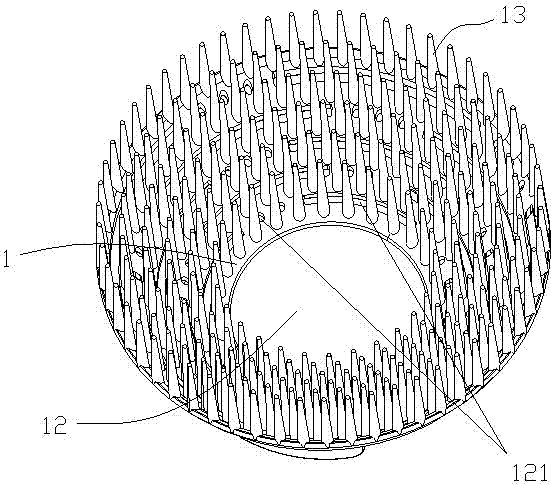

Gentleman urinal splash prevention device

The invention discloses a gentleman urinal splash prevention device which comprises a base, wherein splash prevention teeth are densely arranged on the base. The whole gentleman urinal splash prevention device has the characteristics of simple structure, good effect of splash prevention, no urine residue and avoidance of peculiar smells, and has good popularization benefits.

Owner:TAIZHOU QIBANG IND DESIGN

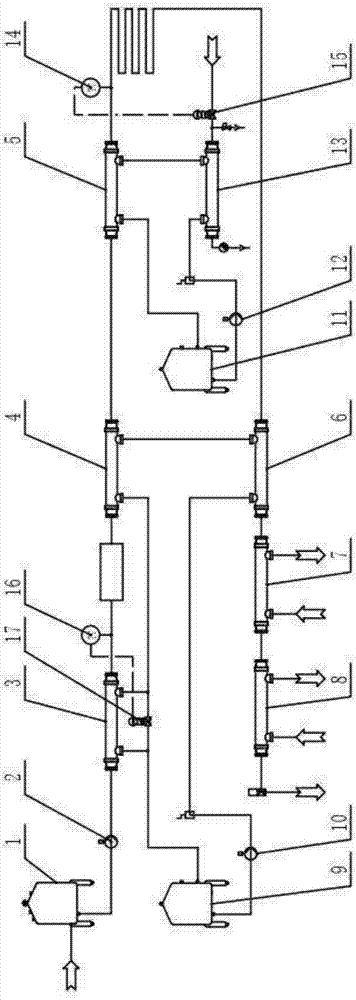

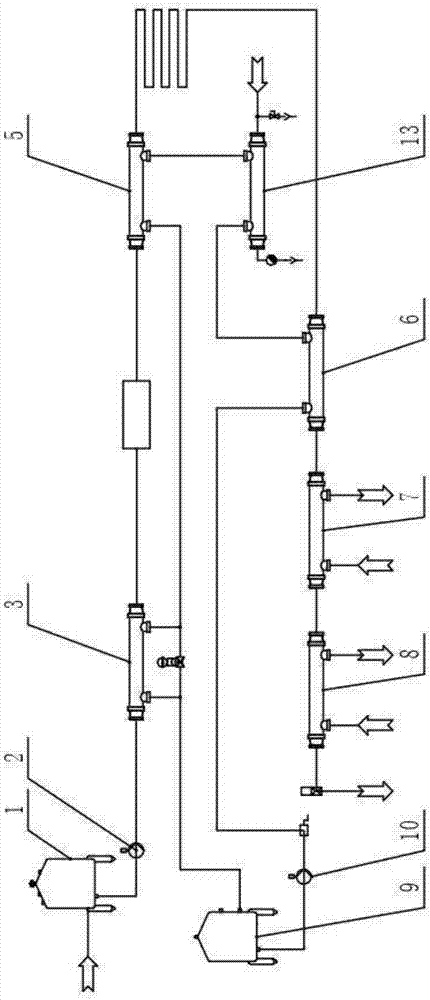

Tube-type UHT high heat recovery rate hot water heat exchange system

PendingCN106865862AReduce consumptionReduce heat transfer areaMultistage water/sewage treatmentWater/sewage treatment by heatingThermodynamicsIce water

The invention relates to a tube-type UHT high heat recovery rate hot water heat exchange system. In a product pipe, a balance tank, a product pump, a degassing section, a heating section, a sterilization section, a heat recovery section, a tower water cooling section and an ice water cooling section are orderly arranged in the product pipe from an inlet to an outlet. A hot water pipe comprises a heat recovery section hot water circulation part and a sterilization hot water circulation part. The heat recovery section hot water circulation part orderly comprises a cooling hot water tank and a cooling hot water pump and the hot water orderly flows through a heat recovery section, a heating section and a degassing section and finally returns to the cooling hot water tank. The sterilization hot water circulation part orderly comprises a sterilization hot water tank, a sterilization hot water pump and a steam section and the hot water flows through the sterilization section and finally returns back to the sterilization hot water tank. Through a reasonable flow ratio of hot water to product, a high heat recovery rate is obtained.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

