Method and equipment for filling primer in semiconductor packaging

A technology of filling equipment and filling method, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of low overall process efficiency, and achieve the effect of shortening the required time and reducing time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

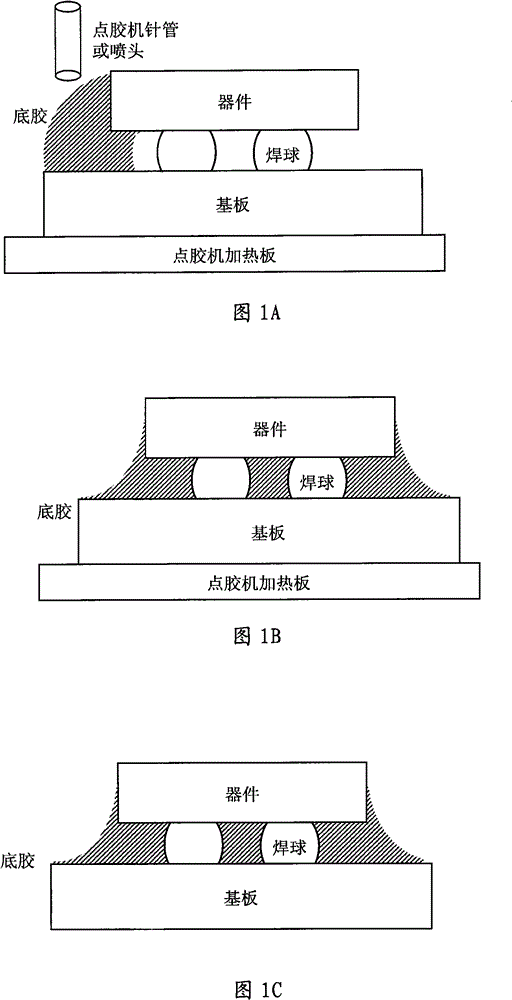

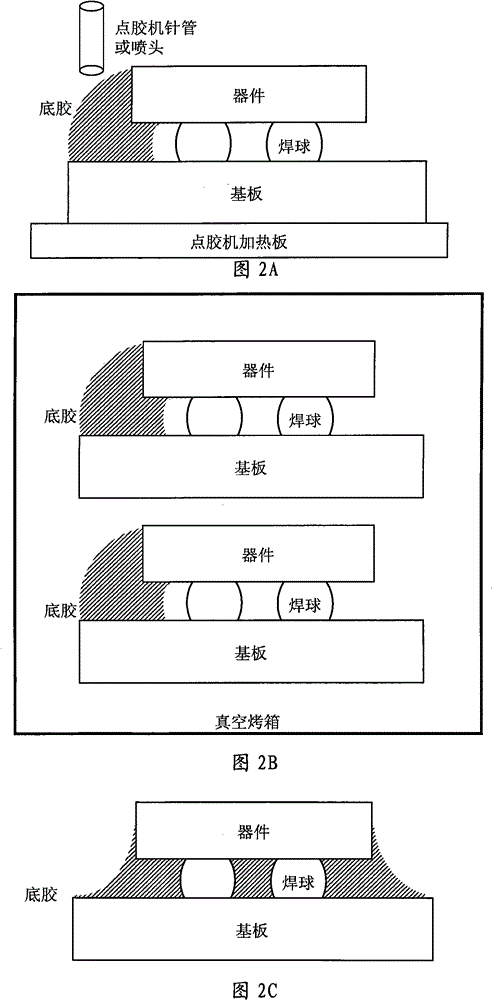

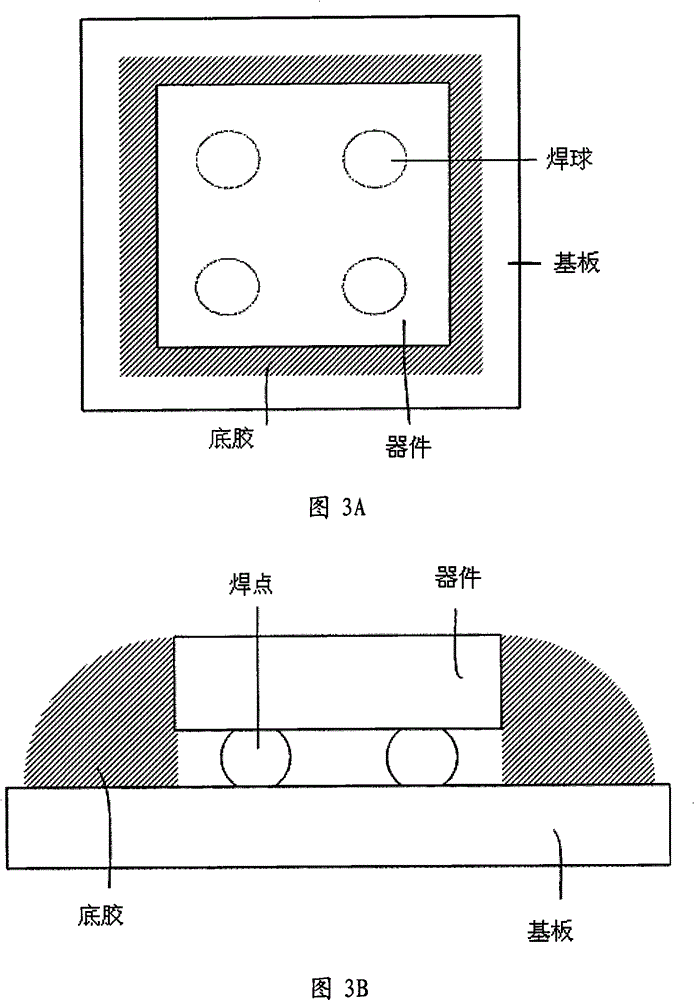

[0034] The invention relates to a method and equipment for filling primers in semiconductor packaging and other devices. Packaging herein refers to the interconnection of one or more semiconductor package devices with a printed circuit board substrate or interconnection between devices using solder and other bonding materials. see figure 1 , the traditional primer filling is to apply the primer on the edge of the packaged components on a machine, and then the primer flows through capillary action in the air environment and fills the gap between the substrate and the device, and finally the primer is in the Cured in a conventional air-heated oven. The main disadvantages of the traditional method are the long time or low production efficiency of the primer flow process for a single component, and the easy occurrence of voids due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com