Flexible AAC plate production technology

A sheet production and process technology, applied in the field of flexible AAC sheet production technology, can solve the problems of long pouring process time, low production efficiency, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

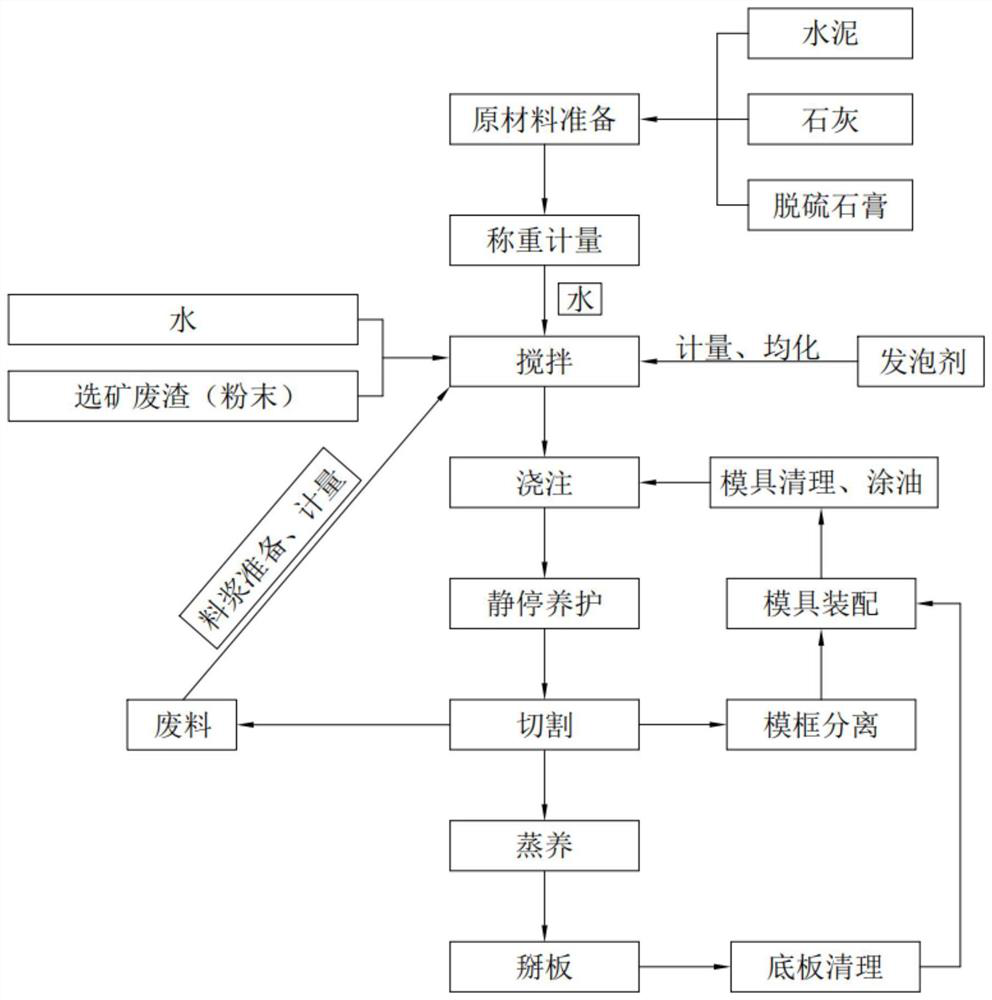

[0082] like figure 1 Shown, a kind of flexible AAC plate production process comprises the following steps:

[0083] Step 1. Raw material preparation, sending a variety of raw materials to be processed into the ball mill and grinding them into fine particles;

[0084] Step 2, weighing and measuring, weighing and measuring the fine particles of various raw materials in step 1 respectively, and continuously inputting them into the mixing chamber 1, and adding water in proportion;

[0085] Step 3, stirring, start the main stirring paddle set in the mixing chamber 1, and stir the raw materials in the step 2; at the same time, add the powdered ore dressing waste residue to the storage area 2112, and use the powder spraying system 2 and the liquid spraying system 3 to spray the powder The powdery ore dressing waste slag and water are sprayed alternately in proportion, so that the powdery ore dressing waste slag and the sprayed mist water droplets are fully mixed in the air and then ...