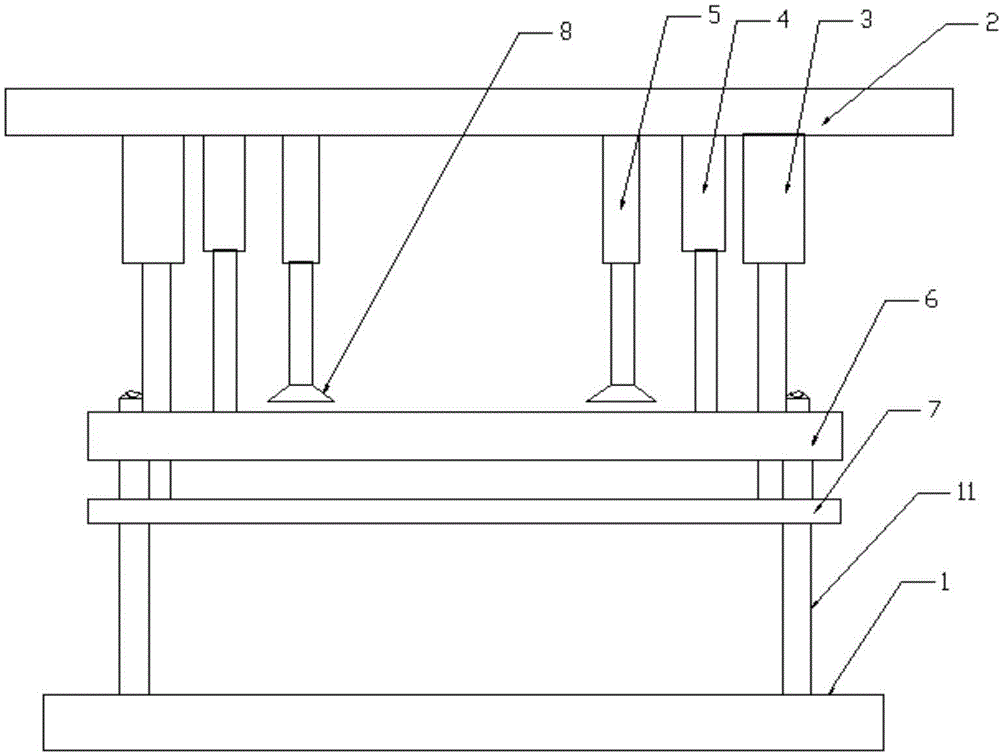

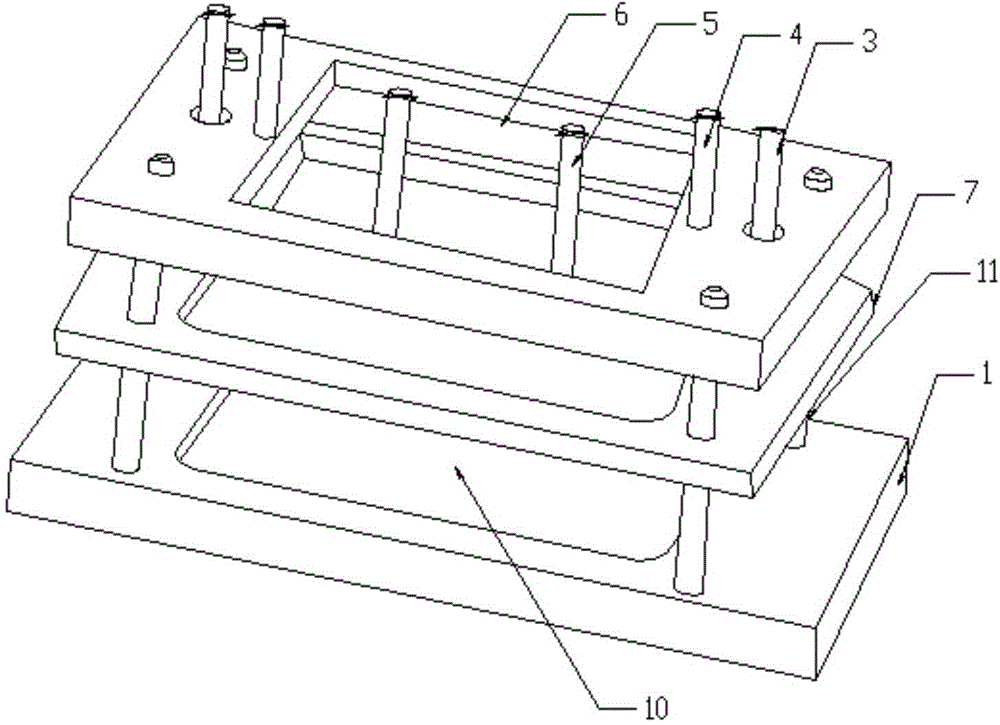

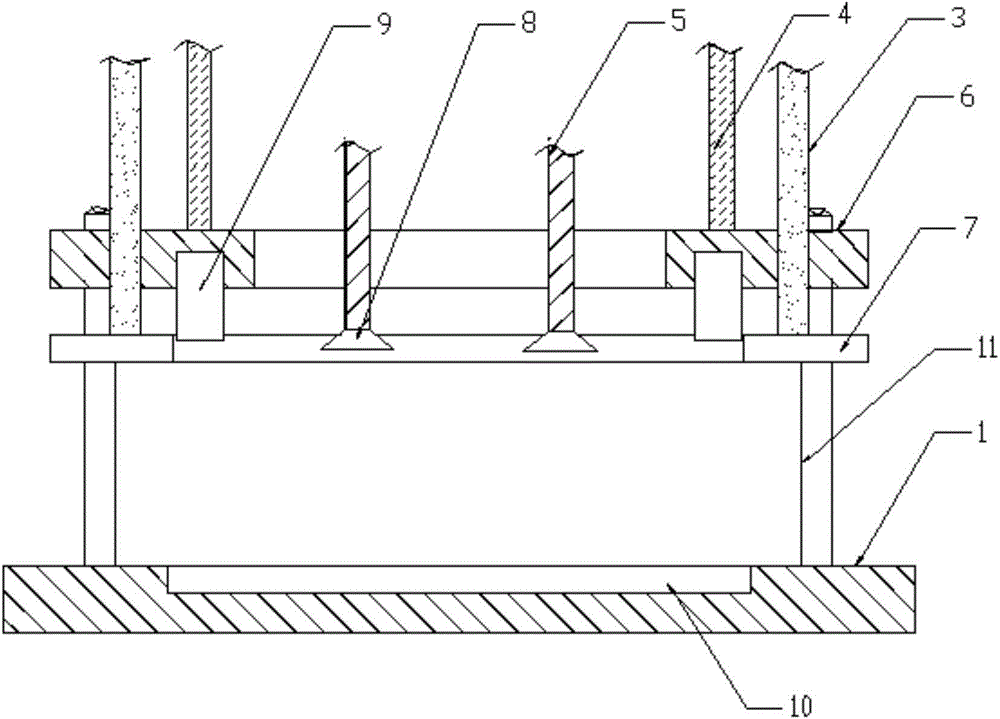

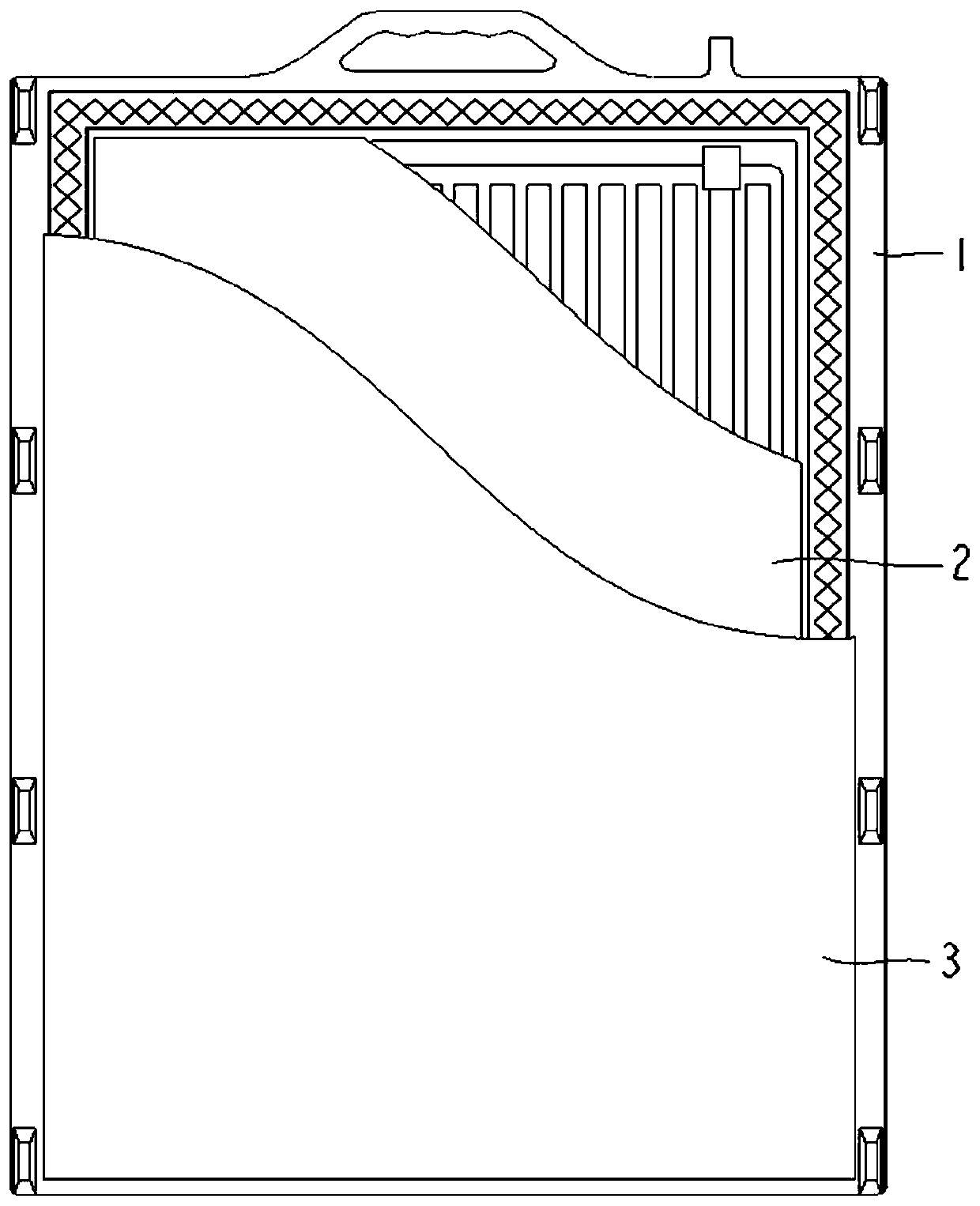

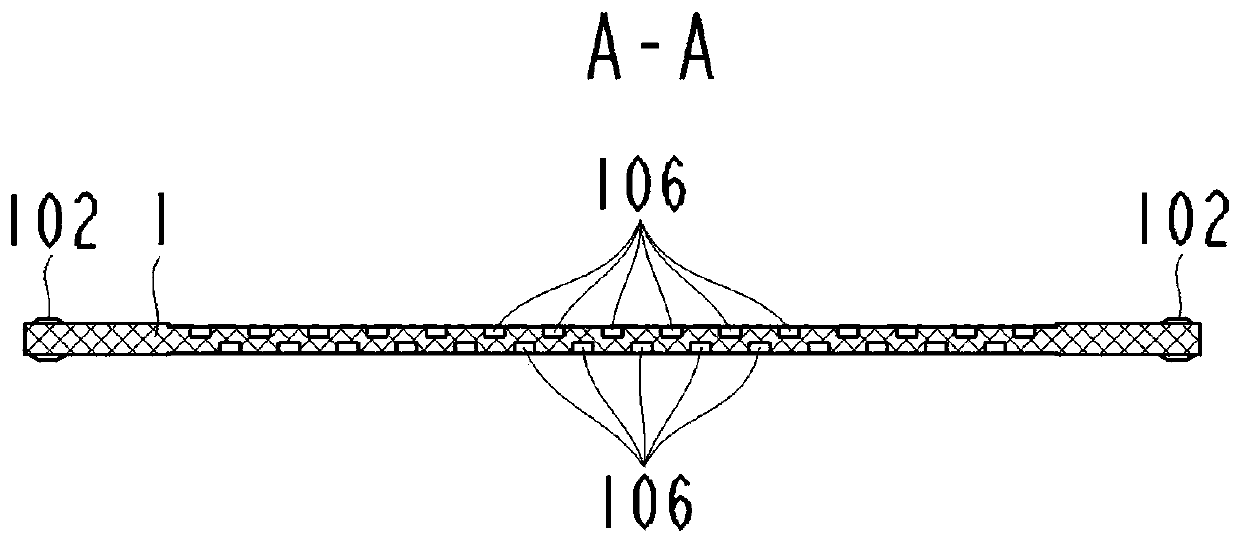

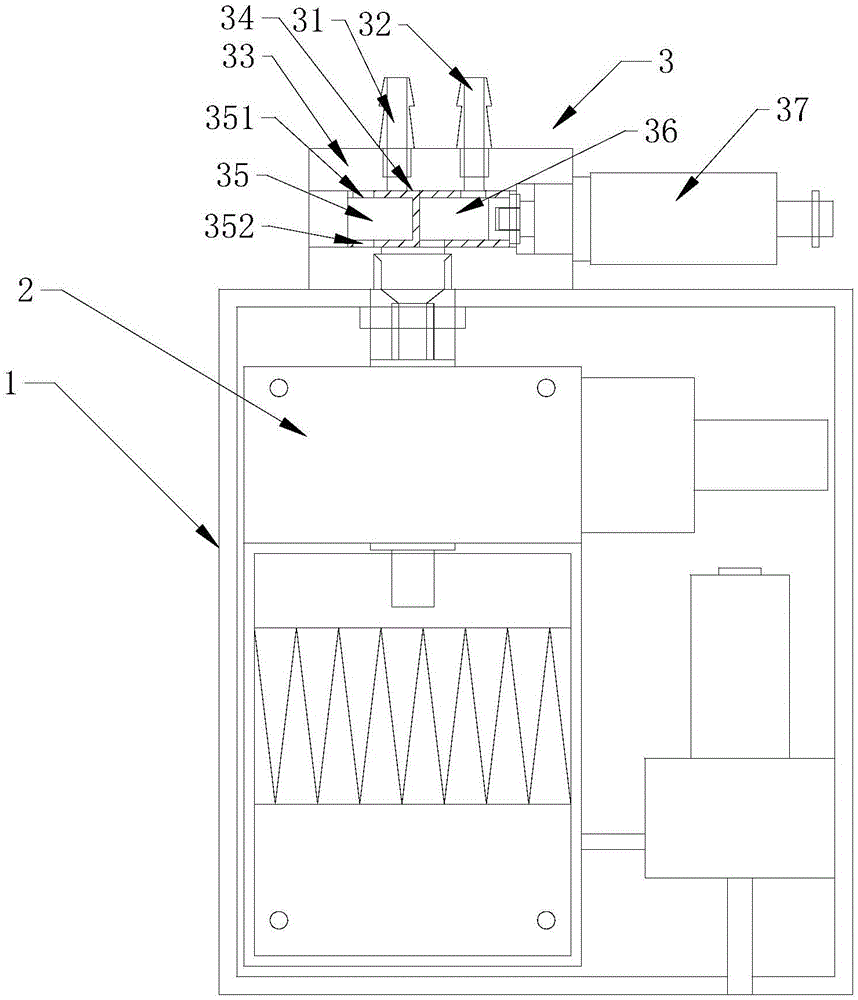

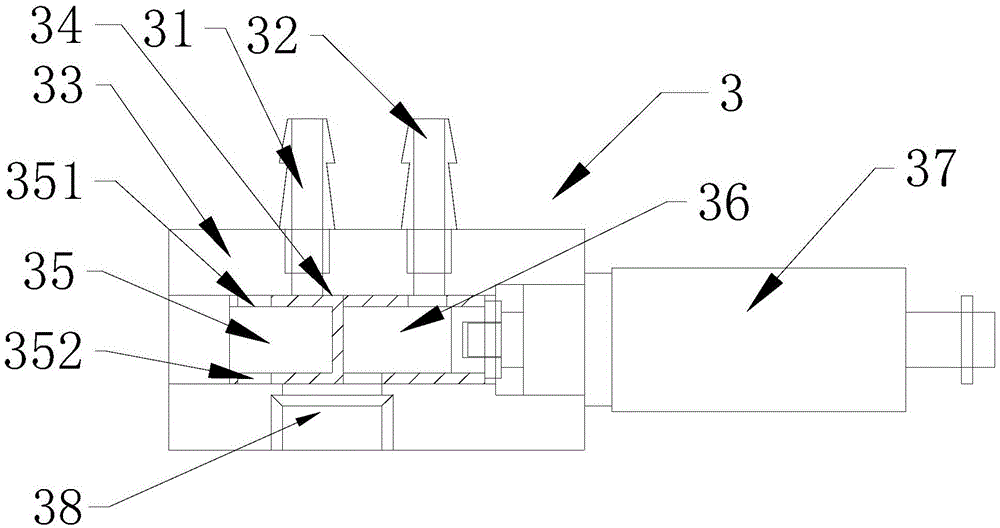

Automatic assembling pressure-closing device for touch screen and control method thereof

ActiveCN104526309AImprove production stabilityStable product quality controlMetal working apparatusSurface mountingTouchscreen

The invention discloses an automatic assembling pressure-closing device for a touch screen and a control method of the automatic assembling pressure-closing device. The device comprises a base for positioning a rear cover of a product to be assembled, and a cantilever on which a first driving mechanism, a second driving mechanism and a third driving mechanism are mounted; a pressure-closing plate is connected to the lower end of the first driving mechanism; the second driving mechanism passes through the pressure-closing plate to be connected with a clearance control plate, wherein the clearance control plate is used for positioning a clearance control sheet between the rear cover of the product to be assembled and the touch screen; the third driving mechanism is connected with a chuck for attaching the touch screen; openings for conveying the touch screen are formed in the pressure-closing plate and the clearance control plate; a pressing head for performing pressure-closing for the touch screen is arranged on the lower surface of the pressure-closing plate. The device has the beneficial effects that the operation is simple, the automation degree is high, and the product quality is stable to control; the surface mounting operation of a touch panel and the pressure-closing operation are integrated, so that the production is sped up.

Owner:重庆蓝岸科技股份有限公司

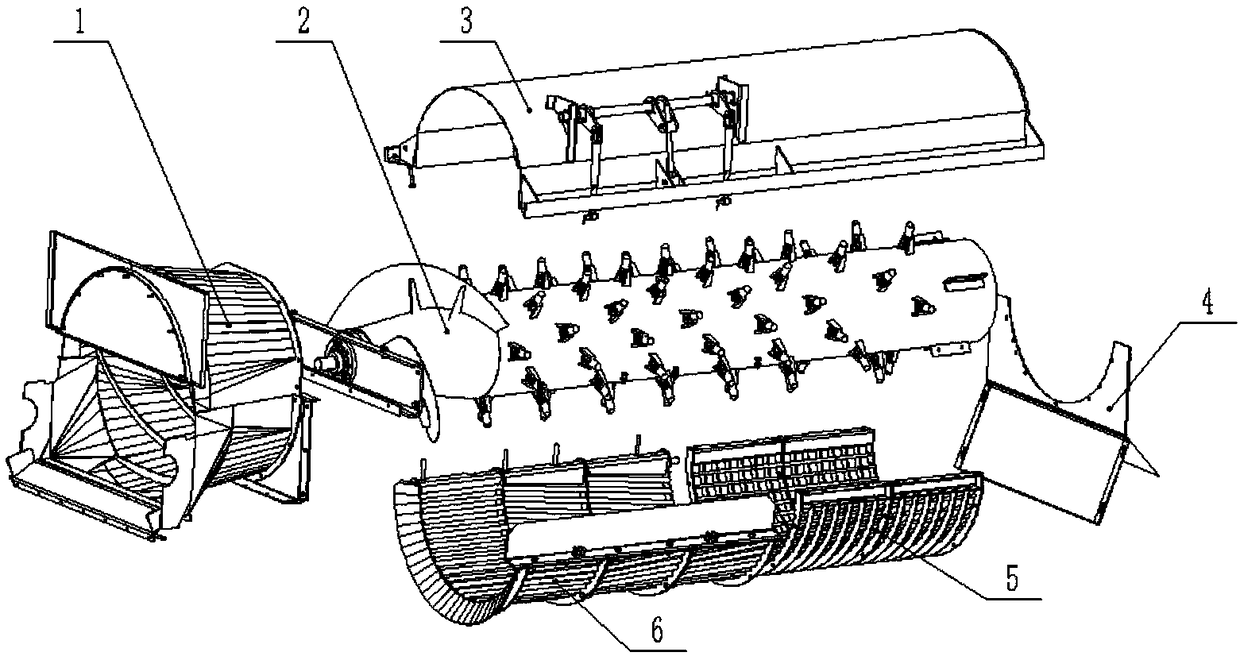

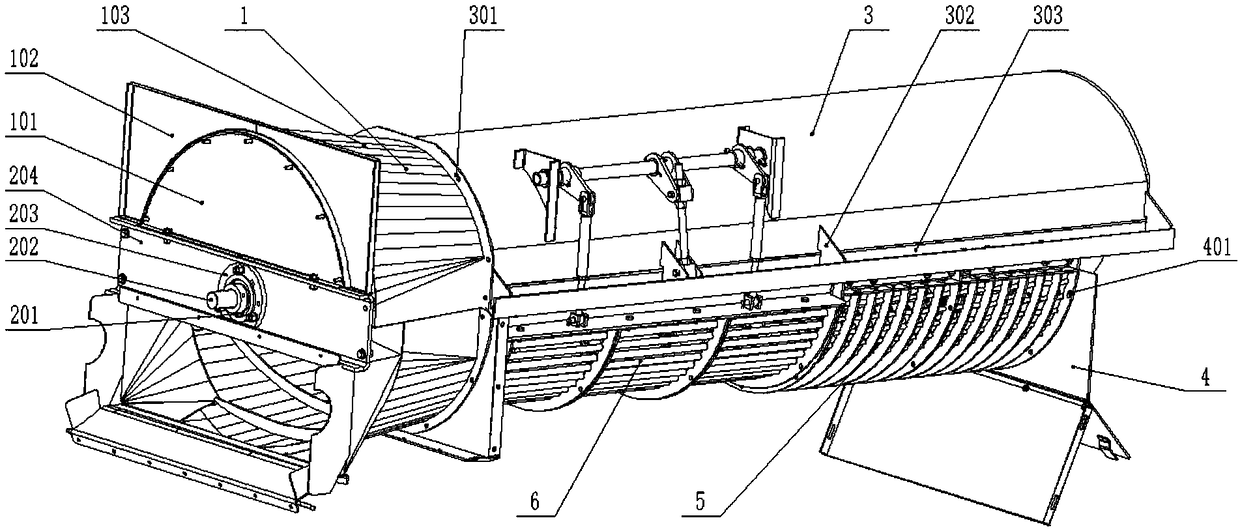

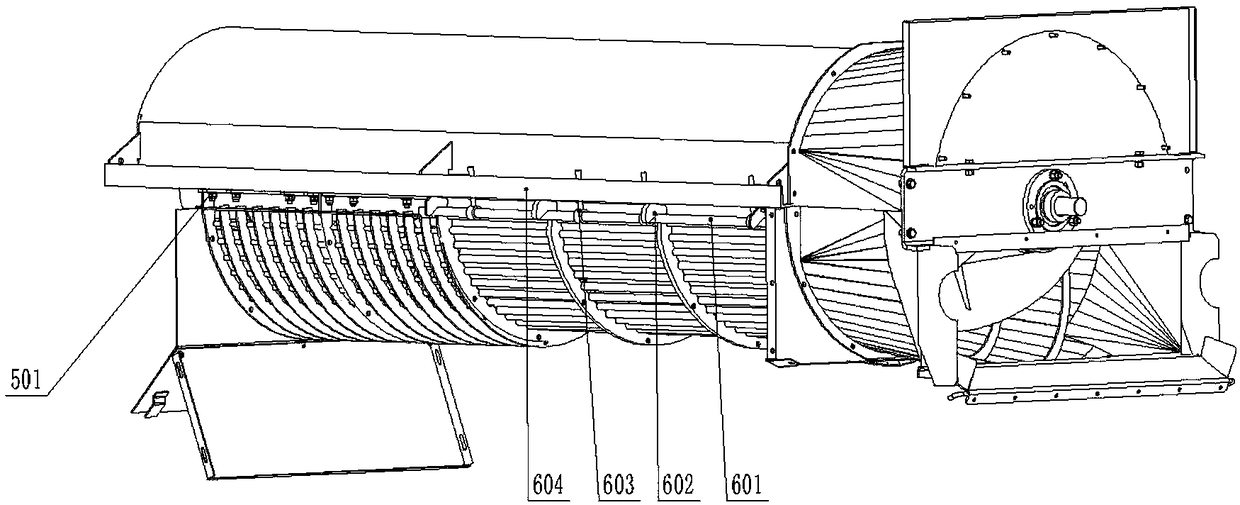

Low-damage anti-clogging gap-adjustable longitudinal-axial-flow high-water-content corn threshing and separation device

The invention discloses a threshing and separation device. The device comprises a feeding protection cover, a threshing roller, a top cover, a separation concave plate, a threshing concave plate and racks; the threshing roller is rotatably mounted on the rear rack, the feeding protection cover is mounted on the front rack and located in front of the threshing roller, the top cover is mounted abovethe threshing roller, the threshing concave plate and the separation concave plate are mounted below the threshing roller separately, and the distance between the threshing concave plate and the feeding protection cover is smaller than that between the separation concave plate and the feeding protection cover. The threshing and separation device can ensure that the corn threshing process under high water content is completed, and reduce the grain breakage rate or even ensure that no grains are broken.

Owner:CHINA AGRI UNIV

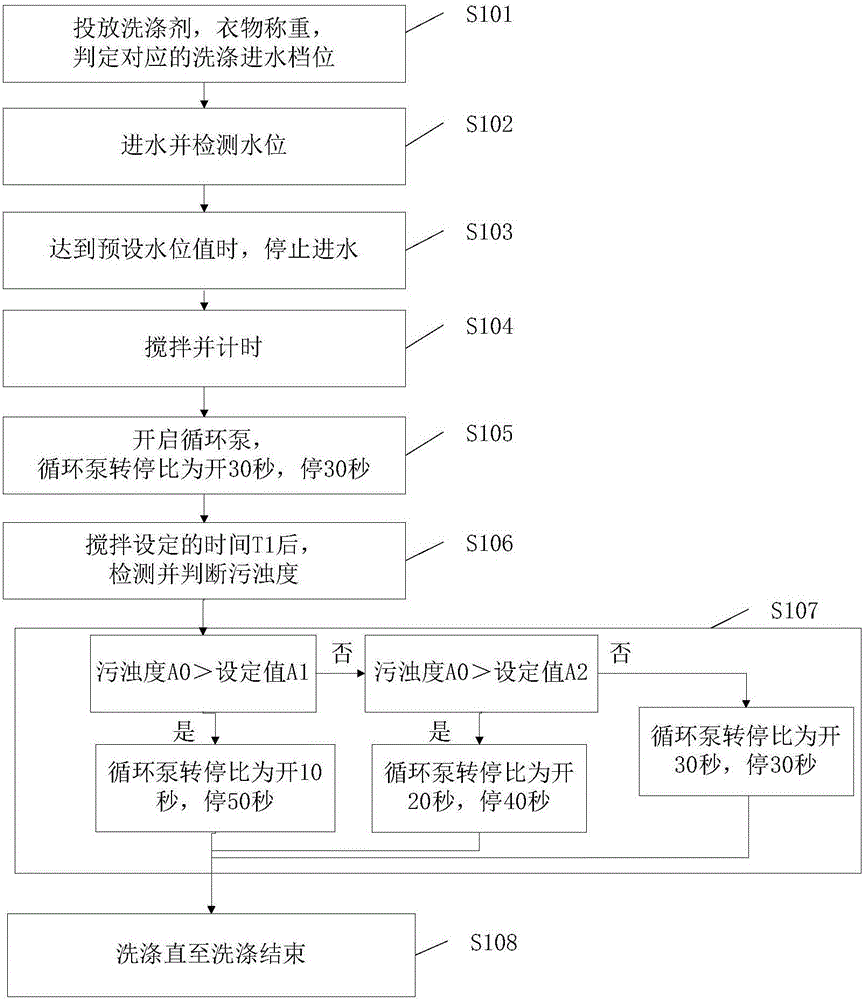

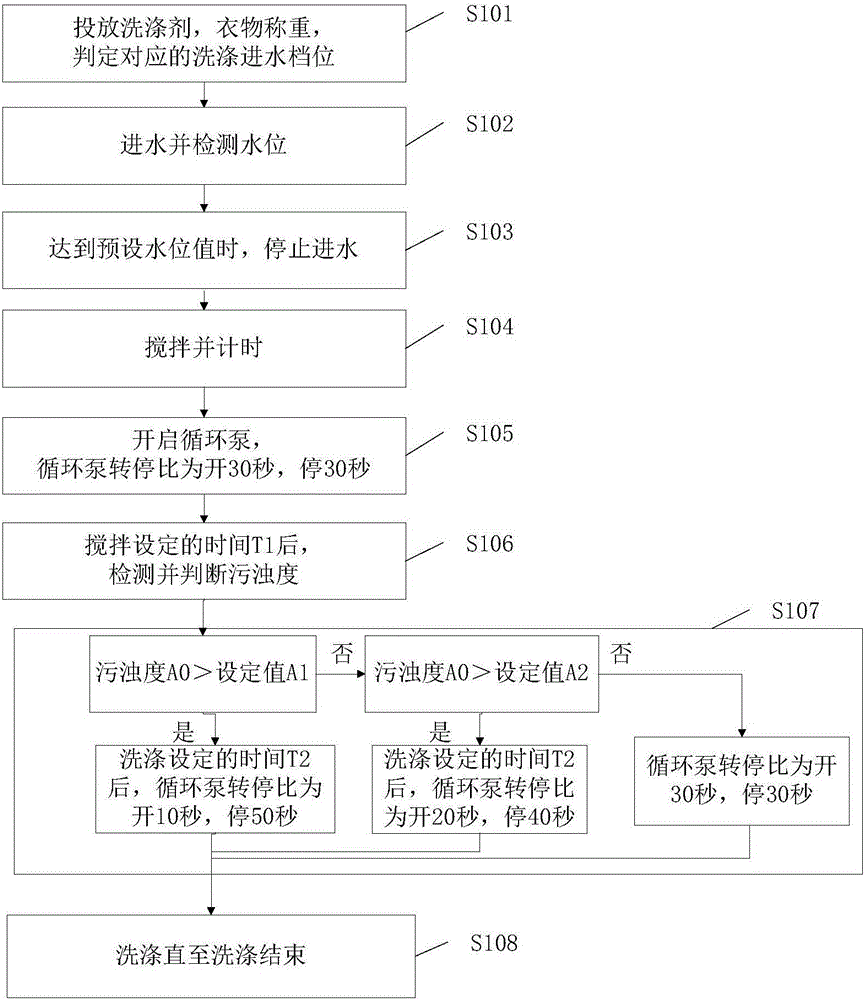

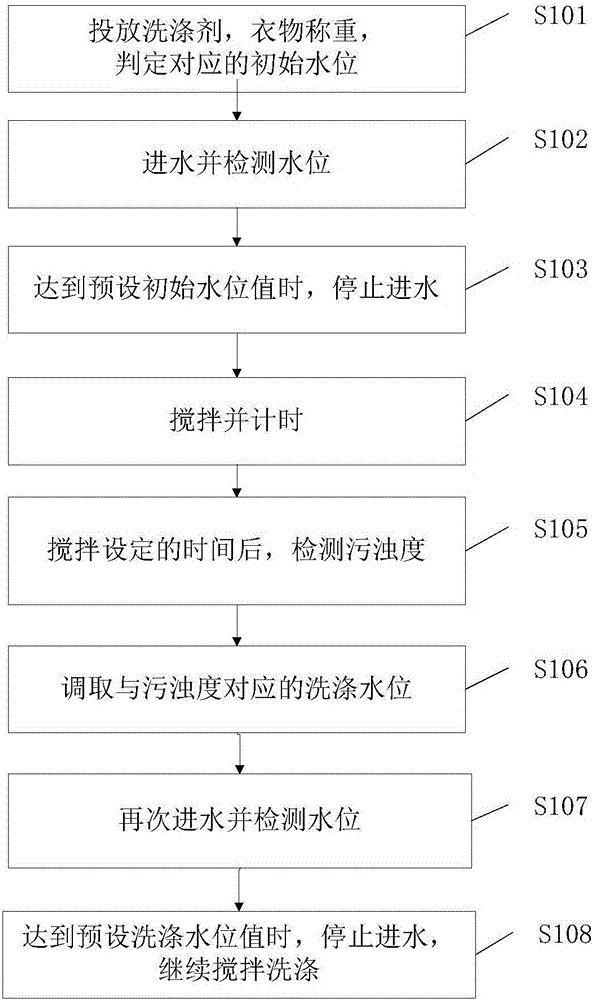

Washing control method and washing machine

ActiveCN107177954AEasy to soakReduce flow timeControl devices for washing apparatusTextiles and paperProcess engineering

The invention provides a washing control method and a washing machine. The external cyclic flowing time of washing water in an outer barrel is determined according to the dirty degree of the washing water, thereby solving the problem that when the dirty degree of clothing is high, in the process that a circulating device pumps the washing water from the barrel bottom and sprays the washing water onto the clothing, the dirty components stripped from the washed clothing adhere to the clothing again and result in poor cleaning effect and low washing efficiency.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

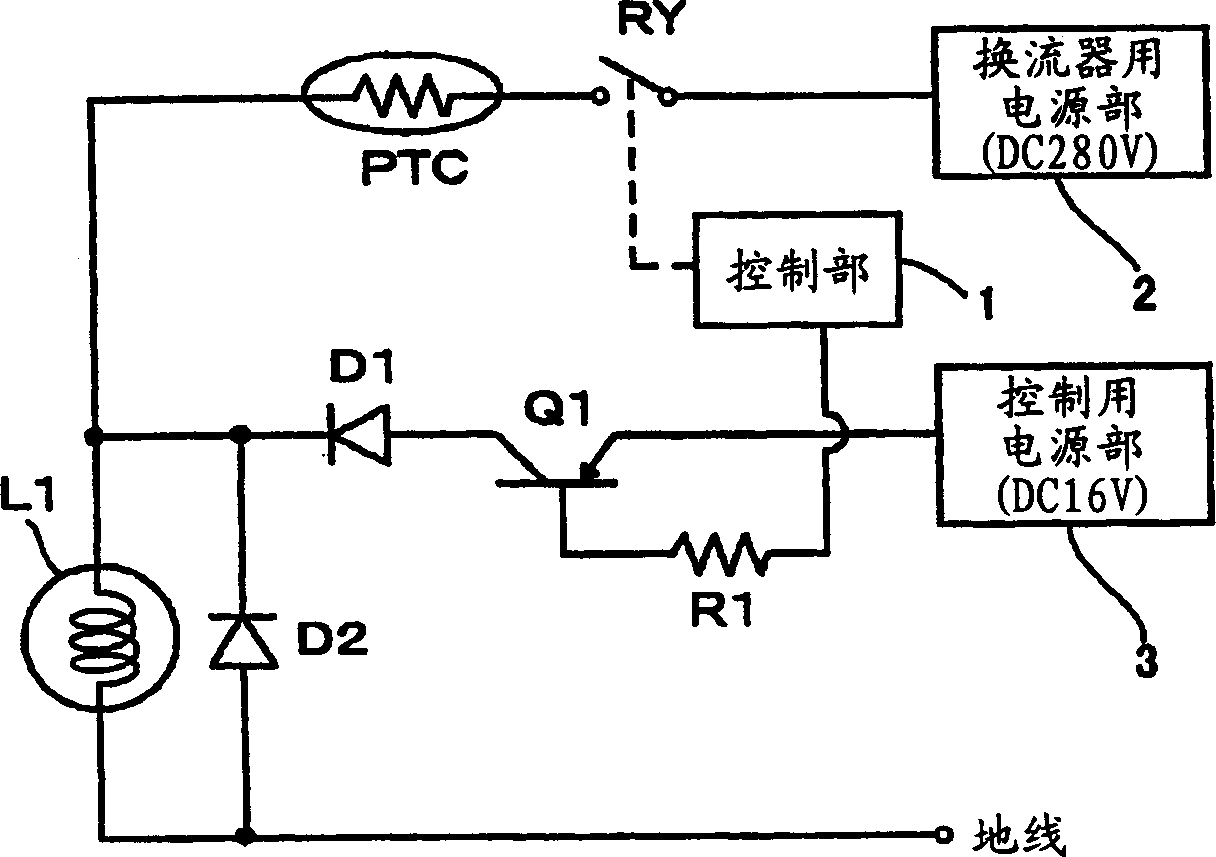

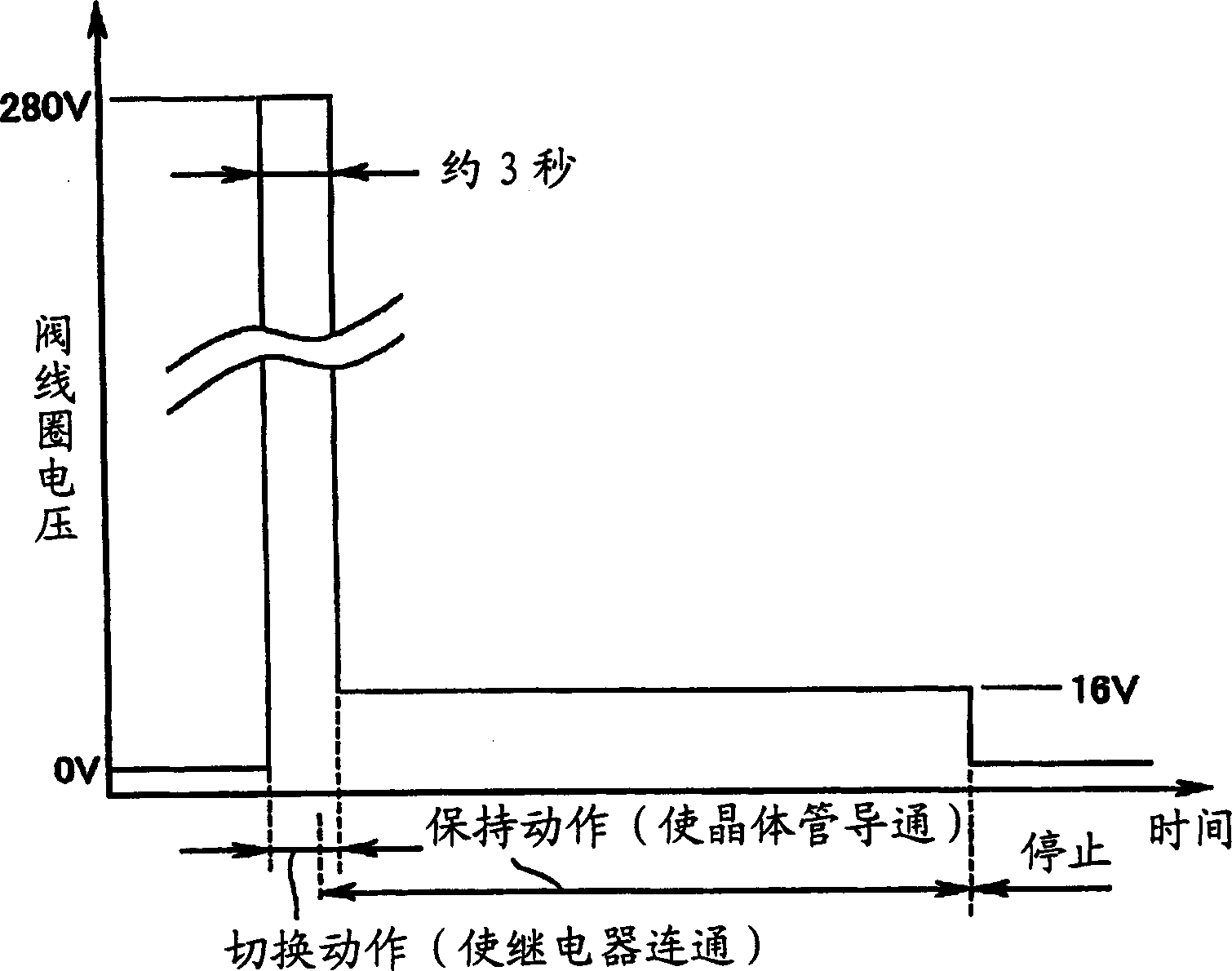

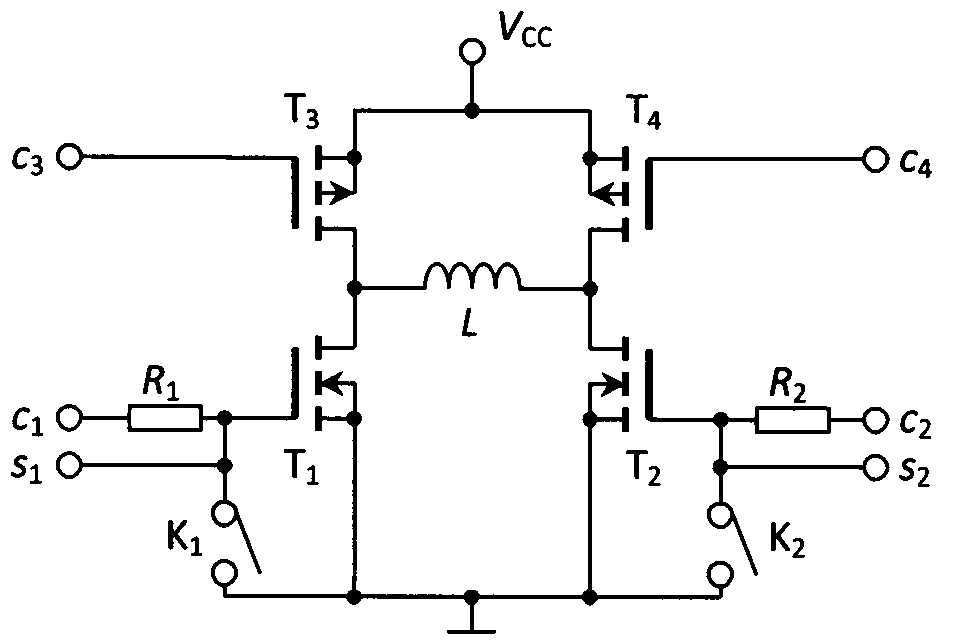

Solenoid valve control device and air conditioner provided with solenoid valve control device

InactiveCN1554003AAvoid damageAvoid consumptionOperating means/releasing devices for valvesFluid circulation arrangementSolenoid valveLow voltage

One end of a relay RY is connected to one end of the valve coil L1 of a 4-way switching solenoid valve, with a dc high voltage DC280V applied to the other end of the relay RY. The collector of a transistor Q1 is connected via a diode D1 to one end of the valve coil L1, with a dc low voltage DC16V applied to the emitter of the transistor Q1. When the valve coil L1 is to be energized, a control unit 1 is used to turn on the relay RY and a dc high voltage is applied to the valve coil L1 via the relay RY and a positive temperature coefficient element PTC to thereby perform a switching operation. After the switching operation, the control unit 1 is used to turn on the transistor Q1 and then turn off the relay RY to apply a dc low voltage to the valve coil L1 via the transistor Q1, thereby enabling a hold operation. Accordingly, a solenoid valve control device capable of reducing power consumption with a simple structure, and an air conditioner provided with the solenoid valve control device are provided.

Owner:DAIKIN IND LTD +1

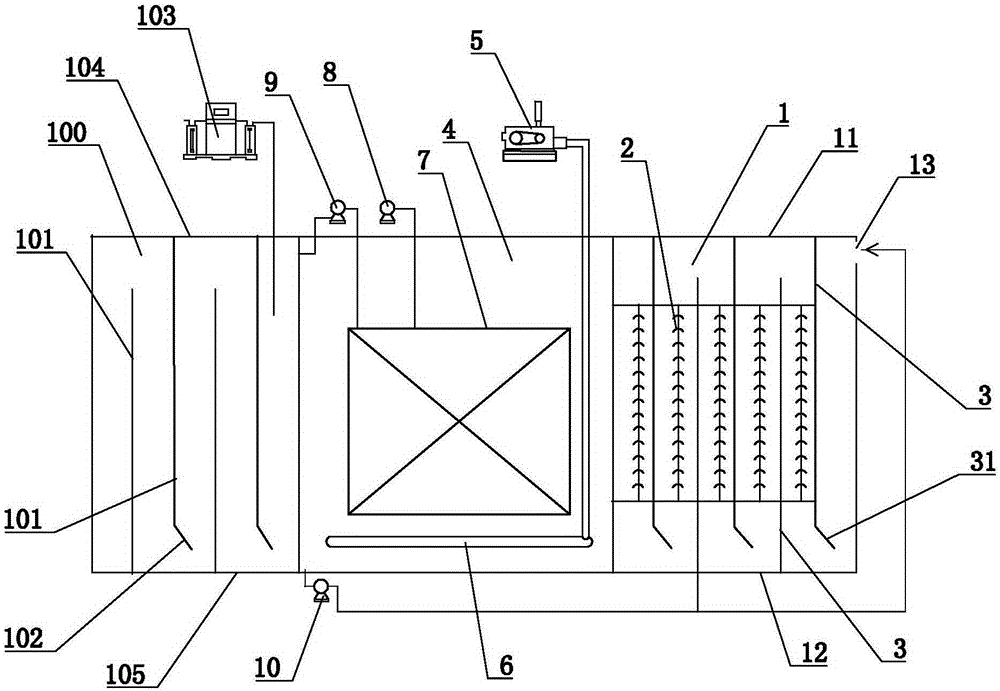

MBR (membrane bioreactor) sewage treatment machine

InactiveCN105174623ASpeed up nitrification and denitrificationShort generation cycleMultistage water/sewage treatmentSewageReflux

The invention discloses an MBR (membrane bioreactor) sewage treatment machine. The MBR sewage treatment machine comprises an anaerobic tank, an MBR membrane tank and a disinfection tank which are sequentially connected in an integrated manner, wherein a sewage inlet is formed in a side wall, far away from the MBR membrane tank, of the anaerobic tank, elastic filler is arranged in the tank wall of the anaerobic tank, and two rows of anaerobic tank separating plates are vertically arranged in the anaerobic tank at intervals and are alternately fixed on a top cover and a bottom wall of the anaerobic tank; an aeration pipeline is arranged at the bottom of the MBR membrane tank, the aeration pipeline is connected with a blast blower, the bottom, far away from the anaerobic tank, of the MBR membrane tank is connected with a reflux pump, and the water outlet of the reflux pump is connected to the sewage inlet of the anaerobic tank; and the disinfection tank is connected with a disinfector, and two rows of disinfection tank separating plates are vertically arranged in the disinfection tank at intervals and are alternately fixed on a top cover and a bottom wall of the disinfection tank. The MBR sewage treatment machine disclosed by the invention has the advantages that sewage treatment effect is good, and service life of an MBR membrane can be prolonged.