Embodiment 2

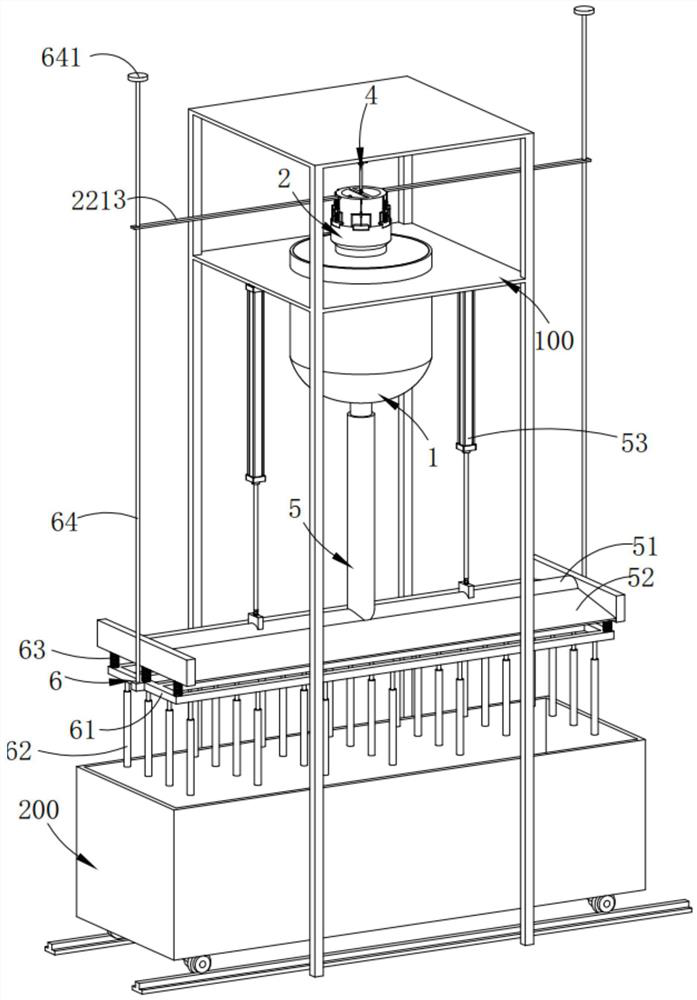

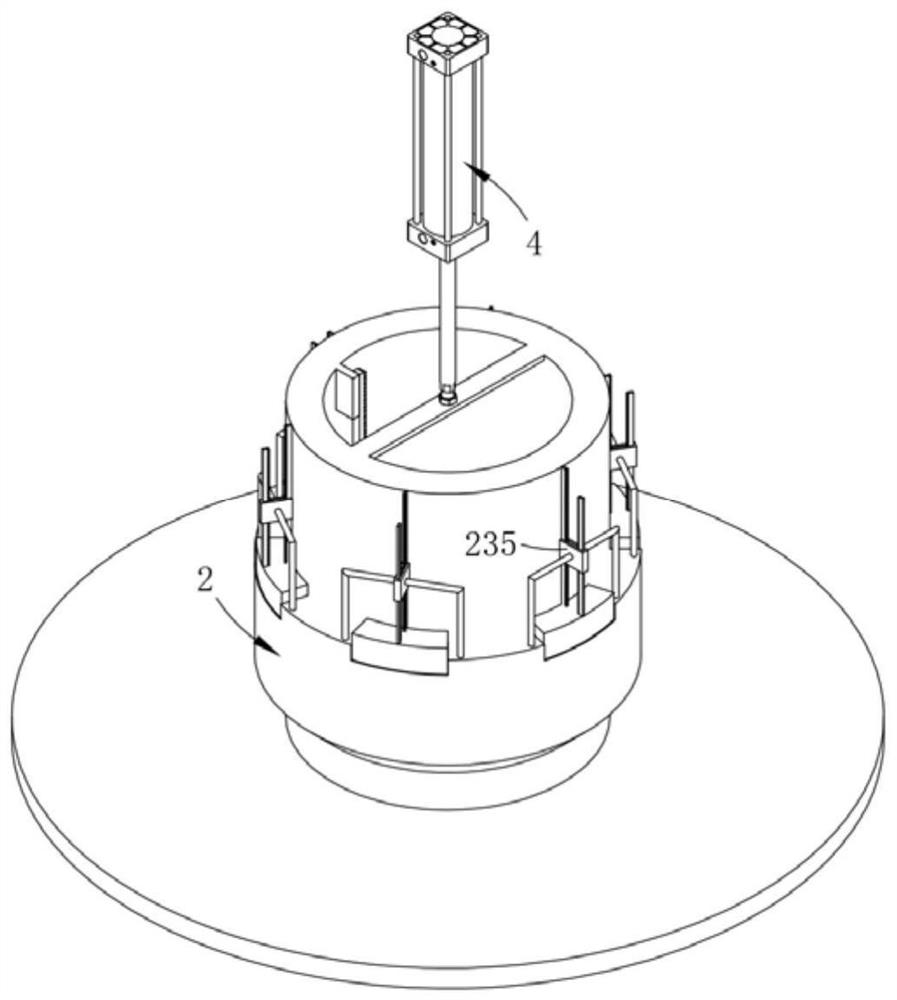

[0101] like Figure 2-4 As shown, a flexible AAC plate production line includes a ball mill system, a weighing and measuring system, a static stop maintenance system, a cutting system, a steam curing system, a board breaking system, and a mixing chamber 1 located on an equipment platform 100. It also includes: The powder spraying system 2 above the mixing chamber 1, the liquid spraying system 3 located inside the powder spraying system 2, and the drive system 4 connected to the powder spraying system 2, the top of the drive system 4 is connected to the The top of the equipment platform is connected; the drive system 4 can choose cylinder transmission, rack and pinion transmission or other linear transmission methods; of course, cam transmission can also be selected;

[0102] The powder spraying system 2 includes a powder spraying unit 21 arranged at the mouth of the mixing chamber 1, a material spraying pressure transformation unit 22 slidingly arranged above the powder sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com