Owner:WEIFANG WOHUA WATER TREATMENT EQUIP

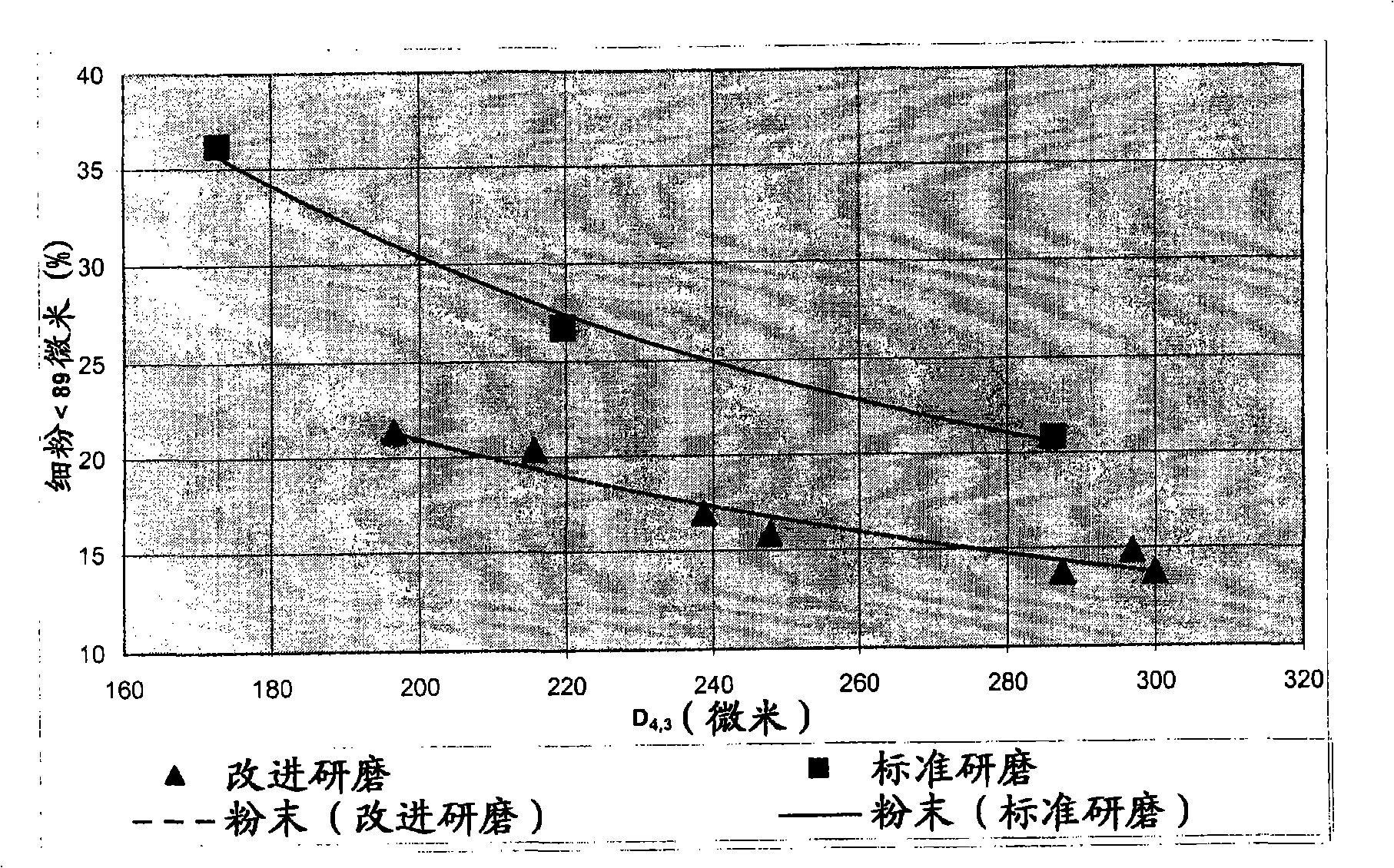

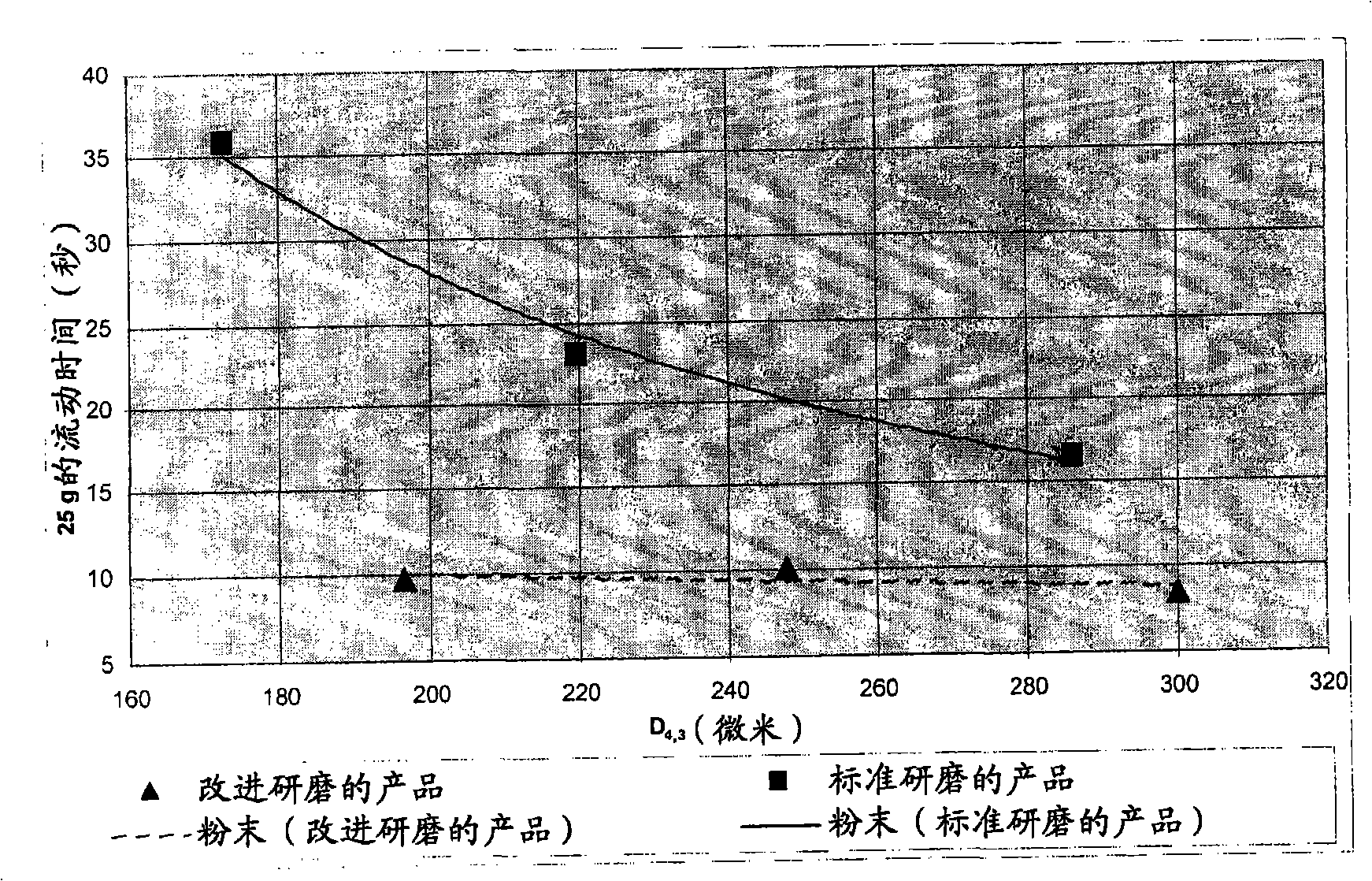

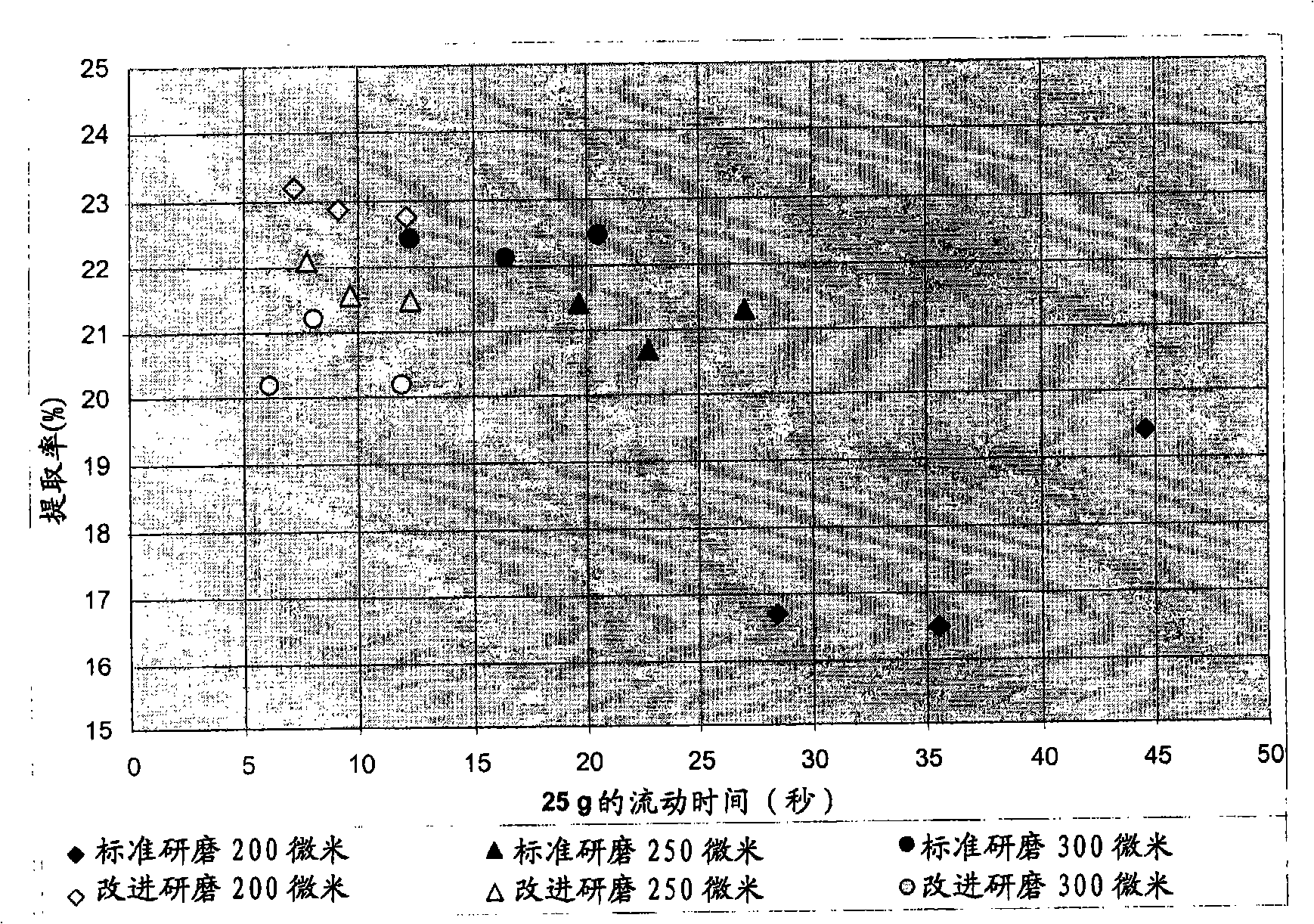

Method for delivering faster a short coffee extract from capsule

InactiveCN101516241ASmall pressure lossReduce flow timeBeverage vesselsCoffee grinding methodsGramEngineering

Method for delivering a short coffee extract faster from a closed capsule containing ground coffee by injecting water under pressure within the capsule. The capsule is filled with ground coffee, has a delivery membrane and is extracted in a coffee extraction device and pressurized water is injected in the capsule under pressure. The coffee beverage is released through the beverage delivery membrane of the capsule with engaging means engaging in and / or against the membrane. The pressure loss is reduced in the coffee bed by providing ground coffee having a reduced percentage of fines (F) depending on the average particle size (D4,3). The extraction yield is maintained between 15 and 30% and the coffee extract of 25 or 40 grams is delivered in a flow time of 20 seconds or less.

Owner:SOC DES PROD NESTLE SA

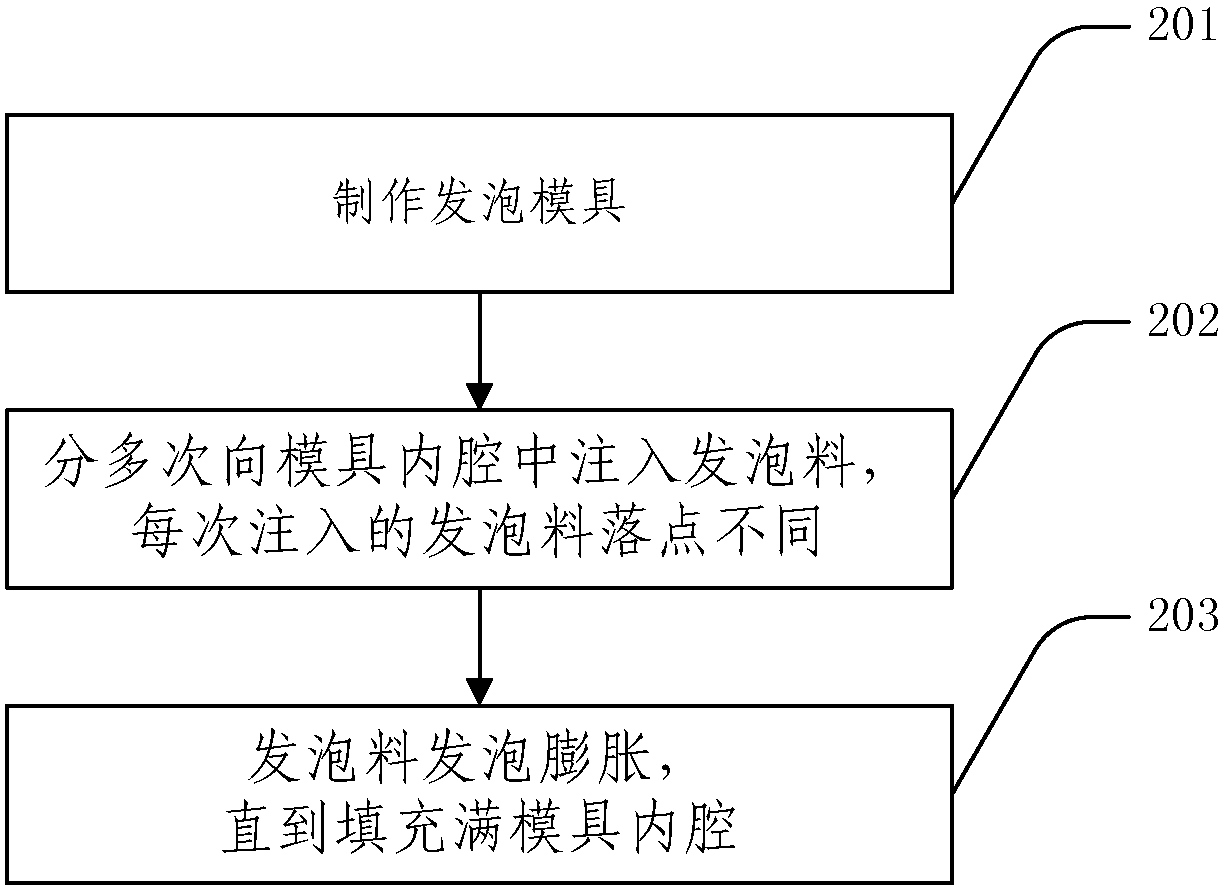

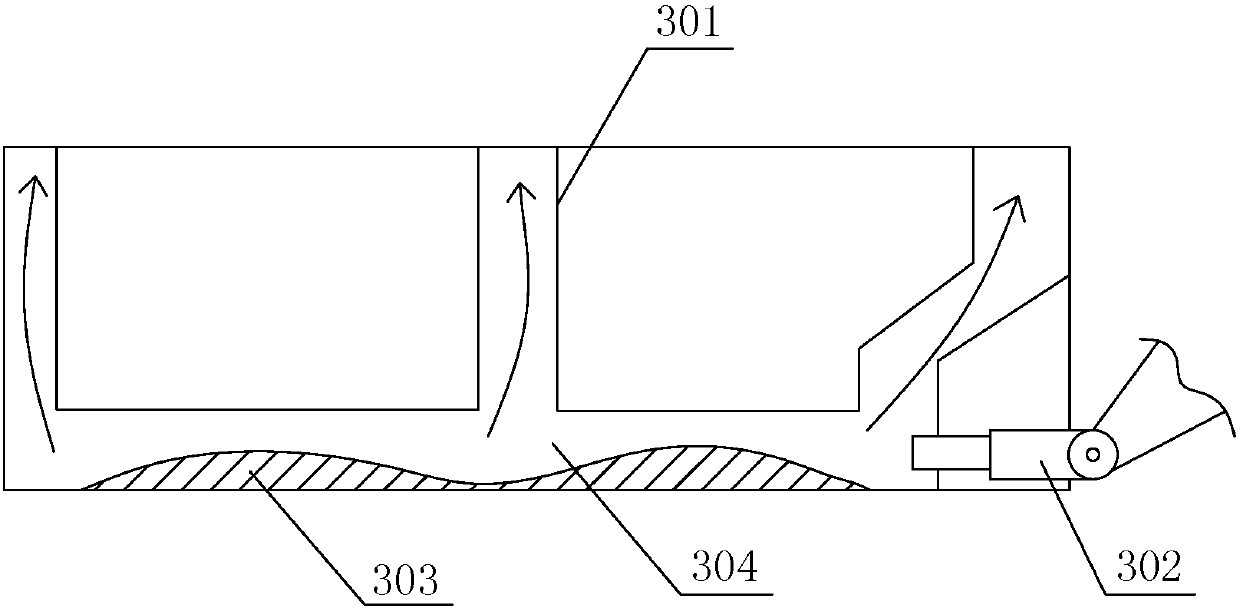

Foaming method

Owner:QINGDAO HAIER REFRIGERATOR INT +2

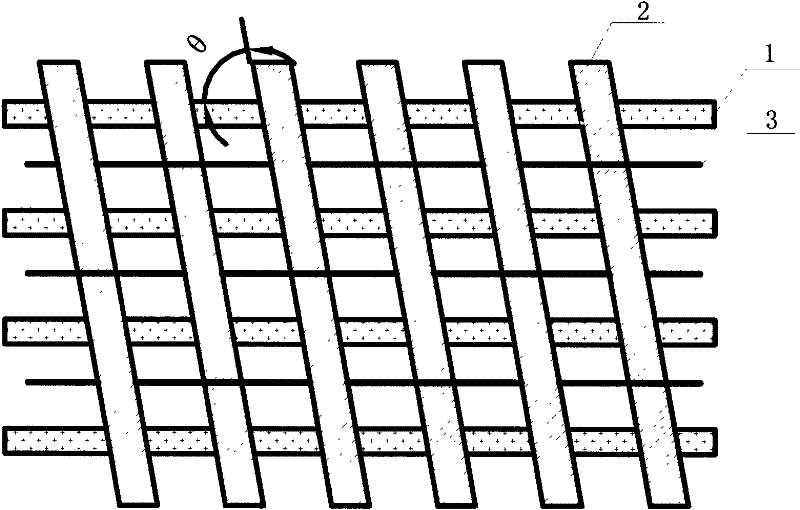

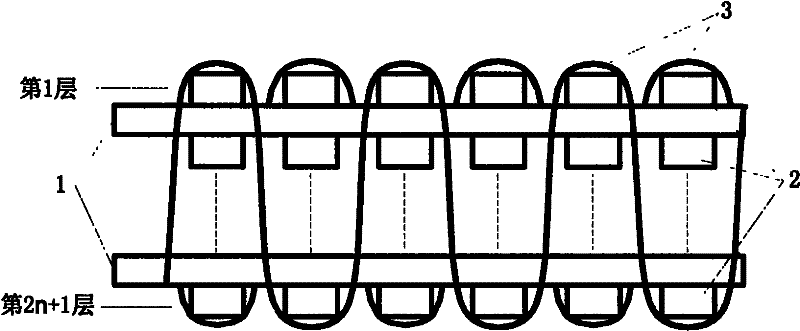

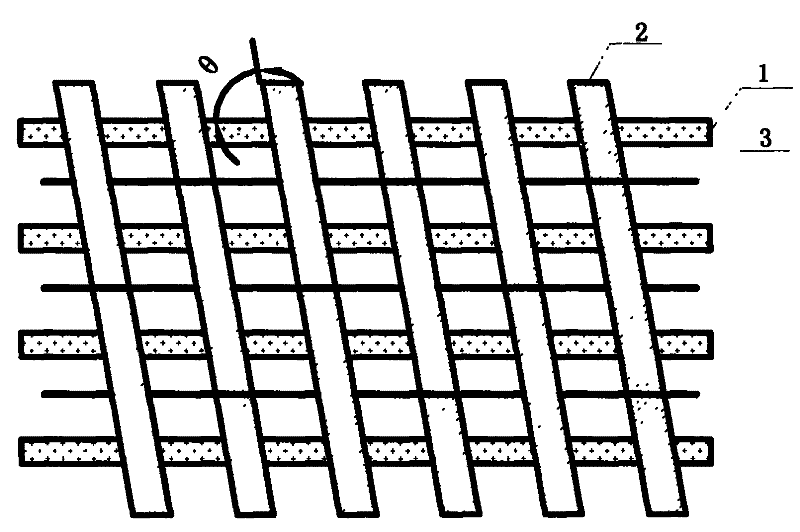

Enhanced permeable medium

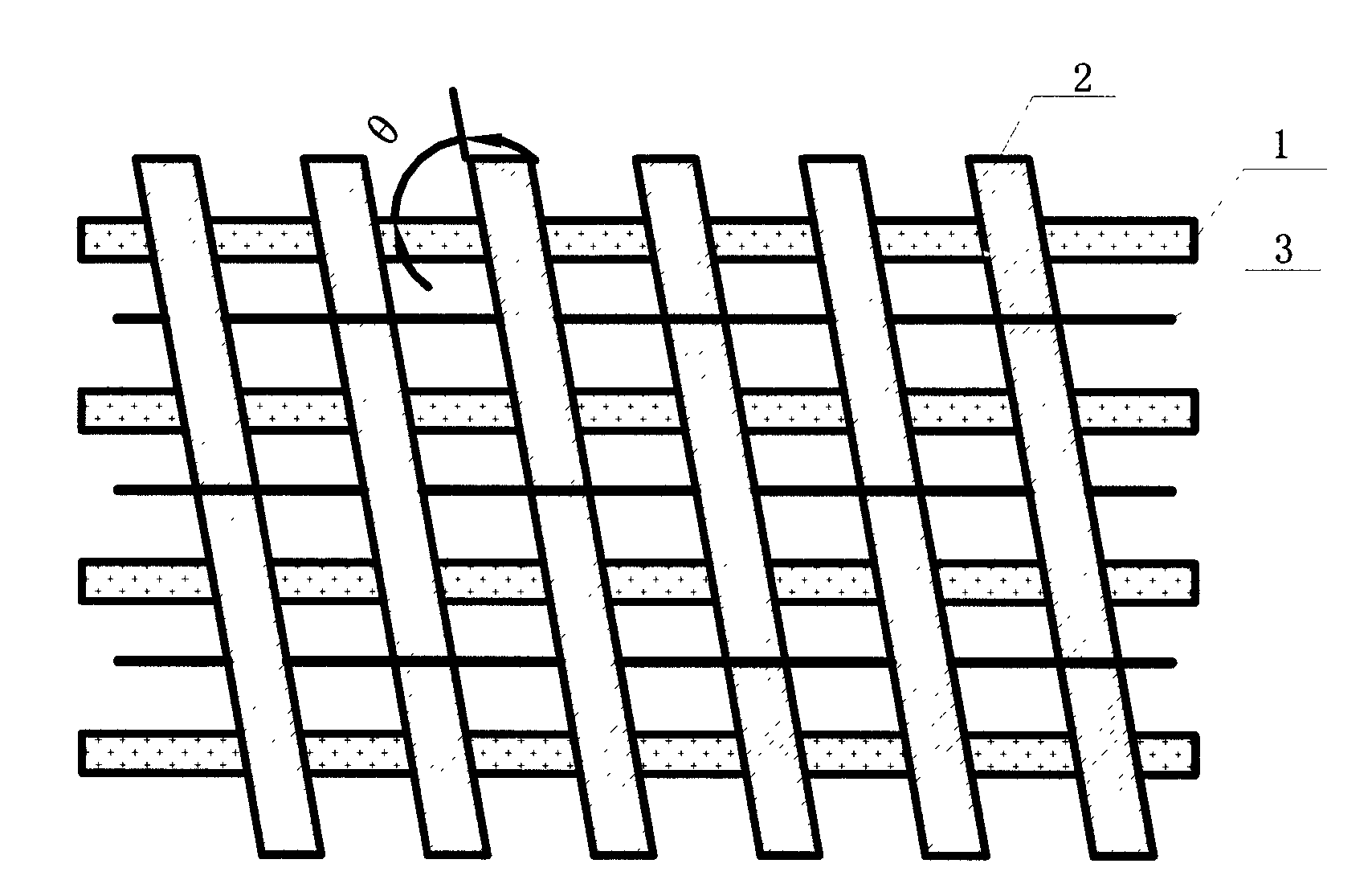

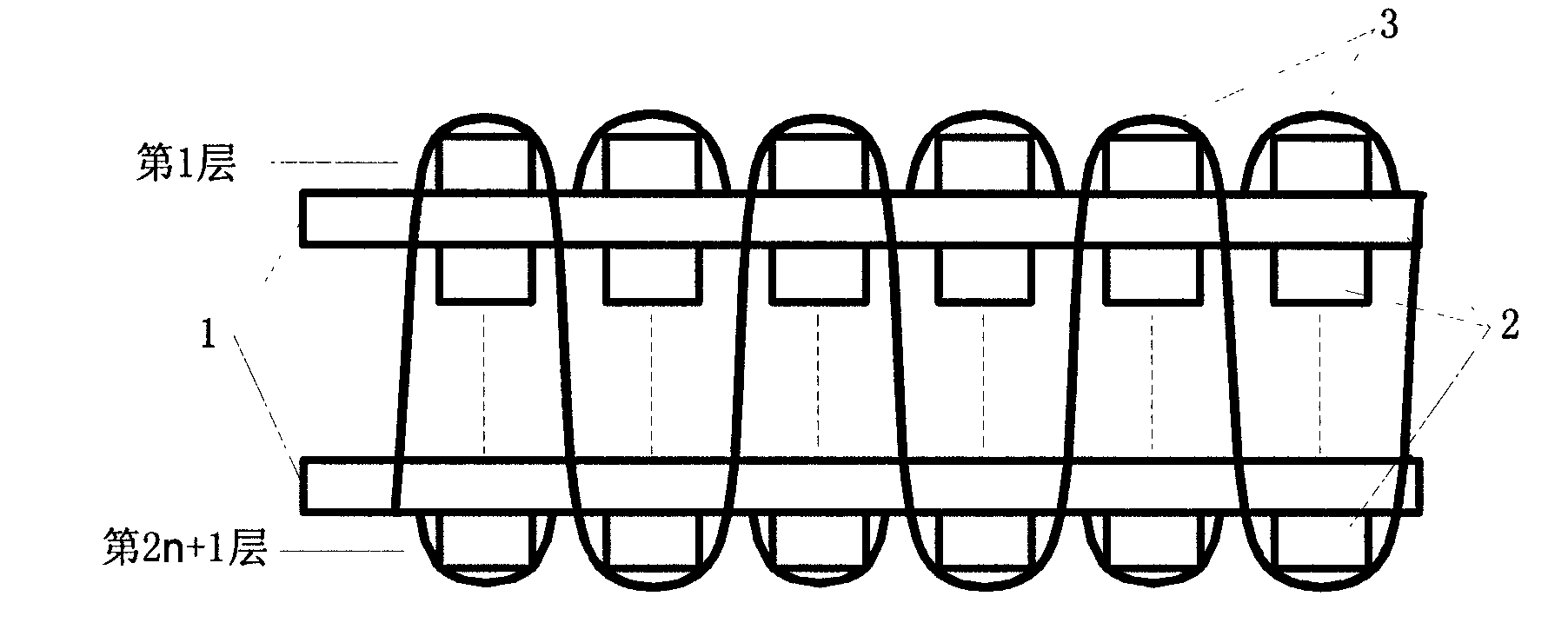

ActiveCN101602271AImprove reliabilityImprove uniformityLayered productsWarp knittingMaterial qualitySmooth surface

The invention belongs to the technical field of composite molding process, relating to an enhanced permeable medium. The enhanced permeable medium is laid by odd layers of non-woven parallel yarns at a certain angle and is weaved by yarns used for weaving in low weaving density to form a three dimensional fabric with sparse weaving points; vast penetrating gaps or grooves are reserved in the fabric to provide channels for air and resin flow, so that the fabric has better permeably property of resin. The enhanced permeably medium of the invention can effectively increase flow rates of resins, realize sound immersion of fiber fabrics in resins, obviously increase reliability of pouring technique and improve uniformity of products. The products with smooth surfaces are directly obtained when using the medium without changing die structure, thus saving time and labor and being economical and efficient. The enhanced permeably medium of the invention has strong designability, and permeable media with demand structures are obtained by designing structural parameters such as material quality, yarns and angles, etc. according to the characteristics of the composite.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

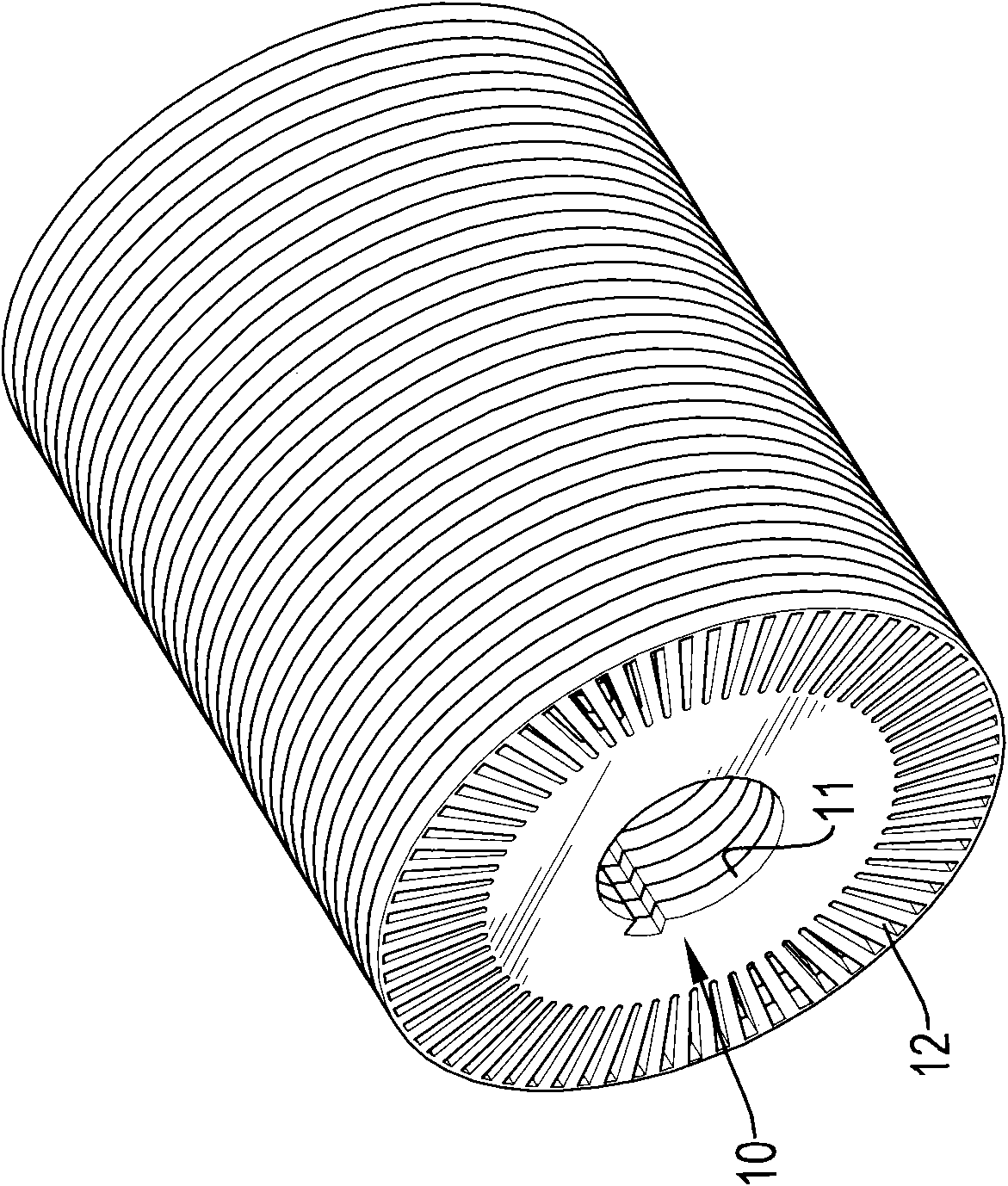

Manufacturing method of motor rotor

InactiveCN102761207AFull of sureReduce flow timeManufacturing stator/rotor bodiesRoom temperatureEngineering

A manufacturing method of a motor rotor comprises the steps of preparing a plurality of silicon-steel plates, a shaft lever, and a mould provided with both an injection opening and a suction opening, sleeving the shaft lever into the laminated silicon-steel plates, placing the shaft lever and the silicon-steel plates into the mould, conducting suction by the suction opening to allow the interior of the mould to be in a vacuum state, injecting molten copper into the mould via the injection opening, allowing the molten copper to flow to the suction opening under the effect of the vacuum state, so as to be filled in the whole mould, cooling the mould, allowing the molten copper to form a copper ring on the silicon-steel plates, and cooling to the room temperature, thereby accomplishing the manufacturing of the motor rotor. The manufacturing method of the motor rotor can increase the product yield.

Owner:张金锋

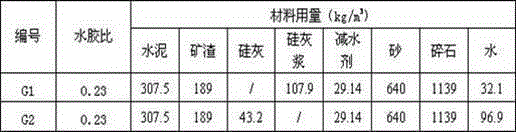

Method for preparing high-fluidity silica mortar

The invention discloses a method for preparing high-fluidity silica mortar. The method includes the steps that 1, material preparation is conducted, wherein the raw material is prepared from 40%-60% of silica fume, 40%-60% of water and dispersing agents which accounts for 0.06%-1.00% the mass of the silica fume; 2, the silica fume and dispersing agents which are prepared ready are placed in a silica mortar stirrer; 3, water is added into the stirrer while stirring is conducted slowly for 4-6 minutes, and then the silica mortar is obtained. The method is simple in process, the high-fluidity silica mortar can be prepared only through the dispersing agents, and the prepared silica mortar can be stored for half a year at the temperature of lower than 80 DEG C without going bad. The harm to human bodies and the pollution to the environment are lowered and even eliminated in the use process of the high-fluidity silica mortar, the function of the silica mortar is fully played, and the mechanical property and the endurance quality of concrete are improved. The obtained silica mortar can be widely applied to important engineering of high requirements for the concrete, such as, high-strength concrete, marine concrete and hydraulic concrete.

Owner:SOUTH CHINA UNIV OF TECH

Composite cavity box segment liquid-state forming method

The invention discloses a composite cavity box segment liquid-state forming method. The method comprises following steps of skin and core mold blank body paving and pasting, core mold and secondary runner assembling, upper skin paving and pasting, upper mold and other mold assembly, resin injection, and mold releasing. The forming method is used for liquid-state forming of a composite cavity box segment. Compared with the prior art, the method solves the problems that the injection path is long, the period is long, and deficient glue defects are easily caused, large resin viscosity and difficult injection caused by long-time injection and end injection can be avoided, part manufacturing efficiency is improved, and the manufacturing cost is reduced.

Owner:AVIC BASIC TECH RES INST

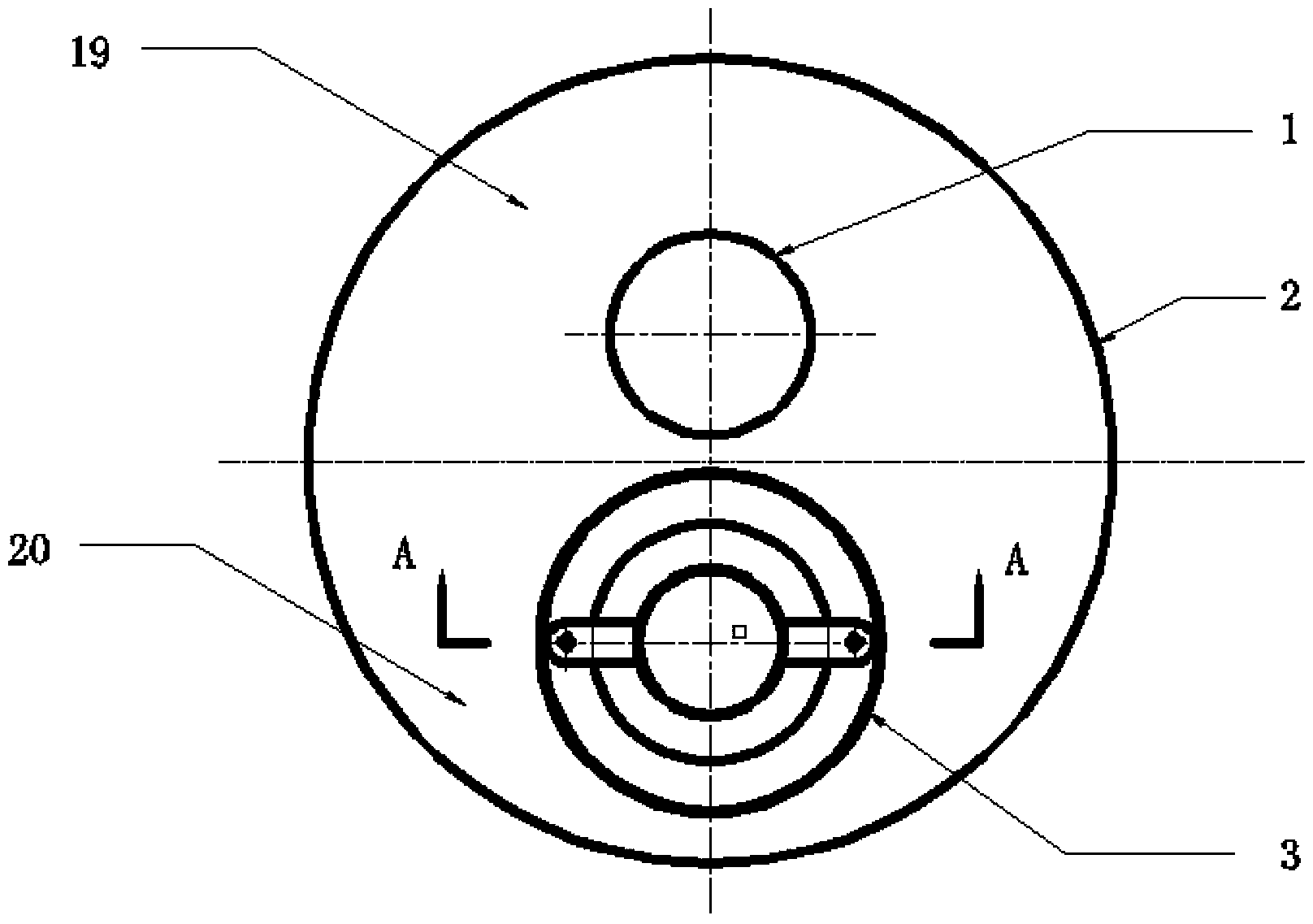

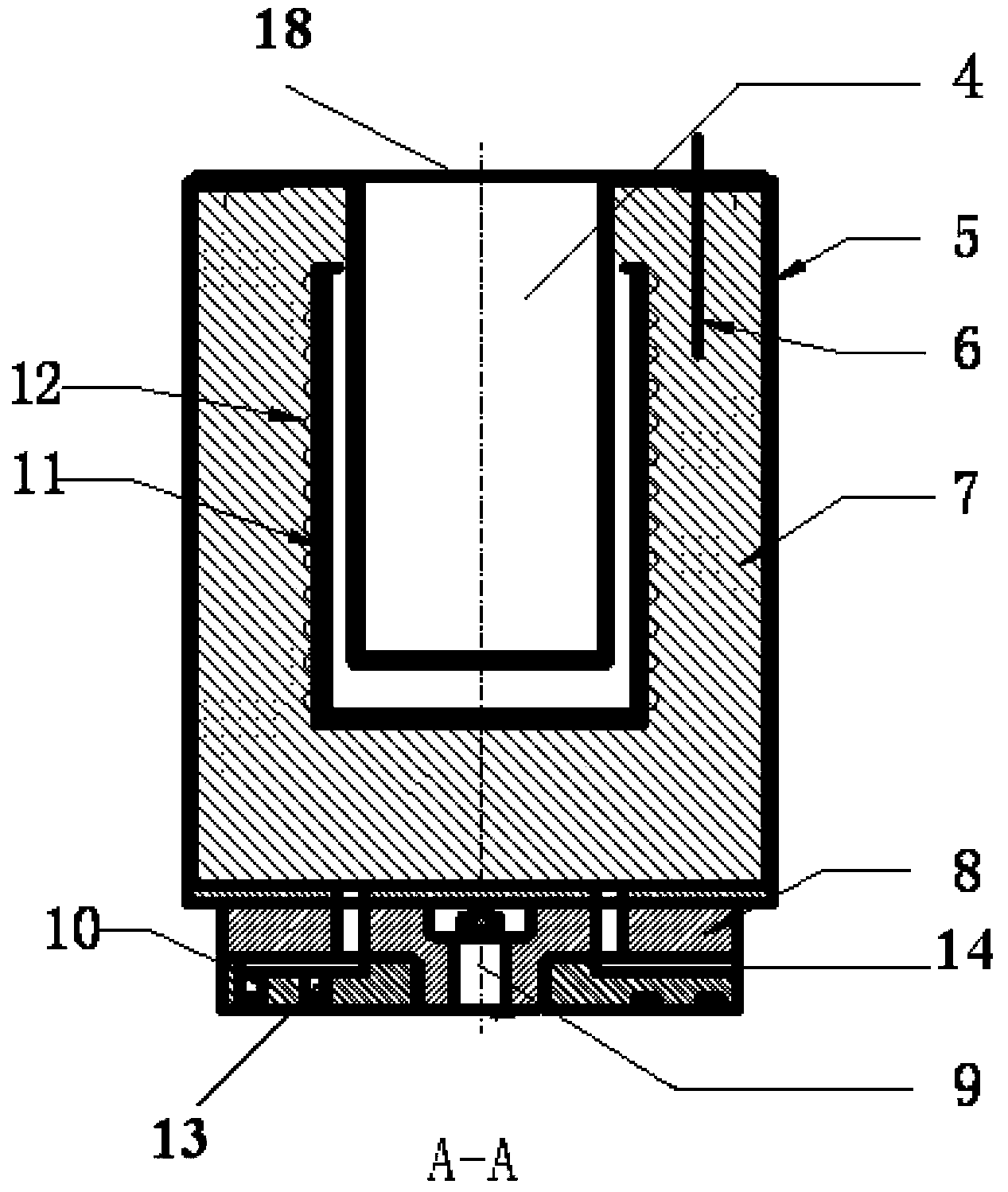

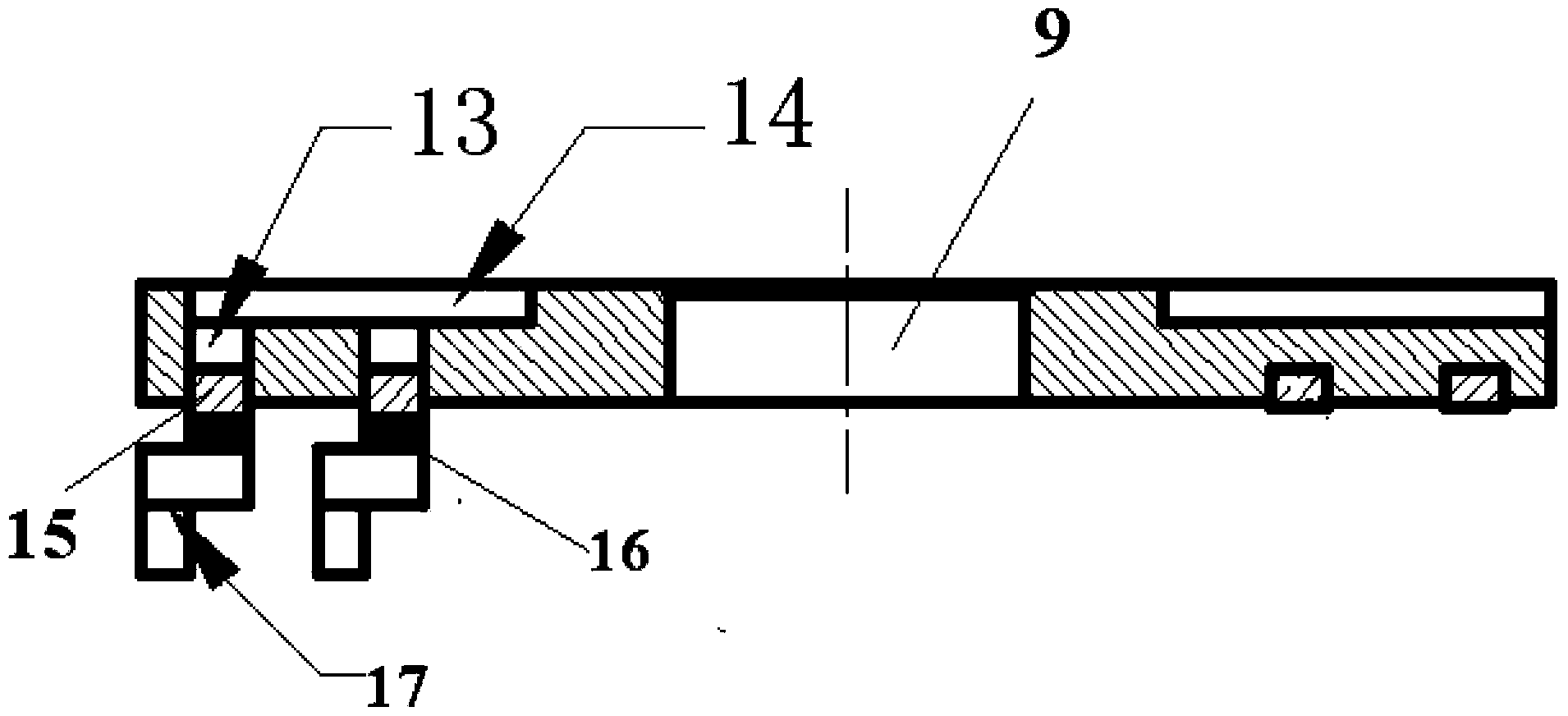

MBR flat membrane element

InactiveCN110255704AReduce weightReduce pollutionSemi-permeable membranesMembranesEngineeringWater processing

The invention belongs to the field of water processing equipment, and discloses an MBR flat membrane element, which comprises a support plate, guide cloth, and filter membranes. The guide cloth is welded on two lateral surfaces of the support plate. The filter membranes are arranged on the external surfaces of the guide cloth and welded on the external frame of the support plate. Two lateral surfaces of the support plate are provided with guide grooves. The guide grooves are vertically arranged in the inner surfaces of the guide cloth; the direction of the guide grooves is the same as the flowing direction of fluids; and the guide grooves are staggered from each other. By arranging guide grooves in the support plates, the resistance during the filtering process is reduced, the water flux is increased, and the operation cost is reduced.

Owner:VONTRON TECH CO LTD

Glue-free super-soft silk-like cotton and preparation method thereof

ActiveCN112553780AImprove efficiencyQuality improvementHeating/cooling textile fabricsNon-woven fabricsPolyesterHollow fibre

The invention discloses glue-free super-soft silk-like cotton and a preparation method thereof, and relates to the technical field of glue-free super-soft silk-like cotton preparation. The problem ofsilk-running in cooling and shaping of the glue-free silk-like cotton is solved. The preparation method specifically comprises the steps that low-melting-point polyester fibers, polyester superfine fibers and hollow fibers are proportioned in proportion, and proportioned fiber blended cotton is put into a mixer to be stirred; meanwhile, the stirred fiber cotton is put into an opening and conveyingmachine to be opened, and the opened fiber cotton is put into a cotton blending box to be mixed; then the mixed cotton is guided into a carding machine to be subjected to cotton loosening, and a cotton layer is conveyed into a lapping machine to be subjected to lapping work; and then the lapping cotton is conveyed into a baking oven to be baked and cohered. The cold pressing shaping of a cold pressing roller is included, and cold air cooling shaping is included; and meanwhile, the high efficiency of cooling shaping of the glue-free silk-like cotton is guaranteed, and adjustment of the cold pressure degree of the silk-like cotton fabric is facilitated to a certain extent.

Owner:舒城娃娃乐儿童用品有限公司

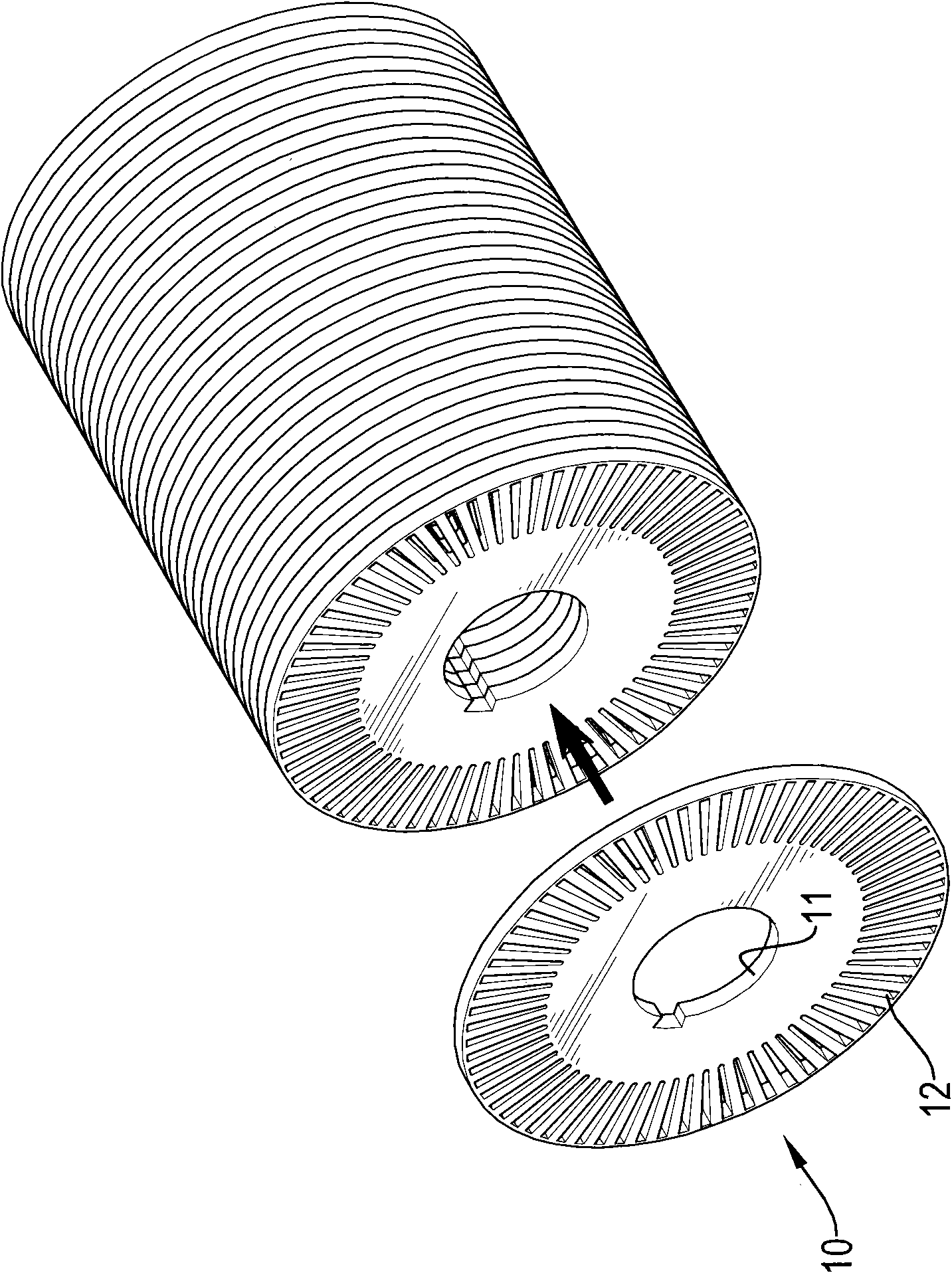

Centrifugal casting method for irregular titanium thin-wall casting

InactiveCN109454212AReduce flow timeUniform textureFoundry mouldsFoundry coresInsulation layerTitanium metal

The invention relates to a centrifugal casting method for an irregular titanium thin-wall casting. The centrifugal casting method for the irregular titanium thin-wall casting comprises the steps of manufacturing of a mold shell, metallic titanium melting, mold shell casting, centrifugal injection, solidification, shell removal, riser removal, overall heat treatment, grinding and the like. Rapid filling at the thin wall position of the thin-wall titanium casting can be realized by centrifugation, the uniformity of texture of a casting material at the thin wall position is ensured, meanwhile a high-temperature resistant layer which is prepared by mixing yttrium oxide with zirconium oxide is arranged in the mold shell, the stability and smoothness of the surface of the thin wall of the casting are ensured, temperature compensation before injection and an insulation layer outside the mold shell ensure temperature maintenance during the injection process, and the fluidity of injected metalliquid is ensured.

Owner:南京宝泰特种材料股份有限公司

Enhanced permeable medium

The invention belongs to the technical field of composite molding process, relating to an enhanced permeable medium. The enhanced permeable medium is laid by odd layers of non-woven parallel yarns at a certain angle and is weaved by yarns used for weaving in low weaving density to form a three dimensional fabric with sparse weaving points; vast penetrating gaps or grooves are reserved in the fabric to provide channels for air and resin flow, so that the fabric has better permeably property of resin. The enhanced permeably medium of the invention can effectively increase flow rates of resins, realize sound immersion of fiber fabrics in resins, obviously increase reliability of pouring technique and improve uniformity of products. The products with smooth surfaces are directly obtained whenusing the medium without changing die structure, thus saving time and labor and being economical and efficient. The enhanced permeably medium of the invention has strong designability, and permeable media with demand structures are obtained by designing structural parameters such as material quality, yarns and angles, etc. according to the characteristics of the composite.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Casting method of aluminum ingot

The invention discloses a casting method of an aluminum ingot. The casting method includes the following steps that aluminum oxide is produced from aluminum ore through a Bayer process, a mixing furnace is preheated, the aluminum oxide is melted in a smelting furnace, molten aluminum liquid is poured into the mixing furnace, then a solvent is added for refining, stirring is conducted back and forth for 0.5 h, then standing is conducted for 5 min to 10 min, dross is fished out, nitrogen is directly led into the aluminum liquid, the aluminum liquid continuously passes through alumina balls, a furnace eye of the mixing furnace is aligned with a second casting die and a third casting die of a casting machine, the temperature of the aluminum liquid in the mixing furnace is maintained at 55 DEGC to 70 DEG C, the furnace eye and the casting machine are connected through a flow groove, and the aluminum liquid is cooled gradually. By means of the casting method, the solvent is used for adsorbing oxidized impurities in the aluminum liquid, the nitrogen is used for removing nonmetallic inclusions and dissolved hydrogen in the aluminum liquid out, the impurity removing rate is high, purity ofthe cast aluminum ingot is ensured, during casting, the temperature of the aluminum liquid in the mixing furnace is ensured, air holes and cracks of the aluminum ingot can be prevented, and the production efficiency is high.

Owner:湖北华力科技有限公司

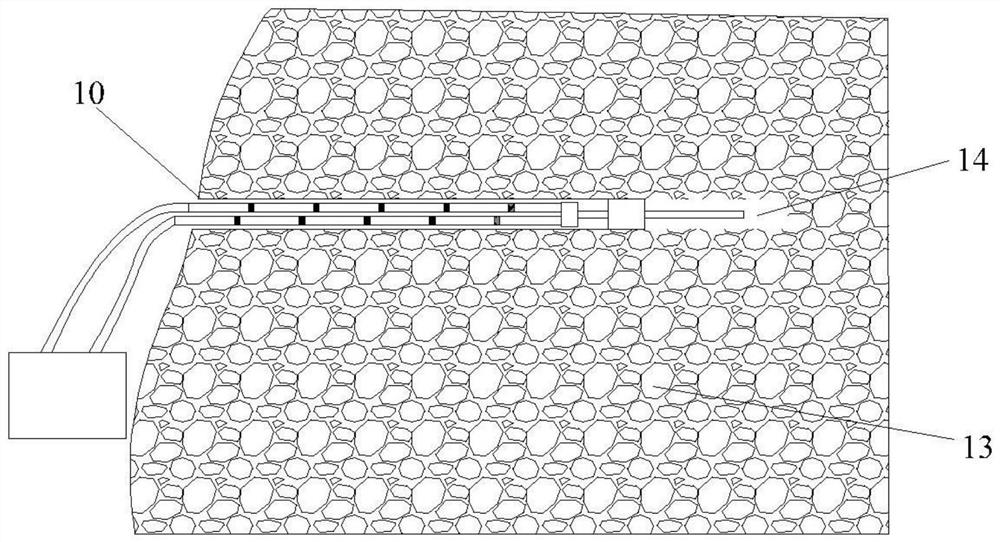

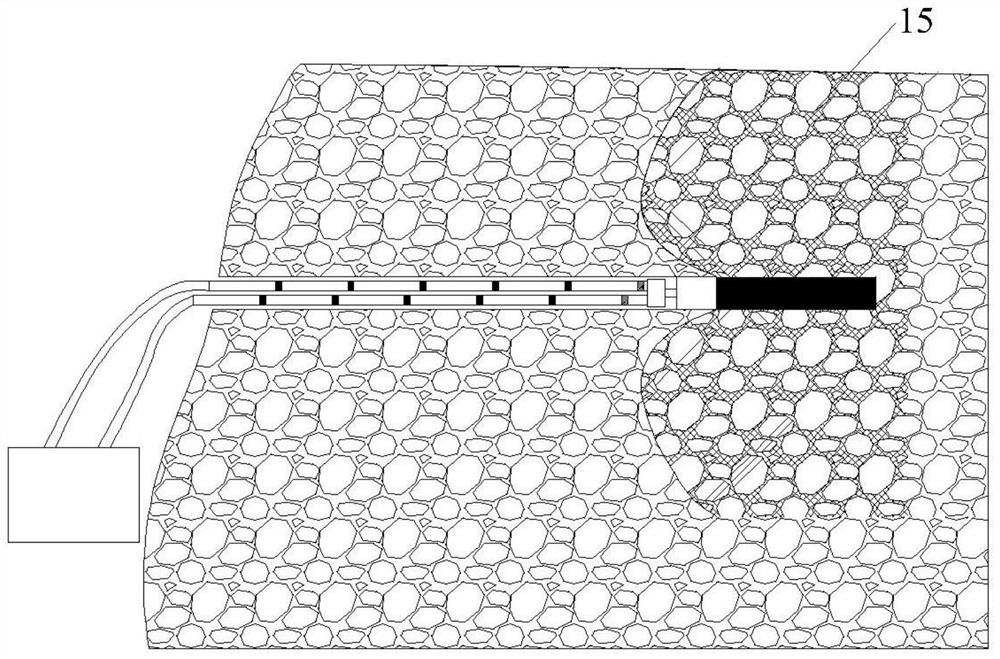

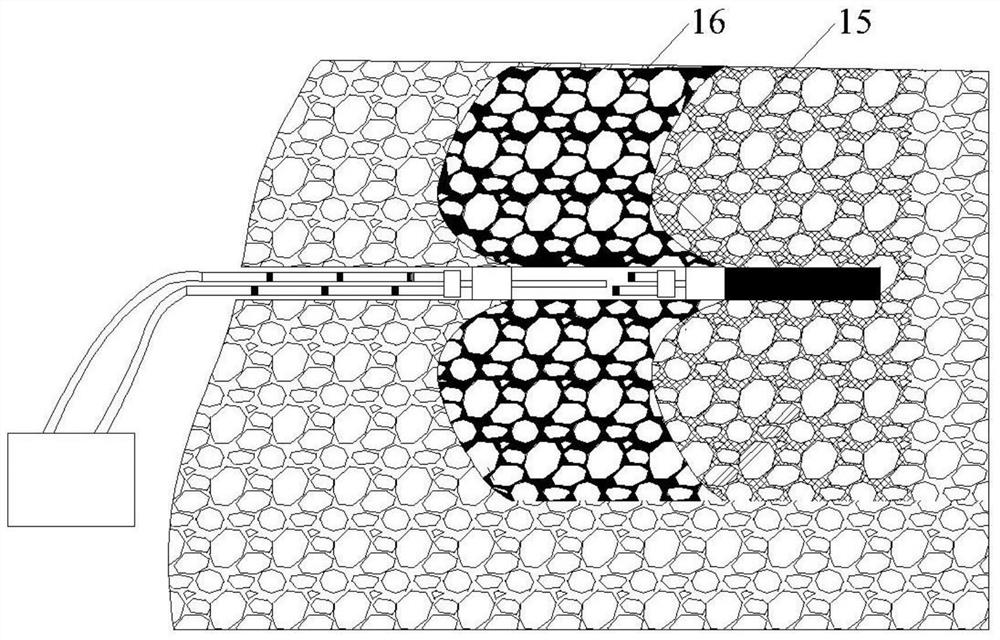

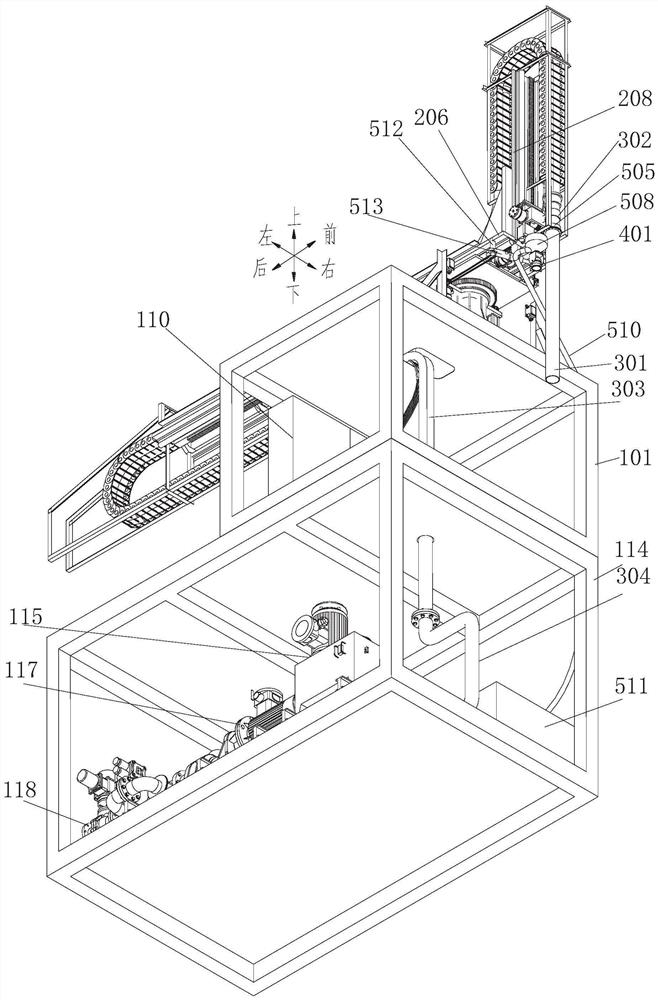

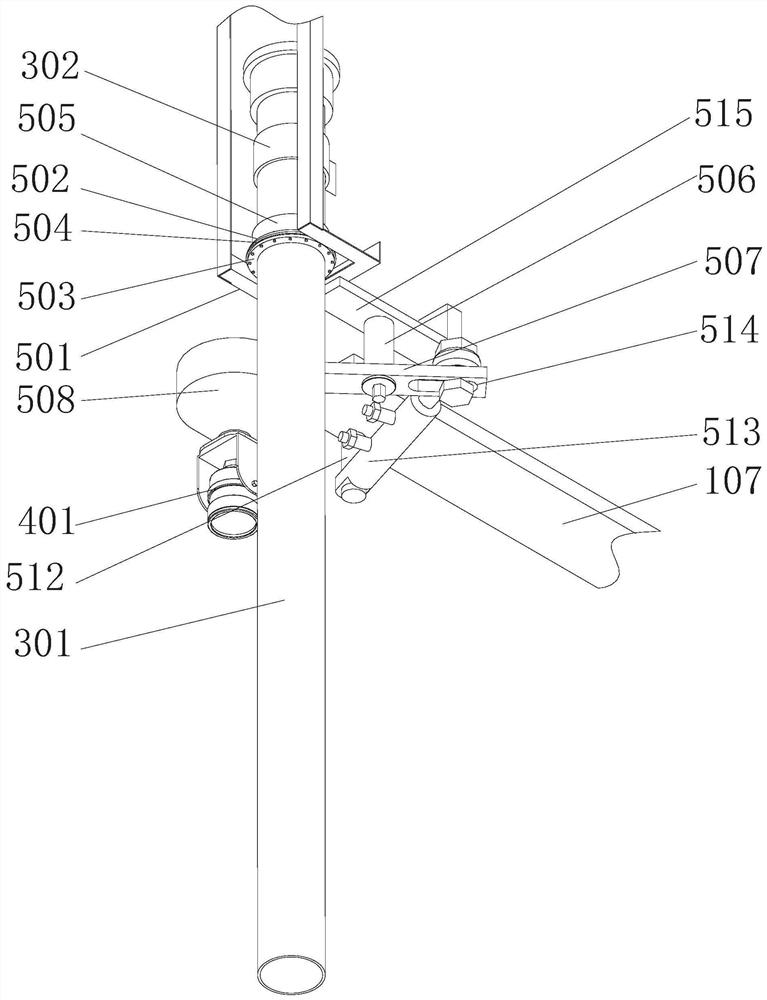

Coal and rock mass deep hole subsection grouting reinforcement device and reinforcement method

ActiveCN111894632AImproves uniformity of diffusionAchieving bottom-hole mixingUnderground chambersTunnel liningStructural engineeringSlurry

The invention discloses a coal and rock mass deep hole subsection grouting reinforcement device and a reinforcement method. The coal and rock mass deep hole subsection grouting reinforcement device comprise a grouting device and at least two groups of grouting pipeline assemblies, wherein the grouting device is provided with slurry outlets matched with the grouting pipe assemblies one by one, connected with the inlet ends of the grouting pipe assemblies and used for conveying different materials, the outlet end of each grouting pipe assembly is connected with a grouting head and can be detached from the grouting head by rotating on its axis. According to the coal and rock mass deep hole subsection grouting reinforcement device and the reinforcement method, the grouting pipeline assembliescan be separated from the grouting heads, so that grouting pipelines are convenient to disassemble, and the grouting heads are secondarily installed for the second time to realize grouting in the nextstage. The grouting range of the structure can be selected, the problems of small effective grouting range, serious slurry leakage phenomenon, complex grouting construction organization and the likeof an existing method for reinforcing a coal and rock mass through shallow hole grouting with high polymer reinforcing materials can be effectively solved, and meanwhile the problems of large diffusion radius fluctuation, difficulty in hole formation and difficulty in reusing drilling holes of deep hole grouting materials can be overcome.

Owner:PINGDINGSHAN TIANAN COAL MINING +1

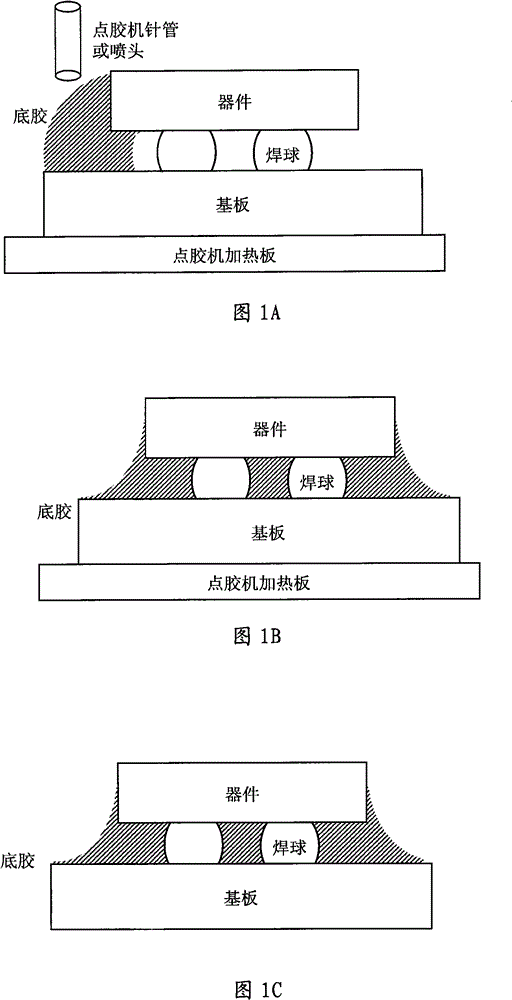

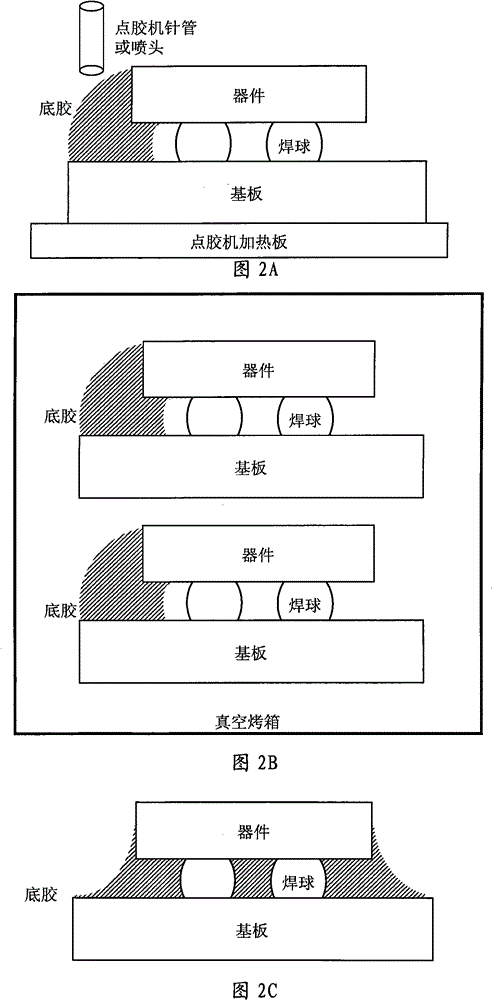

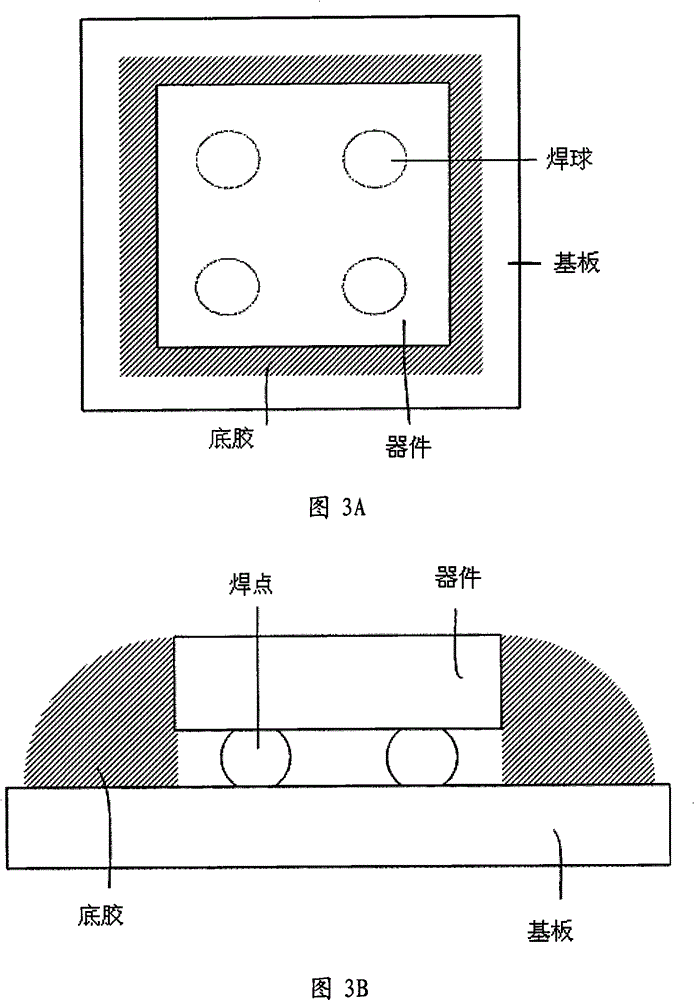

Method and equipment for filling primer in semiconductor packaging

ActiveCN103109361BReduce flow timeShort timeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageAir bubble

Glue (4) filling method and device in the semiconductor package is provided. The glue (4) is coated to one edge or four edges of semiconductor or chips on the substrate, the glue (4) is flowing between the chip and the substrate until the space is full filled. Several edges of device are coated glue (4) and the device is moved to the vacuum box, the glue (4) is batch flowing in the several devices so that the time of filling glue (4) is decreased and the production efficiency is increased. The glue (4) is solidified in the vacuum box and the air bubbles cancel during formed glue (4) time and the cavities cancel due to the gas volatilize during glue (4) solidified. The quality and the reliability of device glue (4) filling is increased.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

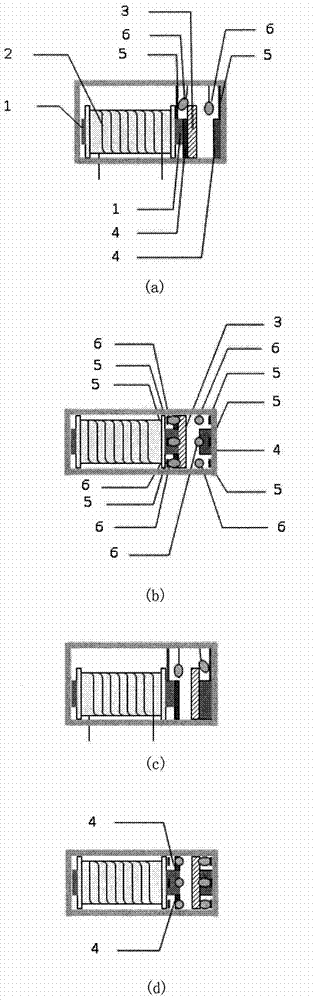

Outage holding relay and drive circuit thereof

The invention discloses an outage holding relay and a drive circuit thereof. A coil in the outage holding relay enables an iron core to reject or attract a movable magnet through electric currents in different directions, and accordingly movable contact points are driven to move so as to enable a switch to close or open. Two fixed iron pieces in the relay fixedly reach the magnet on a preset position through magnetic force, so that after the switch closes or opens, electricity does not need to be supplied to the coil any longer. The relay detects whether the movable contact points reach preset positions or not by using two switches, and the drive circuit finishes supplying the electricity to the coil of the relay according to a signal. The outage holding relay and the drive circuit thereof can automatically stop supplying the electricity to the coil after the movable contact points reach the preset positions, and therefore energy consumption is reduced. A control signal of the outage holding relay does not need adopting a pulse mode of an existing magnetic holding relay control signal, and therefore the outage holding relay is convenient to use, and furthermore close and open of the switches in the relay can be reliably guaranteed.

Owner:NANJING UNIV

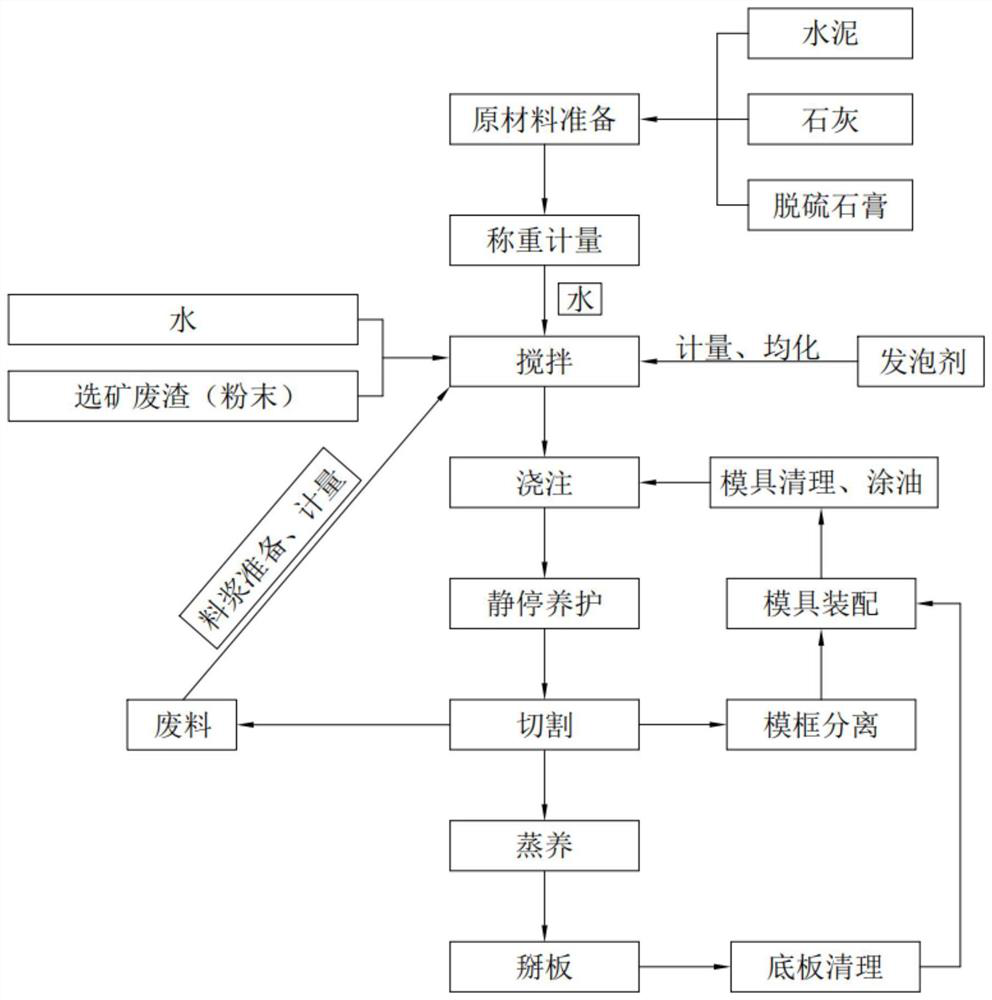

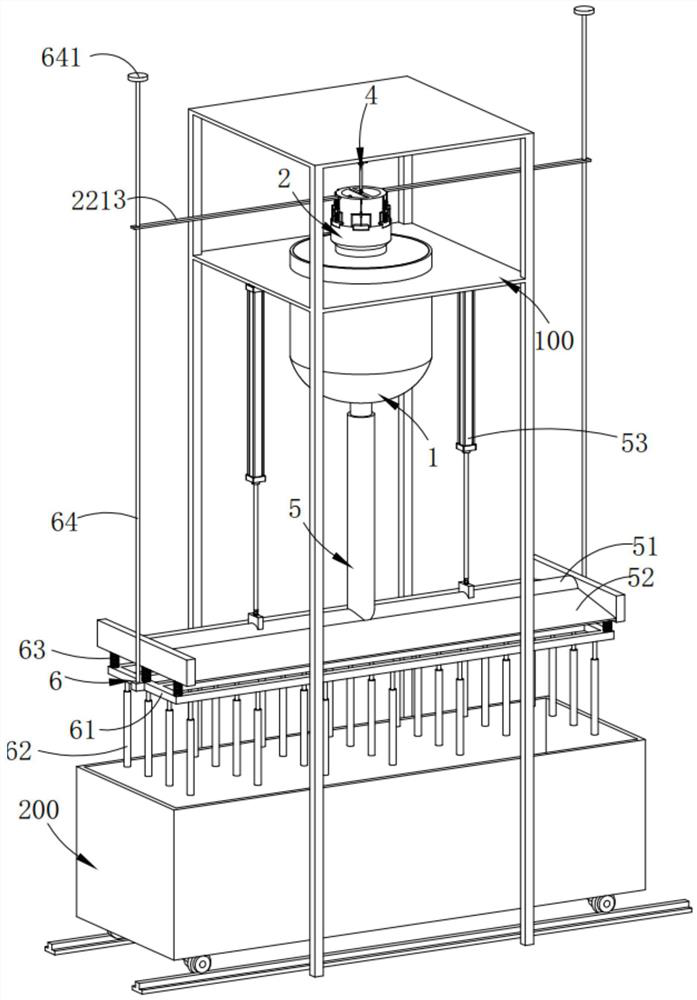

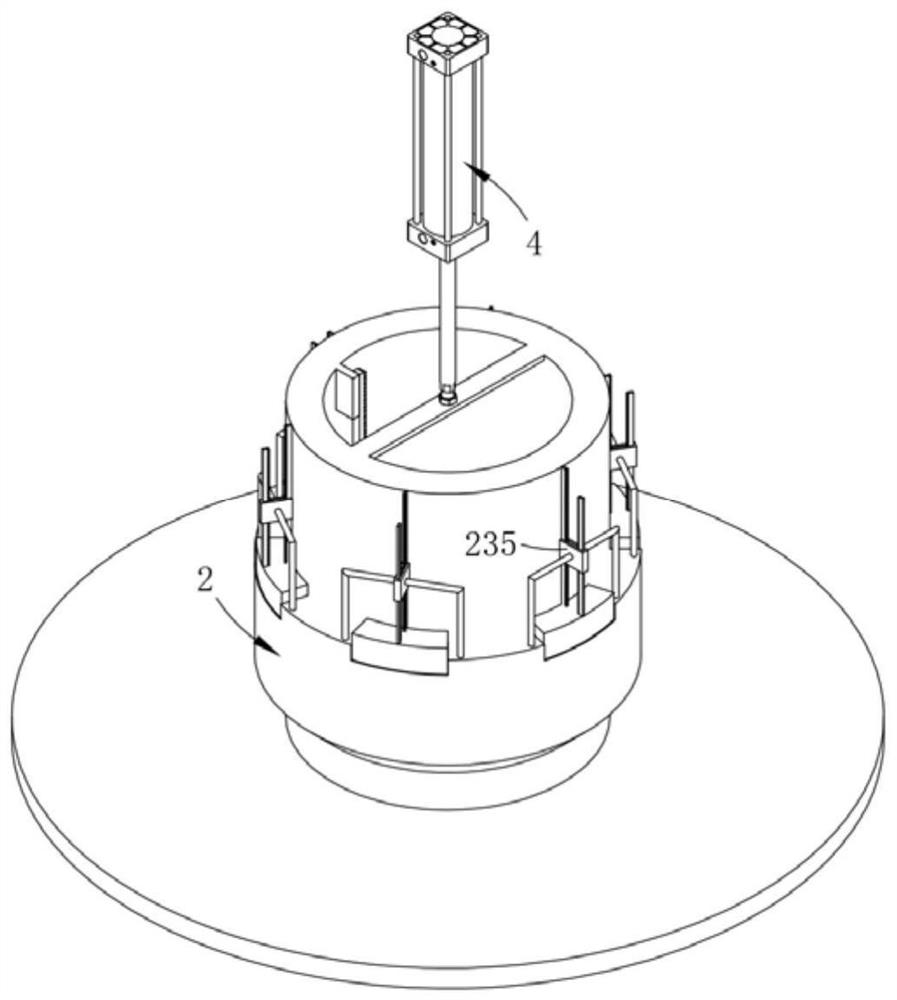

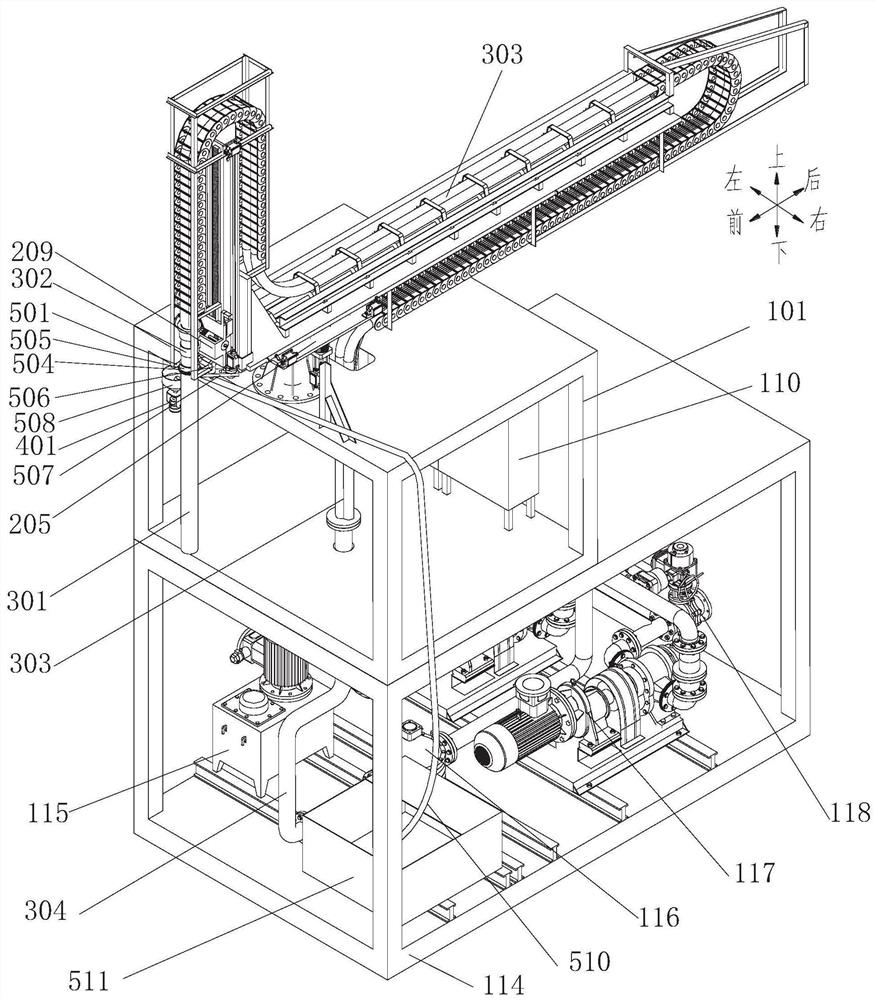

Flexible AAC plate production technology

ActiveCN113070995AFast fillReduce flow timeMixing operation control apparatusCeramic shaping plantsProcess engineeringPowder Spray

The invention provides a flexible AAC plate production technology. Through working procedures of raw material preparation, weighing and metering, stirring, pouring, standing and curing, cutting, steam curing and plate severing, production and manufacturing of autoclaved aerated concrete plates are completed, in the stirring working procedure, a powdery material is added into a powder spraying system, and the powder spraying system matches a liquid spraying system to make the powdery material and liquid mixed in the air, so that the situations that a large amount of a powdery material is added into a stirring tank to form a large number of dust bubbles, consequently the subsequent stirring time is long, and half-cooked materials generated in subsequent production are caused by the bubbles which are not fully stirred are avoided; and the production efficiency is improved by means of synchronous stirring, pouring and vibrating.

Owner:优博络客新型建材(天津)有限公司

Anti-oil-dripping liquid loading and unloading platform device

ActiveCN112093768AQuick alignmentReduce flow timeLiquid transferring devicesTank truckHydraulic pump

The invention relates to an anti-oil-dripping liquid loading and unloading platform device which comprises a pump skid-mounted device, an upper support arranged on the upper end face of the pump skid-mounted device, a remote alignment system, an automatic loading crane pipe installed on the upper support, a control box and an oil scraping assembly. The pump skid-mounted device comprises a lower support, a hydraulic pump station arranged in the lower support, a recycling container, an oil receiving opening, an oil pump and a flow meter, wherein the oil receiving opening, the oil pump and the flow meter are sequentially connected through a pipeline in the flow direction of fluid, and an outlet of the flow meter is connected with an oil conveying pipe. Movement and lifting of a vertical pipeare remotely controlled based on a real-time transmission image of a first camera so that the vertical pipe can be quickly aligned with a tank opening of a tank truck, oil on the pulled-out vertical pipe is received by an oil receiving bowl and recycled into the recycling container, accordingly, on-site environment maintenance personnel are not needed, on-site unattended operation is realized, andthe labor cost is reduced. The anti-oil-dripping liquid loading and unloading platform device can be transferred to other stations for reuse, and the enterprise cost is saved.

Owner:郑州智慧通测控技术有限公司

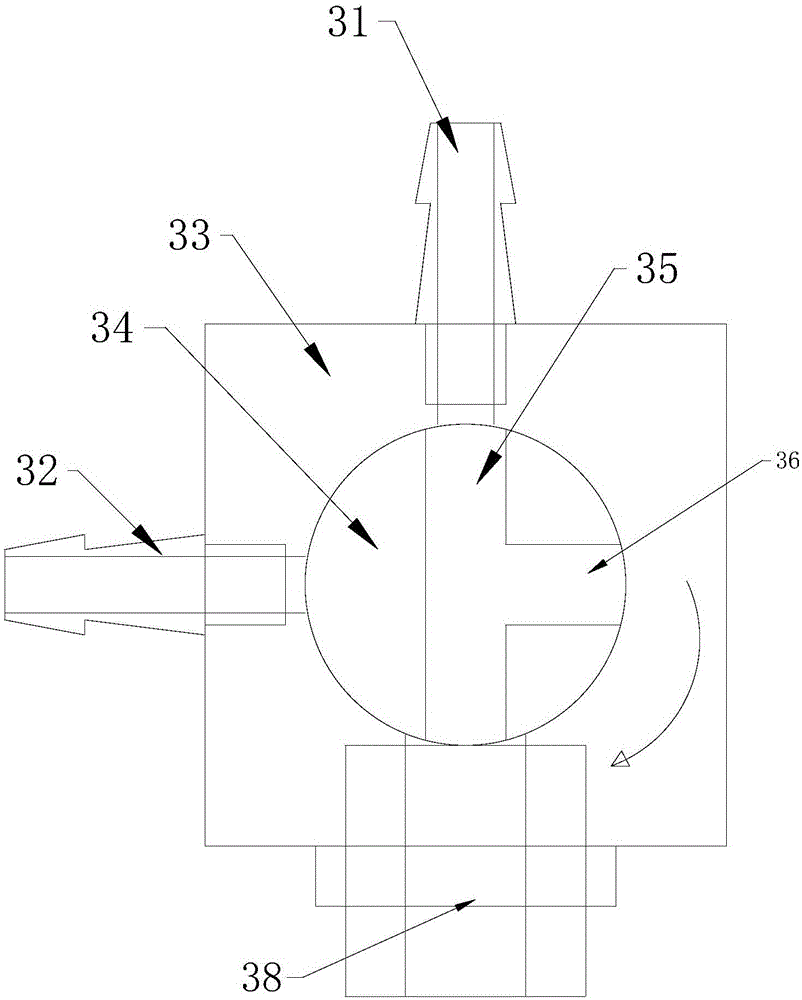

Sampling distribution valve for vehicle particle concentration detector

ActiveCN103953754BAvoid accumulationImprove accuracyOperating means/releasing devices for valvesMultiple way valvesParticulatesHigh concentration

Owner:张家港谱析传感科技有限公司

Filter device for saline-alkali land

InactiveCN108218023AReduce flow timeExtended flow timeSpecific water treatment objectivesTreatment involving filtrationWater flowWater resources

The invention discloses a filter device for saline-alkali land. After being filtered by a precipitate filter mechanism and a stirring filter mechanism which is communicated with a connection water pipe net, saline-alkali water is used through a water outlet pipe and can also be stored in a water collection groove for standby through a water collection pipe, and a water resource is saved; the connection water pipe net is connected with a three-way joint with the shape adapted to the shape of multiple connection water pipes through the connection water pipes to be in a bow shape, so that with the arrangement structure, the flowing time of the saline-alkali water is prolonged, and impurities which flow into the stirring filter mechanism are reduced; each connection water pipe comprises a semicircular upper pipe and a rectangular lower pipe which is detachably connected with the semicircular upper pipe fixedly; the bottom surface of each rectangular lower pipe is divided into a first rectangular lower pipe bottom slanting surface and a second rectangular lower pipe bottom slanting surface which are mutually connected in a water flow direction, the two edges of each bottom surface are relatively high, the middle part of each bottom surface is relatively low, the adjacent part of each front portion and the corresponding back portion protrudes downward, and each protrusion position isconnected with a collection groove used for collecting precipitates; and the connection water pipes are separated and cleaned separately, the upper pipes are opened, the lower pipes are cleaned, andblockage is prevented.

Owner:WEIFANG YOURONG IND

Grease injection head facilitating conductive grease filling of strain clamp

PendingCN110465448AReduce flow timeImprove injection efficiencyLiquid surface applicatorsCoatingsBiomedical engineering

The invention relates to a grease injection head facilitating conductive grease filling of a strain clamp. The grease injection head comprises a body. The body includes an outer sleeve and an inner sleeve. A grease injection channel is arranged in the middle portion of the inner sleeve, and the inner sleeve comprises a connecting section and a positioning section. The outer sleeve comprises a positioning end surface and a fixing head, the body is fixed on the strain clamp by the positioning section and the positioning end surface. The grease injection head has the advantages that the body is fixed on the strain clamp by the positioning section and the positioning end surface arranged on the outer sleeve, then conductive grease is injected into the strain clamp through the grease injectionchannel on the inner sleeve, since the positioning section extends into the strain clamp, the conductive grease can be accurately injected into the specified position of the strain clamp, the flowingtime of the conductive grease in the strain clamp is reduced, and the injection efficiency of the conductive grease is improved; and in addition, because the positioning end surface is always in contact with the strain clamp, the mutual sliding between the grease injection head and the strain clamp is effectively avoided, so that the waste phenomenon of the conductive grease in the injection process is reduced, and the working efficiency of the grease injection is improved.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com